Patents

Literature

36results about How to "Sufficient binding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

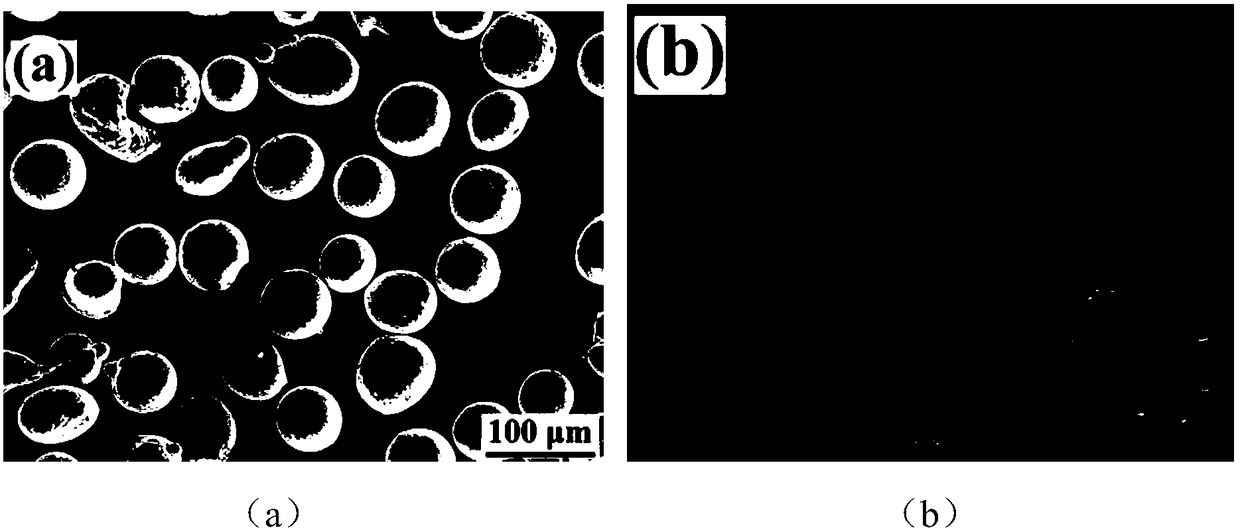

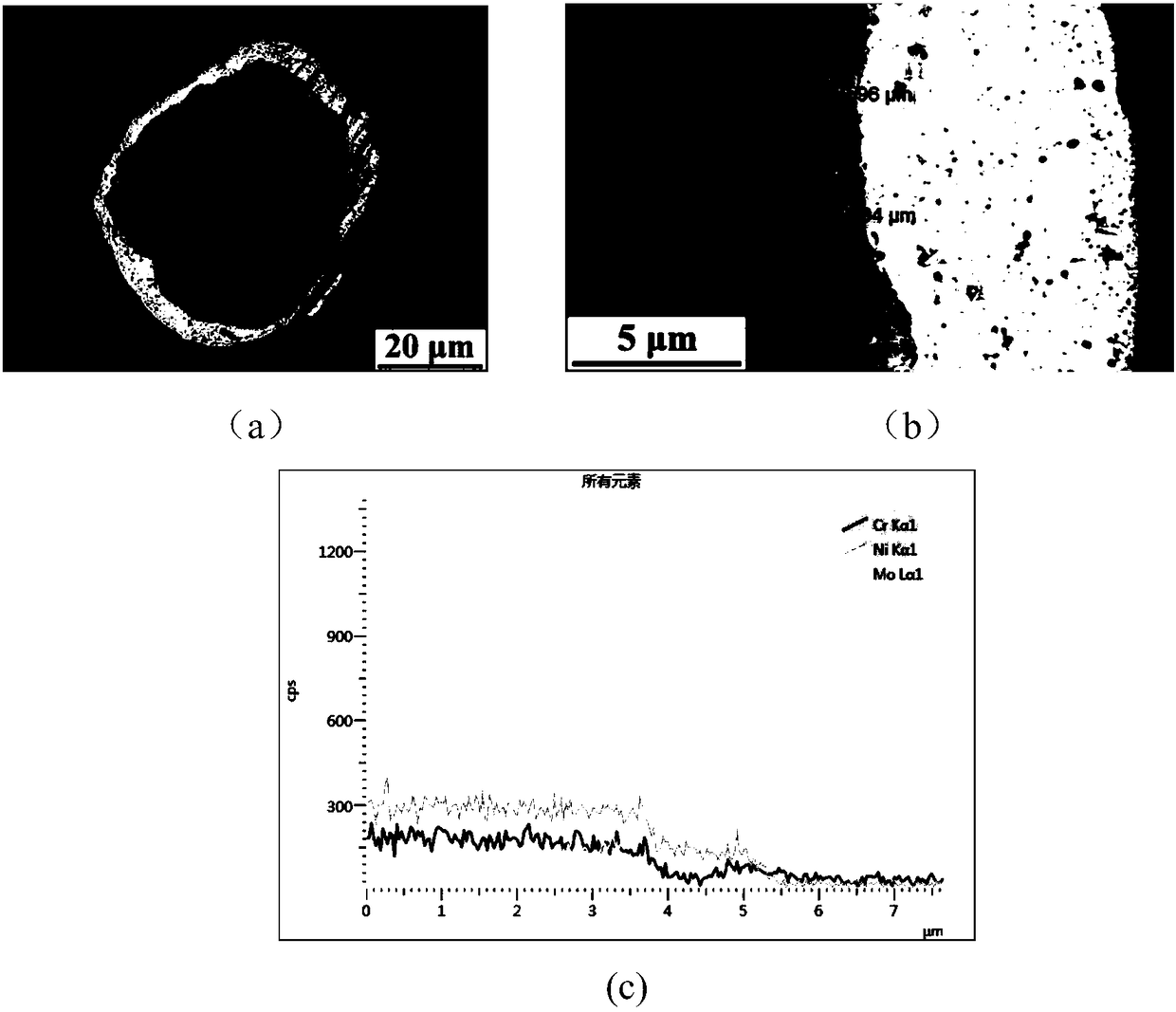

Thermal spraying self-bonding metal alloy powder with coated composite structure

ActiveCN105642885AIncrease temperatureComposite firmMolten spray coatingTransportation and packagingThermal sprayingMetal alloy

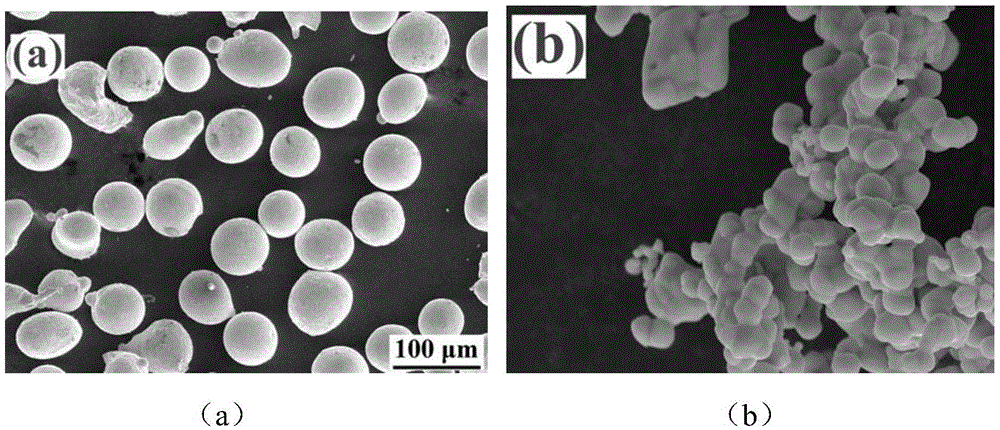

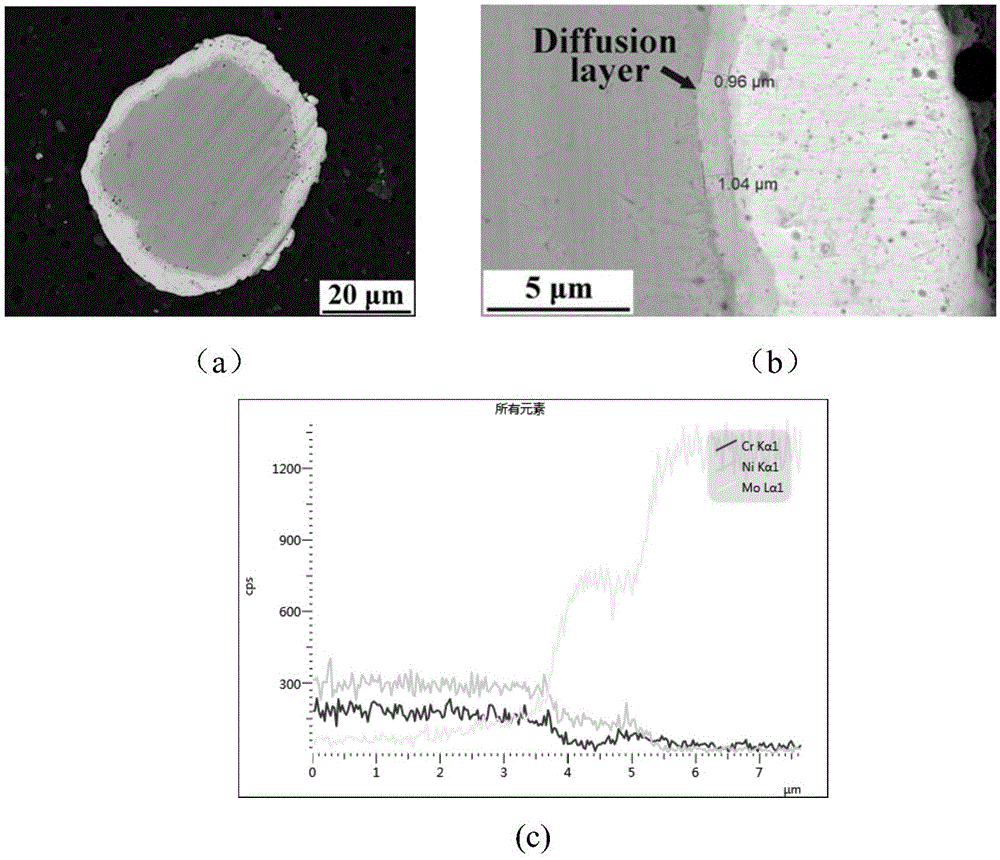

The invention discloses a thermal spraying self-bonding metal alloy powder with a coated composite structure and belongs to the technical field of material processing. The metal alloy powder is composite structural powder formed by coating outer-layer metal and coated metal particles, the surfaces of the coated metal particles are uniformly coated with the coating outer-layer metal, a melting point of the coating outer-layer metal is higher than a melting point of the coated metal particles, the coating layer and the coated metal particles are metallurgically bonded to form the composite structural powder. When a metal alloy coating prepared by the composite structural powder is adopted, due to the fact that metallurgical bonding reaction occurs between the coating and a substrate and also occurs among particle layer interfaces in the coating, the interface bonding can be firm, accordingly the bonding strength between the coating and the substrate and the cohesion bonding strength of the particle layers in the coating are remarkably improved, and the long-term usage stability of the coating is ensured. The metal alloy coating prepared by the metal alloy powder has excellent corrosion resistance properties.

Owner:XI AN JIAOTONG UNIV

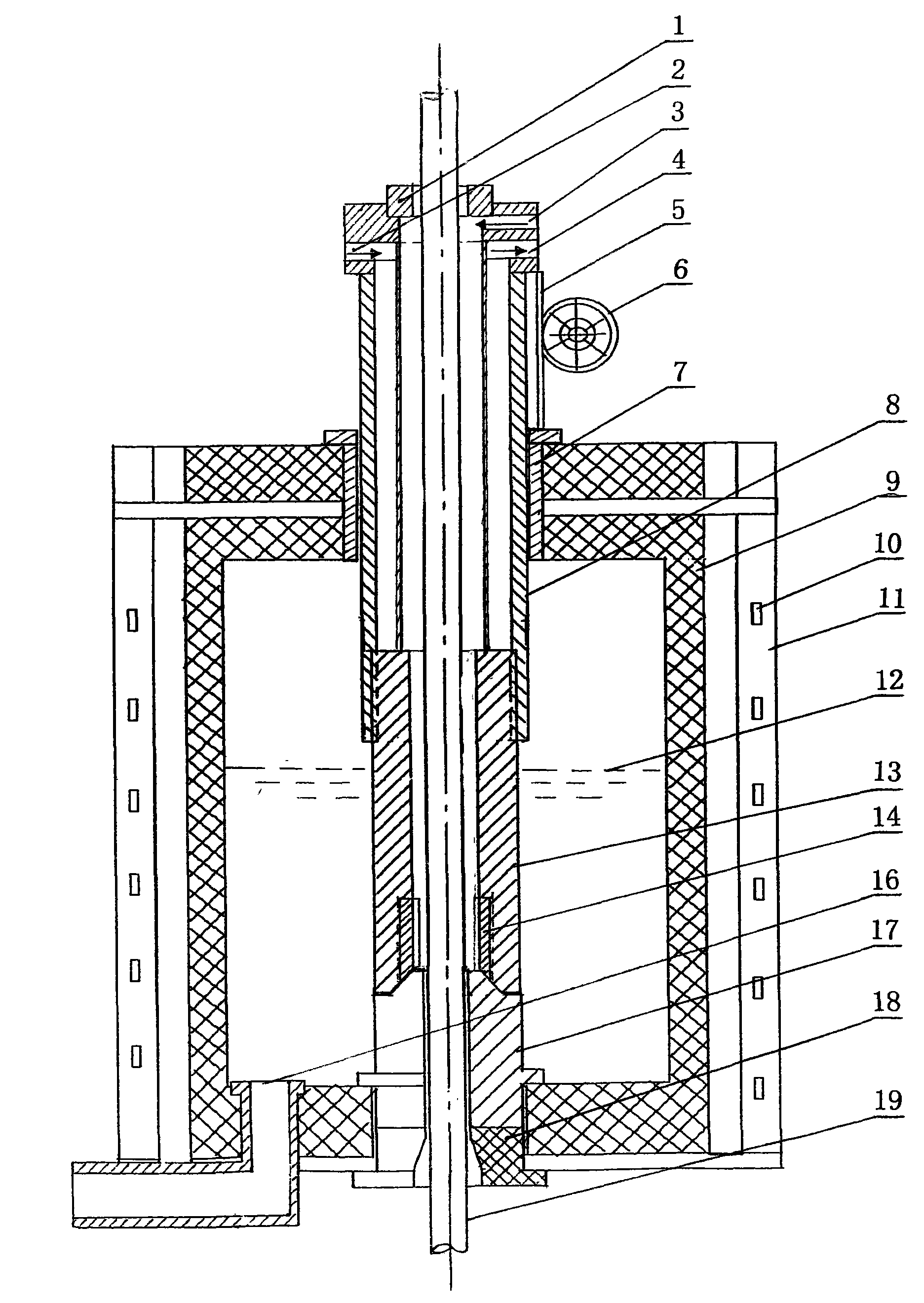

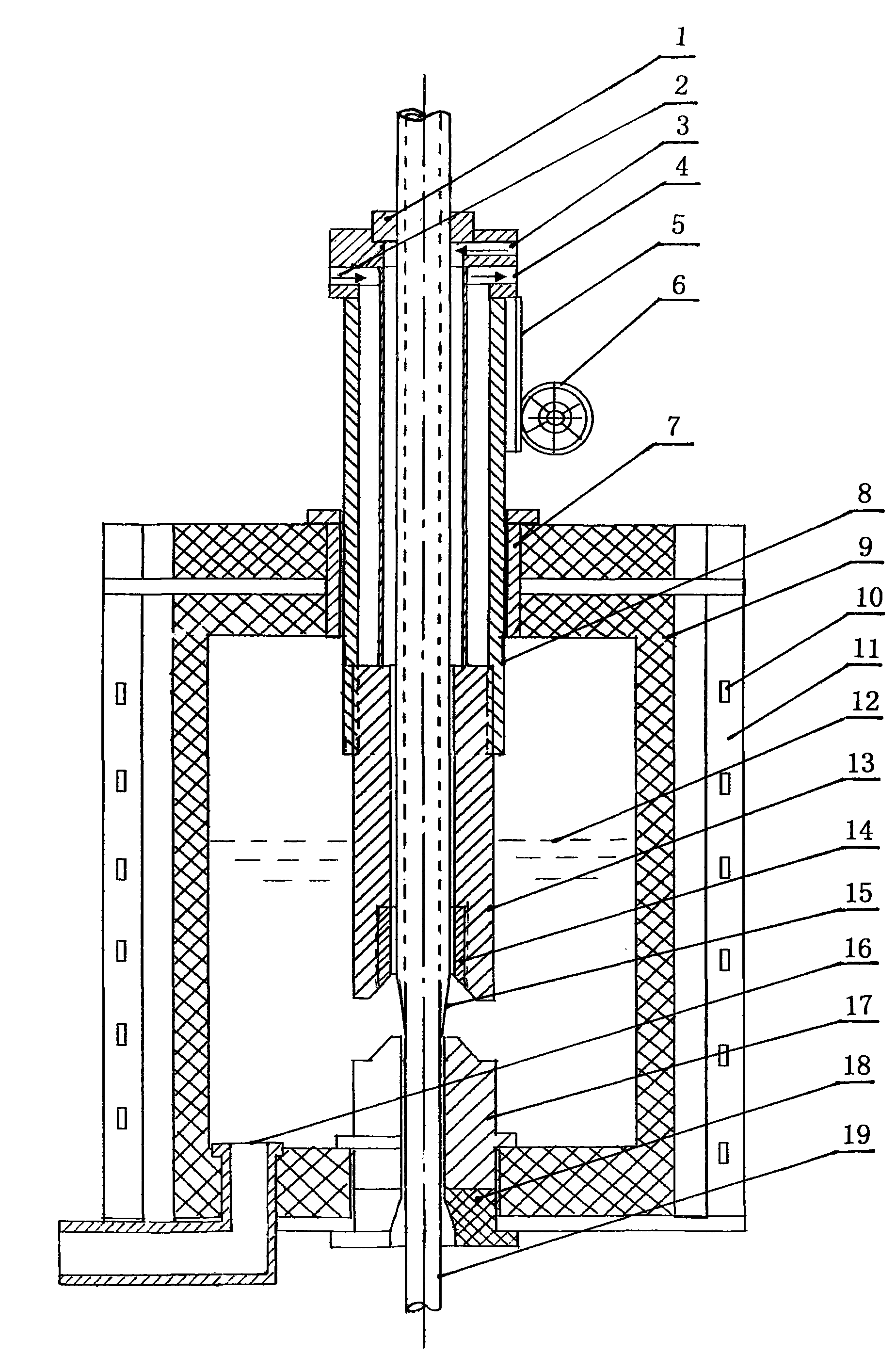

Upward forming method of thermal dip-coating copper covered steel and upward forming device thereof

InactiveCN101629274AHigh bonding strengthHigh strengthHot-dipping/immersion processesAbsorption capacityPhosphonium

The invention relates to an upward forming method of thermal dip-coating copper covered steel. The upward forming method mainly comprises the following steps: enabling a preheated steel bar to enter the bottom of a crucible; sequentially dipping and coating the preheated steel bar in copper water of the crucible; and vertically pulling out the preheated steel bar from the upper part of the crucible. An upward forming device corresponding to the method comprises a copper water pretreatment device, a steel bar pretreatment device, the crucible, a winding device, a graphite tube, an upper graphite tube, a cooling tube, a lifting tube and a lifting device. The method mainly changes the prior horizontal forming into vertical upward forming to equalize the surface periphery temperature and the surface heat absorption capacity of the steel bar, thoroughly solves the problem of eccentric copper coating, controls the preheating temperature, the copper water temperature, the dip-coating distance and the dip-coating speed of the steel bar in suitable ranges, not only enables a copper-steel interface to have enough bonding strength, but also effectively prevents phosphonium ions in the steel bar from entering to pollute the copper water, enables the copper covered steel product to have the advantages of high strength, high conductivity, low cost, and the like and is most suitable for being used as overhead conductors and lightning conductors of a power network.

