Waterproof breathable composite garment fabric

A waterproof and breathable clothing technology, applied in the field of clothing fabrics, can solve the problems of no waterproof, breathable, unable to meet the needs of outdoor sports, poor waterproof and breathable fabrics, etc., to achieve the effect of improving thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

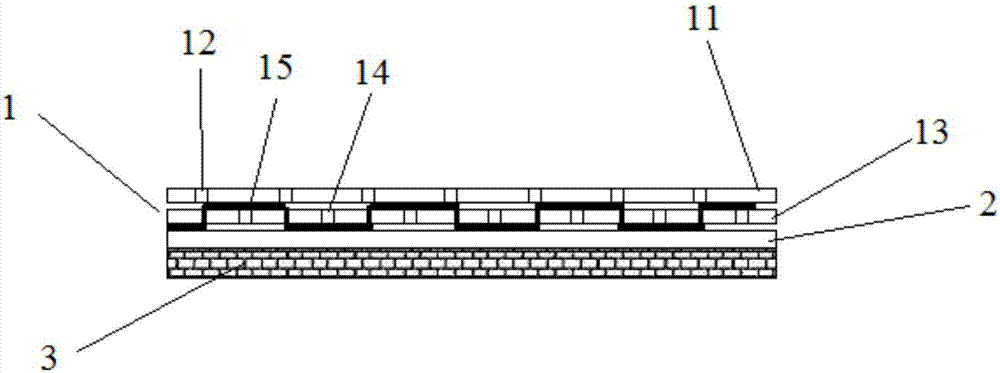

[0032] A waterproof and breathable composite clothing fabric, its structure is as figure 1 As shown, it includes a waterproof surface layer 1, a warm middle layer 2 and a breathable inner layer 3 that are sequentially compounded from outside to inside, wherein the waterproof surface layer 1 is a double-layer composite structure, and wherein the outer layer is a PU film that seals the first air hole 12 11. The inner layer is a PUR microporous membrane 13. On the PUR microporous membrane 13, a cotton thread 15 is also used to pass through and interweave on both sides of the PUR microporous membrane 13. The PUR microporous membrane 13 is also provided with one end covered by the cotton thread 15. The second ventilation hole 14;

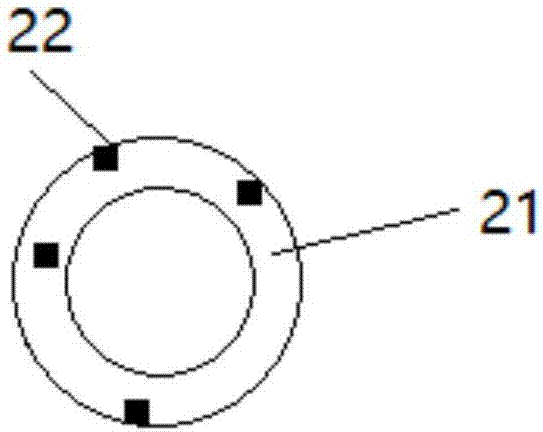

[0033] The warm-keeping middle layer 2 is formed by interweaving hollow polyester fibers 21 and cotton fibers as warp yarns and weft yarns respectively;

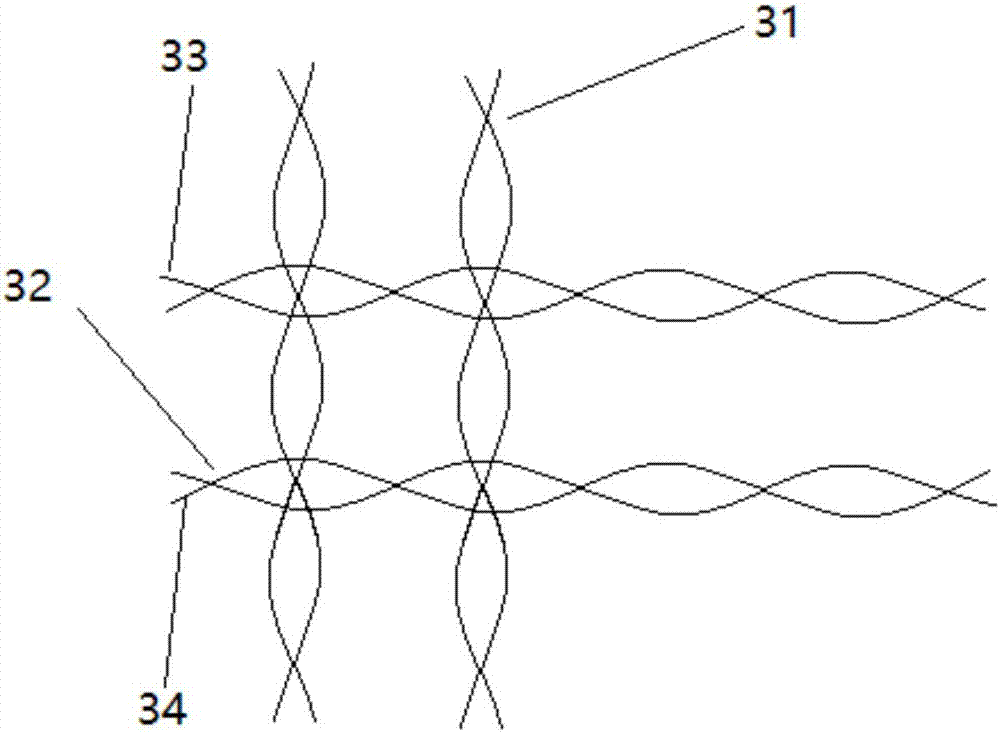

[0034] The air-permeable inner layer 3 adopts the inner layer yarn composed of the first fiber bun...

Embodiment 2

[0041] The difference from Example 1 is that in this example, the diameter of the first air holes 12 on the PU membrane 11 is 0.02 μm, and the diameter of the second air holes 14 on the PUR microporous membrane 13 is 0.03 μm.

Embodiment 3

[0043] The difference from Example 1 is that in this example, the diameter of the first vent hole 12 on the PU film 11 is 0.05 μm, and the diameter of the second vent hole 14 on the PUR microporous film 13 is 0.08 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com