Patents

Literature

117results about How to "Increase heat input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

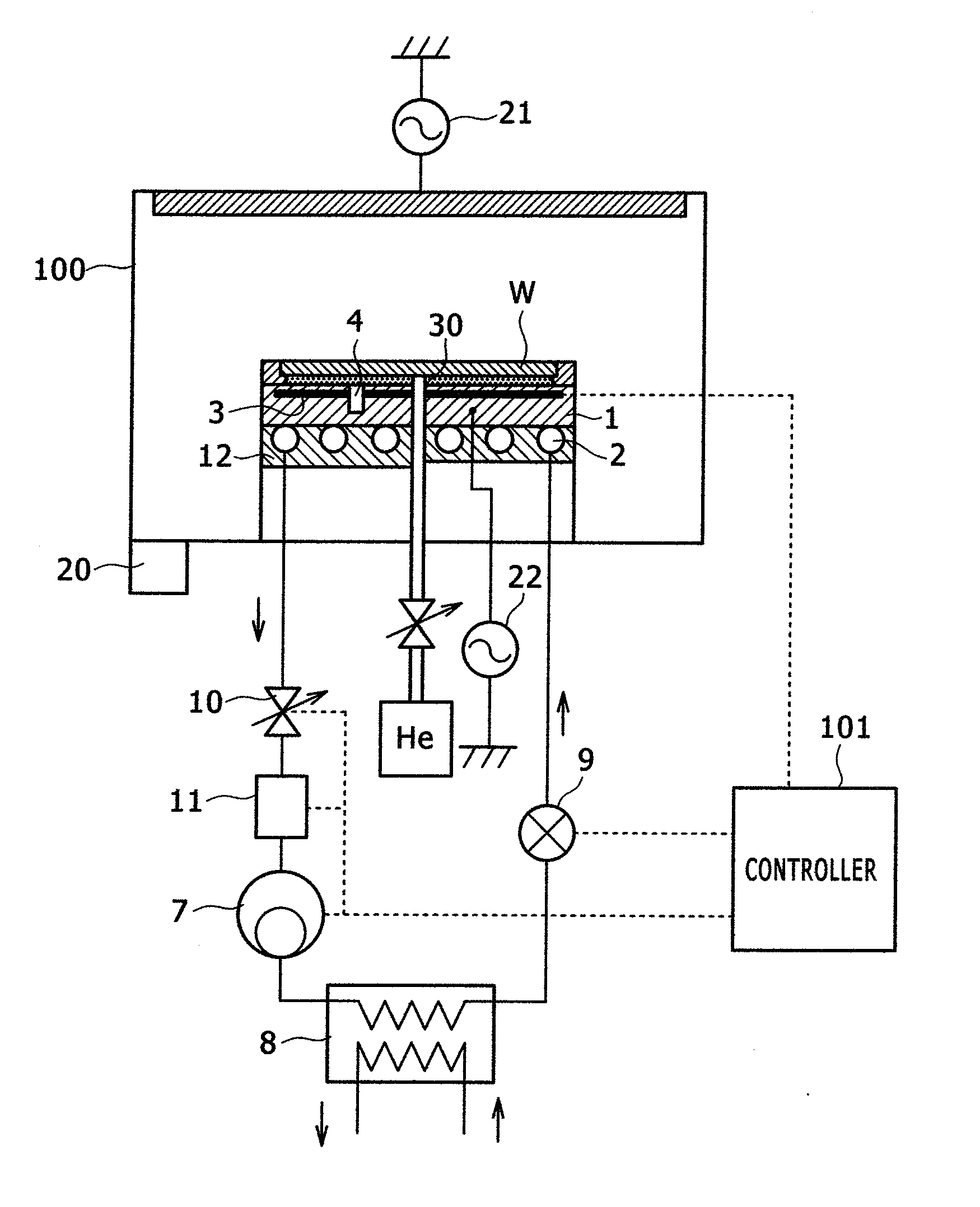

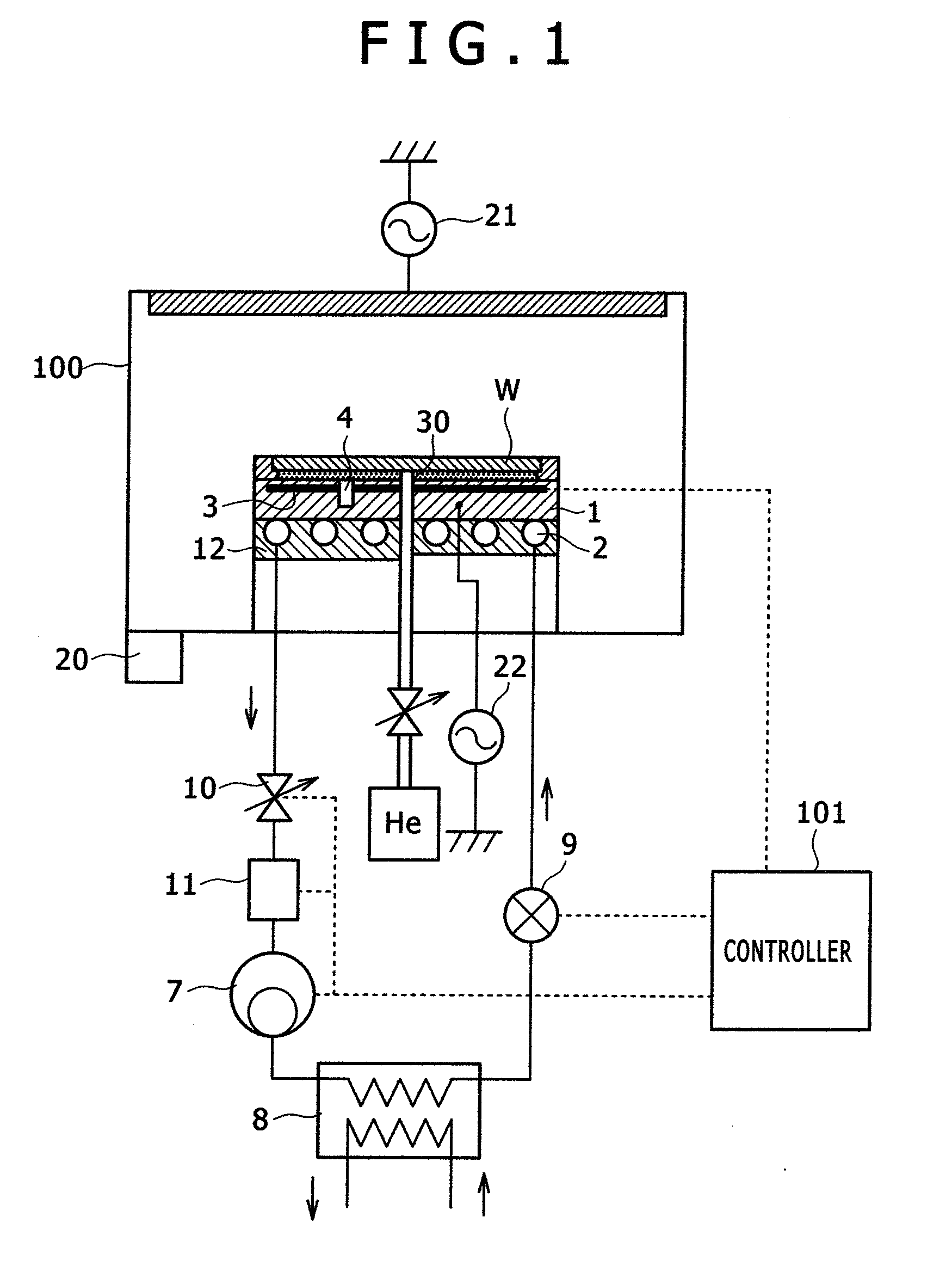

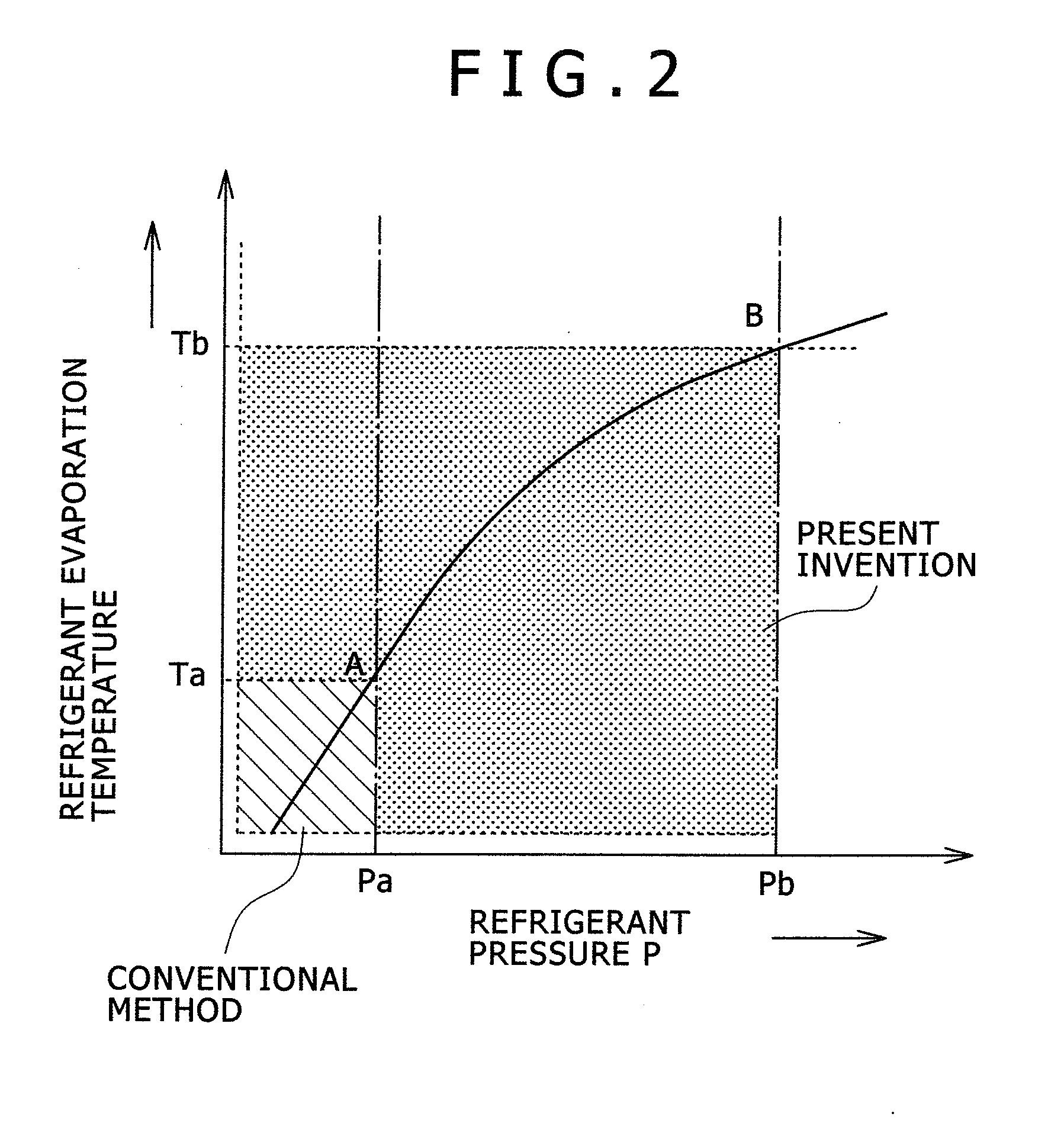

Plasma processing apparatus

ActiveUS20080289767A1High bias powerWide temperature rangeMechanical apparatusDomestic cooling apparatusIn planeEtching

The present invention provides a temperature control unit for an electrostatic adsorption electrode that is capable of controlling the wafer temperature rapidly over a wide temperature range without affecting in-plane uniformity while high heat input etching is conducted with high wafer bias power applied. A refrigerant flow path provided in the electrostatic adsorption electrode serves as an evaporator. The refrigerant flow path is connected to a compressor, a condenser, and a first expansion valve to form a direct expansion type refrigeration cycle. A second expansion valve is installed between the electrostatic adsorption electrode and the compressor to adjust the flow rate of a refrigerant. This makes it possible to compress the refrigerant in the refrigerant flow path of the electrostatic adsorption electrode and adjust the wafer temperature to a high level by raising the refrigerant evaporation temperature. Further, a thin-walled cylindrical refrigerant flow path is employed so that the thin-walled cylinder is deformed only slightly by the refrigerant pressure.