Owner:曹佩荣

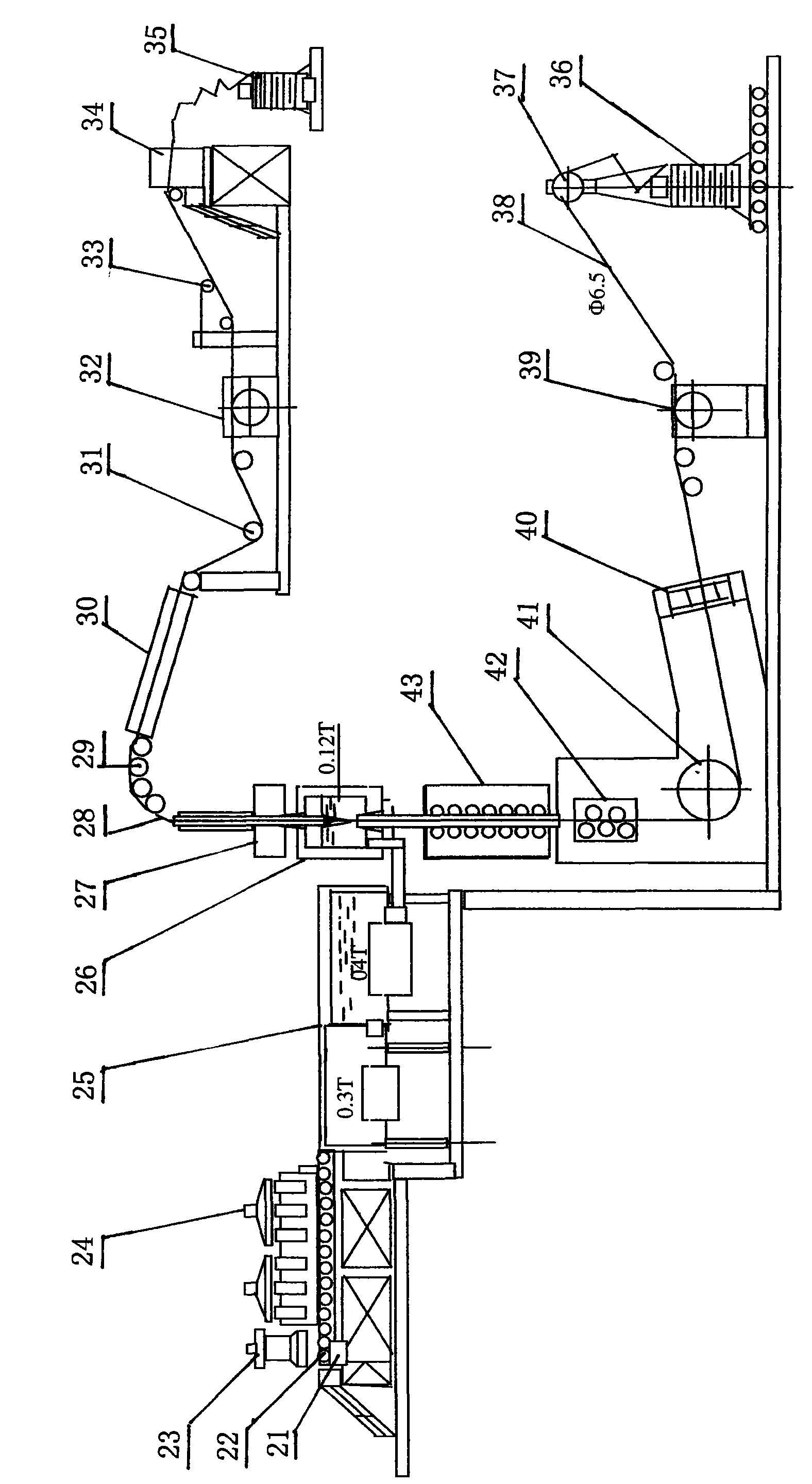

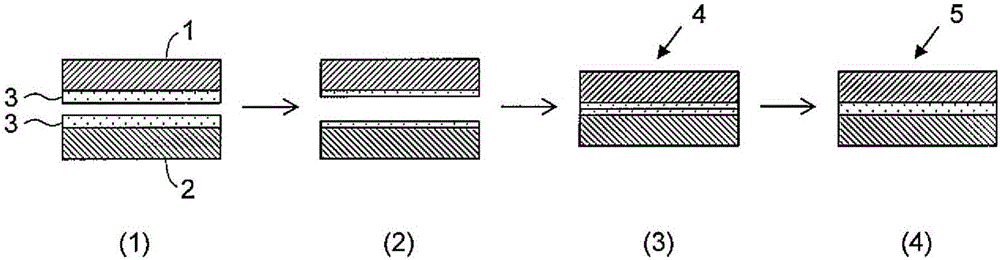

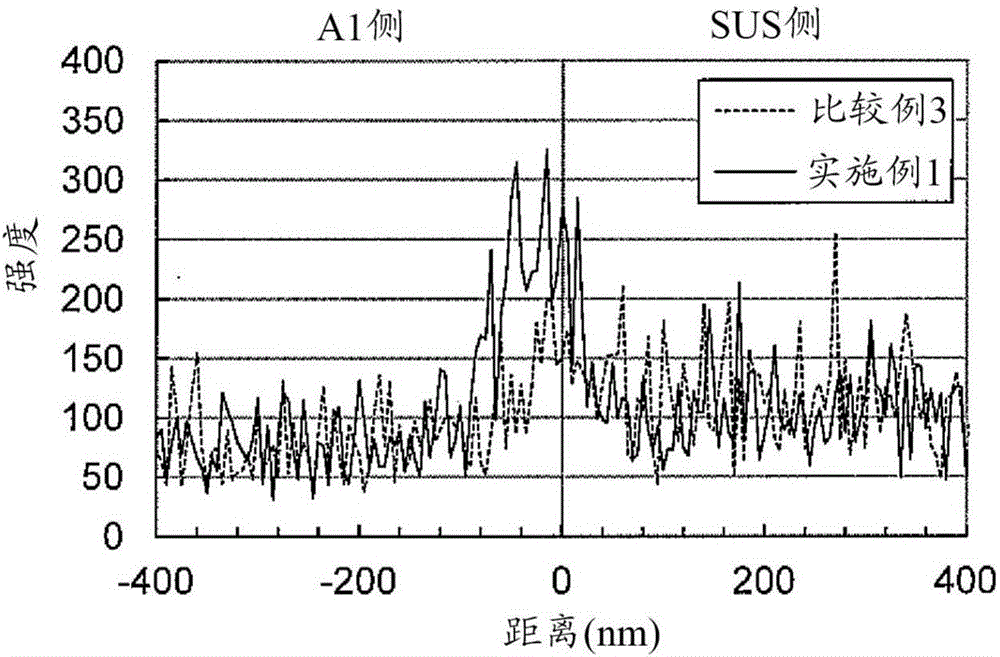

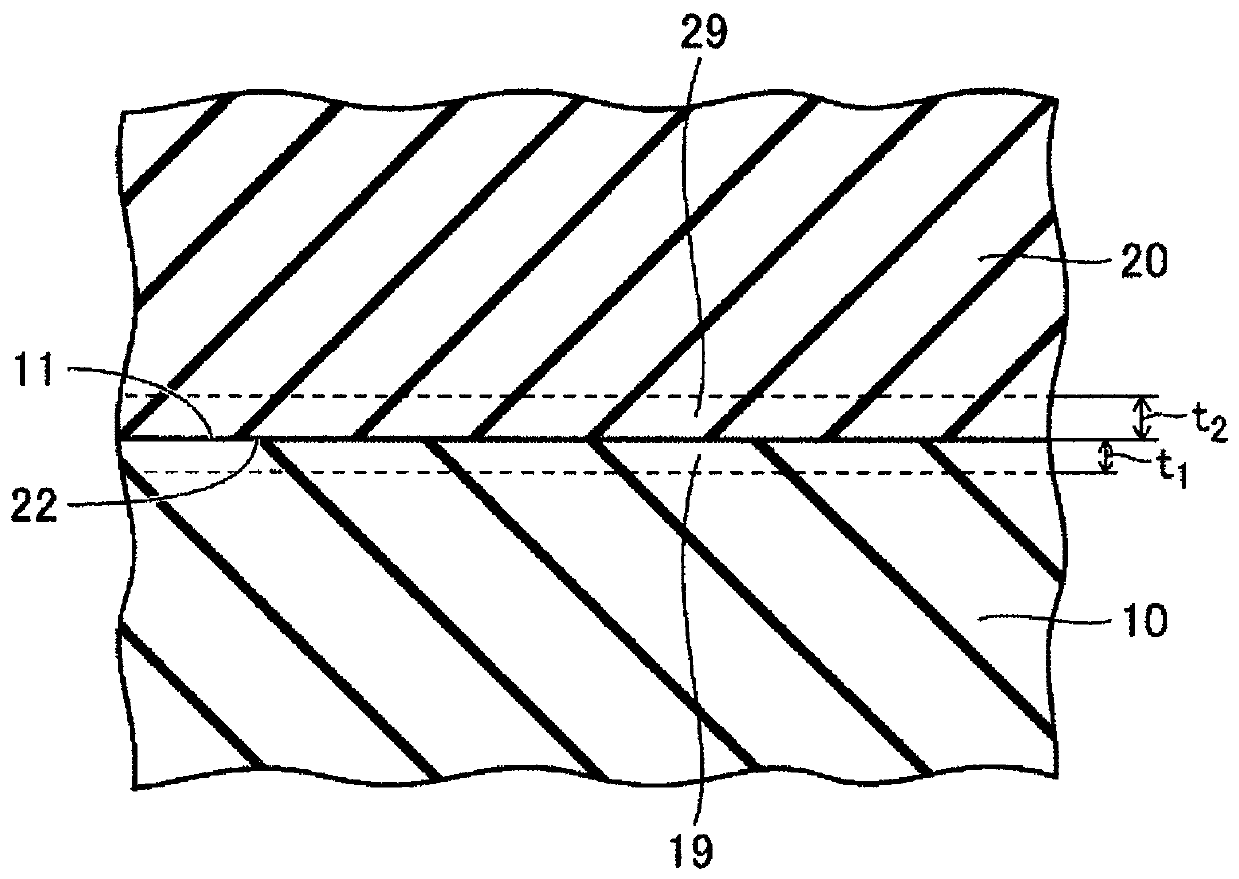

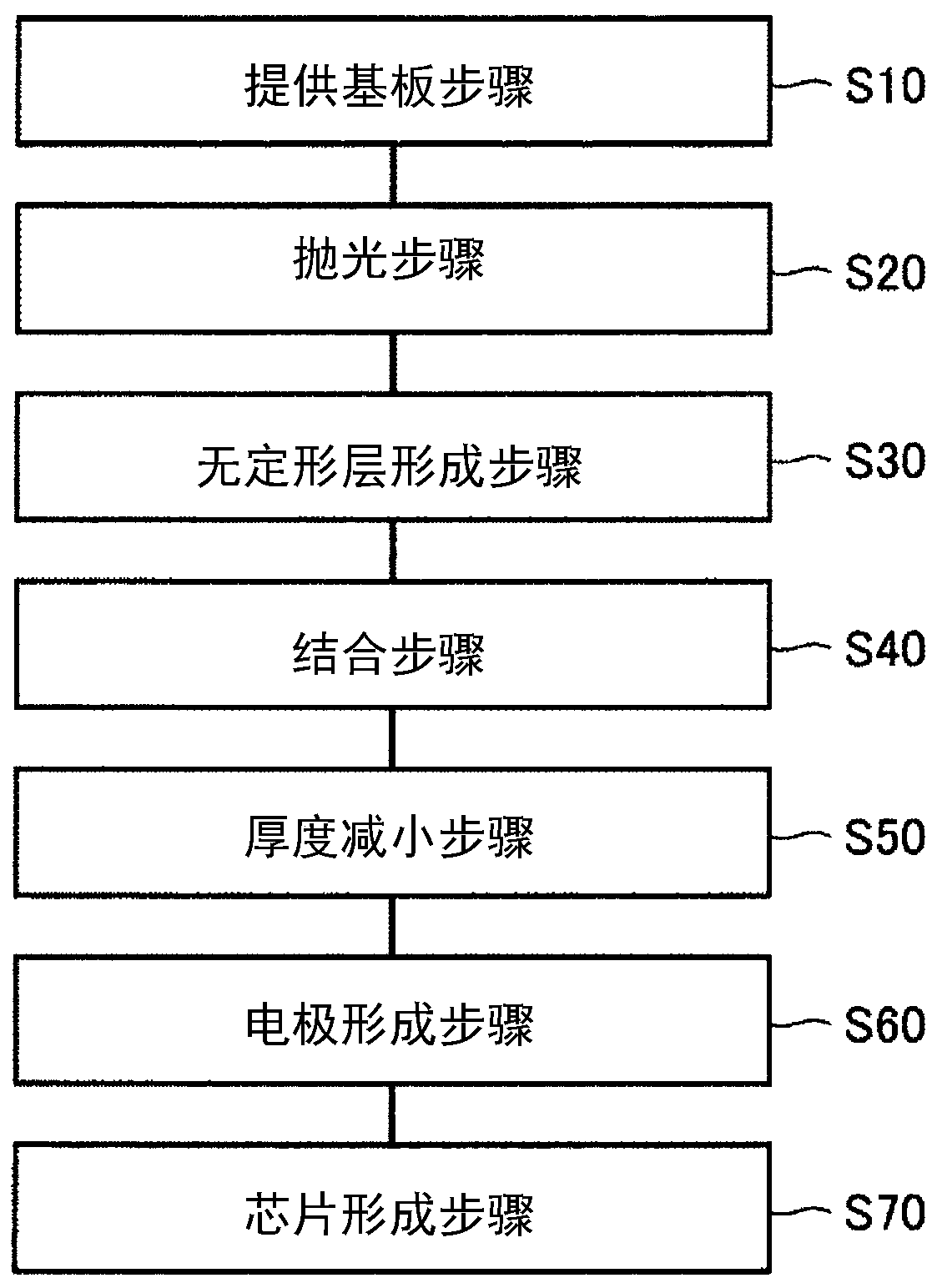

Method for producing metal laminate material

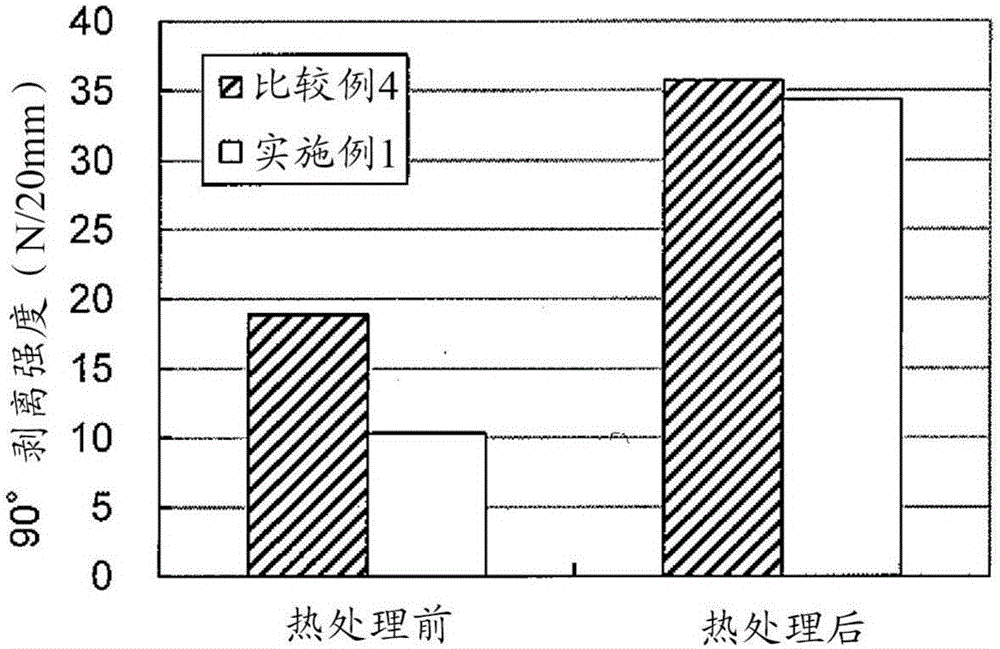

InactiveCN106102978ASufficient binding strengthImprove productivityElectric discharge tubesLaminationSurface layerBonding strength

Owner:TOYO KOHAN CO LTD

Method for spraying and preparing high temperature sulfidation resistant alloy layer on the surface of cast iron

InactiveCN101575693ASufficient binding strengthHigh bonding strengthMolten spray coatingWire rodSulfidation

The invention belongs to the technical field of metal surface spray and provides a method for spraying and preparing a high temperature sulfidation resistant alloy layer on the surface of cast iron. The method includes the following steps of: (1) pre-treating the surface of a cast iron workpiece before spraying, and exposing the clean and coarsening metal surface of the workpiece; (2) adopting a subsonic speed oxyacetylene flame hot spray method to spray prime coat on the surface of the cast iron workpiece, wherein the prime coat adopts nickel aluminum compound powder; and (3) adopting a high speed arc wire spray method to spray an FeCrAl working layer on the surface of the cast iron workpiece. The technique of the invention is characterized by simple and convenient operation and strong applicability, can save high alloy material and is convenient for promotion and use. Compared with the overall high temperature sulfidation resistant material, the cast iron part prepared by means of the method is low in cost, has excellent resistance to high temperature sulfidation and favorable wearing resistance, and can strikingly improve the service life of the cast iron part in a high temperature sulfidation environment.

