Patents

Literature

81 results about "Defective Component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The problem statement, all variables and given/known data. Components of a certain type are shipped to a supplier in batches of ten. suppose that 50% of all such batches contain no defective components, 30% contain one defective component, and 20% contain two defective components.

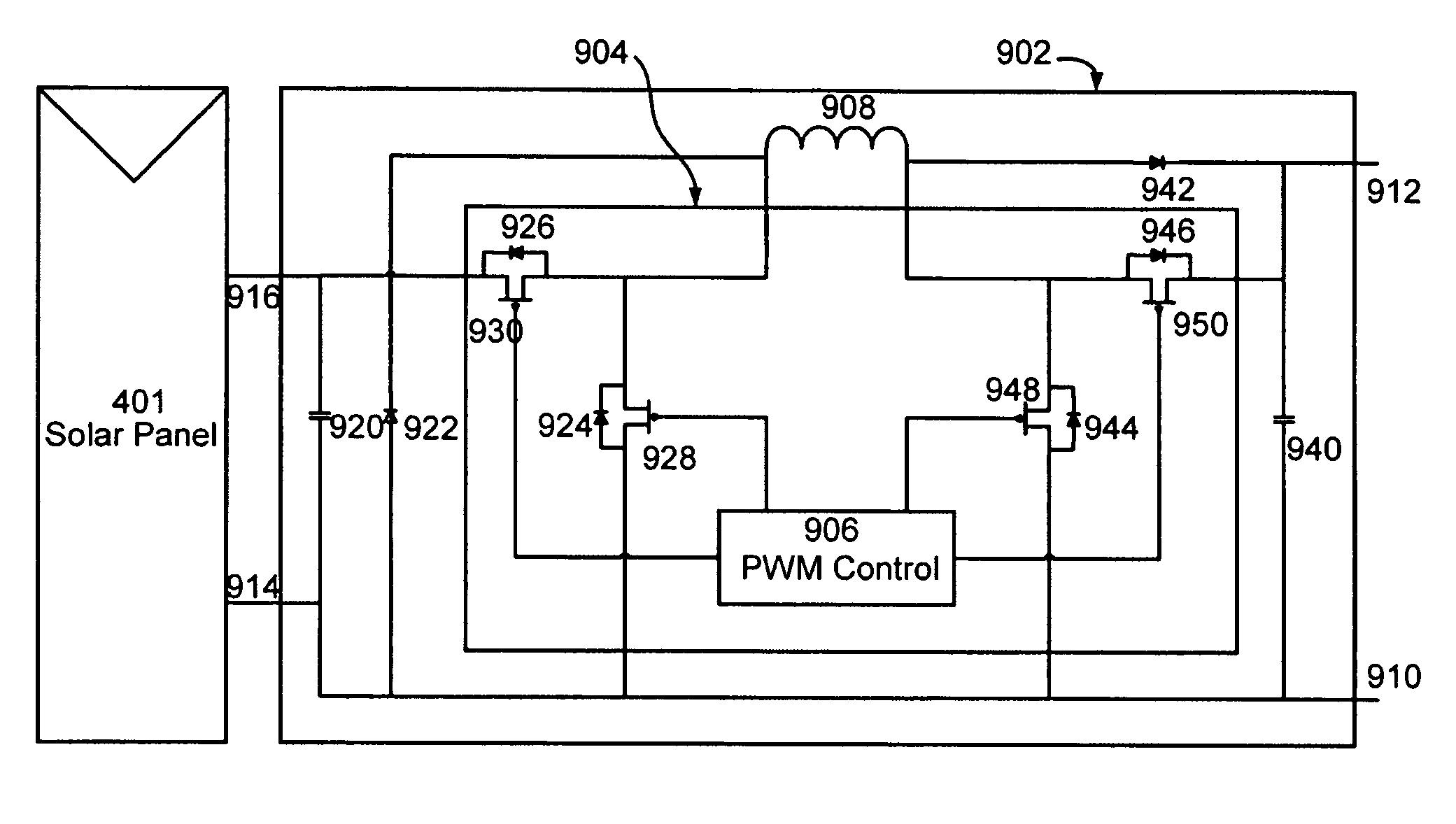

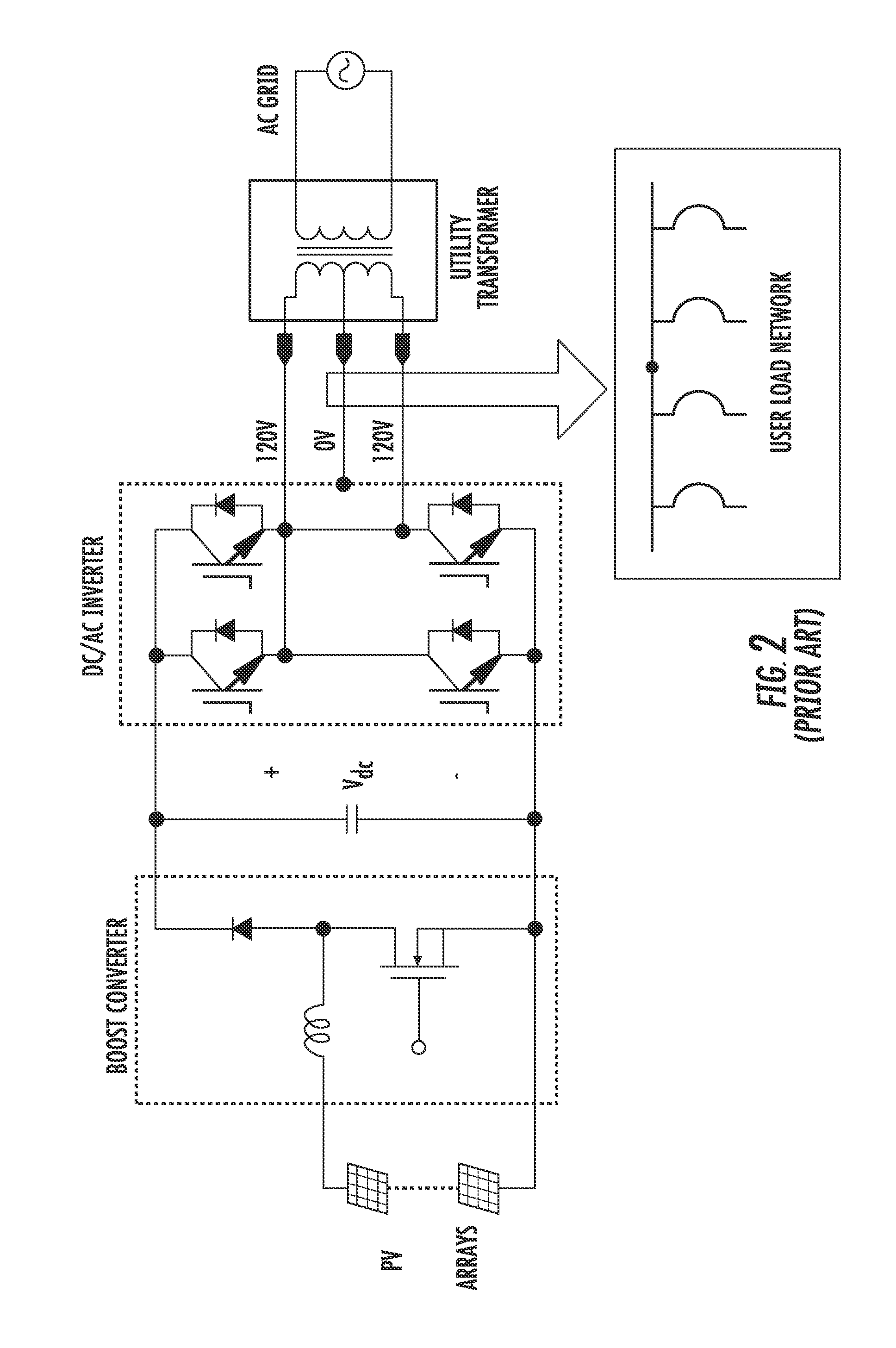

Current bypass for distributed power harvesting systems using DC power sources

ActiveUS7900361B2Improve reliabilityGuaranteed functionDc-dc conversionDc source parallel operationEngineeringElectric power

A converter circuit providing multiple current bypass routes between the output leads to provide reliability in a series connection of several converters. If the converter malfunctions due to component failure, the current bypass routes provide a path for the current that views the malfunctioning converter as substantially a short. Diodes prevent backflow into the power source connected to the converter. Redundancy is provided in the bypass portions of the converter circuit that provides alternate parallel paths in case a defective component in one of the paths opens the circuit along that path. In one example, the converter is implemented as a buck plus boost converter where either the buck or the boost portion or both are operative responsive to a controller controlling the switches of both portions. Most of the converter circuit may be implemented in an integrated circuit.

Owner:SOLAREDGE TECH LTD

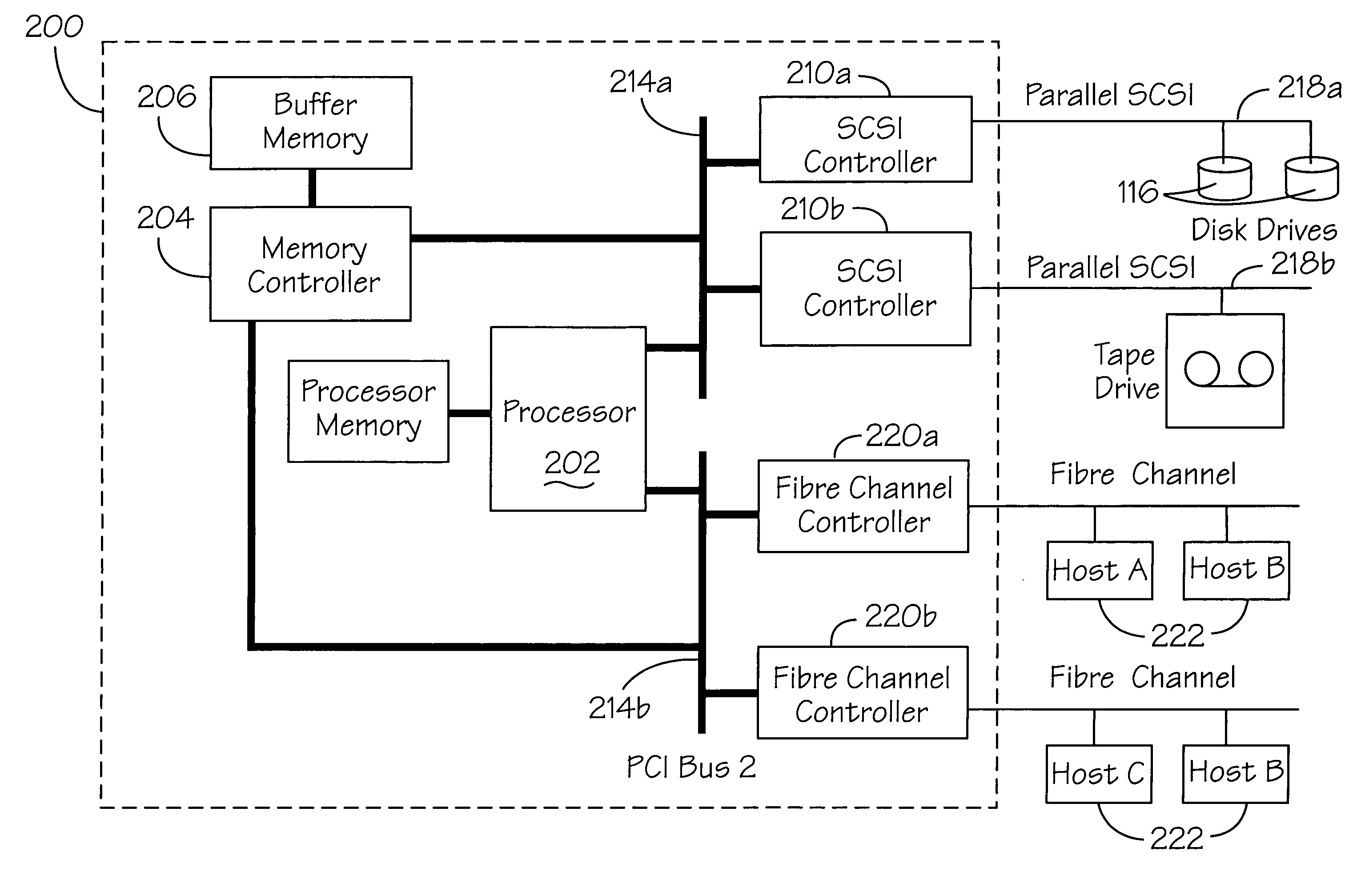

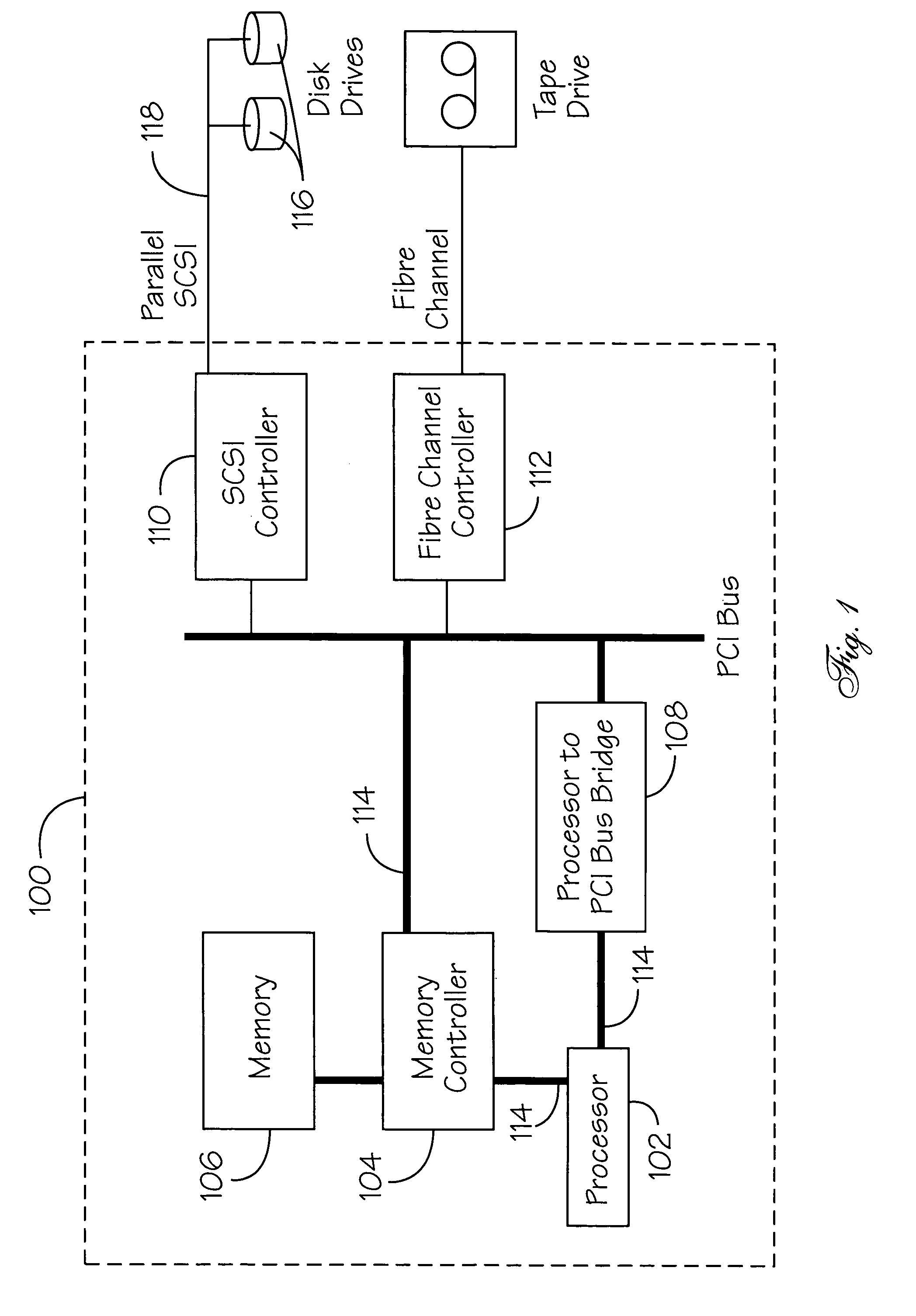

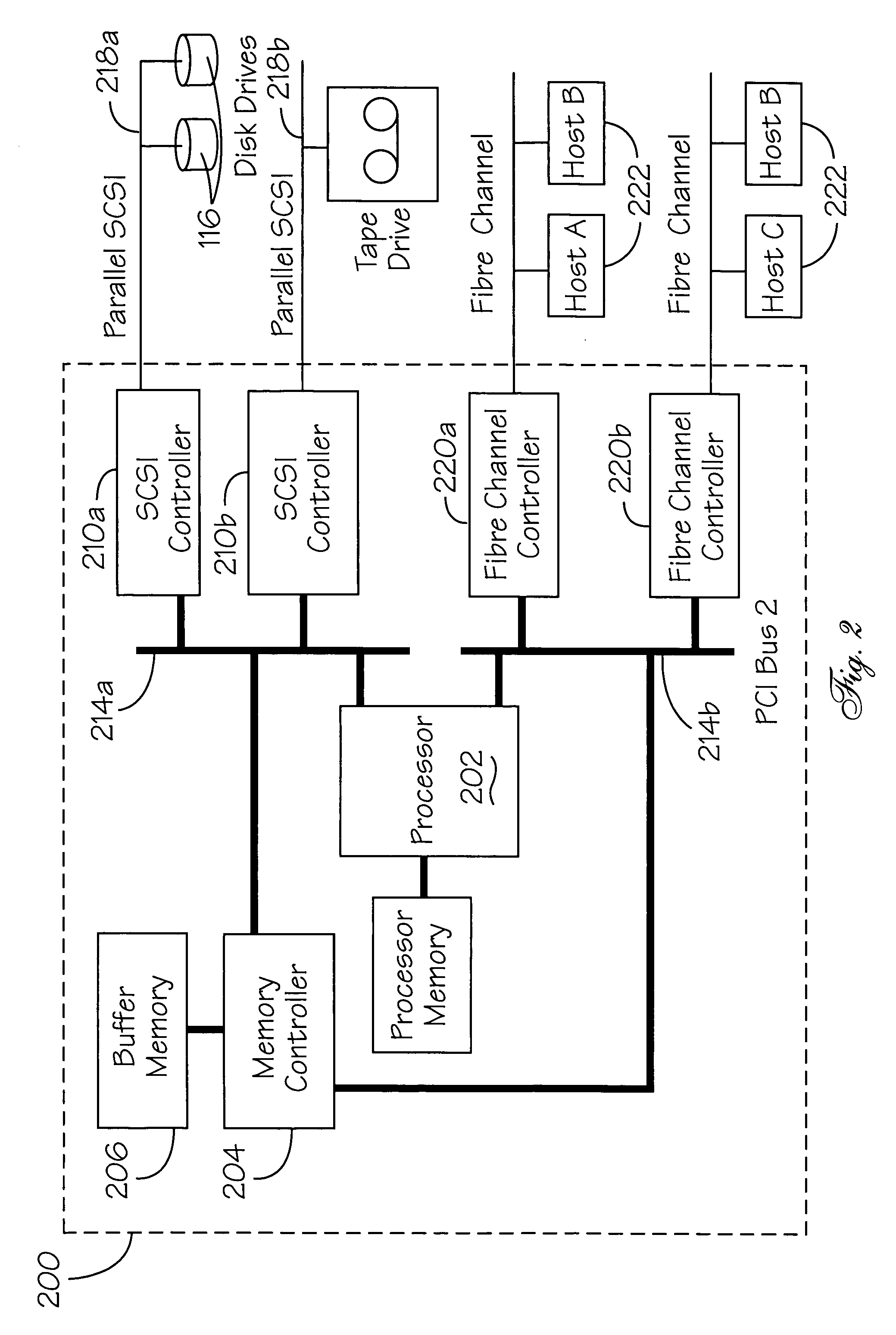

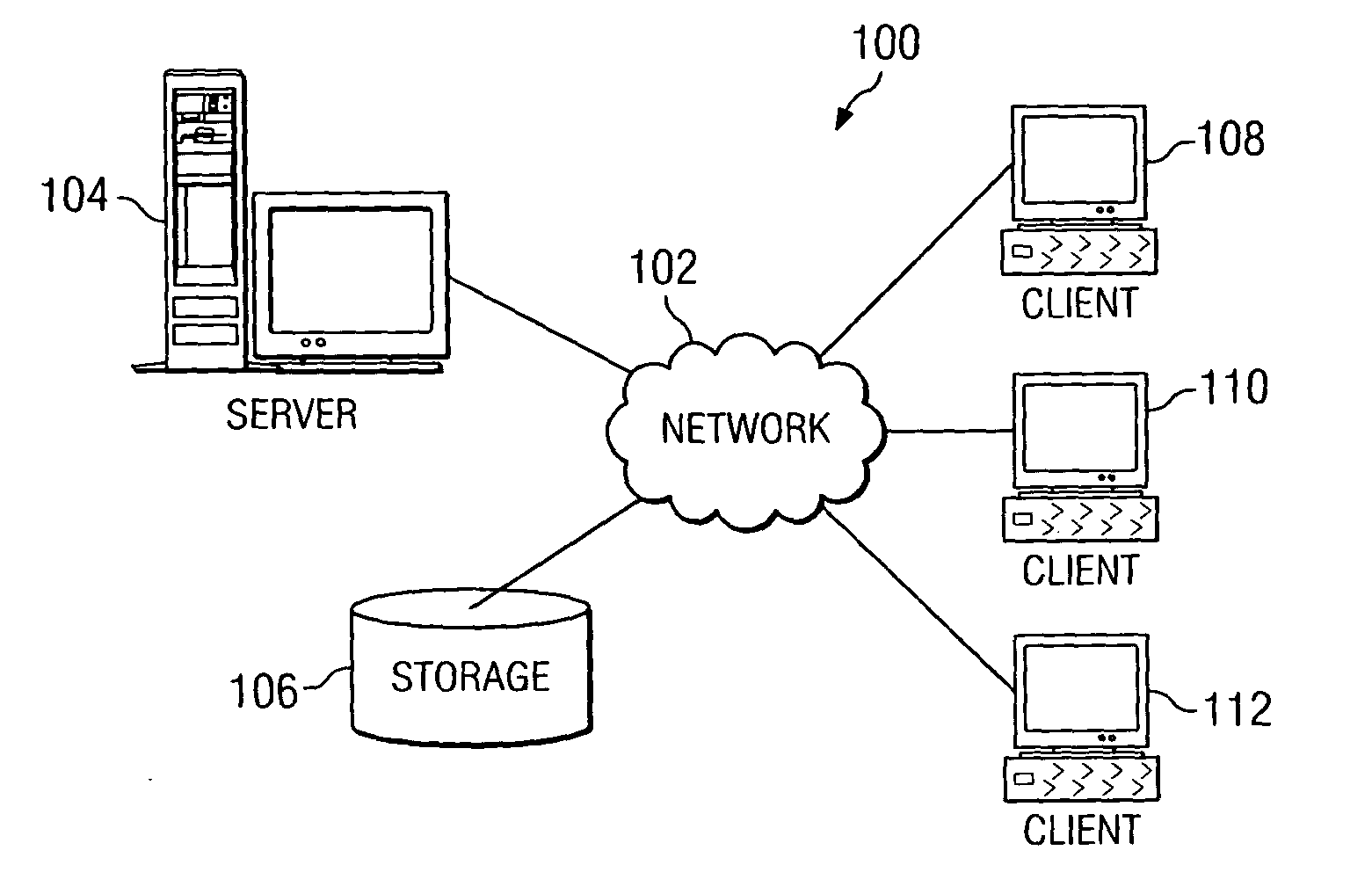

Method for verifying functional integrity of computer hardware, particularly data storage devices

The present invention features a method for performing an end-to-end data path integrity check in a computer or computer-like system such as a storage router. A predetermined data test pattern is stored in a memory and then transmitted across a data path by a data initiator to a data receiver. The received data test pattern is then retransmitted to the data initiator where it is compared to the original data. Any discrepancies cause an error condition to be declared. The data path may be disabled until the defective component in the data path is isolated and fixed. The method is hardware independent so it may be easily used in an open systems environment where hardware components may be provided by different vendors.

Owner:QUANTUM CORP

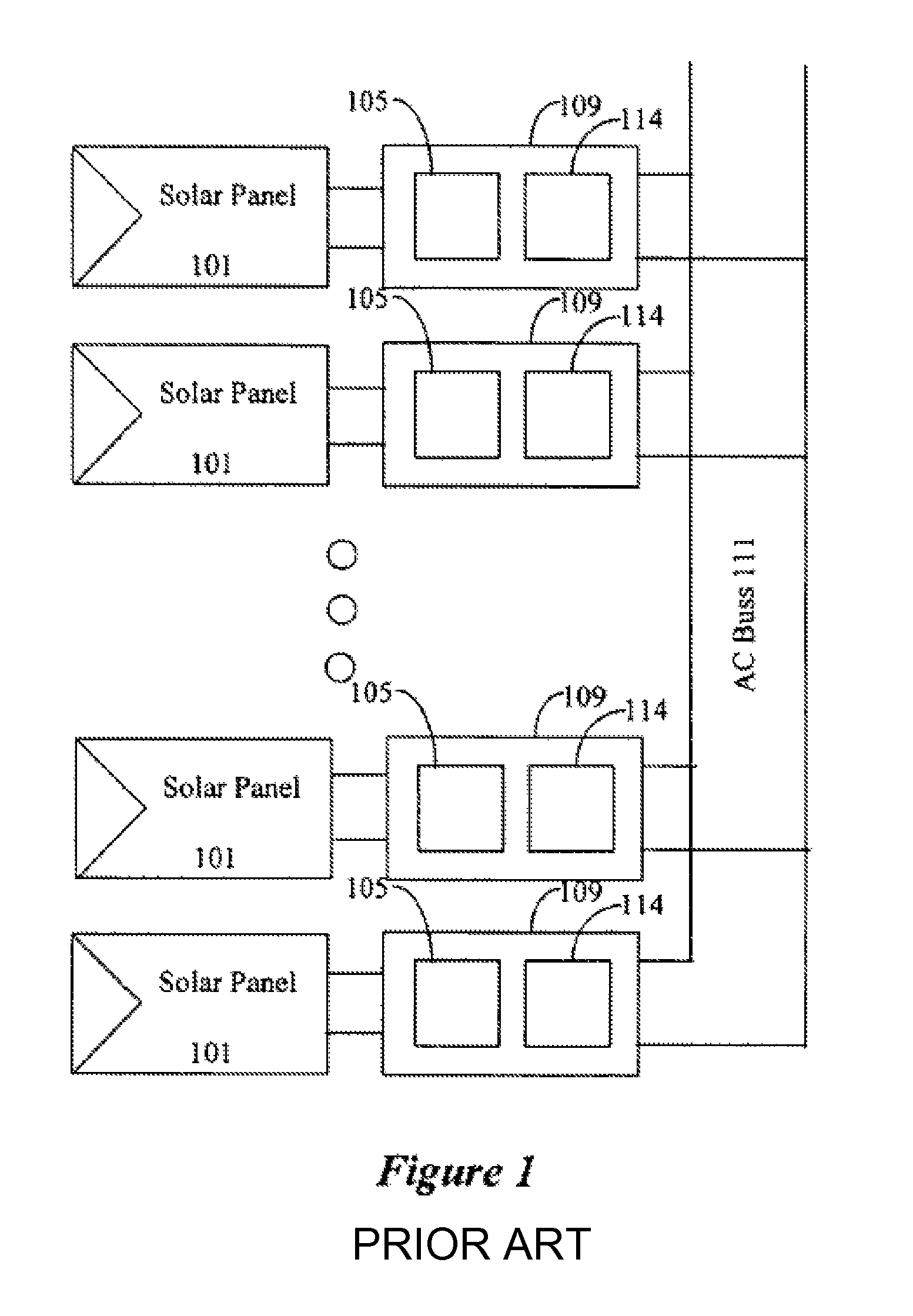

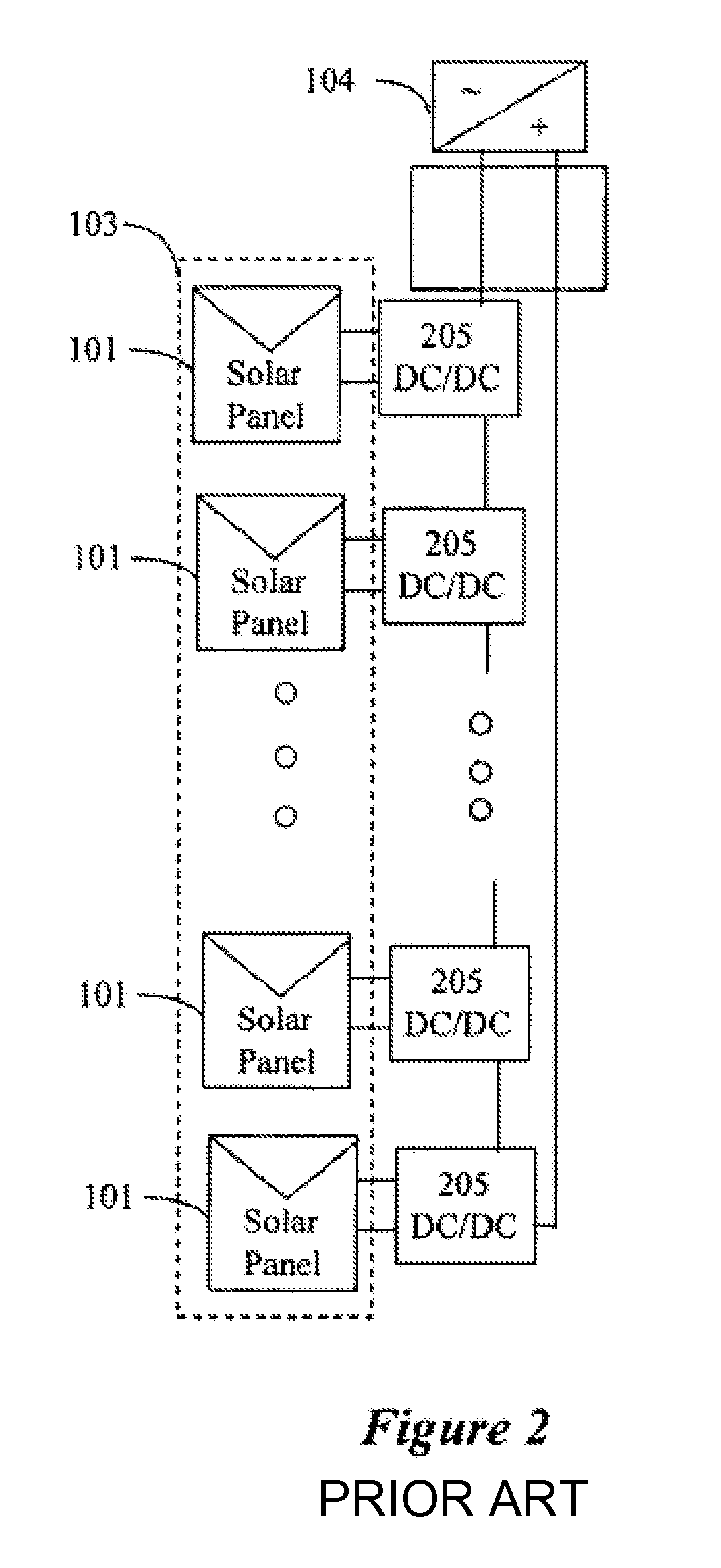

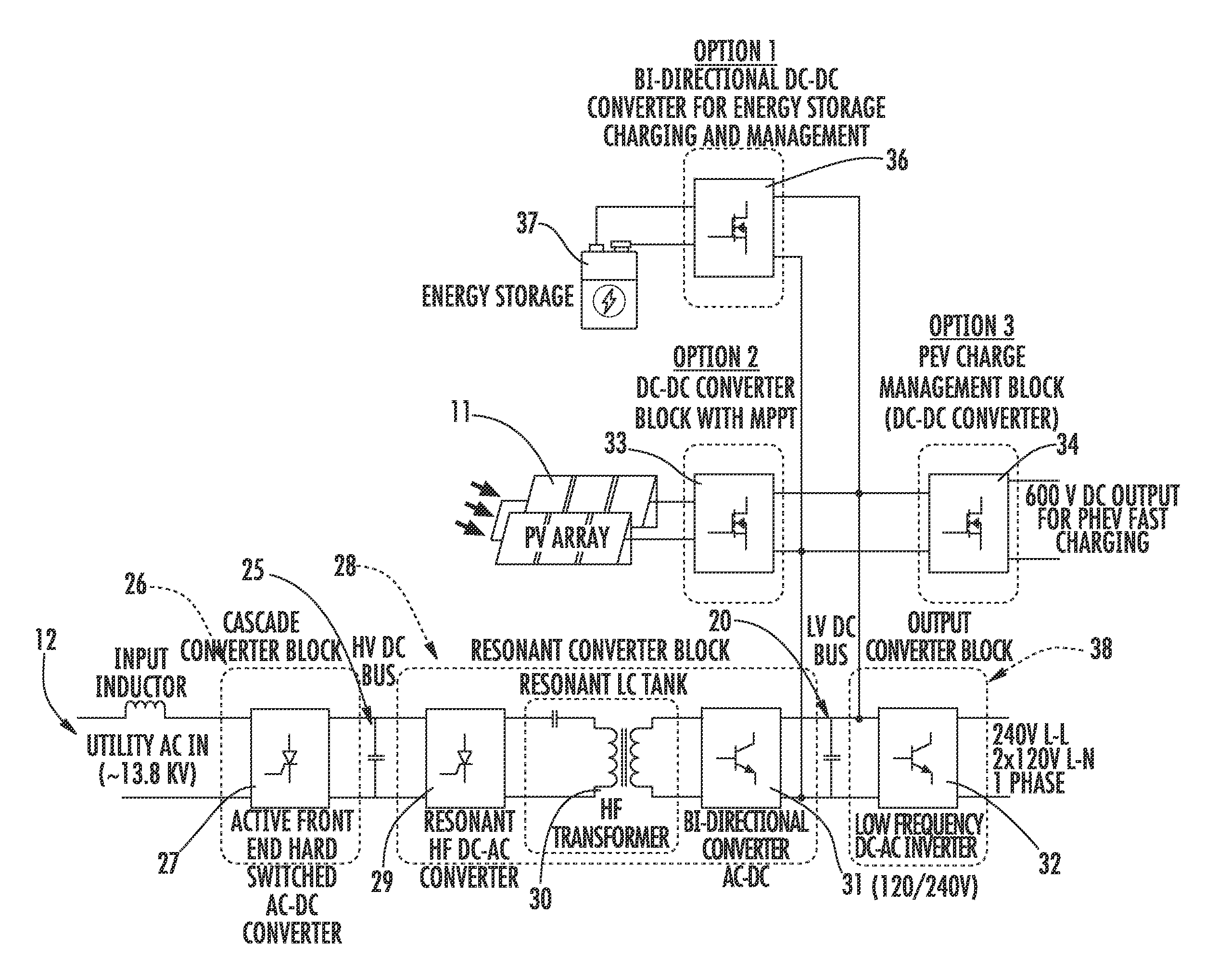

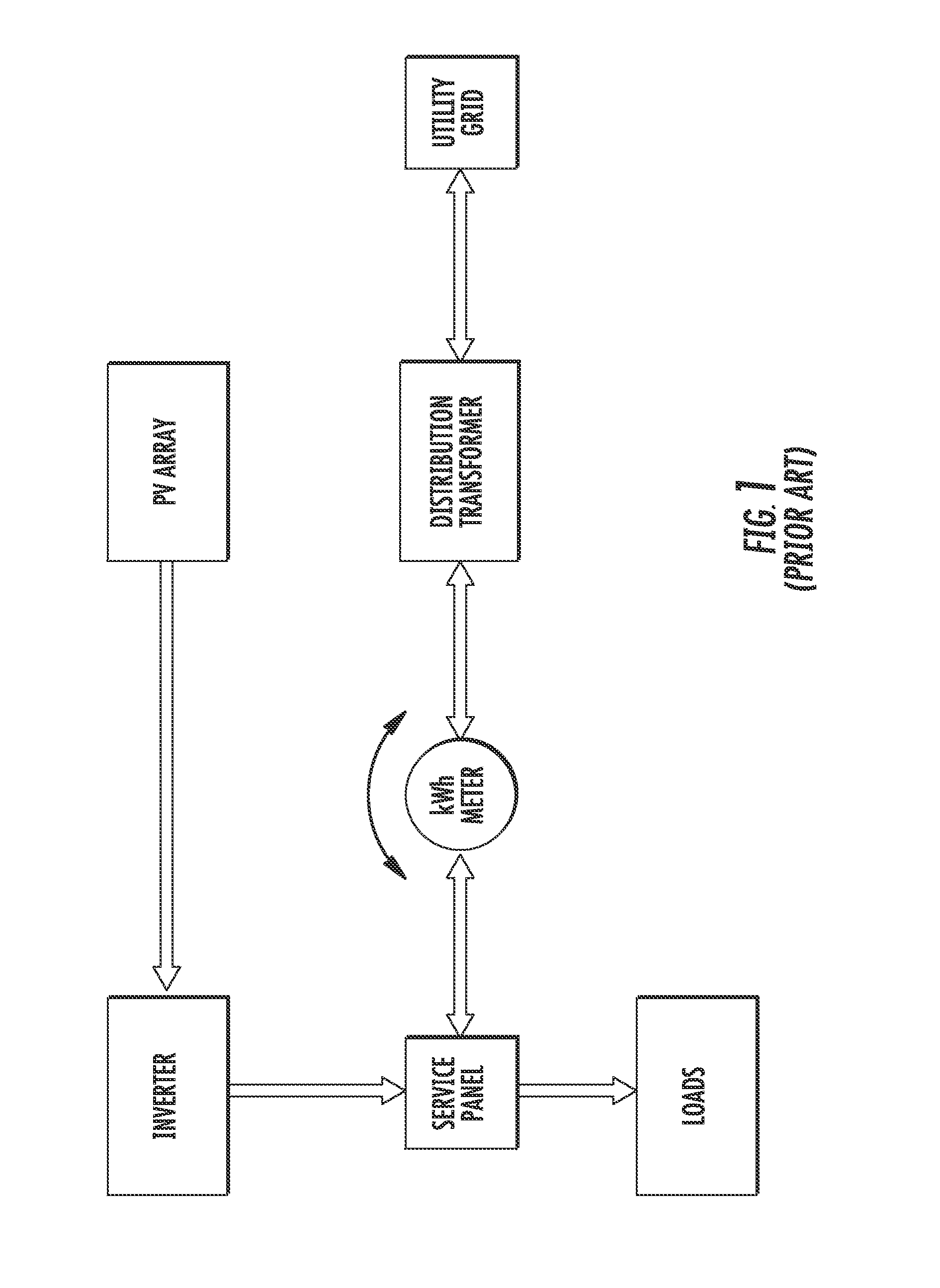

Intelligent photovoltaic interface and system

InactiveUS20110273917A1Increase market penetrationIntegration of PV panels simpler, more efficientPhotovoltaicsSingle network parallel feeding arrangementsCommunications systemPower flow

The present invention relates to a photo-voltaic interface for integration of photo-voltaic modules in a power system. The photo-voltaic interface includes a power conversion system adapted to convert power to a pre-determined voltage and current type, a control and monitoring system adapted to allow monitoring and control of power flow to optimize grid operation, and a communications system adapted to allow remote monitoring of the photo-voltaic interface to detect defective components.

