A device for preparing nanoporous film and its application

A nanoporous, control device technology, applied in the field of materials, to achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

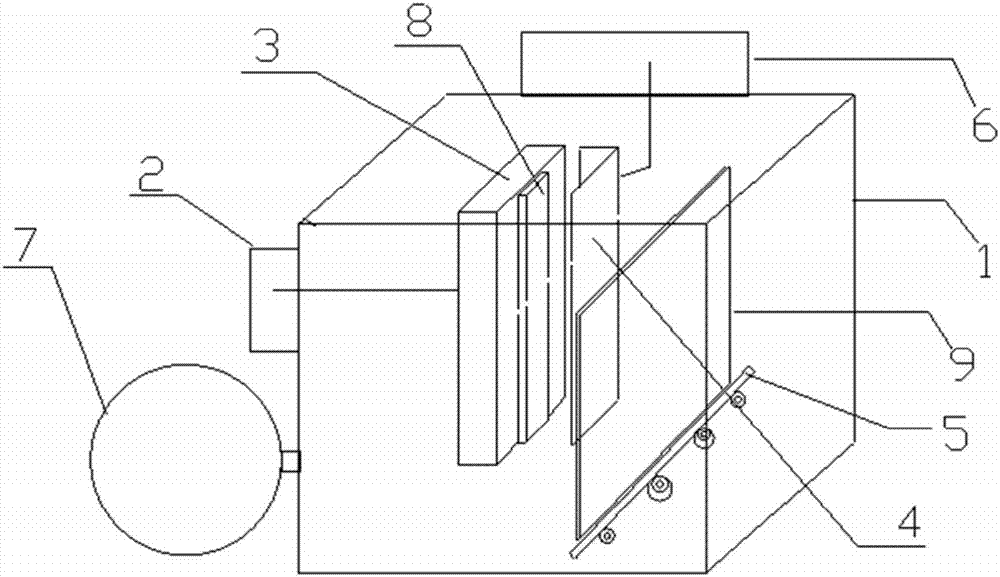

[0034] Devices for preparing nanoporous thin films, see figure 1 , including a deposition chamber (1), a voltage source (2), a shield support and control device (6), a vacuum pump (7), and a magnetron (3) and a shield ( 4), the substrate transport track (5); the voltage source (2) is connected to the magnetron (3); the sputtering target (8) is fixed on the magnetron (3). The substrate transport track (5) is used to carry the substrate through the deposition chamber (1).

[0035] The shield support and control device (6) is connected to the shield (4), and adopts common mechanical control technology to control and change the geometric shape, size and physical position of the shield (4) relative to the sputtering target during the deposition process. For example, the shielding screen (4) is controlled to move in parallel in front of the sputtering target (8); half of the deposited particle flow or one third of the particle flow is blocked. As another example, remove the shadow...