Owner:HENAN POLYTECHNIC UNIV

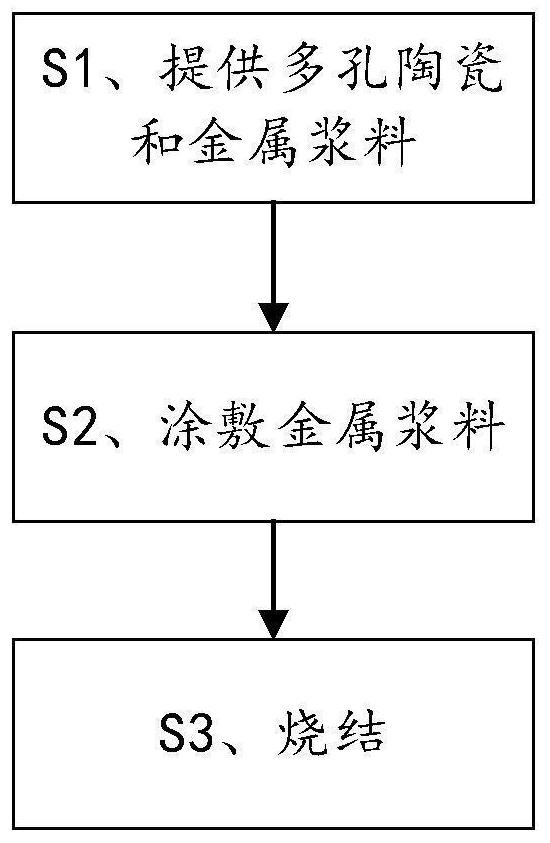

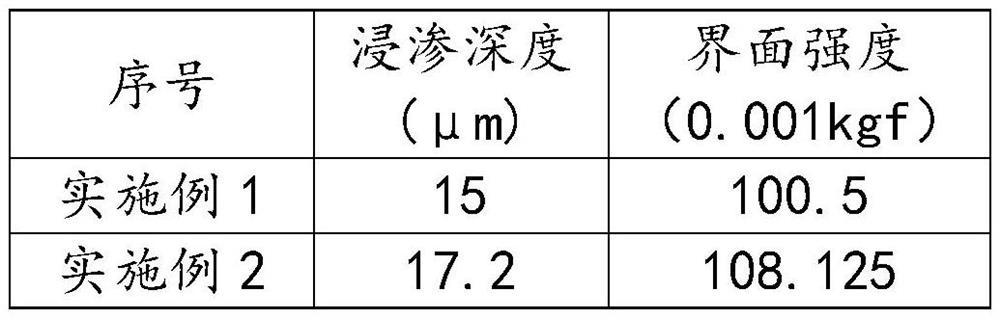

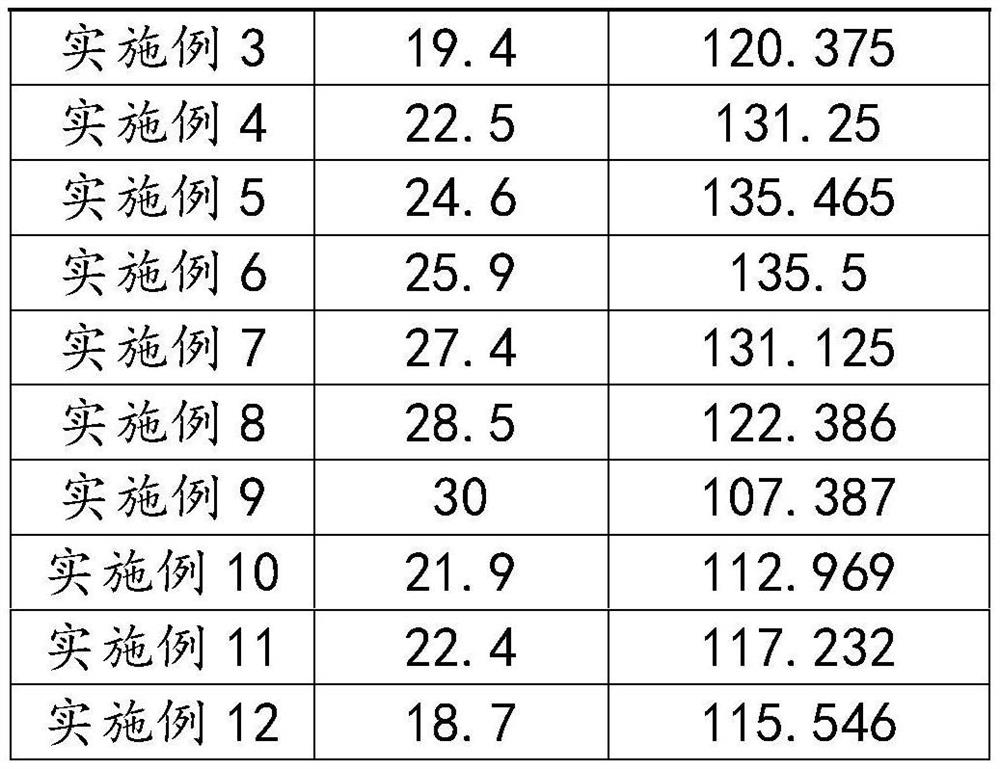

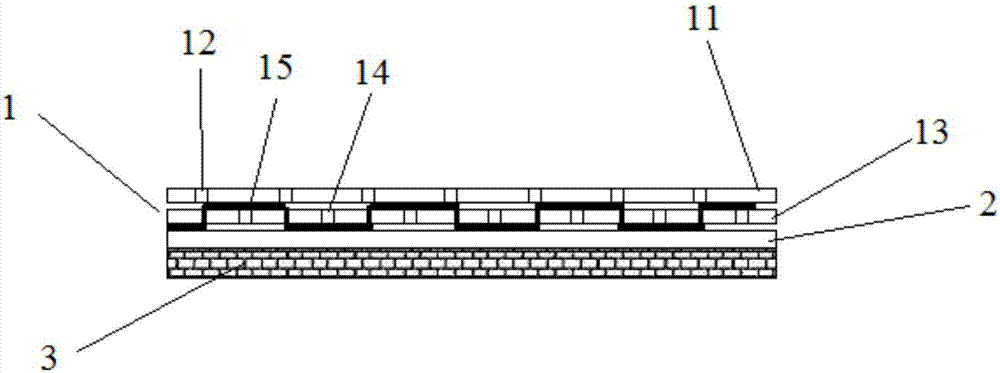

Metal slurry, heating circuit, atomizing core, preparation method of atomizing core, and electronic cigarette

ActiveCN113421691AGuaranteed resistance stabilityGuaranteed continuityApparatus for heat treatmentApparatus for manufacturing conducting/semi-conducting layersAlkaline earth metalSlurry

The invention provides metal slurry, which comprises metal powder, glass powder and an organic carrier, wherein a mass ratio of the metal powder to the glass powder to the organic carrier is 100:(5-10):(10-20); the metal powder comprises Ni powder, Cr powder and NiCr20 alloy powder; the median particle size of the Ni powder and the median particle size of the Cr powder are both smaller than 10 microns, and the median particle size of the NiCr20 alloy powder ranges from 15 microns to 50 microns; and the chemical formula of the glass powder is B-Si-Al-M2O-NO, M is alkali metal, and N is alkaline earth metal. The invention further provides a heating circuit made of the metal slurry, an atomizing core comprising porous ceramic and the heating circuit, a preparation method of the atomizing core and an electronic cigarette. The bonding strength between the heating circuit prepared from the metal slurry and the porous ceramic is high, the strength of the porous ceramic is not affected, the assembly and use requirements of the atomizing core of the electronic cigarette can be met, and the service life of the electronic cigarette is prolonged.

Owner:SHENZHEN TAOTAO TECH CO LTD

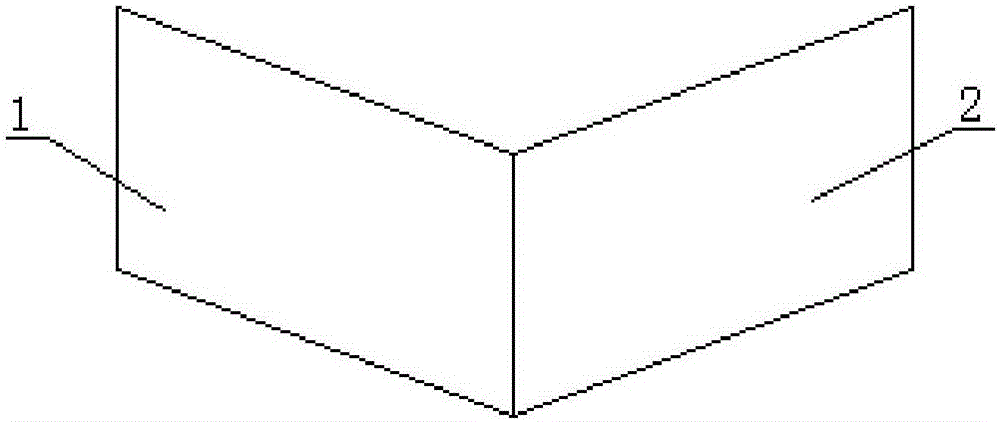

Manufacturing technology of high-performance composite plate

ActiveCN106425292AGood toughness and weldabilityImprovement of heat treatment deformationDistortionIon

The invention discloses a manufacturing technology of a high-performance composite plate. The manufacturing technology comprises the steps that corrosion resistant metal materials are selected and smelted, and a proper amount of a titanium carbide alloy is added in the smelting process; a pipe blank is formed by smelted metal materials through centrifugal complex casting and subjected to heat treatment, the inner and outer surfaces of the pipe blank are cleaned through a turning lathe and a boring lathe, and the pipe blank is equally cut into three arc blocks through an ion cutting machine; the cut arc blocks are subjected to forging and pressing, leveling and heat treatment, an alloy plate is trimmed through a milling machine, the inner and outer surfaces of the alloy plate is cleaned through the turning lathe and the boring lathe, and the alloy plate with titanium carbide accumulated on one side is manufactured; and a low-carbon steel plate or a stainless steel plate is selected, cut and subjected to surface treatment, the low-carbon steel plate or the stainless steel plate and the manufactured alloy plate are buckled together, a double-metal welding body is heated and forged repetitively, and a baseplate and the alloy plate are firmly pressed together to manufacture the high-performance composite plate. According to the manufacturing technology, the high-performance composite plate is high in corrosion resistance and good in welding performance and toughness and has enough bonding strength, heat treatment distortion is greatly improved, and the manufacturing technology is widely applied to rolling mill slide plates, heat resistant and corrosion resistant guide plates and the like.

Owner:TAIAN BONA METAL ABRASION RESISTANT TECH

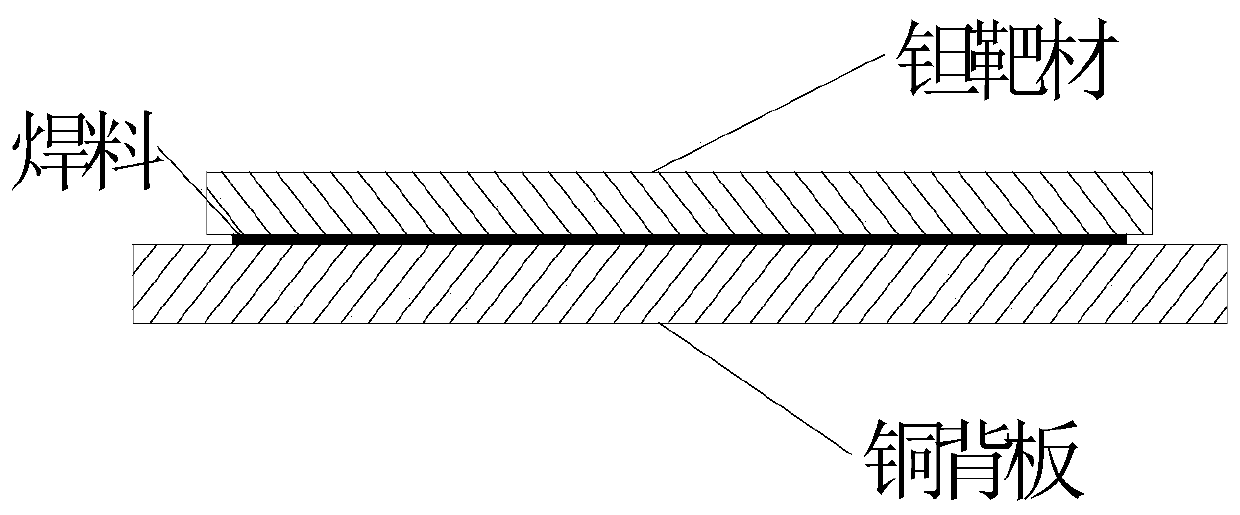

Soldering method of tantalum target material and copper back plate

InactiveCN111195757AIncrease roughnessHigh bonding strengthSoldering apparatusWelding apparatusSand blastingSoldering

The invention provides a soldering method of a tantalum target material and a copper back plate. The soldering method comprises the following steps that (1) the warping degree of the tantalum target material is corrected to make the flatness of the target material less than or equal to 0.2 mm; (2) welding surfaces of the tantalum target material and the copper back plate are respectively and independently subjected to surface sandblasting treatment; (3) the welding surfaces of the tantalum target material and the copper back plate are respectively and independently subjected to nickel plated treatment; and (4) after the nickel plated treatment, the tantalum target material and the copper back plate are subjected to soldering connection to complete soldering welding connection. According tothe soldering method, the roughness of the welding surfaces is improved through the sandblasting treatment, and the tantalum target material and the copper back plate are effectively combined throughthe nickel plated treatment, and thus the welding effect of the tantalum target material and the copper back plate is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

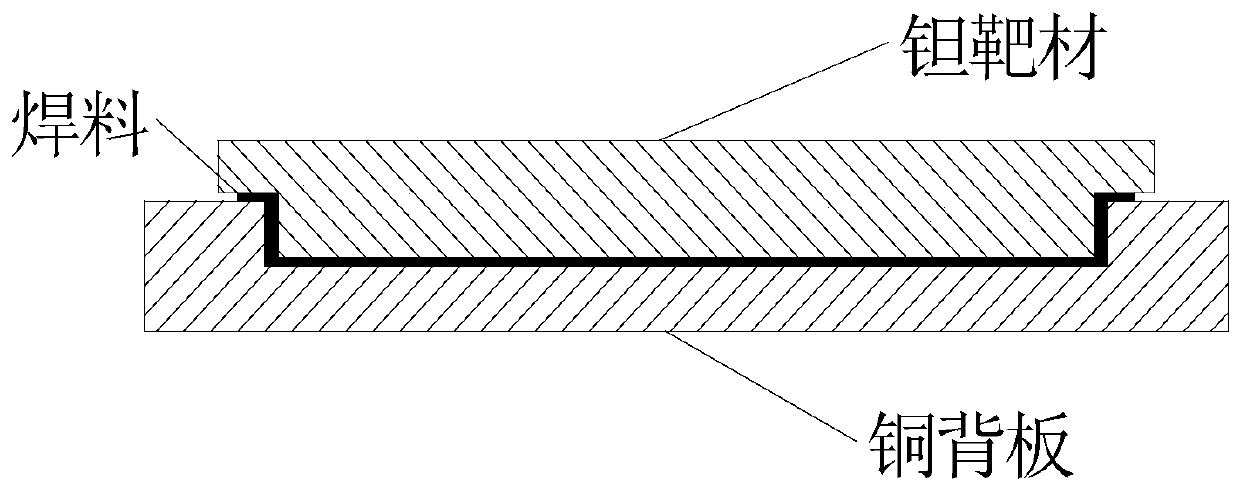

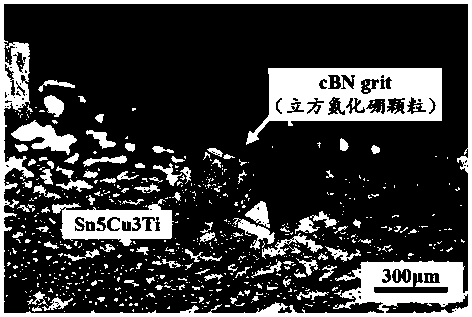

Method for brazing CBN (Cubic Boron Nitride) abrasive particles at low temperature

ActiveCN108655524ASufficient binding strengthReduce residual stressWelding/cutting media/materialsSoldering mediaMetallic materialsBoron nitride

The invention discloses a method for brazing CBN (Cubic Boron Nitride) abrasive particles at a low temperature and belongs to the technical field of superhard abrasive material tool manufacture. The method comprises the following steps: adopting acetone to clean CBN abrasive particles ultrasonically and drying the CBN abrasive particles, sequentially paving and spraying Sn-Cu-Ti alloy powder and CBN abrasive particles on a polished tool substrate; placing the tool substrate in a quartz tube and vacuumizing; then, moving the tool substrate to a heating furnace and heating the tool substrate for5-60 minutes at 350-700 DEG C; and finally, cooling the tool substrate to the room temperature under the vacuumizing state. The method has the following technological advantages: on the premise thatbrazing filler metal and the CBN abrasive particles are ensured to generate chemical bonding and the abrasive particles have sufficient bonding strength, the brazing temperature is greatly reduced toreduce loss of the metal material performance, size and shape of the tool substrate and the residual thermal stress at the bonding interface of the CBN abrasive particles and brazing filler metal is reduced.

Owner:HUAQIAO UNIVERSITY

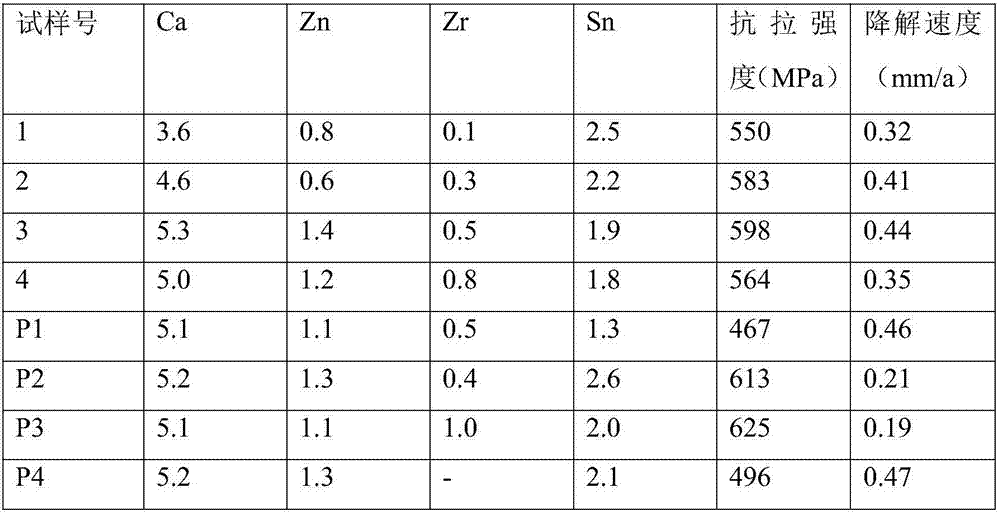

Artificial joint material

InactiveCN107029284AGuaranteed StrengthGuaranteed reliabilityTissue regenerationProsthesisArtificial jointsAdditive ingredient

The invention provides an artificial joint material which is divided into a joint friction contact surface, a joint main body and a joint and human body contact surface. The three parts are formed by materials made of different ingredients. The joint friction contact surface is formed by a composite material of ceramic particles and titanium alloy. The joint main body is formed by titanium alloy. The joint and human body contact surface is formed by titanium alloy and degradable magnesium alloy. The joint friction contact surface is formed by using the composite material of the ceramic particles and the titanium alloy to improve abrasion resistance characteristics of an artificial joint; and by using the titanium alloy and degradable magnesium alloy, the surface in contact with the human body is formed to improve interfacial stability between the artificial joint and host bone tissues.

Owner:郑超

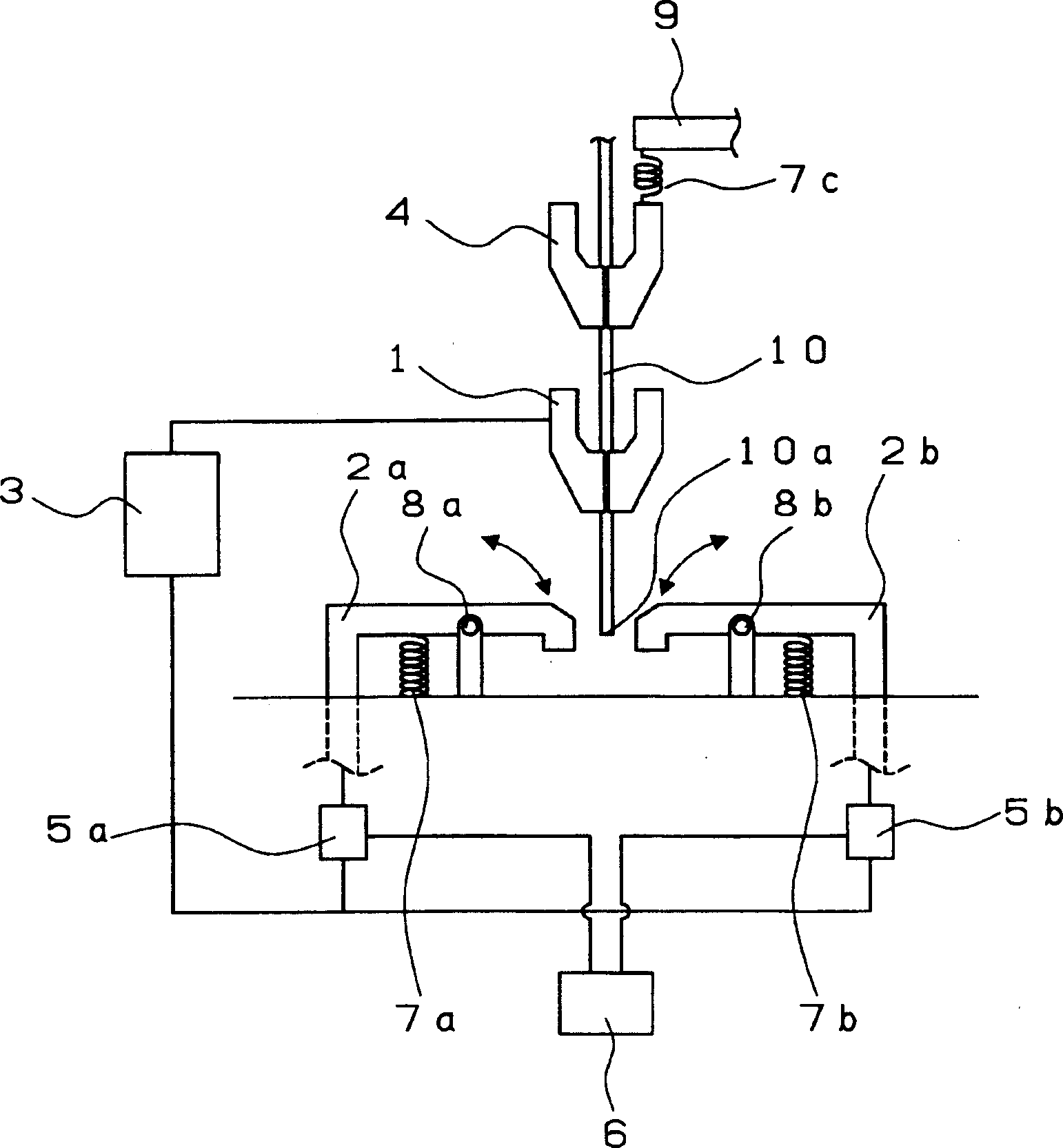

Resistance welding method, resistance welding equipment and method for manufacturing electronic component

InactiveCN1517169ASufficient binding strengthPrevent uneven current distributionWelding monitoring devicesConductorsElectrical resistance and conductanceCurrent distribution

In a resistance welding method and a resistance welding apparatus which prevent a decrease in bonding strength between a lead wire and a metal member due to a partially formed current flow path and which immediately removes a defective component from a manufacturing line, a plurality of second welding electrodes in contact with the metal member is provided so as to provide a plurality of current flow paths, and accordingly, to prevent an unevenly distributed current flow. The bonding strength is measured to determine whether it is satisfactory or not on the basis of currents flowing through the second welding electrodes. Also, the electronic component is fixed by the second welding electrodes after resistance welded.

