Reinforcement method for fiber reinforced composite plastic and concrete

A fiber-reinforced composite and concrete technology, which is applied in the field of composite materials and building materials, can solve the problems of accelerating FRP peeling, affecting structural durability, and low grouting pressure, so as to expand the application range, optimize the force form, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

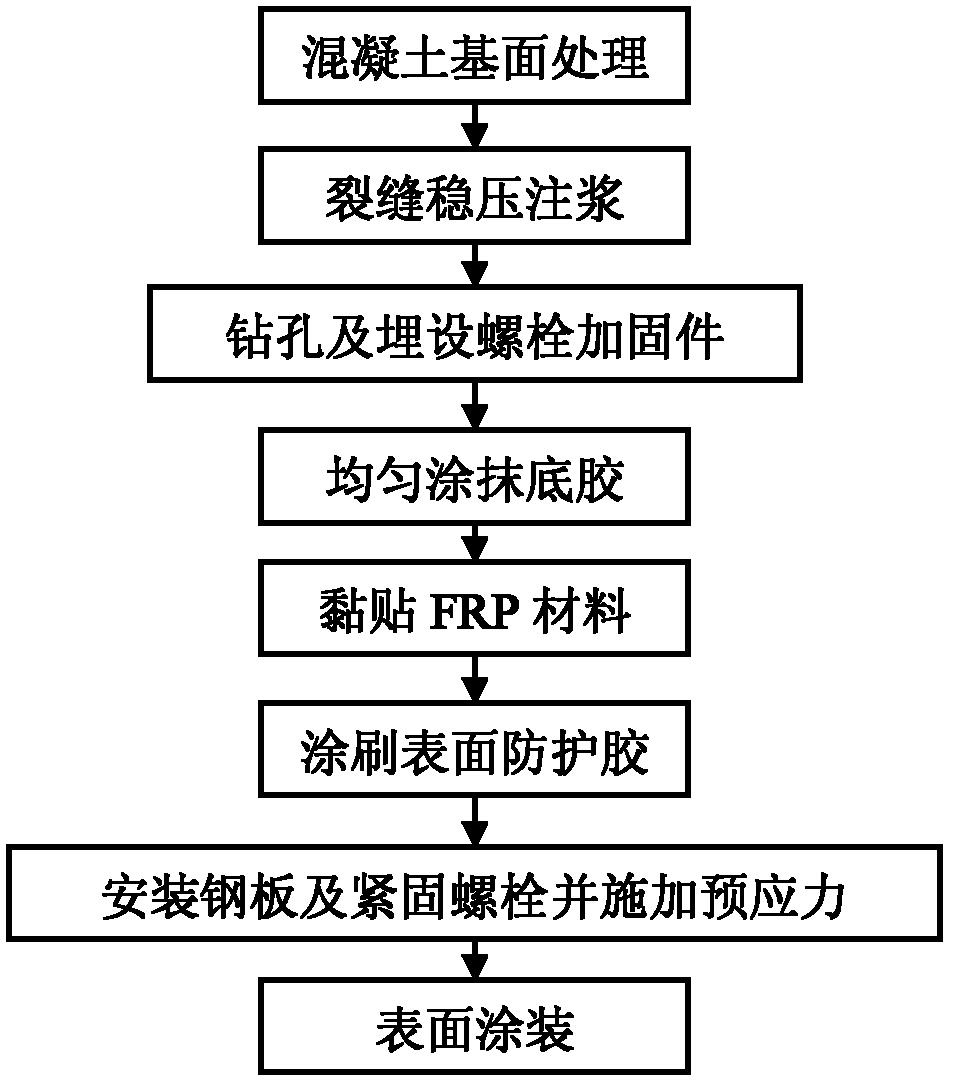

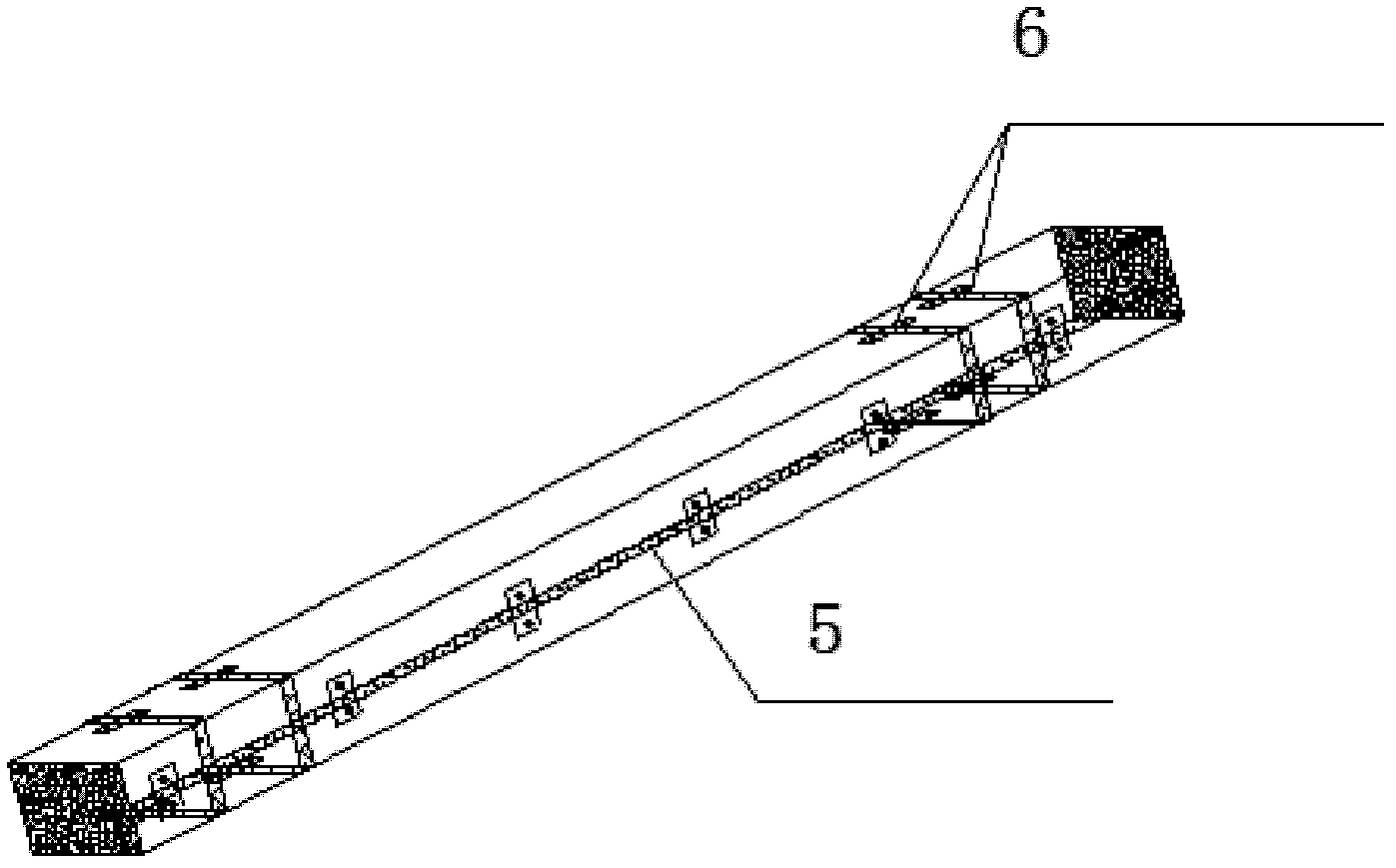

[0044] A reinforcement method between FRP material and concrete, the steps are as follows:

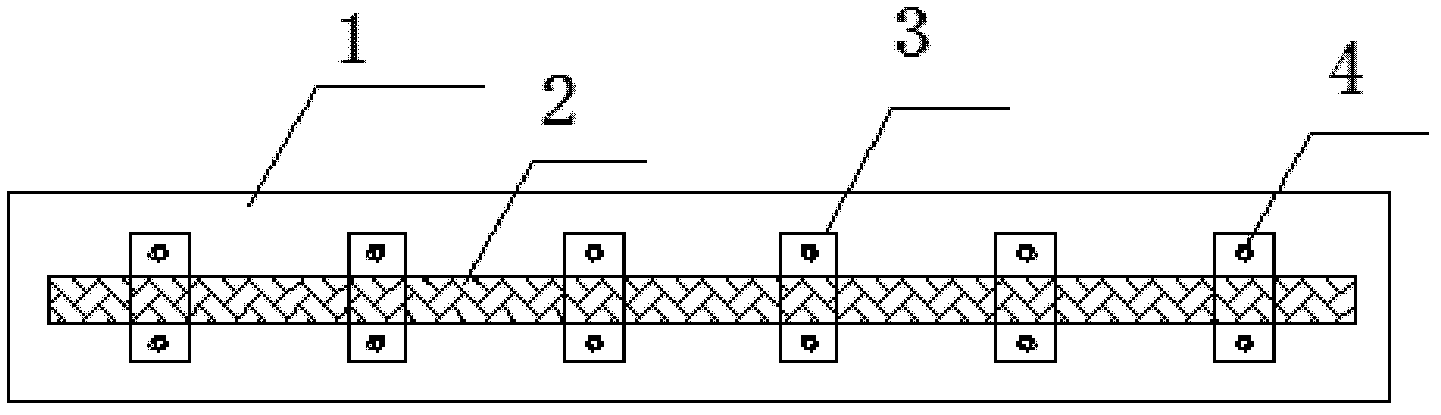

[0045] (1) Concrete base surface treatment

[0046] ① Use a wire wheel or an angle grinder to remove the degraded layer of the surface of the concrete 1 (peeling, honeycomb, laitance, cement foaming due to corrosion or weathering, mold release glue) along the FRP design adhesion position and crack direction (5cm wide range) Layer, loose concrete debris, asphalt, etc.), and blow it with an air compressor to expose a clean, solid surface. After cleaning off the dust and loose scum on the base surface, clean the base surface with water or blow it with a hair dryer to ensure that the base surface is clean, free of oil and fully dry.

[0047] ②For the phenomenon of concrete 1 cracking, looseness, and corrosion of steel bars, first remove the loose parts, manually derust the corroded steel bars, and then use epoxy resin for anticorrosion treatment, and use epoxy resin cement as a leveling material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com