Owner:ELECTRIC POWER RES INST INC

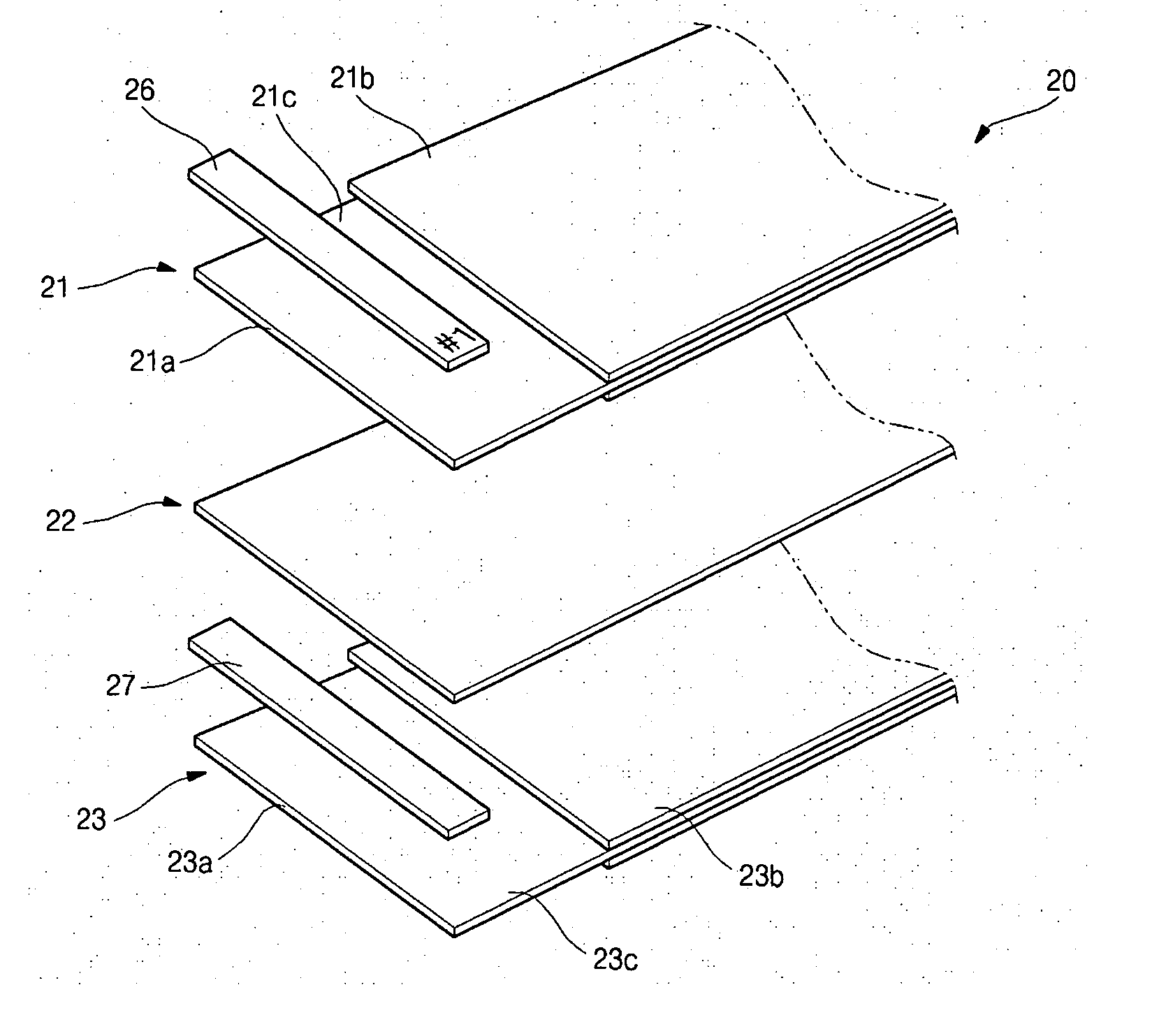

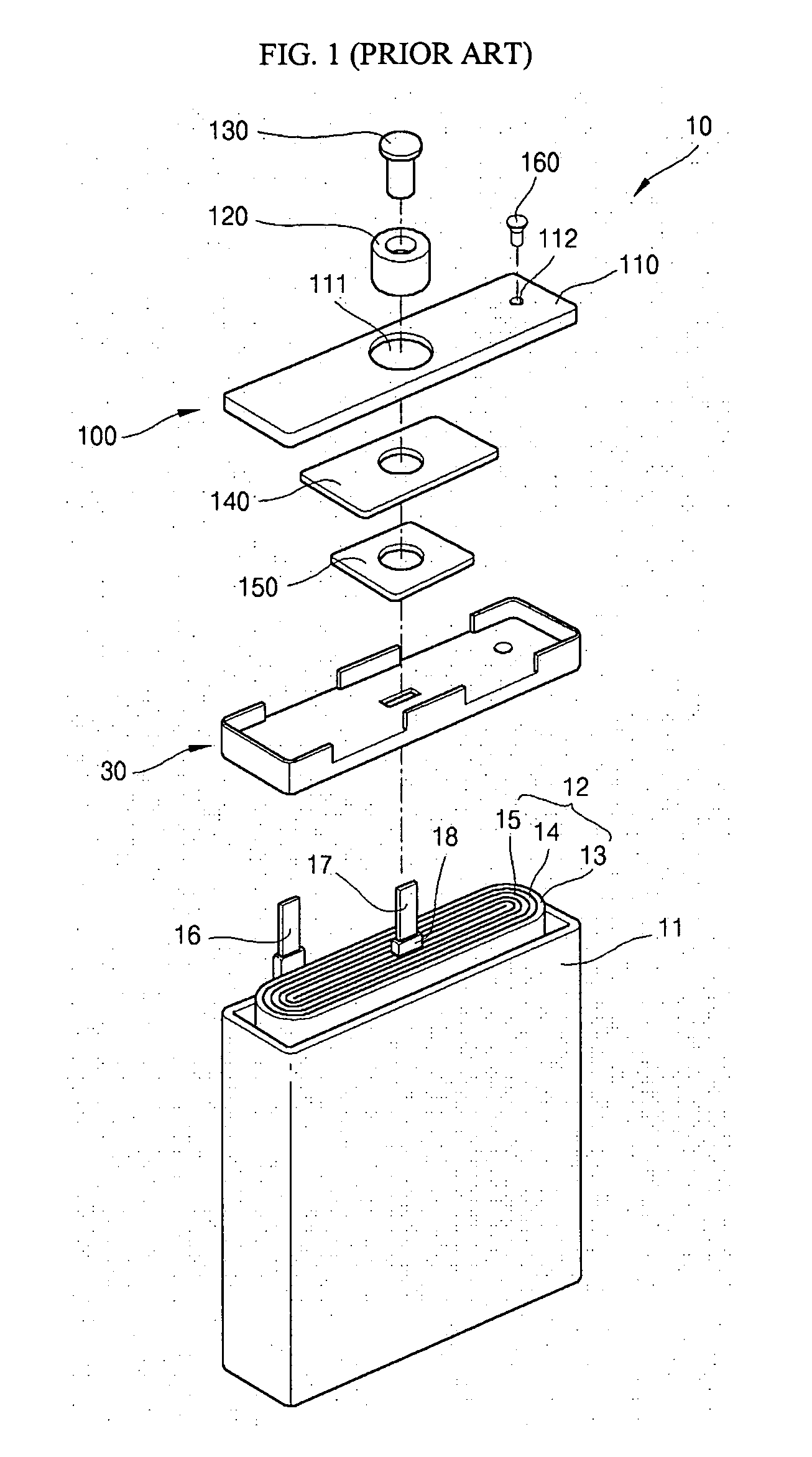

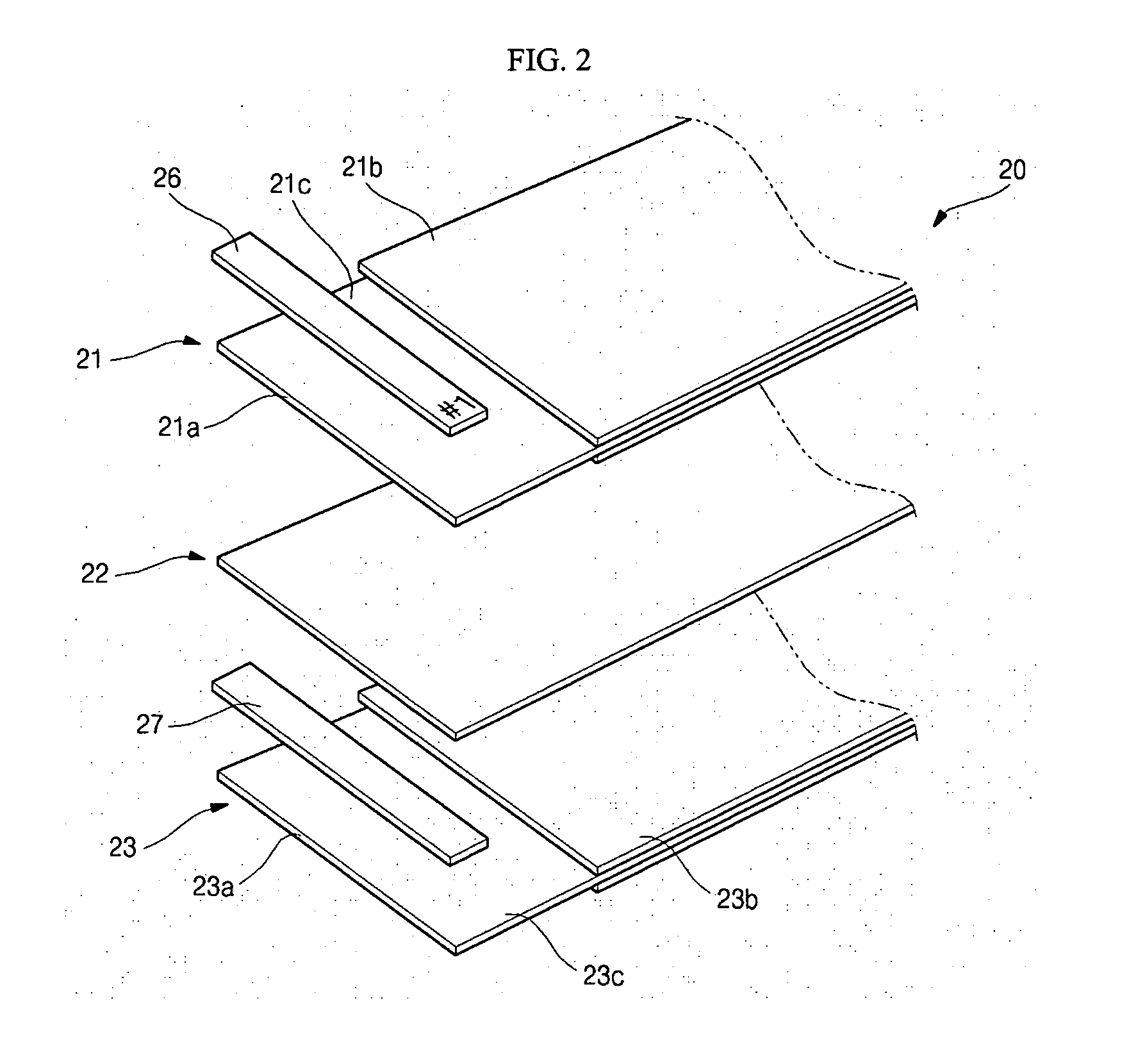

Electrode assembly and lithium rechargeable battery using the same

InactiveUS20060040181A1Convenient verificationInhibit productionFinal product manufactureSmall-sized cells cases/jacketsLithiumManufacturing line

An electrode assembly comprising an electrode tab or an electrode plate substrate which has an identification mark formed thereon and a lithium rechargeable battery using the same are disclosed. This identification mark makes it possible to easily check the record of the manufacturing processes of the battery, including production equipment, production date, line operators, and production lines when a battery malfunctions. This identification mark may prevent a replica of the defective component from being manufactured.

Owner:SAMSUNG SDI CO LTD

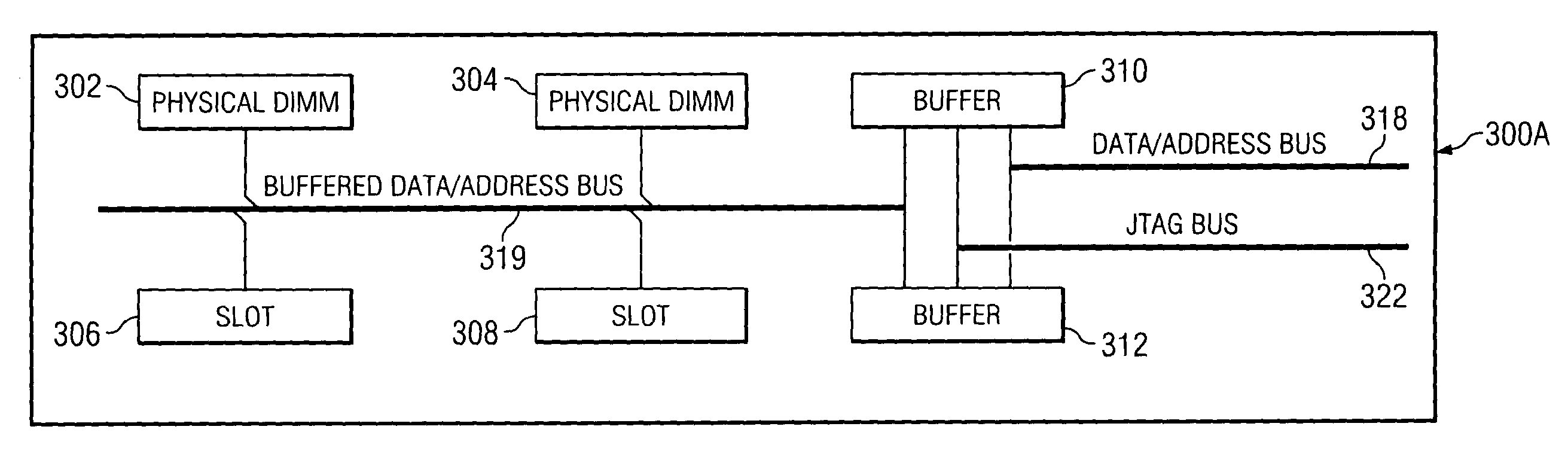

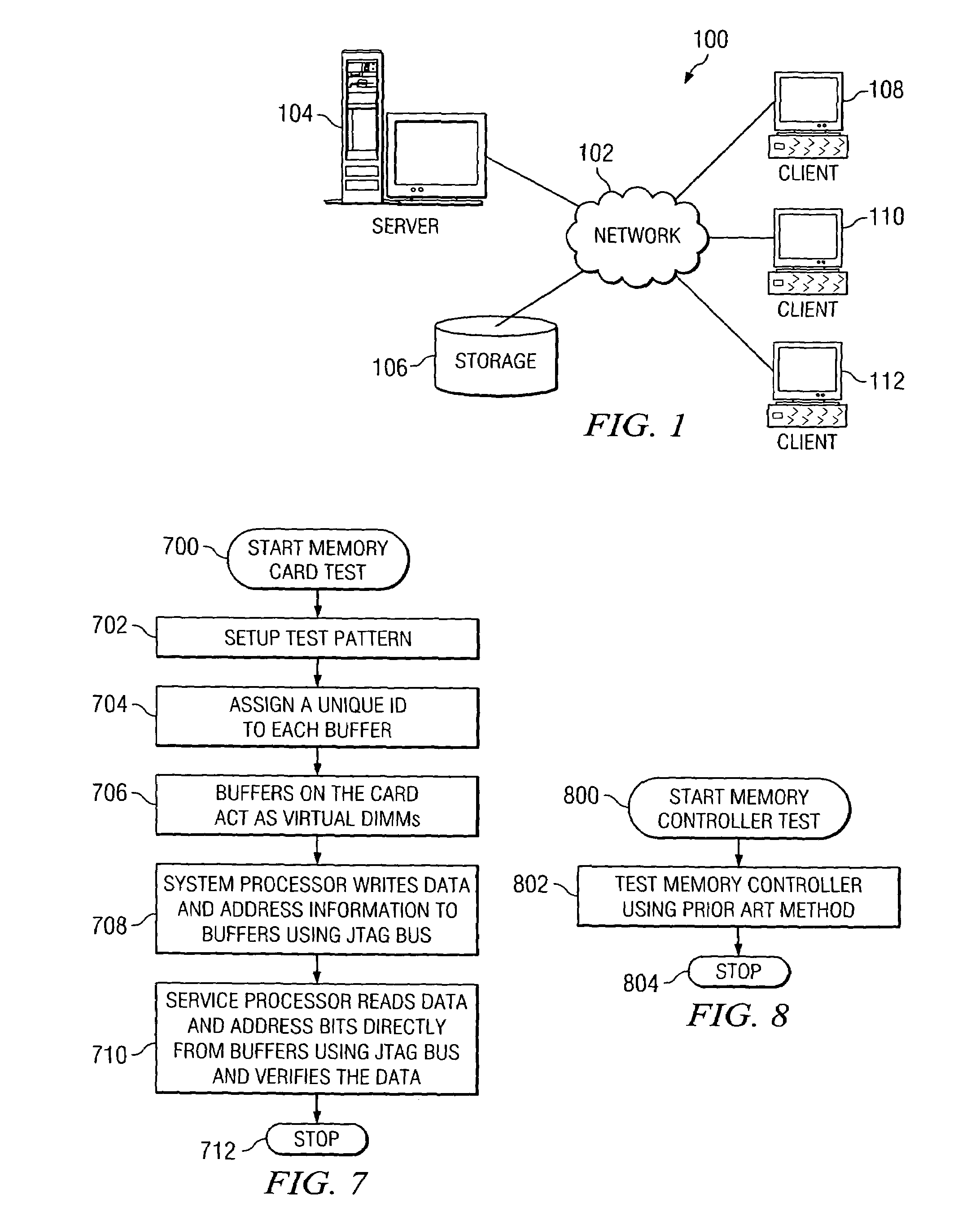

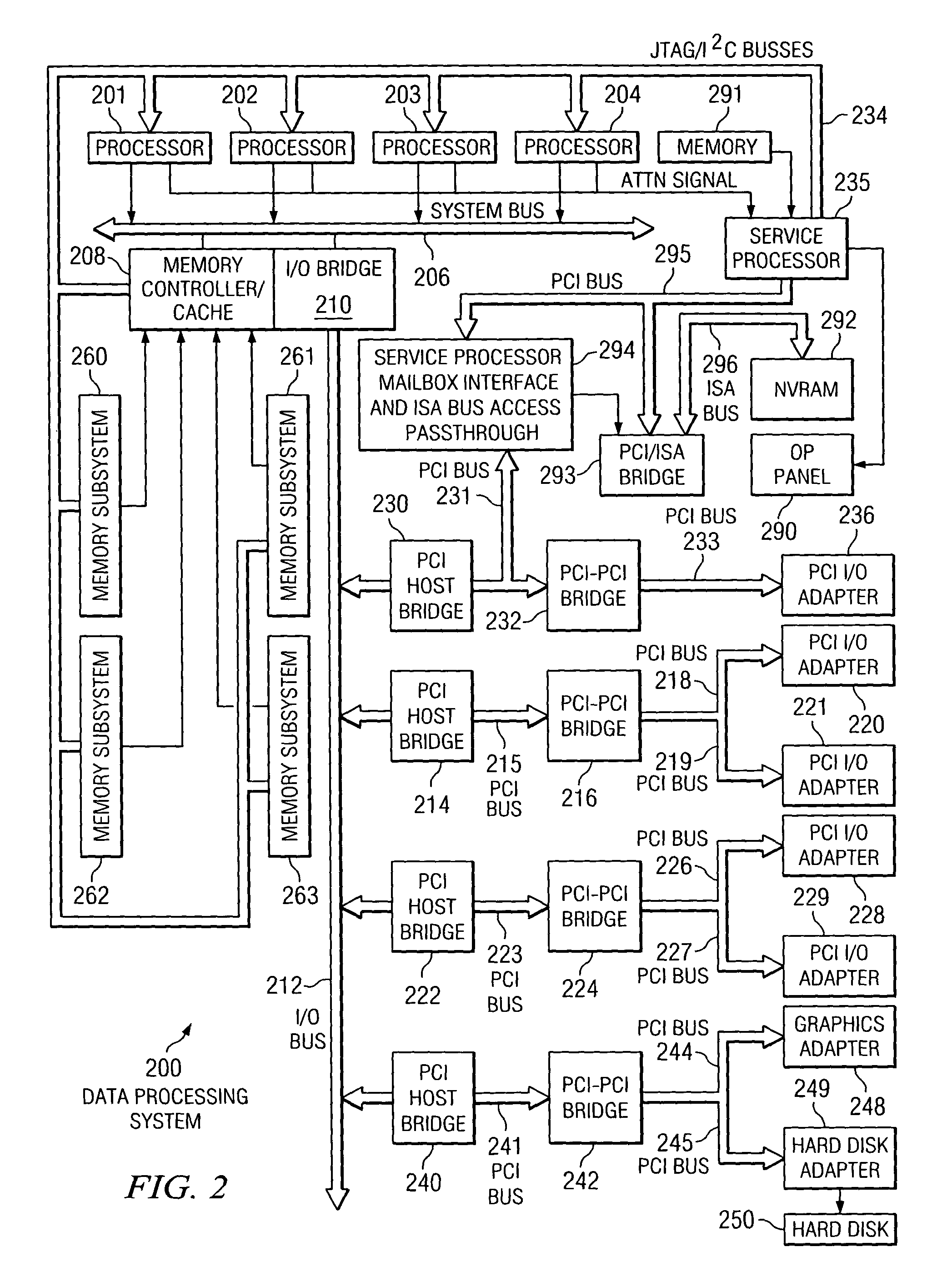

Method, system, and product for isolating memory system defects to a particular memory system component

InactiveUS7305595B2Detecting faulty computer hardwareElectrical testingVirtual memoryComputer module

Owner:INT BUSINESS MASCH CORP

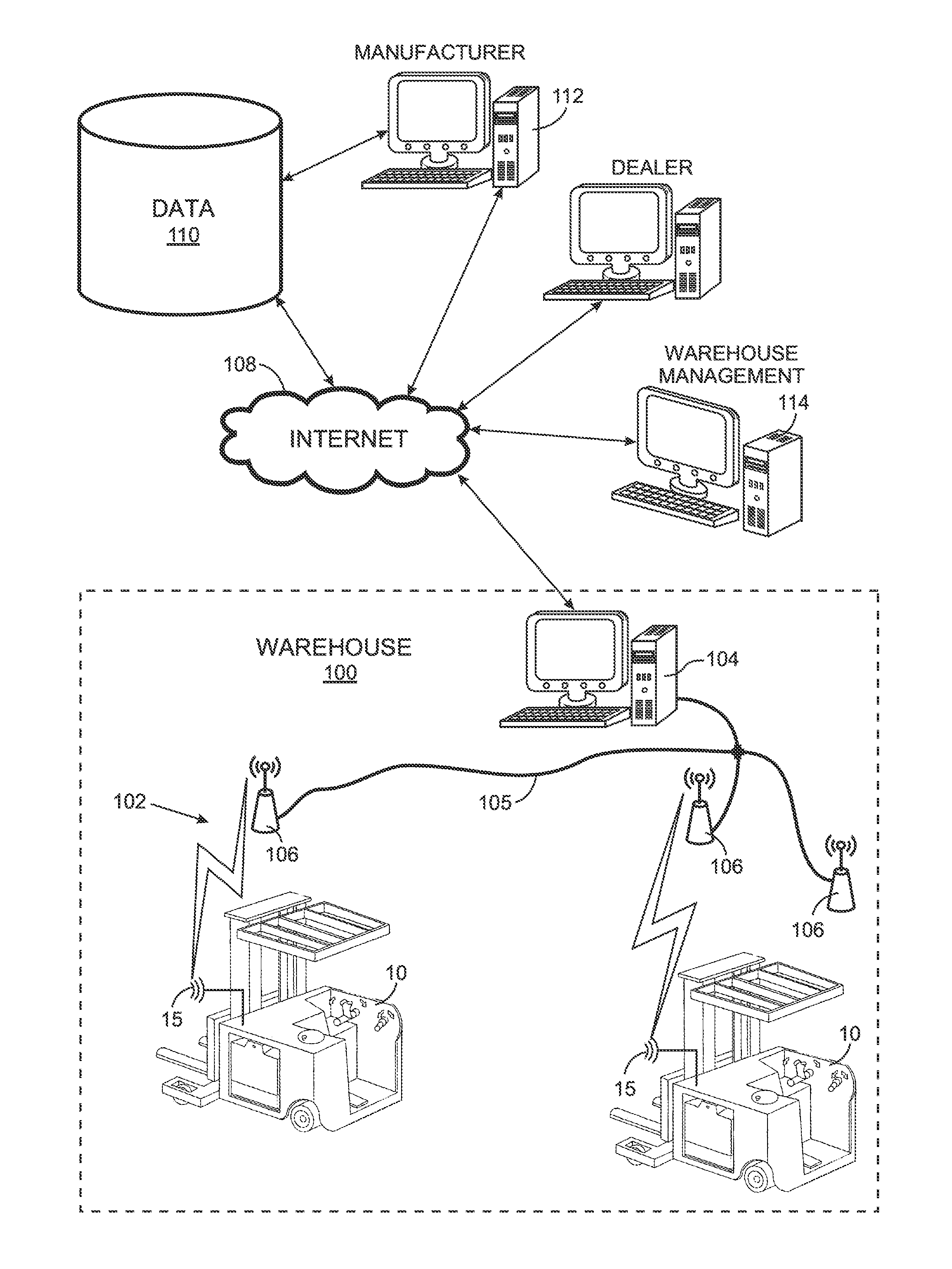

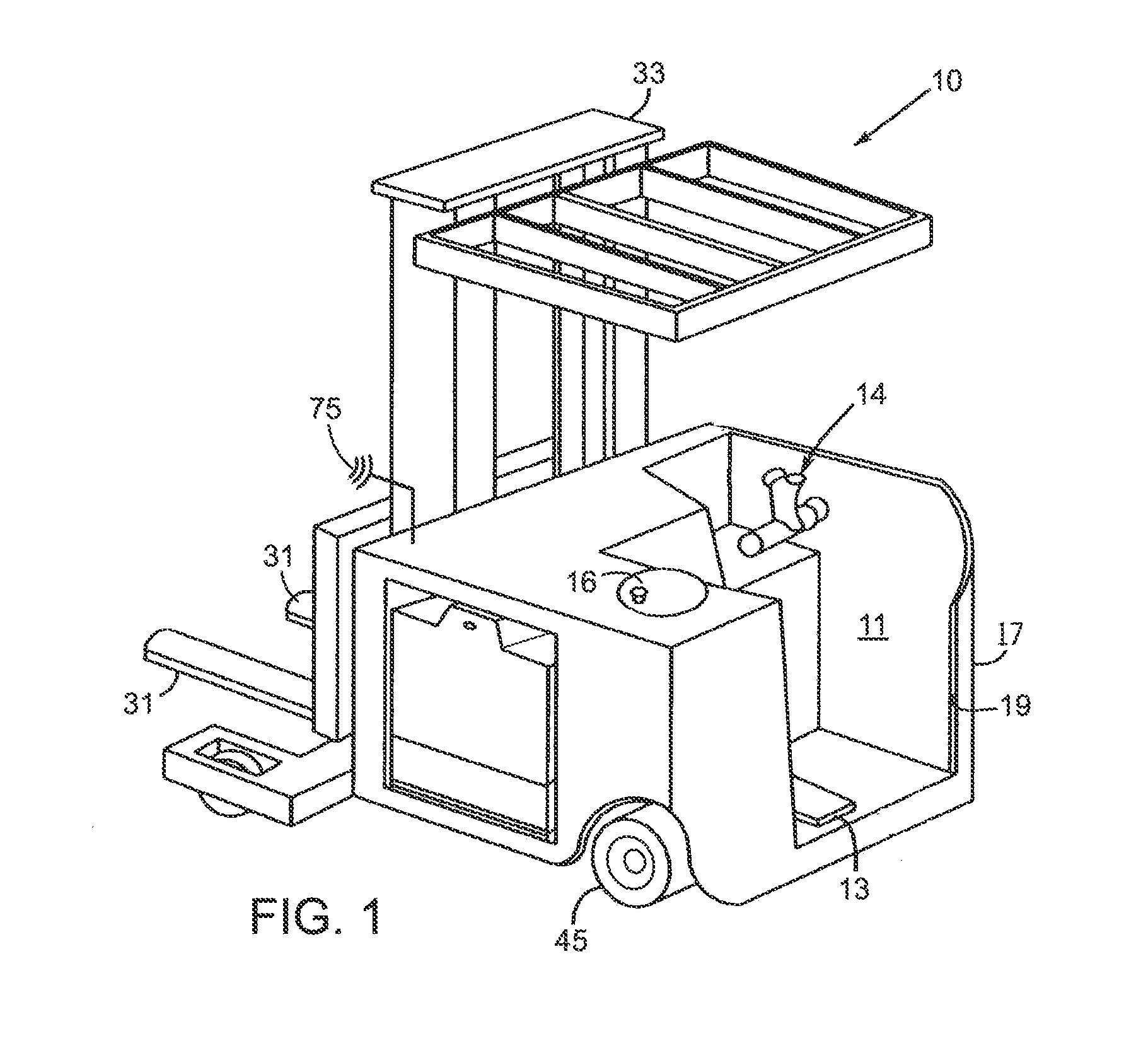

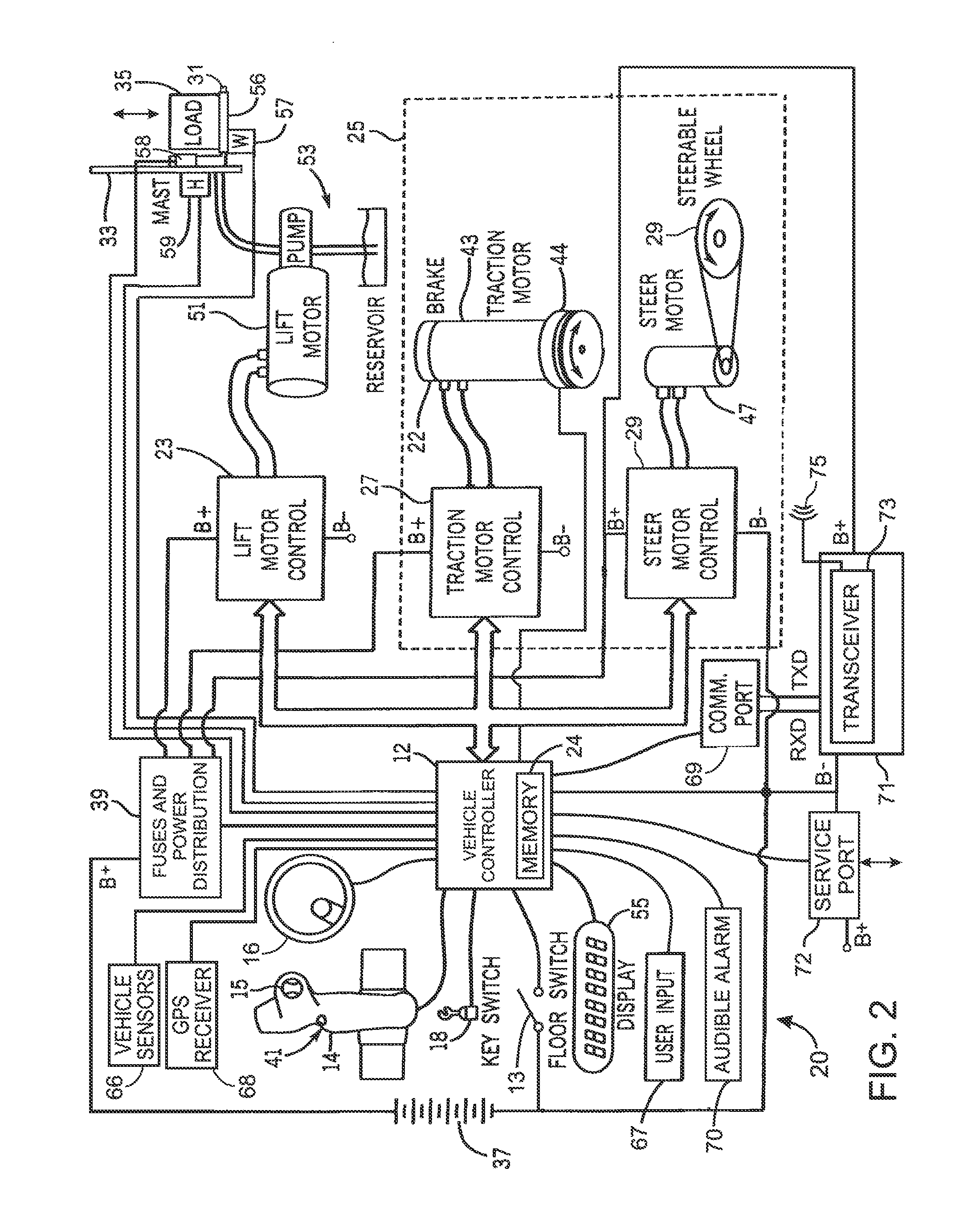

System for accessing information for maintaining and repairing industrial vehicles

InactiveUS20120239243A1Vehicle testingRegistering/indicating working of vehiclesComputerized systemDefective Component

A database, contained in a computer system onboard the industrial vehicle, stores repair information and as built information about the specific optional features incorporated into that particular industrial vehicle. For example, the database contains one or more of a repair manual, a parts manual, an operating manual, and service bulletins. Upon occurrence of an operating problem, the industrial vehicle generates a fault code designating the operating problem. The computer system uses the fault code to access the database and obtain the as built information and the repair information associated with the operating problem. The repair information may describe a process for diagnosing a cause of the operating problem, a process for identifying a defective component, and a process for replacing the defective component. The computer system also may place an order for a replacement component.

Owner:MEDWIN STEVE +1

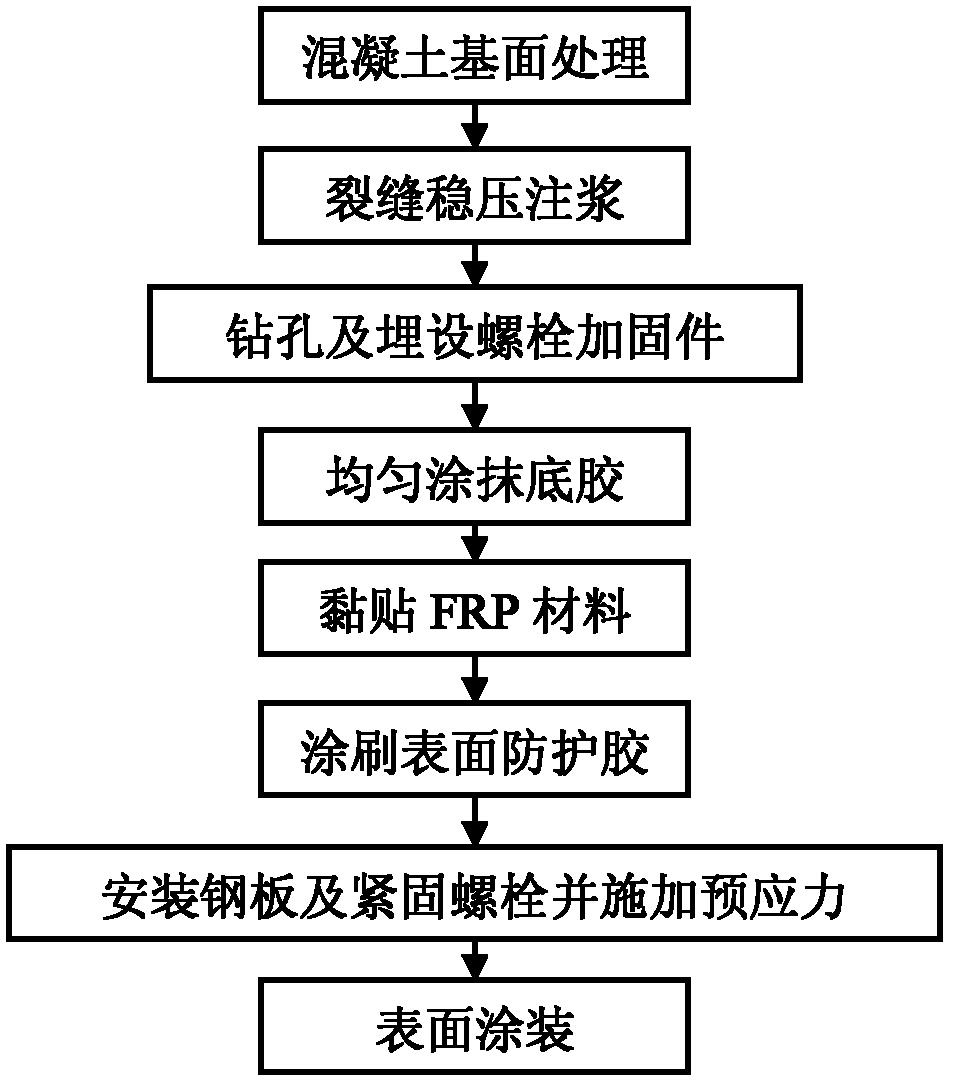

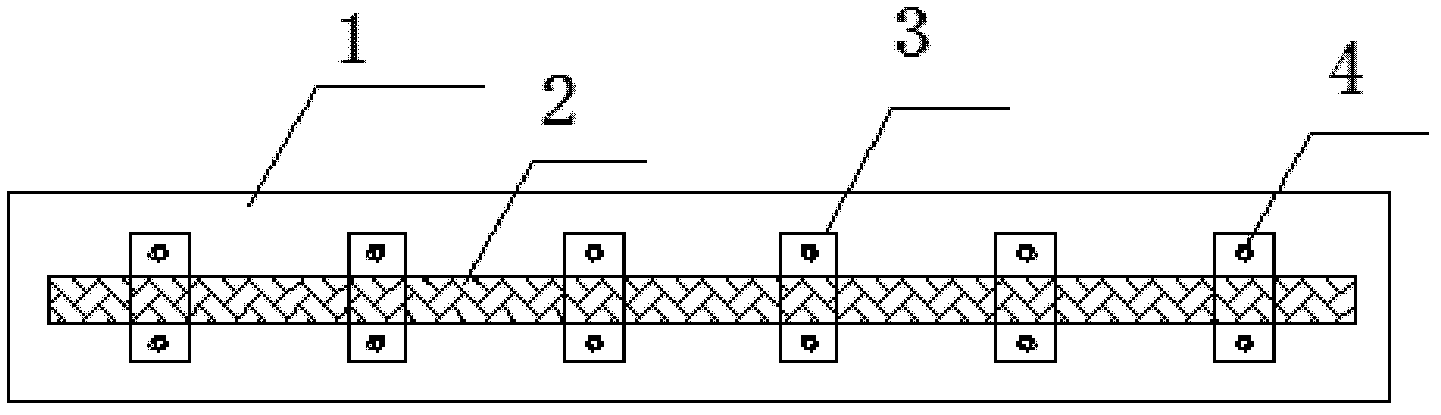

Reinforcement method for fiber reinforced composite plastic and concrete

InactiveCN102561412AImprove carrying capacityMaintenance and reinforcementArtificial islandsBuilding repairsSheet steelChemical grouting

The invention relates to a reinforcement method for fiber reinforced composite plastic and concrete, which includes: firstly performing crack grouting on the surface of concrete to be reinforced; secondly, drilling holes at set positions and embedding bolt reinforcing members according to the need of reinforcement; thirdly, applying base cement to the positions with FRP (fiber reinforced plastic) material and adhering the FRP material; fourthly, painting surface protection glue, mounting steel plates and fastening the bolts; and fifthly, performing surface coating. The fiber reinforced composite plastic and the concrete are technically integrated, optimized and modified according to respective characteristics of FRP and HB-FRP (hybrid bonded fiber reinforced plastic) technology and high (stable) pressure chemical grouting technology, so that the fiber reinforced composite plastic and the concrete have respective technical advantages, technical complementation and comprehensive improvement in reinforcing repair of defective components can be realized, material function utilization rate is increased greatly, the reinforcing effect is improved evidently, and the application range of the fiber reinforced composite plastic and the concrete can be widened greatly.

