Laminate and saw device

A layered body and main surface technology, which is applied to electrical components, impedance networks, etc., can solve the problems of increased production costs of SAW devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

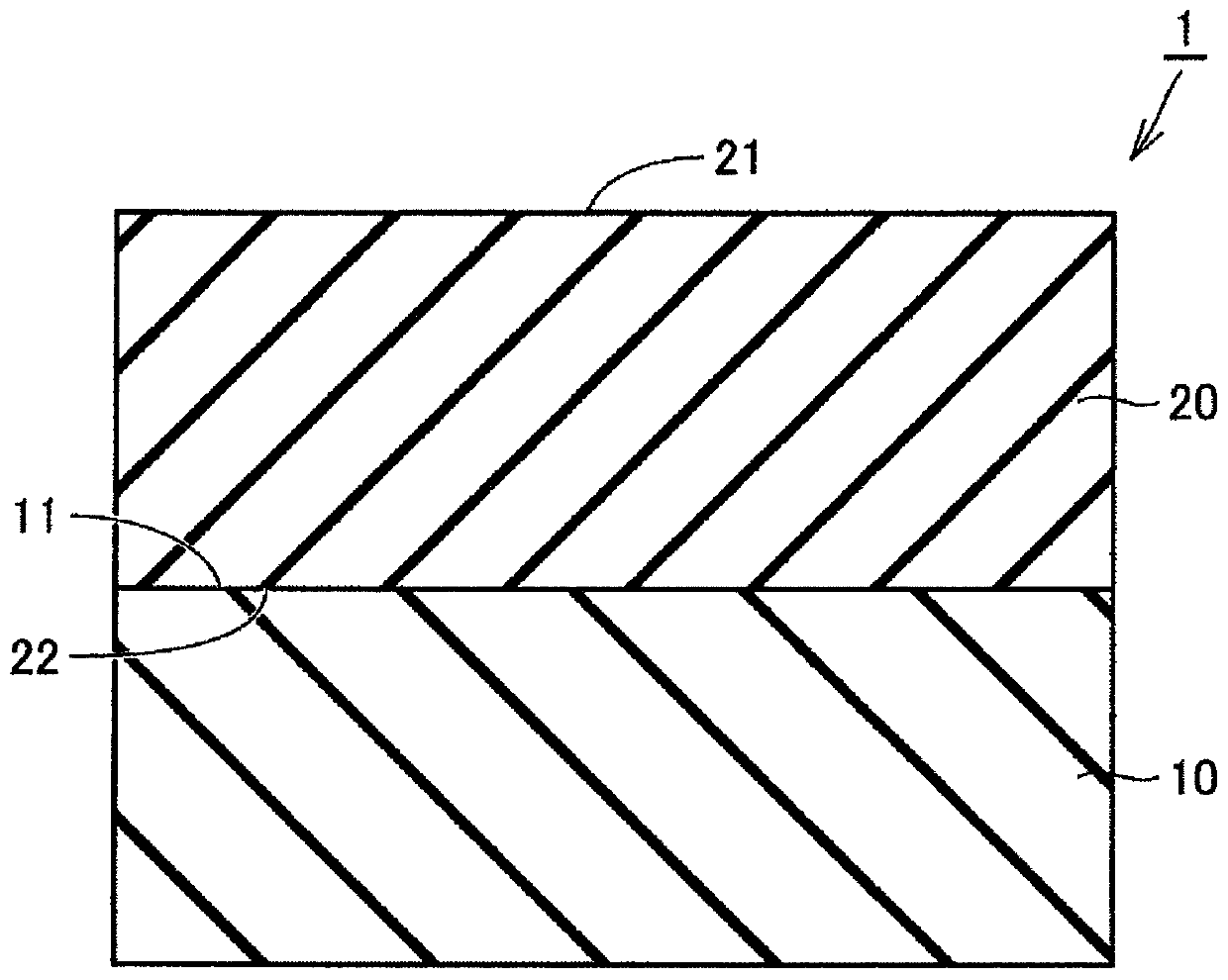

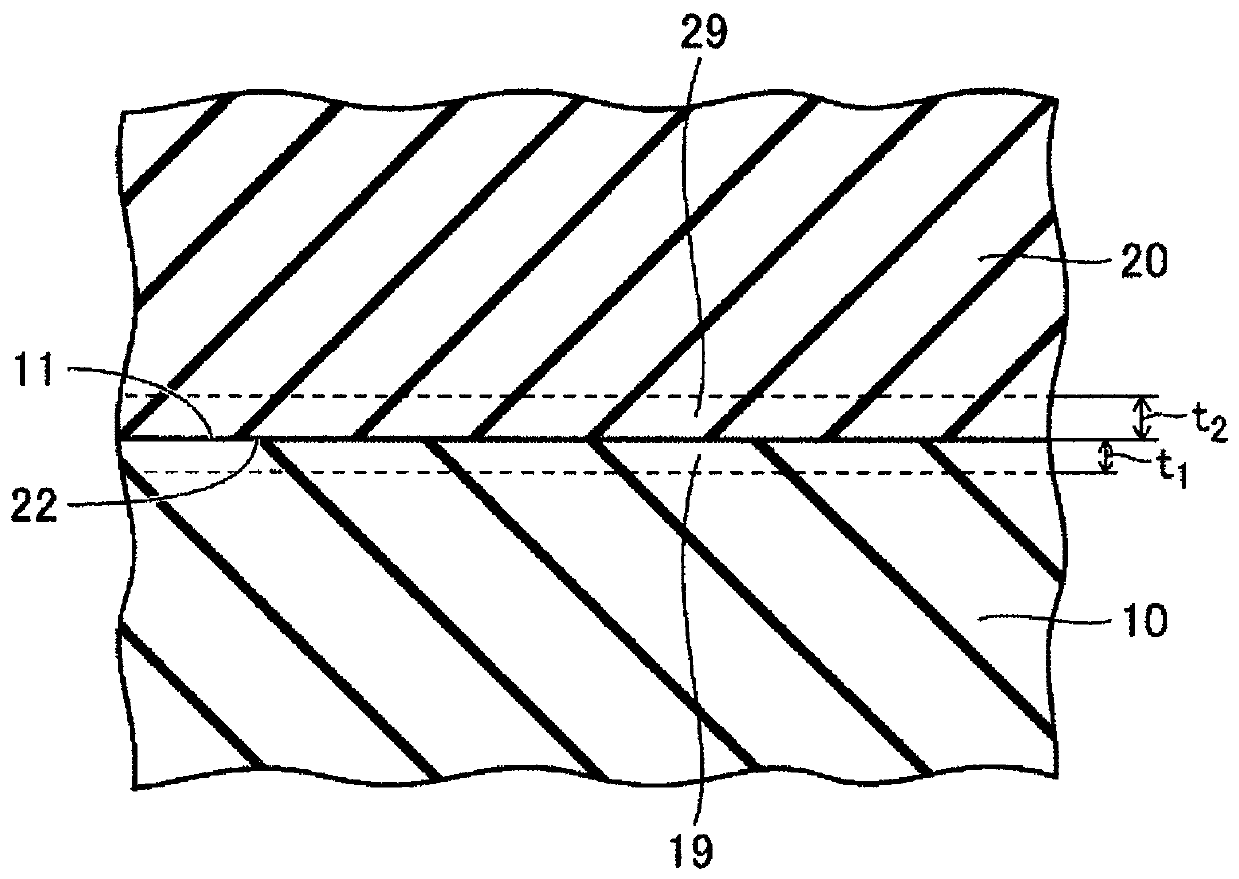

[0022] First, embodiments of the present invention will be listed and described. A layered body according to the present application includes a ceramic substrate formed of polycrystalline ceramics and having a supporting main surface, and a piezoelectric substrate formed of a piezoelectric material and having a bonded main surface bonded to the supporting main surface by van der Waals force. The ceramic substrate includes a supporting major surface amorphous layer formed to include the supporting major surface. The piezoelectric substrate includes a bonded major surface amorphous layer formed to include the bonded major surface. The thickness of the supporting major surface amorphous layer is less than the thickness of the bonding major surface amorphous layer.

[0023] In the layered body according to the present application, the supporting main surface of the ceramic substrate and the bonding main surface of the piezoelectric substrate are bonded to each other by van der Wa...