Owner:HITACHI HIGH-TECH CORP

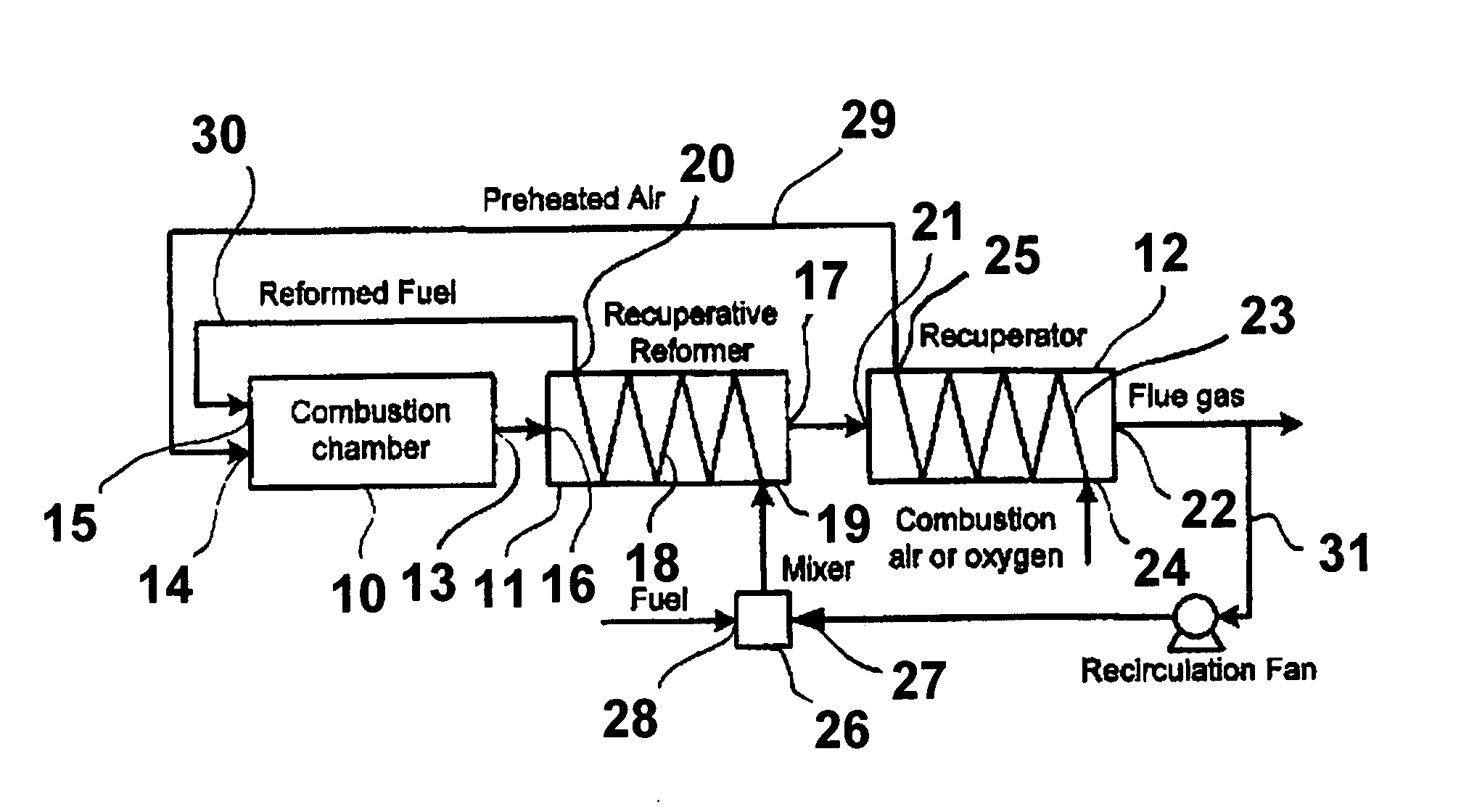

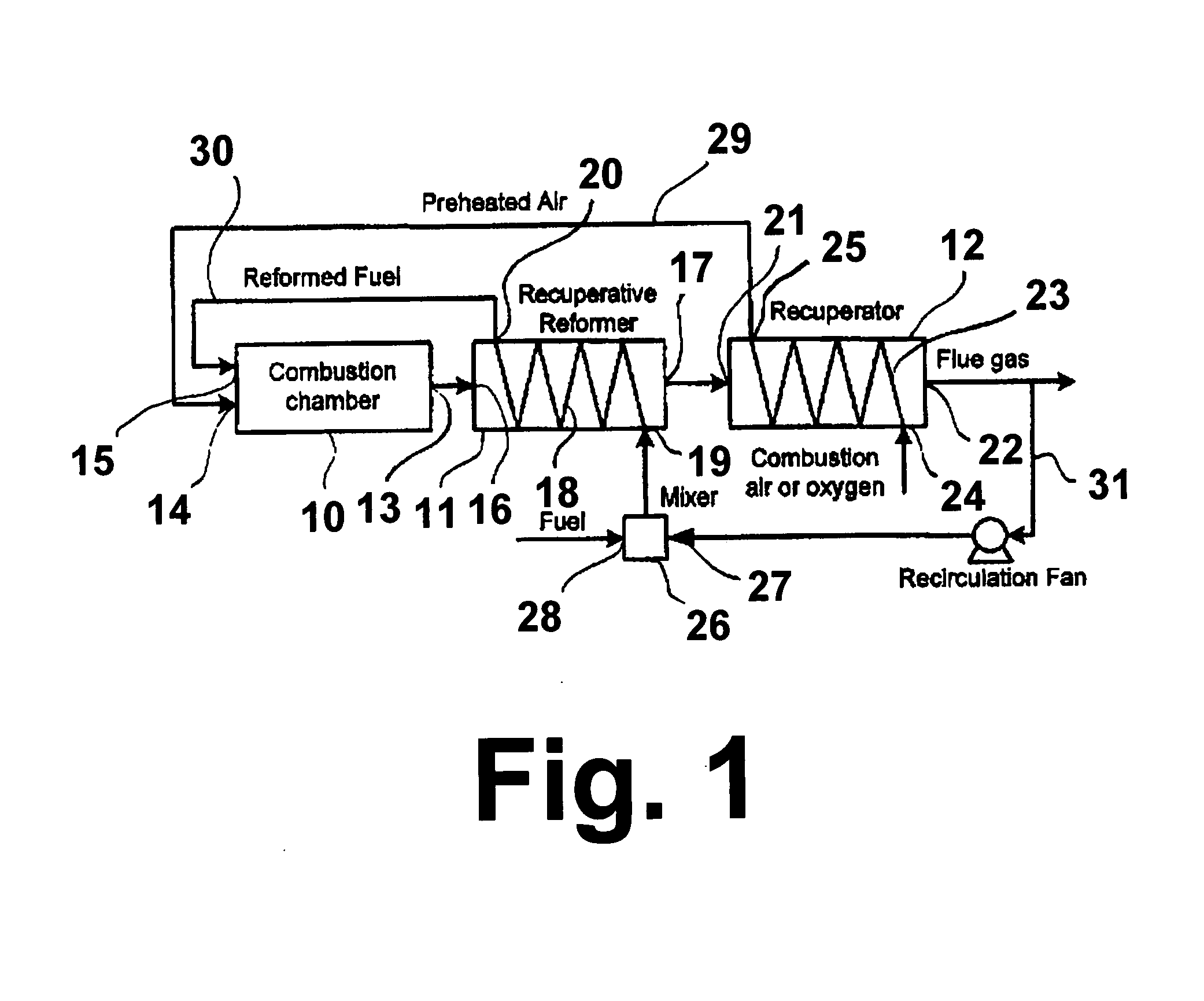

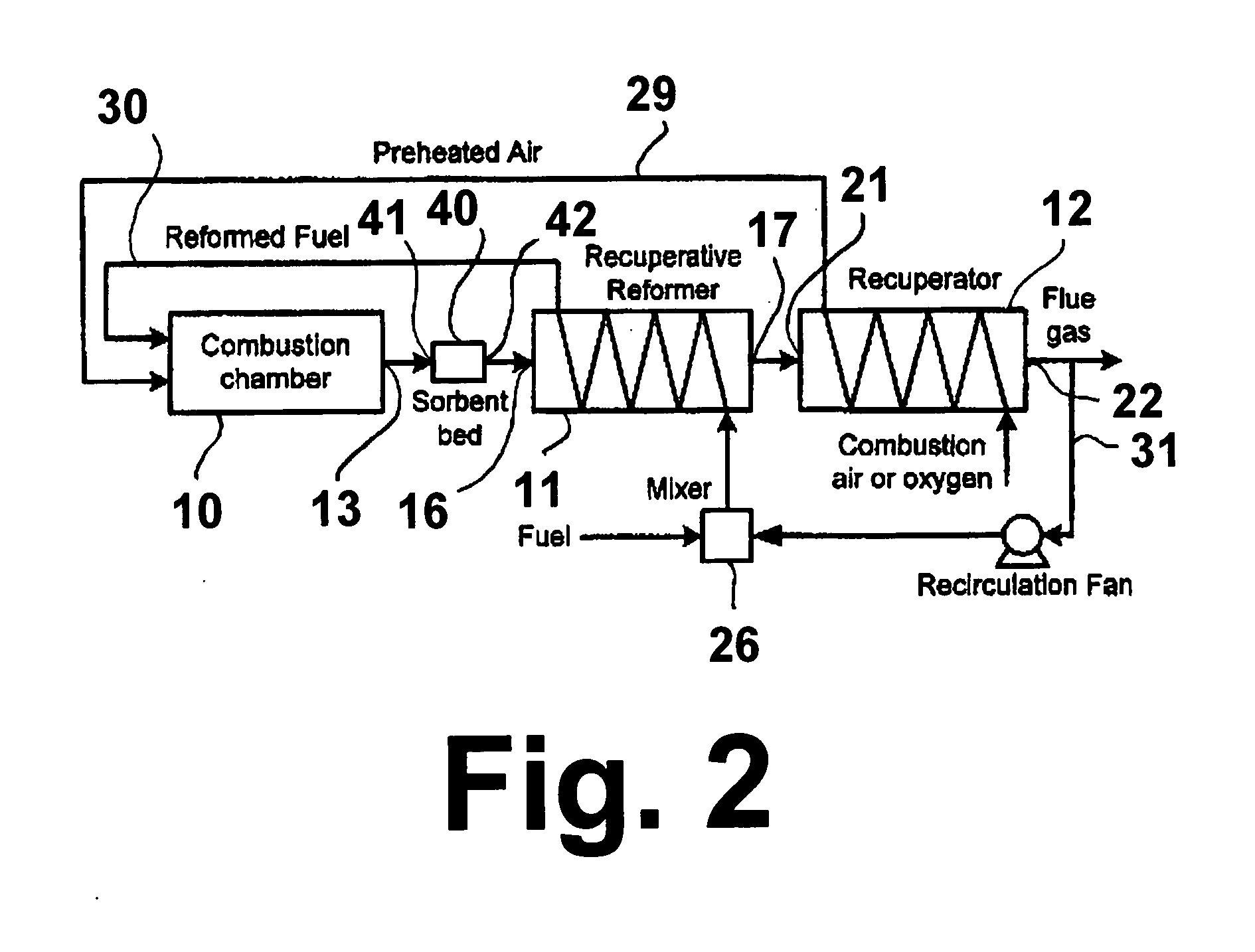

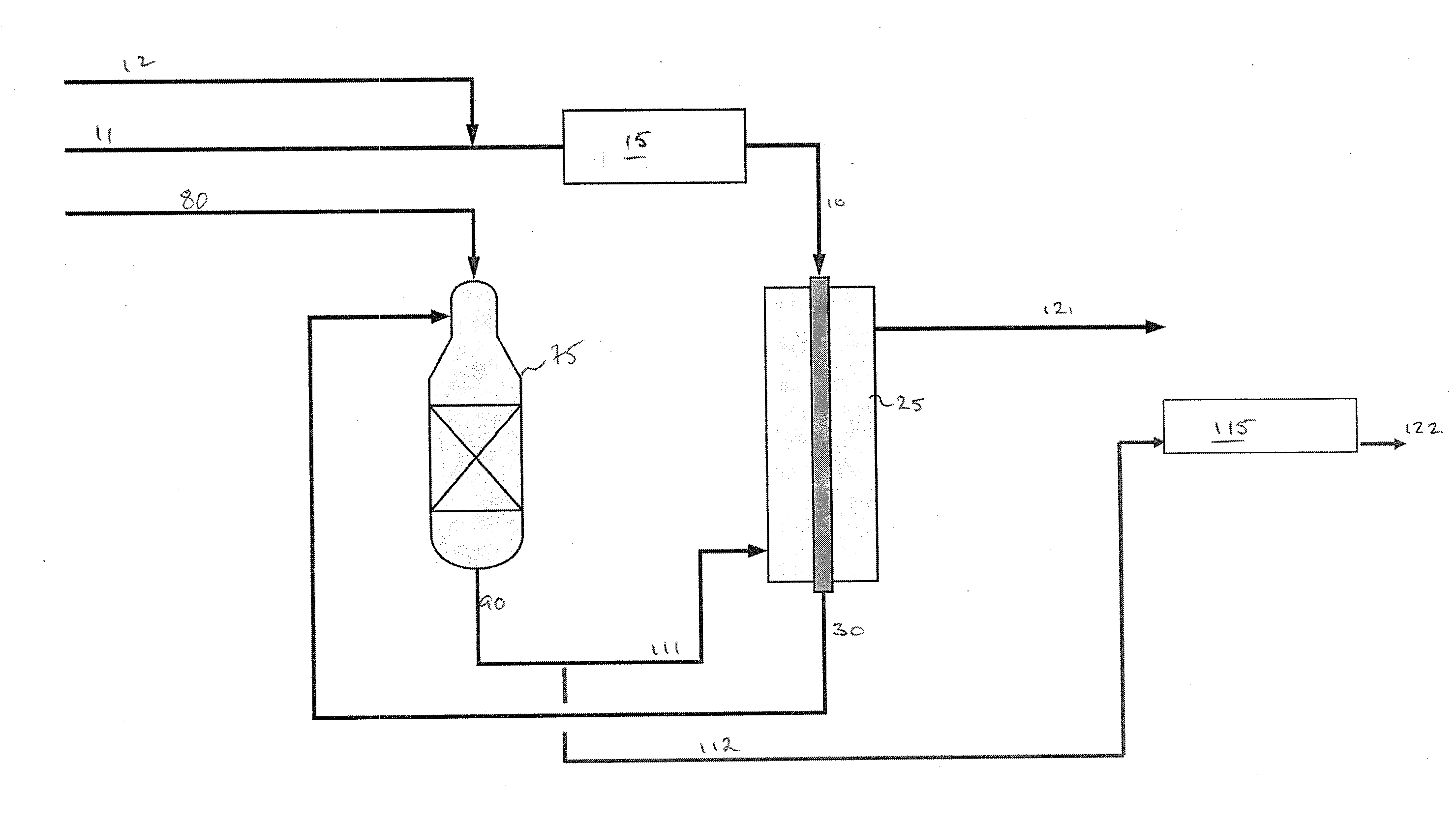

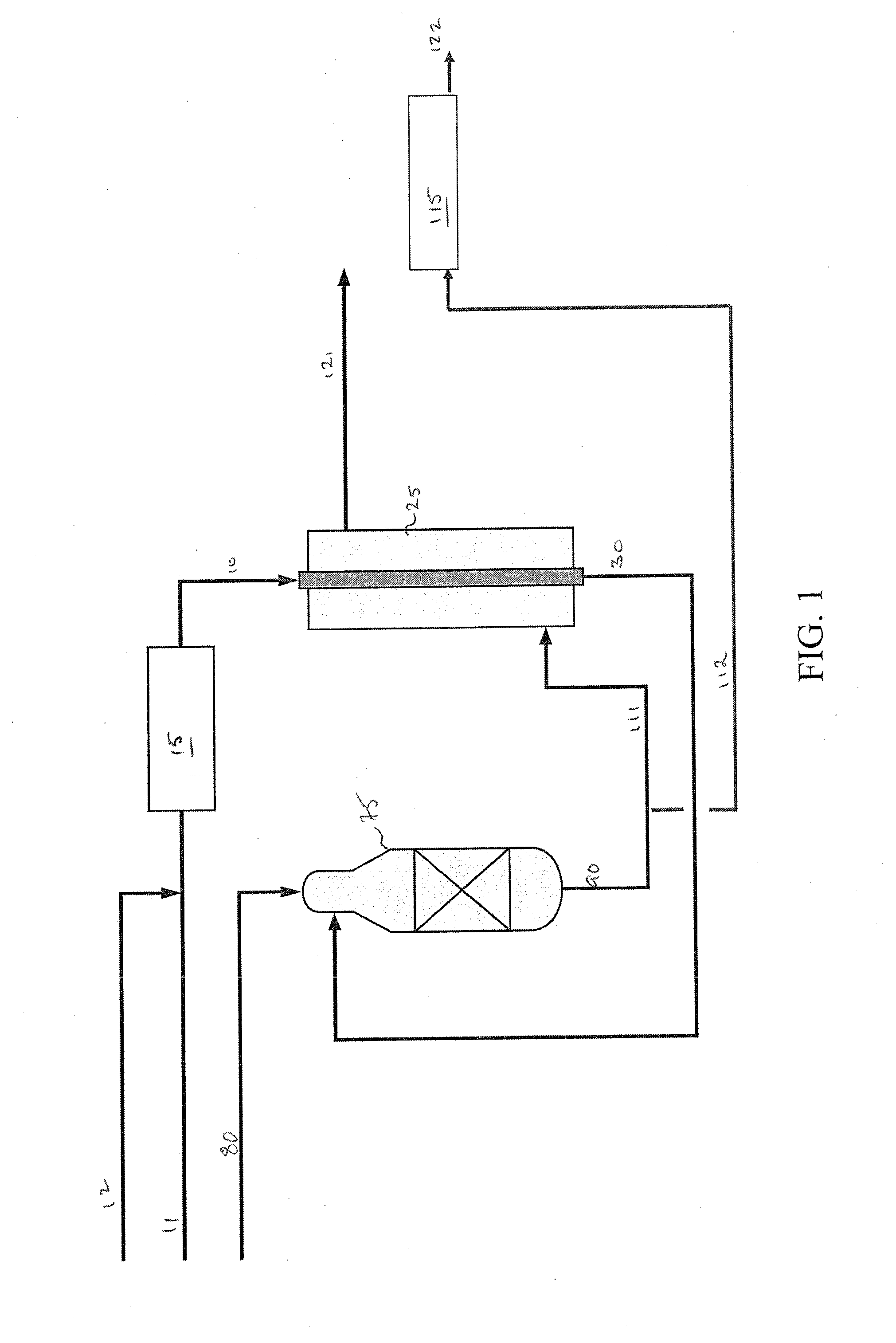

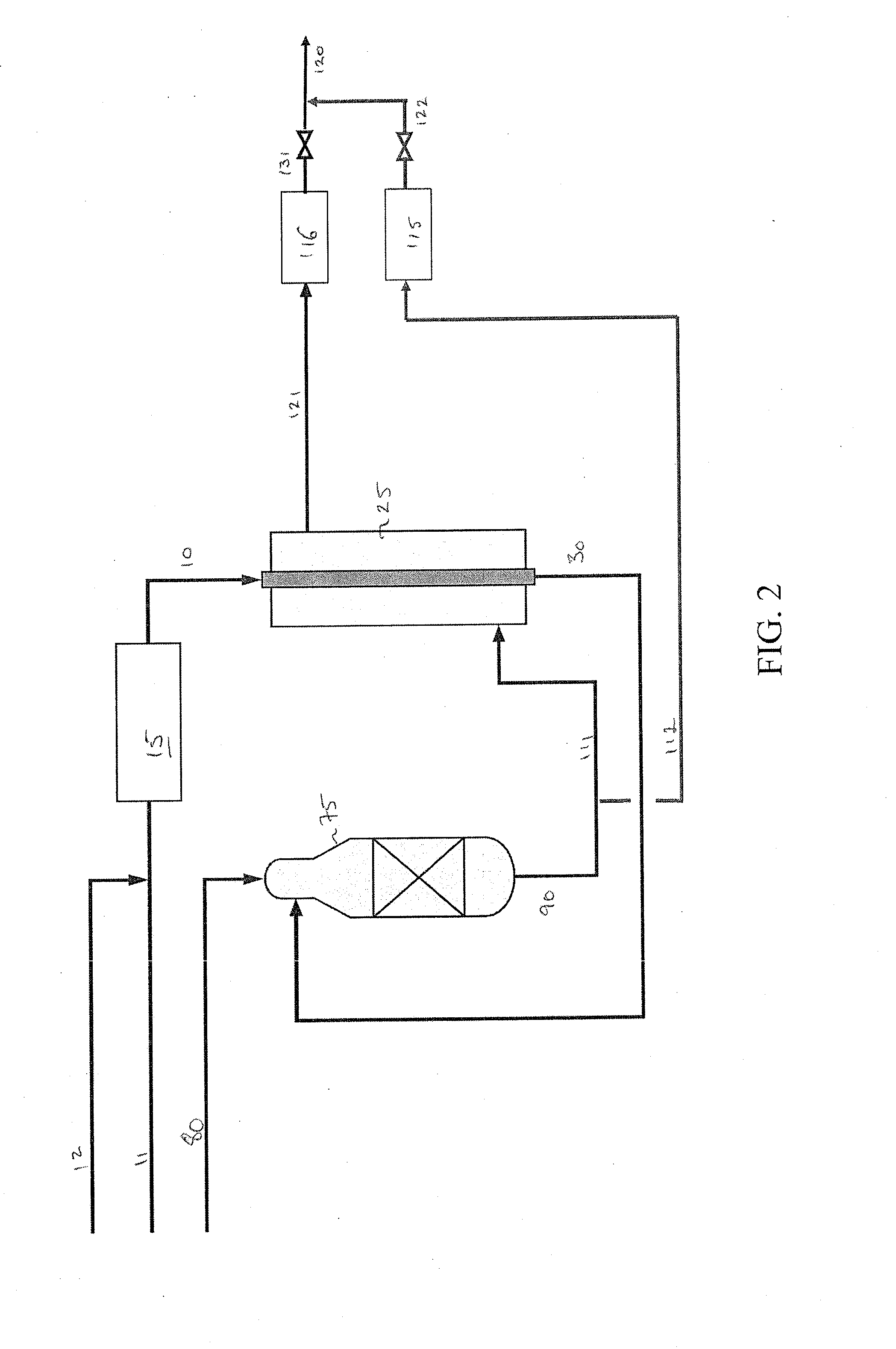

Method and apparatus for thermochemical recuperation with partial heat recovery of the sensible heat present in products of combustion

InactiveUS20090011290A1Increase enthalpyIncrease heat inputHydrogenProductsEngineeringCombustion process

A system and method for fuel reforming in which at least a portion of the exhaust gases from a combustion process, such as an industrial furnace, is mixed with a fuel, such as natural gas, and the mixture is introduced into a first stage heat exchange vessel in which the fuel is reformed. The reformed fuel is then returned to the combustion process for burning. In accordance with one embodiment, primary combustion oxidant is introduced into a second stage heat exchange vessel in which it is heated by a portion of the exhaust gas exiting the first stage heat exchange vessel. The heated oxidant is then introduced into the combustion process for burning of the fuel(s) therein.