Owner:SHANDONG UNIV

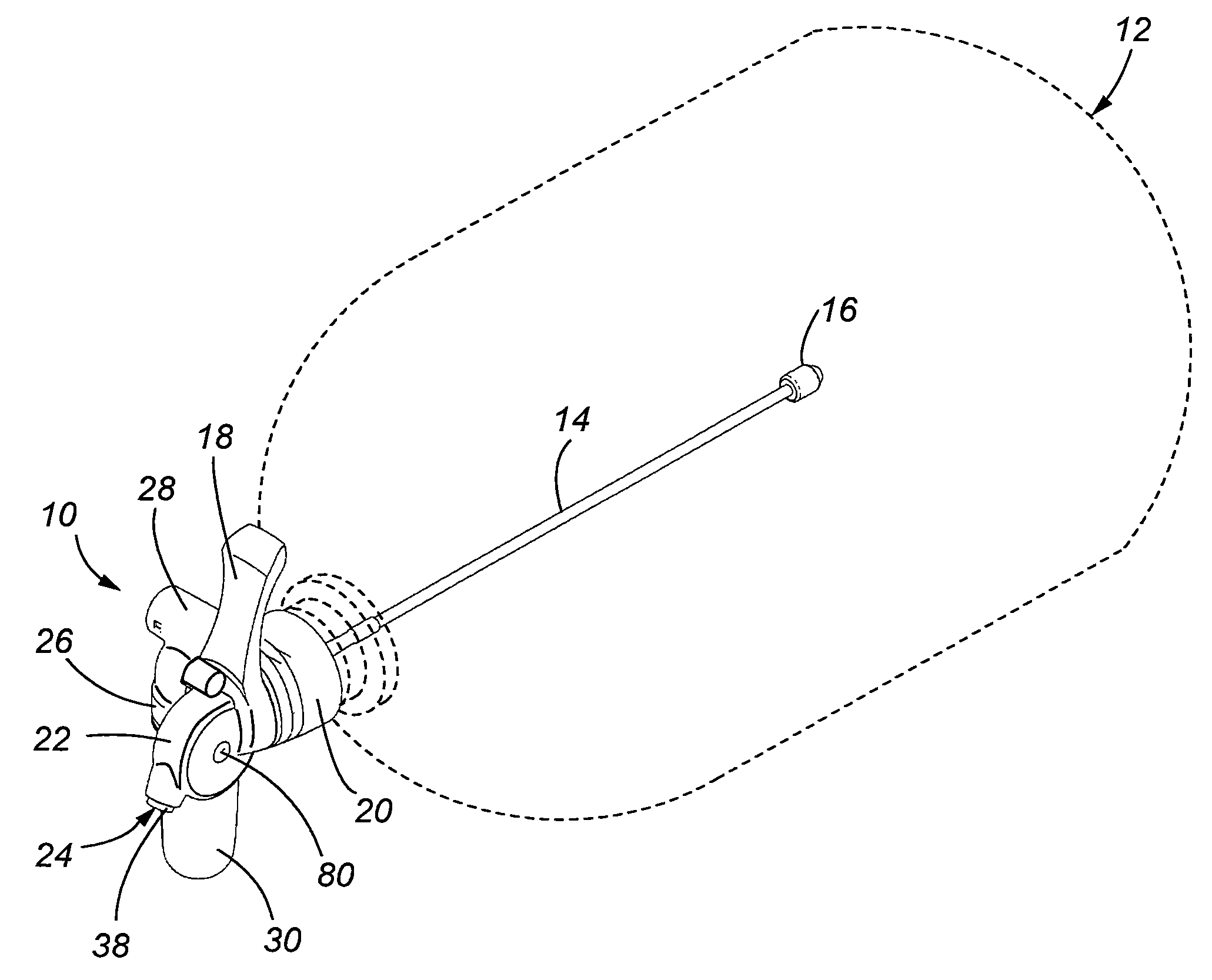

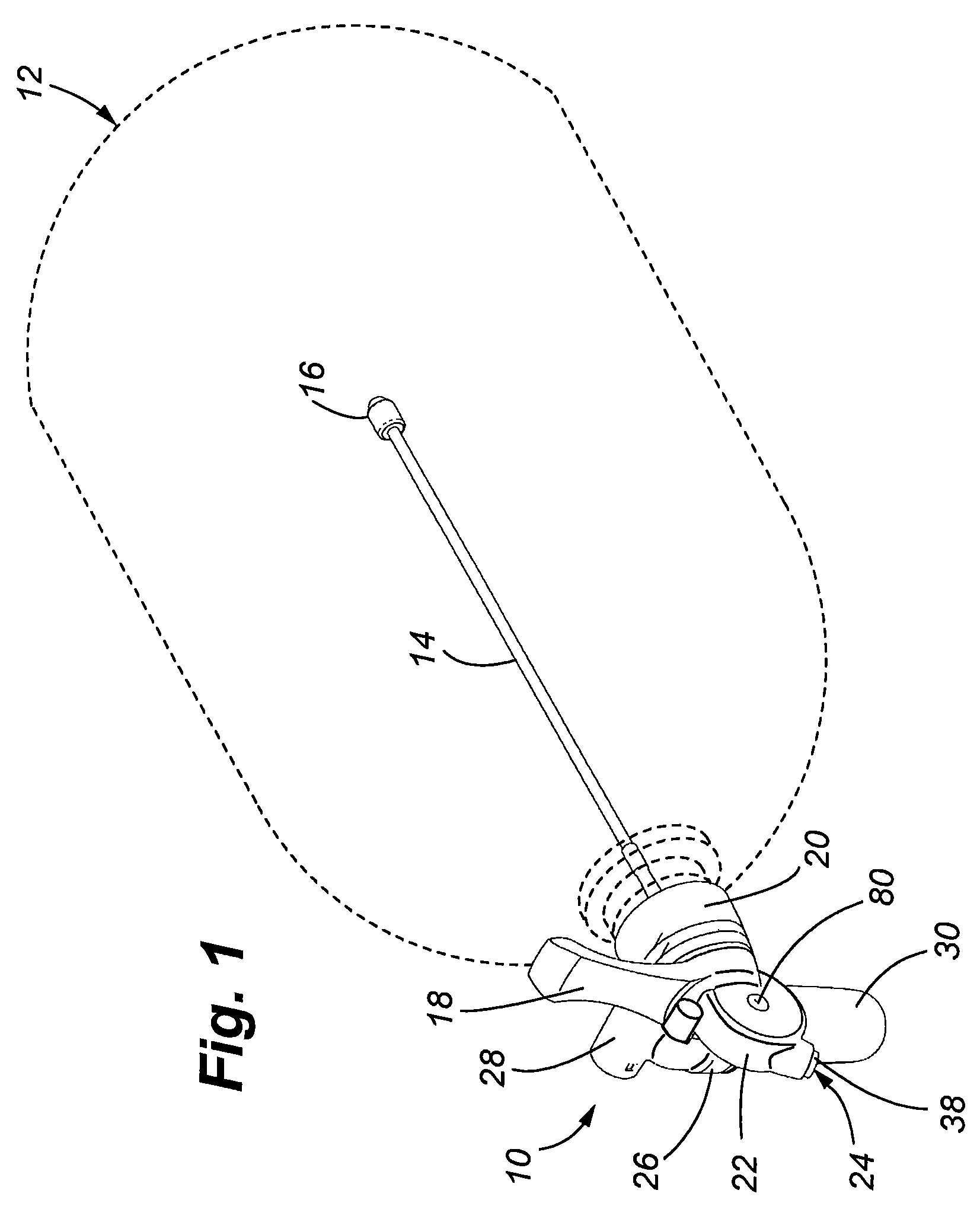

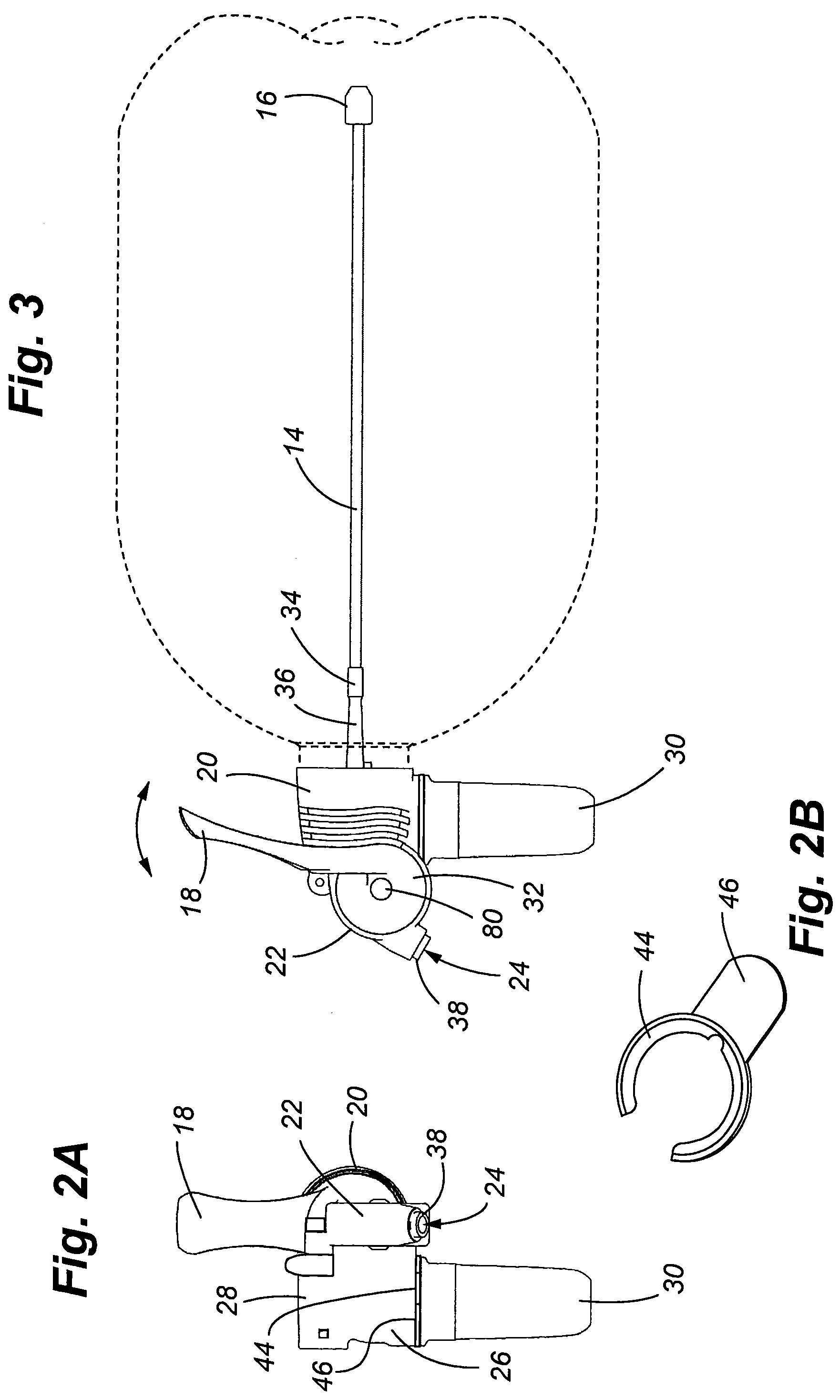

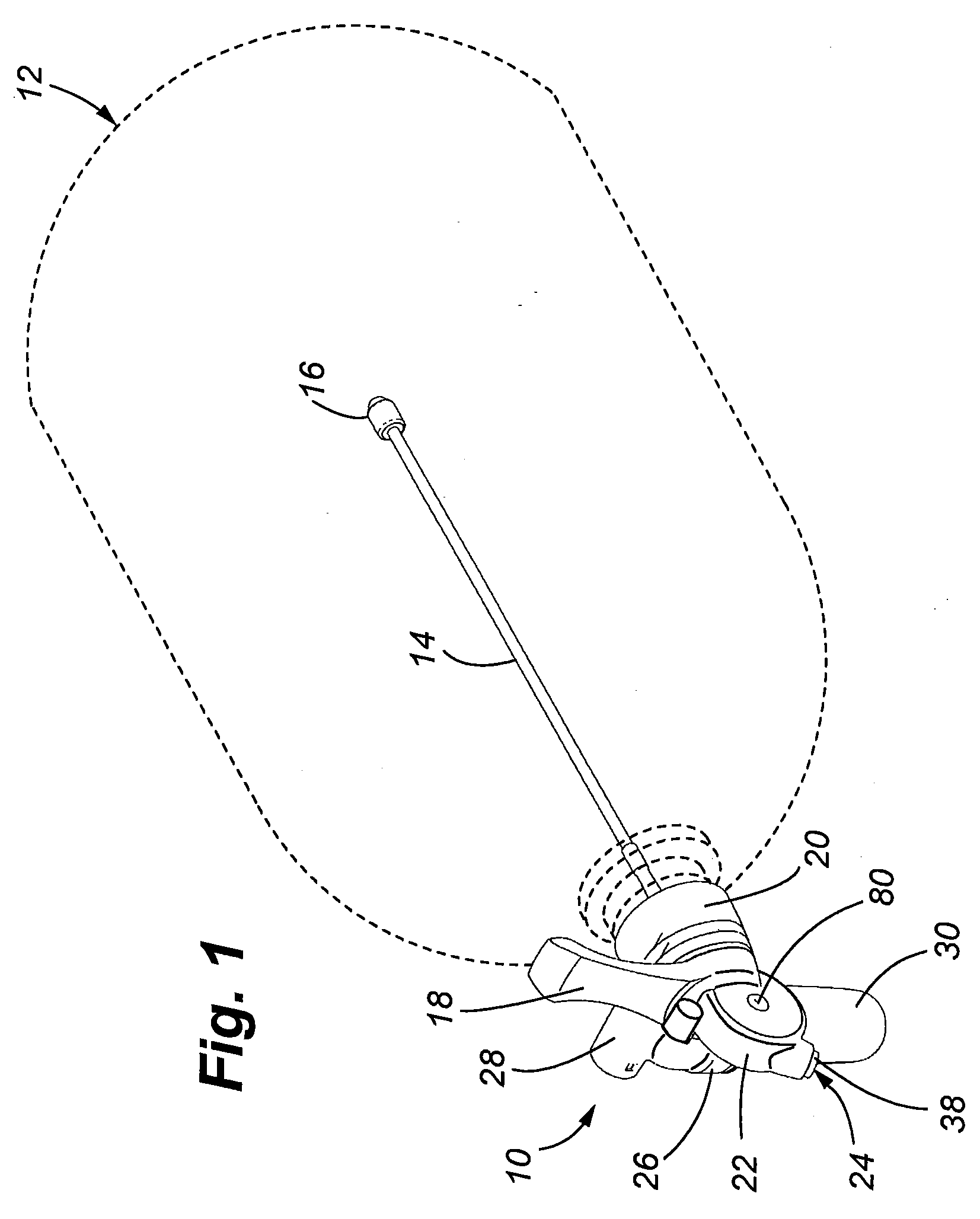

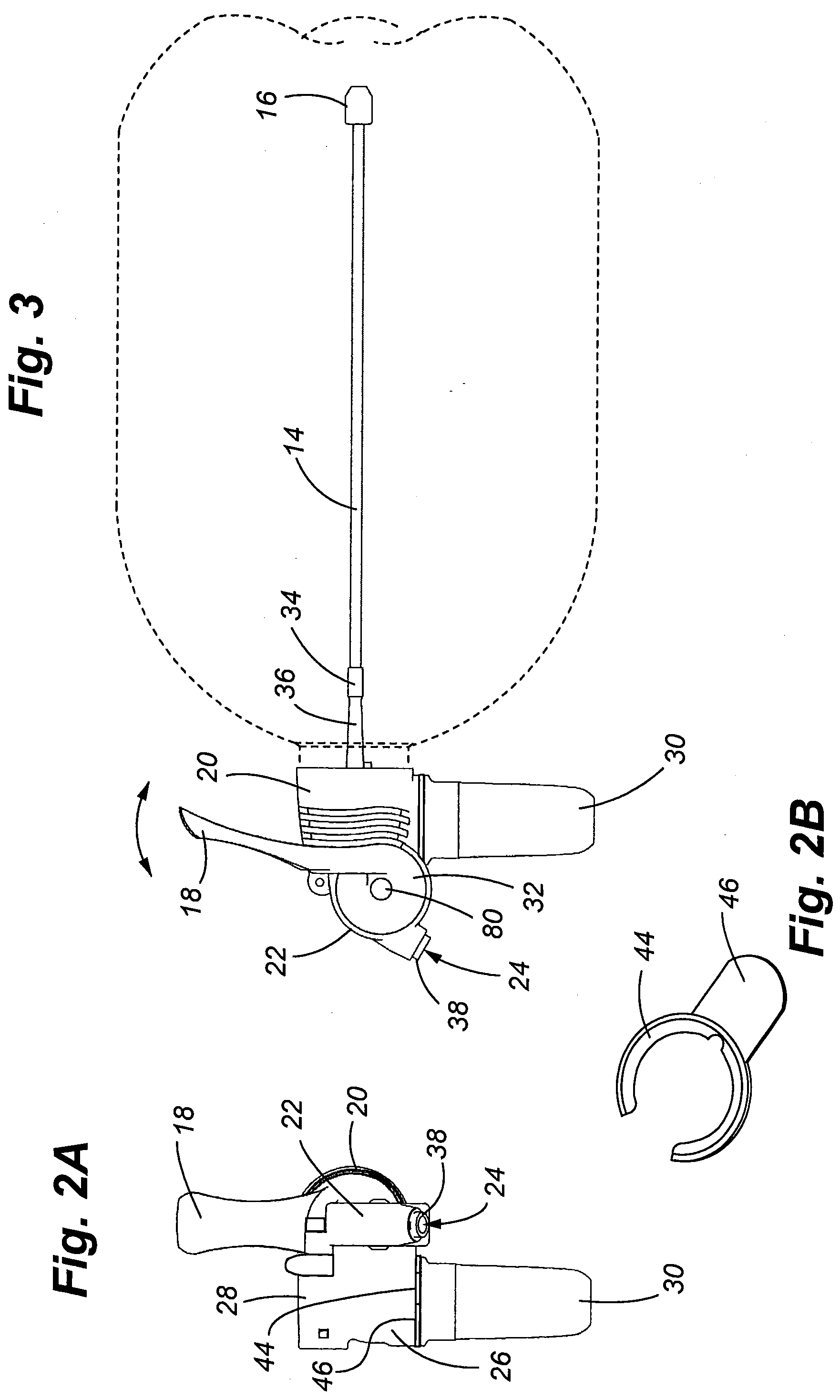

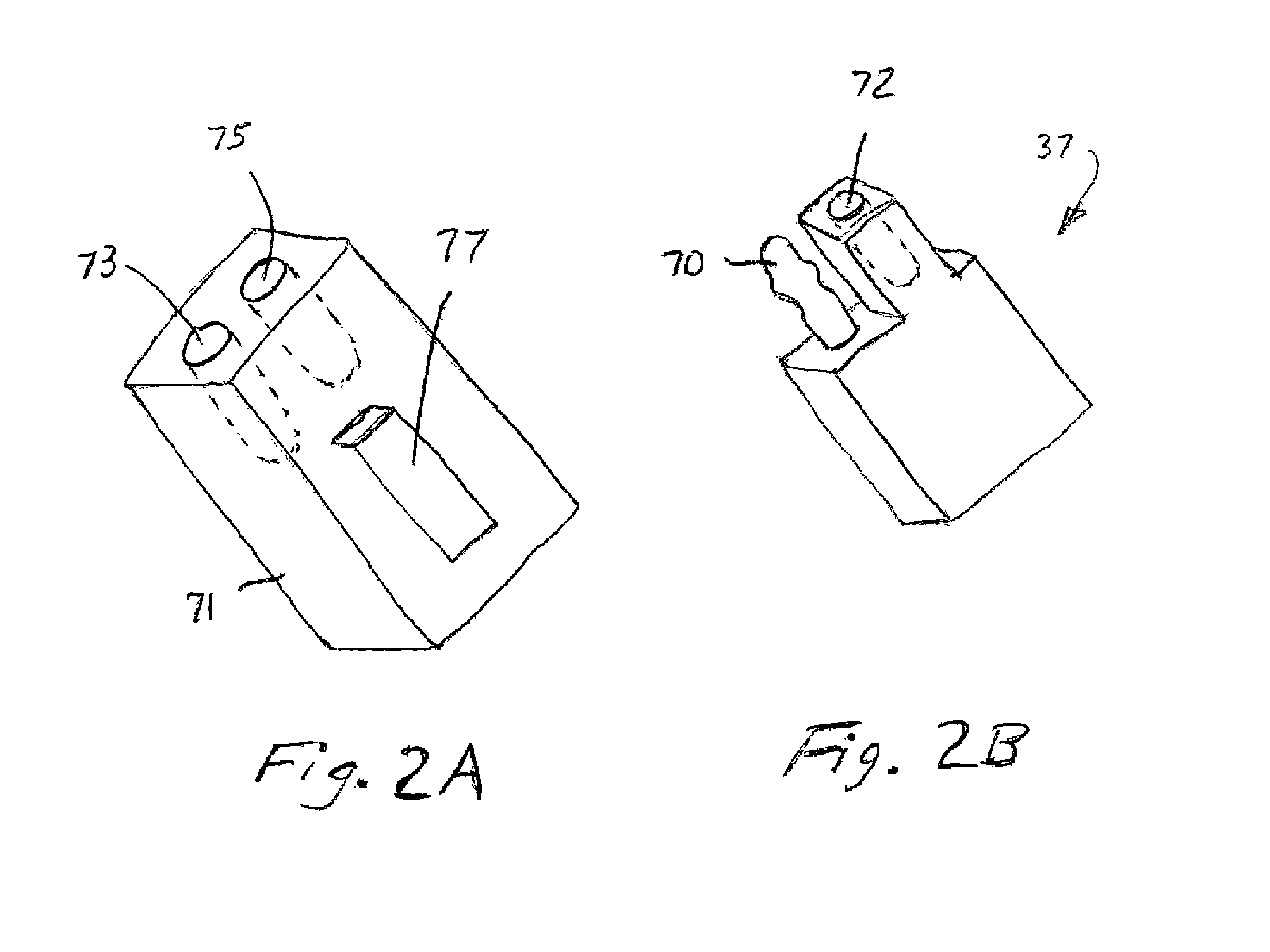

Modular constructed regulated fluid dispensing device

ActiveUS8191740B2Excellent stateEasy to assembleClosure using stoppersLiquid dispensingControl flowEngineering

A device and method are provided for dispensing a beverage from a pressurized container. The dispensing device includes an integral source of compressed gas for maintaining the beverage within the container at a desired pressurized state. The dispensing device also includes a regulator for controlling the flow of gas from the compressed gas source to the interior of the container, as well as a pressure relief mechanism that accounts for potential over pressurization of the container. The beverage is selectively dispensed by actuation of a tap handle. Delivery is achieved through the device by a resilient delivery tube, and the delivery tube is either pinched closed or allowed to decompress by the actuation of the tap handle. In another embodiment, a check valve is used to control flow of the beverage in which the tap handle activates a transfer rod to seat and unseat a check element. The device can be manufactured in either a unitary construction or a modular construction. Modular construction provides greater flexibility in testing and replacement of defective components.

Owner:ADOLPH COORS +1

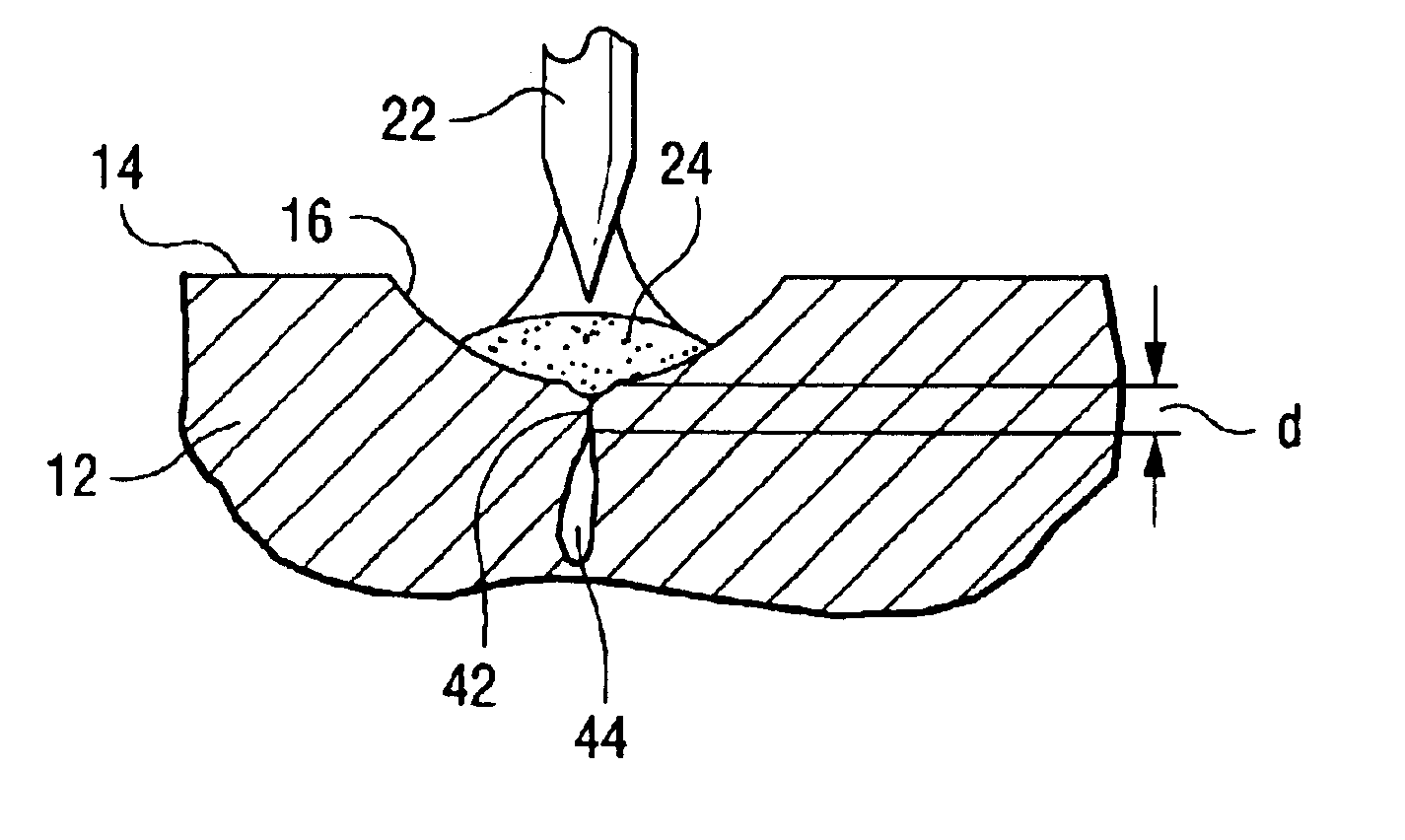

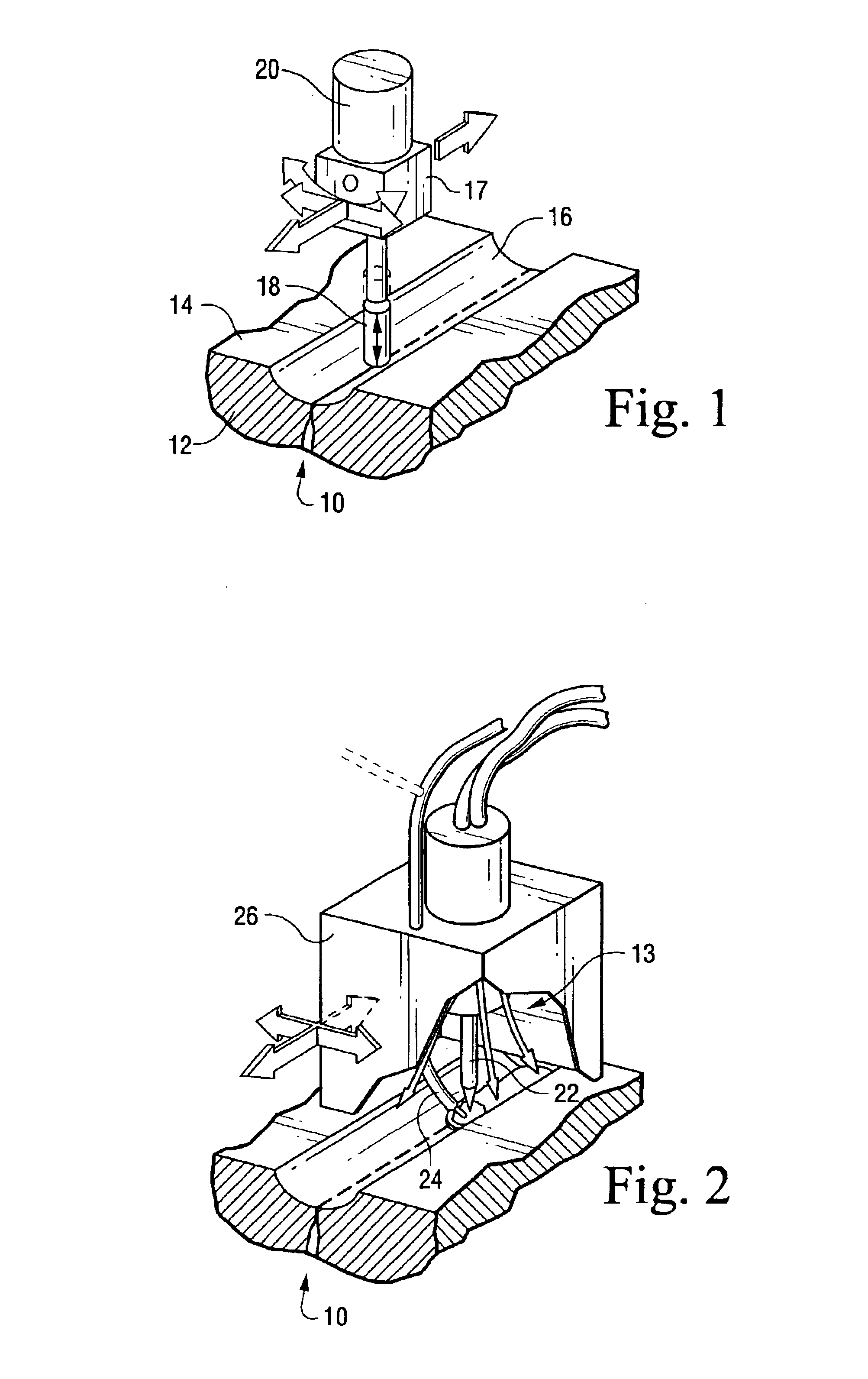

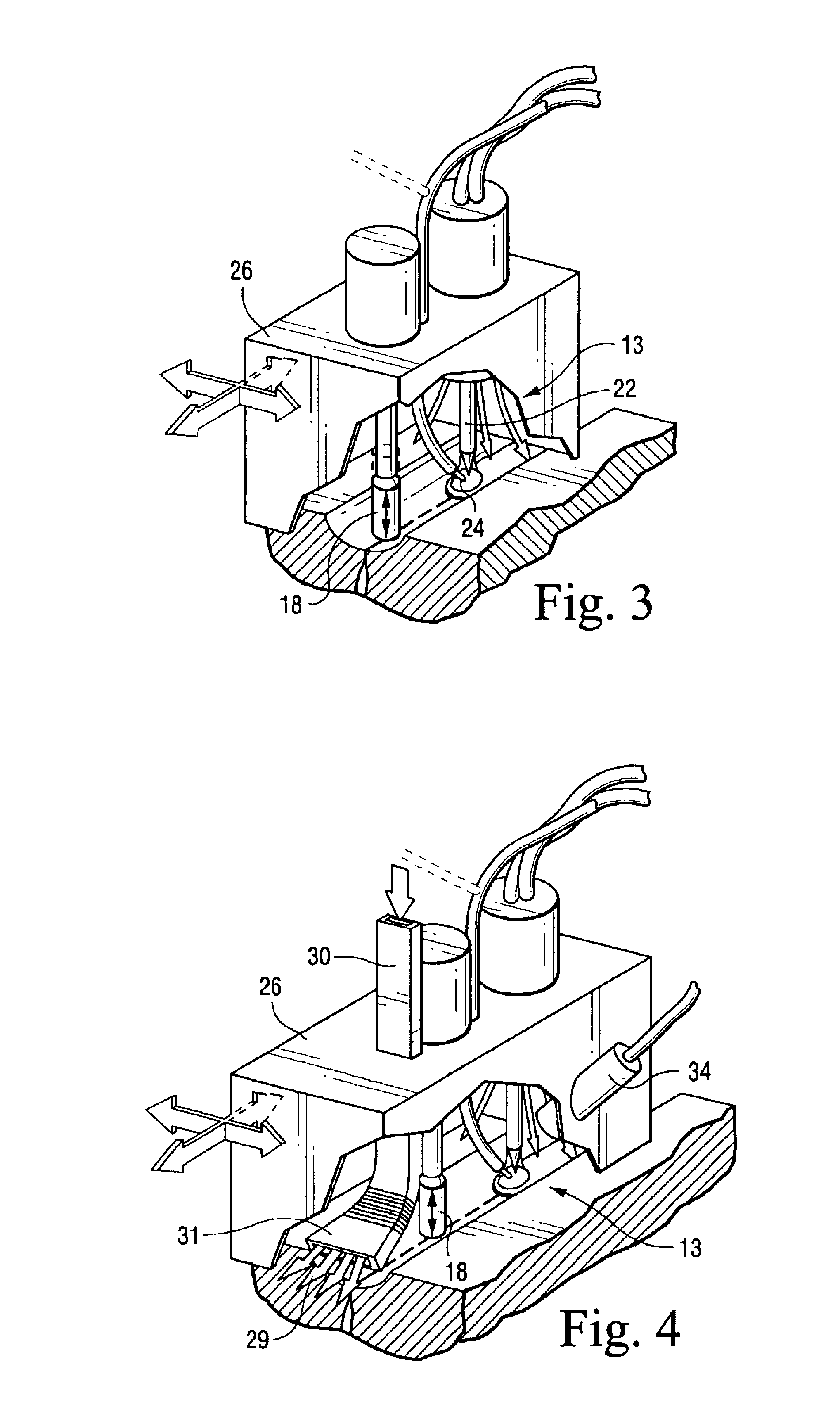

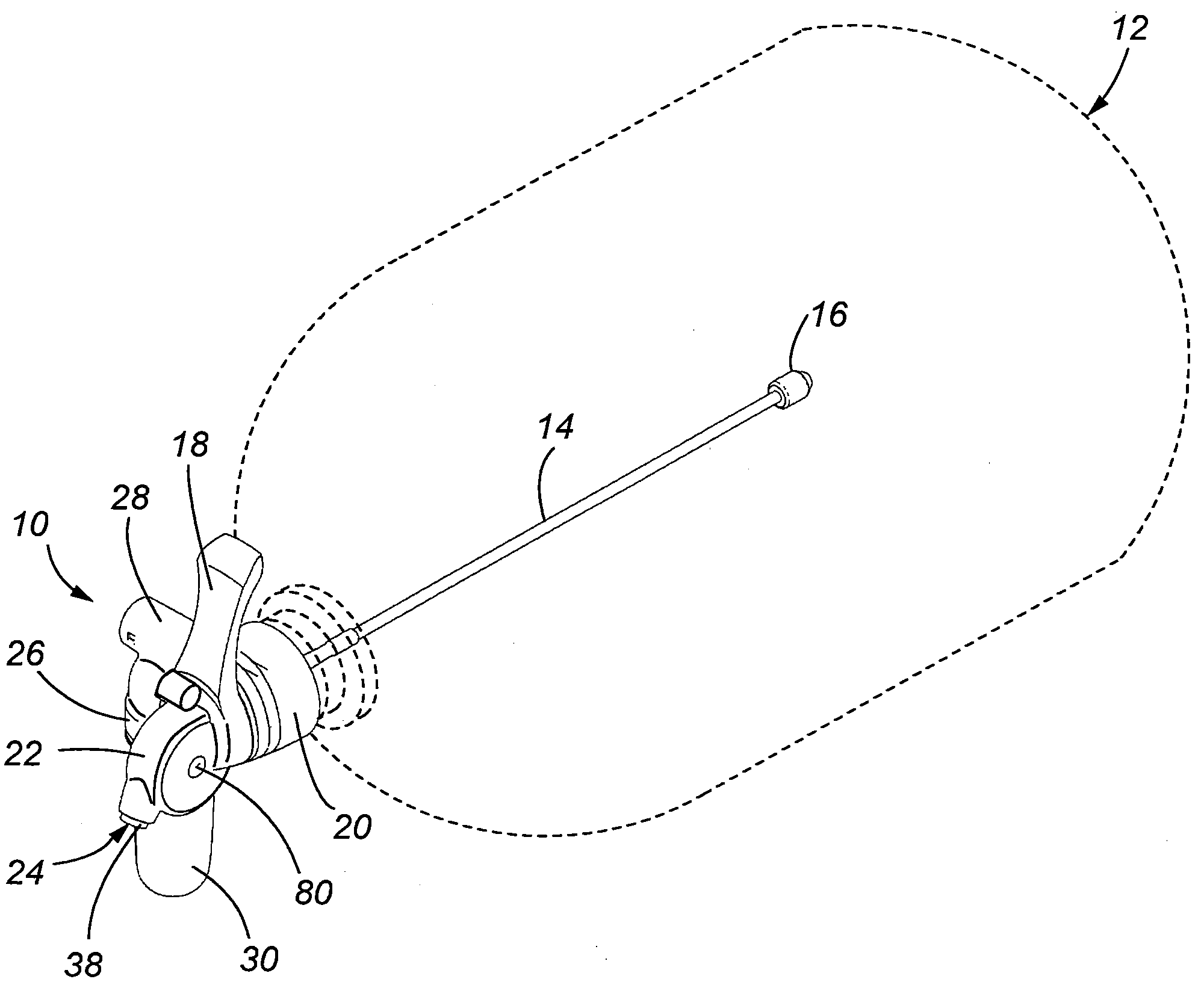

Fusion-welding of defective components to preclude expulsion of contaminants through the weld

InactiveUS6889889B2Increase weld penetrationIncrease heat inputArc welding apparatusElectron beam welding apparatusDepth of penetrationEngineering

A component which has a surface crevice or crack and contaminants on at least one face of the opening is welded. The weld is effected by first plastically deforming the surface of the component to close the surface opening to a predetermined depth less than the depth of the opening and contaminated faces defining the opening to form a sealed ligament. The sealed ligament leaves unclosed a portion of the crack below the sealed ligament. The closed surface is hermetically sealed by fusion-welding to a depth of penetration equal to or less than the predetermined depth of the sealed ligament to minimize or eliminate expulsion of contaminants in the sealed ligament.

