Silver/graphene composite plating solution, using method thereof and silver/graphene composite plating layer

A technology of graphene composite and graphene sheet, applied in the direction of coating, electrolytic coating, etc., to achieve the effect of improving anti-sulfurization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

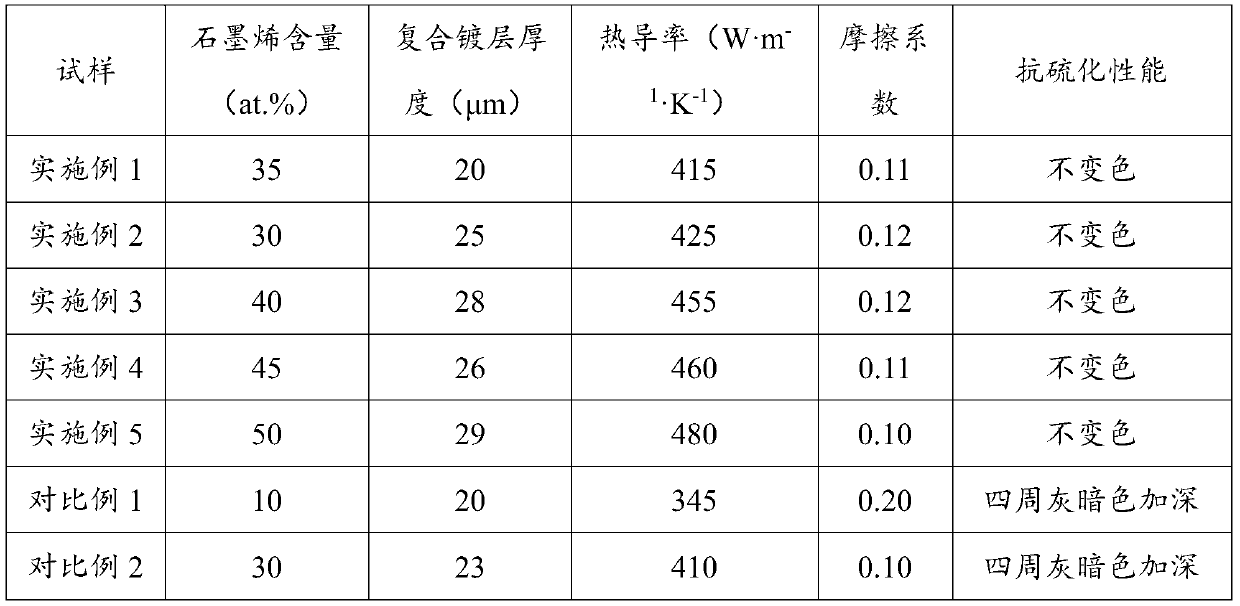

Examples

Embodiment 1

[0050] Step 1: Configure pre-silvering solution and composite plating solution

[0051]Pre-plating silver solution: KI 120g / L, AgNO 3 4g / L, Na 2 S 2 o 3 50g / L, HNO 3 4g / L and deionized water, pH 5;

[0052] Composite plating solution: AgNO 3 15g / L, KI 160g / L, Na 2 S 2 o 3 70g / L, HNO 3 4g / L, dispersant 3g / L, auxiliary agent 3g / L, defoamer 0.5g / L, graphene sheet 2g / L and deionized water, pH is 5; among them, the number of graphene sheet layers is 3 layers, medium The maximum particle size is 3 μm; the dispersant is sodium dodecylbenzenesulfonate, the auxiliary agent is isooctyl acetate and N-acetyl-L-proline with a mass ratio of 1:2, and the defoamer is polyoxyethylene Polyoxypropylene amine ether.

[0053] Step 2: Surface pretreatment of the substrate

[0054] Grinding: use 400 # Grind the substrate evenly with water sandpaper;

[0055] Degreasing: Soak the polished substrate in degreasing solution for 10 minutes, degreasing solution: 30g / L NaOH, 50g / L NaOH ...

Embodiment 2

[0065] Step 1: Configure pre-silvering solution and composite plating solution

[0066] Pre-plating silver solution: KI 240g / L, AgNO 3 6g / L, Na 2 S 2 o 3 60g / L, HNO 3 3g / L and deionized water, pH 3;

[0067] Composite plating solution: AgNO 3 18g / L, KI 360g / L, Na 2 S 2 o 3 50g / L, HNO 3 8g / L, dispersant 2.5g / L, auxiliary agent 4g / L, defoamer 0.02g / L, graphene sheet 1.5g / L and deionized water, pH is 5; among them, the number of graphene sheet is 2 layers , the median particle size is 6 μm; the dispersant is sodium dodecylbenzenesulfonate, the auxiliary agent is isooctyl acetate and N-acetyl-L-proline in a mass ratio of 3:5, and the defoamer is polyoxyethylene Polyoxypropylene amine ether;

[0068] Step 2: Surface pretreatment of the substrate

[0069] Grinding: use 400 # Grind the substrate evenly with water sandpaper;

[0070] Degreasing: Soak the polished substrate in degreasing solution for 6 minutes, degreasing solution: 150g / L NaOH, 40g / L NaOH 2 CO 3 ,...

Embodiment 3

[0080] Step 1: Configure pre-silvering solution and composite plating solution;

[0081] Pre-plating silver solution: KI 120g / L, AgNO 3 4g / L, Na 2 S 2 o 3 50g / L, HNO 3 4g / L and deionized water, pH 5;

[0082] Composite plating solution: AgNO 3 50g / L, KI 200g / L, Na 2 S 2 o 3 60g / L, HNO 3 10g / L, dispersant 3g / L, auxiliary agent 1g / L, defoamer 0.5g / L, graphene sheet 1g / L and deionized water, pH is 7; among them, the number of graphene sheets is 2 layers, medium The maximum particle size is 2μm; the dispersant is sodium dodecylbenzenesulfonate, the auxiliary agent is isooctyl acetate, and the defoamer is polyoxyethylene polyoxypropyleneamine ether;

[0083] Step 2: Surface pretreatment of the substrate

[0084] Grinding: use 400 # Grind the substrate evenly with water sandpaper;

[0085] Degreasing: Soak the polished substrate in degreasing solution for 10 minutes, degreasing solution: 100g / L NaOH, 50g / L NaOH 2 CO 3 , 30g / L Na 3 PO 4 .

[0086] Cleaning: wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com