Owner:MURATA MFG CO LTD

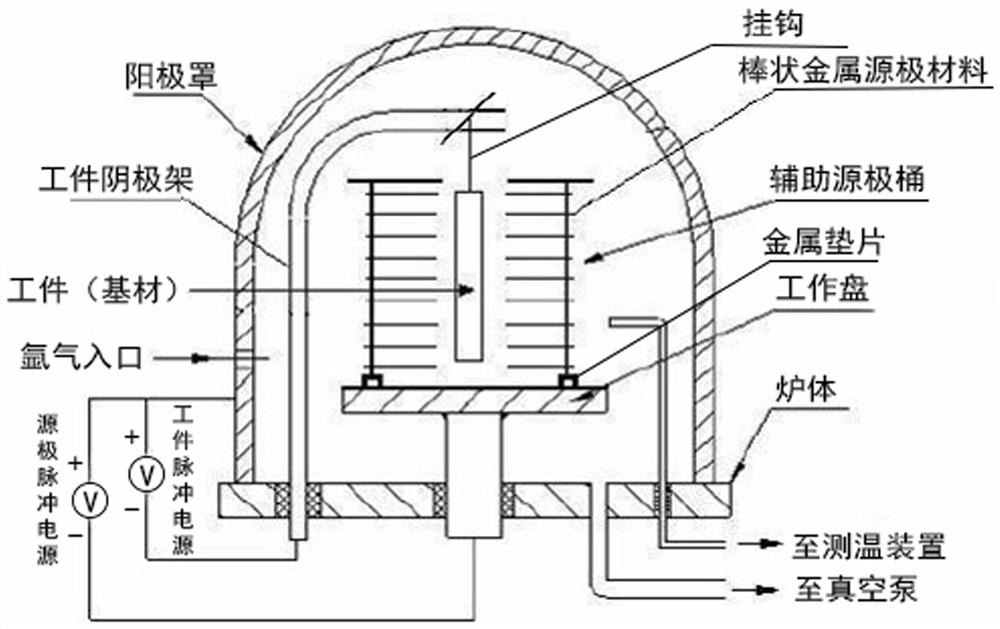

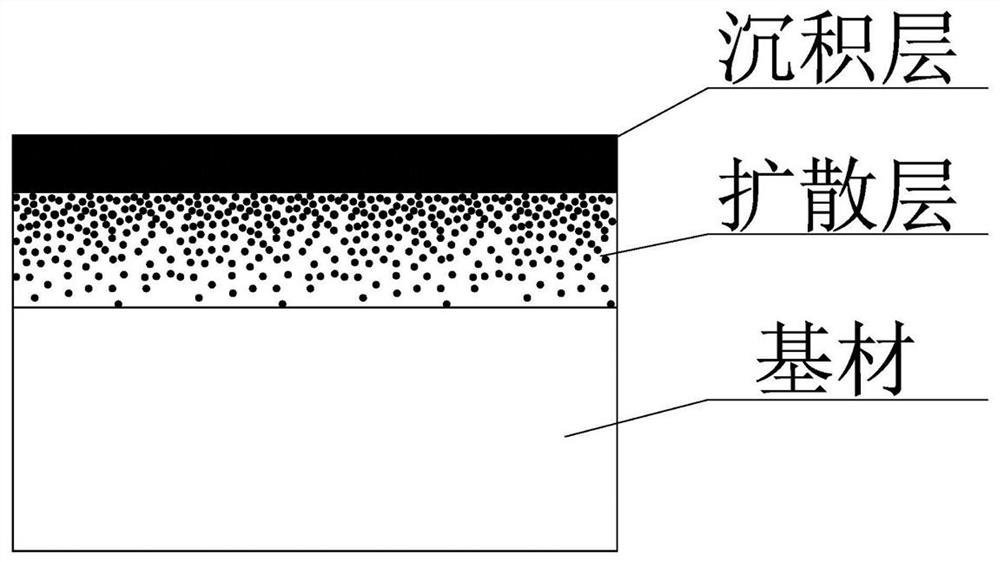

Surface gradient high-entropy alloy layer and preparation method thereof

ActiveCN112501569AImprove surface modification efficiencyComposition controllableVacuum evaporation coatingSputtering coatingHigh entropy alloysPulse power supply

The invention discloses a surface gradient high-entropy alloy layer and a preparation method thereof. The method comprises the steps that rod-shaped metal source electrode materials such as Cr, Ni, Fe, Cu, Ti, W, Mo and Nb are inserted into small holes of an auxiliary source electrode barrel, and the auxiliary source electrode barrel inserted with the rod-shaped source electrode materials is connected to a working disc of a source electrode pulse power source. The pre-infiltrated base material is suspended in the auxiliary source electrode barrel through a workpiece cathode frame connected into a workpiece pulse power supply and hooks, a double-cathode plasma solid-state metallurgy method is adopted for infiltrating pre-infiltrated elements to the surface of the base material so as to formthe surface gradient high-entropy alloy layer, and the alloy layer comprises a surface deposition layer and a diffusion layer from top to bottom and is metallurgically combined with the base material. The components are in gradient distribution, and the binding force is high. The thickness of the deposition layer can reach up to 60 microns, the thickness of the diffusion layer can reach up to 100microns, and the thicknesses of the deposition layer and the diffusion layer can be adjusted by adjusting process parameters as required. The high-entropy alloy layer can be prepared on the surfacesof workpieces of various complex shapes, the components are controllable, and the organization structure characteristic is good.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

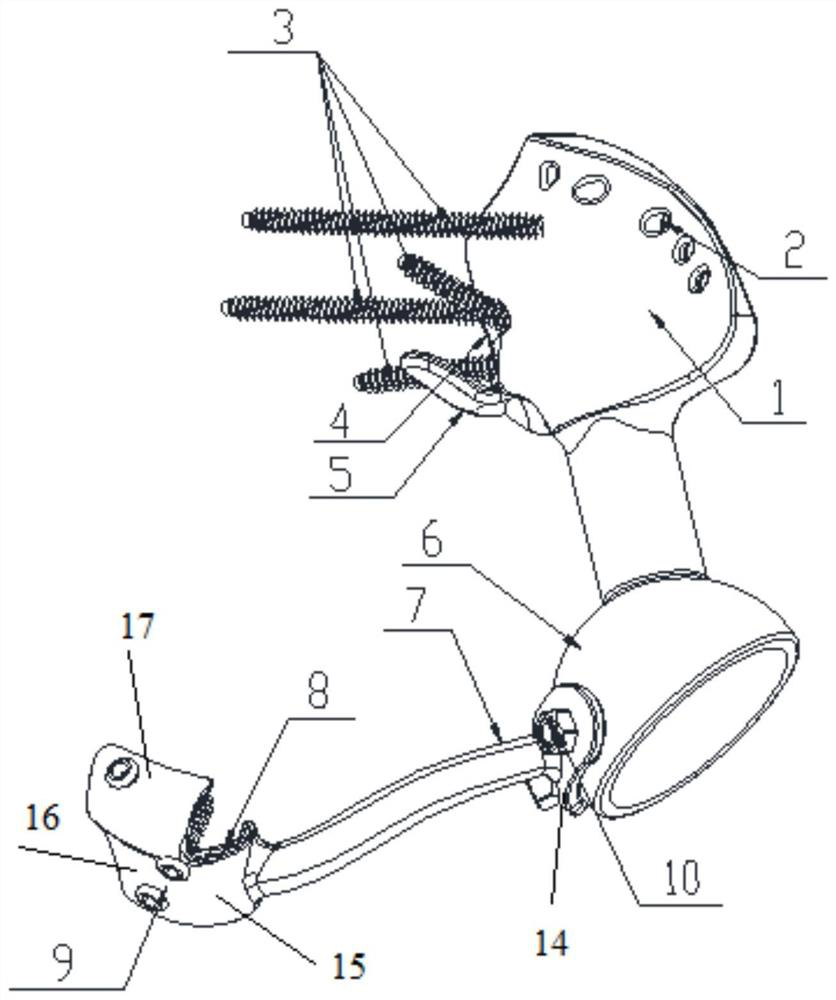

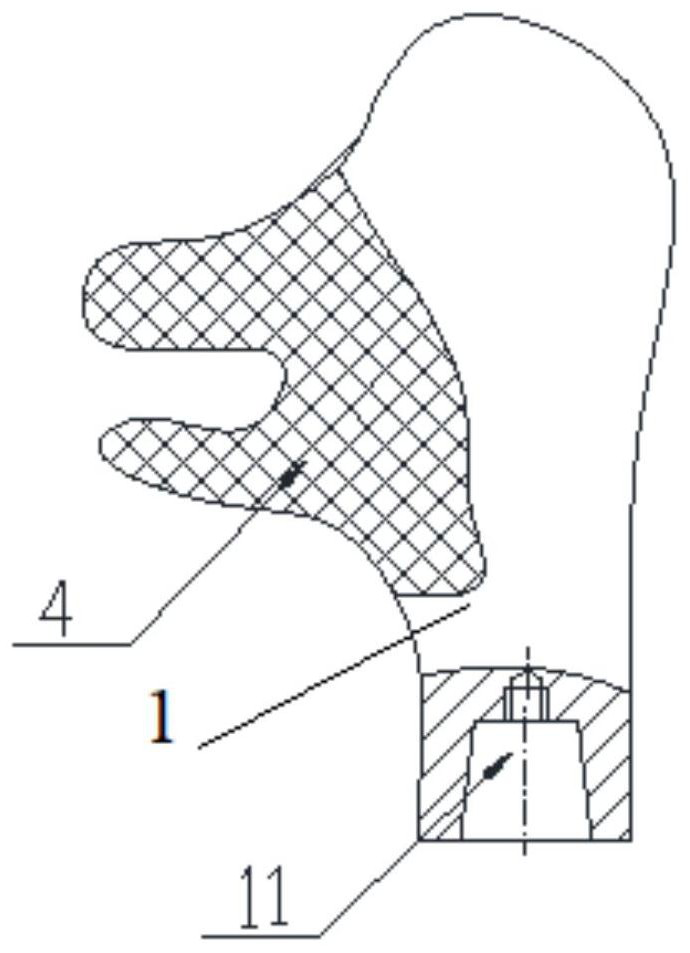

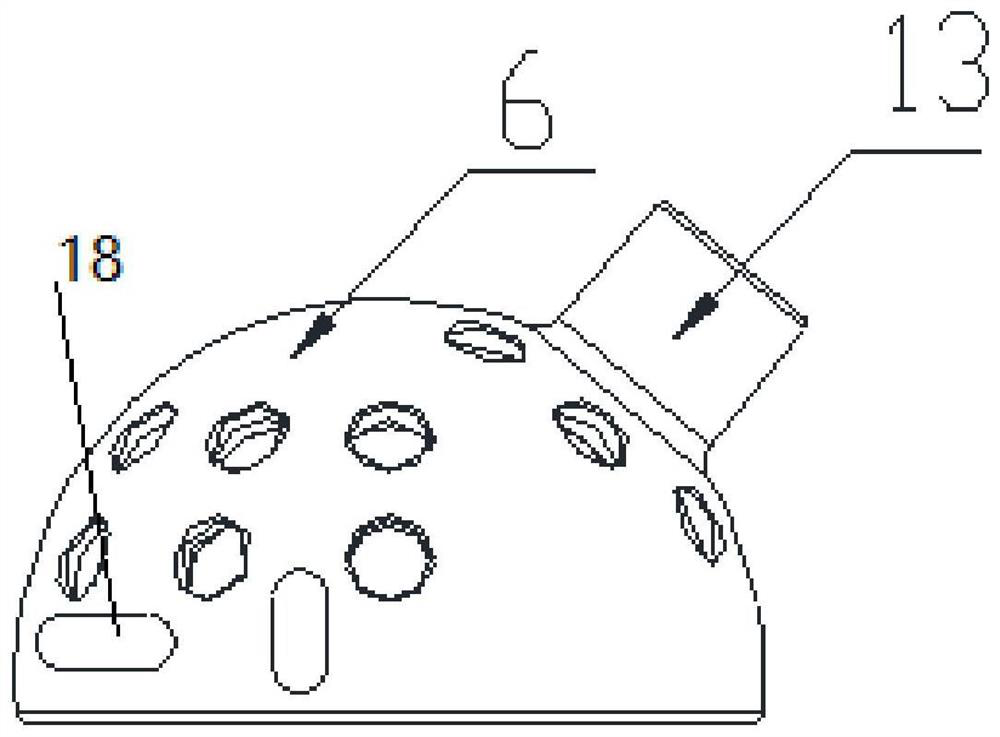

Pelvic prosthesis

PendingCN111759546AImprove stabilityReduce installation difficultyJoint implantsAcetabular cupsLong nailsBone tissue

The present invention provides a pelvic prosthesis. The pelvic prosthesis comprises an acetabular cup, an ilium support and a pubis plate are respectively arranged on the acetabular cup, an ilium support connecting plate is arranged on the ilium support, and tantalum coating porous bone trabecular interfaces are arranged at a contact part of the ilium support connecting plate and an ilium, a contact part of the pubis plate and a pubis, and a contact part of the ilium support and human body; a shape of the ilium support is irregular polygon, a plurality of locking long nail holes are arranged in the ilium support, axial directions of the plurality of the locking long nail holes are different, and locking long nails penetrate through the locking long nail holes of the ilium support to be connected with sacrum or lumbar vertebrae. The tantalum coating porous bone trabecular interfaces on the ilium support can ensure a sufficient bonding strength of the prosthesis and a host bone interface, improve long-term stability of the prosthesis in vivo and realize deep fusion of the prosthesis and a host bone tissue; the tantalum coating porous bone trabecular interfaces of the ilium support connecting plate increase stability and safety of the prosthesis and can play roles in mechanical support and bone ingrowth; and the locking long nail holes increase the stability of the prosthesis andreduce mounting difficulty of the prosthesis..

Owner:BEIJING LIDAKANG TECH

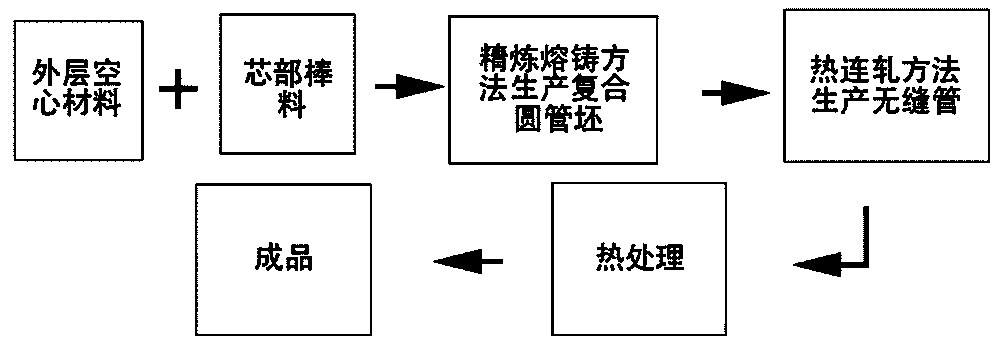

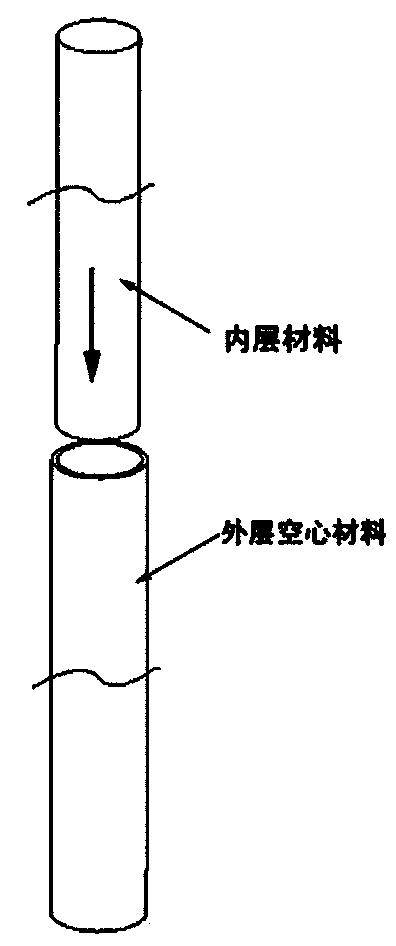

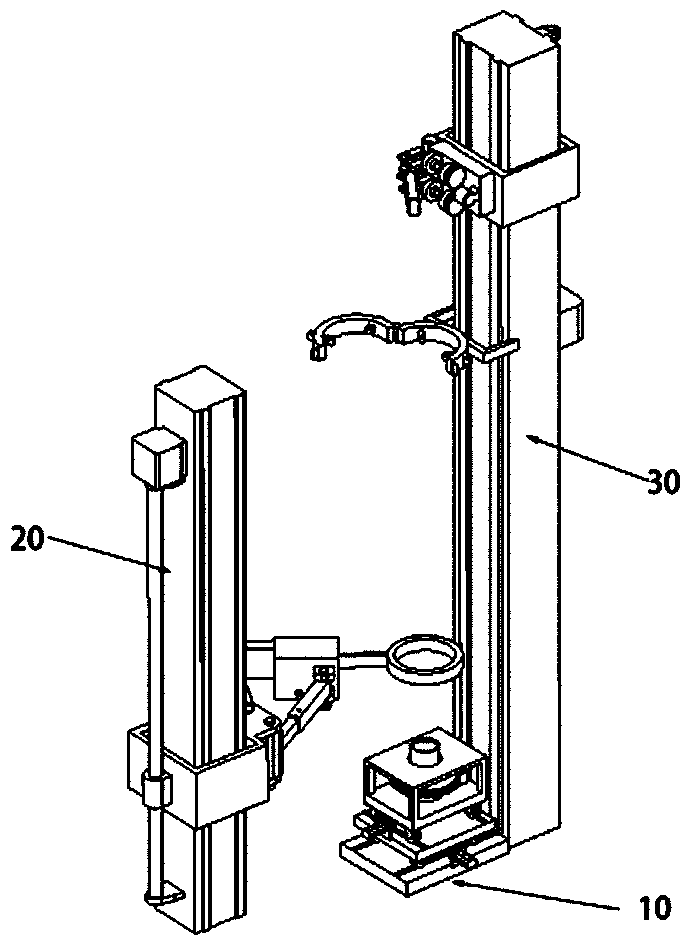

Bi-metal metallurgical bonding composite seamless pipe blank production process and device

The invention belongs to the technical field of composite pipe production processes, and particularly relates to a bi-metal metallurgical bonding composite seamless pipe blank production process. Thebi-metal metallurgical bonding composite seamless pipe blank production process comprises the following steps that S1, raw materials are prepared, specifically, outer-layer hollow materials and inner-layer materials are prepared; S2, preheating is conducted, specifically, the outer-layer hollow materials are preheated; S3, slag is fused, specifically, pre-slag is put into the outer-layer hollow materials and is heated and fused; S4, metallurgical bonding is conducted, specifically, the inner-layer materials extend into the outer-layer hollow materials, and are heated and fused to be combined with the outer-layer materials; and S5, a pipe blank is obtained, specifically, after the inner-layer materials are fused, cooling is conducted and the metallurgical bonding composite metal pipe blankis obtained. A bi-metal composite pipe is produced in the mode of blank metallurgical compounding and hot continuous rolling, a base layer and a composite layer of a finished steel pipe are combined in a metallurgical mode, the intensity of the combined layer is high and is equivalent to the intensity of base metal, and the common problem of inner-layer stripping of mechanical composite pipes is avoided.

