Method for preparing nano-porous gold film through treating graphene as template

A nanoporous gold and graphene technology, applied in the field of mesoporous materials, achieves the effects of non-toxic and environmentally friendly reagents, good controllability, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

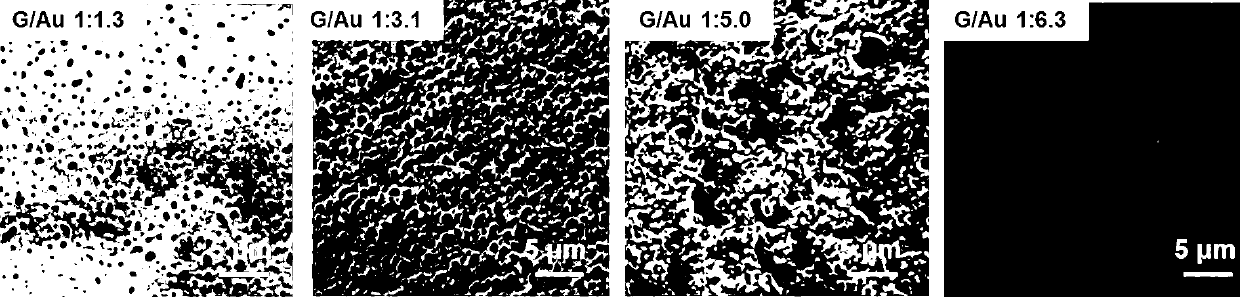

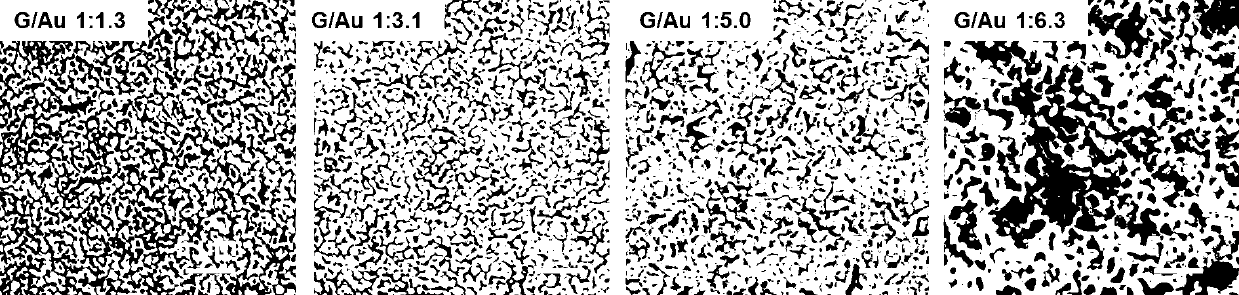

Embodiment 1

[0023] Sonicate chloroauric acid trihydrate (0.6, 1.6, 2.5 or 6.5 mmol / L), graphene oxide (0.1 mg / mL) and sodium citrate (10 mg / mL) in water for 2 min to disperse evenly; the mixture put in 100 o Stirring and heating reaction in C oil bath for 24 h to prepare gold nanoparticles / graphene composites (gold:graphene mass ratios were 1:1.3, 1:3.1, 1:5.0 and 1:6.3); After cooling, pour off the supernatant as much as possible, then centrifuge and wash the product three times at 5000 rpm until the supernatant is colorless, and the washing solvent is deionized water; redisperse the product in deionized water at a concentration of 0.1 mg / mL (with graphite olefin is the reference concentration); take 20 mL of the product dispersion, vacuum filter and wash with deionized water, the filter membrane is a mixed cellulose ester membrane with a pore size of 0.2 microns; dry the wet membrane in air for 1-2 days , the black composite film can be peeled off by itself; take about 10 mg of the com...

Embodiment 2

[0026] Sonicate chloroauric acid trihydrate (0.6, 1.6, 2.5 or 6.5 mmol / L), graphene oxide (0.1 mg / mL) and sodium citrate (10 mg / mL) in water for 2 min to disperse evenly; the mixture put in 100 o Stirring and heating reaction in C oil bath for 24 h to prepare gold nanoparticles / graphene composites (gold:graphene mass ratios were 1:1.3, 1:3.1, 1:5.0 and 1:6.3); After cooling, pour off the supernatant as much as possible, then centrifuge and wash the product three times at 5000 rpm until the supernatant is colorless, and the washing solvent is deionized water; redisperse the product in deionized water at a concentration of 0.1 mg / mL (with graphite olefin is the reference concentration); take 20 mL of the product dispersion, vacuum filter and wash with deionized water, the filter membrane is a mixed cellulose ester membrane with a pore size of 0.2 microns; dry the wet membrane in air for 1-2 days , the black composite film can be peeled off by itself; about 10 mg of the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com