Owner:GENERAL ELECTRIC CO

Modular constructed regulated fluid dispensing device

ActiveUS20090283553A1Excellent stateEasy to assembleClosure using stoppersLiquid dispensingEngineeringCheck valve

A device and method are provided for dispensing a beverage from a pressurized container. The dispensing device includes an integral source of compressed gas for maintaining the beverage within the container at a desired pressurized state. The dispensing device also includes a regulator for controlling the flow of gas from the compressed gas source to the interior of the container, as well as a pressure relief mechanism that accounts for potential over pressurization of the container. The beverage is selectively dispensed by actuation of a tap handle. Delivery is achieved through the device by a resilient delivery tube, and the delivery tube is either pinched closed or allowed to decompress by the actuation of the tap handle. In another embodiment, a check valve is used to control flow of the beverage in which the tap handle activates a transfer rod to seat and unseat a check element. The device can be manufactured in either a unitary construction or a modular construction. Modular construction provides greater flexibility in testing and replacement of defective components.

Owner:ADOLPH COORS +1

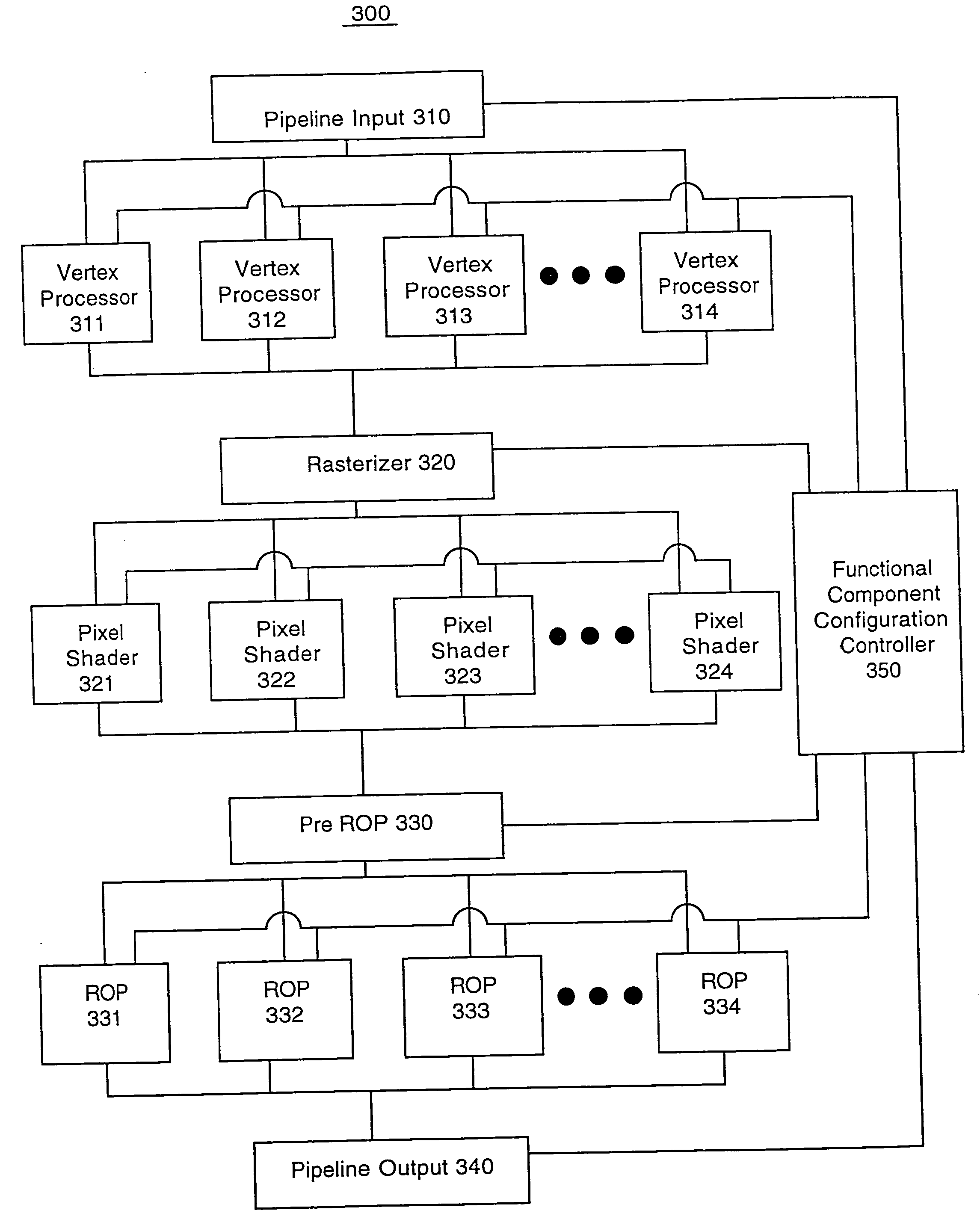

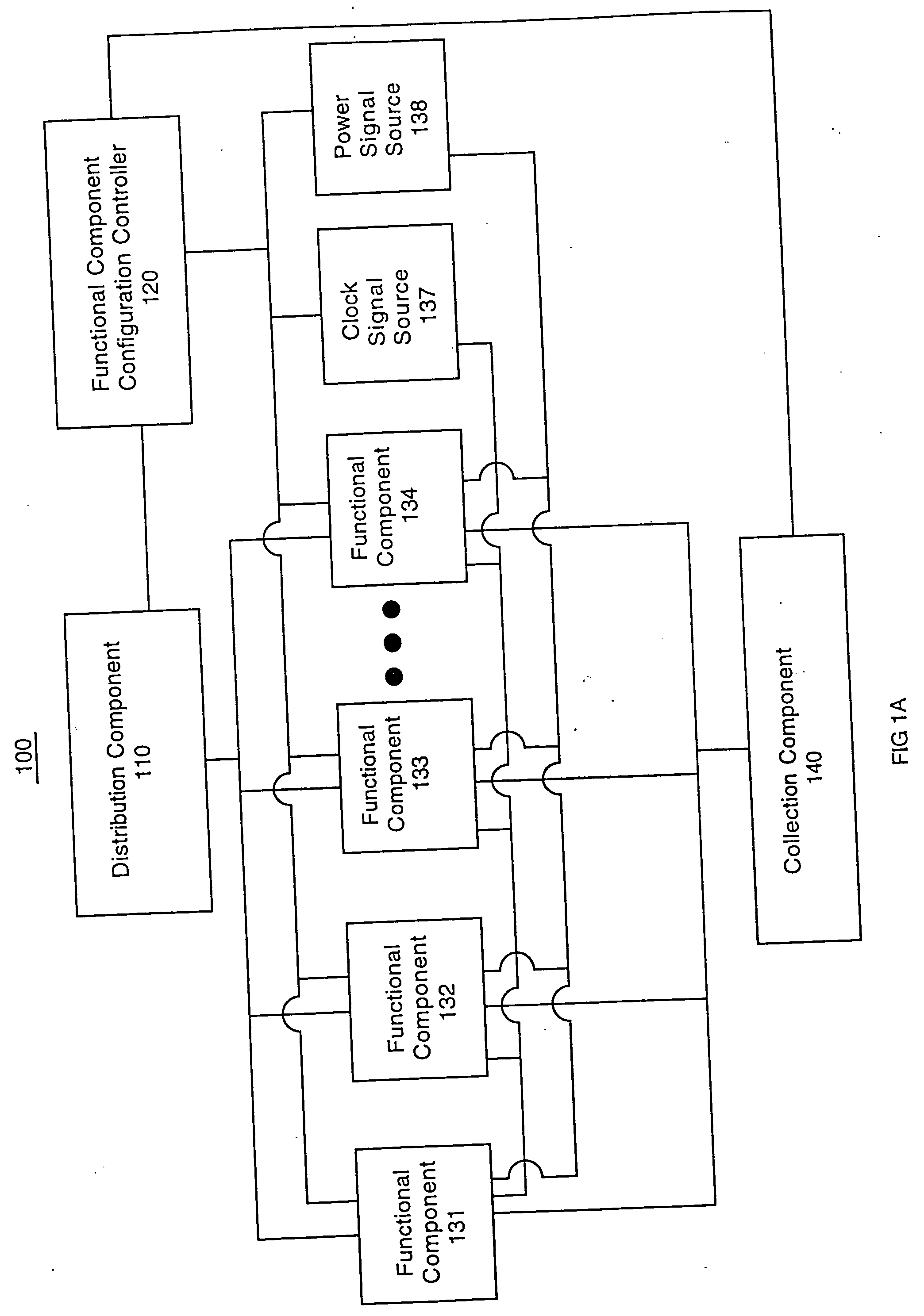

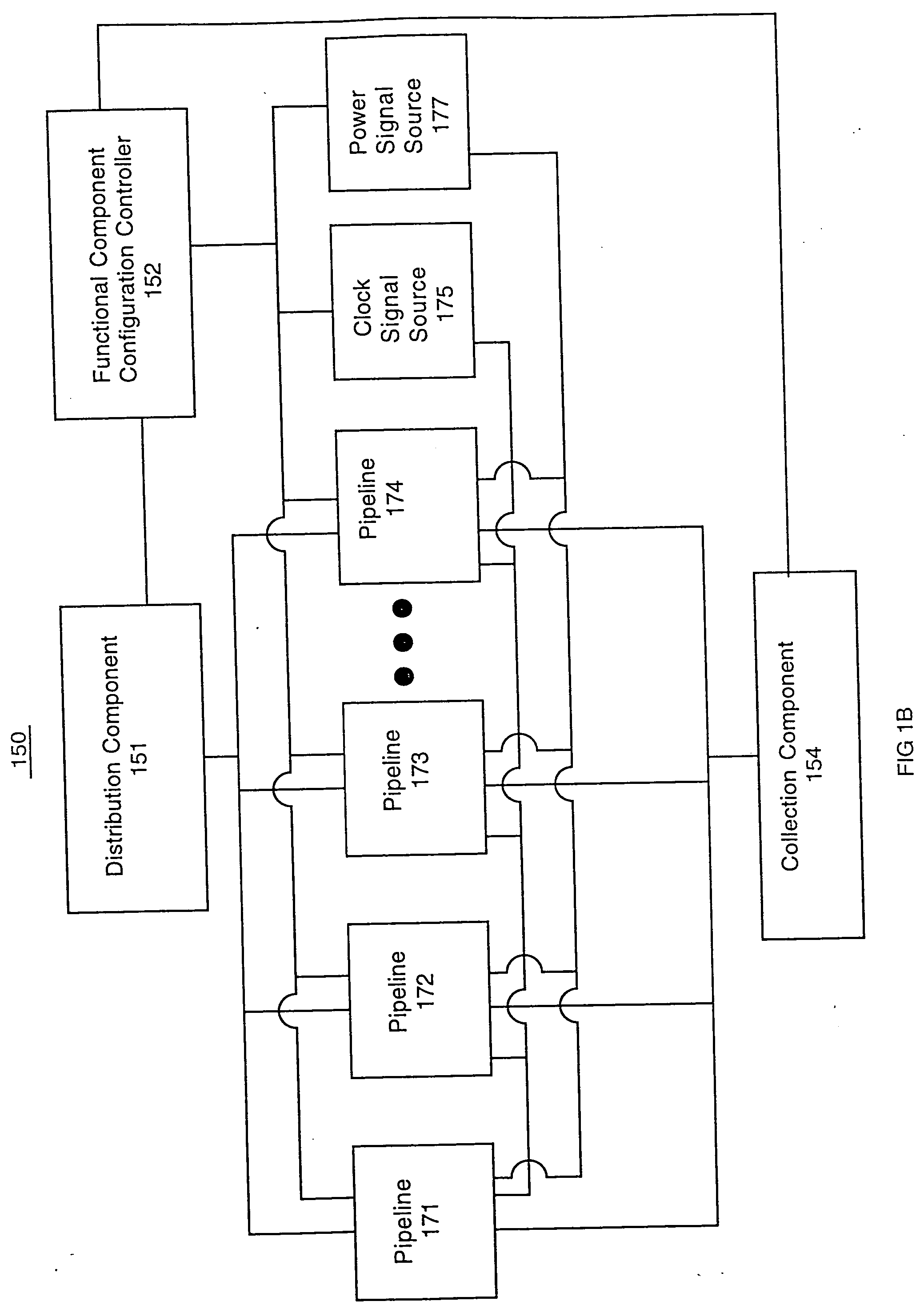

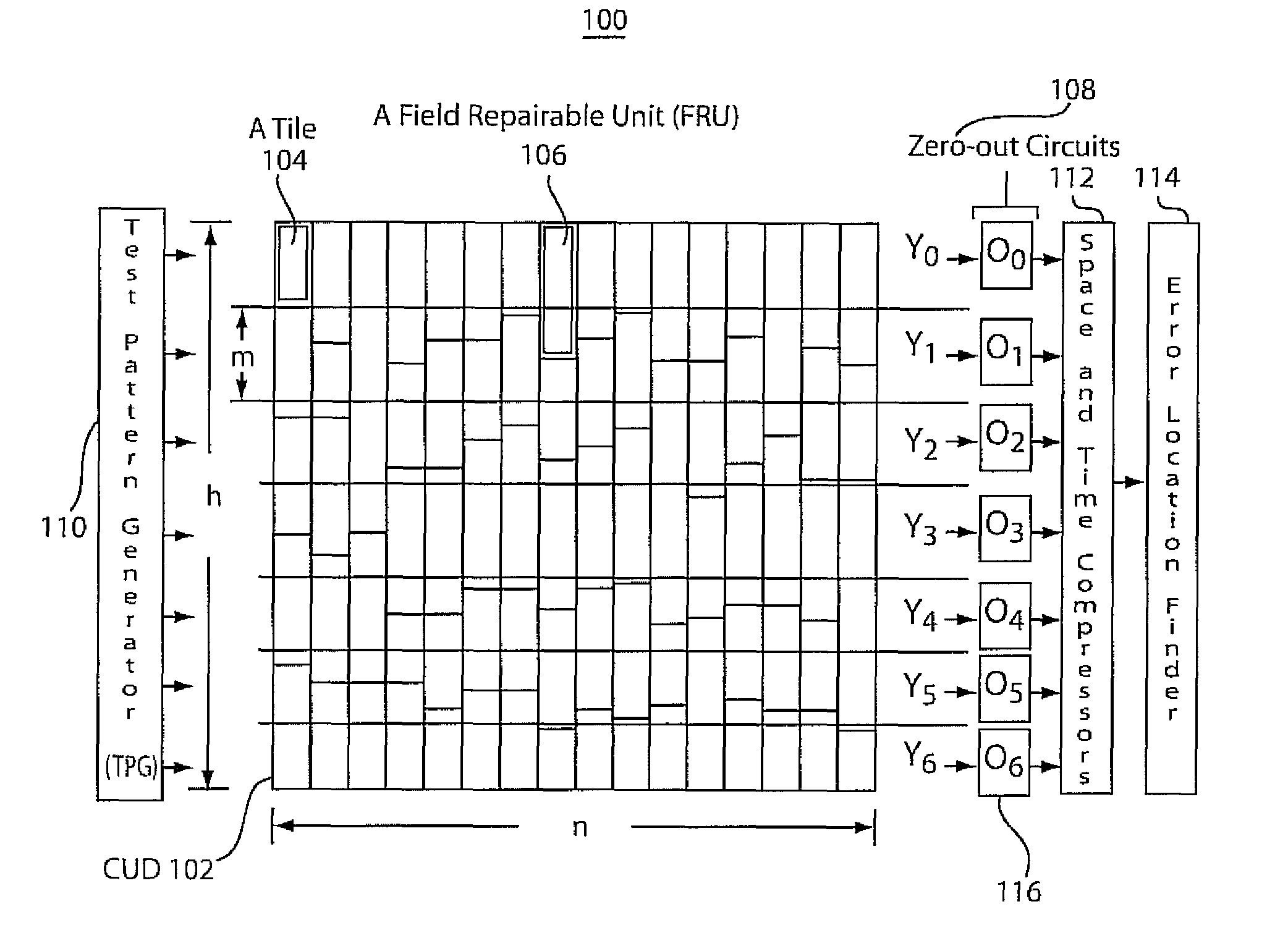

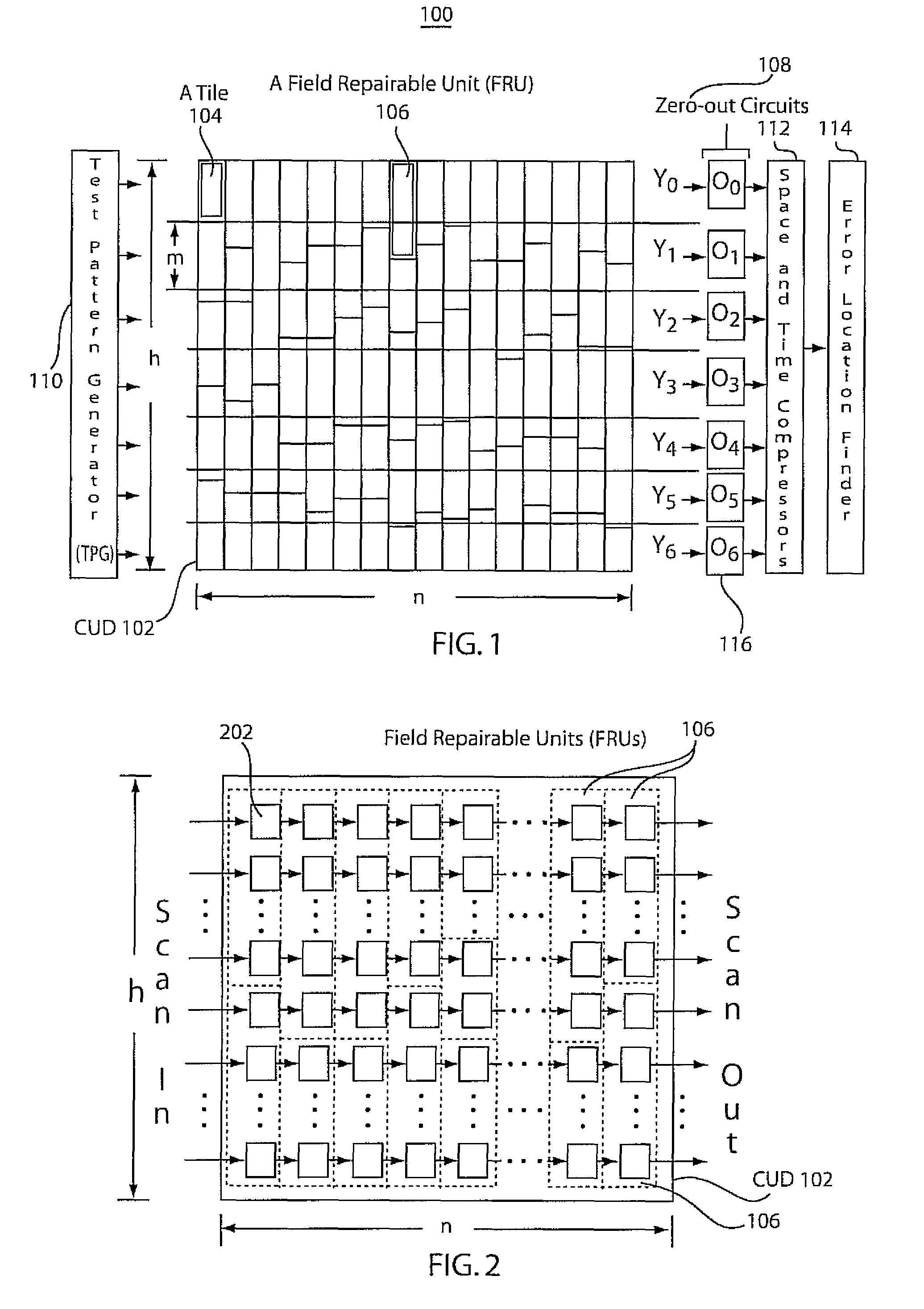

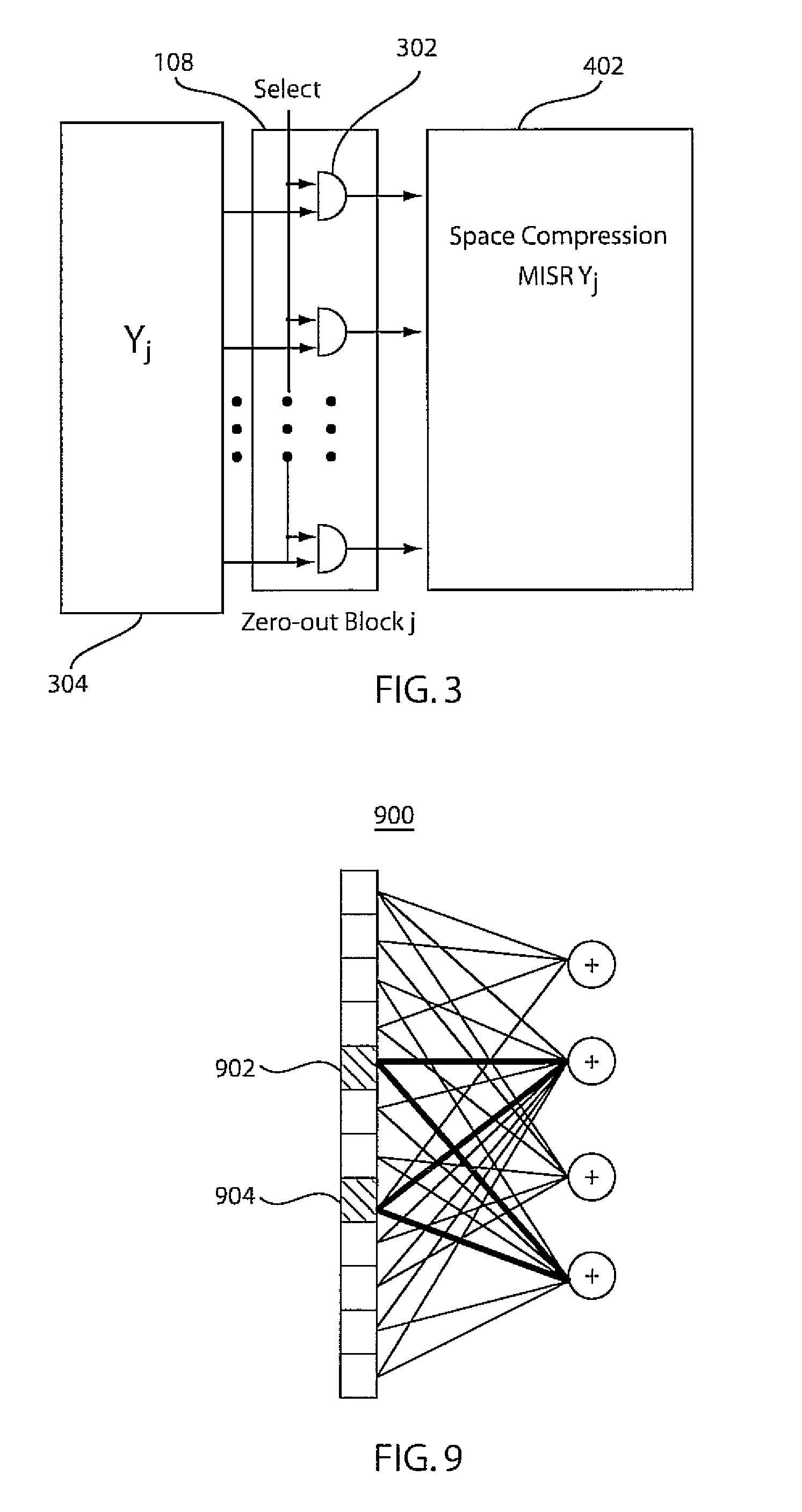

Integrated circuit configuration system and method

ActiveUS20050261863A1High yieldCost of producingSemiconductor/solid-state device testing/measurementDetecting faulty hardware by configuration testEmbedded systemDefective Component

The present invention systems and methods enable configuration of functional components in integrated circuits. A present invention system and method can flexibly change the operational characteristics of functional components in an integrated circuit die based upon a variety of factors, including if the die has a defective component. An indication of the defective functional component identification is received. A determination is made if the defective functional component is one of a plurality of similar functional components that can provide the same functionality. The other similar components can be examined to determine if they are parallel components to the defective functional component. The defective functional component is disabled if it is one of the plurality of similar functional components and another component can handle the workflow that would otherwise be assigned to the defective component. Workflow is diverted from the disabled component to other similar functional components.

Owner:NVIDIA CORP

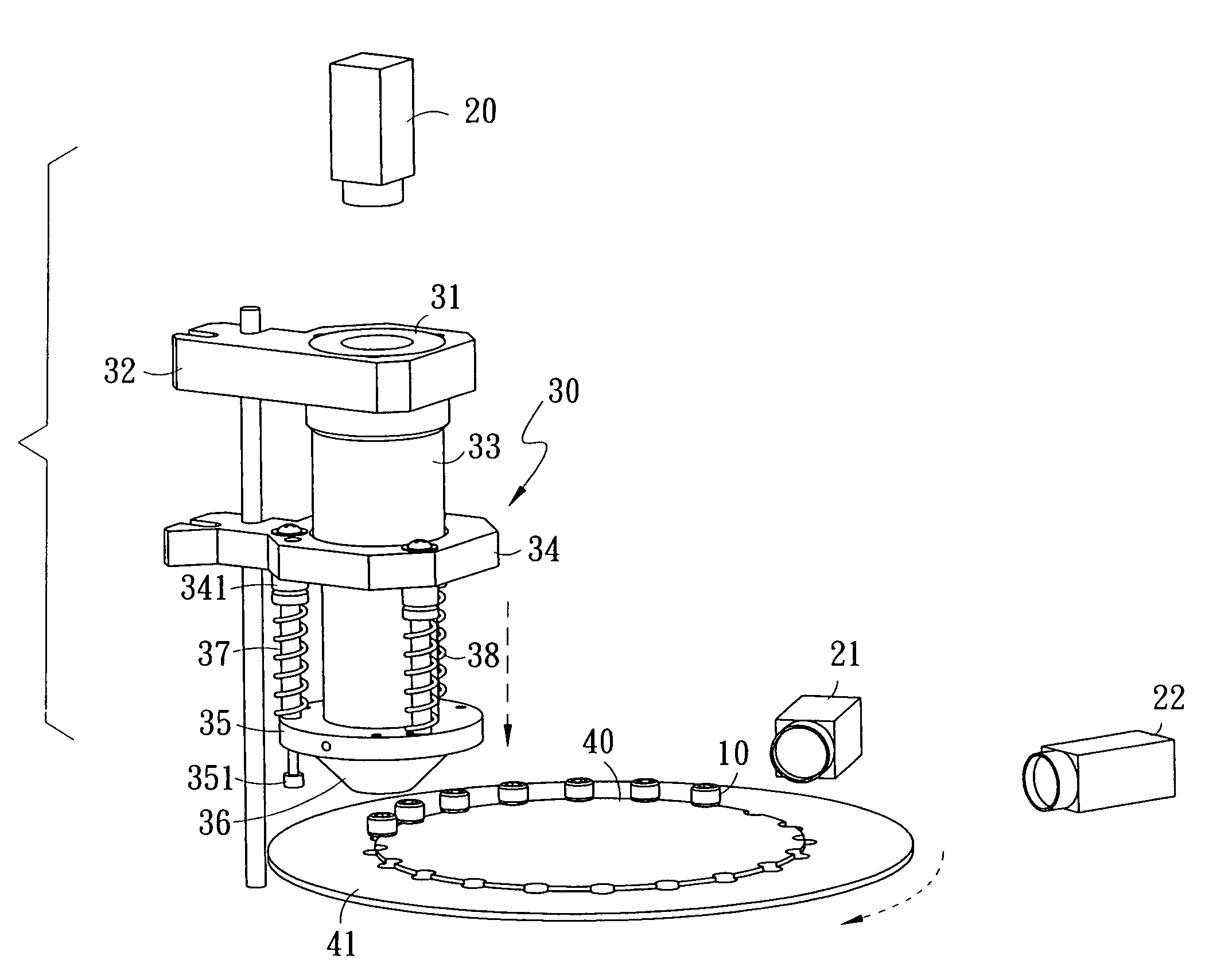

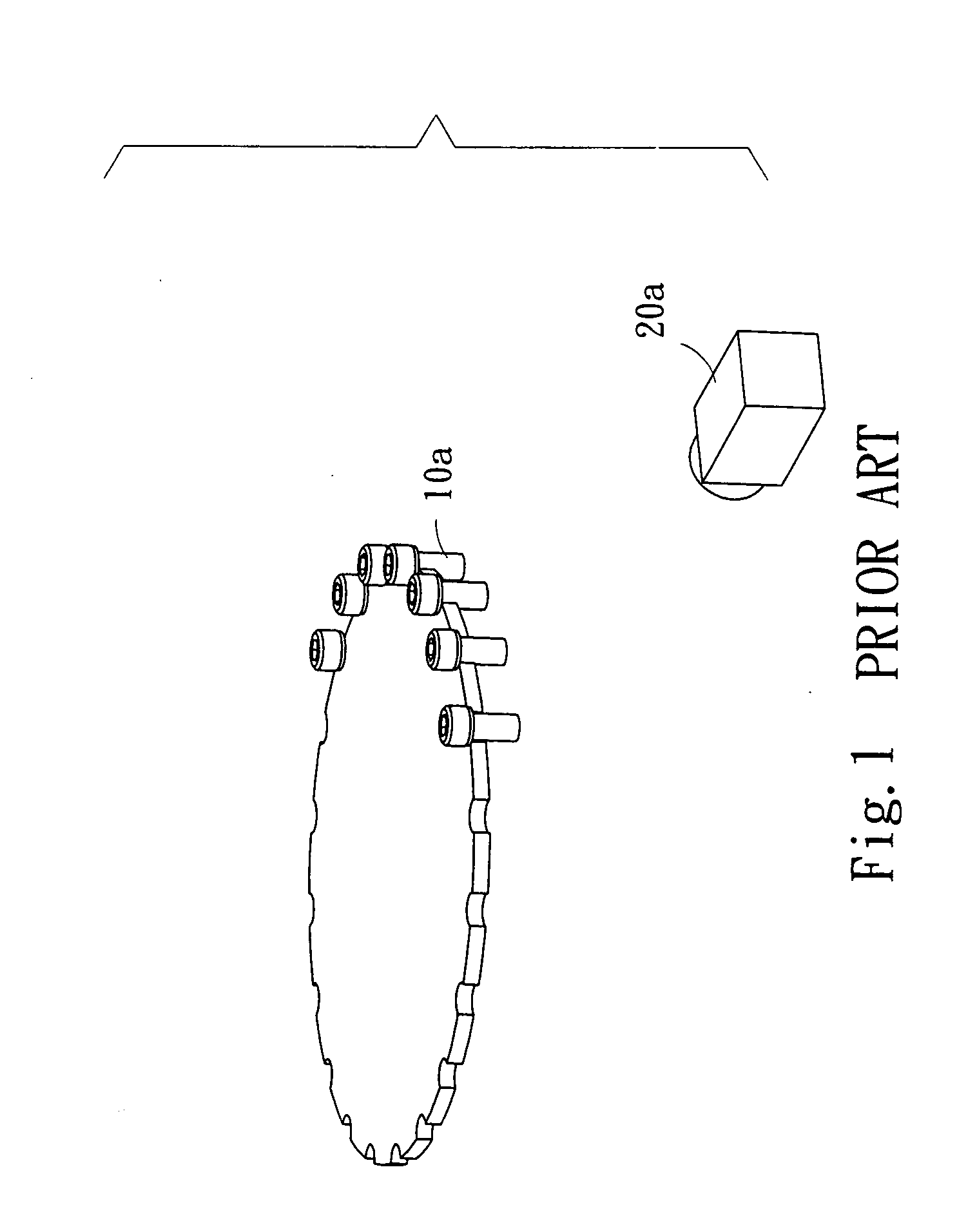

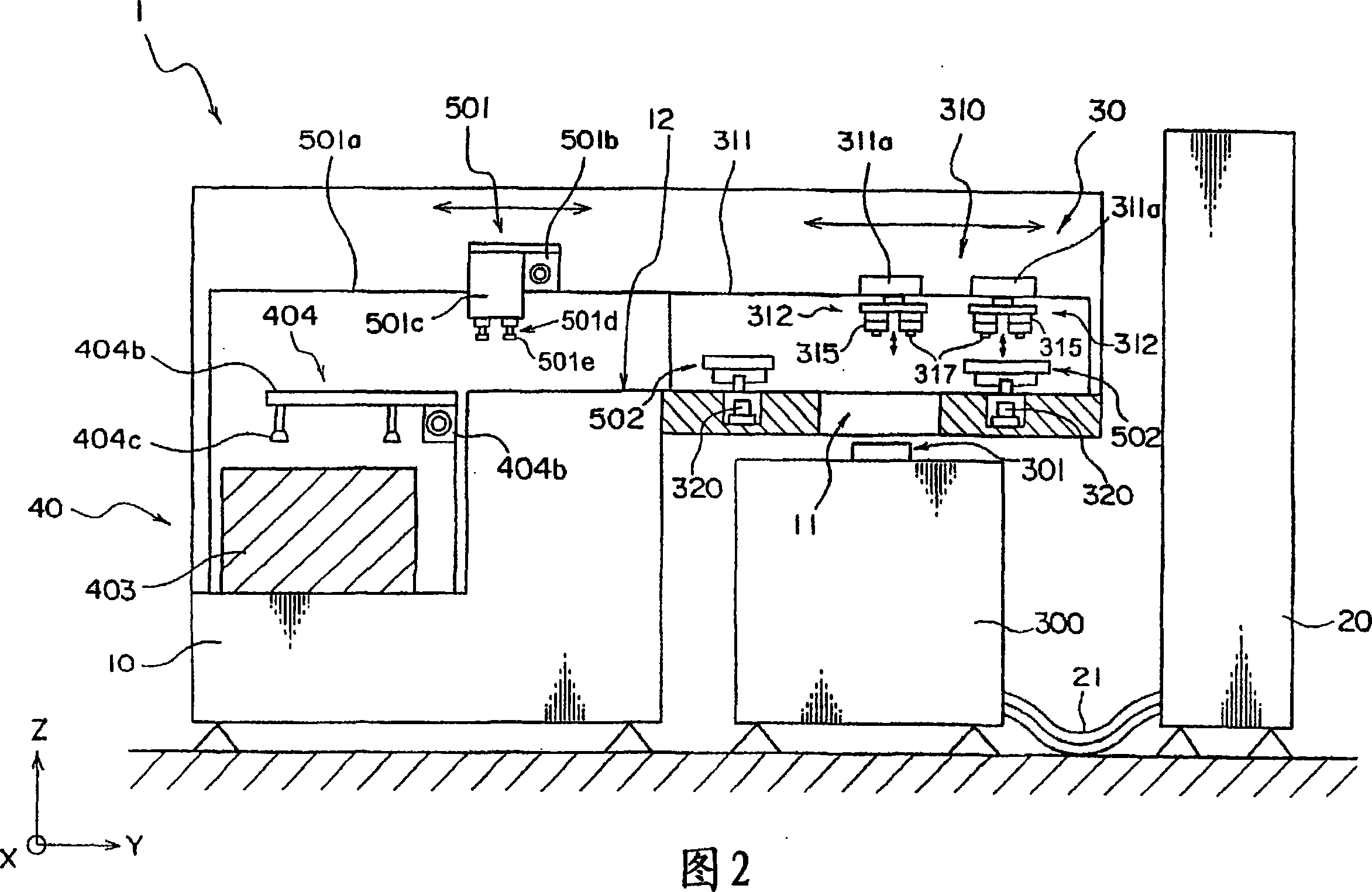

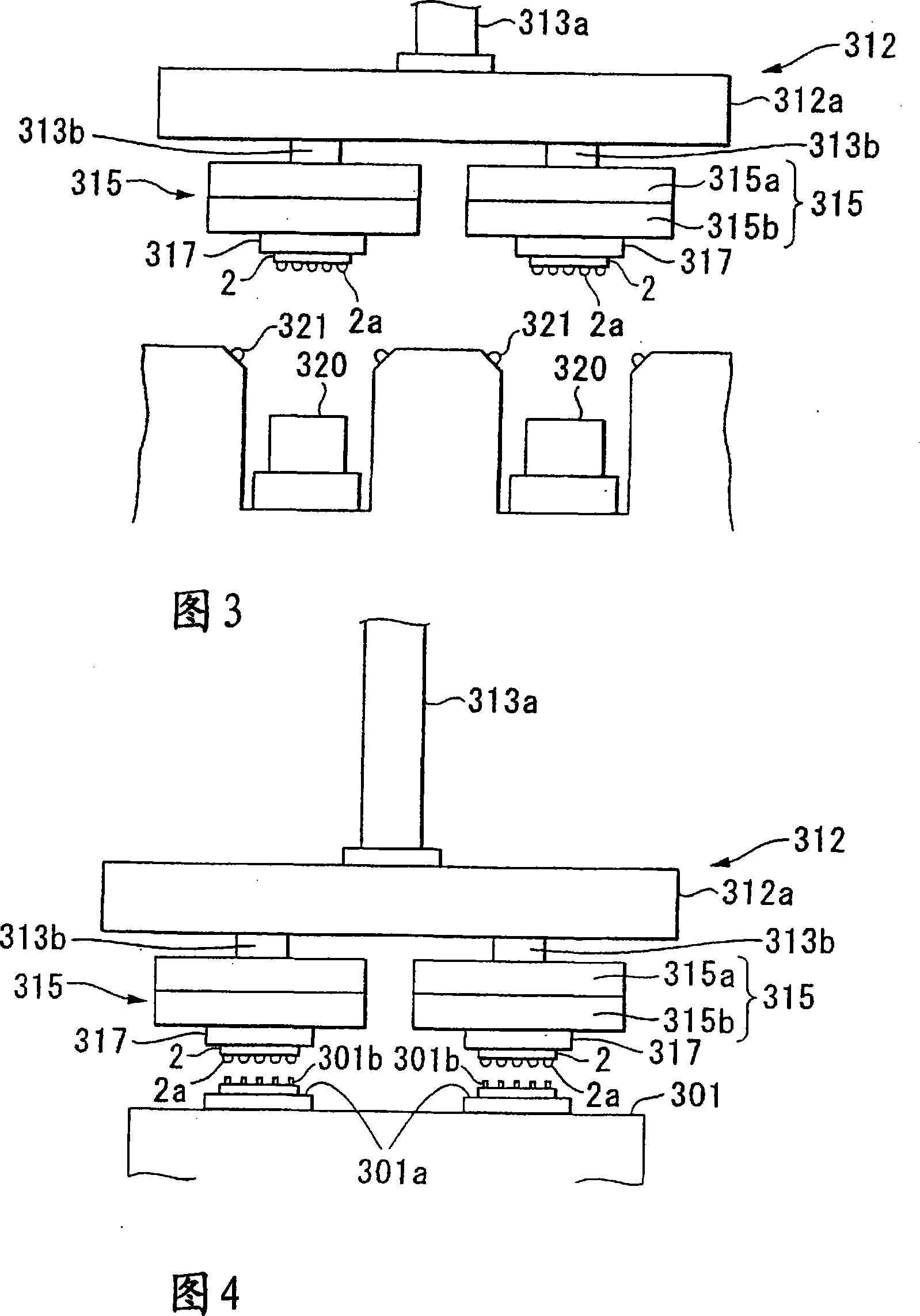

Component inspection imaging apparatus structure

InactiveUS20080253643A1Improve accuracyImprove integrityMaterial analysis by optical meansCharacter and pattern recognitionEngineeringImaging equipment

An improved component inspection imaging apparatus structure comprises a component inspection imaging apparatus, a component retaining turntable and a plurality of image capturing devices. The component inspection imaging apparatus comprises an extension tube fixing rack, an extension tube, a mirror extending rack, a mirror fixing rack and a conical mirror. A mirror plane portion is disposed on an internal side of the conical mirror, and an inspecting component is put onto the component retaining turntable and rotated under the component inspection imaging apparatus. The component inspection imaging apparatus covers the inspecting component for inspection. An image of the surrounding at the head of the inspecting component is formed at the mirror plane portion in the conical mirror. The image capturing device at the top of the component inspection imaging apparatus captures an image of the head of the inspecting component from top to bottom to determine a defective component quickly.

