A thermally sprayed self-adhesive metal alloy powder with clad composite structure

A composite structure, metal alloy technology, applied in metal processing equipment, metal material coating technology, coating and other directions, can solve the problem of metallurgical self-bonding reaction difficult to obtain a dense coating between particles, and achieve strong interface bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

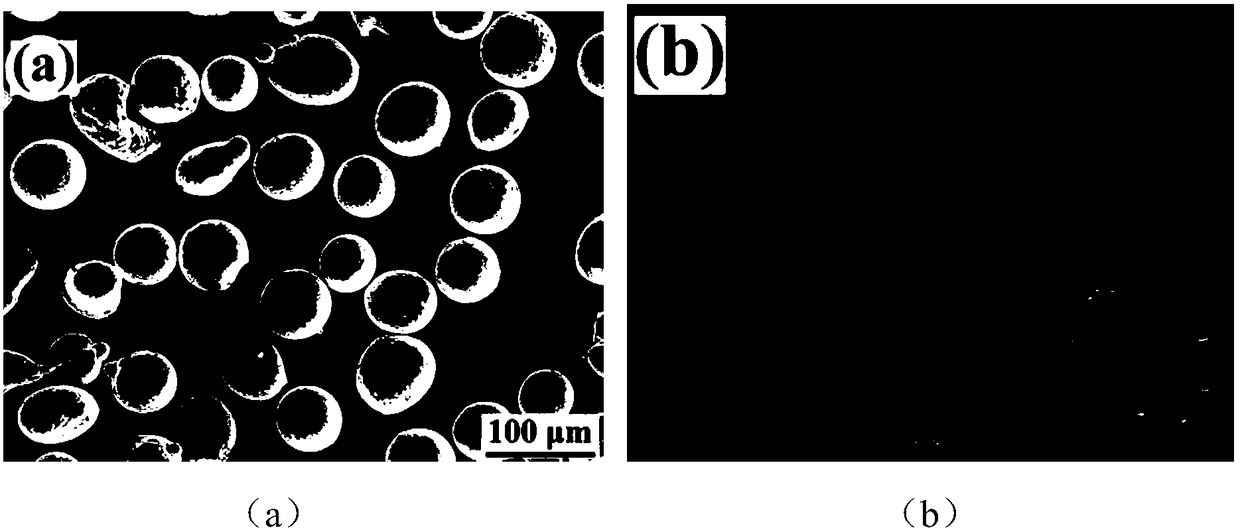

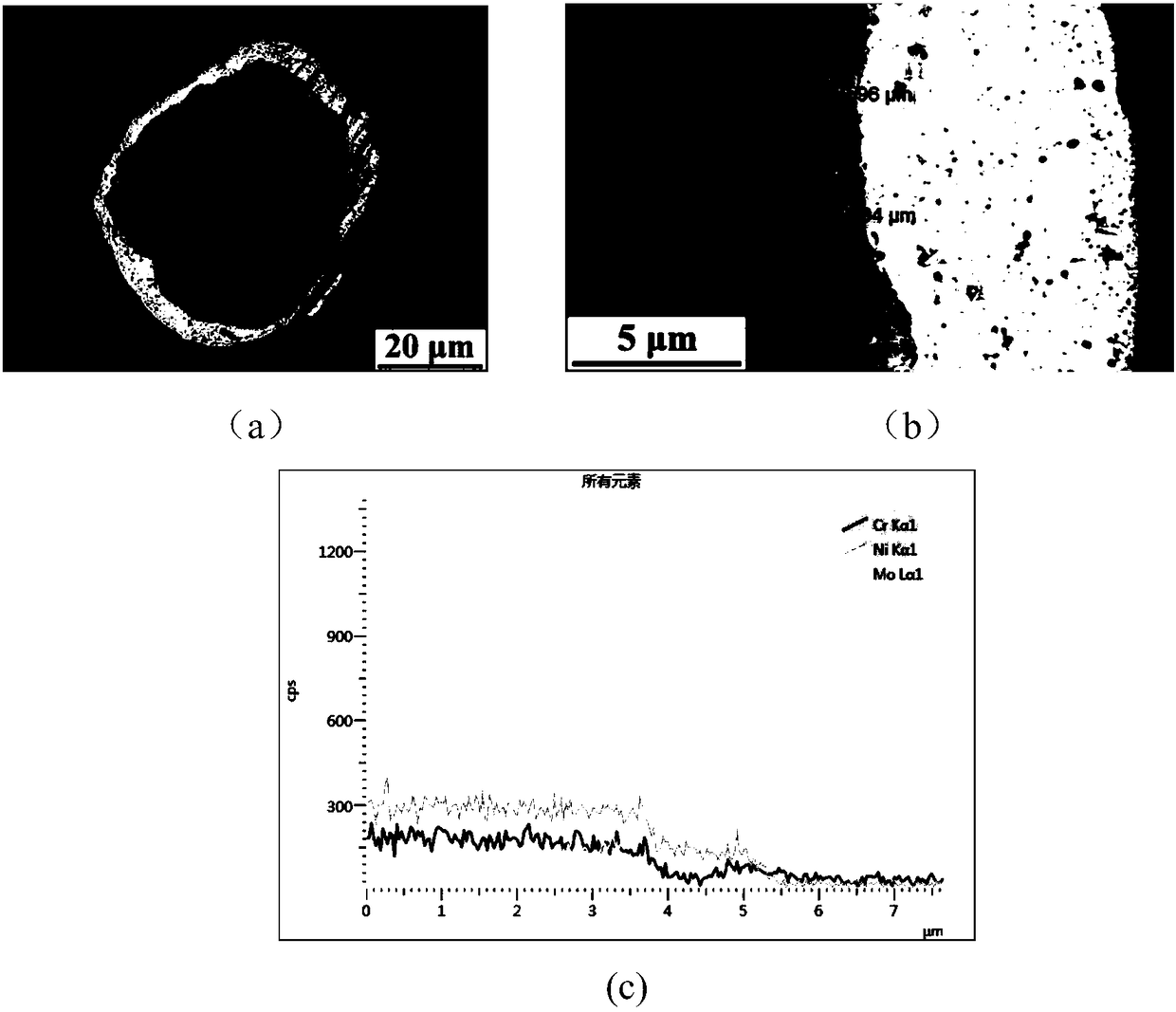

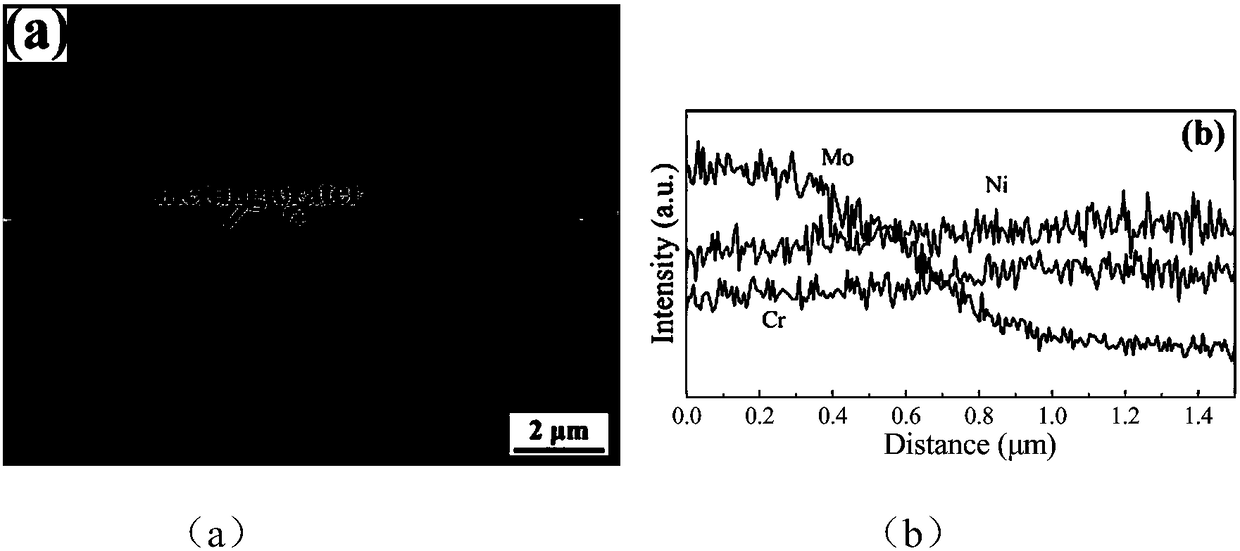

[0027] as figure 1 (a) Spherical Ni20Cr powder with a particle size between 50-75 μm and figure 1 (b) The submicron Mo powder shown in (b) is the original powder. After the two are mixed uniformly at a mass ratio of 25 / 75, the ball milling method is used to perform ball milling coating under the protection of an argon atmosphere. After the coating treatment, the result after heat treatment at 1000°C for 30 minutes in a protective atmosphere is as follows: figure 2 shown by figure 2 (a) The cross-sectional morphology of the coated powder shows that the Mo powder is uniformly and densely coated on the outer layer of the Ni20Cr powder with a thickness of about 10 μm. figure 2 (b) It can be seen that a diffusion layer is formed between the cladding layer (in white contrast) and the NiCr alloy, that is, the Mo cladding layer and the coated NiCr are metallurgically bonded together, figure 2 (c) Powder energy spectrum analysis shows that there is a Mo diffusion layer between t...

Embodiment 2

[0032] Using Mo with a diameter of 0.5 μm to 2 μm and nickel-based self-fluxing alloy powder (Ni35 powder) with a diameter of 50-100 μm, in N 2 Under a protective atmosphere, it was grinded by mechanical alloying for 5 hours, and the Mo particles were evenly covered on the surface of the nickel-based alloy, and heat-treated at 900°C for 6 hours under a hydrogen atmosphere to obtain Ni35 powder firmly coated with metal Mo.

Embodiment 3

[0034] Use the hydroxyl Ni powder with the original particle size of submicron and the Zn powder with the particle size of 40-100 μm as the original powder, mix them at a mass ratio of 15 / 85, and grind for 4 hours by mechanical alloying under the protective atmosphere of Ar. Ni Uniform coating on the surface of the nickel-based alloy to obtain metal Ni-coated Zn spray powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com