Organic silicon prime paint composition and preparation method thereof

A technology of primer and composition, applied in the direction of coating, etc., can solve the problems of anti-vulcanization and anti-cold shock performance, etc., and achieve the effect of solving anti-vulcanization and resistance to cold and heat shock, preventing corrosion, and improving anti-vulcanization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

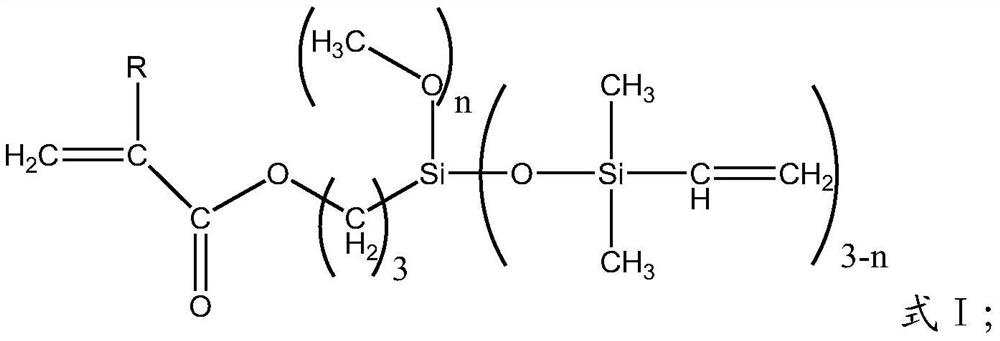

[0047] Synthesis Example 1 Synthesis of silicon-containing vinyl methacrylate

[0048] In a 500ml four-neck flask equipped with a serpentine condenser and a thermometer, add 124.18g of methacryloxypropyl trimethoxysilane, 167.76g of 1,3-divinyl-1,1,3, 3-Tetramethyldisiloxane, adjusted to below 10°C in an ice bath. After cooling, 11.7 g of concentrated sulfuric acid was added and mixed for 20 minutes. After mixing, 13.5 g of water was added dropwise for hydrolysis and equilibrium reaction. After reacting for 5 hours, 4.5 g of water was added for liquid separation and deacidification, 250 g of 10% Glauber's salt water and 200 g of toluene were added, and then further purified by washing with water. The solvent was removed by concentration at 100° C. / 5 mmHg to obtain methacryloxypropyltris(dimethylvinylsiloxy)silane of the following structure.

[0049]

Synthetic example 2

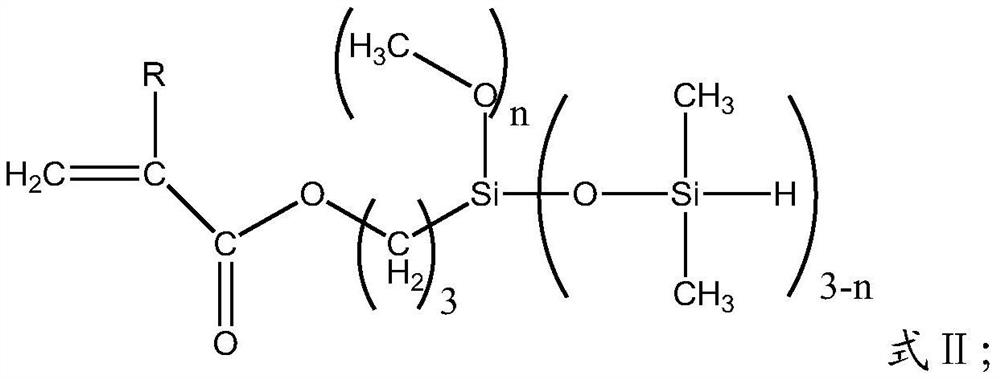

[0050] Synthesis Example 2 Silicon Hydrogen-Containing Methacrylate

[0051] In a 500ml four-necked flask equipped with a serpentine condenser and a thermometer, add 124.18g of methacryloxypropyltrimethoxysilane, 120.89g of 1,1,3,3-tetramethyldisiloxane Alkanes, adjusted to below 10°C in an ice bath. After cooling, 9.8 g of concentrated sulfuric acid was added and mixed for 20 minutes. After mixing, 13.5 g of water was added dropwise for hydrolysis and equilibrium reaction. After reacting for 5 hours, 4.5 g of water was added for liquid separation and deacidification, 250 g of 10% Glauber's salt water and 200 g of toluene were added, and then further purified by washing with water. The solvent was removed by concentration at 50° C. / 5 mmHg to obtain methacryloxypropyltris(dimethylsiloxy)silane of the following structure.

[0052]

Synthetic example 3

[0053] Synthesis example 3 methacrylate polymer containing silicon vinyl and silicon hydrogen

[0054]In a four-neck flask equipped with a serpentine condenser and a thermometer, add 50 parts by mass of methyl methacrylate, 10 parts by mass of SiCH=CH obtained from Example 1 2 bonded methacrylate, 5 parts by mass of methacrylate containing silicon-hydrogen bonds obtained in Example 2, a mixed solvent of isopropanol and ethyl acetate of 350 parts by mass, 0.5 parts by mass of 2,2' -Azobisisobutyronitrile, stirred at 85°C for 5 hours, cooled to 50°C, added 0.4 parts by mass of p-hydroxyanisole to prepare a methacrylate polymer containing silicon-containing vinyl groups and silicon-hydrogen bonds The solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com