Micro linear slide rail and sliding base thereof

A linear slide, miniature technology, applied in the direction of linear motion bearings, bearings, shafts, etc., can solve the problems of complex shapes, many parts, inconvenient assembly, etc., and achieve the effect of simple frame structure and easy injection molding manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Based on the above technical features, the main functions of the miniature linear slide rail and its sliding seat of the present invention will be clearly presented in the following embodiments.

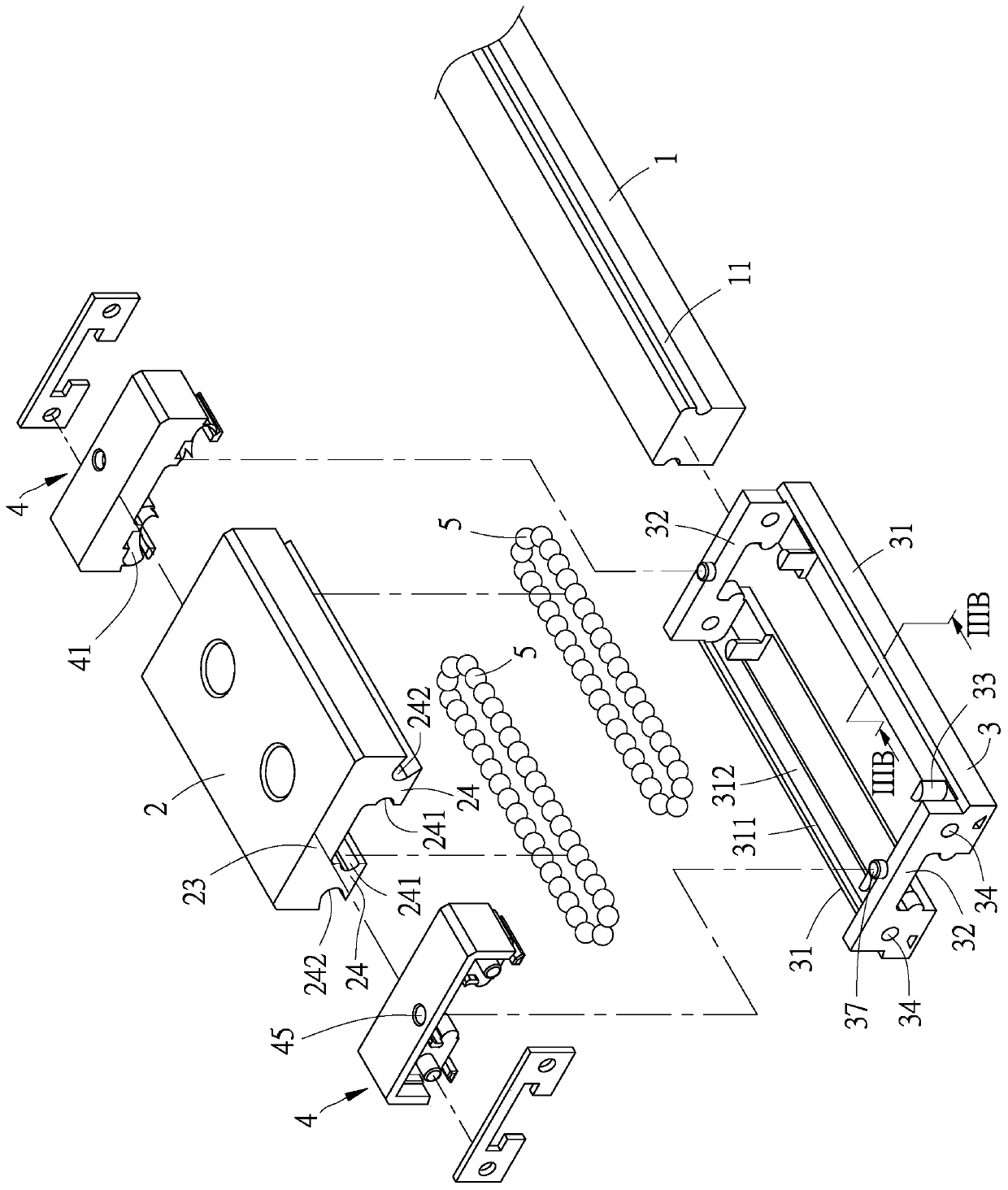

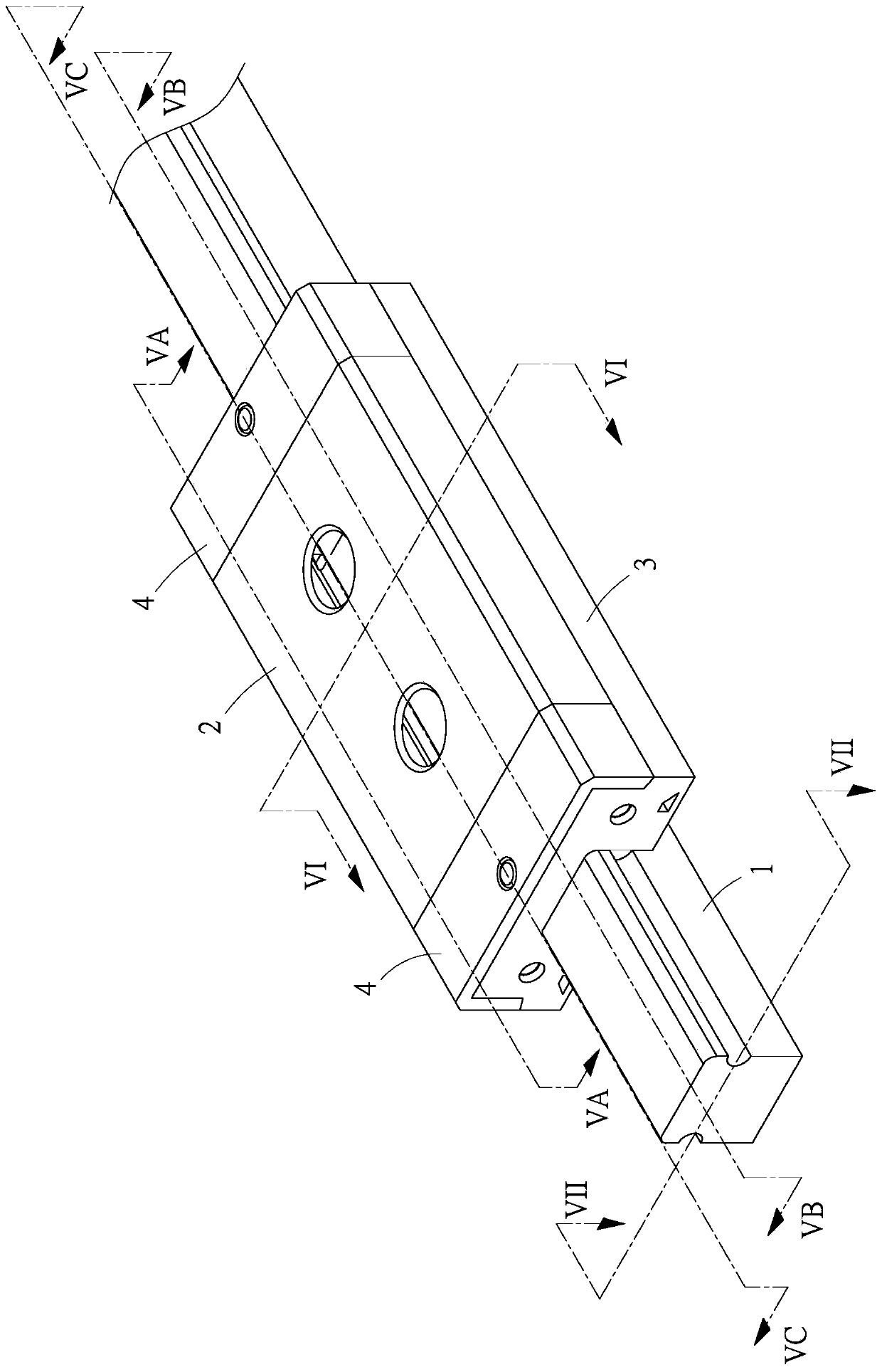

[0057] refer to figure 1 and figure 2 As shown, the present embodiment includes: a slide rail 1, a slide seat straddling the slide rail 1, wherein the slide seat includes a base body 2 and a frame 3 assembled under the base body 2, and two End caps 4 are assembled on both ends of the seat body 2 . A rolling element 5 is placed between the sliding rail 1 and the sliding seat, and the sliding seat is linearly displaced on the sliding rail 1 by virtue of the rolling of the rolling element 5 .