Owner:WU CHUN NAN

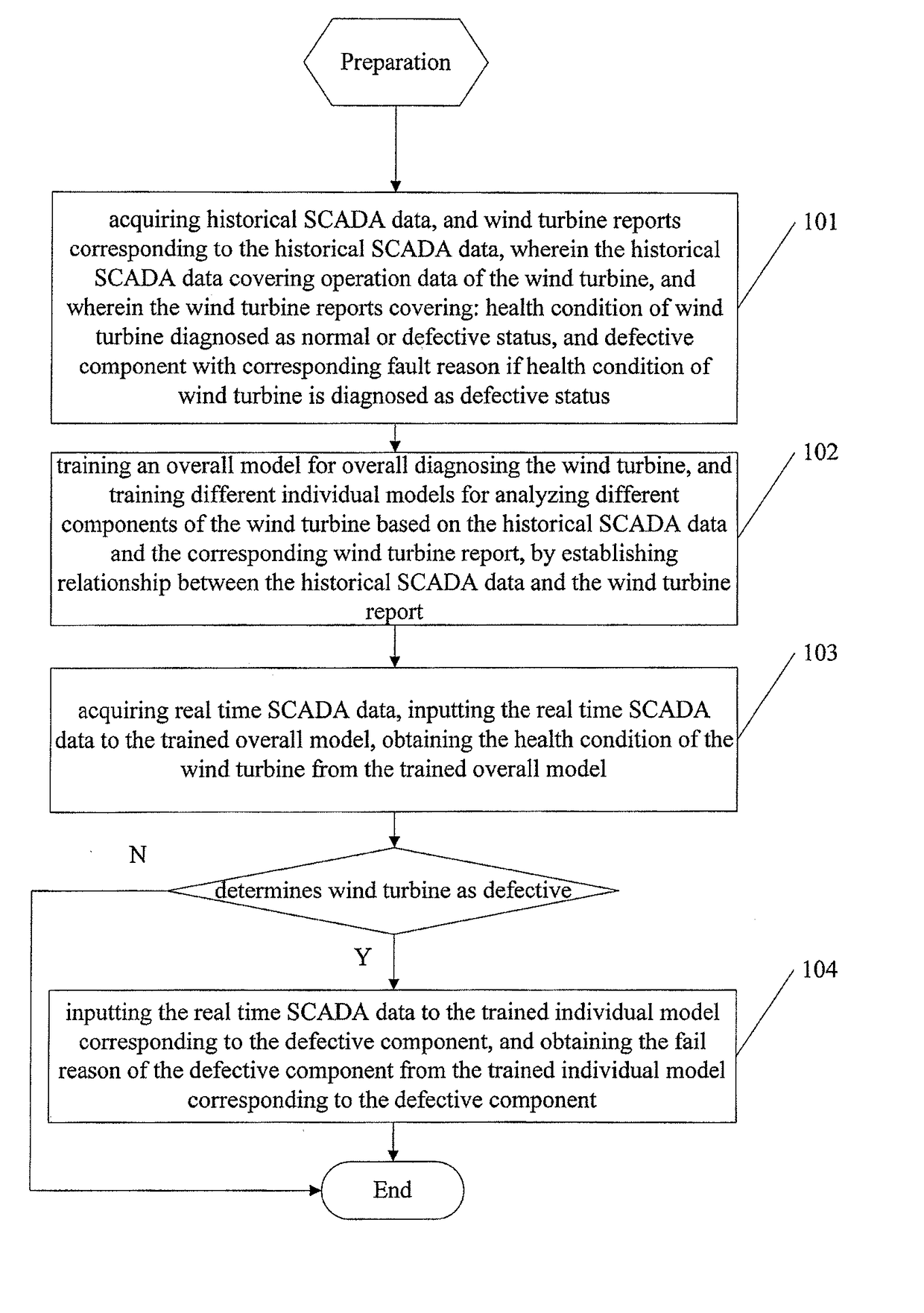

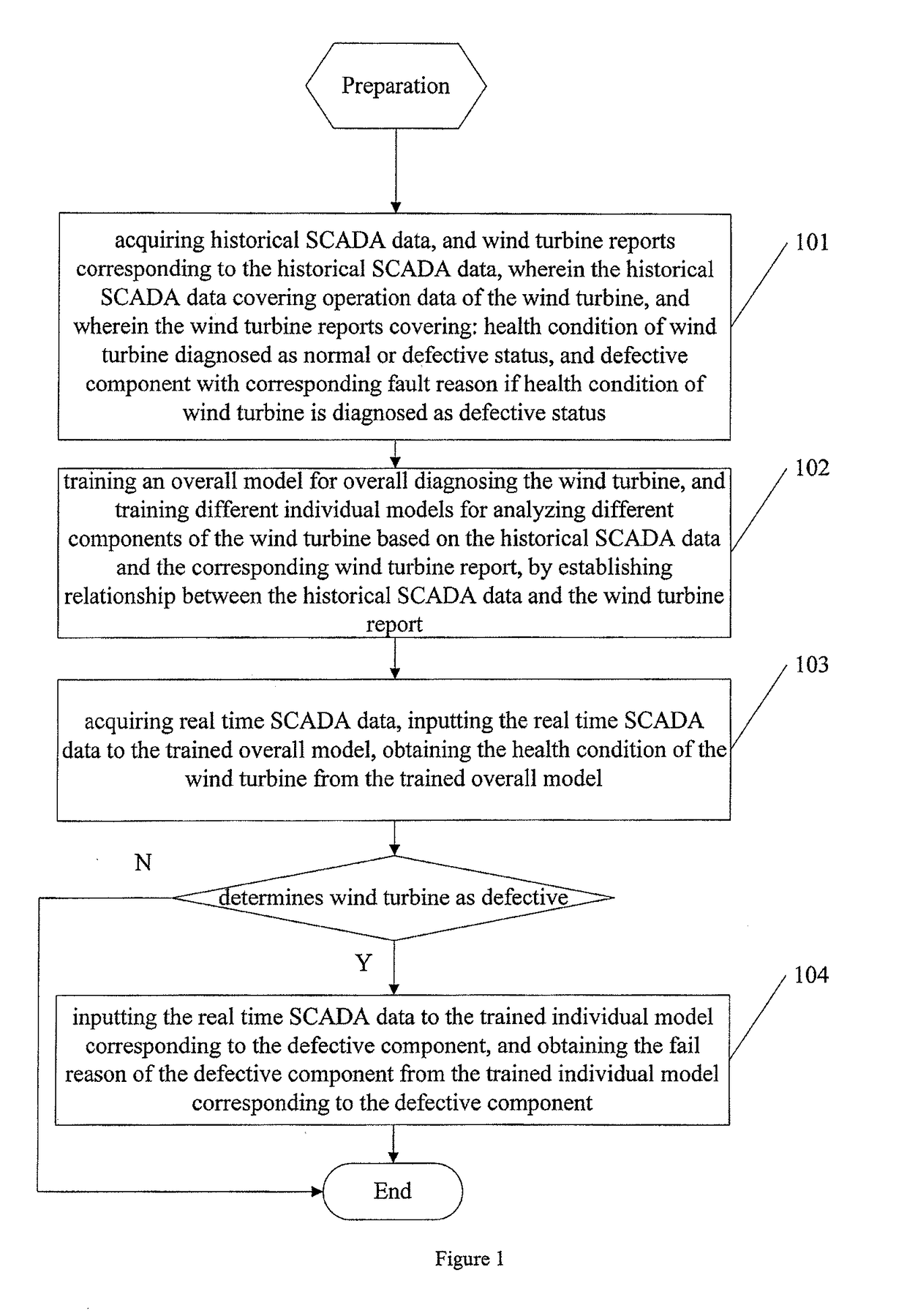

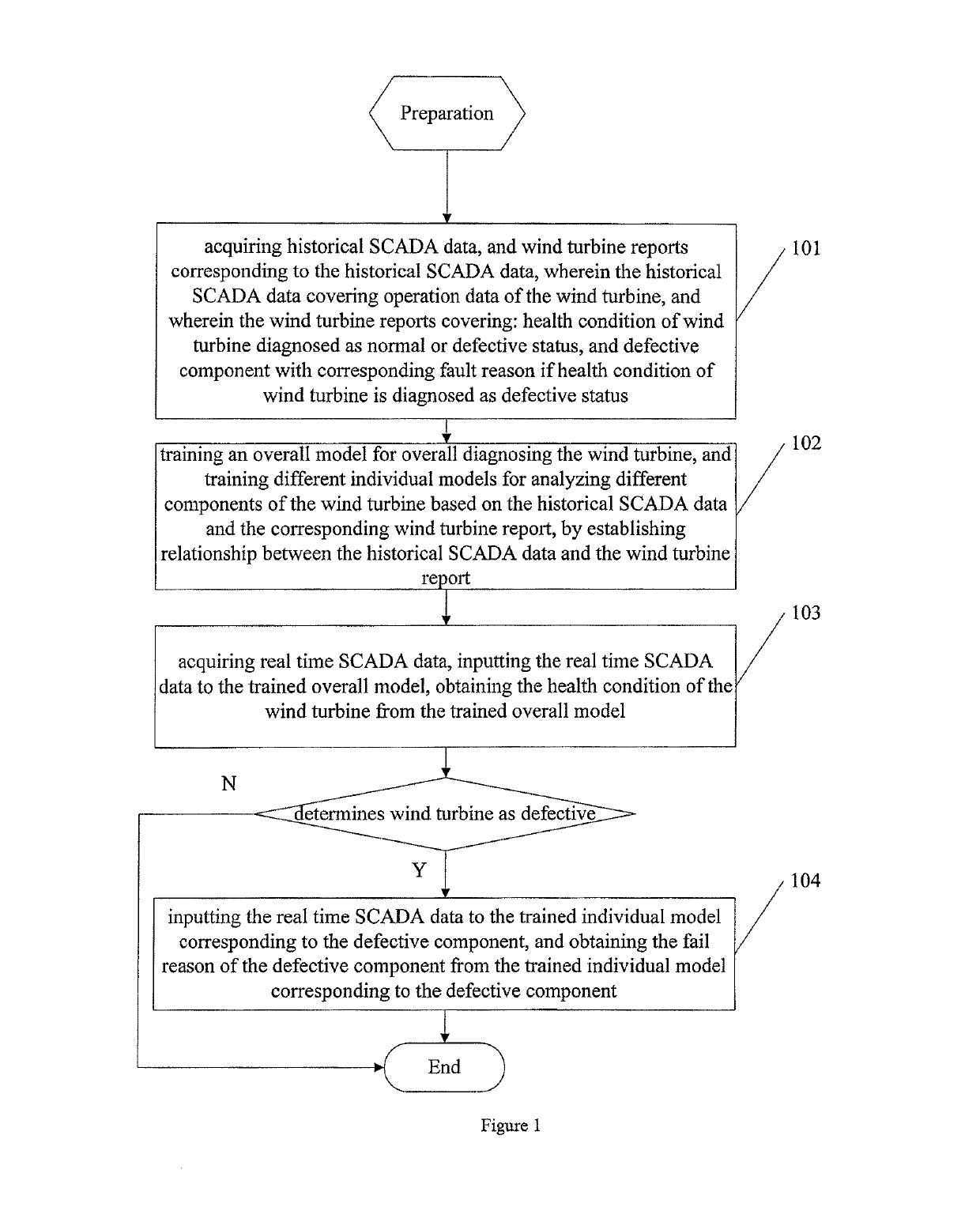

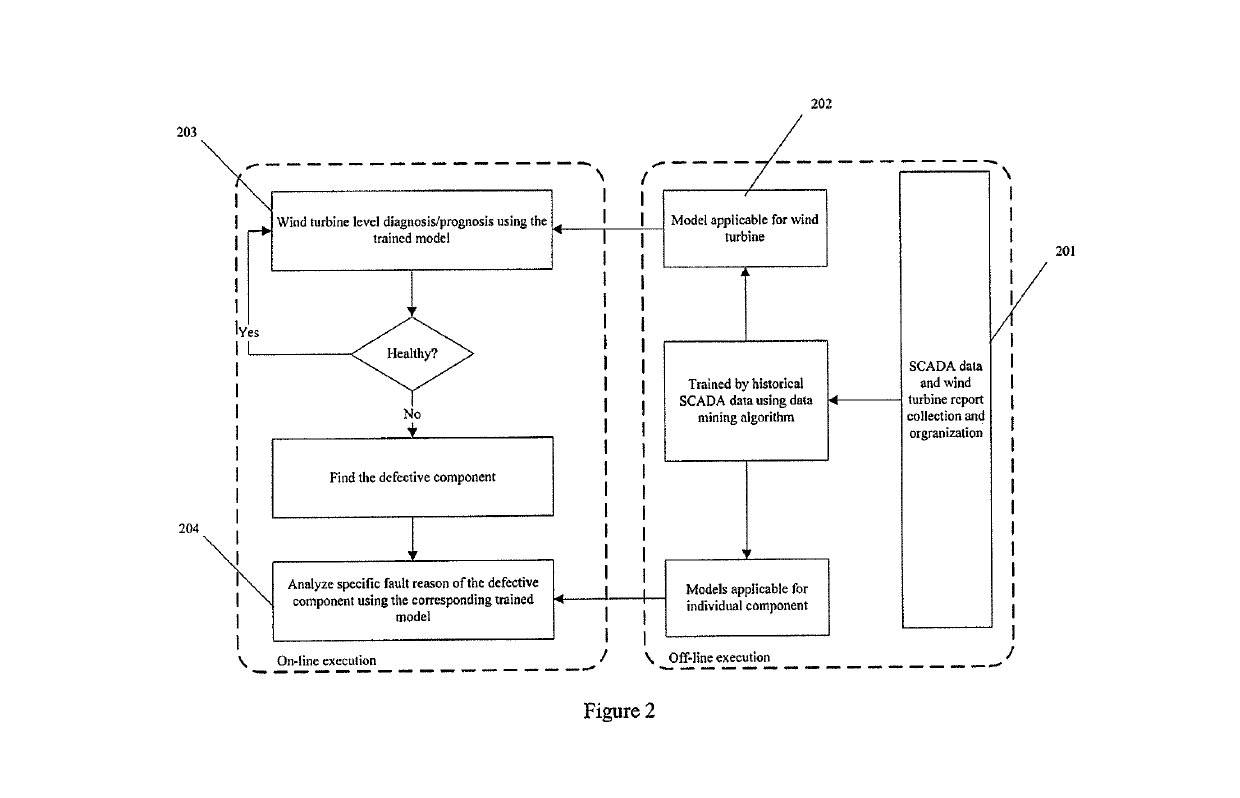

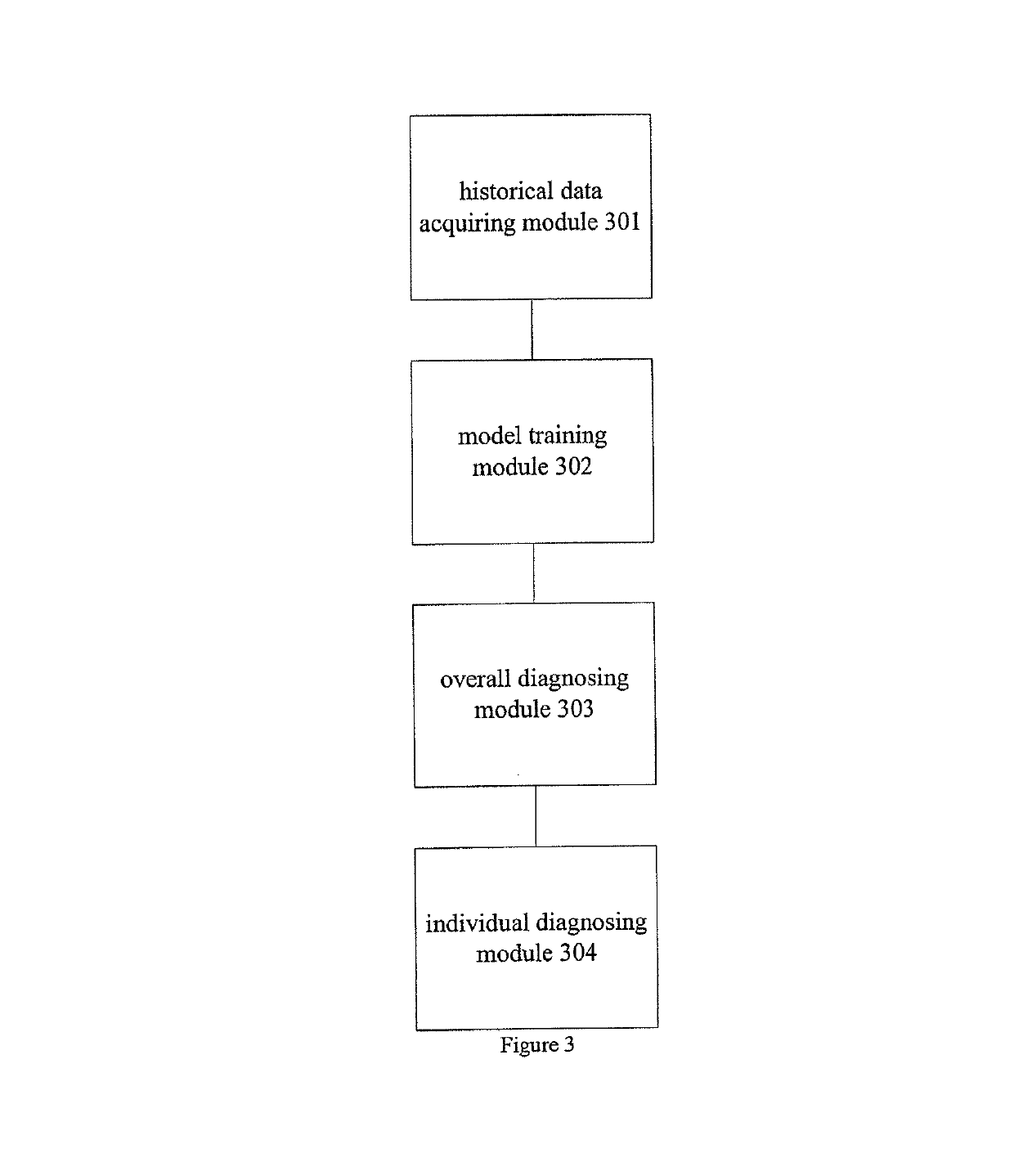

Wind turbine condition monitoring method and system

ActiveUS20170074250A1Accelerating algorithm execution efficiencyCorrective maintenance activityEngine fuctionsMachines/enginesSCADASimulation

The present application includes wind turbine condition monitoring method and system. The method comprises: acquiring historical SCADA data, and wind turbine reports corresponding to the historical SCADA data; training an overall model for overall diagnosing the wind turbine, and training different individual models for analyzing different components of the wind turbine based on the historical SCADA data and the corresponding wind turbine report, by establishing relationship between the historical SCADA data and the wind turbine report; acquiring real time SCADA data, inputting the real time SCADA data to the trained overall model, obtaining the health condition of the wind turbine from the trained overall model, and performing individual diagnosing step if the trained overall model determines wind turbine as defective status; inputting the real time SCADA data to the trained individual model corresponding to the defective component, and obtaining the fault details of the defective component from the trained individual model corresponding to the defective component.

Owner:HITACHI ENERGY SWITZERLAND AG

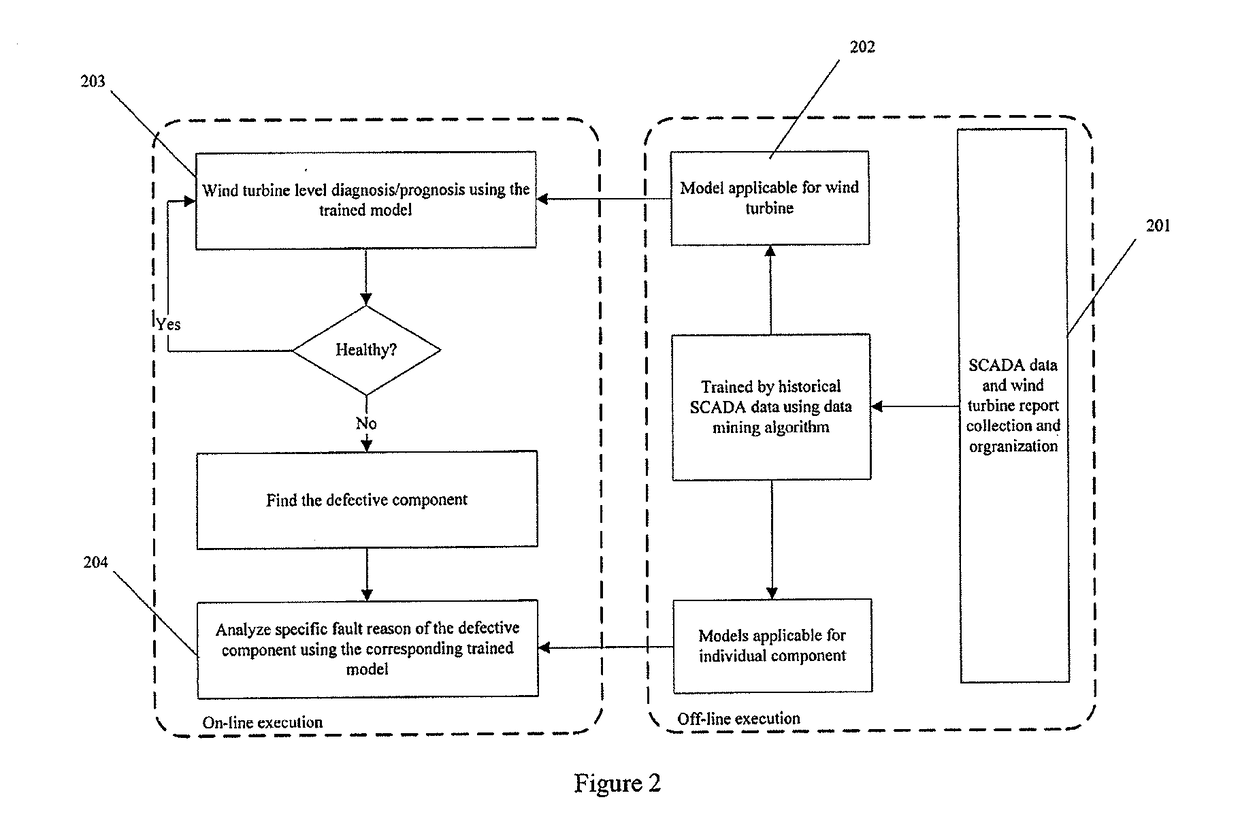

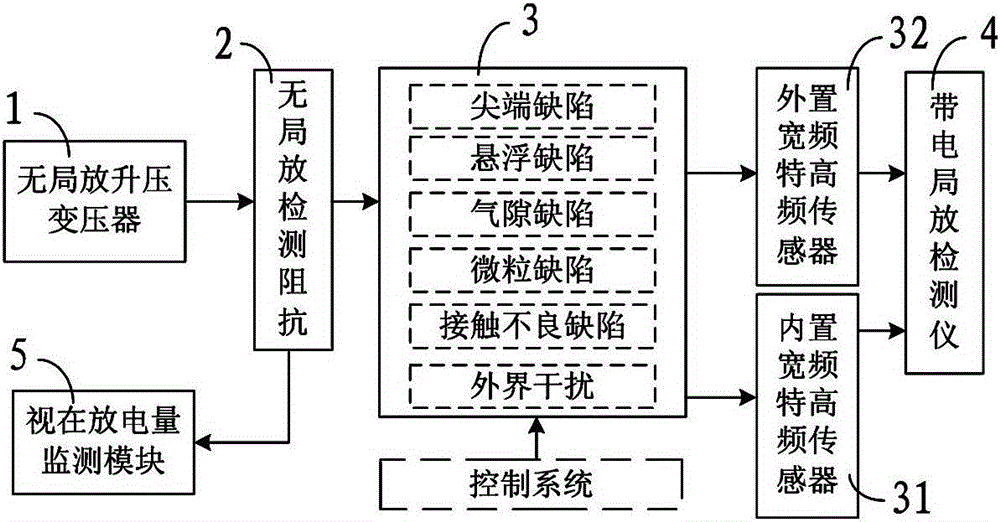

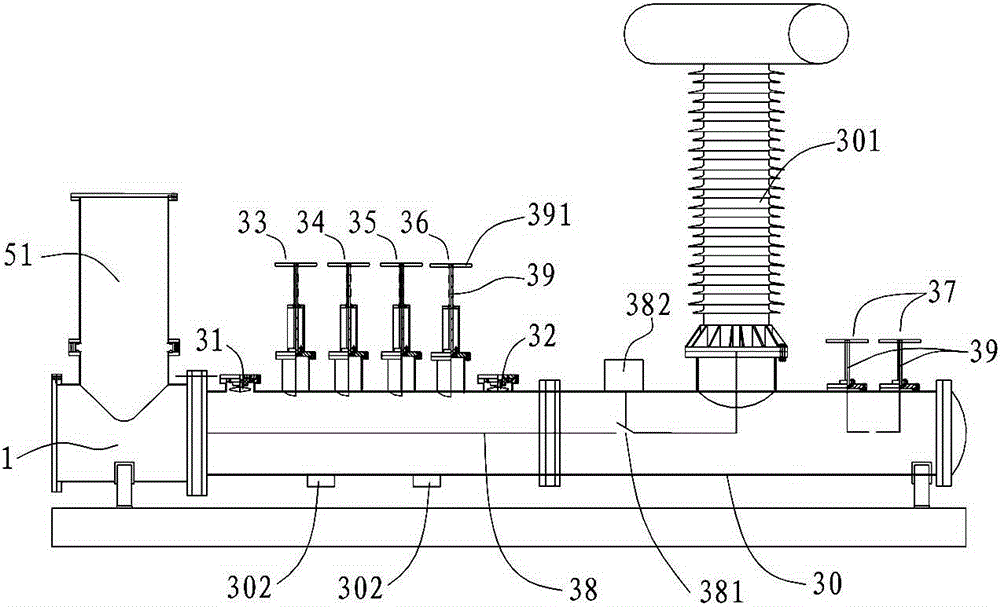

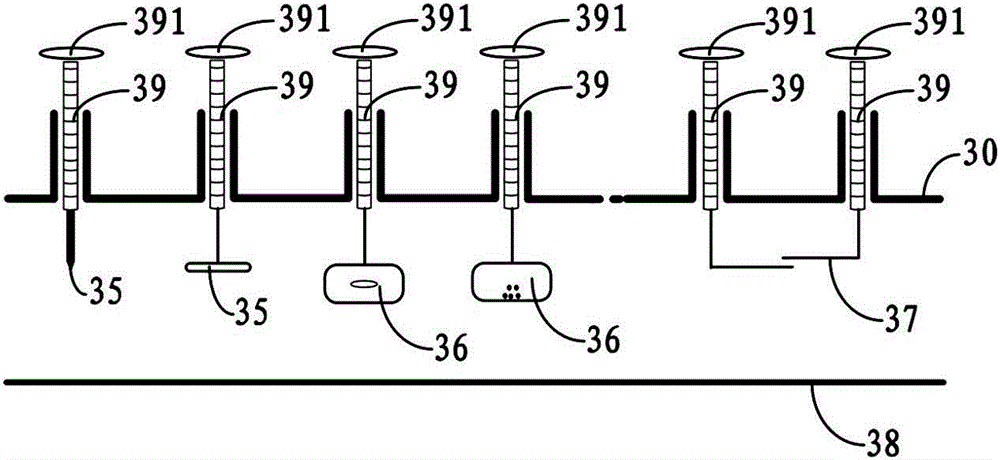

GIS partial discharge charged detection test device based on defect simulation

InactiveCN105223478AImprove reliabilitySimple structure and principleTesting dielectric strengthTransformerCharge detection

The invention discloses a GIS partial discharge charged detection test device based on defect simulation, comprising a no-partial-discharge test transformer, a no-partial-discharge detection impedor, GIS defect simulation equipment, and a charged partial discharge detector. The no-partial-discharge test transformer is connected with defective components pre-arranged in the GIS defect simulation equipment through the no-partial-discharge detection impedor. A built-in broadband ultrahigh-frequency sensor is arranged inside the GIS defect simulation equipment, an external broadband ultrahigh-frequency sensor is arranged outside the GIS defect simulation equipment, and the built-in broadband ultrahigh-frequency sensor and the external broadband ultrahigh-frequency sensor are connected with the input end of the charged partial discharge detector. The device of the invention can be applicable to GIS partial discharge charged detection test under all kinds of defect simulation, can be used for simulating various defects truly and conducting charged detection test of local discharge signals for the defects, and has the advantages of simple structure principle, low cost and high reliability of test results.