Owner:GAS TECH INST

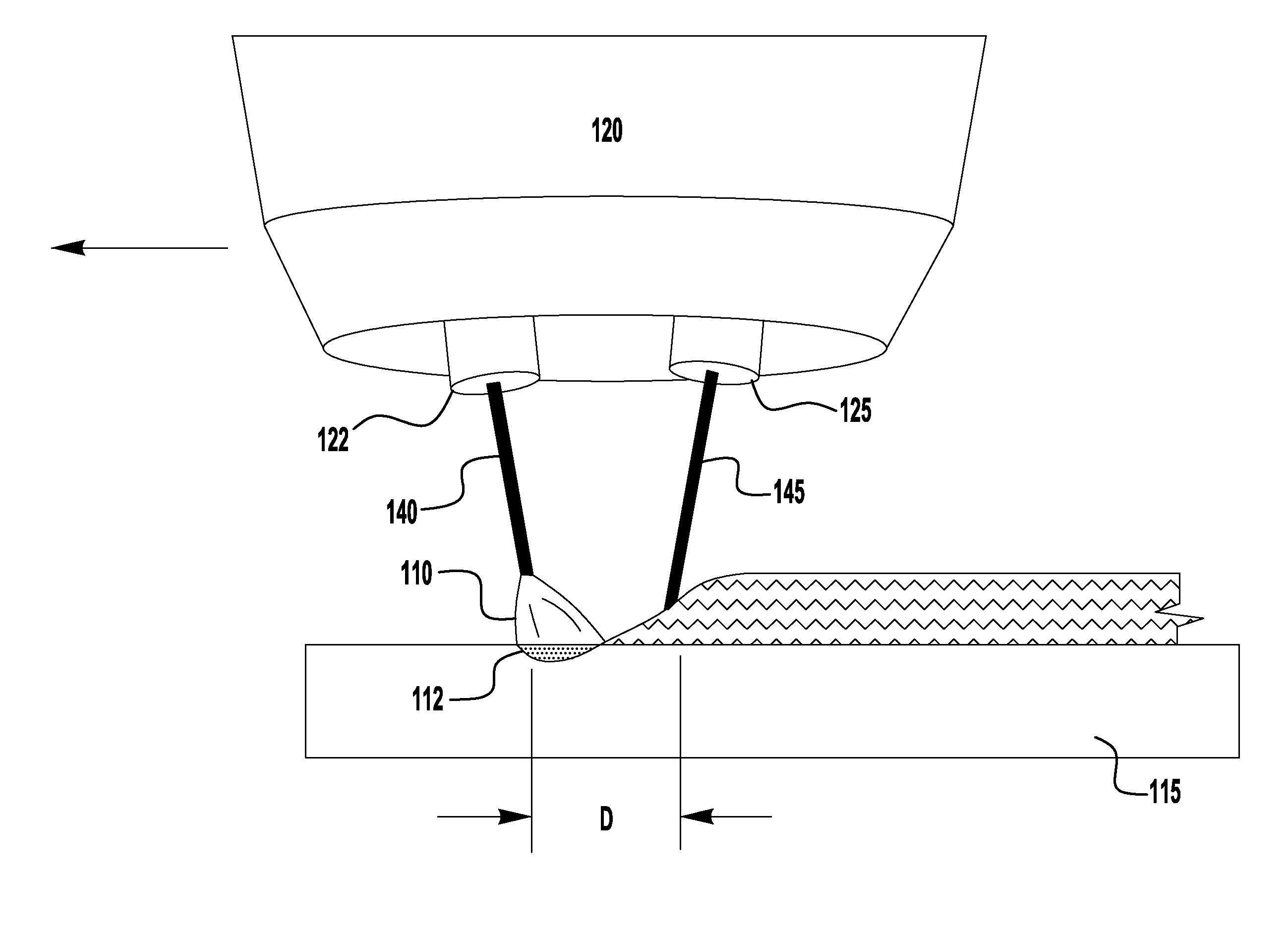

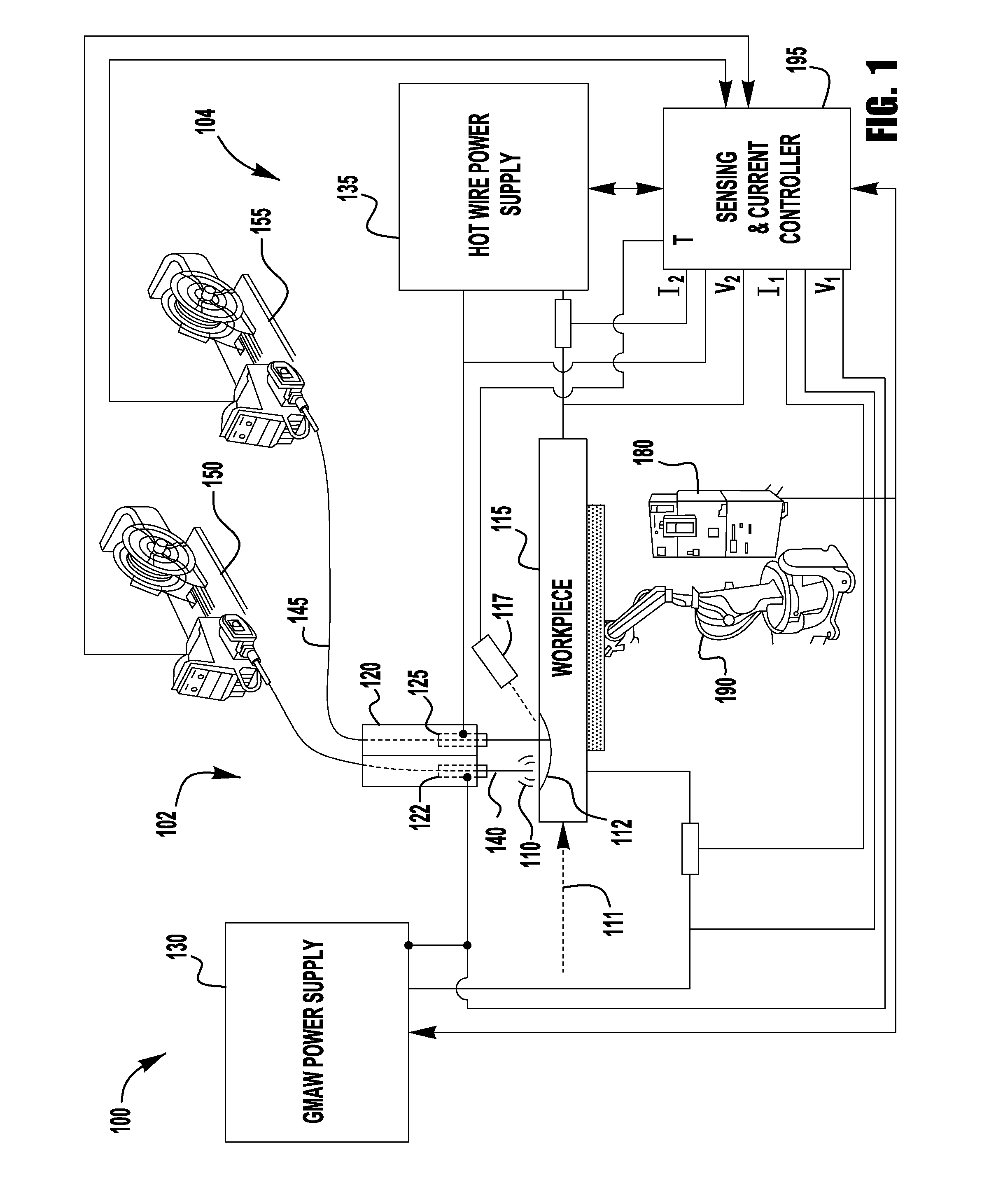

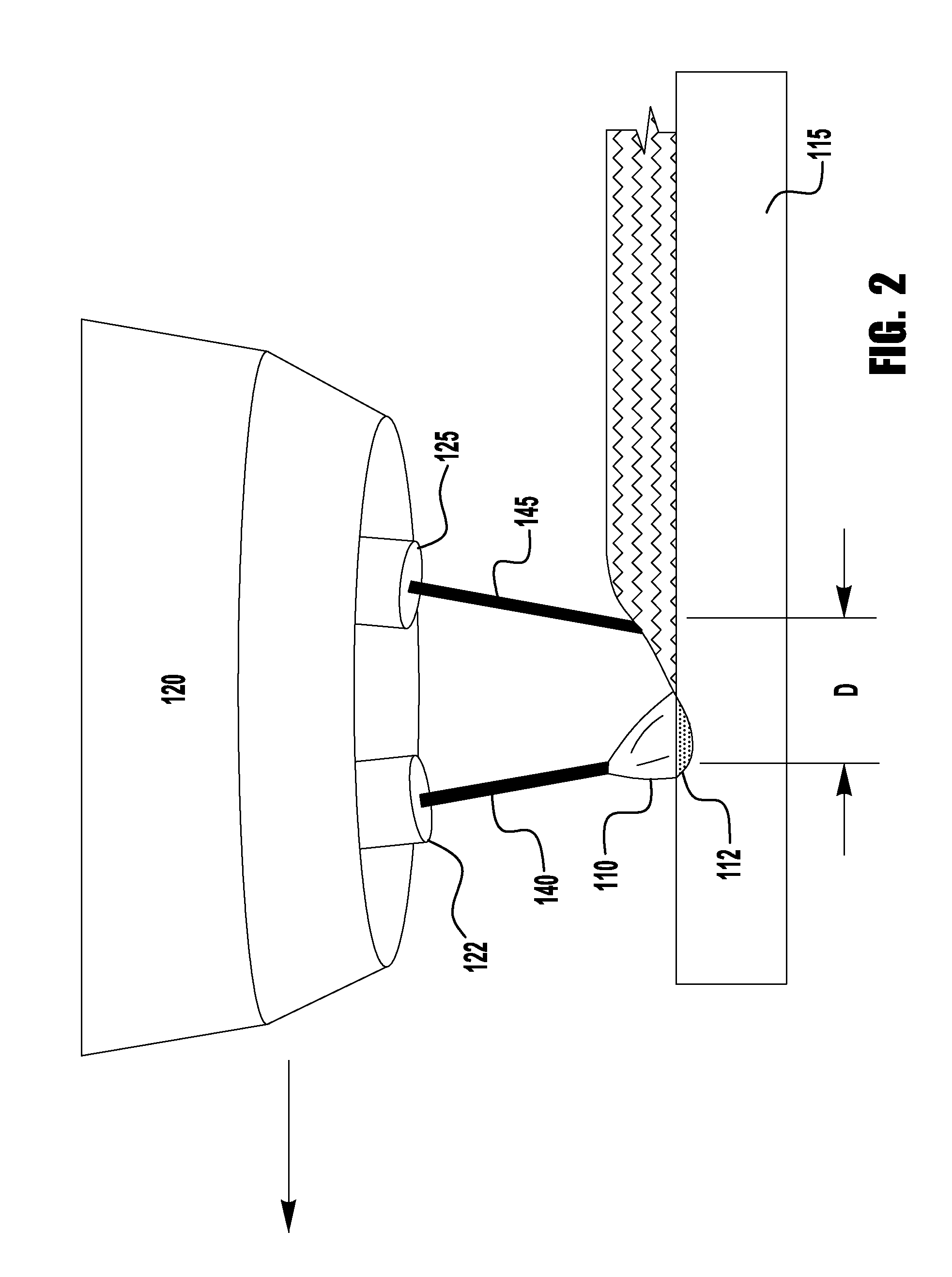

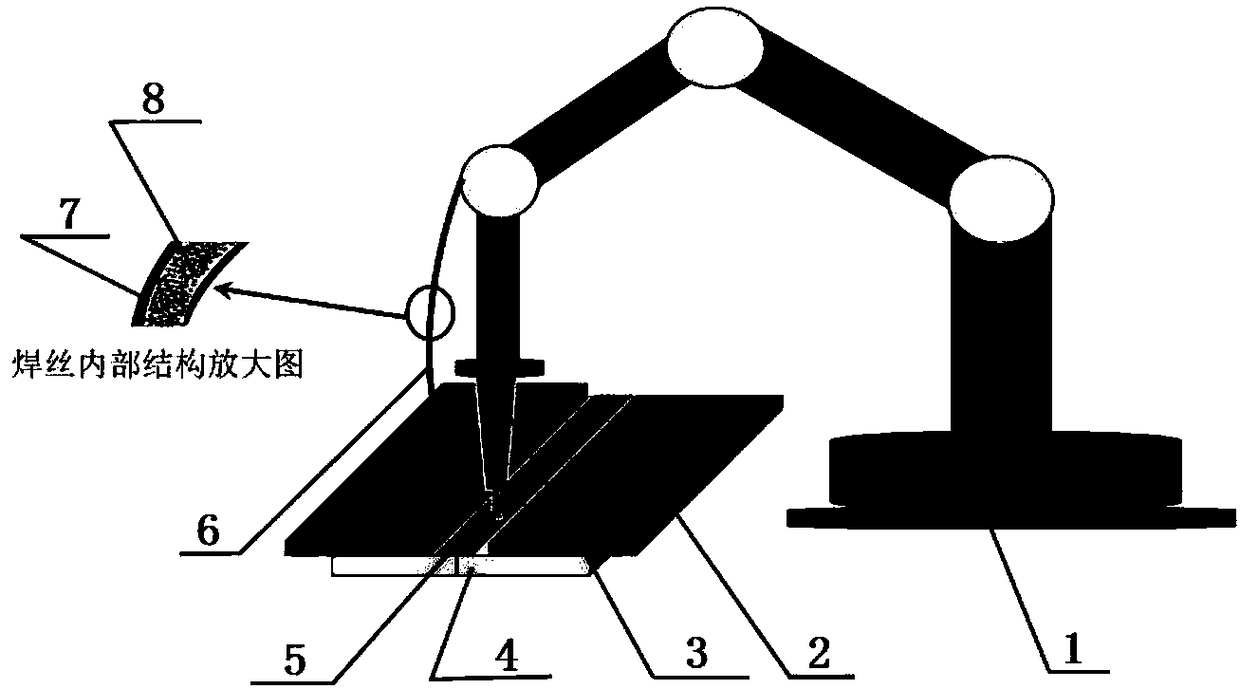

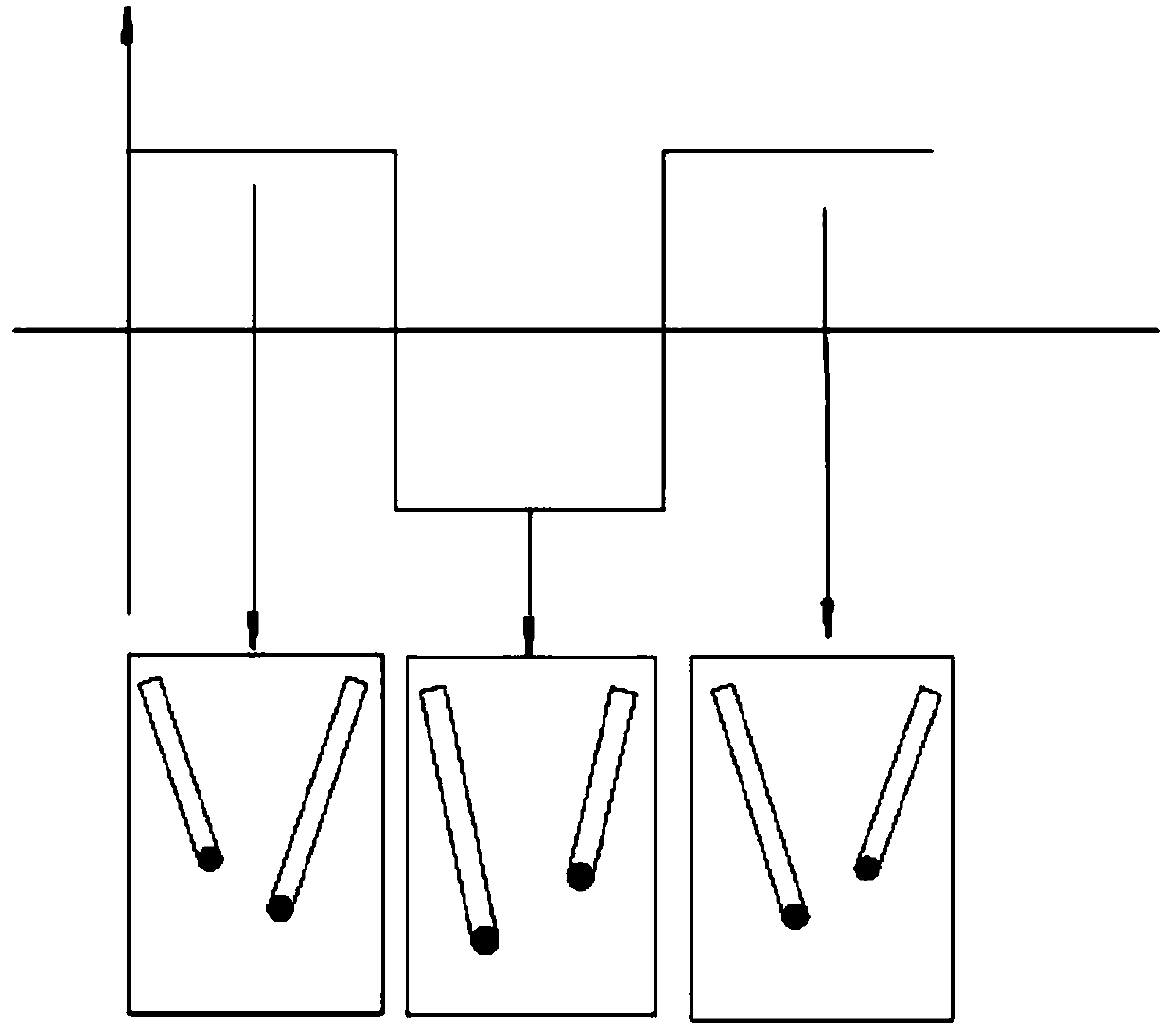

System and method of controlling heat input in tandem hot-wire applications

InactiveUS20150028011A1Increase heat inputHigh energyArc welding apparatusLaser beam welding apparatusNuclear engineeringHigh intensity

A system and method is provided. The system includes a high intensity energy source to create a molten puddle on a surface of a workpiece and a wire feeder that feeds a wire to the molten puddle via a contact tube. The system also includes a power supply that outputs a first heating current during a first mode of operation and a second heating current during a second mode of operation. The system further includes a controller that initiates the first mode of operation in the power supply to heat the wire to a desired temperature and switches the power supply from the first mode of operation to the second mode of operation to create a micro-arc. The second mode of operation provides at least one of an increased heat input to the molten puddle and an increased agitation of the molten puddle relative to the first mode of operation.