Embodiment

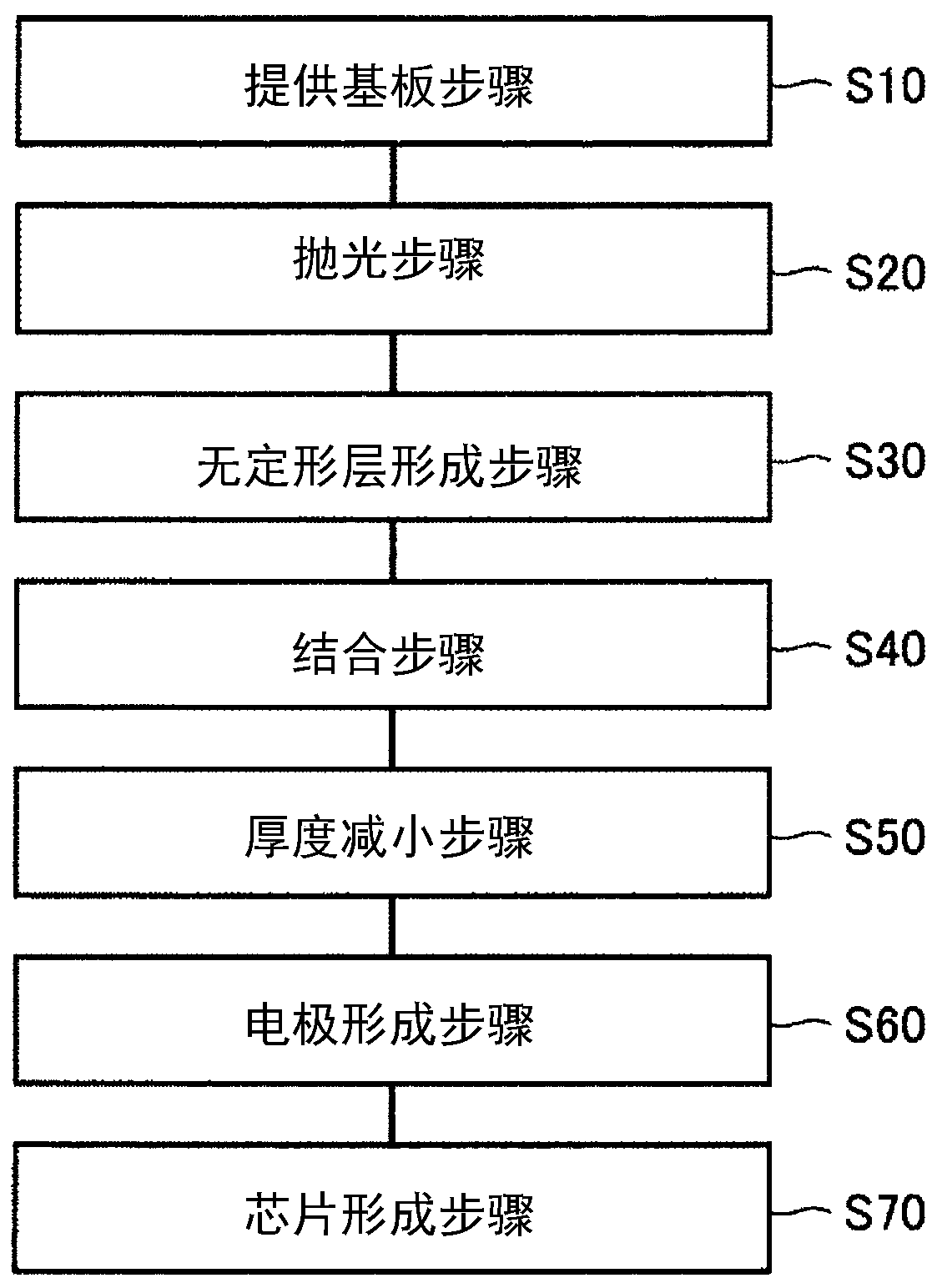

[0055] Steps ( S10 ) to ( S40 ) according to the above-described embodiment were performed to manufacture layered body 1 , and experiments were performed to examine the bonding strength between base substrate 10 (ceramic substrate) and piezoelectric substrate 20 . Specifically, a base substrate 10 formed of polycrystalline spinel and a piezoelectric substrate 20 formed of single crystal lithium tantalate are provided in step (S10), and steps (S20) to (S40) are performed to manufacture a layered Body 1. By differentiating the irradiation conditions of Ar beams in the step (S30), two kinds of layered bodies 1 (sample A and sample B) were produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com