Owner:STATE GRID CORP OF CHINA +2

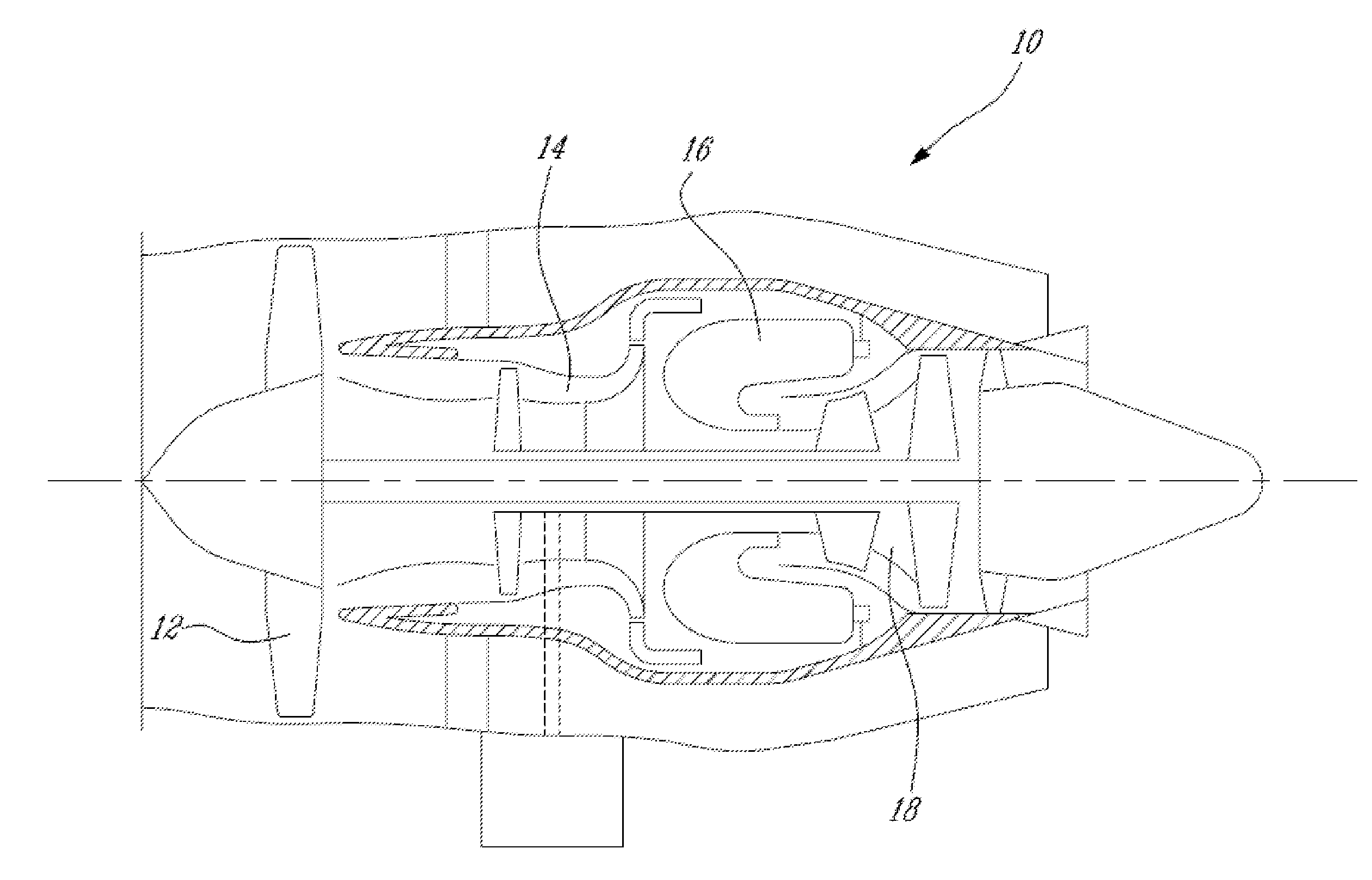

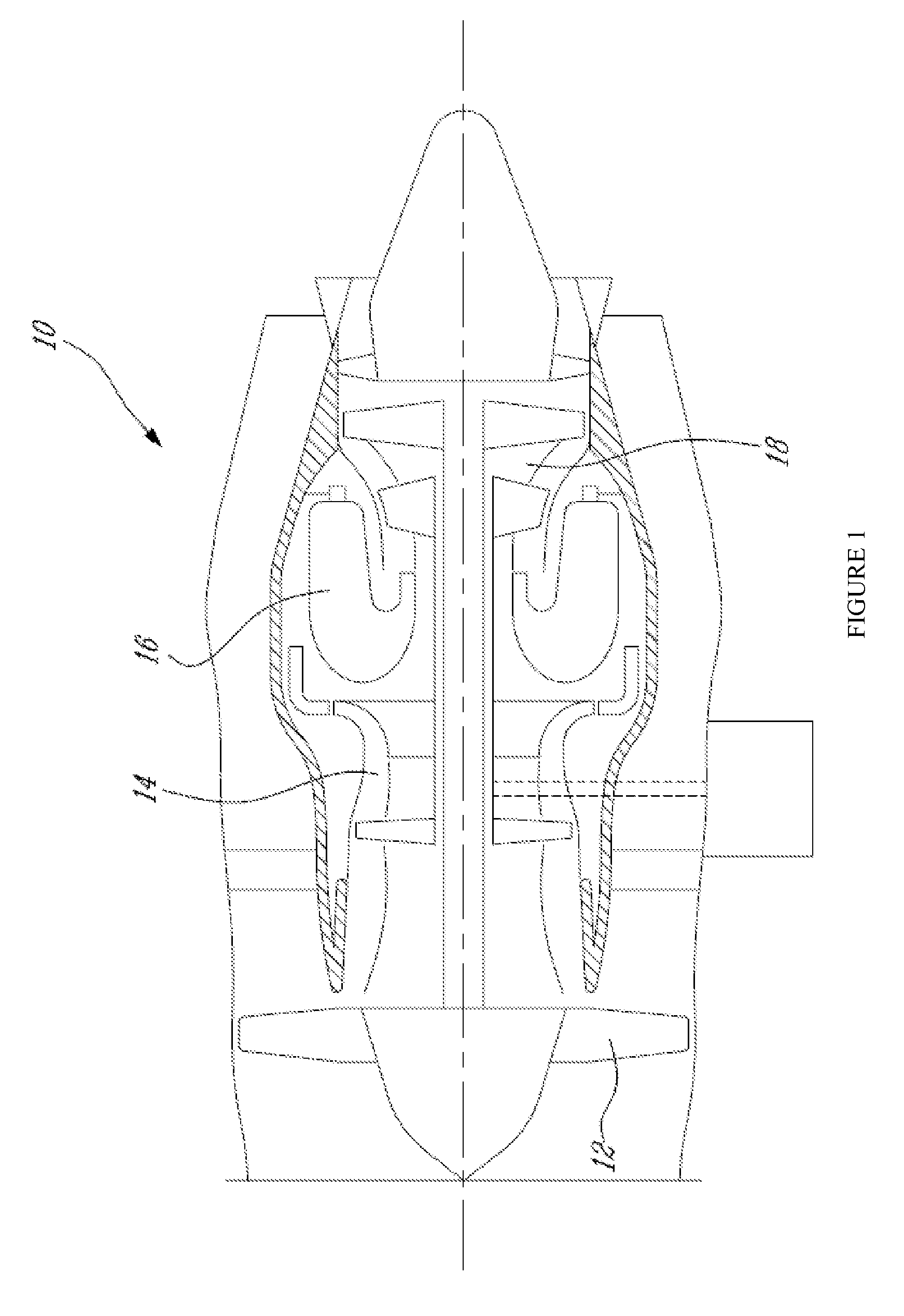

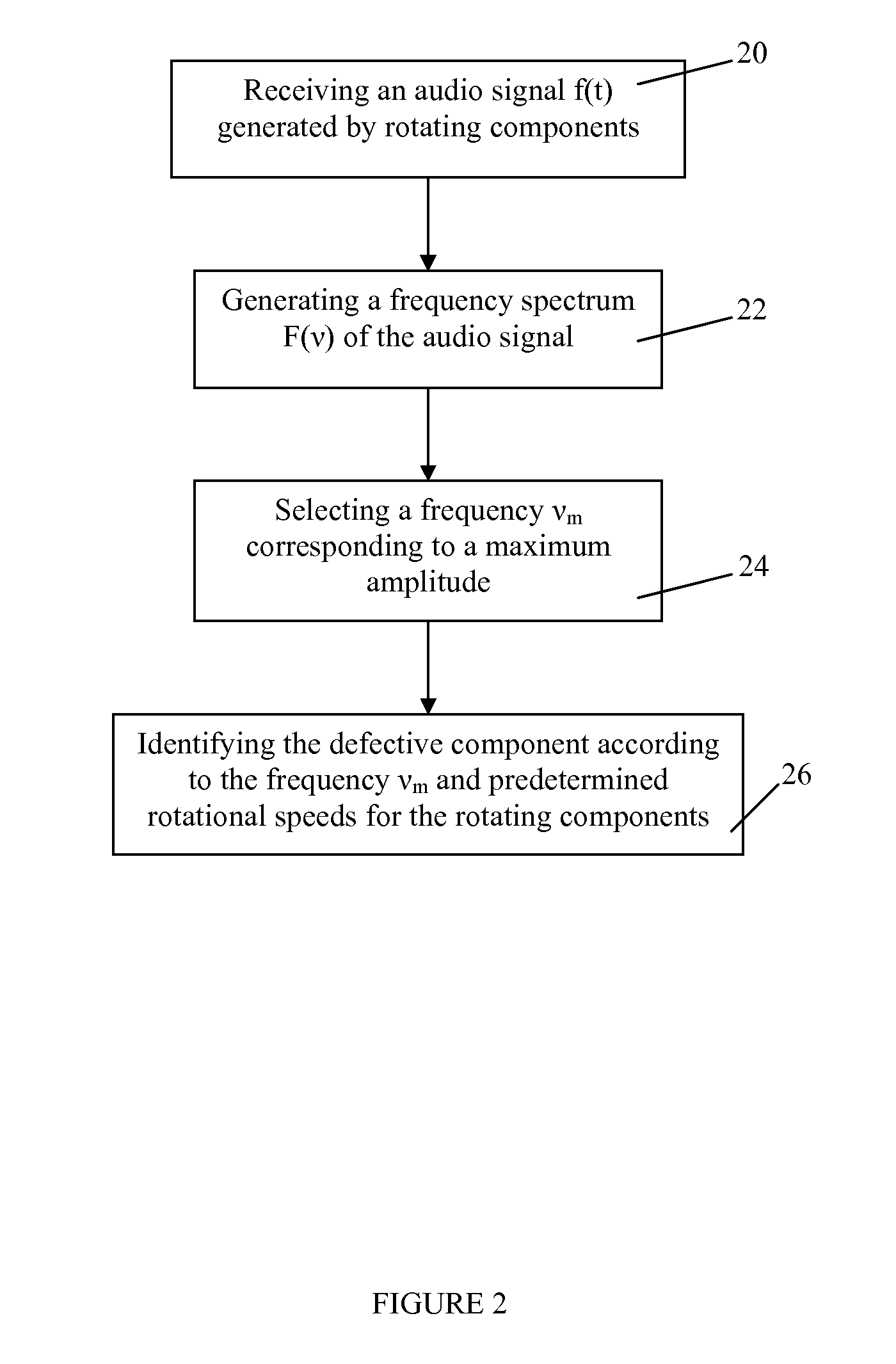

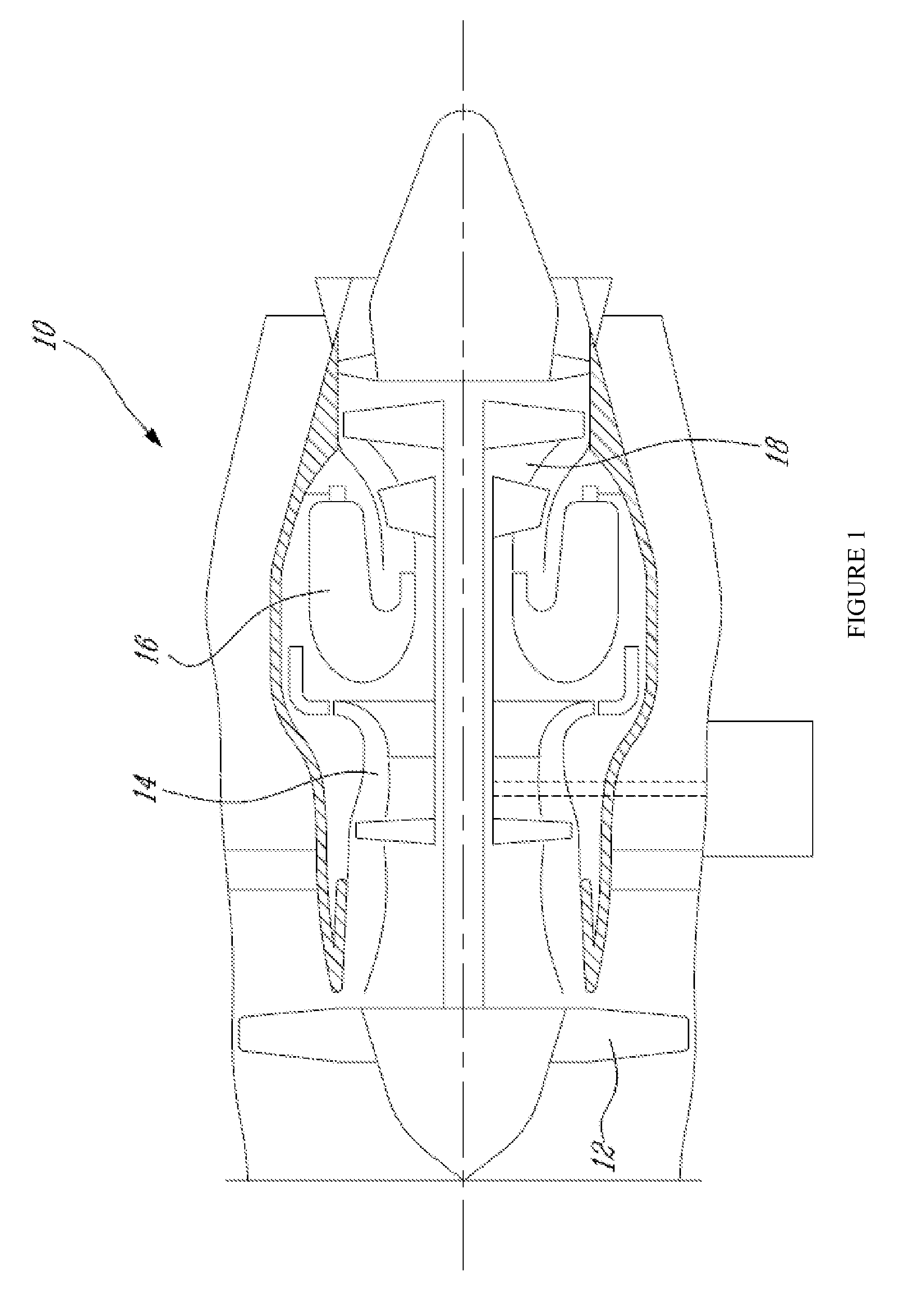

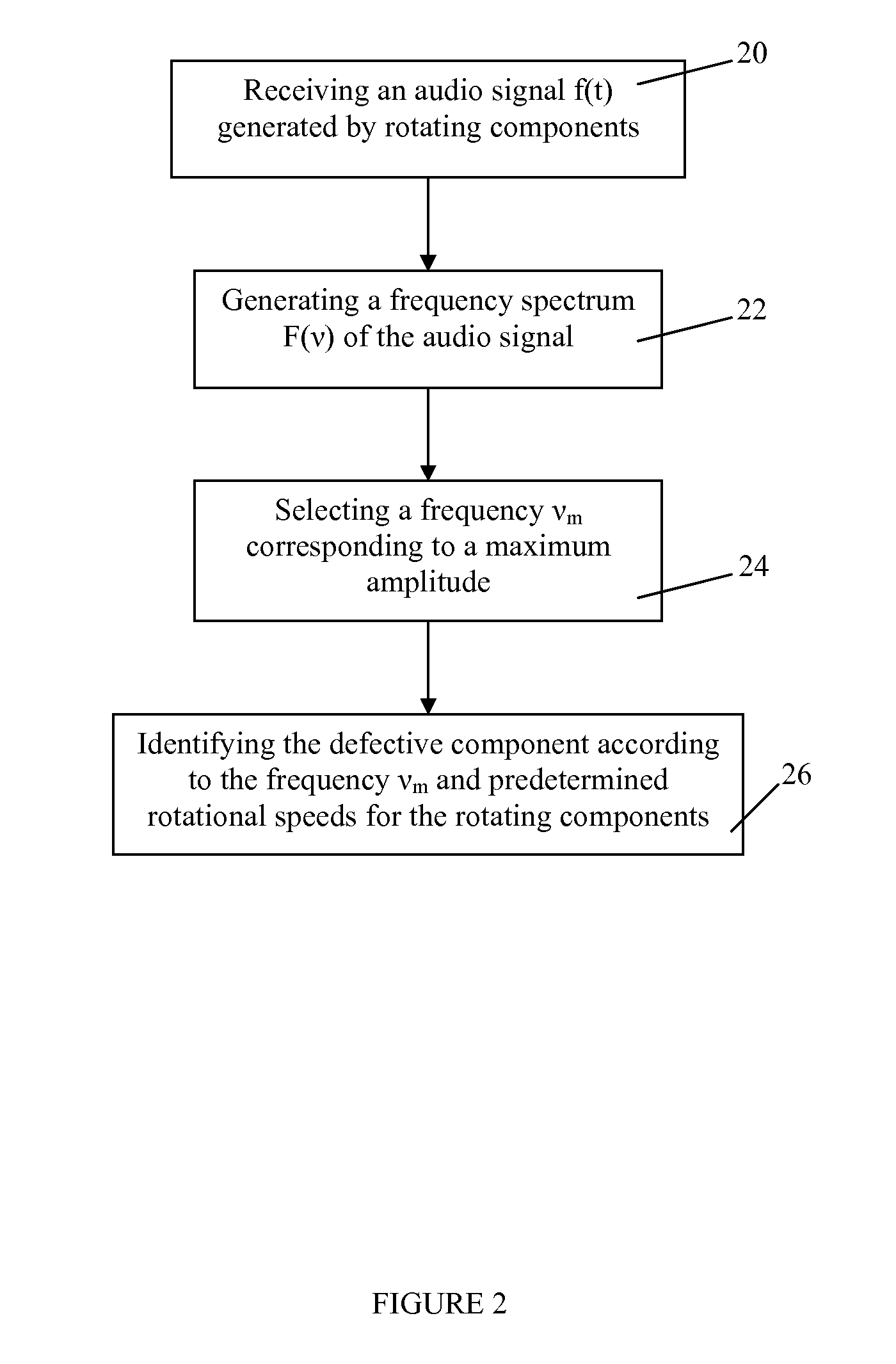

Method and Apparatus for Troubleshooting Noise/Vibration Issues of Rotating Components

ActiveUS20100101310A1Vibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesFrequency spectrumEngineering

There is provided a method for troubleshooting noise / vibration issues of rotating components, the method comprising: receiving an audio signal of the rotating components in operation; generating a frequency spectrum corresponding to the audio signal; selecting a frequency νm in the frequency spectrum corresponding to a maximum amplitude; and comparing the frequency νm to a set of predetermined rotational speeds of the rotating components to find a match; thereby identifying a potentially defective component.

Owner:PRATT & WHITNEY CANADA CORP

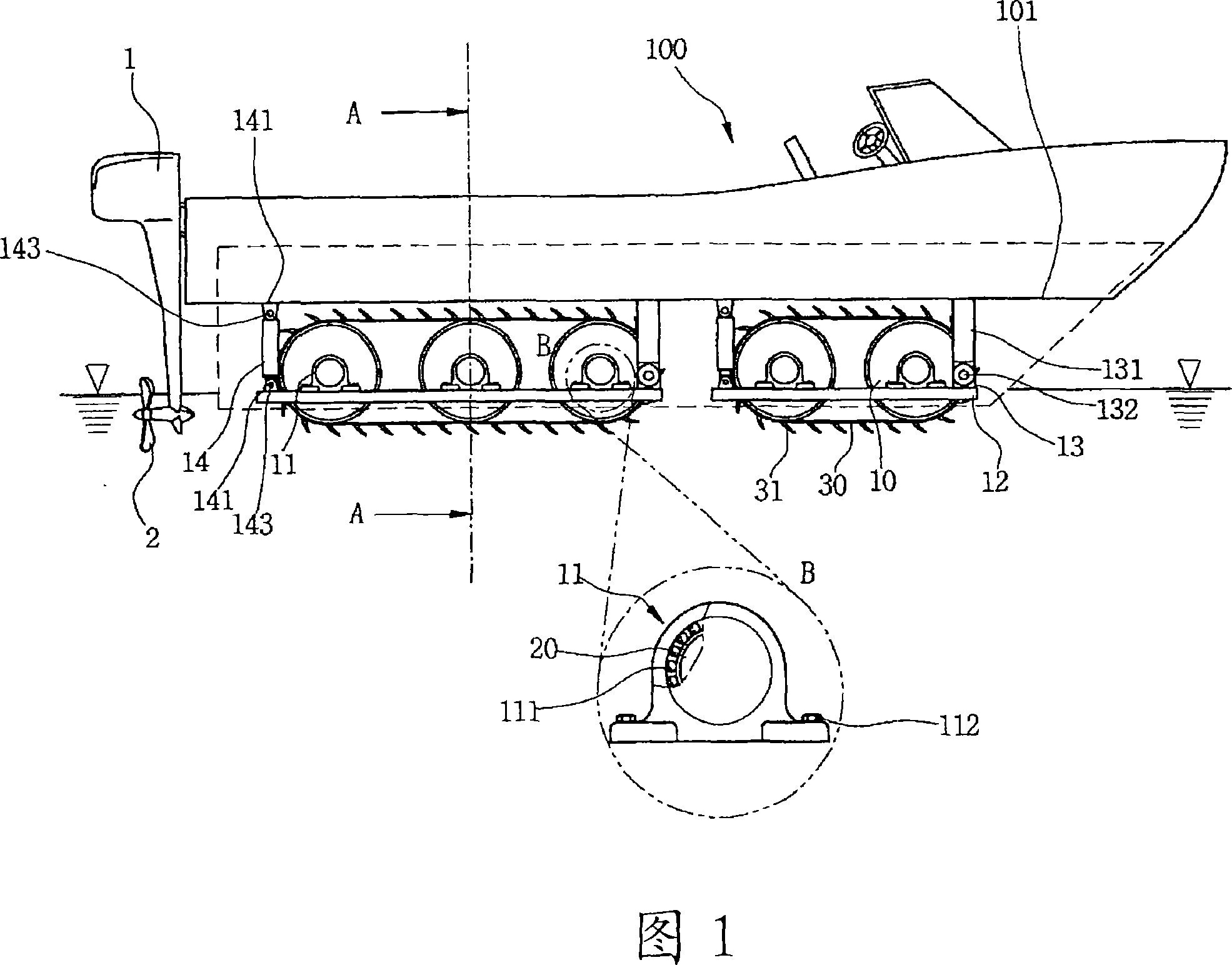

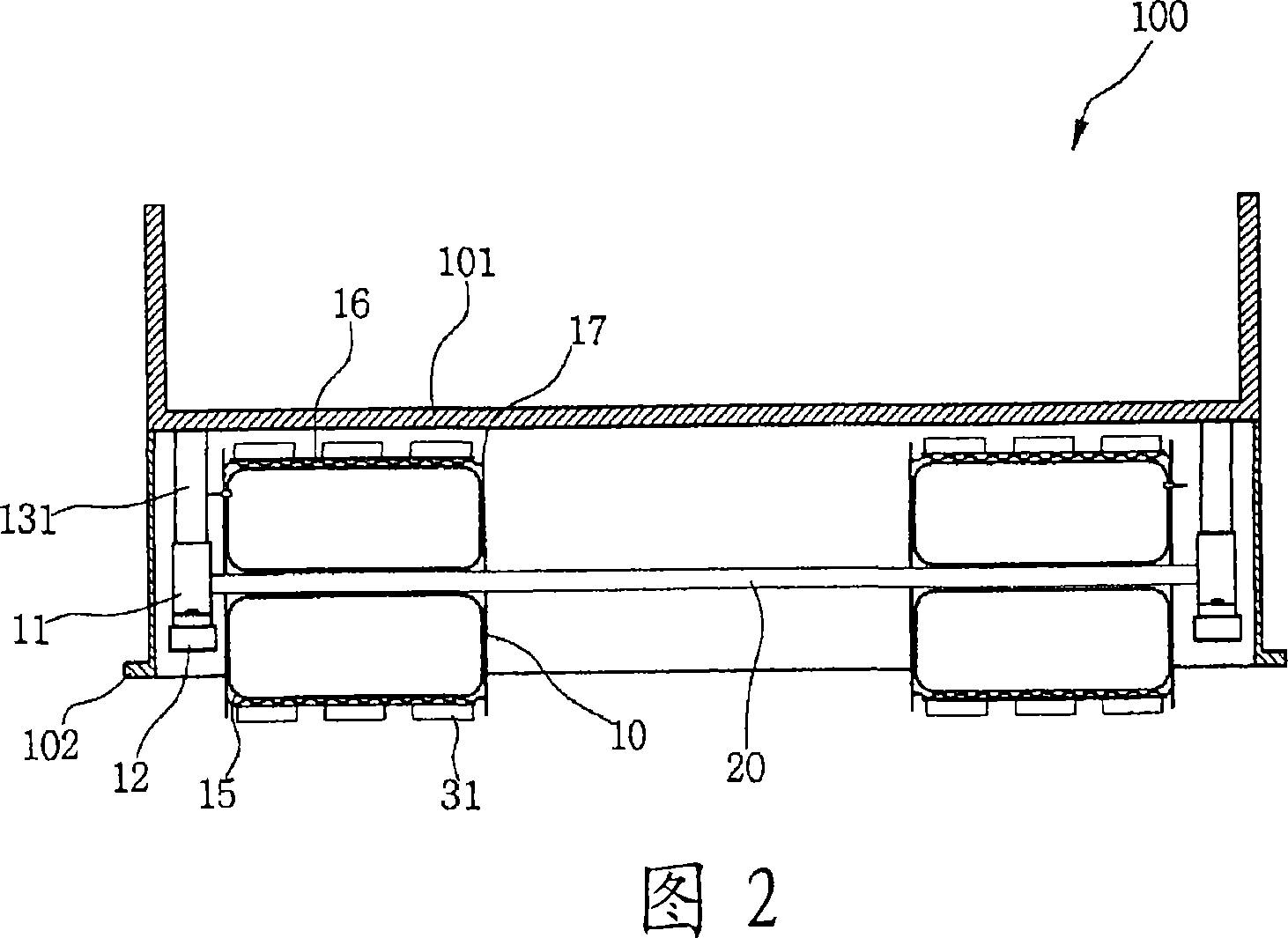

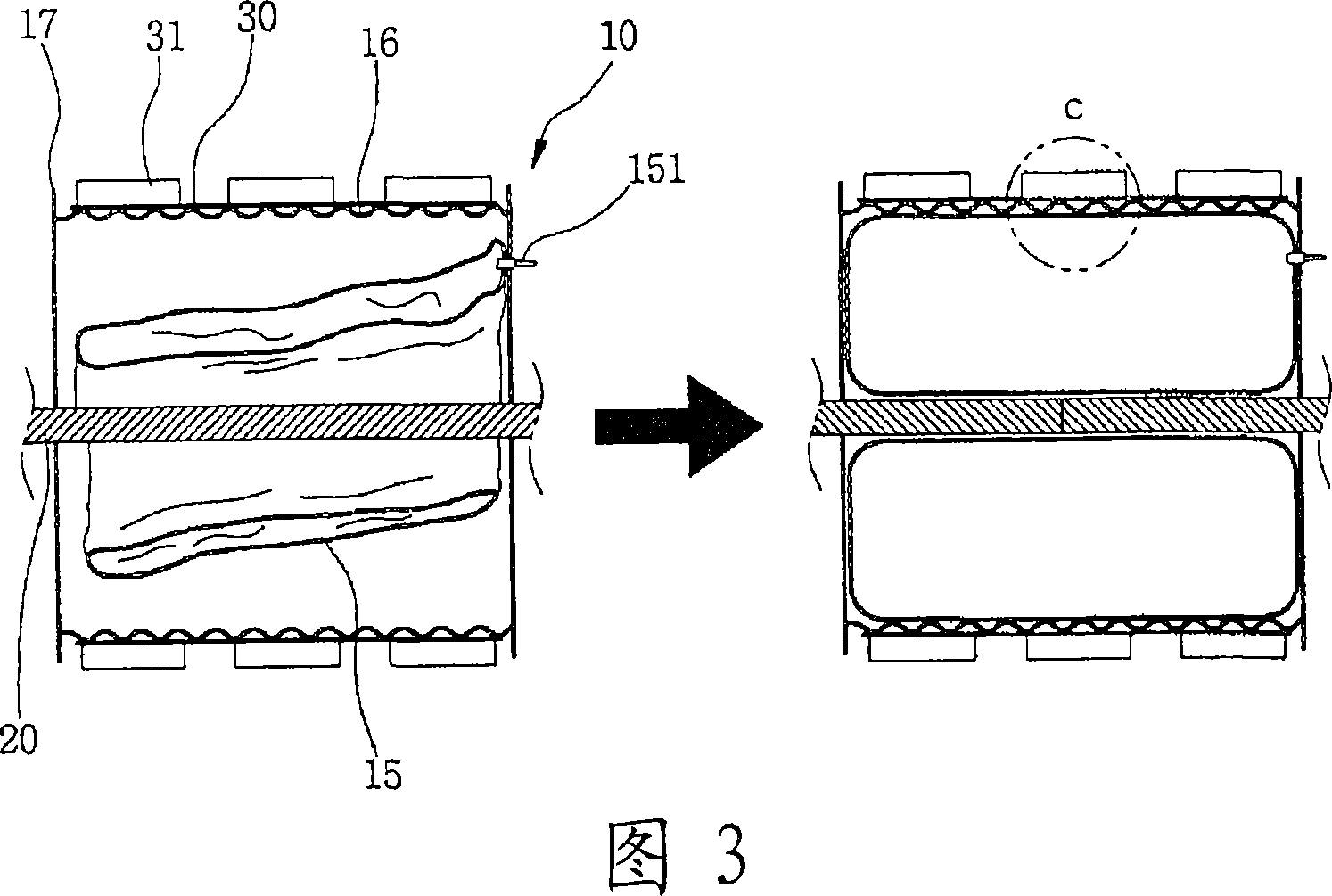

Acceleration system for link belt-mounted ship

InactiveCN101056795AEasy to manufactureWatercraft hull designPropulsive elements of non-rotary typeBall bearingWater wheel

Disclosed herein is an acceleration system for a link belt-mounted ship. The acceleration system comprises water wheels(10), rotating shafts(20) mounted through the water wheels, link belts(30) surrounding the water wheels and formed an outer peripheral surface thereof at with hook-shaped blades(31), ball bearing units(11) mounted external to the water wheels so that the rotating shafts are inserted therethrough, square pipes(12) onto which the ball bearing units are bolted, hinges(13) bolted onto the square pipes and each hinge having a hinge rod(131) bolted to the hull, and hydraulic cylinders(14) fastened on the square pipes so that they are fixed to the bottom surface of the hull by way of upper brackets(141) and associated pins(143), and fixed to the square pipes by way of lower brackets(141) and associated pins(143). The system can simplify repair works thereof and enables required defective components to be individually exchanged thus facilitating its manufacture.

Owner:朴南洙

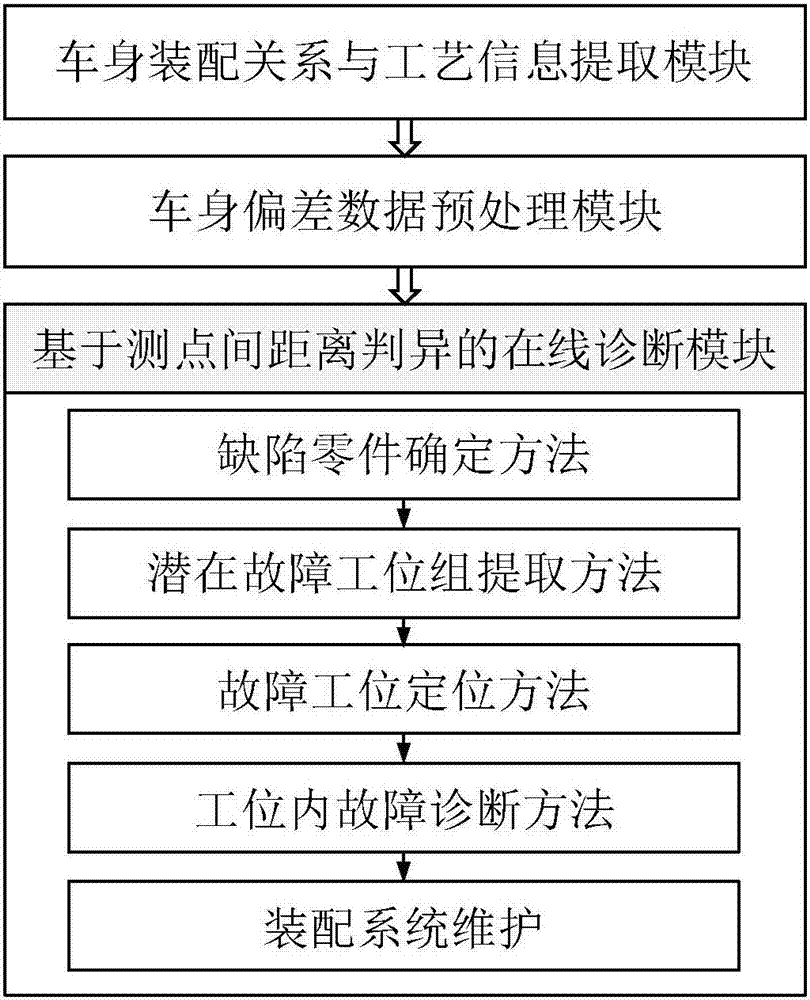

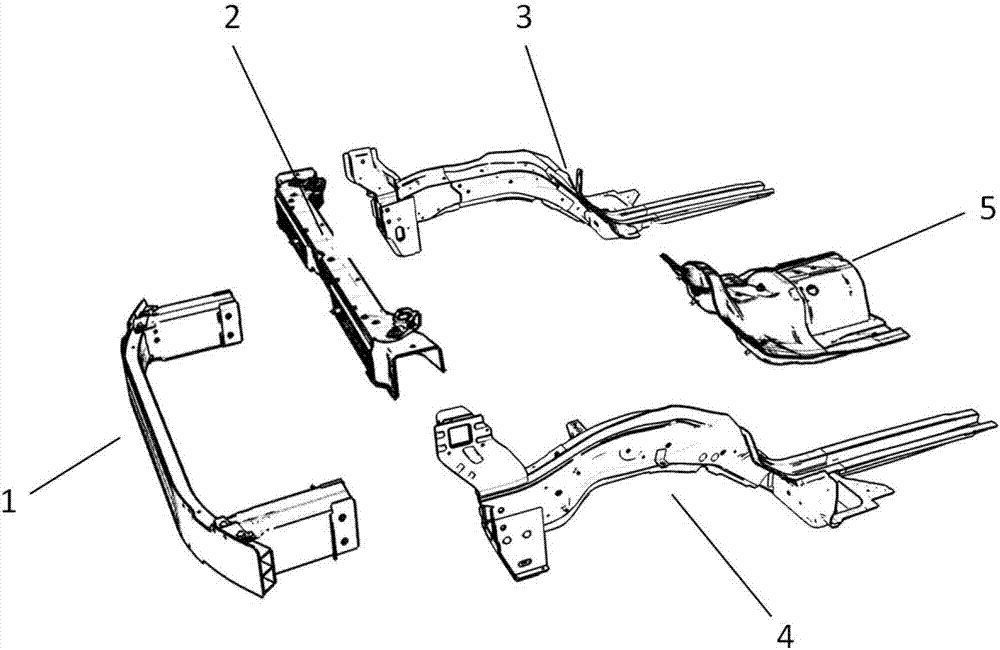

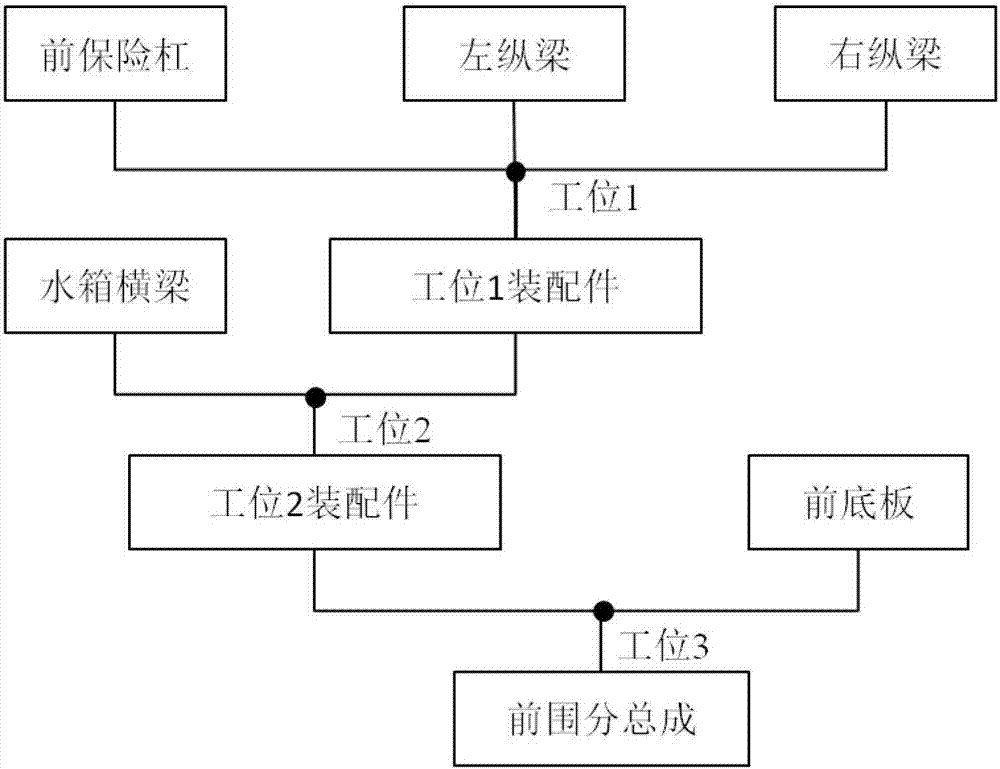

Vehicle body assembly quality online diagnosis method based on component measuring point distance abnormality judgment

ActiveCN106895810AOvercoming situations that cannot be applied to multi-stationHigh precisionMeasurement devicesTotal factory controlProcess systemsMaintenance strategy

The invention relates to a vehicle body assembly quality online diagnosis method based on component measuring point distance abnormality judgment, which combines the vehicle body assembly process relation and the clamp positioning process information, extracts out-of-tolerance measuring points in measuring data of a tail end detection station, and achieves determination of defective components. The positioning of the faulty station is realized by discriminating the potential faulty stations related to the defective components from top to bottom and judging and analyzing the difference between the actual distance and the standard distance of the measuring points on the defective parts. In the fault station, the relative distances between the key points on the defective parts are different, so as to achieve the diagnosis of the parts' defects. Meanwhile, according to the in-station deviation relation model and the estimation method, the element positioning deviation is solved, so as to achieve the fault diagnosis of the clamp and to guide the making of the assembly system maintenance strategy. With the method, the diagnosis precision is improved, the system fault source can be found more timely based on the single-vehicle fault diagnosis, thereby reducing loss caused by the process system fault.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

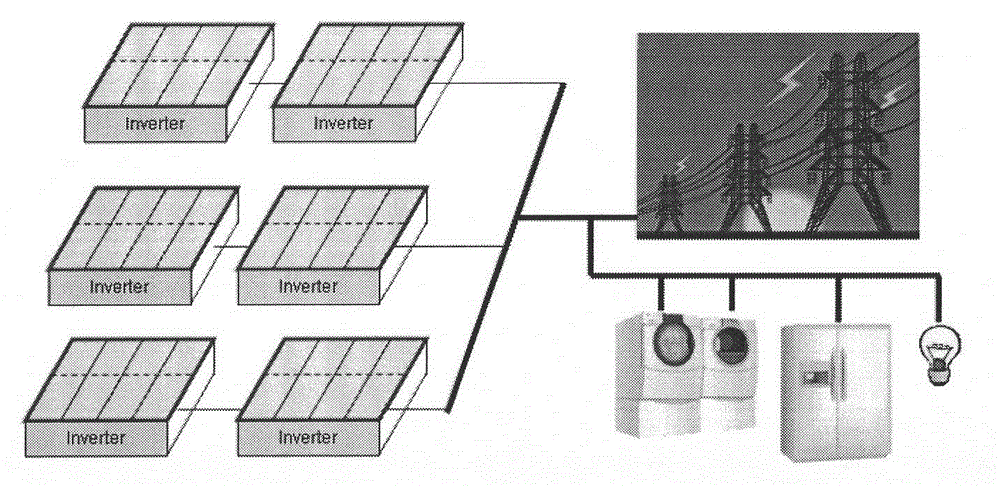

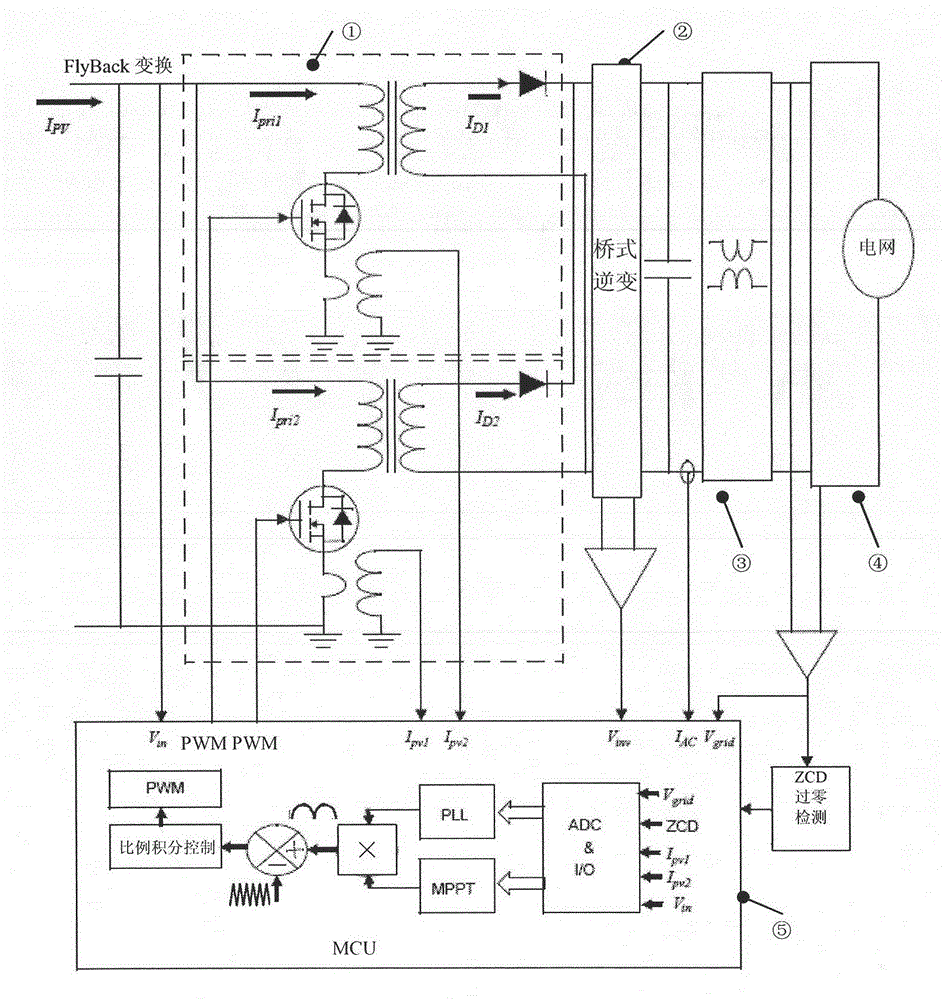

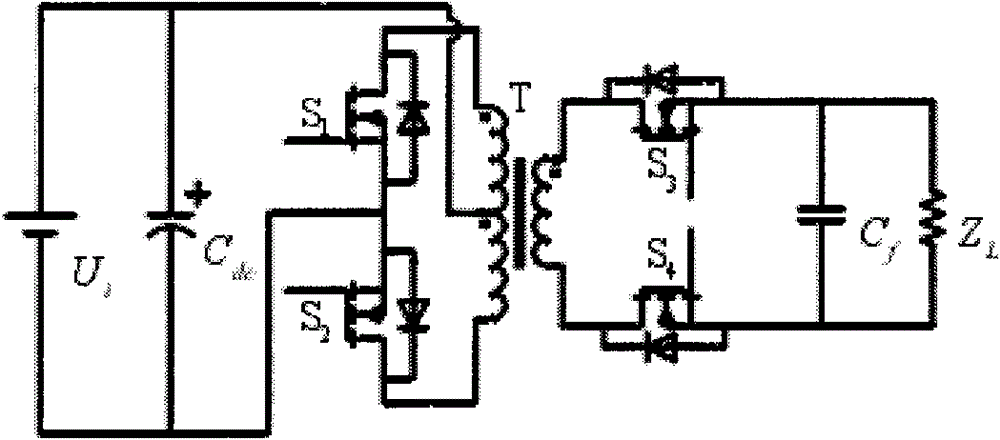

Photovoltaic grid-connected micro-inverter system

InactiveCN102801179AAdaptableLower Consistency RequirementsClimate change adaptationAc-dc conversionFailure rateHigh-voltage direct current

The invention relates to a photovoltaic grid-connected micro-inverter system. The input voltage and current of a single solar panel component are detected, a Flyback topological circuit structure is used for obtaining the maximum energy output of solar panels by utilizing a maximum power point tracking (MPPT) technology to design a 150 to 250W photovoltaic grid-connected micro-inverter, each solar panel is subjected to independent component inversion, and alternating current bus voltage is directly output, so that maximum power and maximum energy output can be obtained from each component, and the maximum energy conversion efficiency of the whole solar panel array can be achieved. A high-cost and highly-risky high-voltage direct current circuit is eliminated, and the influence of an independent defective component on the other components is avoided, so that the overall efficiency of the system cannot be remarkably reduced, and the shortcomings of the conventional centralized inverter are overcome. The system has the characteristics of low failure rate, high flexibility and convenience for maintenance, and is easy to mount.