Owner:LINCOLN GLOBAL INC

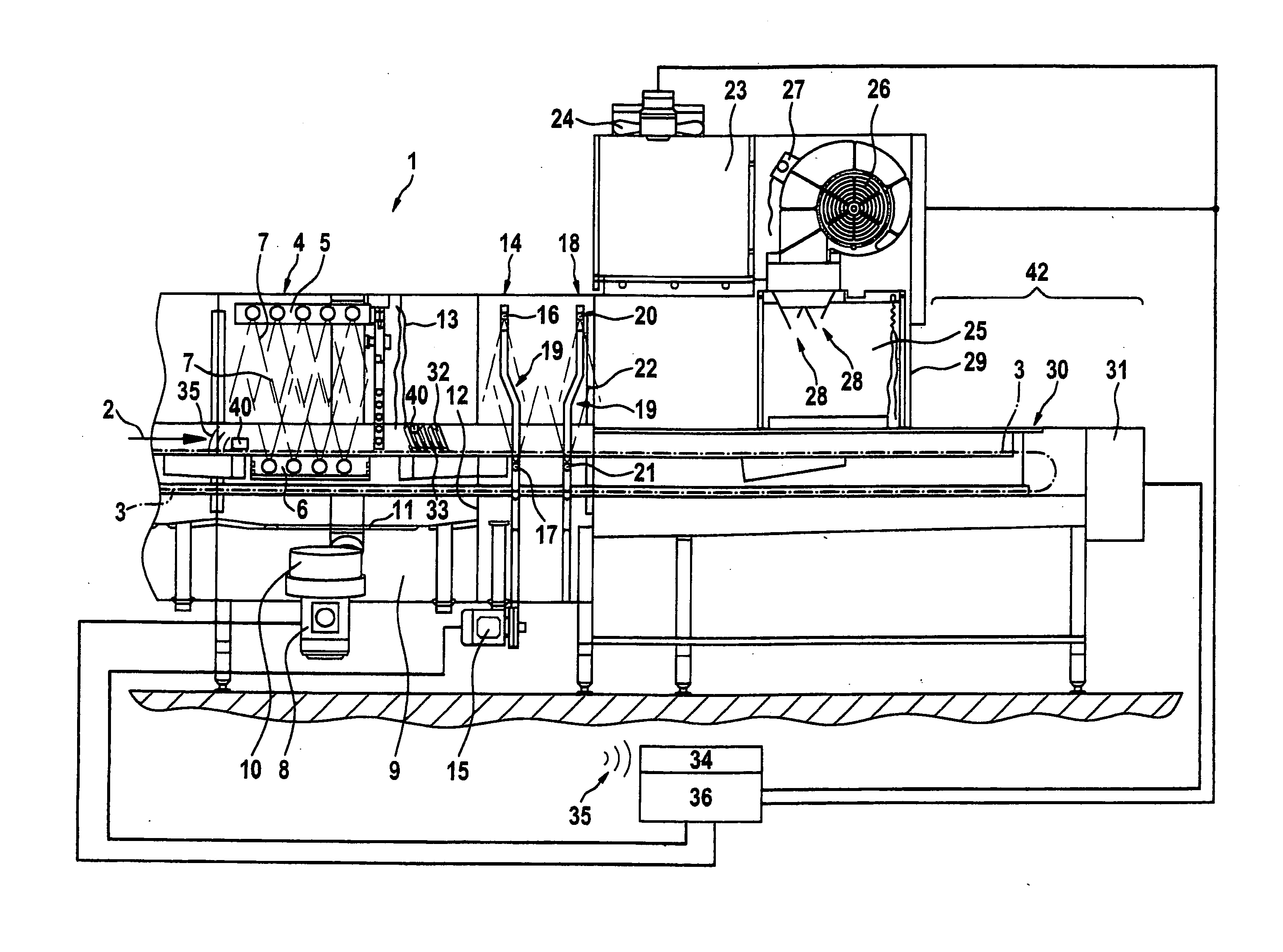

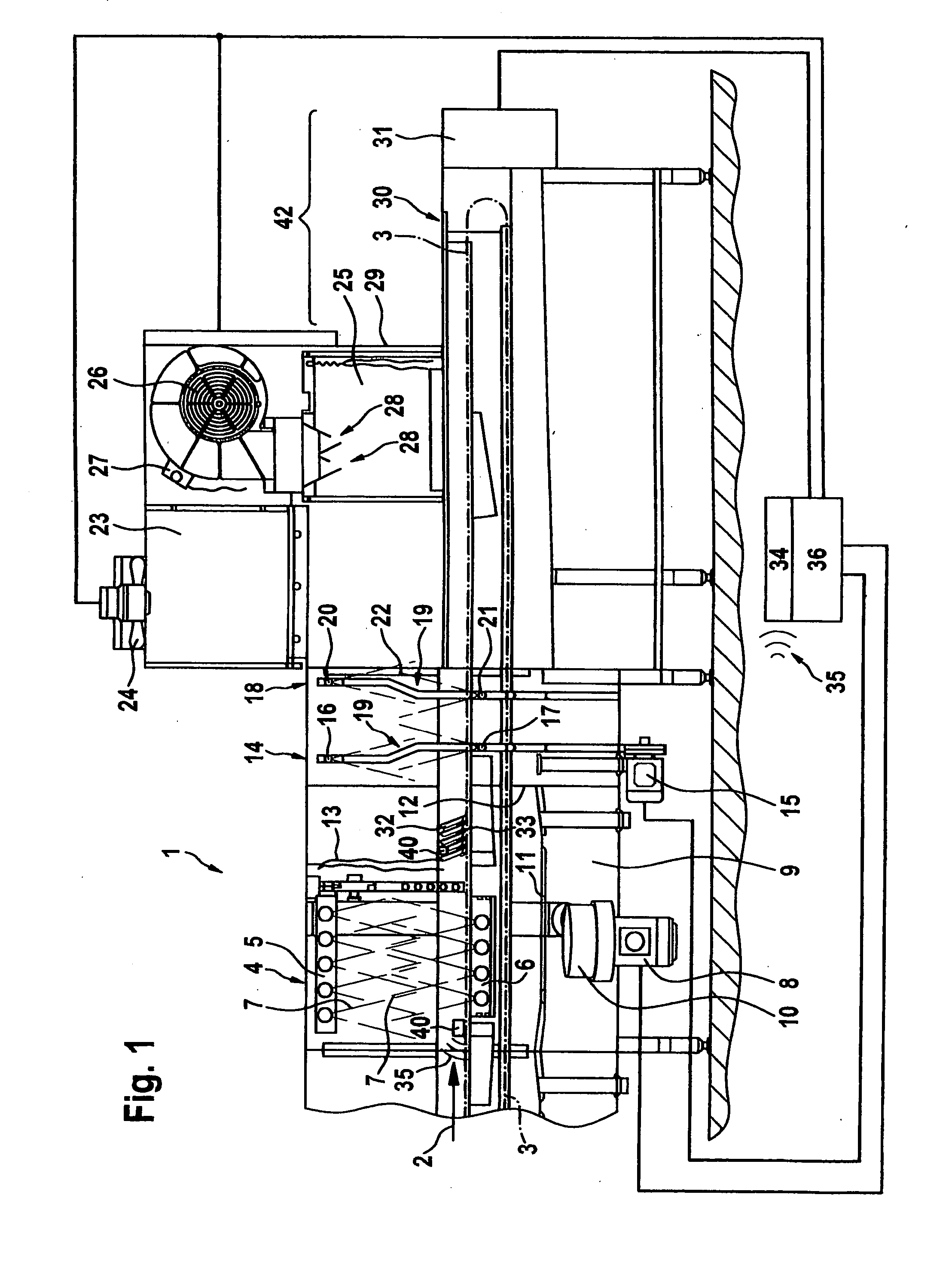

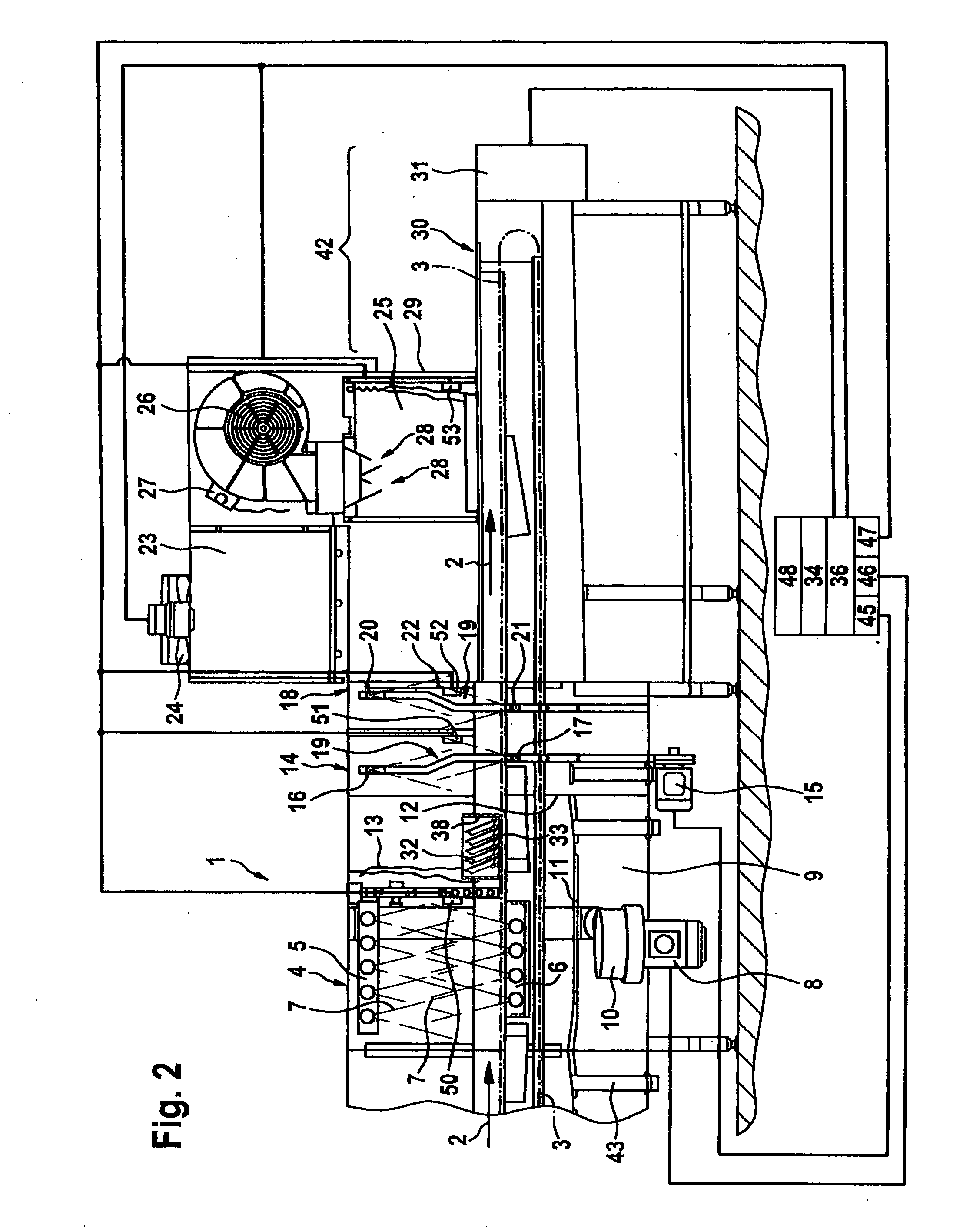

Method for assessing and guaranteeing the thermal hygiene efficiency in a multi-tank dishwasher

ActiveUS20080077281A1Improve securityEliminate disadvantagesTemperatue controlAutomatic washing/rinsing machine detectionMachine controlControl system

A method for assessing and guaranteeing the thermal hygiene efficiency in a multi-tank dishwasher in which there is at least one sensor that transmits a temperature inside at least one treatment zone to a machine control system, in particular to the control system of the multi-tank dishwasher, the method includes: detecting the temperature inside at least one of the treatment zones by the sensor; determining the heat input applied to the items to be cleaned in at least one of the treatment zones on the basis of the temperature determined; comparing the heat input in the at least one treatment zone with a predefined heat input; and, as a function of the result of the comparison of the heat input values, varying the transport speed of the items to be cleaned through the multi-tank dishwasher, or varying the temperature of at least one of the process parameters acting on the heat input values as a control variable in a control loop for at least one of the treatment zones.