Owner:山西凯通源管业有限公司

Composite board and preparation method thereof

InactiveCN107775269AImprove wear resistanceSimple processLaminationLamination apparatusSteelmakingMetallic materials

The invention discloses a composite board and a preparation method thereof. A carbonized titanium alloy is added in the steel smelting process; centrifugation is conducted on the smelted metal material to compositely cast a pipe blank, heat treatment is conducted on the pipe blank which is formed by centrifugation and composite casting, the pipe blank is cut into arc blocks and subjected to forging and pressing, leveling and heat treatment, and an alloy plate with titanium carbide being accumulated on one side is prepared through forging and pressing and heat treatment; a low carbon steel plate or a stainless steel plate is selected to be buckled together with the prepared alloy plate, so that one side, where the titanium carbide is accumulated, of the prepared alloy plate faces up, welding and sealing are conducted on joint seams at the periphery to make a vacuum opening, and pressure sealing is conducted on the steel pipe after vacuumizing is conducted; a double-metal welding body issubjected to heating, forging and pressing repeatedly, so that the base plate and the alloy plate are firmly pressed and combined together, leveling is conducted, the inner surface and the outer surface are cleaned by using a turning lathe and a boring lathe, and thus the high performance composite board with one side being titanium carbide accumulated alloy steel and the other side being low-carbon steel or stainless steel is prepared. According to the prepared composite board, titanium carbide is accumulated on the surface of the composite layer, and the composite board is high in abrasionresistance, has a good welding property and toughness, and has enough adhesive strength.

Owner:黄绍华

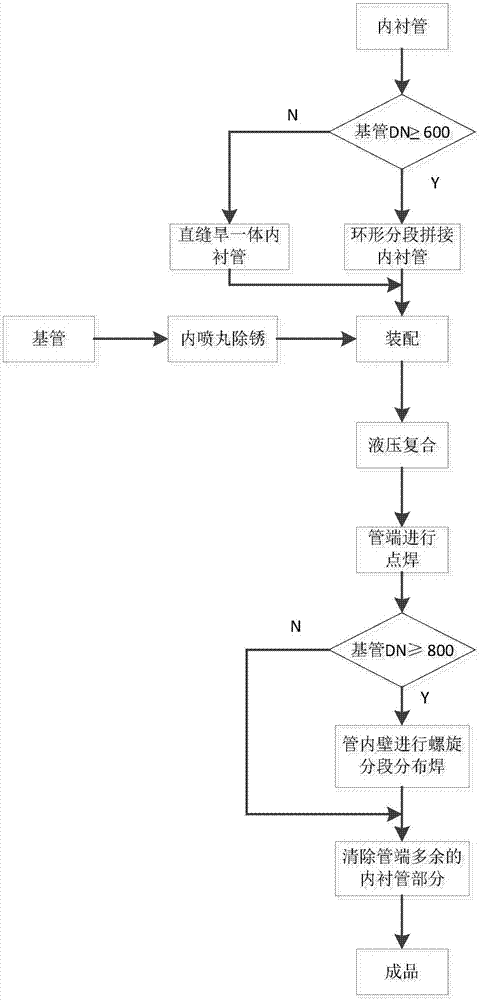

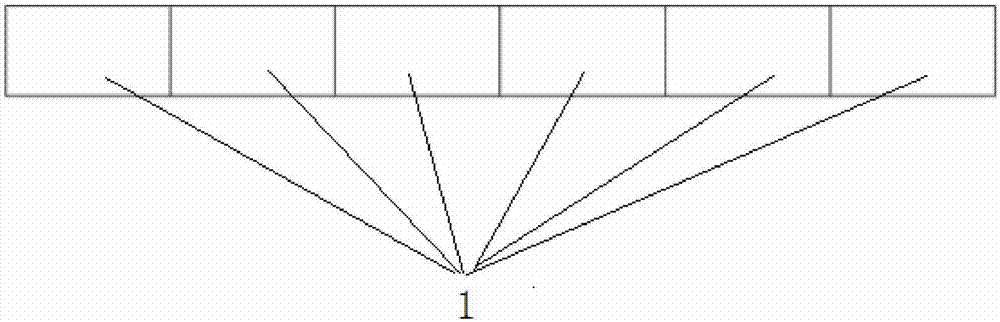

Preparation method for bimetallic composite internal anticorrosive pipe

InactiveCN107962311ASufficient binding strengthStrong application valueMetal working apparatusWelding apparatusAlloySeam welding

The invention relates to a preparation method for a bimetallic composite internal anticorrosive pipe. A bimetallic pipe body is composed of a lining pipe and a base pipe, the base pipe is made of different types of carbon steel according to different purposes, and the lining pipe is an alloy pipe or a metal pipe with corrosion resistance; in the molding process of the bimetallic pipe, different composite methods and lining pipe molding processes are adopted for different base pipe diameters, and the lining pipe is made to be combined to the inner wall of the base pipe; and the molding processof the lining pipe is that the lining pipe is molded by straight seam welding when the base pipe DN is less than 600 mm, and the lining pipe is molded by circular seam splicing when the base pipe DN is larger than or equal to 600 mm. According to the preparation method for the bimetallic composite internal anticorrosive pipe, different composite strategies are adopted for different pipe diameters,a combination process of hydraulic composite and metallurgy is adopted in producing the bimetallic composite internal anticorrosive pipes of larger diameters, the fact that sufficient combining strength exists between the base pipe and the lining pipe can be guaranteed, the product property is excellent, conditions for mass production are provided, and the preparation method for the bimetallic composite internal anticorrosive pipe has high application value and wide application prospects.

Owner:郑博元

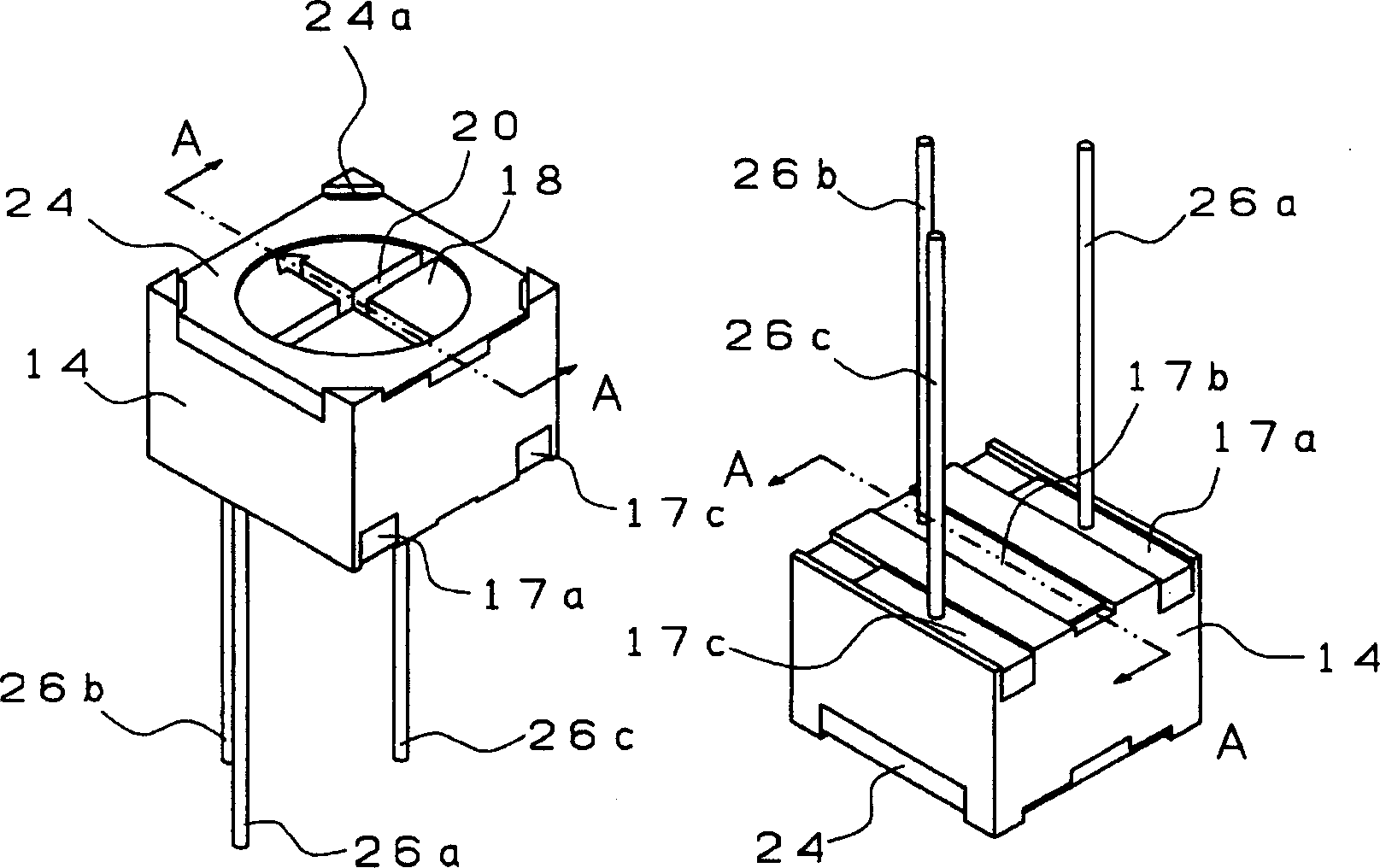

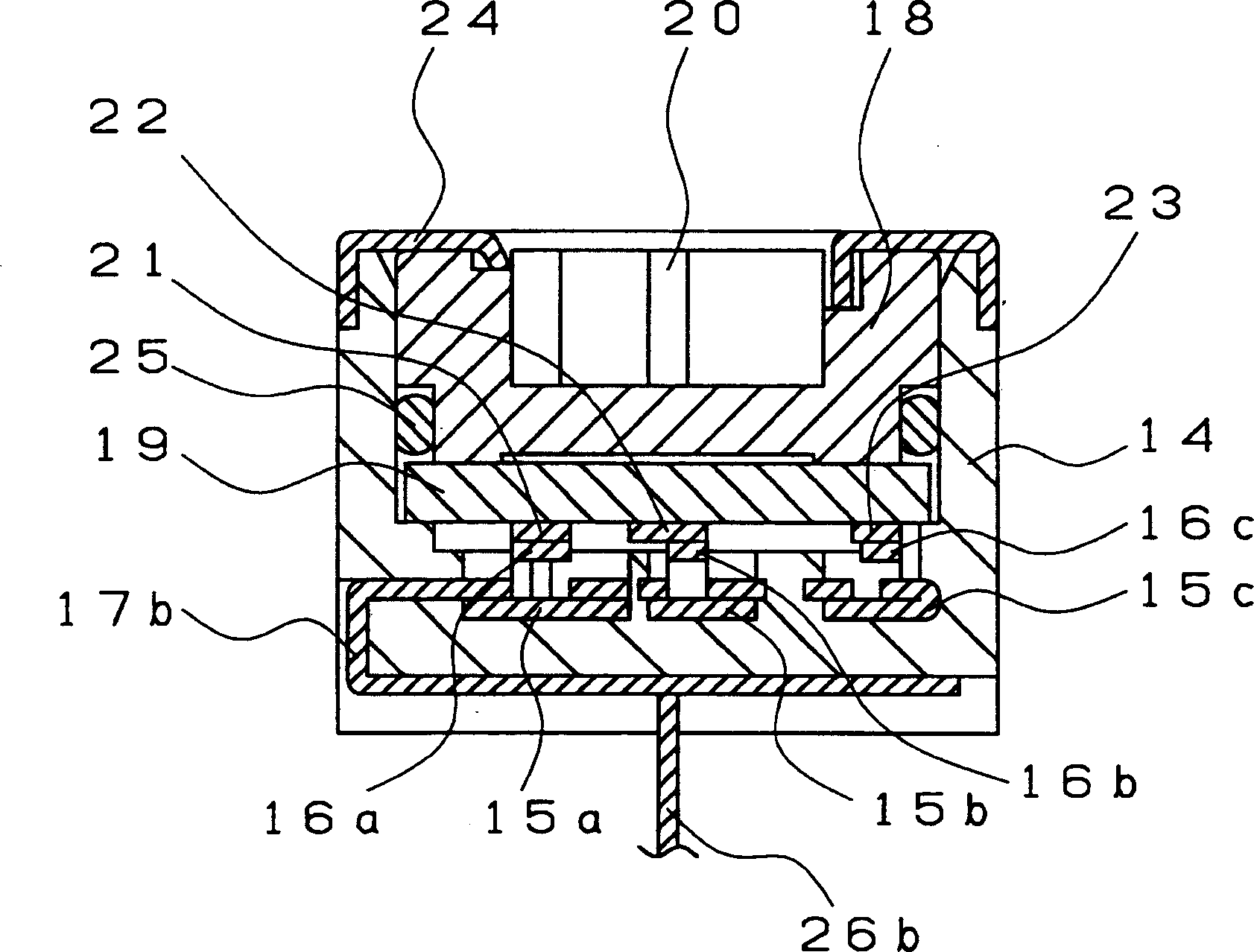

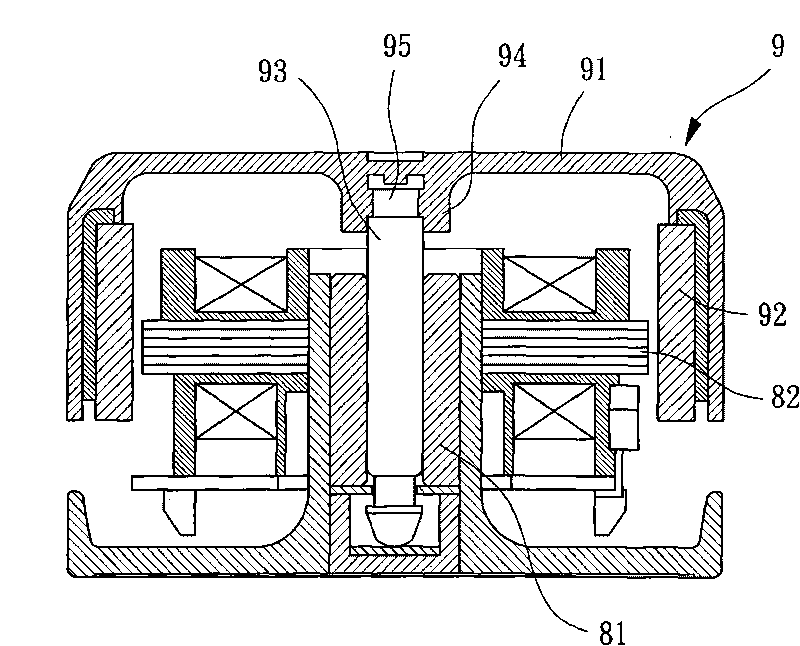

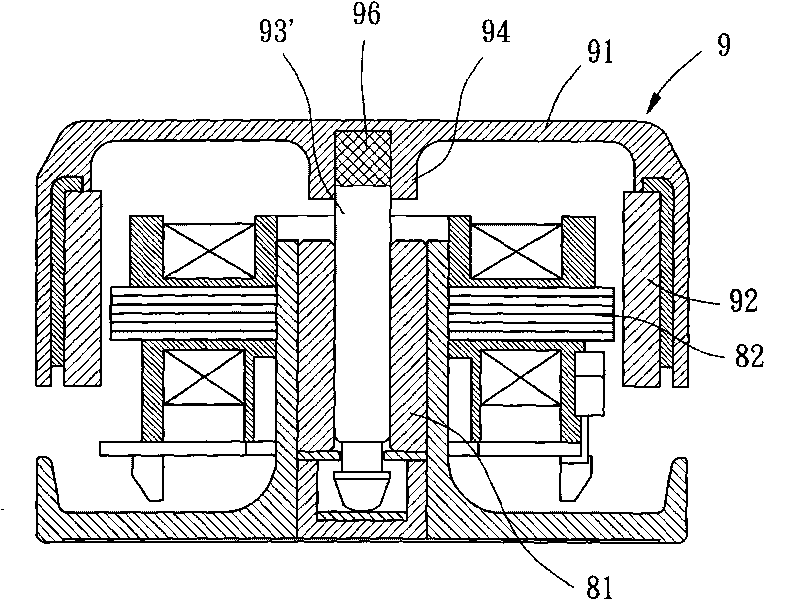

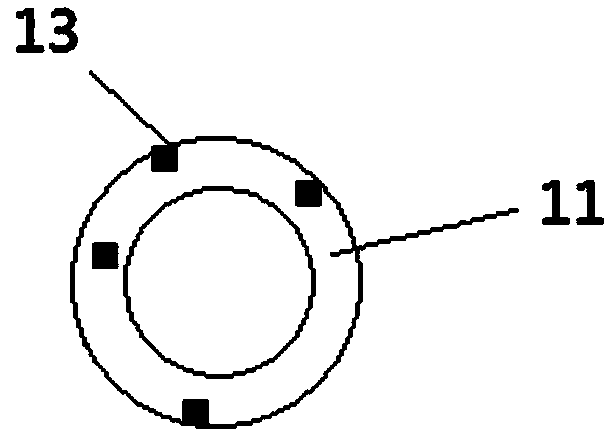

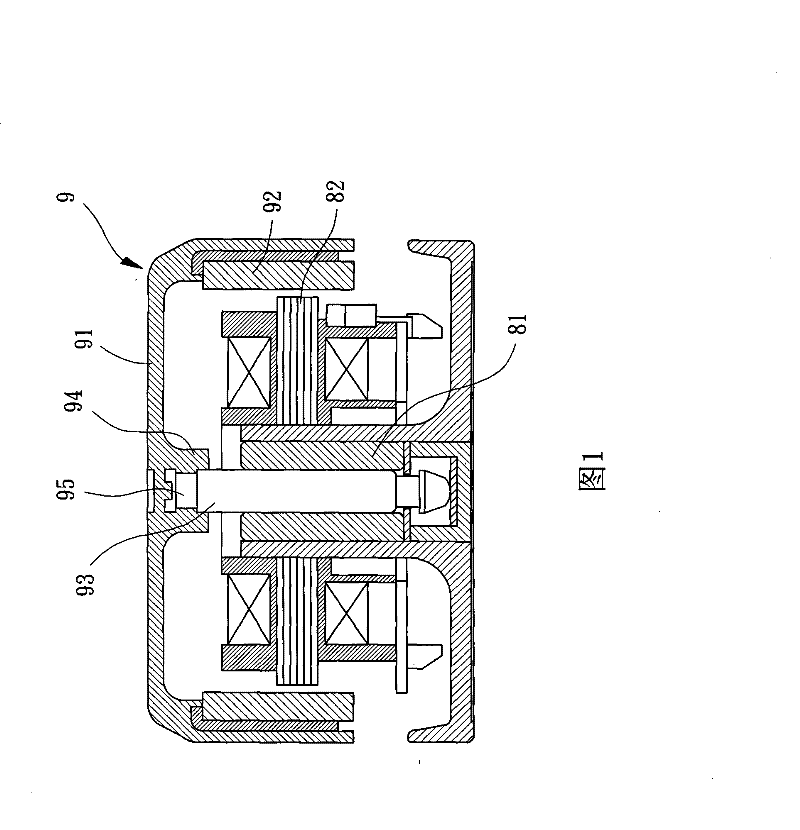

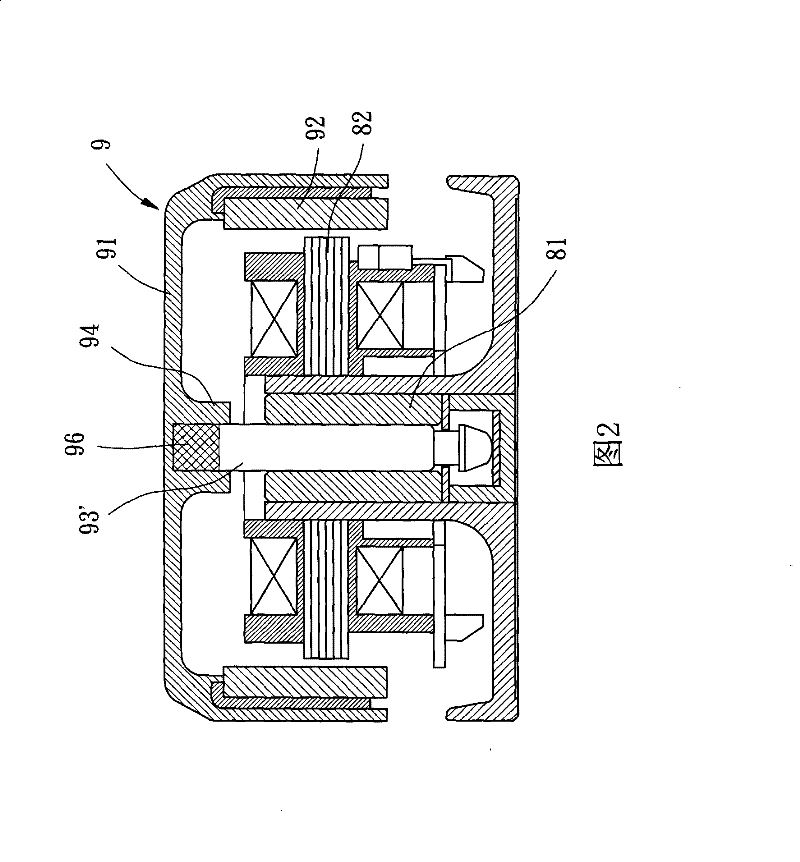

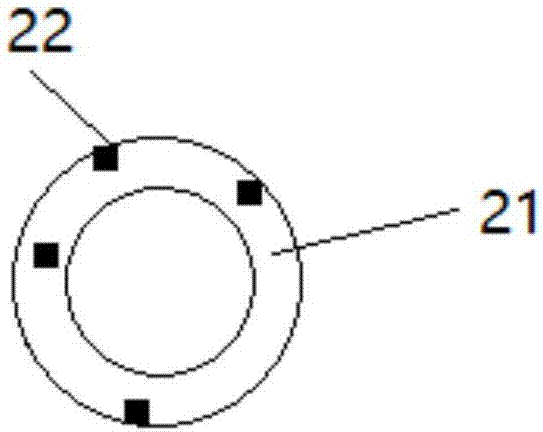

Motor rotor

ActiveCN101752919AIncrease binding areaSufficient binding strengthMagnetic circuit rotating partsMechanical energy handlingEngineeringDesign space

