Cobalt-based powder used for plasma arc surfacing and capable of resisting high-temperature corrosion and wear

A high-temperature corrosion-resistant, plasma arc technology, used in surface engineering and metallurgy fields, can solve the problems of reduced durability of coatings, insufficient wear resistance, insufficient wear resistance and corrosion resistance, etc., to achieve excellent anti-oxidation, Improve the efficiency of use and the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

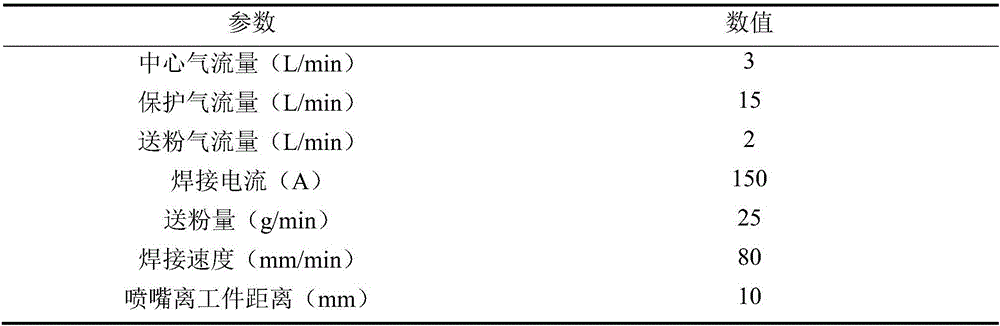

Method used

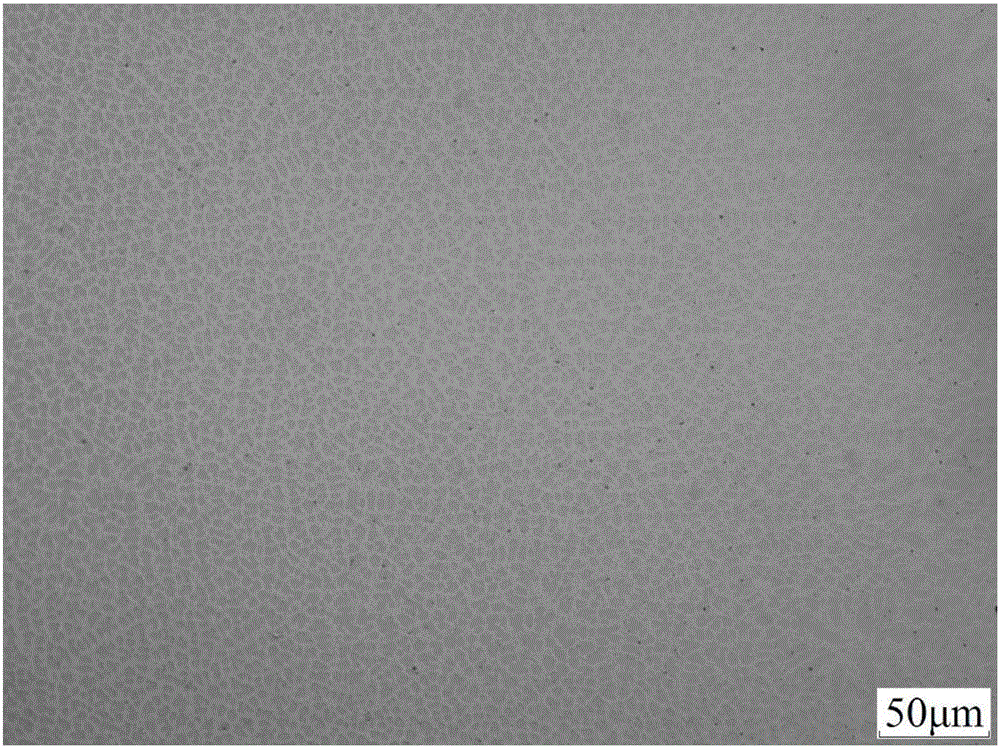

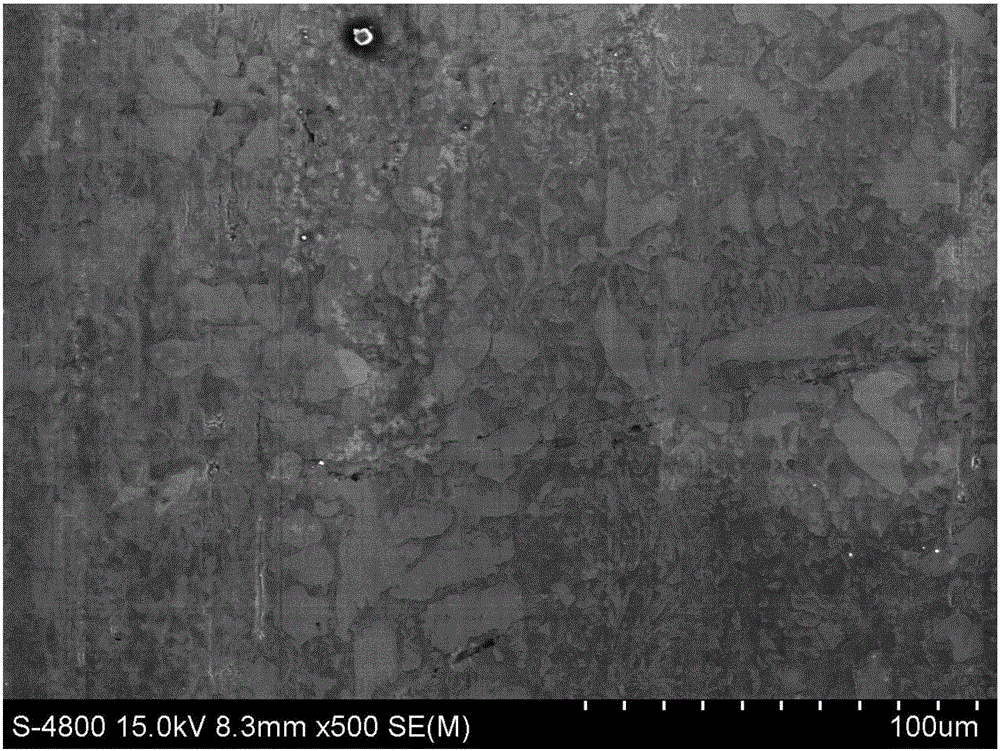

Image

Examples

Embodiment 1

[0028] Step One, Ingredients

[0029] Use the balance that accuracy is 0.01g to carry out batching 1000g to each component by the weight percent of each component of Table 1 Example 1, and weigh 5g of stearic acid by 0.5wt% of the total weight.

[0030] Step Two: Spherical Ink

[0031] According to the ball-milling ratio of 1:10, weigh the weight of the required grinding balls. It should be noted that the grinding balls require mixing balls of different diameters. Fatty acid is used as a process control agent to prevent the powder from sticking during the ball milling process, and then the sealed ball milling tank is charged and deflated 6 times with Ar gas to ensure the Ar environment in the ball milling tank and avoid the oxidation of the alloy components during the ball milling process , set the rotation speed of the planetary ball mill to 150r / min and the time to 10h. After the nodular ink is finished, put the ball mill jar into the refrigerator to cool the ball mill jar ...

Embodiment 2

[0035] The target composition is Example 2 in Table 1. The ingredients and powder output are as shown in Example 1. The difference is: in the ball ink, the set speed is 150r / min, and the ball milling time is 15h to obtain cobalt-based powder.

Embodiment 3

[0037] The target composition is Example 3 in Table 1. The ingredients and powder output are as shown in Example 1. The difference is: in the ball ink, the set speed is 180r / min, and the ball milling time is 12h to obtain cobalt-based powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com