Owner:MEIKO MASCHENBAU

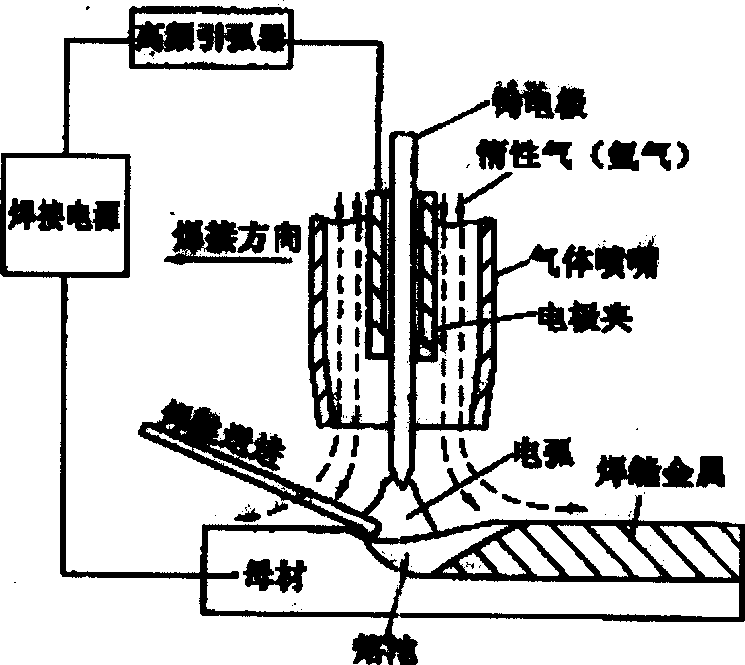

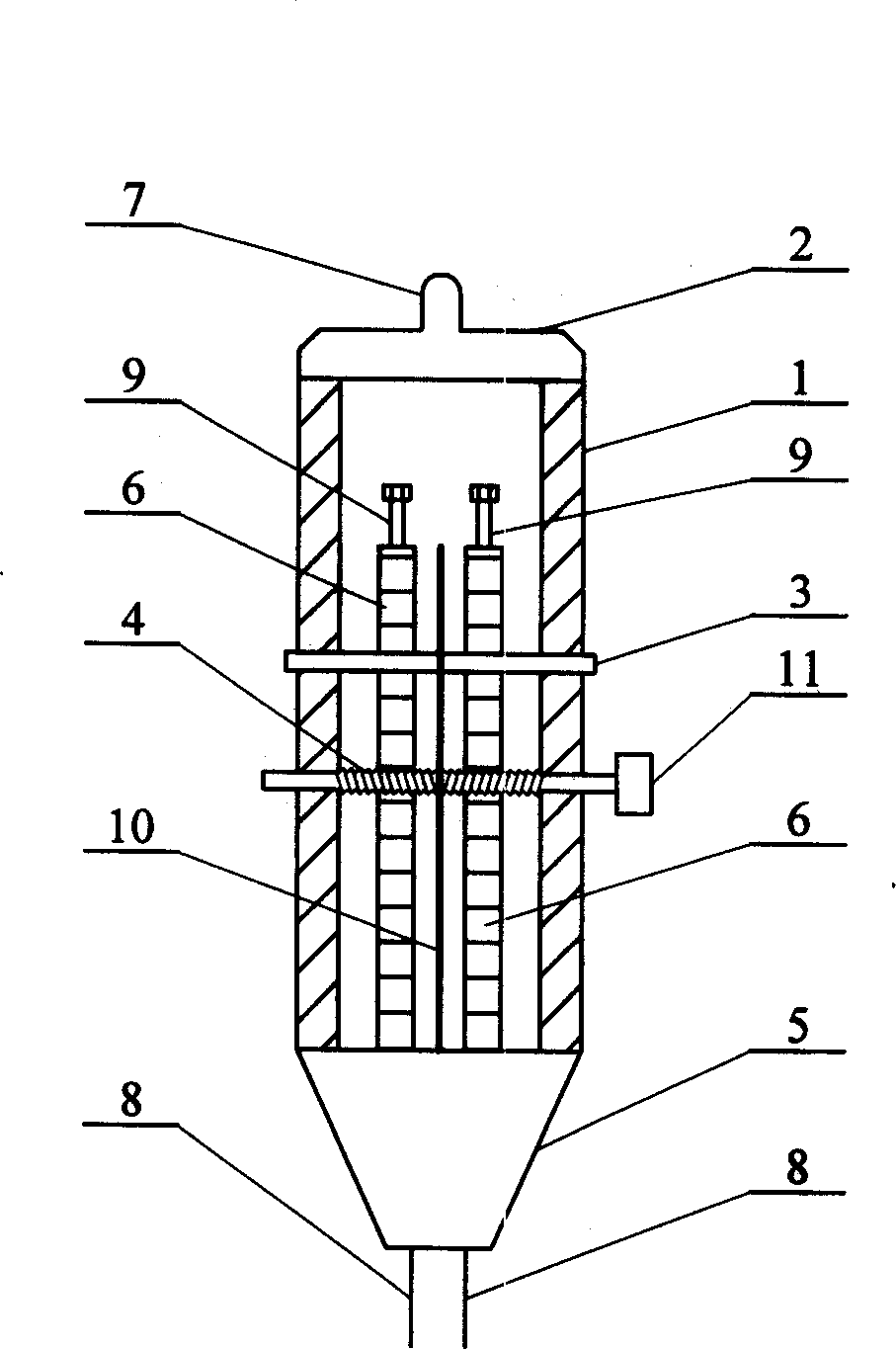

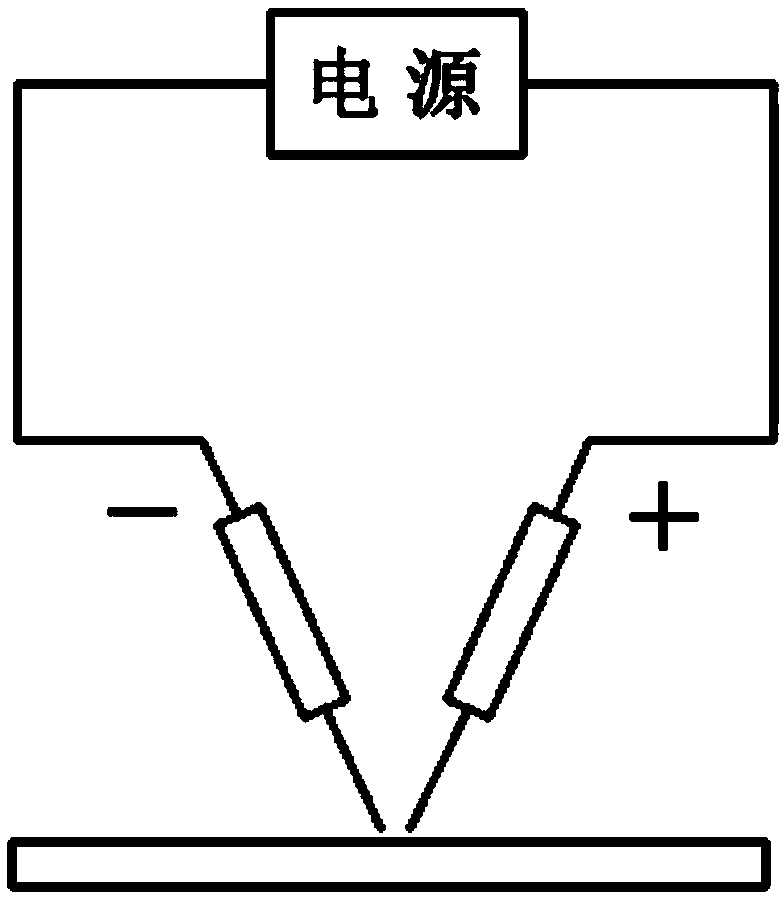

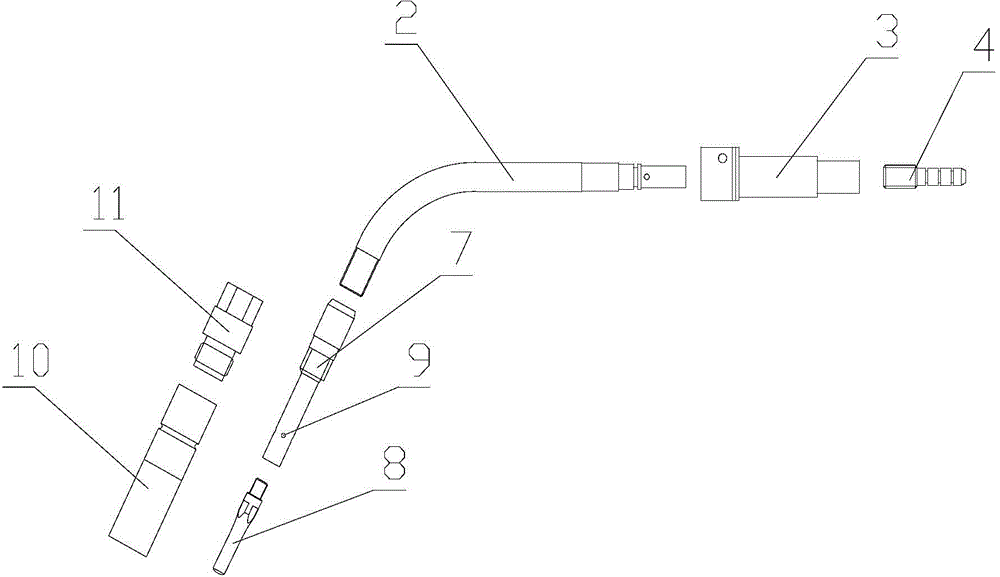

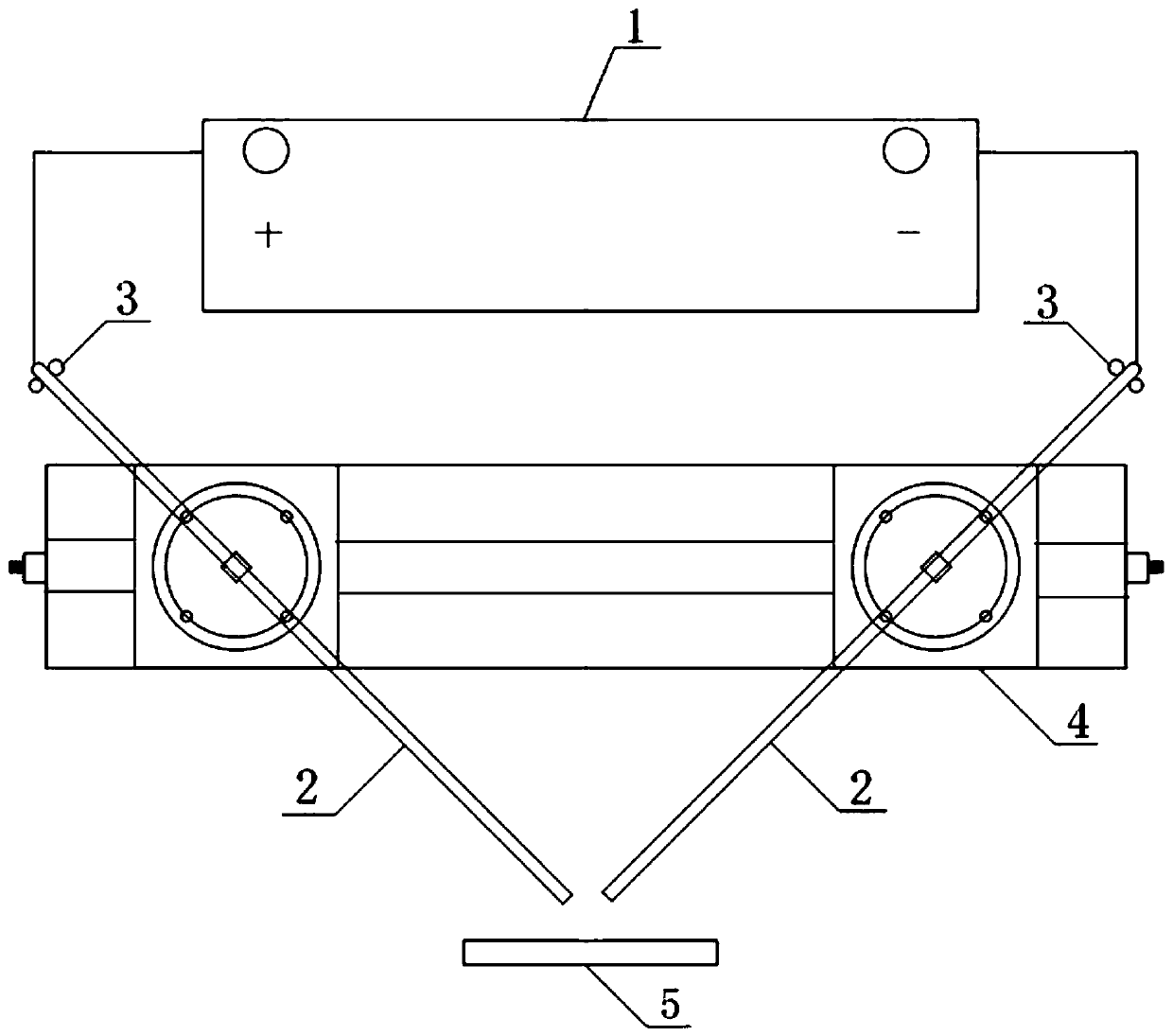

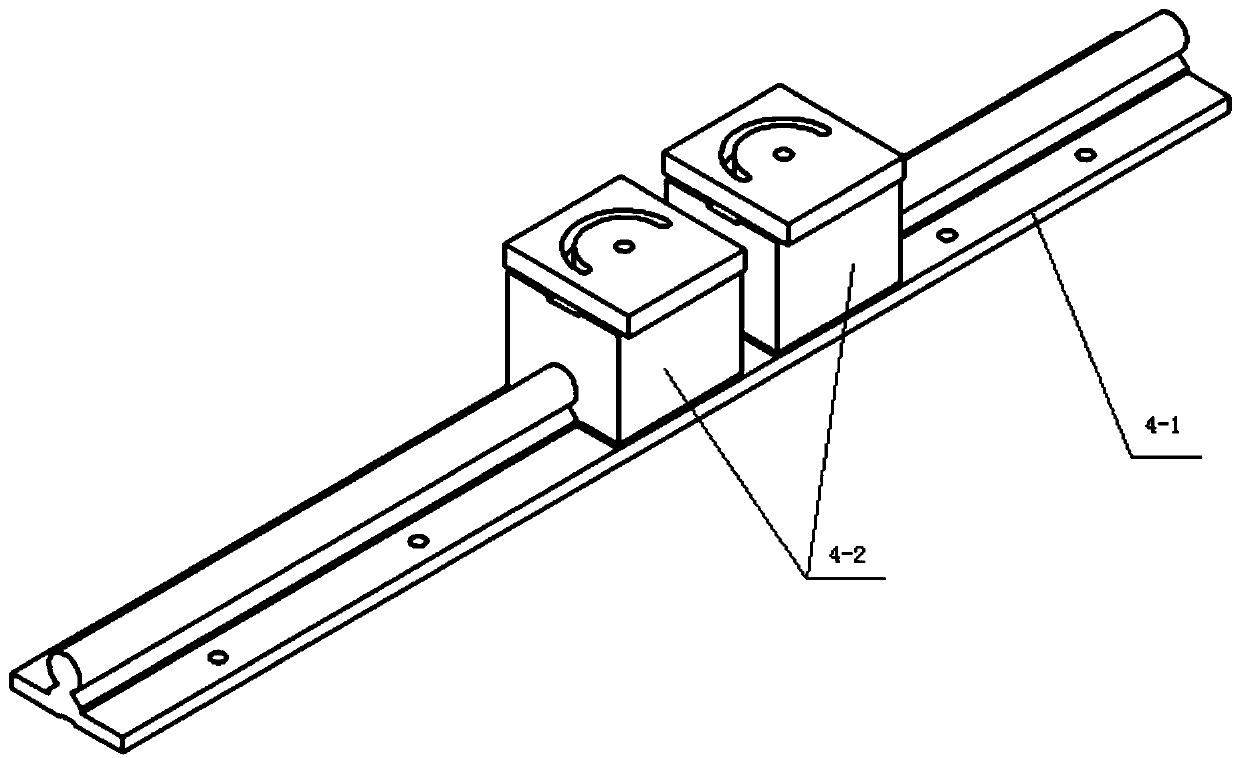

Dual tungsten electrodes welding torch in use for argon are welding

InactiveCN1600491AIncrease heat inputSimple structureElectrode supporting devicesWelding power supplyEngineering

An argon shielded arc welding torch with two tungsten electrodes is composed of main body, two electric conducting bodies parallel in the main body, two tungsten electrodes fixed to lower ends of said electric conducting bodies, two cable fastening screw bolts, and an insulating plate between two electric conducting bodies.

