Insulating corrosion-resistant bonding wire with inorganic amorphous coating and preparation method of insulating corrosion-resistant bonding wire

A bonding wire, inorganic non-technology, used in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problem of rising bonding wire manufacturing costs, inability to be widely used, and easy oxidation of bonding wires. and other problems, to achieve the effect of reducing arc height, good wire-bonding workability and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

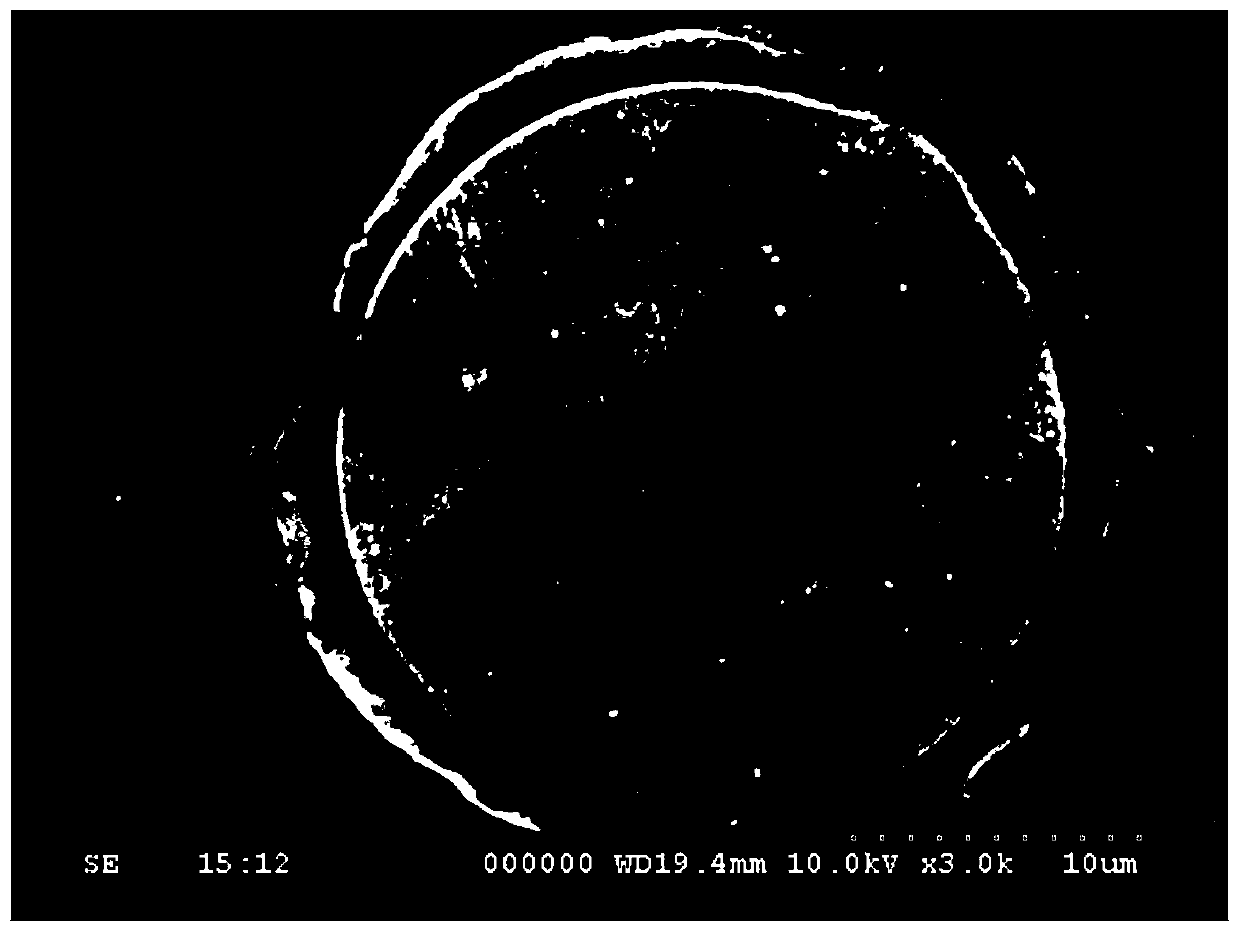

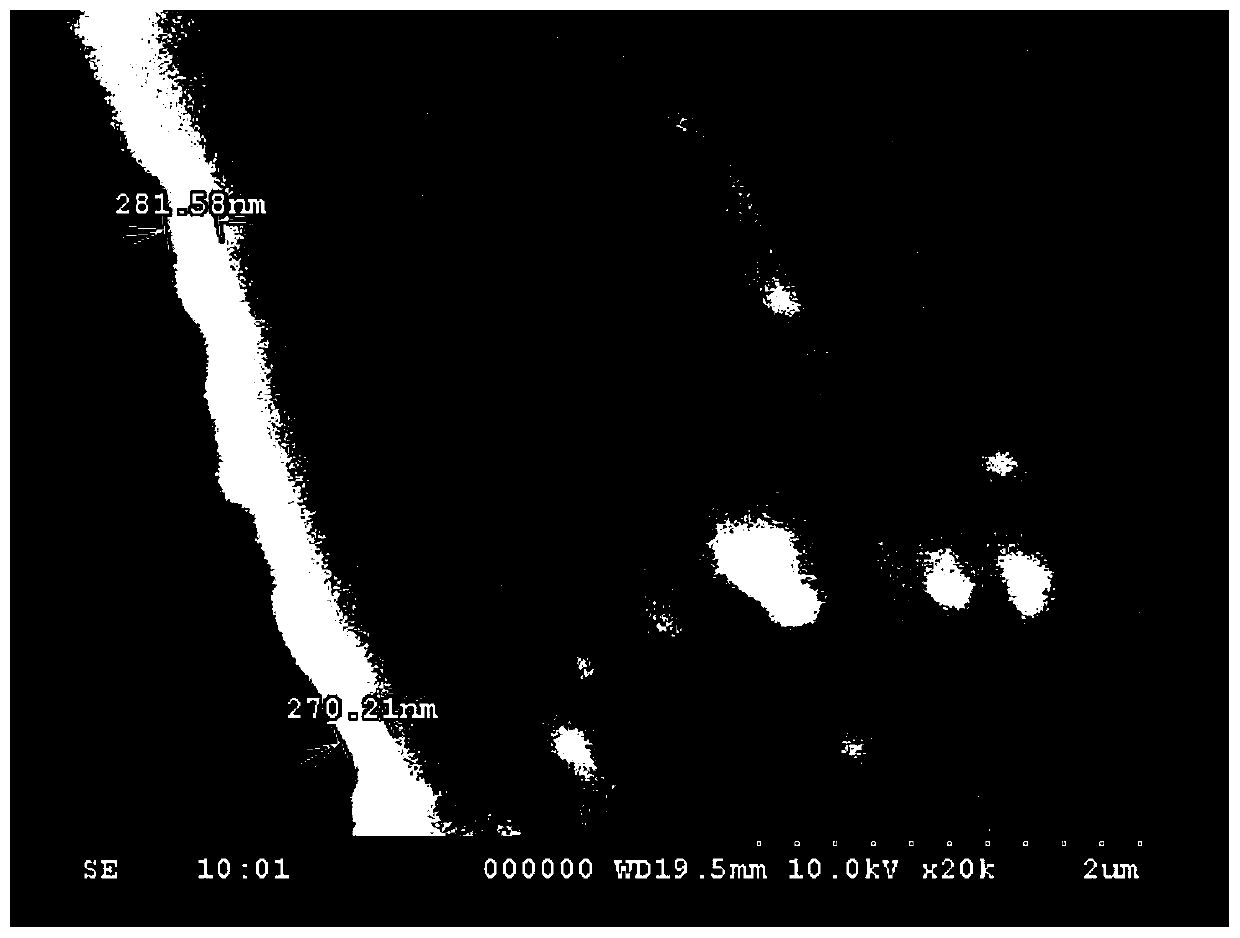

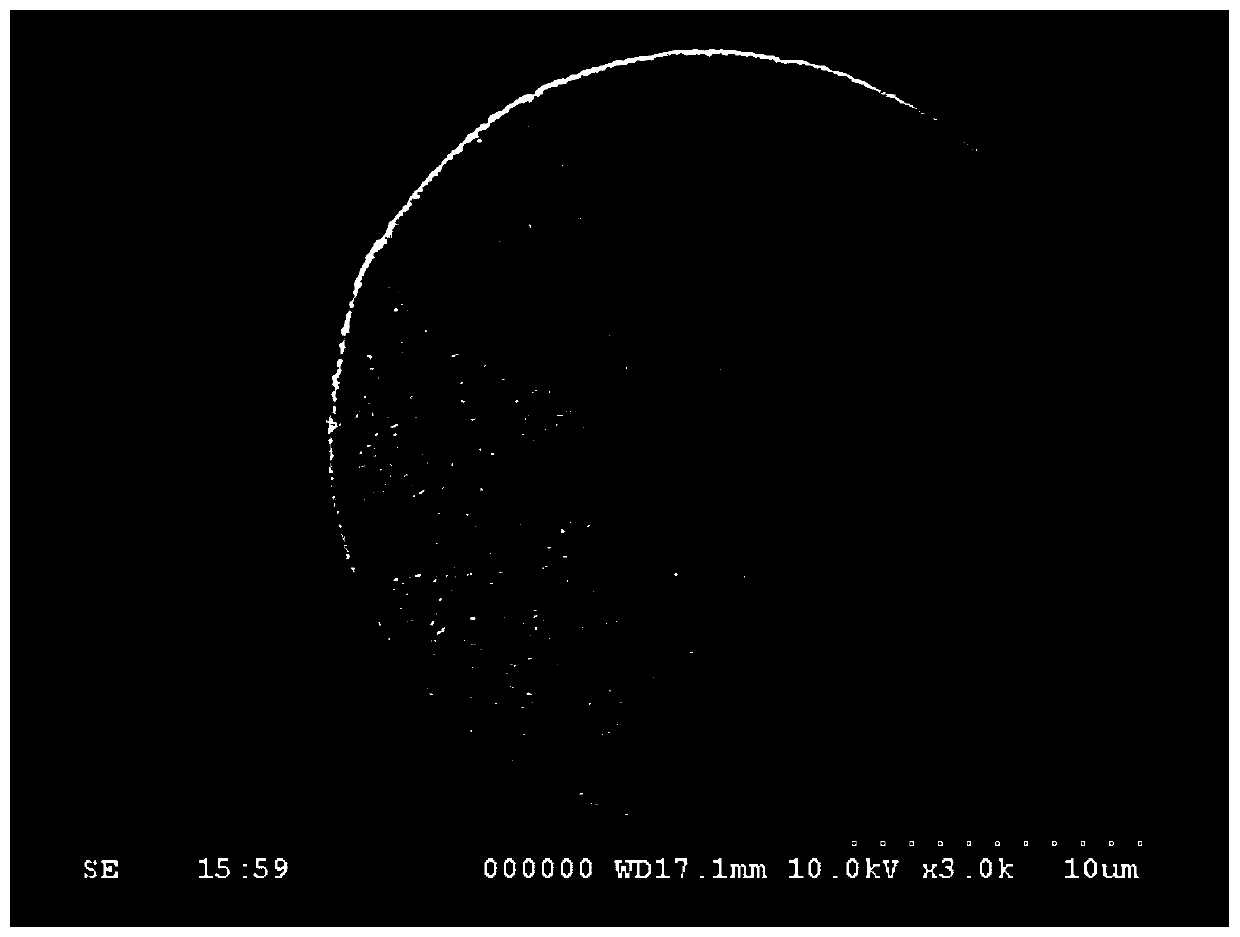

[0019] An insulating and corrosion-resistant inorganic amorphous coating silver bonding wire with a diameter of 25 μm (1.0 mil, not including the thickness of the coating), the weight percentage of each component of the material constituting the bonding wire is:

[0020] The amount of Au is 0.2%, the amount of Pd is 0.1%, the amount of La is 30ppm, and the balance is Ag as the alloy substrate; the material of the outer insulating and corrosion-resistant inorganic amorphous coating is SiO 2 55%, Al 2 o 3 26%, B 2 O 15%, Li 2 O 4%.

[0021] Its preparation method comprises the following steps:

[0022] The first step is to select the alloy base material: select silver metal raw materials with a high purity of more than 99.999%;

[0023] The second step, smelting: according to the percentage of alloy composition, pre-alloy and stir at 1250°C with argon protection, and perform continuous drawing at 1150°C to form alloy rods with a diameter of 8±0.3mm;

[0024] The third step...

Embodiment 2

[0034] An insulating and corrosion-resistant inorganic amorphous copper bonding wire with a diameter of 25 μm (1.0 mil, not including the thickness of the insulating film), the weight percentage of each component of the material constituting the bonding wire is:

[0035] The Cu content of the copper bonding wire is greater than 99.99%; the outer insulation and anti-corrosion inorganic amorphous coating material is SiO 2 58%, Al 2 o 3 25%, B 2 O 16%, Li 2 O 1%.

[0036] Its preparation method comprises the following steps:

[0037] The first step is to select the base material: select a high-purity copper metal raw material with a purity of more than 99.999%;

[0038] The second step, smelting: according to the percentage of alloy composition, continuous drawing casting is carried out at 1200°C, and drawing casting is made into alloy metal rods with a diameter of 7±0.3mm;

[0039]The third step, wire drawing: firstly, the alloy metal rod is drawn into a wire with a diamet...

Embodiment 3

[0046] An insulating and corrosion-resistant inorganic amorphous coating gold bonding wire with a diameter of 20 μm (0.8 mil, not including the thickness of the coating), the weight percentage of each component of the material constituting the bonding wire is:

[0047] The content of Au is 85%, the amount of Pd is 1.5%, and the amount of Ag is 17.5%; the material of the outer insulating and anti-corrosion inorganic amorphous coating is SiO 2 52%, Al 2 o 3 27%, B 2 O 18%, Li 2 O 3%.

[0048] Its preparation method comprises the following steps:

[0049] The first step is to select the alloy base material: select high-purity gold raw materials that reach 99.999% or more;

[0050] The second step, smelting: according to the percentage of the alloy composition, the process of pre-alloying and stirring under the protection of argon at 1550°C, and continuous casting at 1250°C is used to cast alloy metal rods with a diameter of 8±0.3mm ;

[0051] The third step, wire drawing: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com