The invention relates to a motor rotor which comprises a hub, a permanent magnet and a mandrel; wherein the hub is provided with an inner surface and an outer surface; an assembly hole is formed at the center of the inner surface of the hub; the permanent magnet is arranged on the inner surface of the hub in an encircling manner; the mandrel is provided with two ends, one end is a binding end, and the binding end is fixed in the assembly hole of the hub and is provided with a binding piece; the binding piece radially extends to the peripheral surface of the mandrel and is embedded in the hub. Therefore, the binding piece can radially extend and the binding area between the hub and the mandrel is increased, so that the excellent binding strength is provided, and simultaneously, the whole motor has miniaturized or thin design space.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

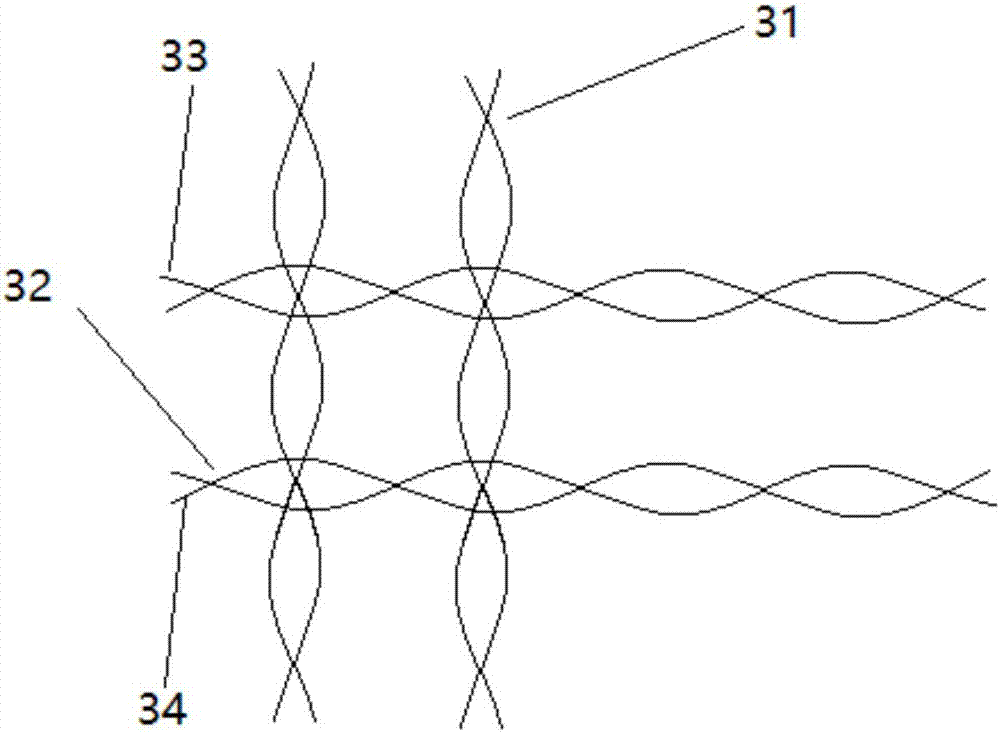

Anti-ultraviolet motor function shell fabric

InactiveCN107933024AGood UV reflectivityKeep coolSynthetic resin layered productsConvex structureFiber

The invention relates to an anti-ultraviolet motor function shell fabric which comprises an anti-ultraviolet layer, a sweat absorbing layer and a ventilating layer which are successively arranged fromoutside to inside, wherein the anti-ultraviolet layer is interwoven by a first warp and a first weft, and anti-ultraviolet nano TiO2 particles are arranged on the first warp; the sweat absorbing layer is interwoven vertically by sweat absorbing yarns woven formed by moisture-absorbing fiber spandex core-spun yarns and moisture-absorbing cotton yarns in a crossed manner as a second warp and a second weft; the ventilating layer is interwoven by a third warp and a third weft in a floating and sinking manner. The hot-shrinkage rate of the third weft is higher than that of the third warp, so thatthe third weft after thermal treatment shrinks and jacks up the third warp to form a concave-convex structure. Compared with the prior art, the anti-ultraviolet motor function shell fabric has excellent ultraviolet preventing, sweat absorbing, ventilating and quick drying effects, is pleasantly cool to wear and is in particular suitable for preparing top grade summer clothing and the like.

Owner:劲霸男装(上海)有限公司

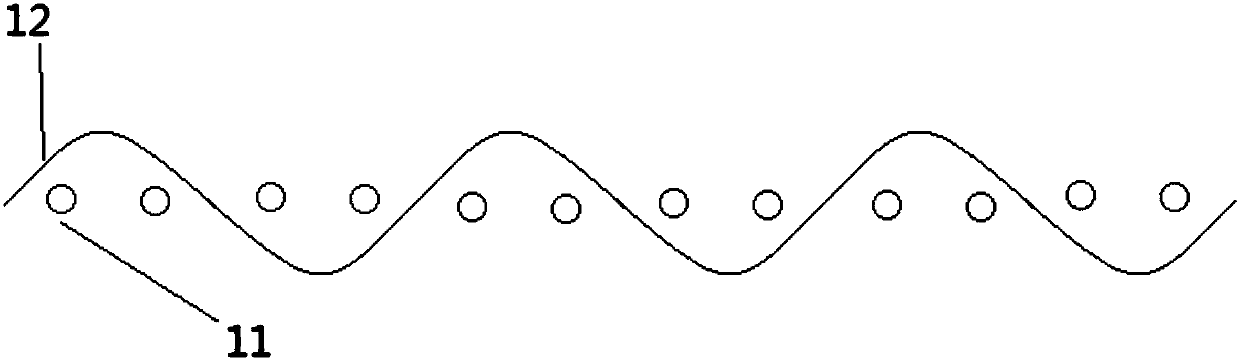

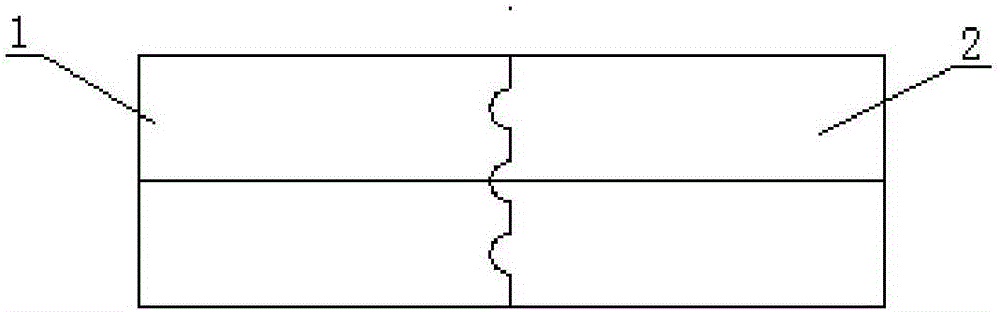

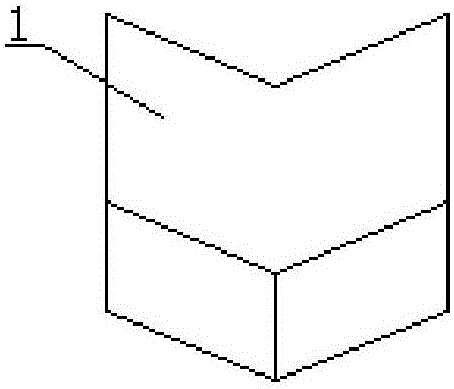

Straw wall material brick and making method thereof

InactiveCN106082831AQuick buildLose weightConstruction materialSolid waste managementBrickFire retardant

The invention provides a straw wall material brick and a making method thereof. The straw wall material brick comprises a first brick body and a second brick body, wherein the first brick body and the second brick body are symmetrically arranged to form the straw wall material brick. The core portions of the first brick body and the second brick body are compacted straw bodies, and the outer sides of the compacted straw bodies are coated with a waterproof agent and a fire retardant. By the adoption of the straw wall material brick, rapid erection of a simple building or a building having lower usage requirements or a temporary building can be achieved. In addition, semi-circular grooves and semi-circular protrusions are arranged at the connecting positions of the straw wall material bricks, a structure formed after combination is firm and stable, and the brick bodies can have enough combination strength. Furthermore, the inner cores are the compacted straw bodies, and the overall self weight of the building is greatly lightened under the situation that a necessary supporting force is provided.

Owner:北京传树建材科技集团有限公司

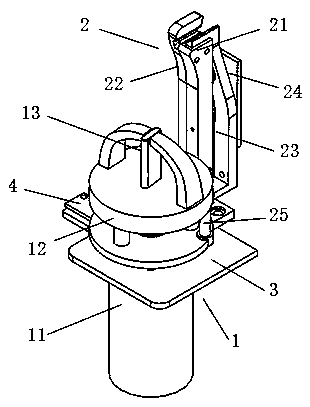

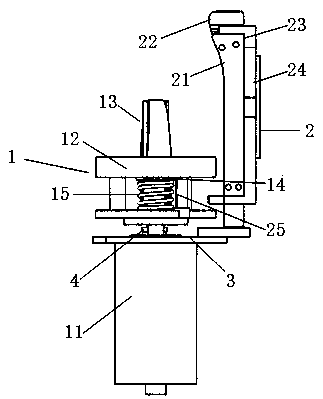

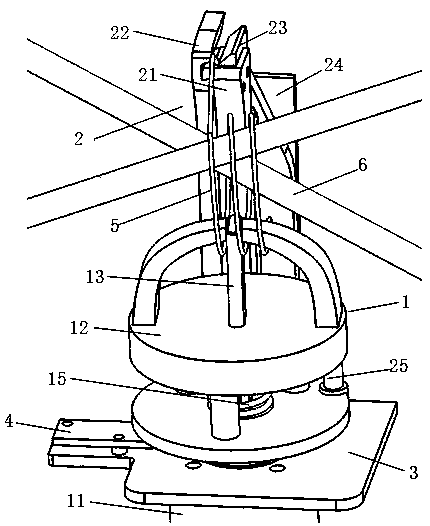

Torsion mechanism for binding

InactiveCN110700595ARealize tightTo achieve prolapseBuilding material handlingRotational axisClassical mechanics

The invention discloses a torsion mechanism for binding. The torsion mechanism for binding comprises a torsion device and a cutting device. The torsion device comprises a motor, a rotating plate, a rotating shaft, a snap spring and a compression spring, wherein the motor and the rotating plate are connected with the rotating shaft, the snap spring and the compression spring are installed on the rotating shaft, the torsion device rotates to enable a binding wire to tightly bundle reinforcing steel bars, a torsion mechanism is lifted up, the snap spring and the compression spring prevent the rotating plate from separating from the rotating shaft in the axial direction, the rotating plate is separated from the rotating shaft by a certain distance, and the tightly-bundled binding wire is separated from the torsion device; and the cutting device comprises a wire outlet plate, a wire outlet side plate, a cutter, a cutter baffle and a cutting column and is used for cutting the binding wire. The torsion mechanism solves the problem that the binding wire bundling strength is poor and the process is complicated in the process of bundling the reinforcing steel bars. While the sufficient binding wire bundling strength is ensured, the number of circles of the binding wire for bundling the reinforcing steel bars is reduced, the binding action is simplified, and the binding efficiency is improved.