Embodiment 2

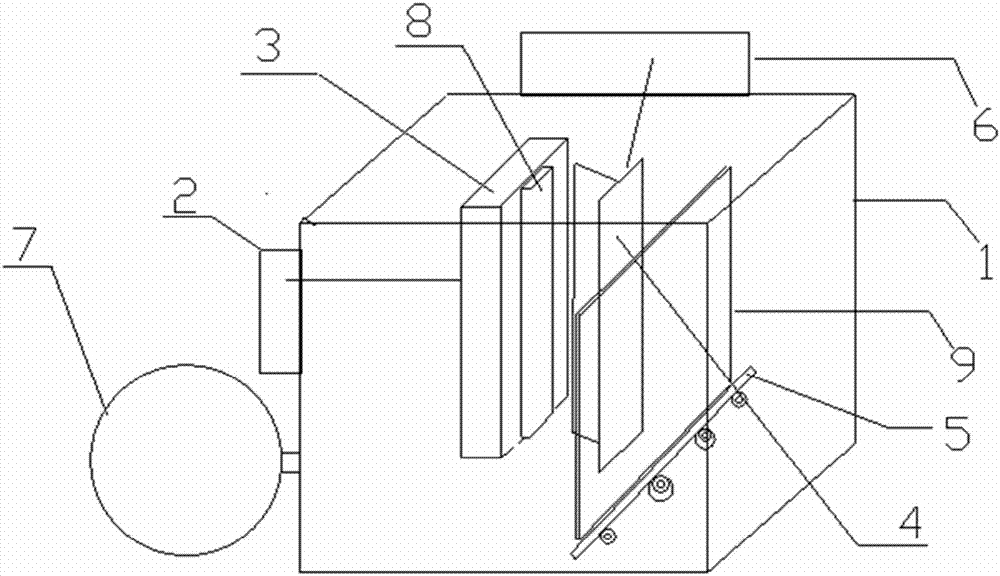

[0055] Devices for preparing nanoporous thin films, see image 3 , including a deposition chamber (1), a voltage source (2), a shield support and control device (6), a vacuum pump (7), and a magnetron (3) and a shield ( 4), the substrate transport track (5); the voltage source (2) is connected to the magnetron (3); the sputtering target (8) is fixed on the magnetron (3). The substrate transport track (5) is used to carry the substrate through the deposition chamber (1).

[0056] The shield support and control device (6) is connected to the shield (4), and adopts common mechanical control technology to control and change the geometric shape, size and physical position of the shield (4) relative to the sputtering target during the deposition process. For example, the shielding screen (4) is controlled to move in parallel in front of the sputtering target (8); half of the deposited particle flow or one third of the particle flow is blocked. As another example, remove the shadow...

Embodiment 3

[0065] The nanoporous structure film was prepared by using the device of Example 2, the method was basically the same as that of Example 1, the only difference was that a rotating target was used instead of a planar target.

[0066] Using this device to prepare nanoporous structure film, the method is the same as in Example 1. By controlling different process parameters, samples of nanoporous structure film with batch numbers 11-15 were prepared, and the porosity was between 0.10 and 0.80, as shown in Table 3.

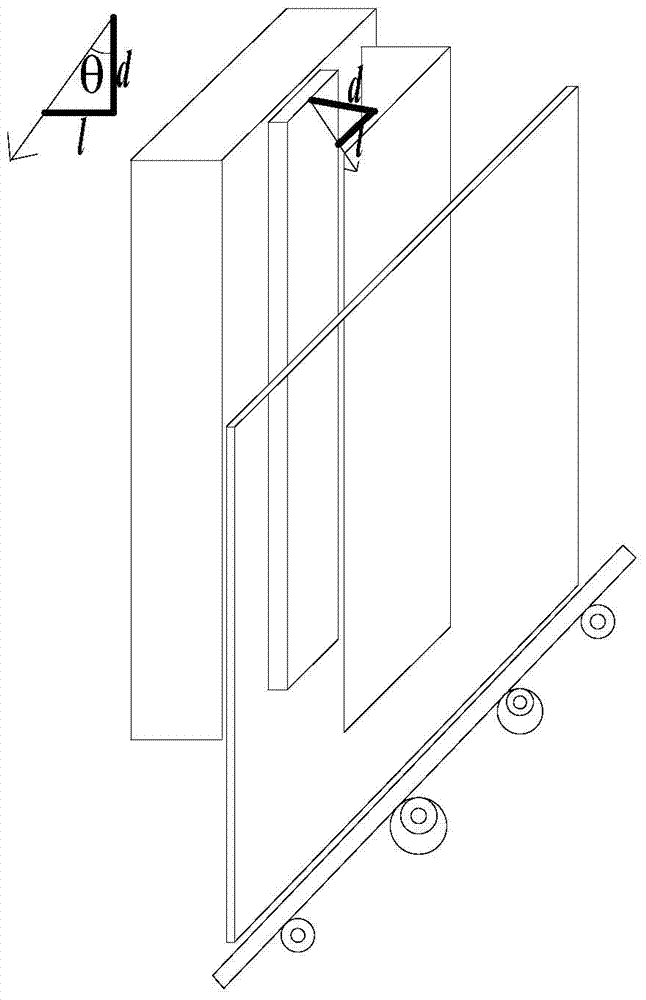

[0067] Five batches of samples of table 3 batch numbers 11-15 experimental conditions and performance measurement

[0068] Sample serial number 11 12 13 14 15 l (cm) 10 10 17.32 56.71 114.3 d (cm) 17.32 10 10 10 10 θ (degrees) 30 45 60 80 85 Film porosity 0.1 0.2 0.3 0.5 0.8

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com