Method for producing high strength, high ductility steel strip

a high ductility, steel strip technology, applied in the field of high ductility steel strip production, can solve the problems of unfavorable strip surface oxidation, unfavorable strip surface removal, and insufficient ductility of conventional high strength steels to produce complex parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

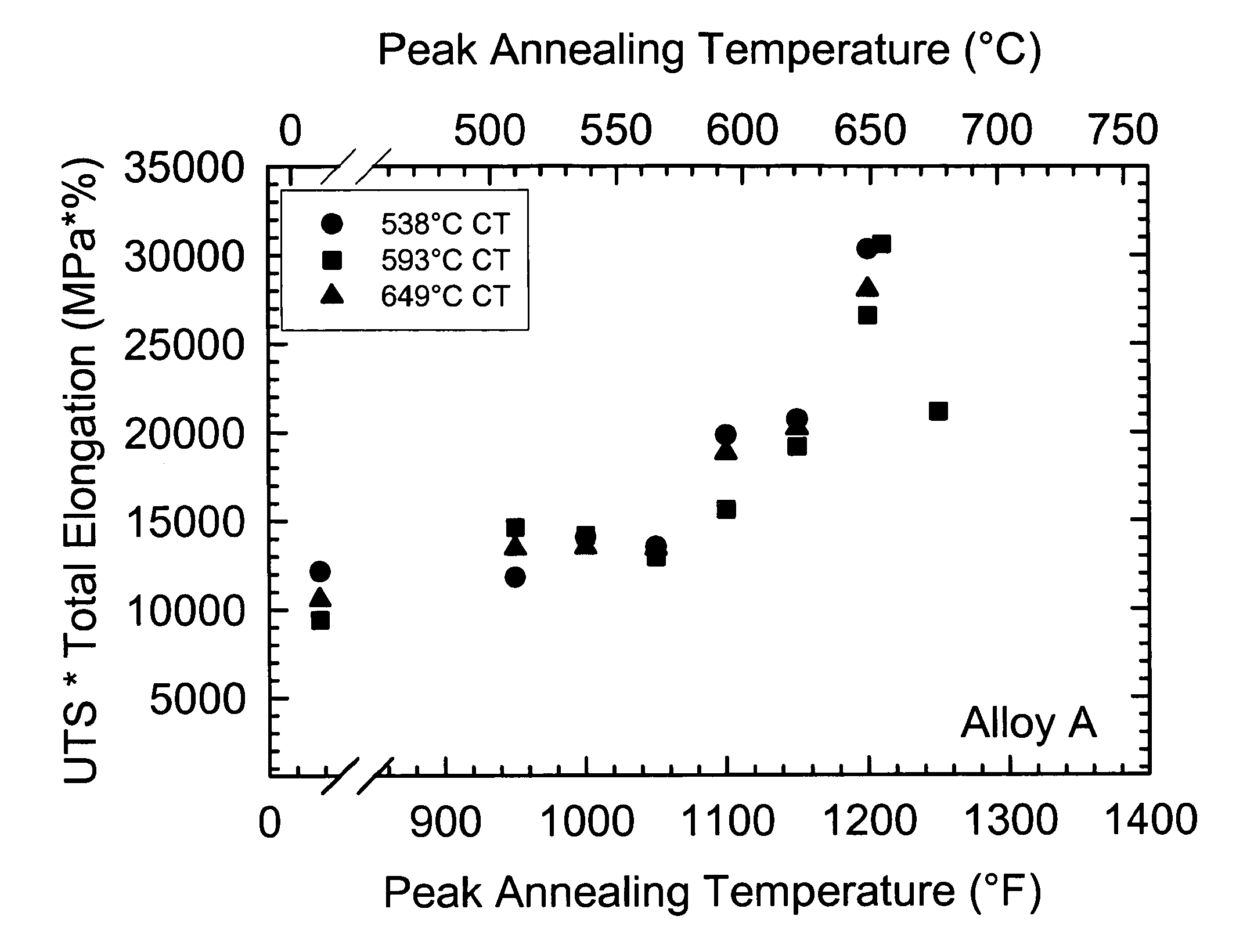

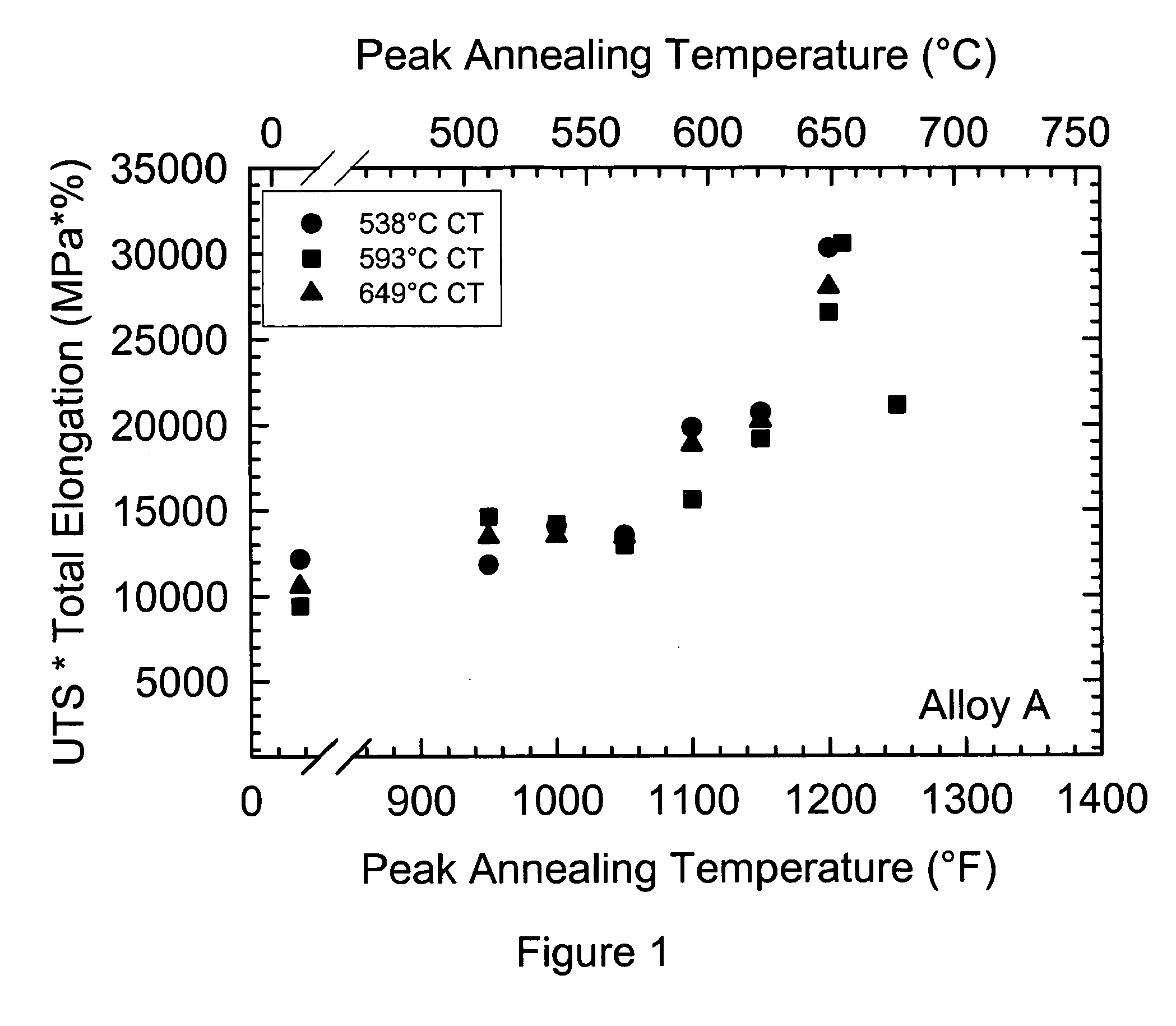

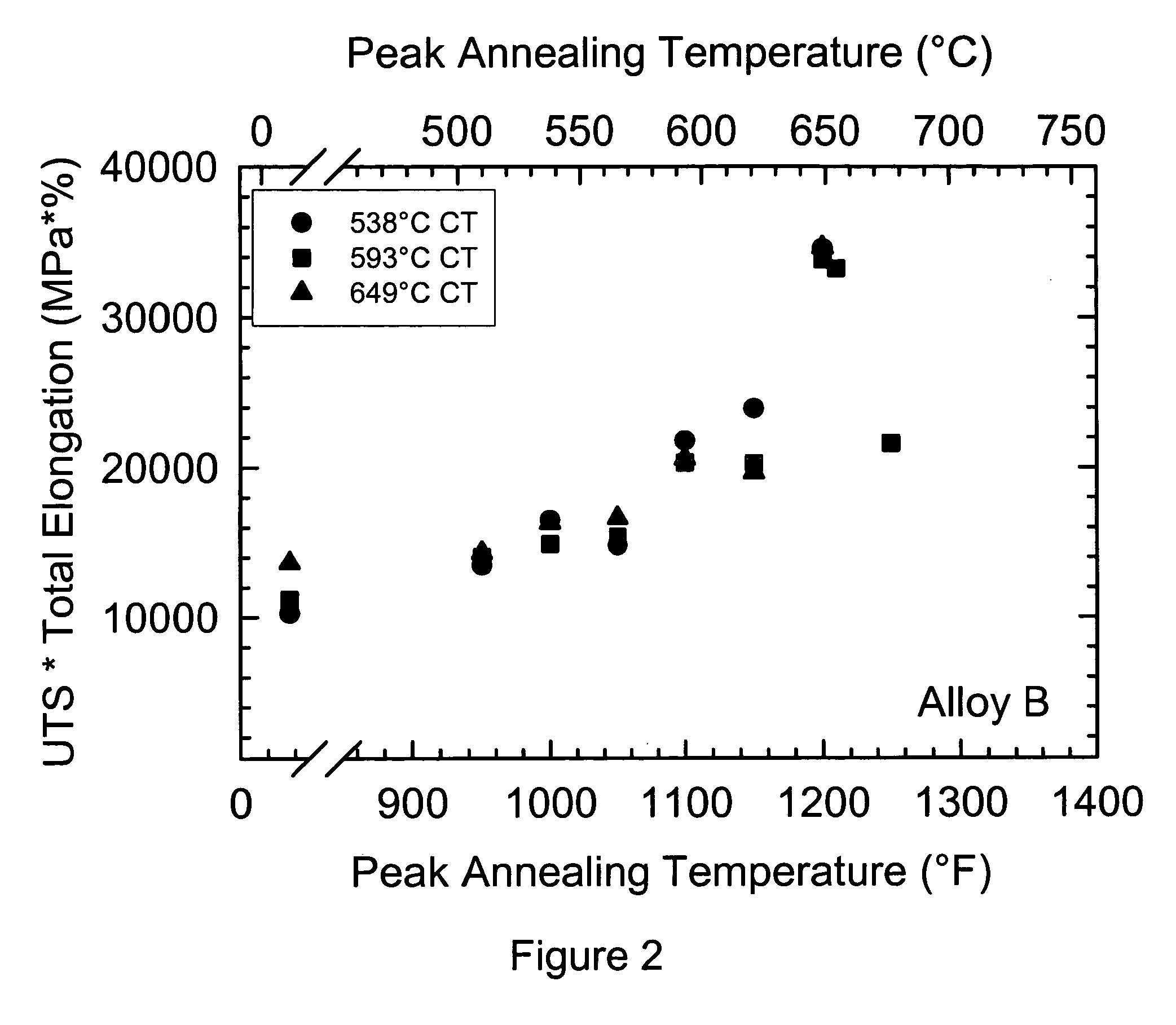

[0012] Tests were conducted in the laboratory to determine whether a high strength, high ductility steel could be produced utilizing conventional hot rolling practices and box annealing techniques. Table 1 below presents the composition of the steel materials studied in these laboratory tests.

TABLE 1SteelCMnPSSiCuNiCrMoAlNA0.1005.18.015.008.12.03.03.04.02.03.009B0.0955.80.013.008.13.04.04.04.02.03.008C0.0997.09.015.008.13.03.03.04.01.03.008

[0013] Laboratory ingots of the above compositions were reheated to 1260° C. (2300° F.) and rolled from 178 mm (7) inch thickness to an intermediate slab thickness of 51 mm (2 inches). The slabs were reheated again to the same temperature and hot rolled in seven passes to 4 mm (0.16 inch) thickness to simulate a conventional hot rolling process. The hot rolled strips were then placed in a programmable furnace which was set to cool at 28° C. / hour (50° F. / hour) from the prescribed “coiling temperature” to simulate coiling on a commercial hot strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com