Owner:理工华汇(潍坊)智能机器人有限公司

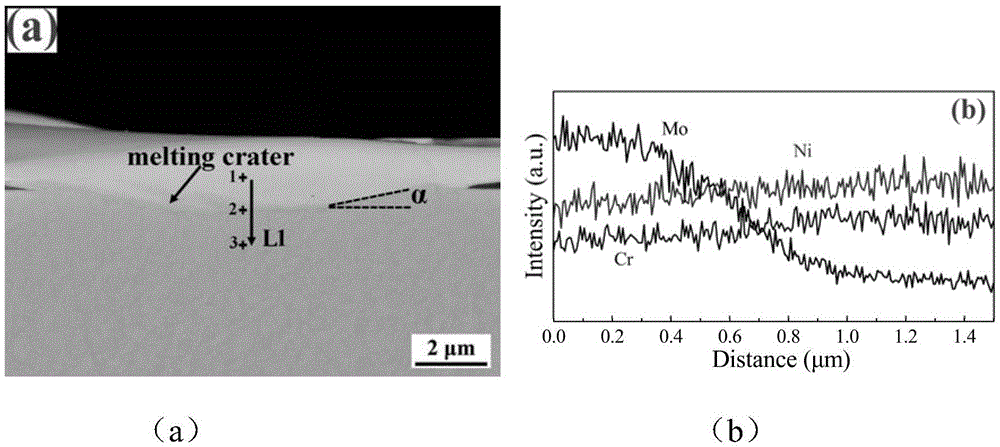

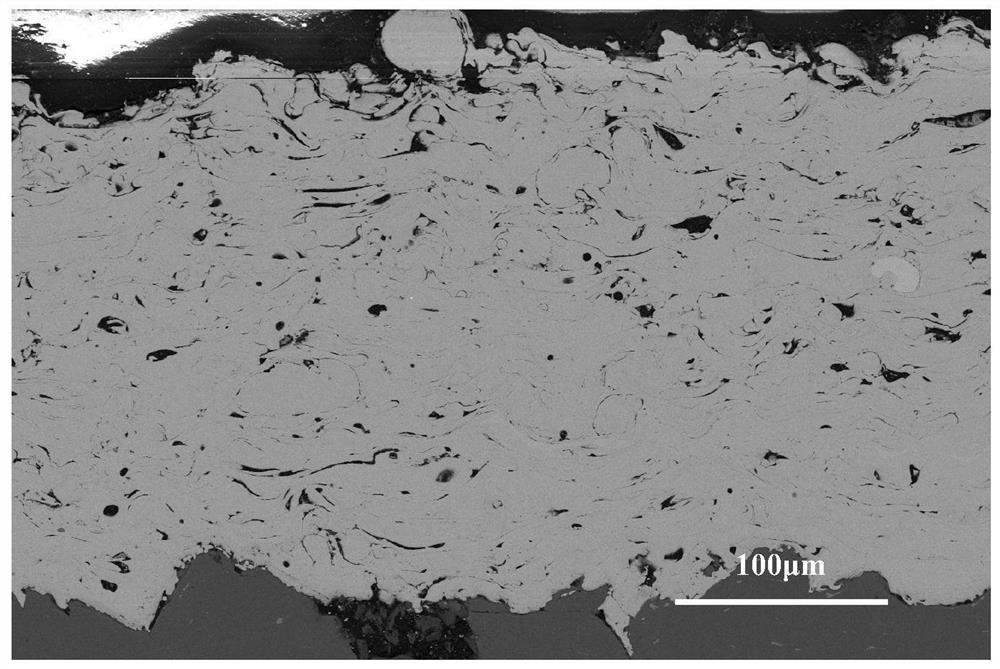

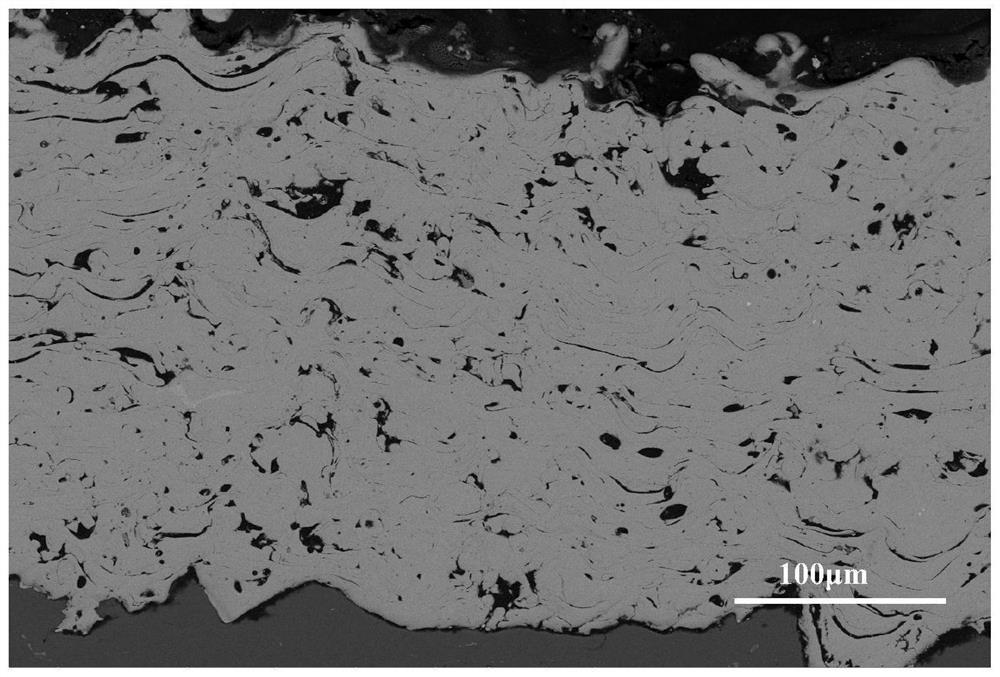

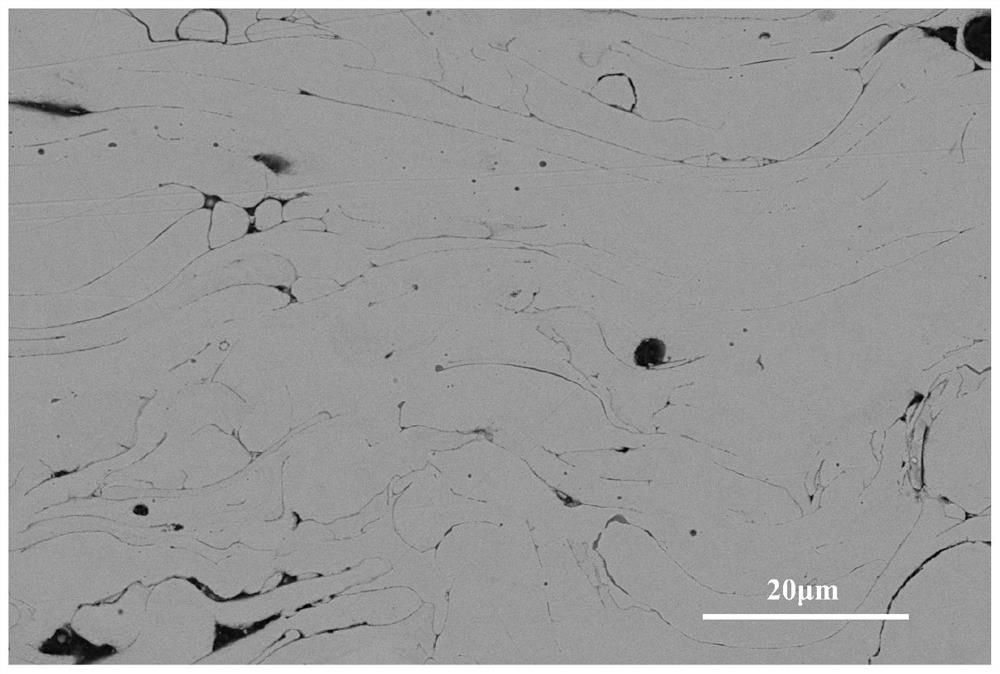

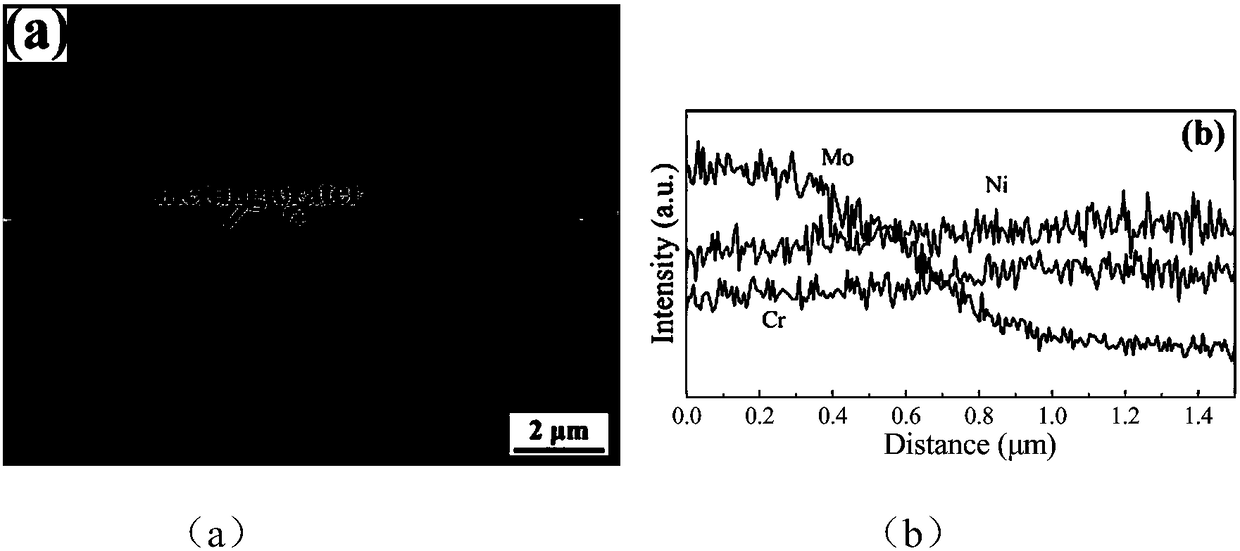

Preparation method of wear-resistant coating on surface of aluminum alloy engine cylinder hole

The invention belongs to the technical field of wear-resistant coatings of engines, and particularly discloses a preparation method of a wear-resistant coating on the surface of an aluminum alloy engine cylinder hole. The preparation method comprises the following steps that step 1, Fe-based alloy powder, Cr powder and Mo powder are uniformly mixed; the mass ratio of the Cr powder is 15%-24%, and the mass ratio of the Mo powder is 5%-8%; and step 2, the powder uniformly mixed in the step (1) is sprayed on the hole wall of an inner hole of an air cylinder with an aluminum alloy base body by adopting a plasma spraying technology to form the wear-resistant coating. According to the scheme, the wear-resistant coating is sprayed on the inner wall of the air cylinder through the plasma spraying technology, so that the wear-resistant coating and the inner wall of the engine cylinder hole are metallurgically bonded, compared with mechanical bonding, the bonding force is higher, and the coating cannot be separated from the inner wall of the cylinder hole in the long-time service process.

Owner:KUNMING UNIV OF SCI & TECH

A kind of straw wall material brick and preparation method thereof

InactiveCN106082831BQuick buildLose weightConstruction materialSolid waste managementBrickFire retardant

The invention provides a straw wall material brick and a making method thereof. The straw wall material brick comprises a first brick body and a second brick body, wherein the first brick body and the second brick body are symmetrically arranged to form the straw wall material brick. The core portions of the first brick body and the second brick body are compacted straw bodies, and the outer sides of the compacted straw bodies are coated with a waterproof agent and a fire retardant. By the adoption of the straw wall material brick, rapid erection of a simple building or a building having lower usage requirements or a temporary building can be achieved. In addition, semi-circular grooves and semi-circular protrusions are arranged at the connecting positions of the straw wall material bricks, a structure formed after combination is firm and stable, and the brick bodies can have enough combination strength. Furthermore, the inner cores are the compacted straw bodies, and the overall self weight of the building is greatly lightened under the situation that a necessary supporting force is provided.

Owner:北京传树建材科技集团有限公司

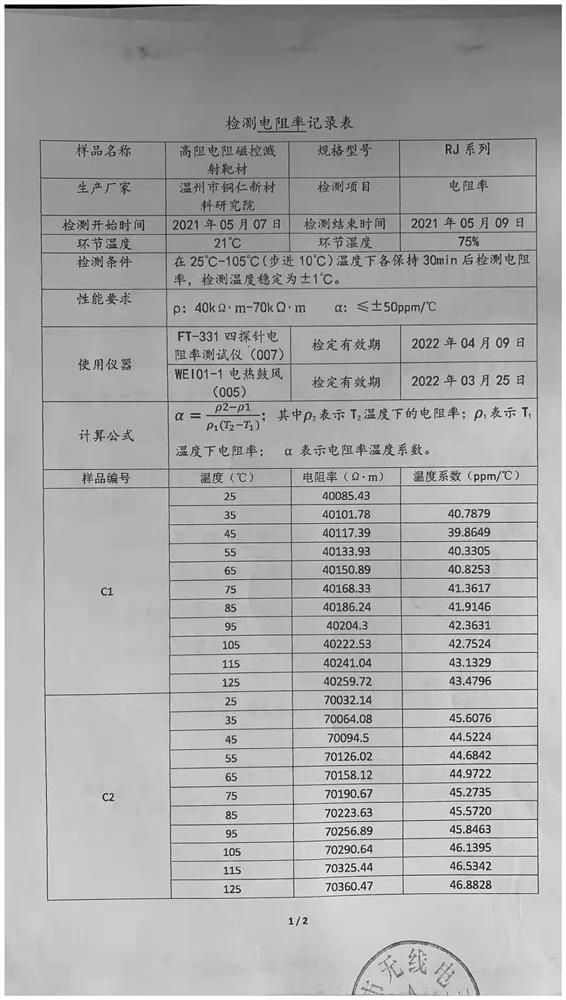

High-resistance resistor magnetron sputtering target material and preparation method thereof

InactiveCN114015921AHigh resistivityLow resistivityVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceCrucible

The invention discloses a high-resistance resistor magnetron sputtering target material and a preparation method thereof. The preparation method comprises the steps of (1) conducting burdening, specifically, burdening according to the following components: 50-57 wt% of Si, 40-42 wt% of Cr and the balance of Ni; (2) placing the graphite and magnesium oxide composite crucible in vacuum induction melting for preheating with the preheating temperature being 850 DEG C, and then putting Cr and Ni into the graphite and magnesium oxide composite crucible for further heating to 1400 DEG C; (3) preheating Si to 850 DEG C, preserving heat for 2.5-4 hours, continuously putting the Si into the graphite magnesium oxide composite crucible, and continuously heating to 2100 DEG C until the Si is completely mixed and melted; (4) reducing the temperature to 1800 DEG C to 1850 DEG C; (5) conducting casting, cooling and molding; (6) conducting machining, specifically, machining the surface of the high-resistance resistor magnetron sputtering target blank to enable the surface to be flat and smooth; and (7) welding to form a finished product of the high-resistance resistor magnetron sputtering target material. The preparation method has the advantages of high resistivity, low resistivity temperature coefficient and the like.

Owner:温州市铜仁新材料研究院 +1

Motor rotor

ActiveCN101752919BIncrease binding areaSufficient binding strengthMagnetic circuit rotating partsMechanical energy handlingEngineeringDesign space

The invention relates to a motor rotor which comprises a hub, a permanent magnet and a mandrel; wherein the hub is provided with an inner surface and an outer surface; an assembly hole is formed at the center of the inner surface of the hub; the permanent magnet is arranged on the inner surface of the hub in an encircling manner; the mandrel is provided with two ends, one end is a binding end, and the binding end is fixed in the assembly hole of the hub and is provided with a binding piece; the binding piece radially extends to the peripheral surface of the mandrel and is embedded in the hub.Therefore, the binding piece can radially extend and the binding area between the hub and the mandrel is increased, so that the excellent binding strength is provided, and simultaneously, the whole motor has miniaturized or thin design space.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

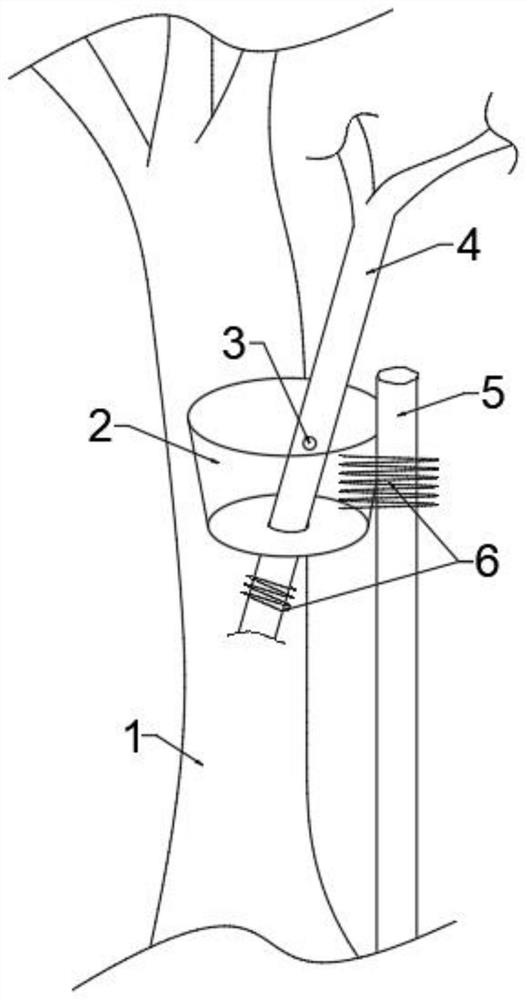

Grafting-free noninvasive colonization method for plants

The invention discloses a grafting-free noninvasive colonization method for plants. The grafting-free noninvasive colonization method is characterized by comprising the following specific steps: selecting a colonization branch in a healthy growth state; selecting a metal wire at a position 5-8 cm away from the base part of the branch, and tightening the metal wire by using a vice; selecting a proper pricking point, cutting one side of a culture container, and sleeving the culture container on the branch from the notch; additionally arranging a fixing rod, and fixing the fixing rod at a position flush with the height of the culture container by using the metal wire; filling the culture container with wet nutrient soil, sealing the surface of the nutrient soil with a preservative film or a plastic bag after filling, and watering frequently to ensure that the nutrient soil is wet; after one month, the branch branches root, and cutting off from the base part of the branch to transplant. Compared with the prior art, the grafting-free noninvasive colonization method has the advantages that the steps are simple and practical, the survival rate is high, no special requirement is needed forcolonization branches, the colonization time domain is wide, colonization can be conducted in all growing seasons, the cost is low, the cost investment is greatly reduced, and popularization is convenient.

Owner:吴宗哲

Waterproof breathable composite garment fabric

InactiveCN107953640APrevent penetrationVentilation does not affectSynthetic resin layered productsClothingsPolyesterFiber bundle

The invention relates to a waterproof breathable composite garment fabric which comprises an outer waterproof layer, a middle warmth retention layer and an inner breathable layer which are sequentially compounded form outside to inside. The outer waterproof layer is of a double-layer composite structure, an outer layer is provided with a PU (polyurethane) membrane for closing first closed breathable holes, an inner layer is provided with a PUR (poly urethane resin) micro-porous membrane, hollow polyester fibers and cotton fibers serve as warp yarns and weft yarns and are interwoven to form themiddle warmth retention layer, first fiber bundles and second fiber bundles are woven crosswise to form inner layer yarns, the inner layer yarns serve as the inner layer warp yarns and inner layer weft yarns which are mutually and vertically interwoven to form the inner breathable layer. Compared with the prior art, the fabric is outstanding in waterproof effect, breathability is not affected, auser feels soft and comfortable when wearing garments prepared from the fabric, and the garment fabric is suitable for preparing high-end outdoor sports garments.

