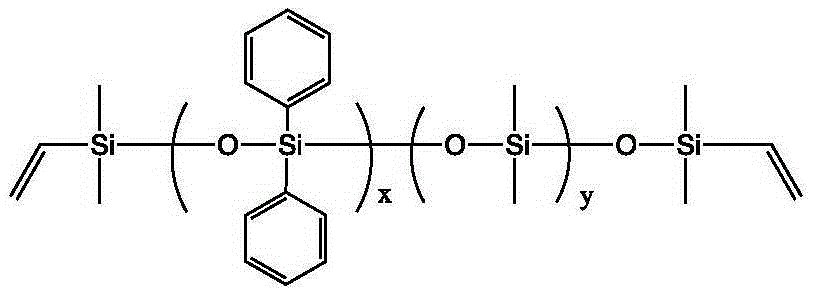

Trifluoropropyl-group-modification methyl phenyl vinyl silicon resin and LED packaging adhesive

A technology based on methylphenylethylene and trifluoropropyl, which is applied in the field of materials, can solve the problems of poor anti-vulcanization performance, thermal stability that cannot meet the needs of medium and high power LEDs, and obvious light decay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

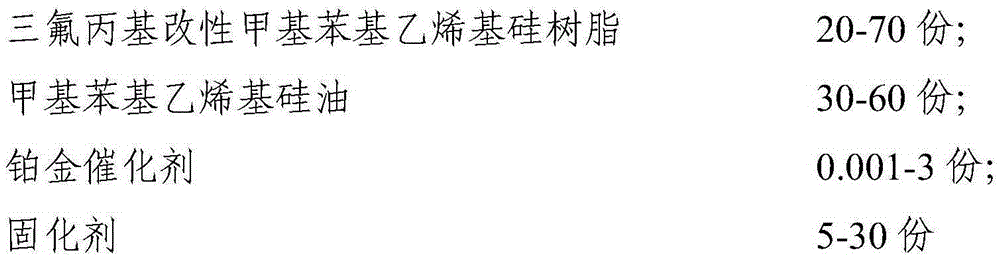

[0057] Example 1 Preparation of Trifluoropropyl Modified Methylphenyl Vinyl Silicone Resin

[0058] Trifluoropropyl modified methylphenyl vinyl silicone resin and preparation method thereof:

[0059] (1) 58.0g (0.426mol) methyltrimethoxysilane, 28.6g (0.238mol) dimethyldimethoxysilane, 145.0g (0.531mol) phenyltrimethoxysilane, 103.6g (0.424mol) ) diphenyldimethoxysilane, 11.5g (0.0443mol) trifluoropropyltriethoxysilane, 300g toluene, 2.3g hydrochloric acid with a concentration of 0.2mol / L, and 48.2g water were mixed uniformly and placed at 56°C Hydrolysis 2h;

[0060] (2) Add 30.0 g (0.161 mol) of vinyl double caps to the reaction solution in step (1), and condense at 85°C for 5 hours;

[0061] (3) Wash the reaction solution of step (2) with deionized water for 5 times, and remove low boilers at 120° C. for 2 hours under a vacuum of 0.096 mPa to obtain 236 g of trifluoropropyl-modified methylphenyl vinyl silicone resin .

[0062] The silicone resin has a viscosity of 19600...

Embodiment 2

[0063] Example 2 Preparation of Trifluoropropyl Modified Methylphenyl Vinyl Silicone Resin

[0064] (1) 55.0g (0.309mol) methyltriethoxysilane, 46.8g (0.316mol) dimethyldiethoxysilane, 559.2g (2.824mol) phenyltrimethoxysilane, 53.2g (0.218 mol) diphenyldimethoxysilane, 27.82g (0.107mol) trifluoropropyl triethoxysilane, 1000g xylene, 5.6g concentration of 0.1mol / L sodium hydroxide solution, 102g water after mixing uniformly, in Hydrolysis at 85°C for 7 hours;

[0065] (2) Add 72.9 g (0.391 mol) of vinyl double-caps to the reaction liquid in step (1), and condense at 125 ° C for 5 h;

[0066] (3) Wash the reaction solution in step (2) with deionized water for 5 times, and remove low boilers at 160°C for 5.5 hours under a vacuum of 0.096mPa to obtain a trifluoropropyl-modified methylphenylvinyl silicone resin 253g.

[0067] The resin has a viscosity of 260000mPaS and a refractive index of 1.542.

Embodiment 3

[0068] Example 3 Preparation of Trifluoropropyl Modified Methylphenyl Vinyl Silicone Resin

[0069] (1) 93.6g (0.526mol) methyltriethoxysilane, 74.6g (0.41mol) methylphenyldimethoxysilane, 121.4g (0.613mol) phenyltrimethoxysilane, 87.8g ( 0.36mol) diphenyldimethoxysilane, 31.2g (0.12mol) trifluoropropyltriethoxysilane, 300g toluene, 3.8g dilute sulfuric acid with a concentration of 0.1mol / L, and 56.8g water were mixed uniformly, at 75 Hydrolysis at ℃ for 3.5h;

[0070] (2) Add 20.88 g (0.112 mol) of vinyl double-caps to the reaction liquid in step (1), and condense at 105 ° C for 3 h;

[0071] (3) Wash the reaction solution of step (2) with deionized water for 5 times, and remove low boilers at 150° C. for 3 hours under a vacuum of 0.096 mPa to obtain 240 g of trifluoropropyl modified methylphenyl vinyl silicone resin .

[0072] The resin has a viscosity of 31600 mPaS and a refractive index of 1.562.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com