[0058] To further clarify:

[0059] The slide rail 1 extends along one direction, and the length of the slide rail 1 depends on the place of use, and there is a first load track surface 11 on opposite sides of the slide rail 1 .

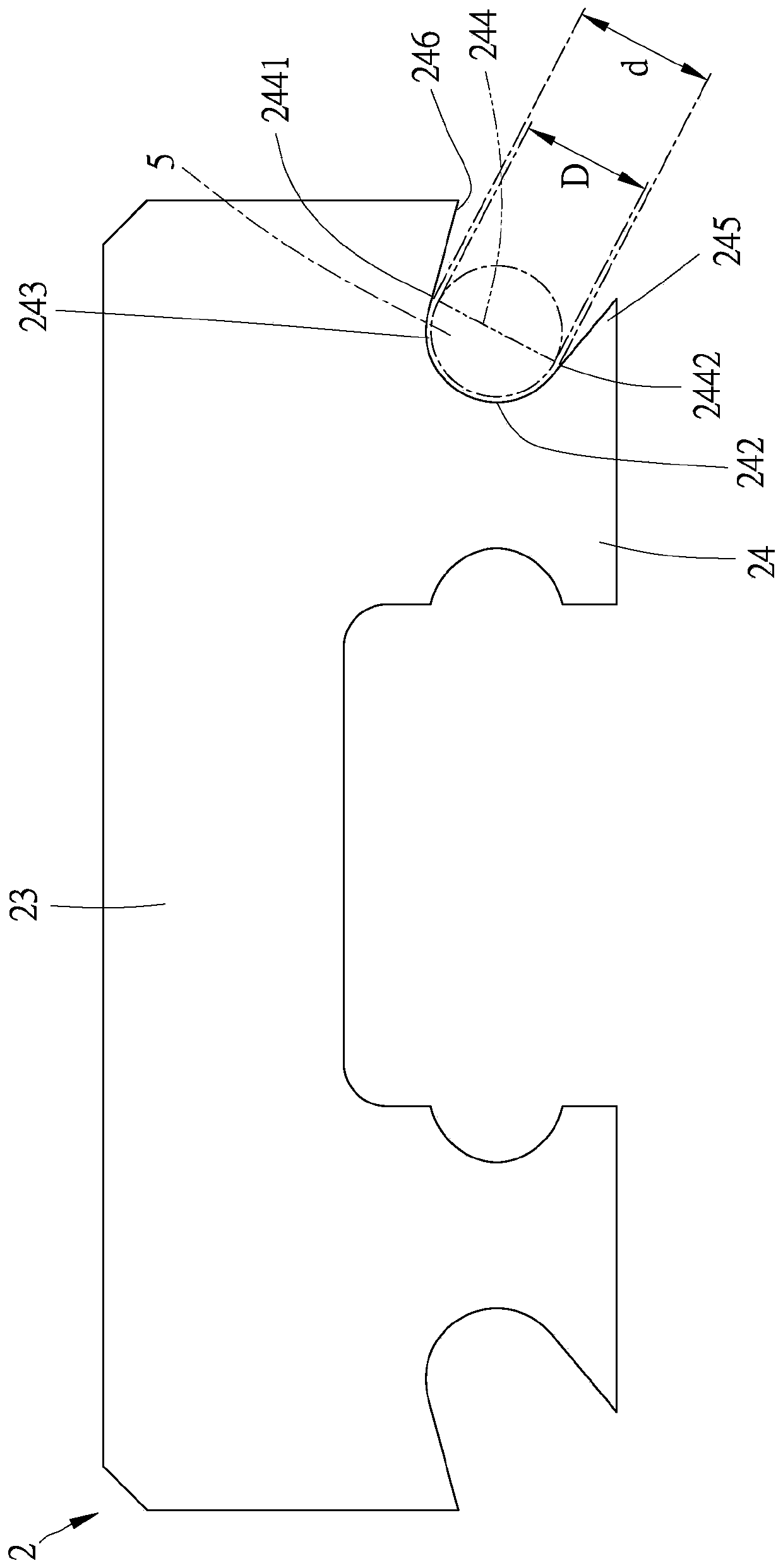

[0060] The base body 2 includes a platform 23 and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com