Owner:HUAZHONG UNIV OF SCI & TECH

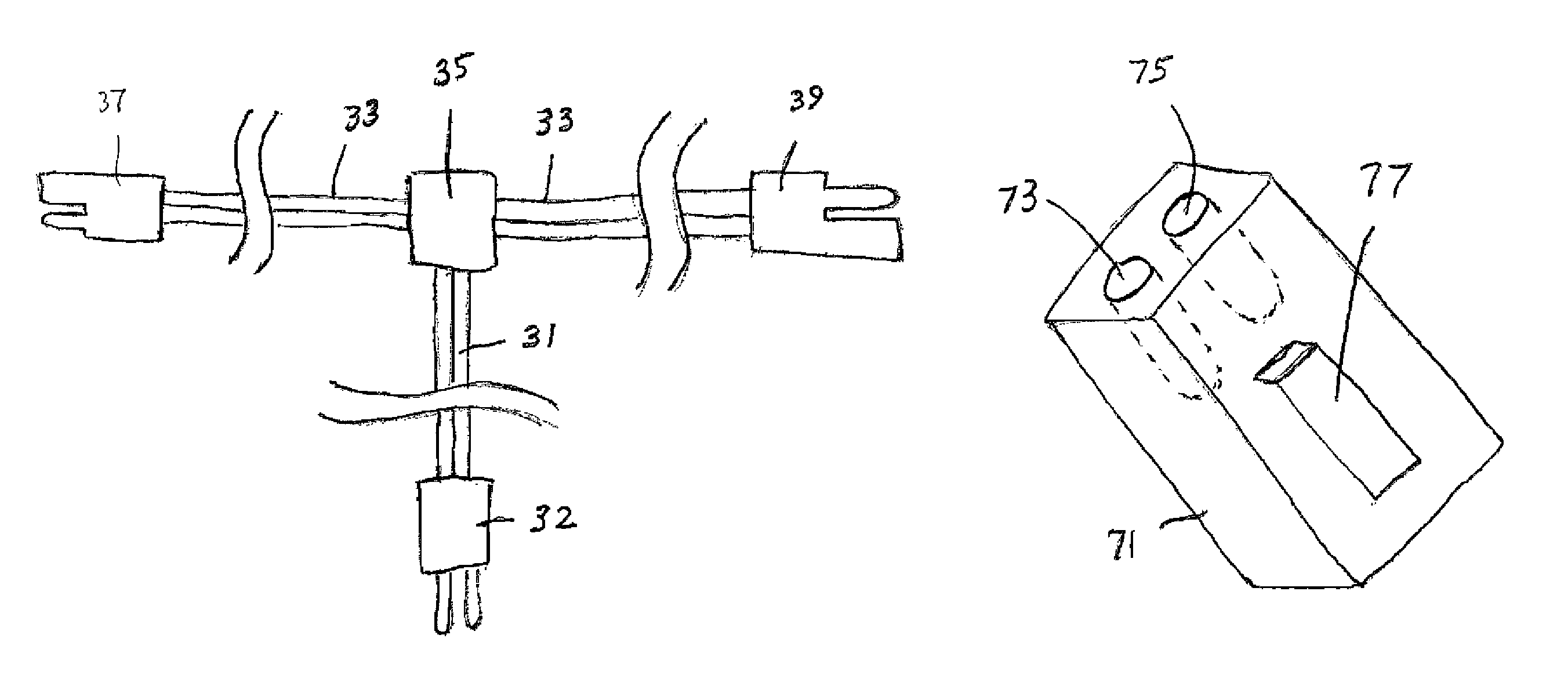

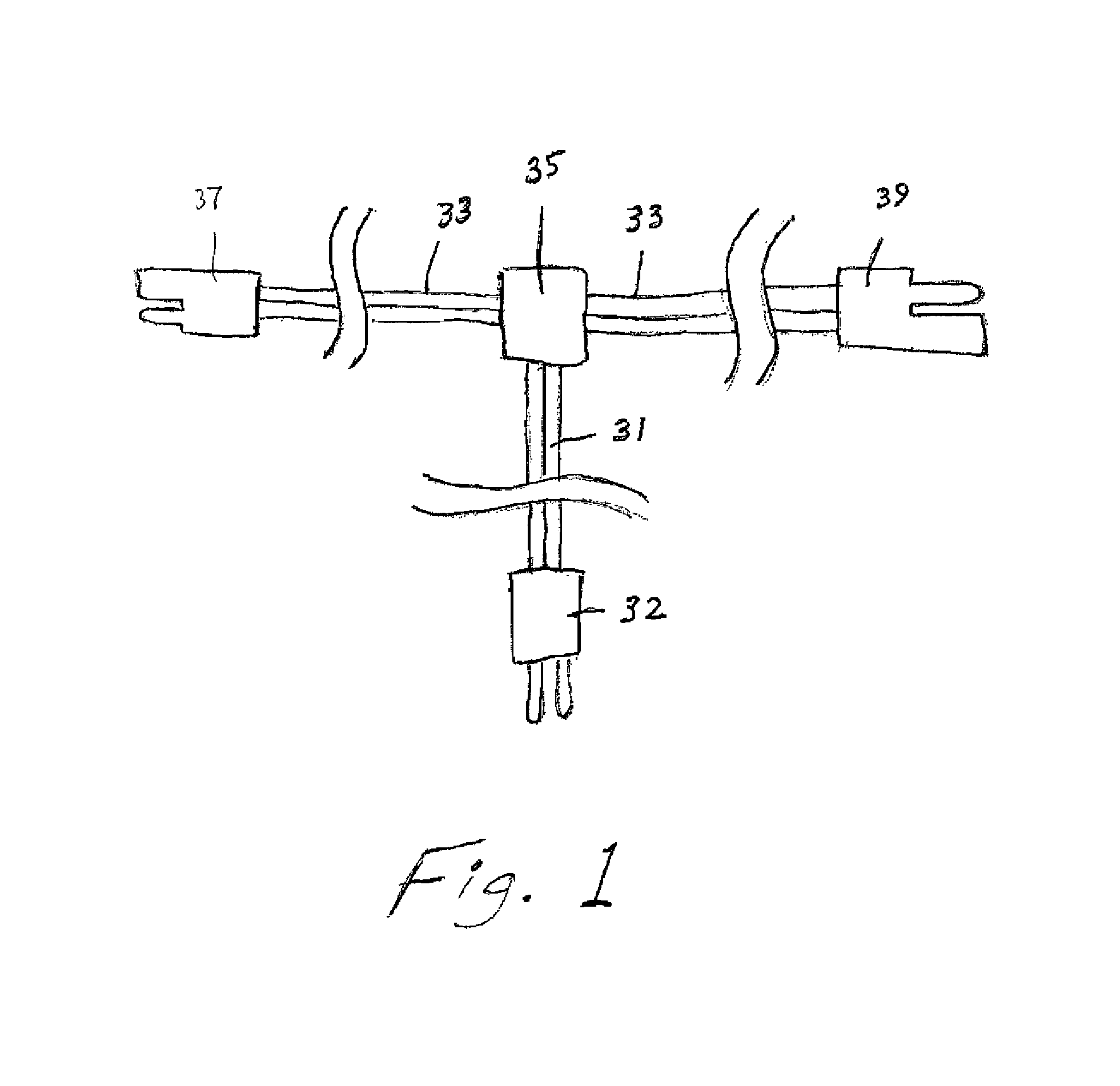

Wiring harness having interchangeable connectors

A low voltage lighting apparatus, and its novel components, for decks and railings stairs or steps, both outdoor and indoor. One aspect of the invention pertains to various wiring harness designs used to conveniently hook up the lighting apparatus. A wiring harness permits the easy swapping out of defective components such as burned out light bulbs, and is customizable in terms of size and shape. Another aspect of the invention pertains to arrangements for placing most of the wiring behind the steps of a staircase, and below the deck surface, or for otherwise concealing wiring that is in front of a step, or above the deck surface.

Owner:VANGUARD MFG

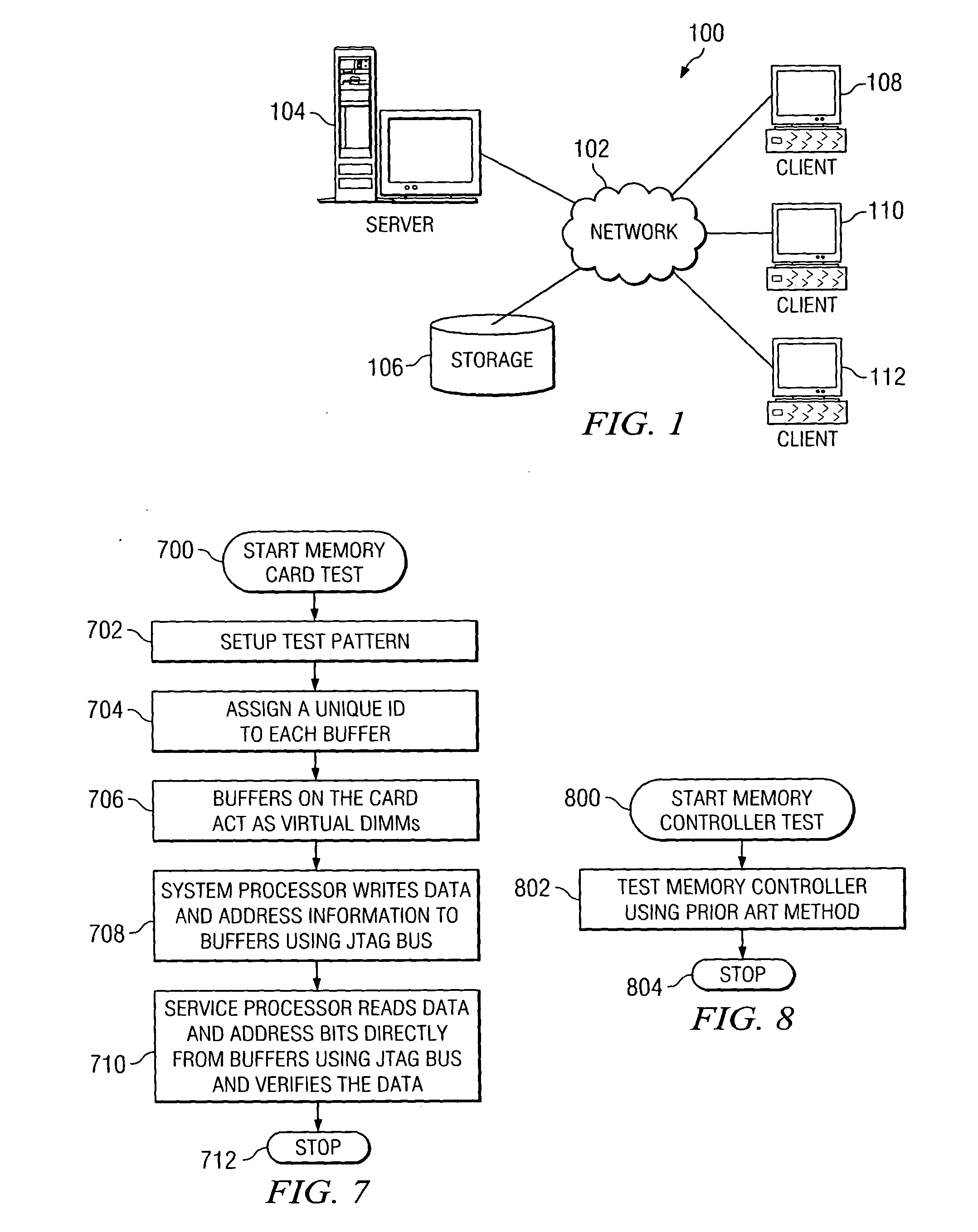

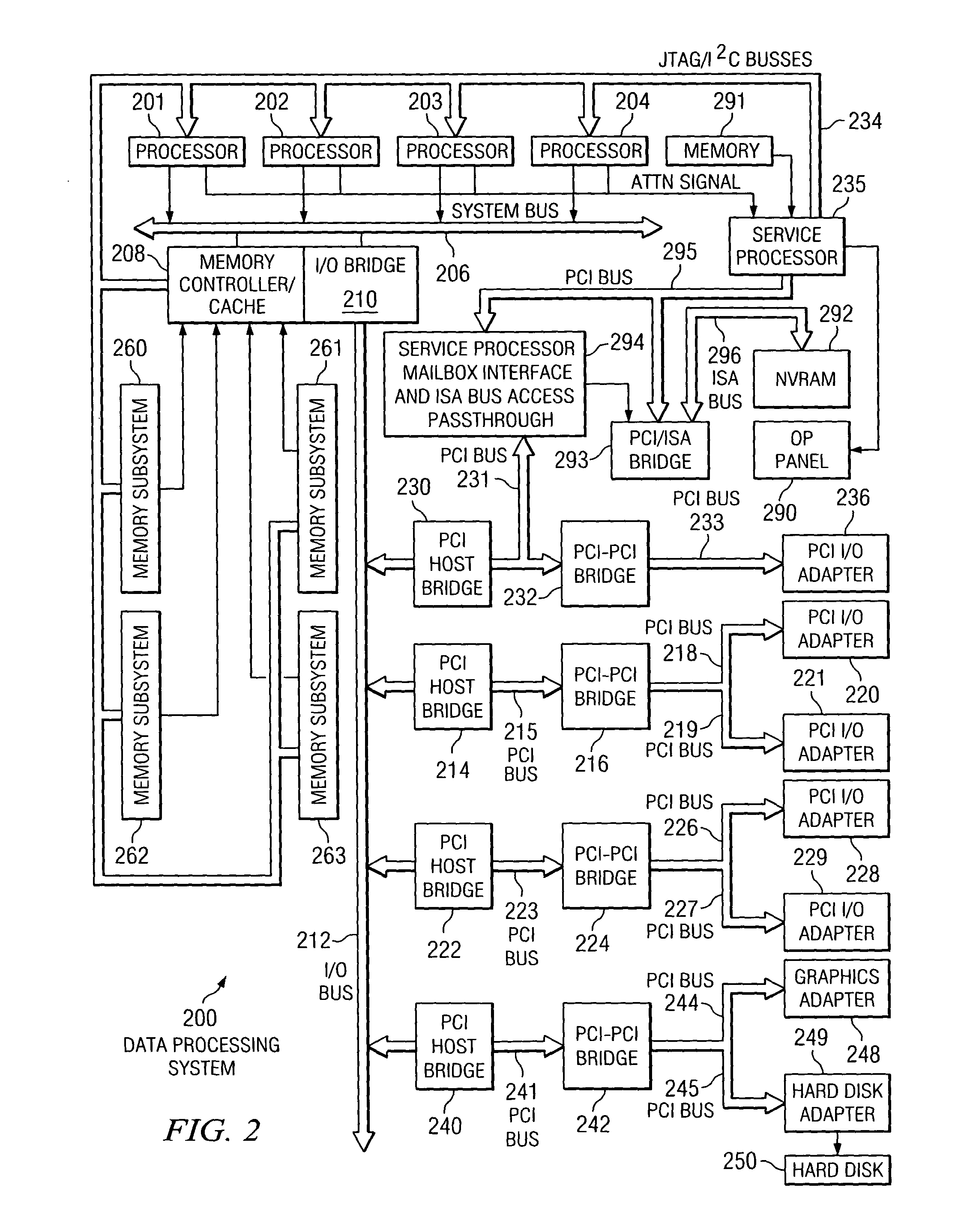

Method, system, and product for isolating memory system defects to a particular memory system component

InactiveUS20050060604A1Detecting faulty computer hardwareElectrical testingVirtual memoryControl store

A method, system, and product are disclosed for isolating a defect in a memory system by determining in which particular component of the memory system the defect exists. The memory system includes multiple components. The components include a physical memory module, a memory card to which the physical memory module is attached, and a memory controller for controlling the memory card. The memory card includes one or more electrical buffers for driving or detecting the memory signals. The buffers may be used as virtual memory elements. Each component is tested separately in order to identify the defective component with the help of virtual memory system elements. The components are tested by first testing the physical memory module. If the physical memory module passes the test, the memory card is then tested. If the memory card passes its test, the memory controller is tested.

Owner:IBM CORP

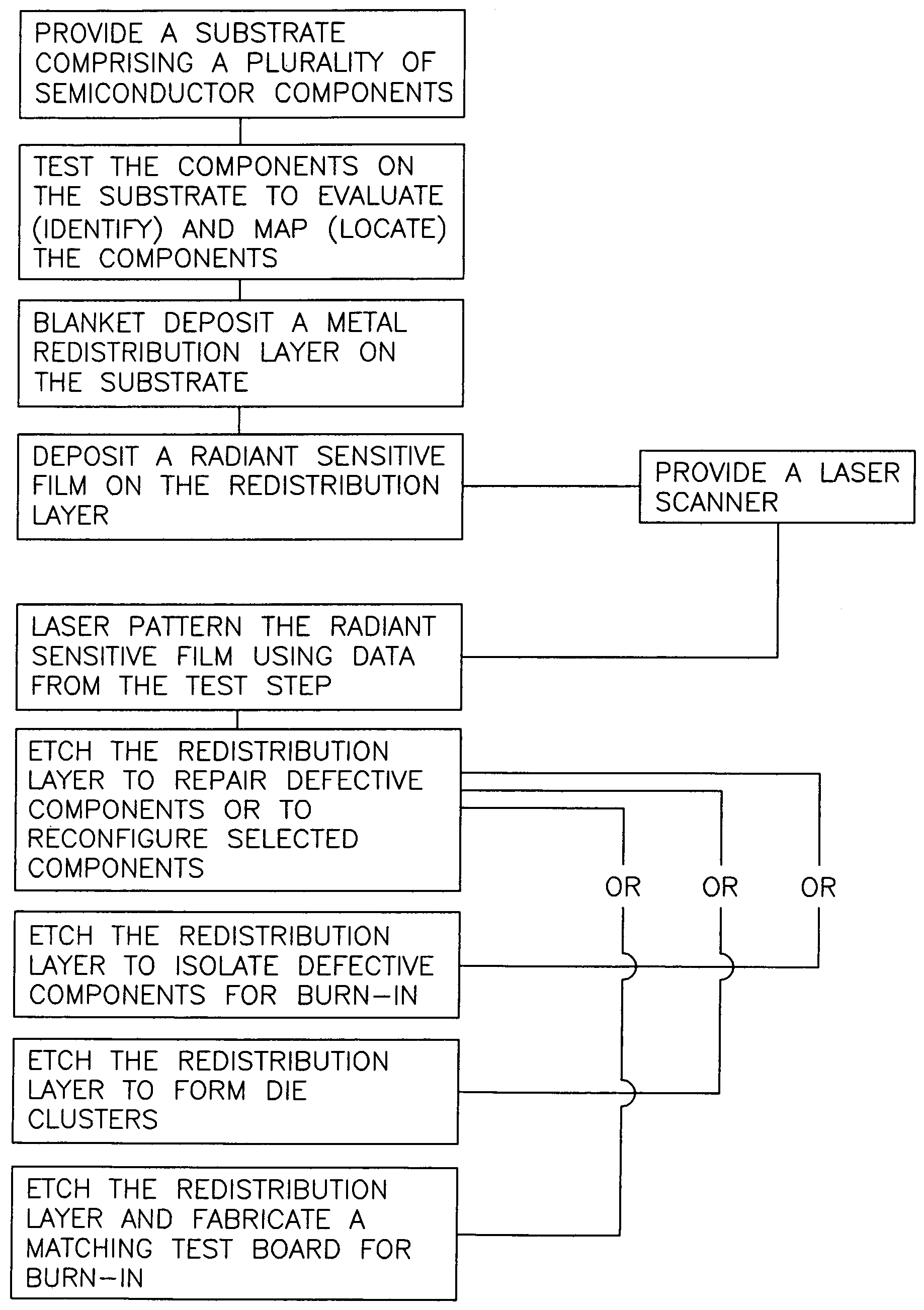

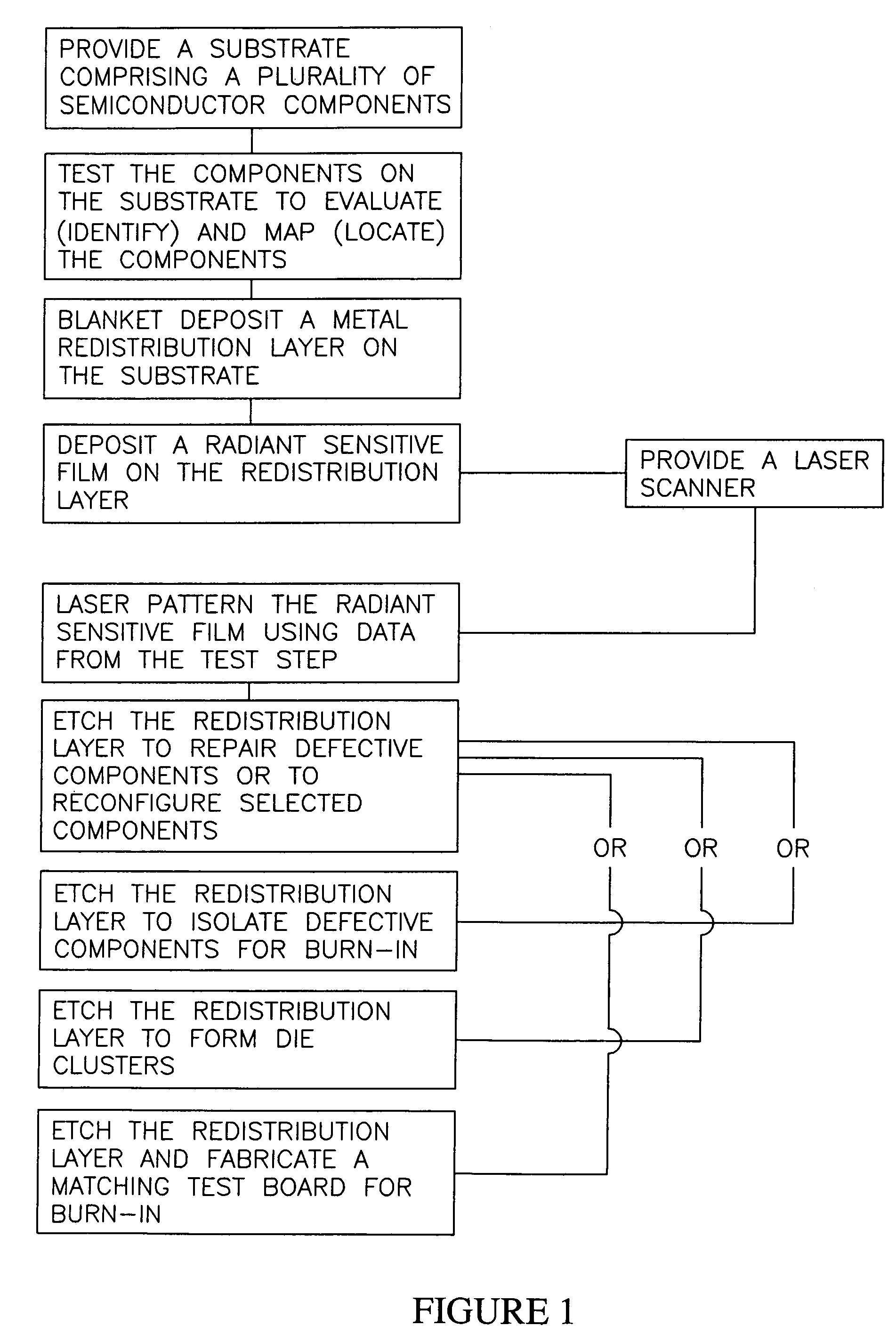

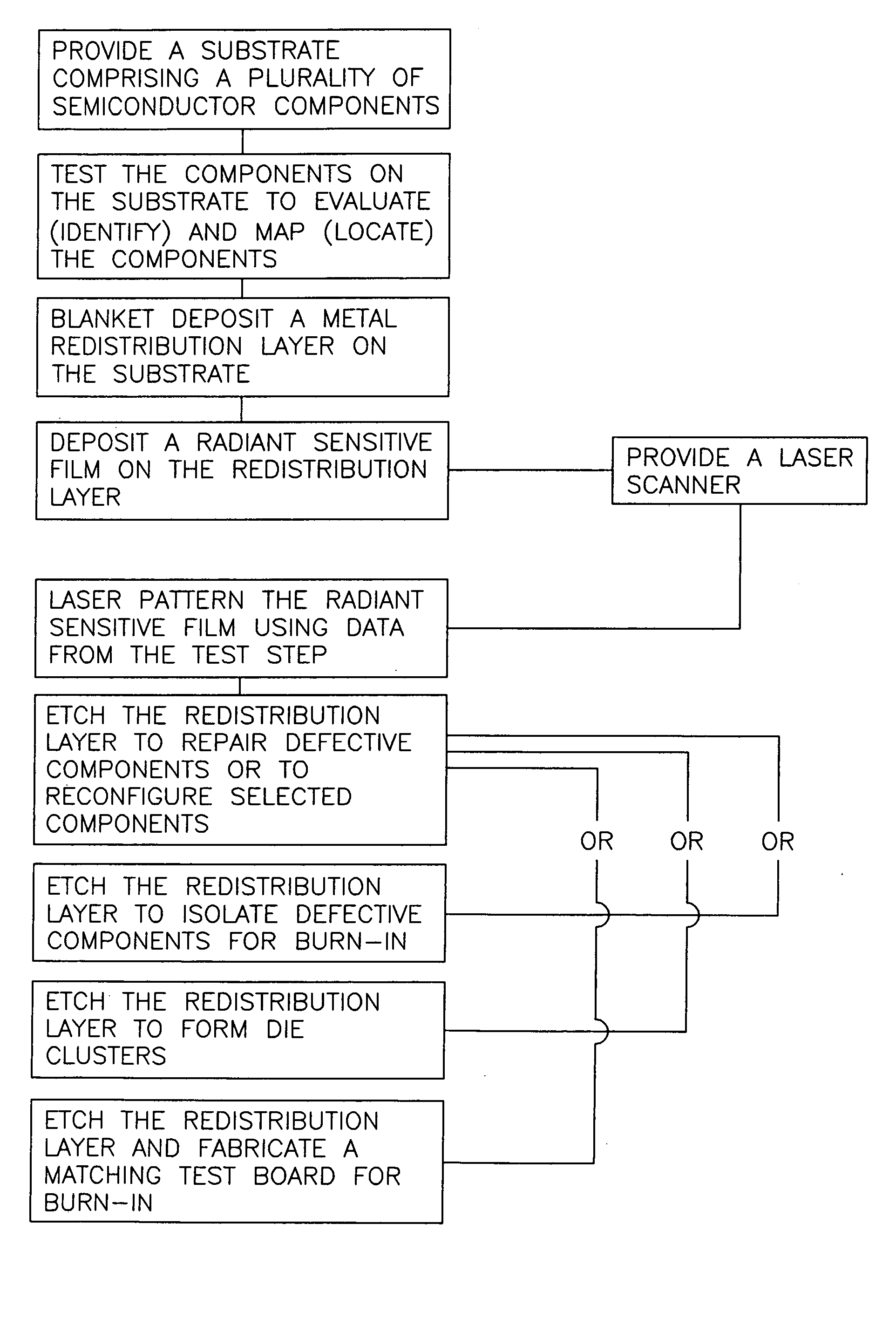

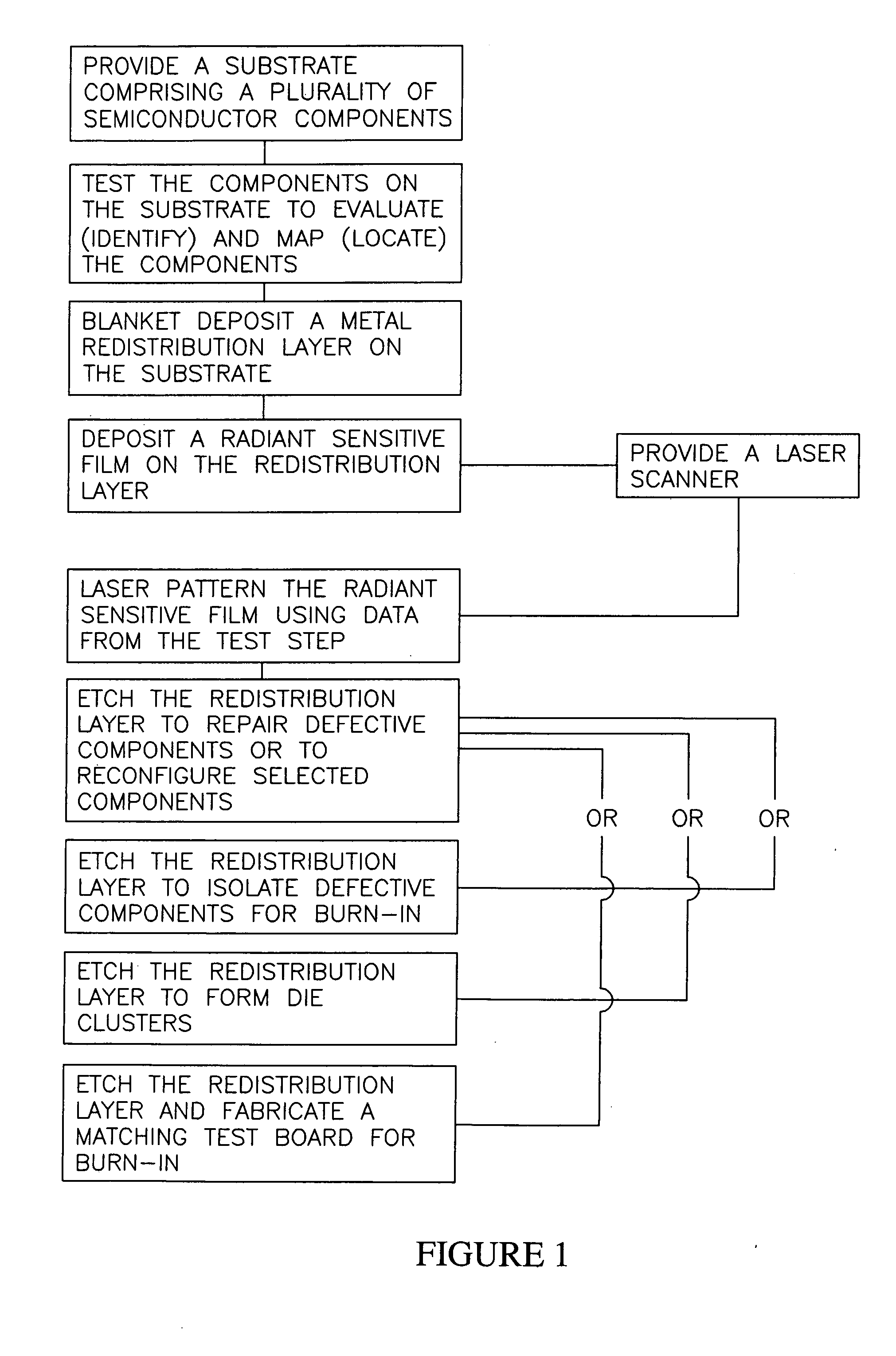

Semiconductor test board having laser patterned conductors

InactiveUS7049700B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMatching testElectrical conductor

A method for fabricating semiconductor components is performed using a laser scanner and a laser imaging process. A substrate, such as a semiconductor wafer, containing multiple semiconductor components, such as dice or packages, is provided. The components include integrated circuits, and component contacts in electrical communication with the integrated circuits. Initially, the components are tested to identify and locate good components and defective components on the substrate. Using data from the testing step and the laser scanner, patterns of conductors are then formed to either repair the defective components, to electrically isolate the defective components for burn-in, or to form component clusters containing only the good components. Alternately, using data from the testing step and the laser scanner, a matching test board can be fabricated, and used to electrically engage the good components, while the defective components remain isolated.