Owner:劲霸男装(上海)有限公司

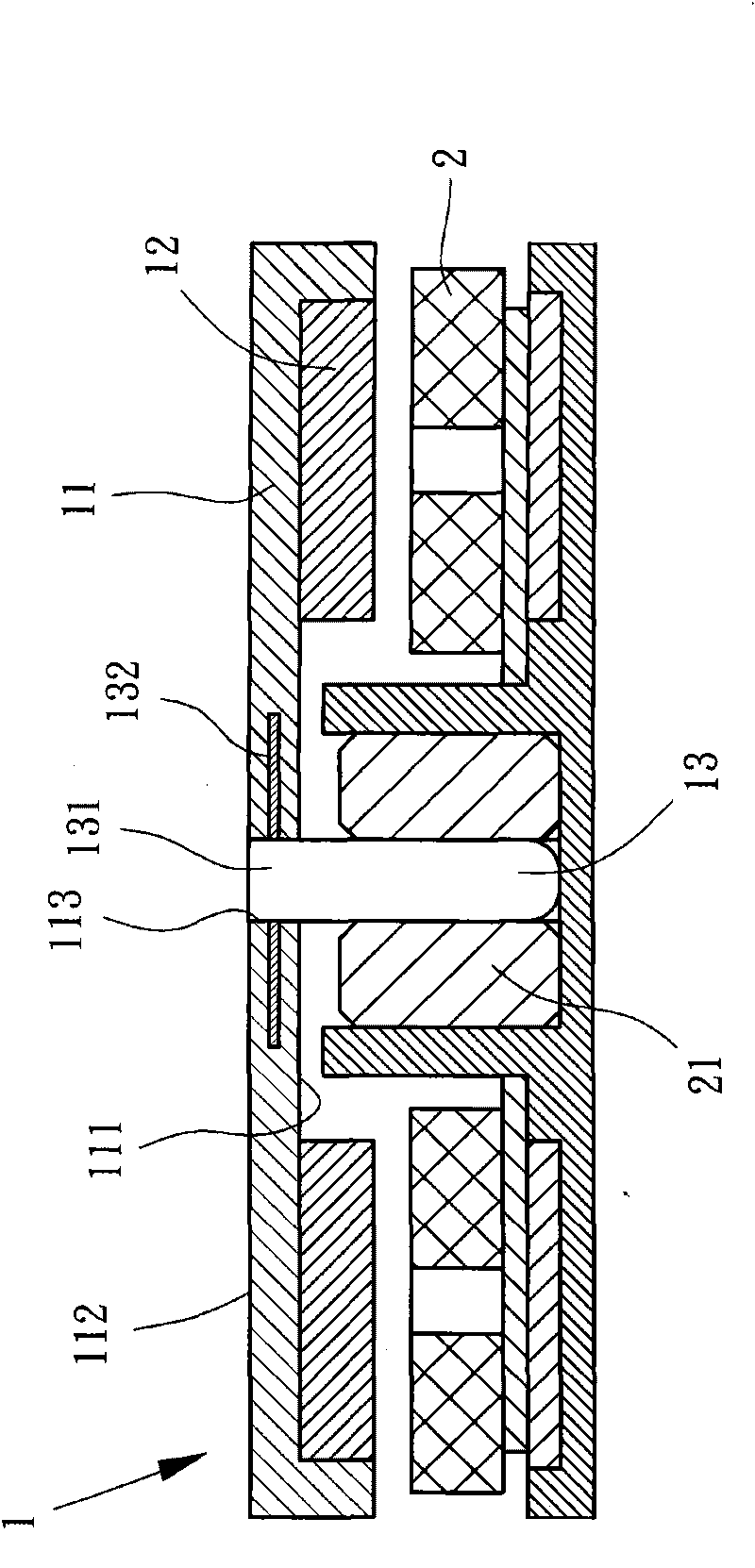

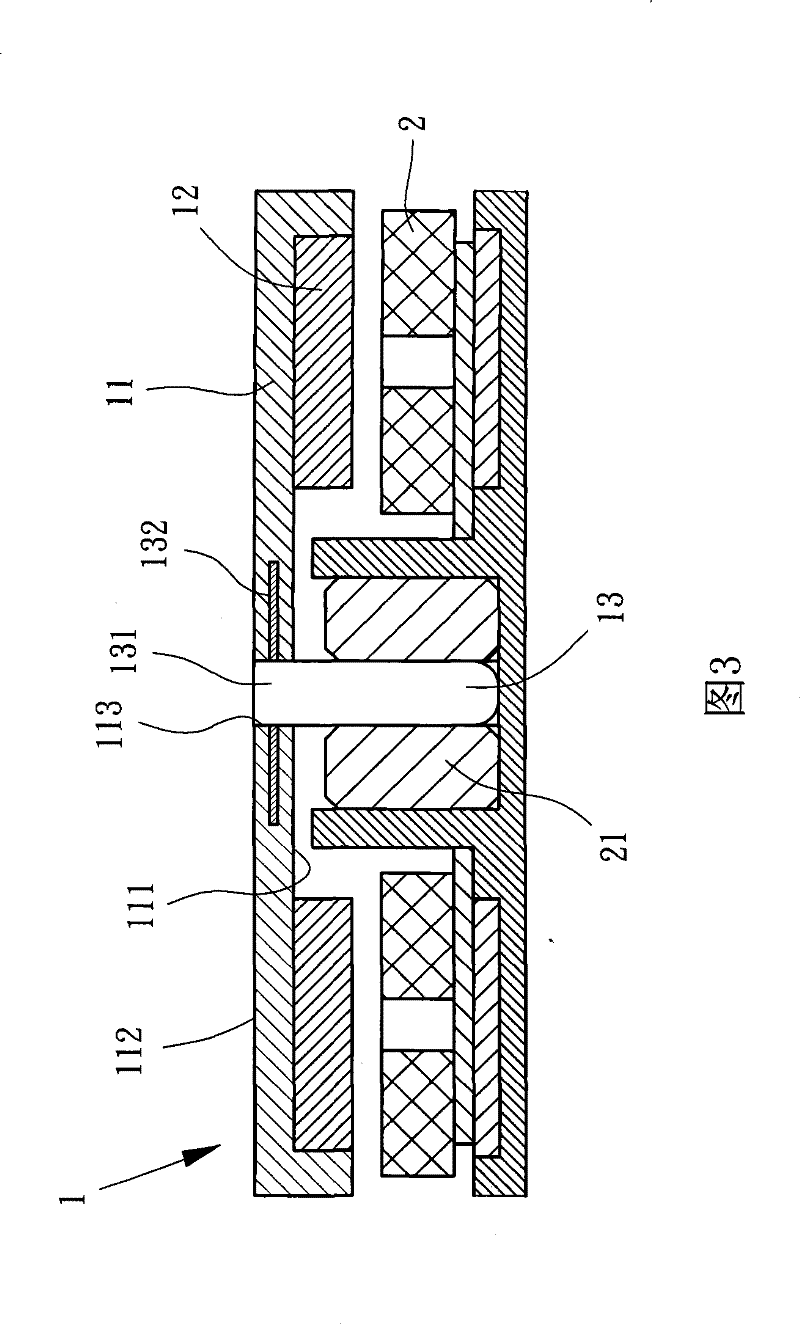

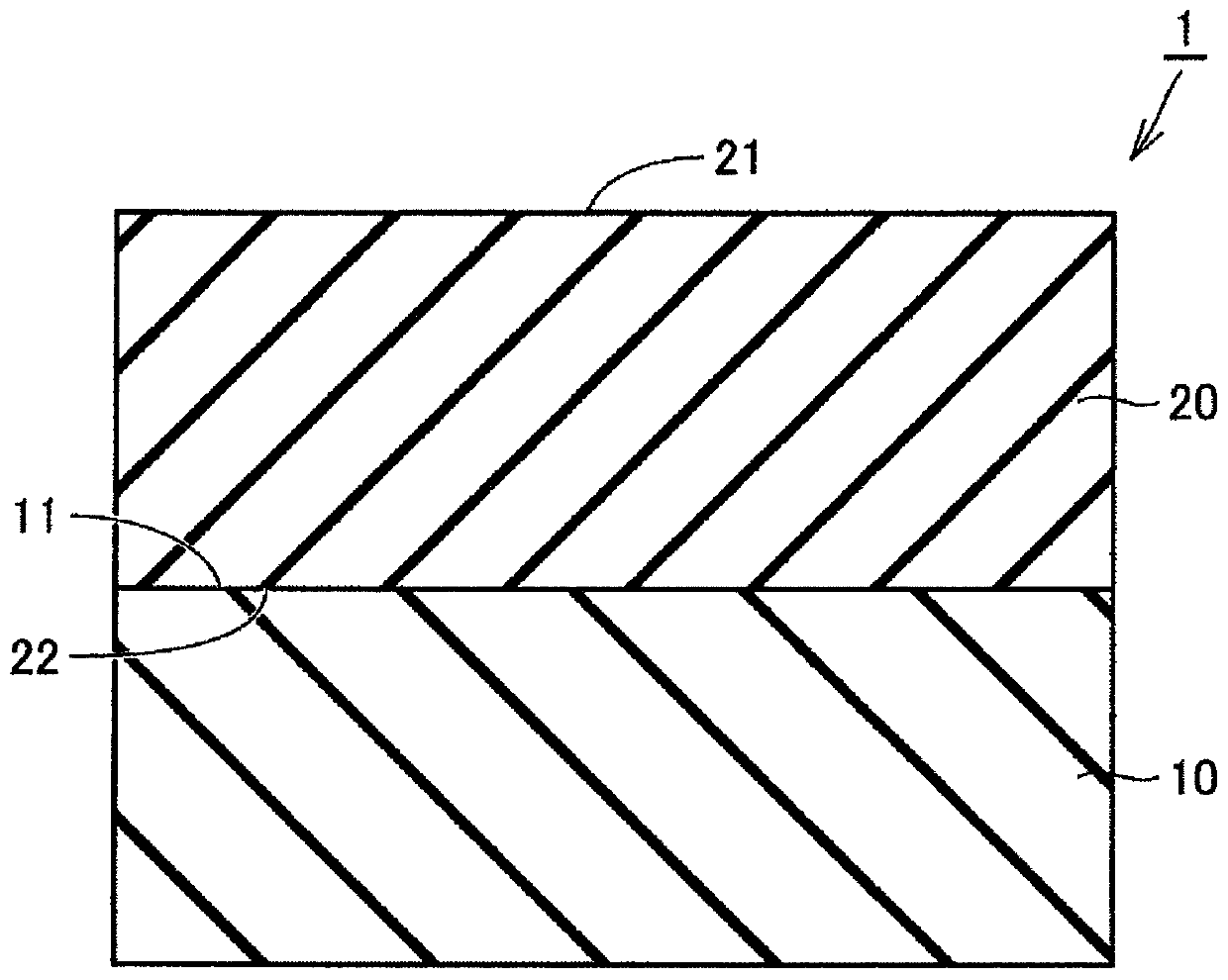

Laminate and saw device

PendingCN110495097ASufficient binding strengthImpedence networksCeramic substratePiezoelectric substrate

A laminate is provided with: a ceramic substrate which is configured from a polycrystalline ceramic and has a supporting main surface; and a piezoelectric substrate which is composed of a piezoelectric body and has a bonding main surface that is bonded to the supporting main surface by the van der Waals force. The ceramic substrate comprises a supporting main surface amorphous layer which is formed so as to contain the supporting main surface. The piezoelectric substrate comprises a bonding main surface amorphous layer which is formed so as to contain the bonding main surface. The thickness ofthe supporting main surface amorphous layer is smaller than the thickness of the bonding main surface amorphous layer.

Owner:SUMITOMO ELECTRIC IND LTD

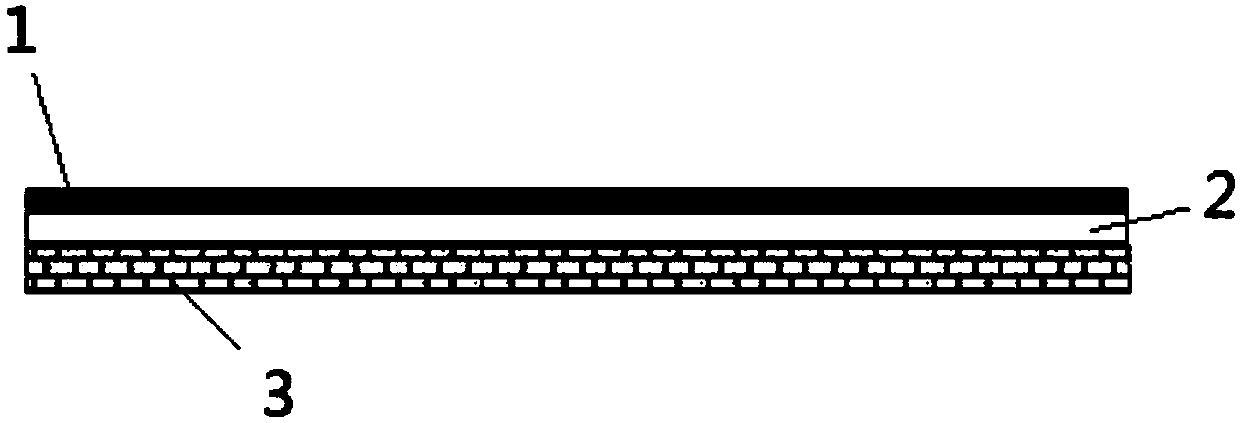

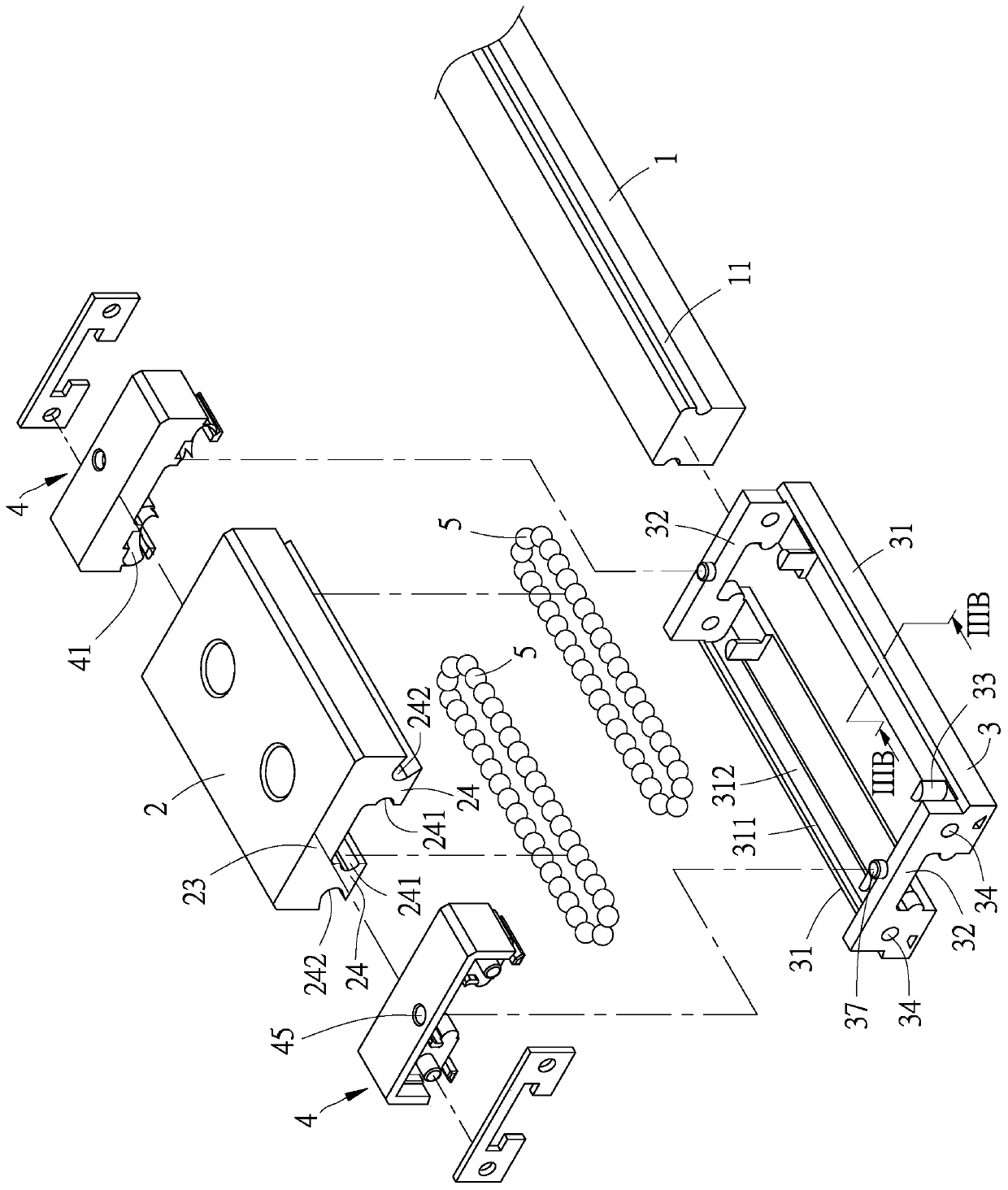

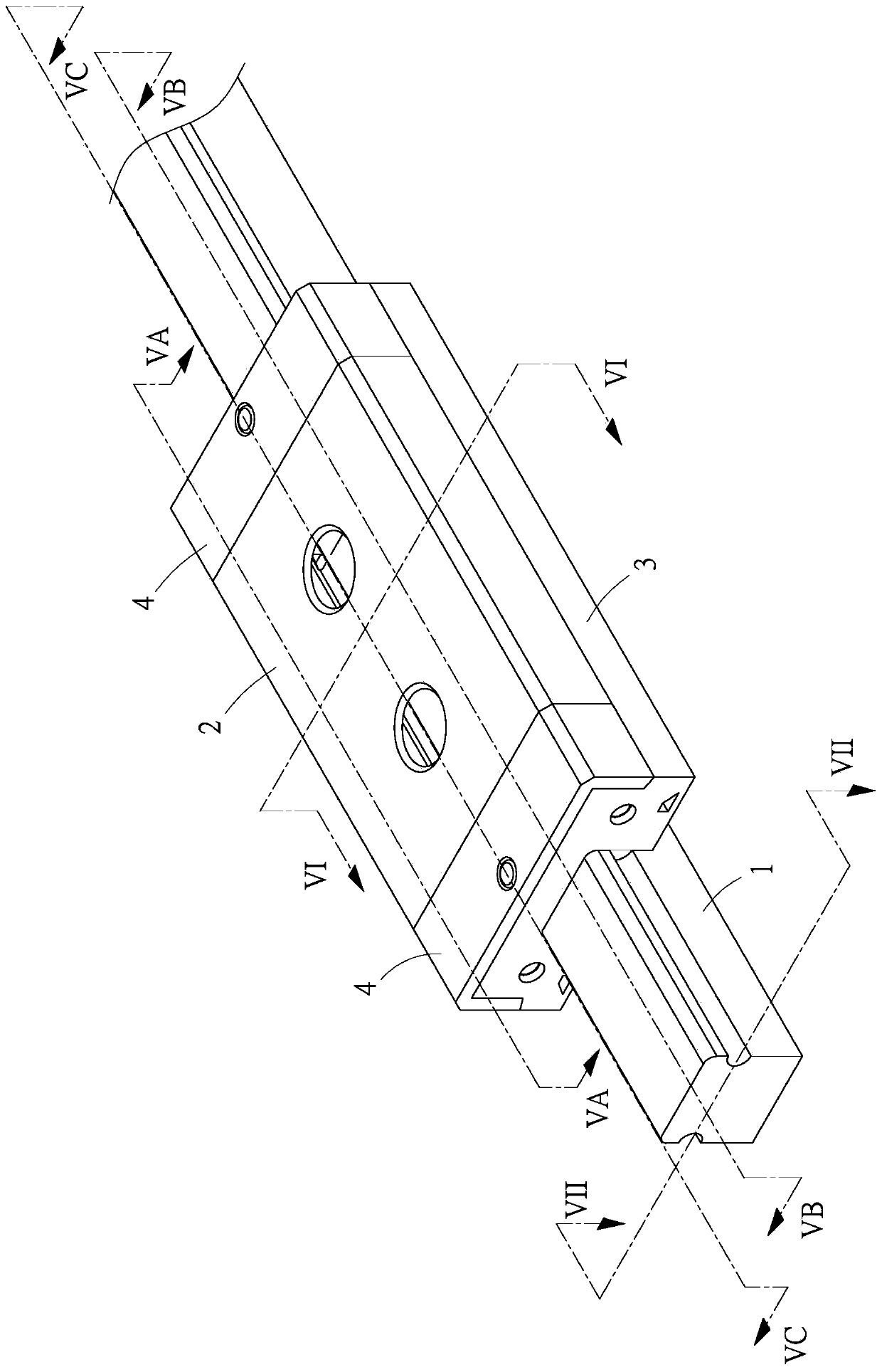

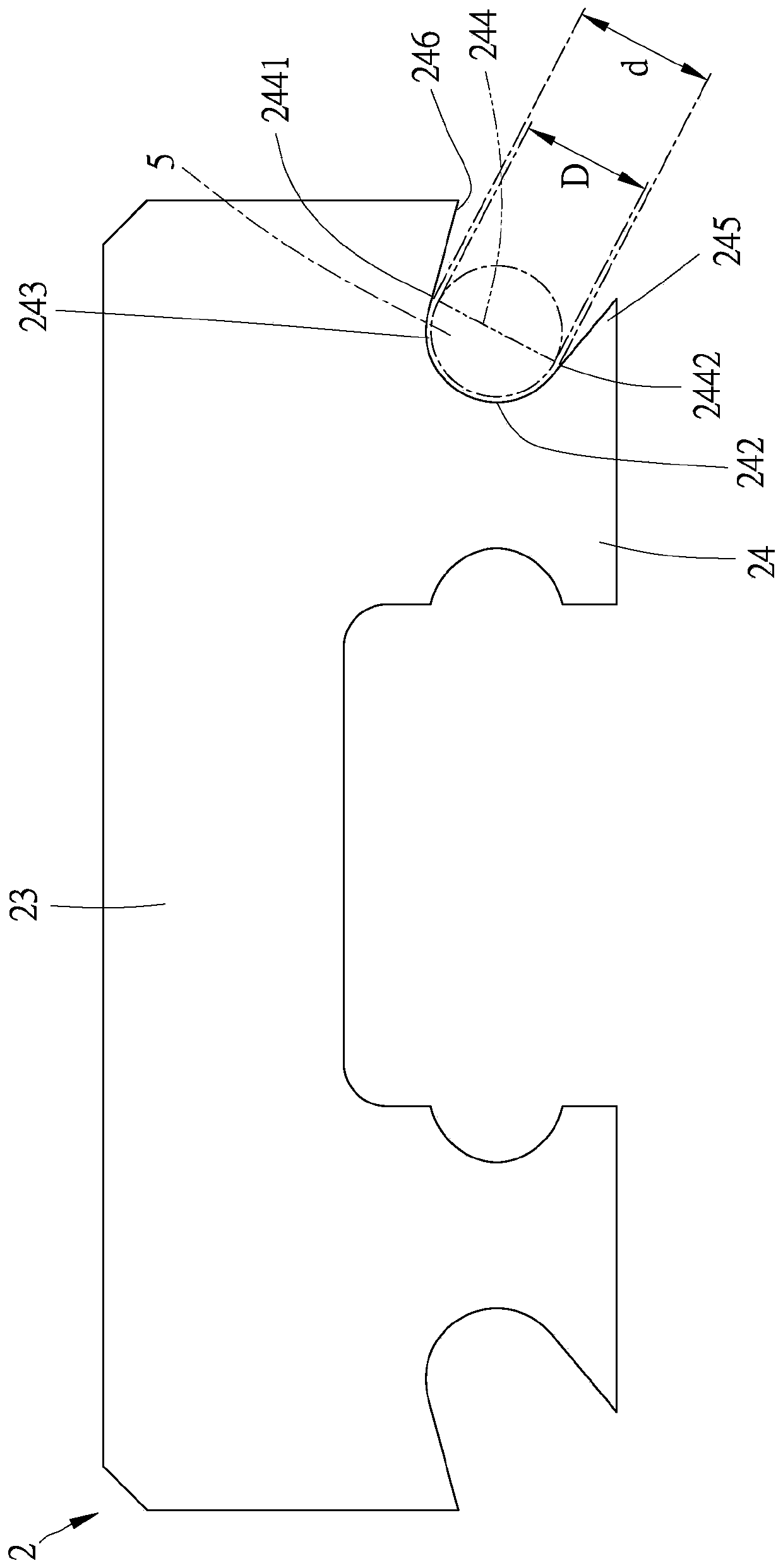

Micro linear slide rail and sliding base thereof

A micro linear slide rail assembly and a slider are disclosed. The slider straddles a slide rail. A rolling member is disposed between the slide rail and the slider. The linear slide rail assembly isthus formed. The slider includes a main body, a frame coupled to the main body, and two end caps connected to two opposite ends of the main body. The slider has a first unloaded track surface. The first unloaded track surface surrounds an accommodating area. A first engaging portion extends from a lower edge of the accommodating area. The frame has a second unloaded track surface. The frame is mounted to the main body through a second engaging portion to be engaged with the first engaging portion. The first unloaded track surface and the second unloaded track surface are combined to form an unloaded path. The frame of the invention can be elastically opened to be mounted to the main body in a bottom-up direction. Through the assembly of the end caps, the frame is limited, so that the framecan be restrained and no longer be opened, whereby the main body, the frame and the end caps are combined firmly and won't disengage from the slide rail.

Owner:CHIEFTECH PRECISION

A high-performance composite board manufacturing process

Owner:TAIAN BONA METAL ABRASION RESISTANT TECH

A thermally sprayed self-adhesive metal alloy powder with clad composite structure

ActiveCN105642885BIncrease temperatureSelf-adhesive realizationMolten spray coatingTransportation and packagingLayer interfaceMetal alloy

The invention discloses a thermal spraying self-adhesive metal alloy powder with a coating composite structure, which belongs to the technical field of material processing. The metal alloy powder is a composite structure powder composed of coated outer metal and coated metal particles. The coated outer metal is evenly coated on the surface of the coated metal particles; the melting point of the coated outer metal is higher than that of the coated metal. The melting point of metal particles; the metallurgical combination between the cladding layer and the coated metal particles forms a composite structure powder. When the metal alloy coating prepared by the composite structure powder is used, due to the metallurgical bonding reaction between the coating and the substrate and the interface of the particle layer in the coating, the interface is firmly bonded, thereby greatly improving the bonding strength between the coating and the substrate. The cohesive bonding strength between particle layers in the coating ensures the long-term stability of the coating. The metal alloy coating prepared by using the metal alloy powder has excellent corrosion resistance.

Owner:XI AN JIAOTONG UNIV

Preparation method of sintered ultrathin siliceous plate for pouring large high-quality steel ingot

The invention discloses a preparation method of a sintered ultrathin siliceous plate for pouring a large-scale high-quality steel ingot, and relates to the technical field of steel production; a lining plate adopts siliceous particles and fine powder with different granularities as main raw materials, rho-Al2O3 micro powder, silica micro powder, graphite, an inhibitor and a sol binder are added, a vibration pressure forming process is adopted, and sintering treatment is carried out in a high-temperature kiln. The prepared lining plate material is high in production forming efficiency, smooth, not prone to bending deformation, small in gap between plates and liners and tight in combination; and a sintered product is high in refractoriness, low in heat conductivity coefficient, high in strength, good in uniformity, convenient to construct, build and dismantle, and beneficial to efficient use of the lining plate material.

Owner:NANJING IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com