Owner:MICRON TECH INC

Electronic component handling device and defective component determination method

InactiveCN101069100ASemiconductor/solid-state device testing/measurementUsing optical meansElectronic componentComputer science

Owner:ADVANTEST CORP

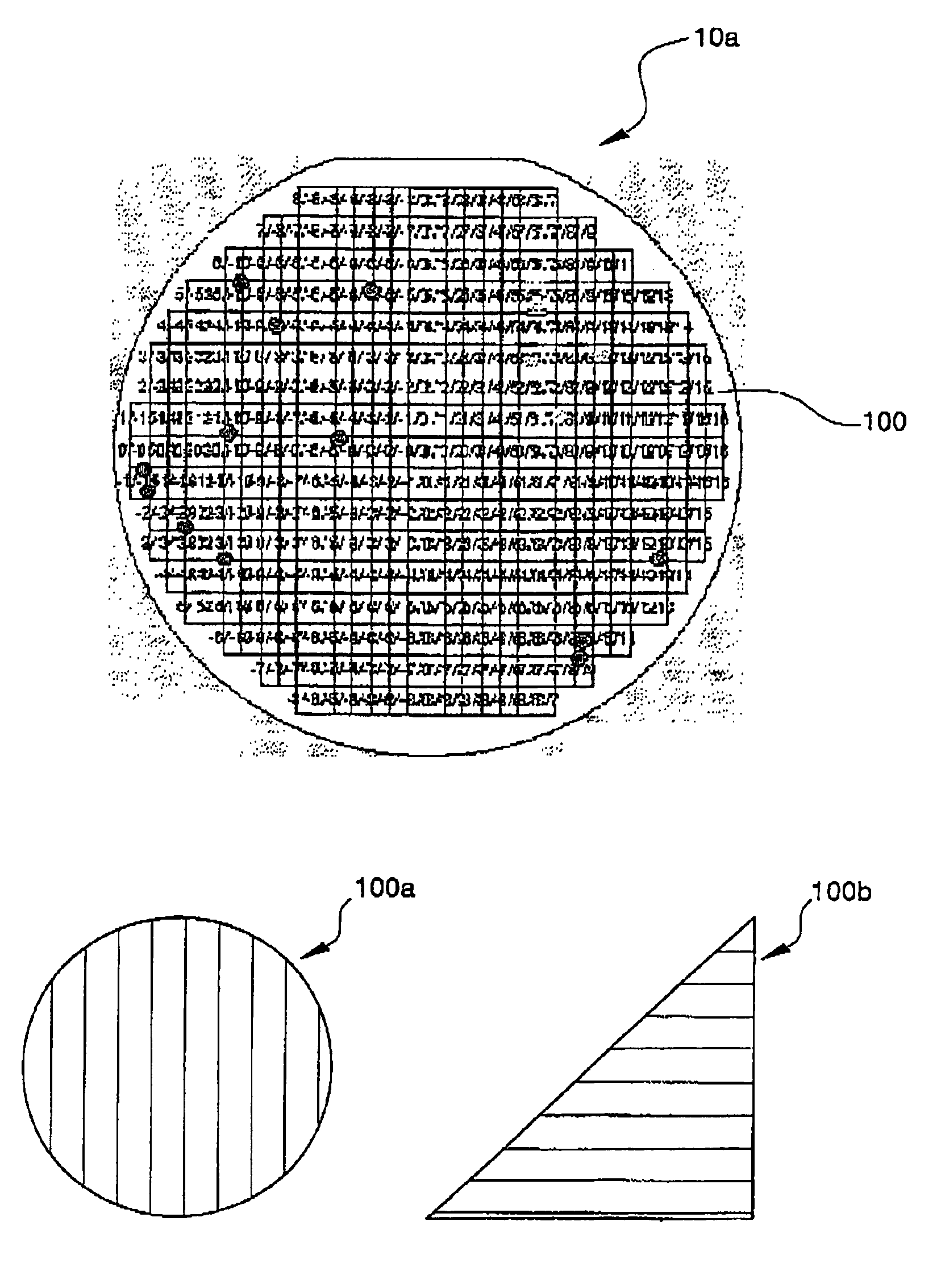

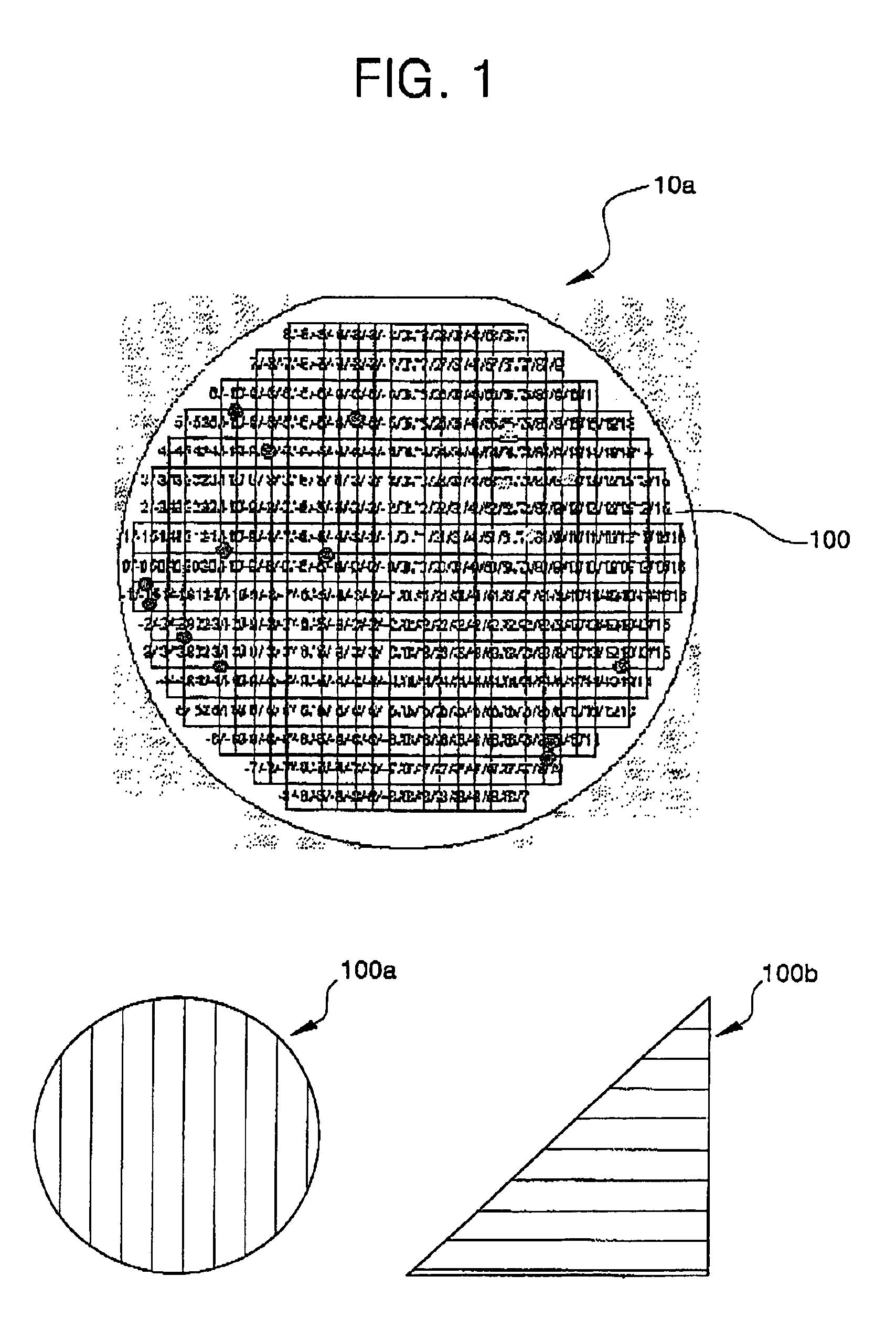

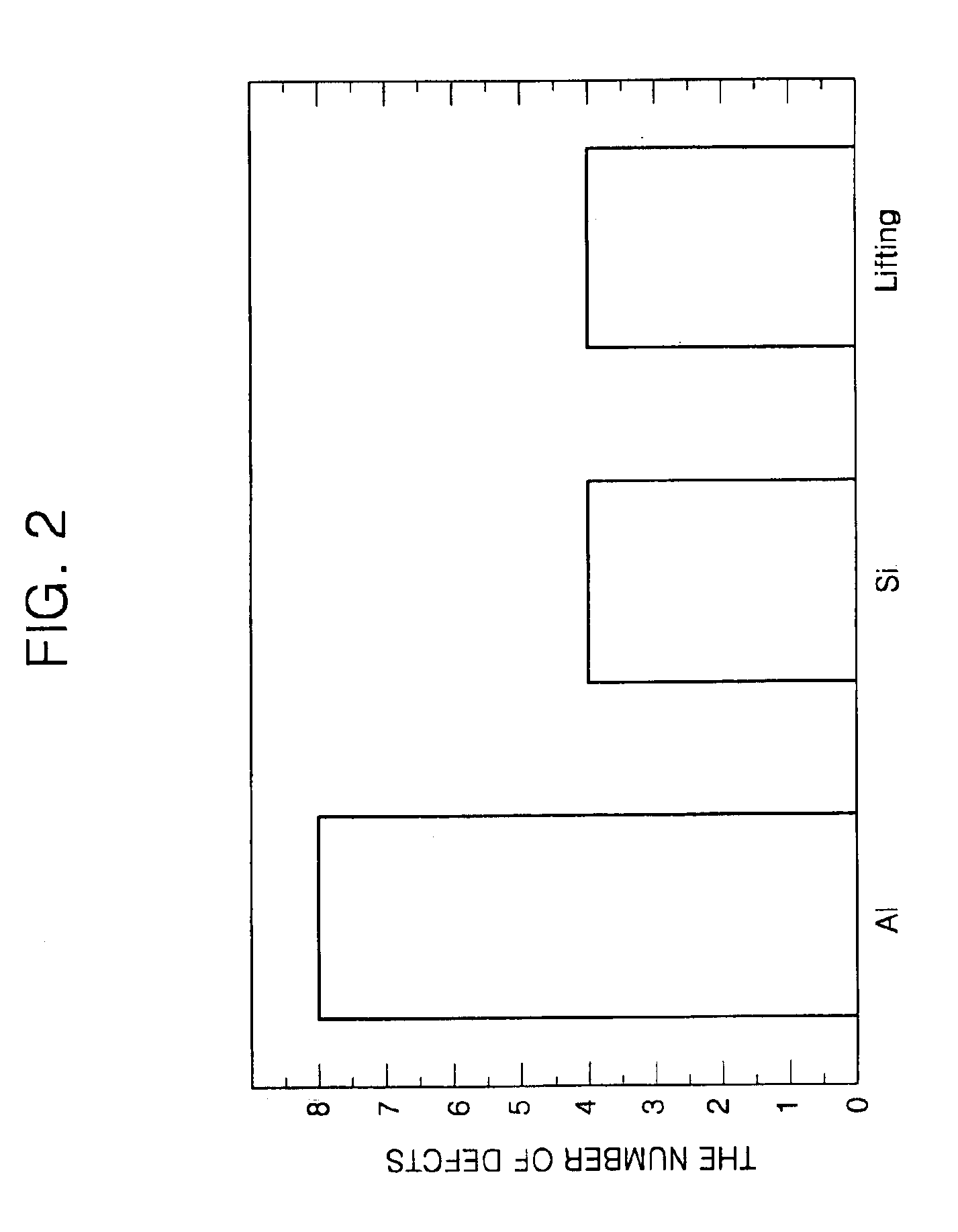

Method of identifying and analyzing semiconductor chip defects

InactiveUS7081769B2Easy mappingEasy to analyzeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsStatistical analysisSemiconductor chip

According to a preferred aspect of this invention, locations of defects on a semiconductor wafer are found using semiconductor defect inspection instrumentation. Defect composition can also be determined using inspection instrumentation. Wafer defects are represented on a wafer defect map using markings wherein locations of the markings on the map correspond to the locations of the defects on the wafer. The markings also preferably represent a defect type and / or composition. Color-coded dots, for instance, can be used to represent like defect causes or types with like colors. Graphs can be prepared to display defect characteristics using distributions and skews to facilitate quick statistical analysis of the defects. In this manner, wafer defects can be analyzed quickly and efficiently based on characteristics thereof, including, for example, defect type, composition, and cause. This information can be used to help prevent future defects during mass production, thereby improving yield.

Owner:SAMSUNG ELECTRONICS CO LTD

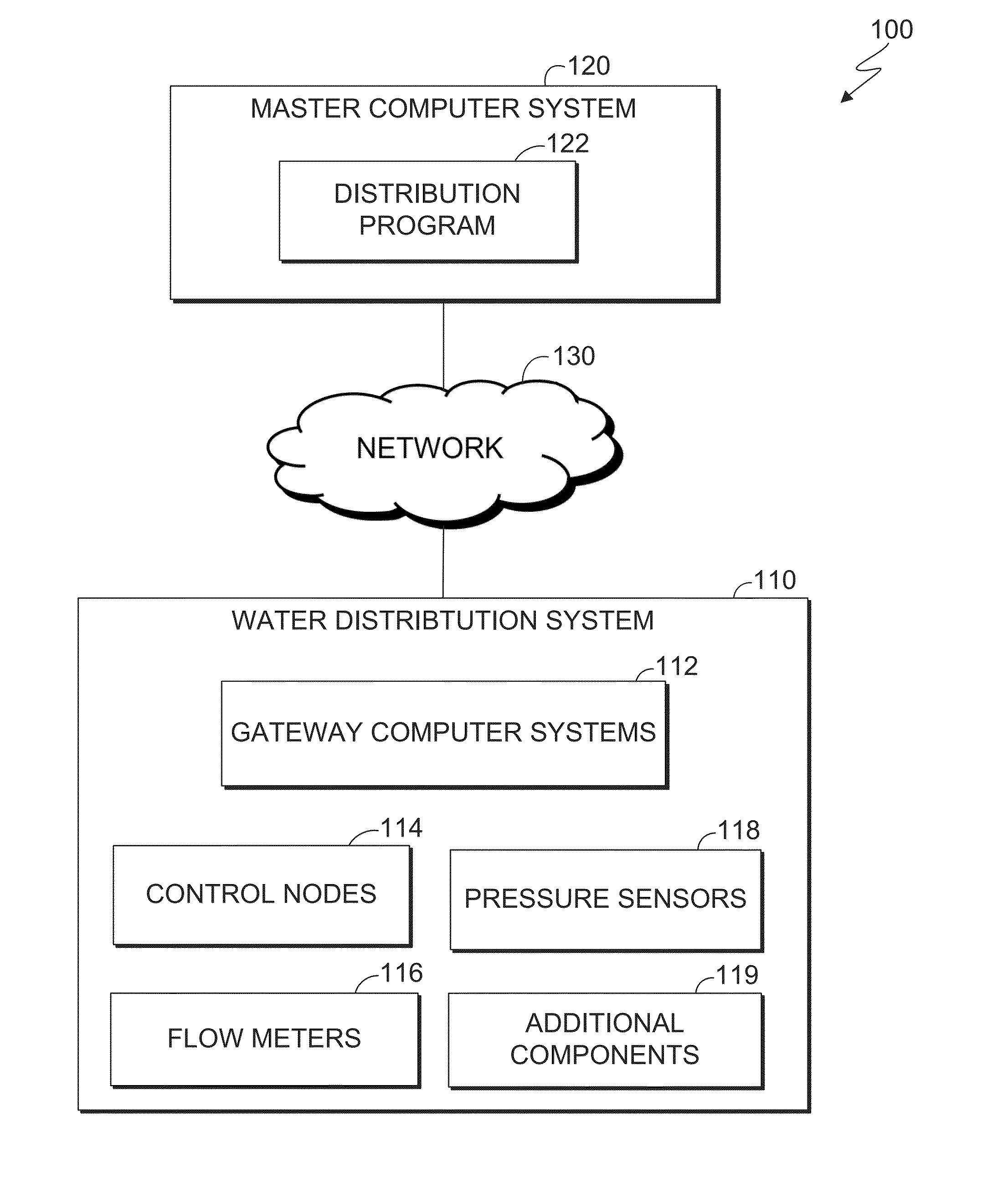

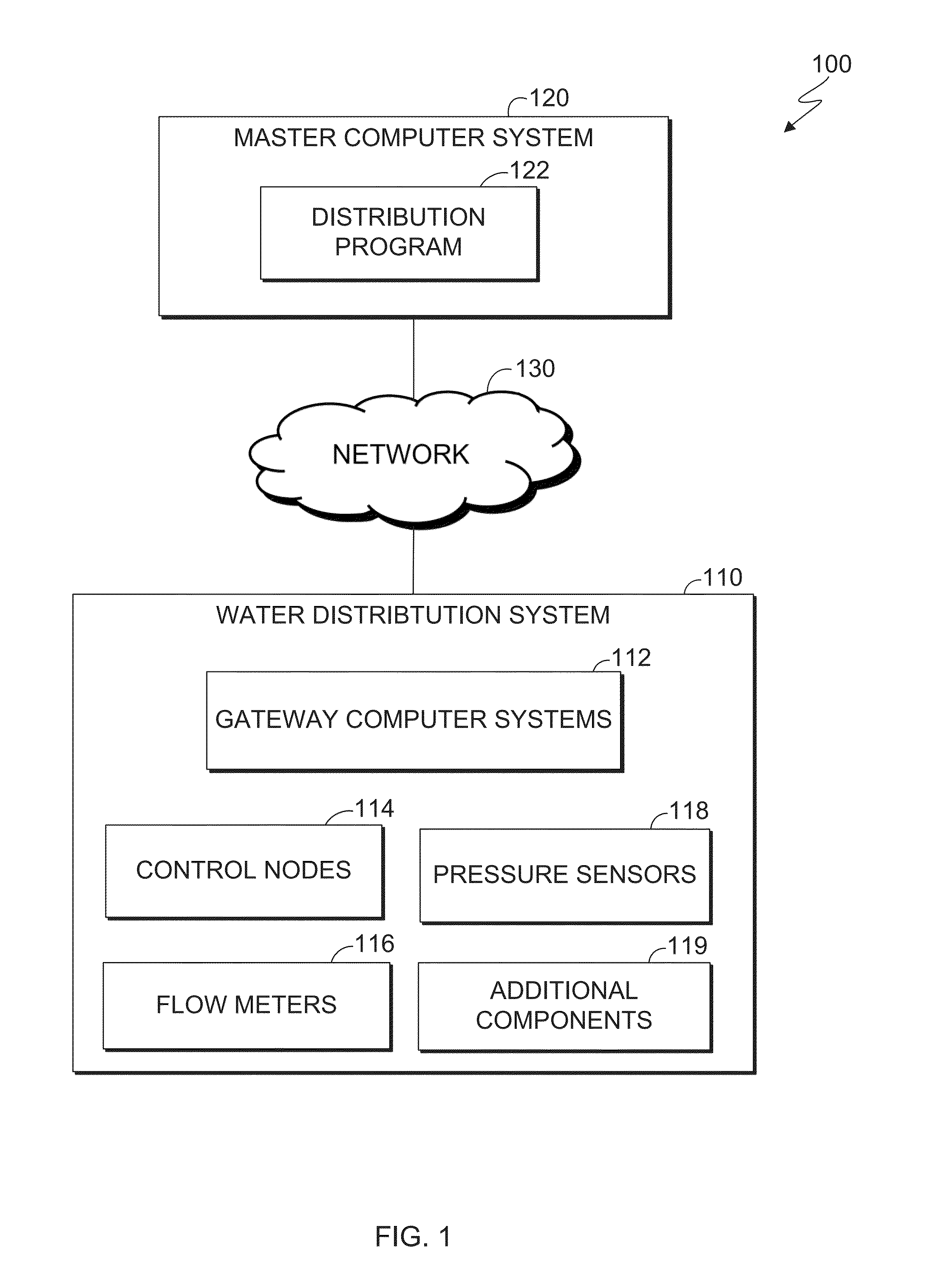

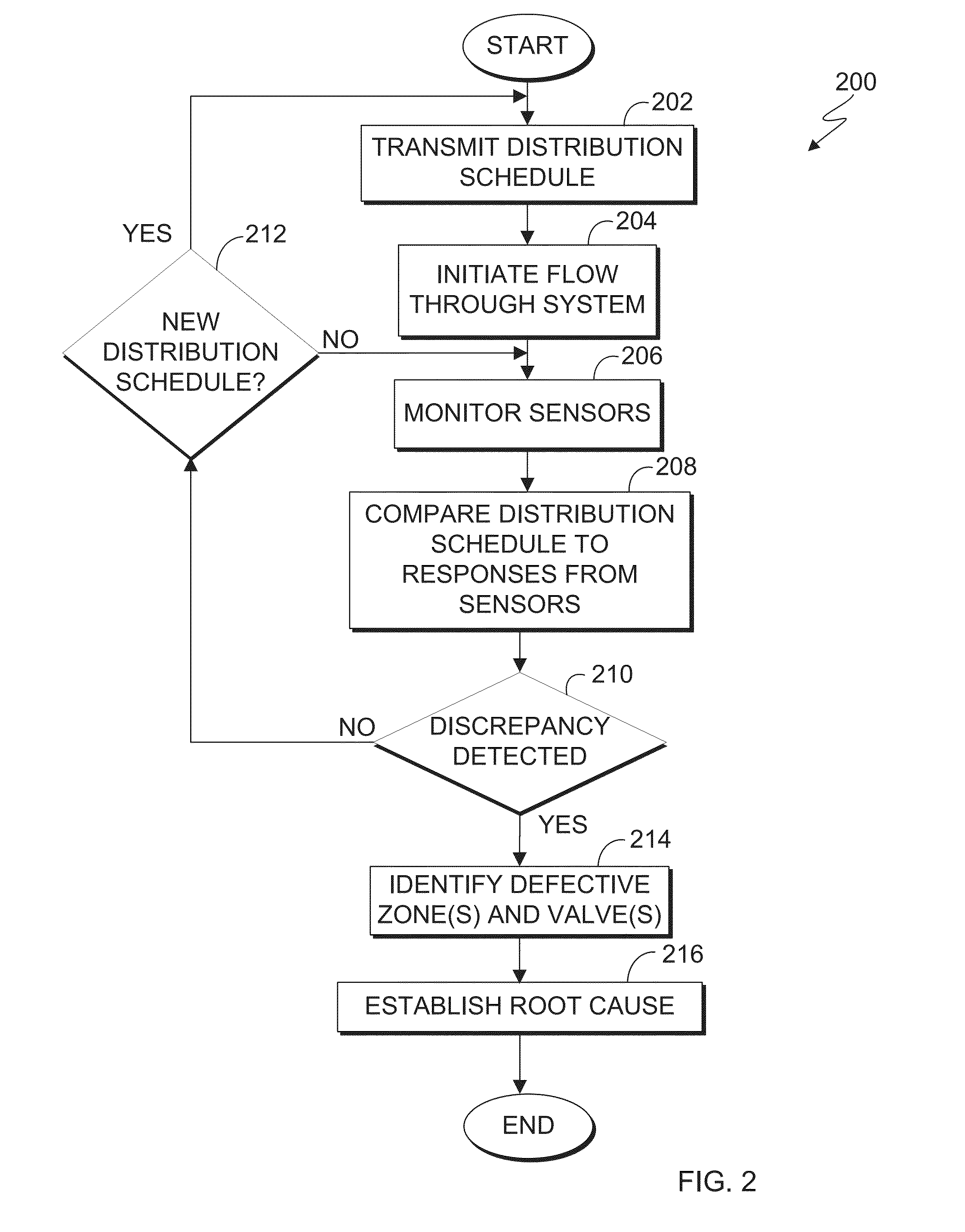

Remote diagnostics of water distribution systems

InactiveUS20160139607A1Water treatment parameter controlFlow control using electric meansDistribution systemComputer science

Embodiments of the present invention provide systems, methods, and computer program products for performing diagnostics on water distribution systems (e.g., automated drip-line irrigation systems). Embodiments of the present invention can afford users with the ability to identify defective components based on the diagnostics. Furthermore, embodiments of the present invention provide users with additional information in regard to potential causes and trends.

Owner:IBM CORP

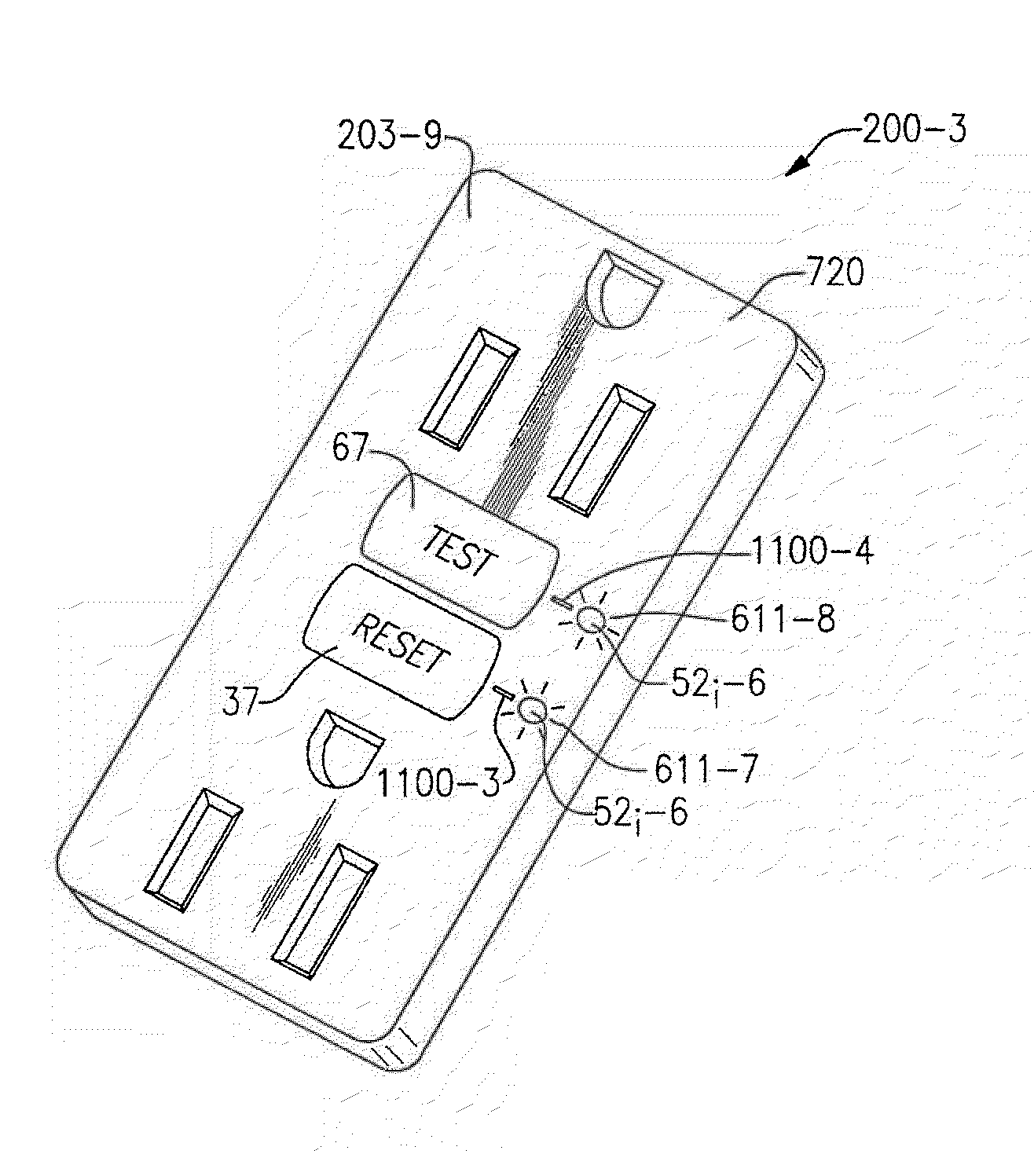

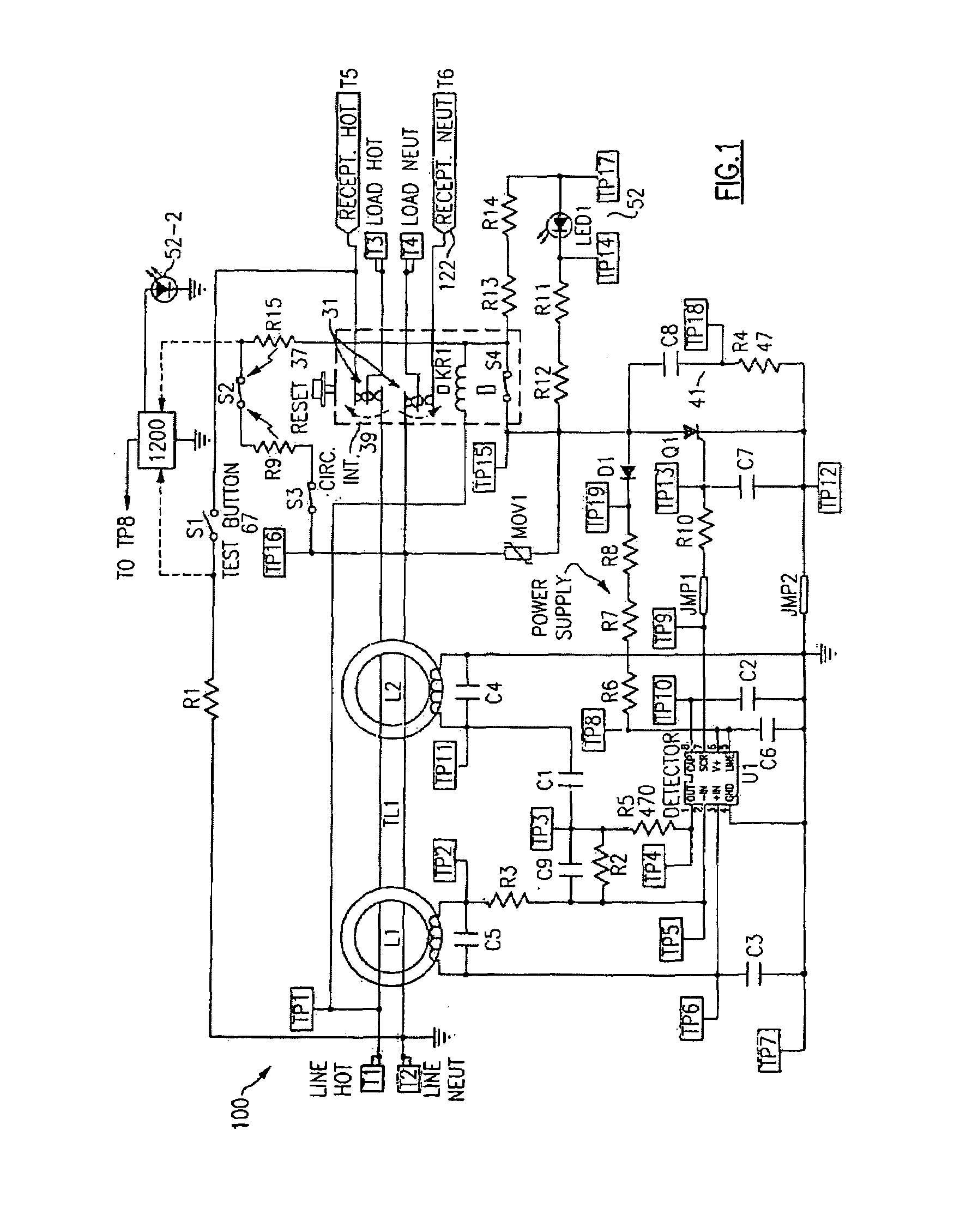

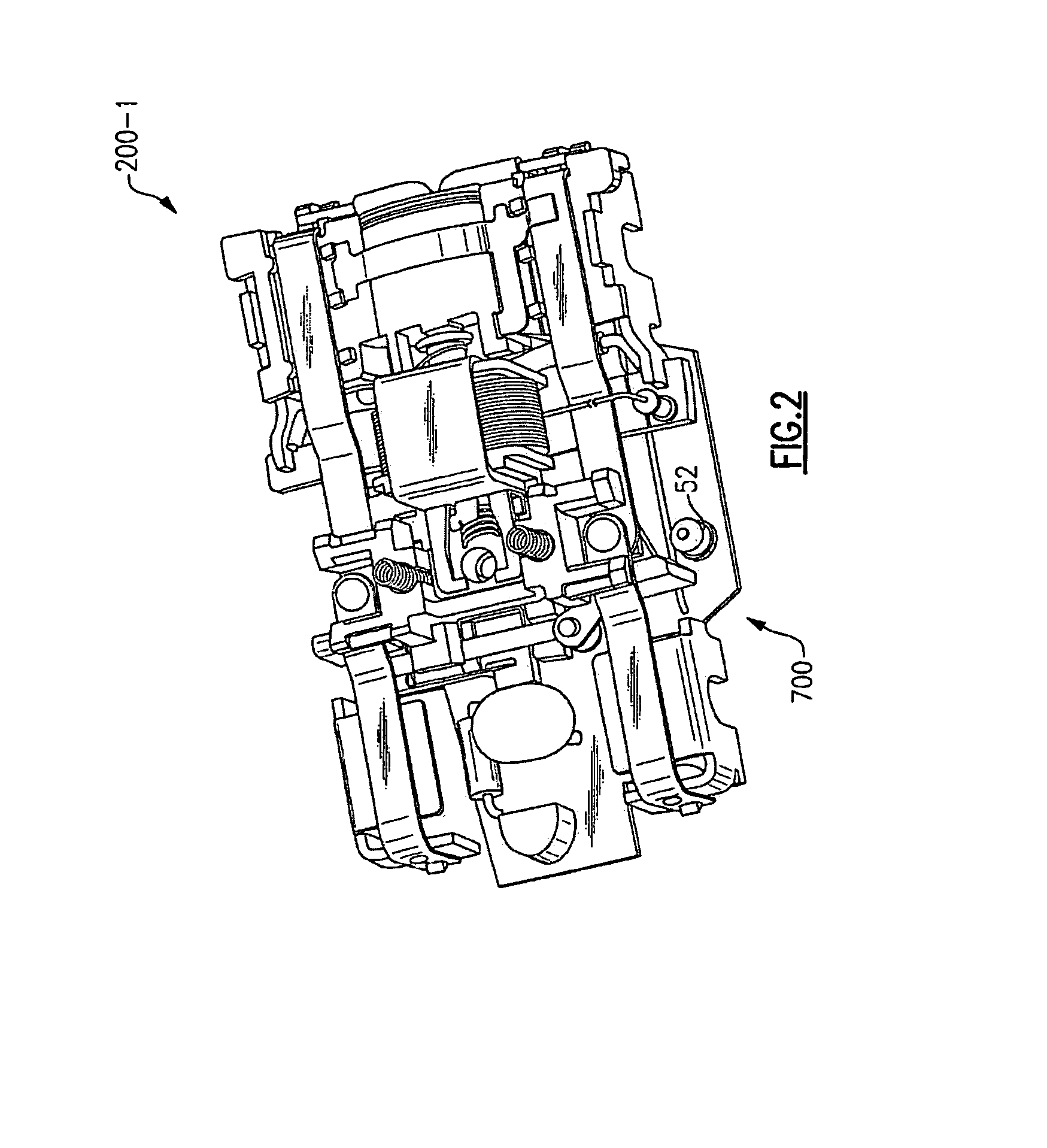

Electrical device with circuit status indicator

ActiveUS7672097B1Switch operated by earth fault currentsEmergency protective arrangements for automatic disconnectionStable stateElectrical control

An electrical control device including an electrical circuit, wherein the electrical circuit has a circuit protection component such as, e.g., a ground fault circuit interrupter (GFCI). The exemplary GFCI includes a TEST circuit activator and a RESET circuit activator, as well as a visual circuit status indicator indicia that is in an active (illuminated) state when the circuit is in a fault condition. The status indicator indicia is visually, physically, ergonomically or otherwise positively informatively associated with the TEST circuit activator and / or the RESET circuit activator. The positive informative association between the indicator indicia and the TEST circuit activator and / or the RESET circuit activator may be made by physical and / or visual boundaries or markings on a cover portion of the device or by integrally incorporating the indicia in the TEST circuit activator and / or the RESET circuit activator. The indicia may be a steady state or a blinking illumination. According to an aspect, a prompting indicator provides a prompting indicia for a user to activate the TEST circuit activator and / or the RESET circuit activator or replace a defective component of the device.

Owner:PASS SEYMOUR

Method and apparatus for troubleshooting noise/vibration issues of rotating components

ActiveUS7997140B2Vibration measurement in solidsMachine gearing/transmission testingFrequency spectrumEngineering

There is provided a method for troubleshooting noise / vibration issues of rotating components, the method comprising: receiving an audio signal of the rotating components in operation; generating a frequency spectrum corresponding to the audio signal; selecting a frequency νm in the frequency spectrum corresponding to a maximum amplitude; and comparing the frequency νm to a set of predetermined rotational speeds of the rotating components to find a match; thereby identifying a potentially defective component.

Owner:PRATT & WHITNEY CANADA CORP

Systems and methods for locating defective components of a circuit

ActiveUS8214172B2Shorten diagnostic timeImprove efficiencyResistance/reactance/impedenceNuclear monitoringComputer scienceDefective Component

Owner:NEC CORP

Wind turbine condition monitoring method and system

ActiveUS10288043B2Cost-effectiveImprove executionEngine fuctionsMachines/enginesSCADAHealth condition

The present application includes wind turbine condition monitoring method and system. The method includes: acquiring historical SCADA data, and wind turbine reports corresponding to the historical SCADA data; training an overall model for overall diagnosing the wind turbine, and training different individual models for analyzing different components of the wind turbine based on the historical SCADA data and the corresponding wind turbine report, by establishing relationship between the historical SCADA data and the wind turbine report; acquiring real time SCADA data, inputting the real time SCADA data to the trained overall model, obtaining the health condition of the wind turbine from the trained overall model, and performing individual diagnosing step if the trained overall model determines wind turbine as defective status; inputting the real time SCADA data to the trained individual model corresponding to the defective component, and obtaining the fault details of the defective component from the trained individual model corresponding to the defective component.

Owner:HITACHI ENERGY SWITZERLAND AG

Semiconductor test board having laser patterned conductors

InactiveUS20050084986A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMatching testElectrical conductor

A method for fabricating semiconductor components is performed using a laser scanner and a laser imaging process. A substrate, such as a semiconductor wafer, containing multiple semiconductor components, such as dice or packages, is provided. The components include integrated circuits, and component contacts in electrical communication with the integrated circuits. Initially, the components are tested to identify and locate good components and defective components on the substrate. Using data from the testing step and the laser scanner, patterns of conductors are then formed to either repair the defective components, to electrically isolate the defective components for burn-in, or to form component clusters containing only the good components. Alternately, using data from the testing step and the laser scanner, a matching test board can be fabricated, and used to electrically engage the good components, while the defective components remain isolated.

Owner:MICRON TECH INC

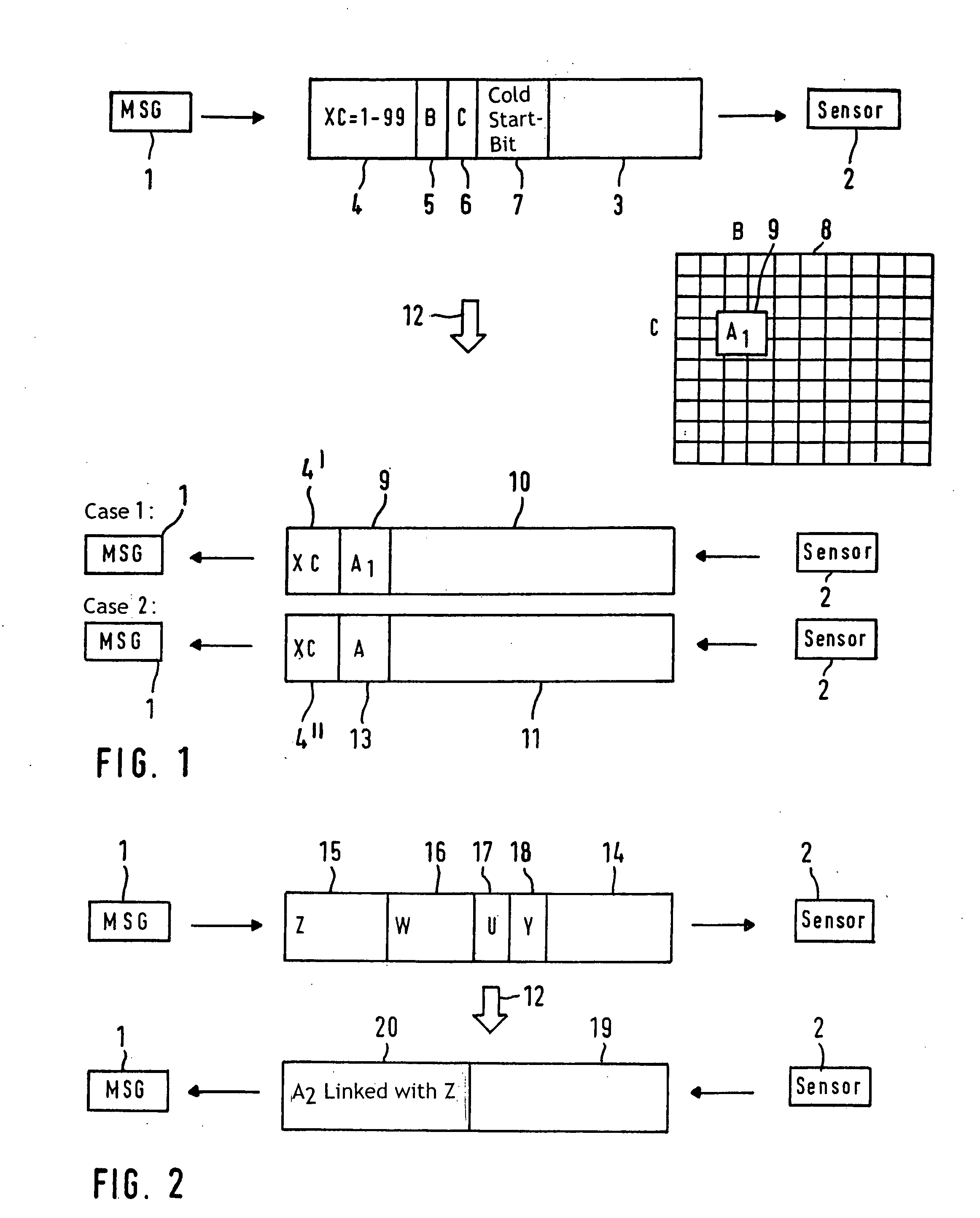

Process for detecting defective component exchanges

ActiveUS20050125655A1Safety arrangmentsDigital data processing detailsComputer hardwareComputer science

Method of detecting an unauthorized exchange of components in the case of a technical system, where the control unit (1) sends an encoded message (3) to a component (2) to be checked, in a data field of the message (3) a randomly generated or not easily reproducible value (5, 6) being entered, which is used for checking the installed component (2). The component (2) accesses an assignment field (8) and, as a result, assigns an identification (9) to each not easily reproducible or random value (5, 6) transmitted together with the message (3), and the component (2) transmits the identification corresponding to the value (5, 6) back to the control unit (1). The control unit (1) decides on the basis of the identification (9) whether the component (2) is that the component (2) which is authorized for use in the particular technical system.

Owner:DAIMLER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com