Owner:HARBIN INST OF TECH

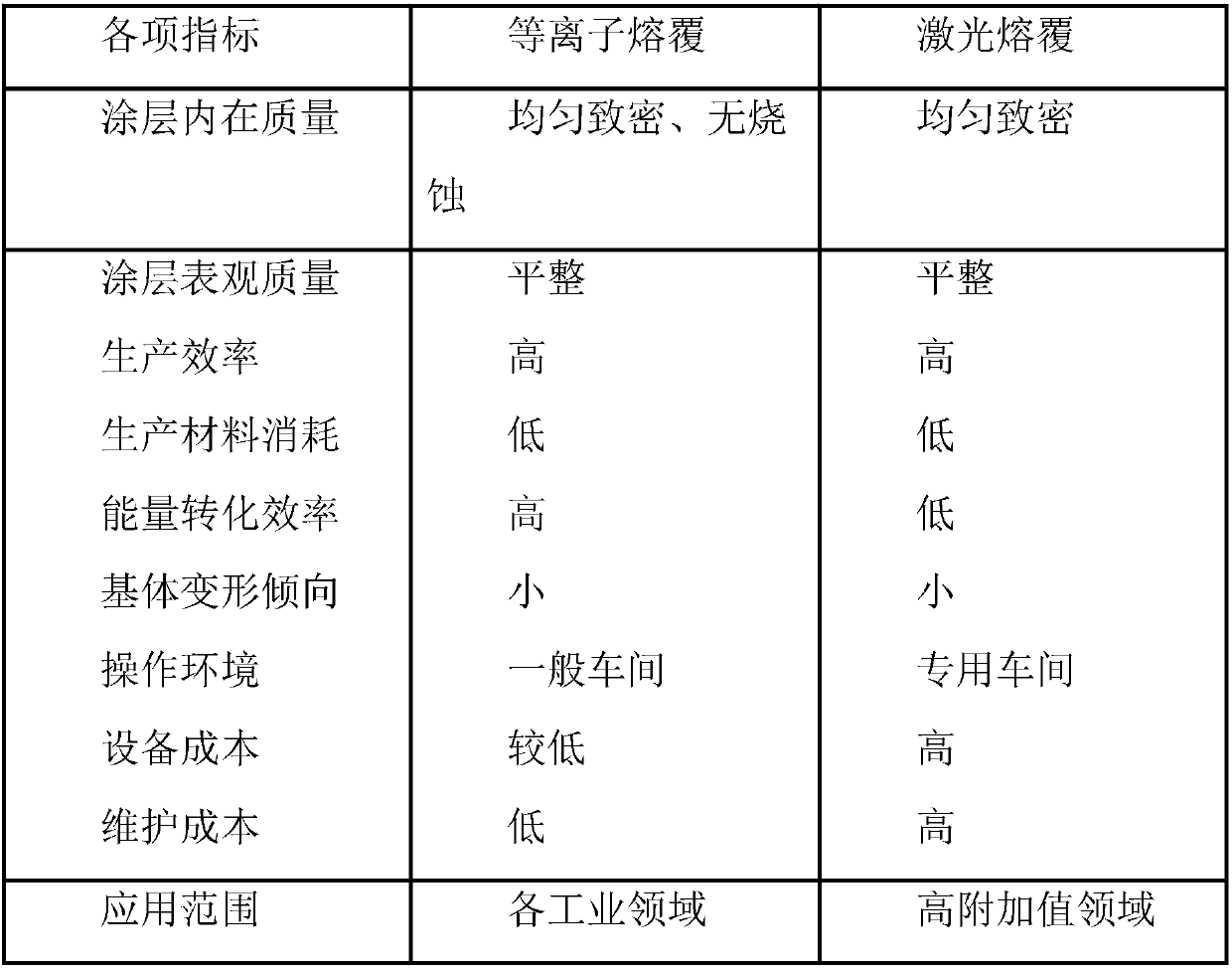

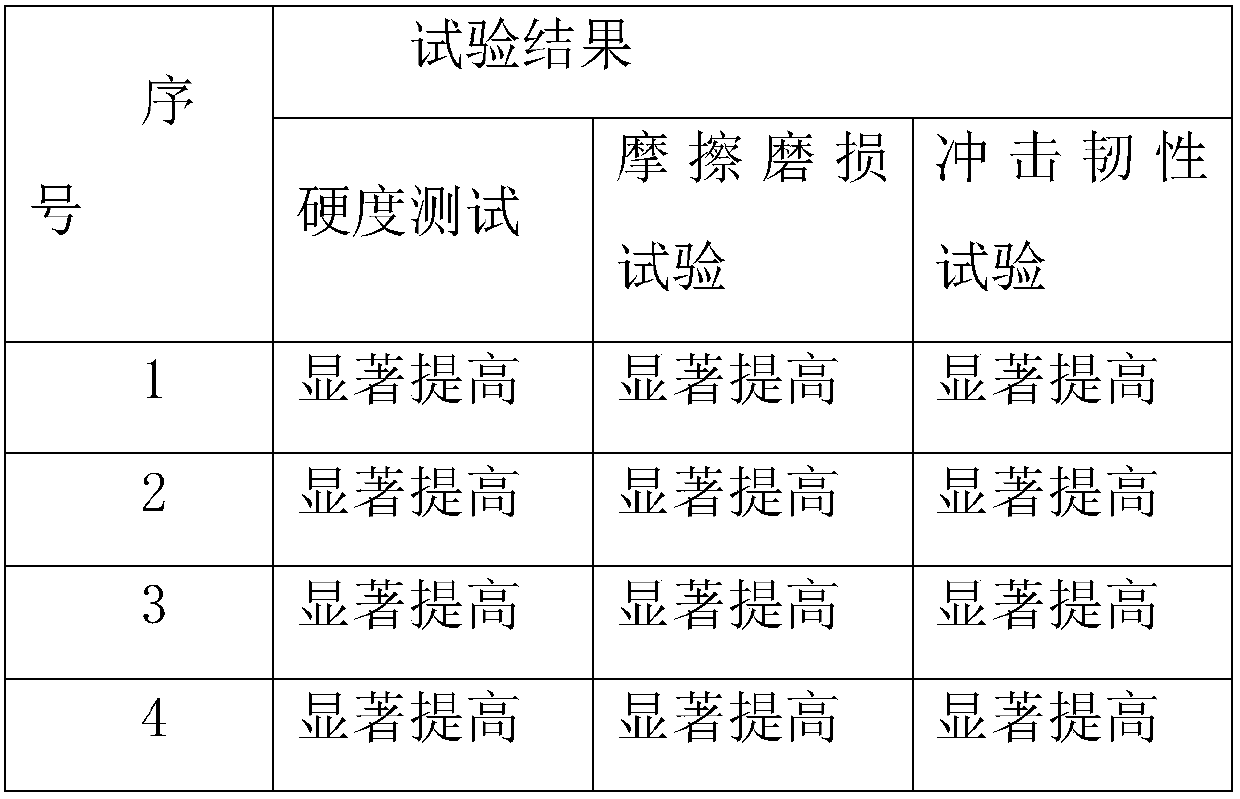

Method for preparing wear-resistance toughening coating layer on surface of high-manganese steel

ActiveCN107815682AReduce pollutionImprove wear resistanceMetallic material coating processesSolution treatmentCoated surface

The invention discloses a method for preparing a wear-resistance toughening coating layer on a surface of high-manganese steel. The method is characterized by comprising the steps of: (S1) pretreatment of a basal body before cladding, (S2) pretreatment of powder before cladding, (S3) cladding, and (S4) heat treatment after cladding. A plasma cladding technology, solid solution treatment and a coating layer surface aging process are adopted to prepare the Fe-Ni base alloy coating layer with high hardness, high wear resistance and high impact toughness; the surface hardness and the wear resistance of the basal body material are improved; the problem of easy cracking of a traditional hard particle reinforcing metal base wear-resistance coating layer under such conditions as medium and high stress is solved; and the prepared coating layer is excellent in metallurgical bonding with the basal body material, so that the comprehensive performance of the coating layer is greatly improved, the basal body material is protected more sufficiently, the service life of the basal body material is prolonged, and the application prospect is broad.

Owner:梧州啟润机械有限公司

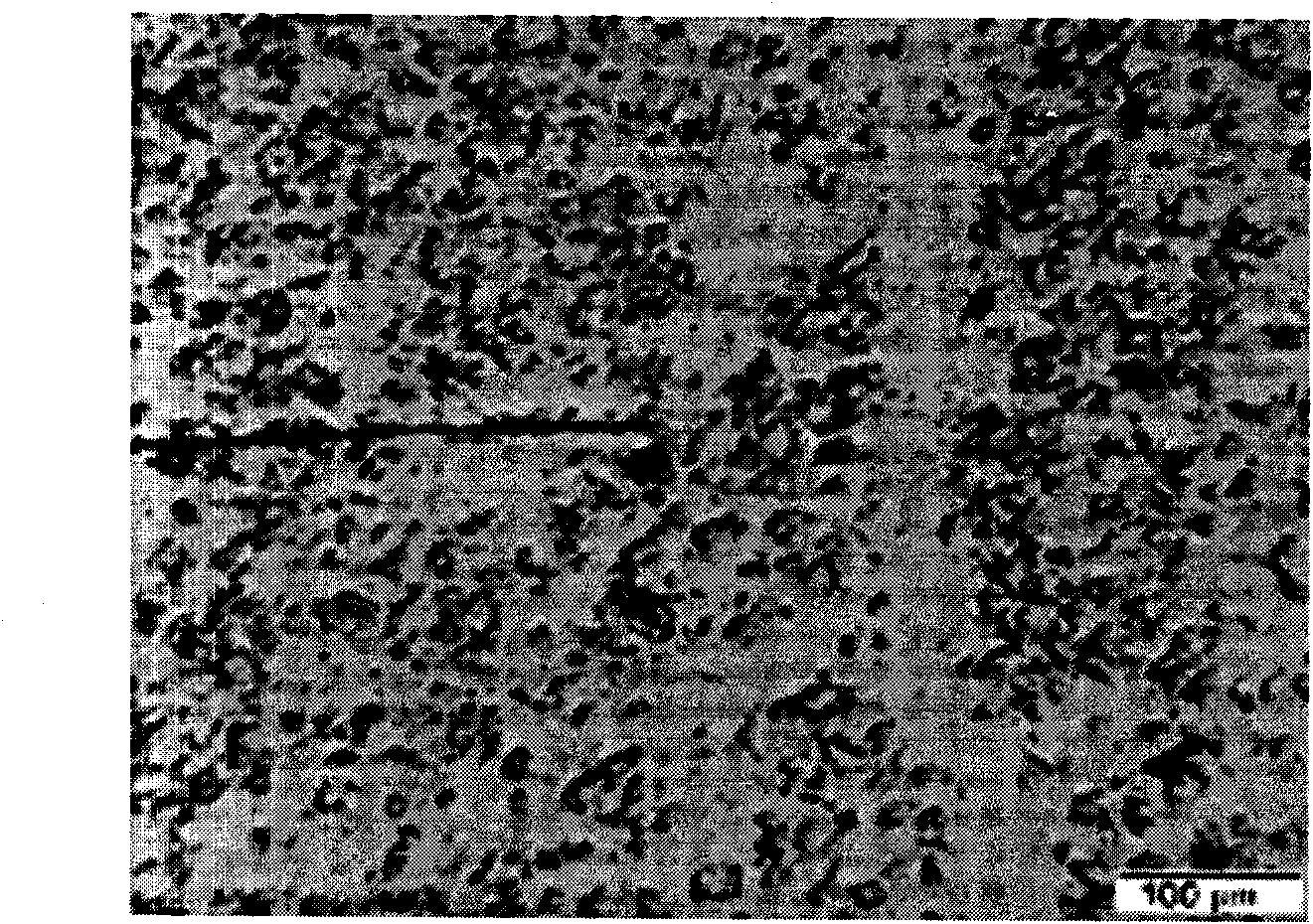

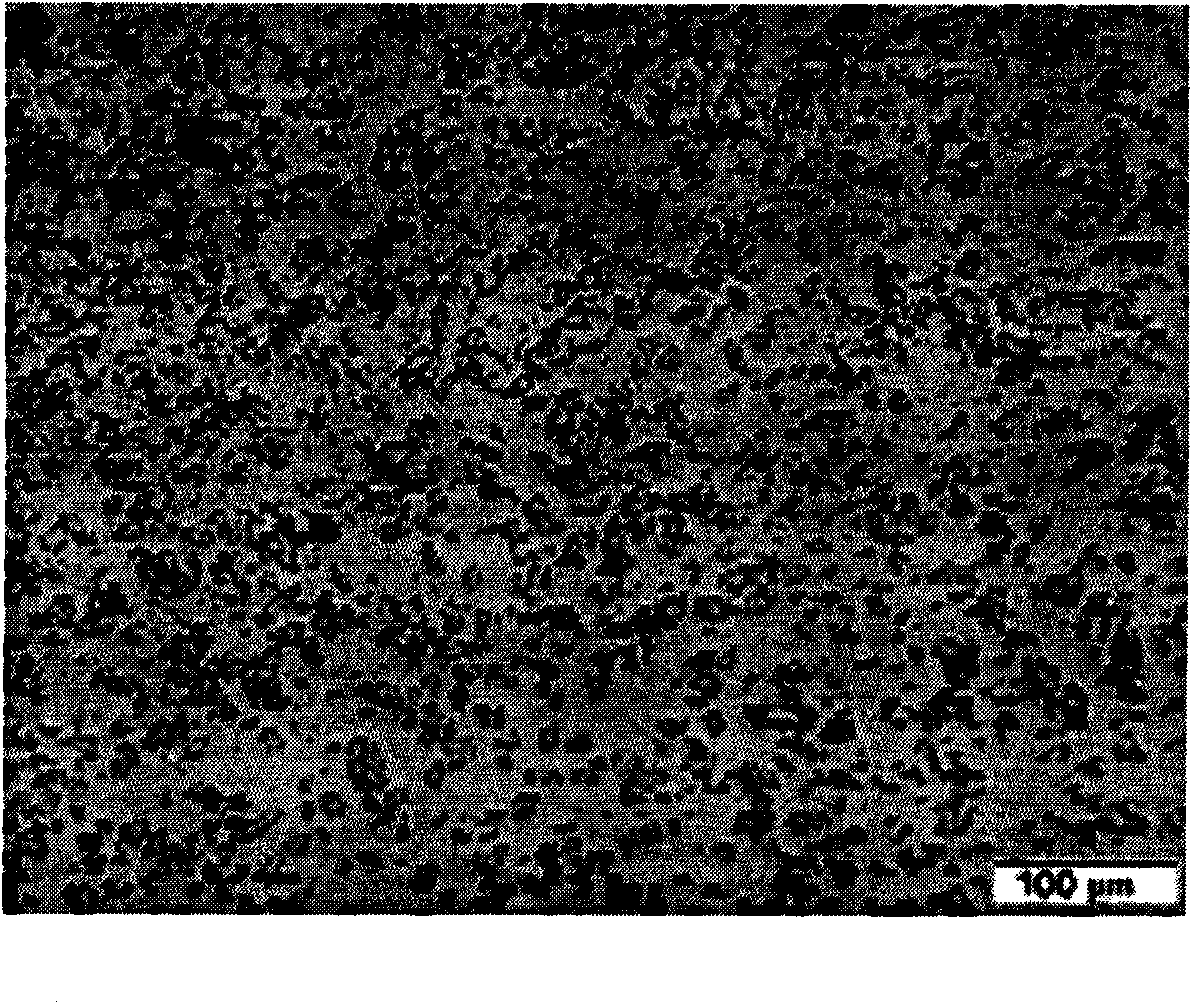

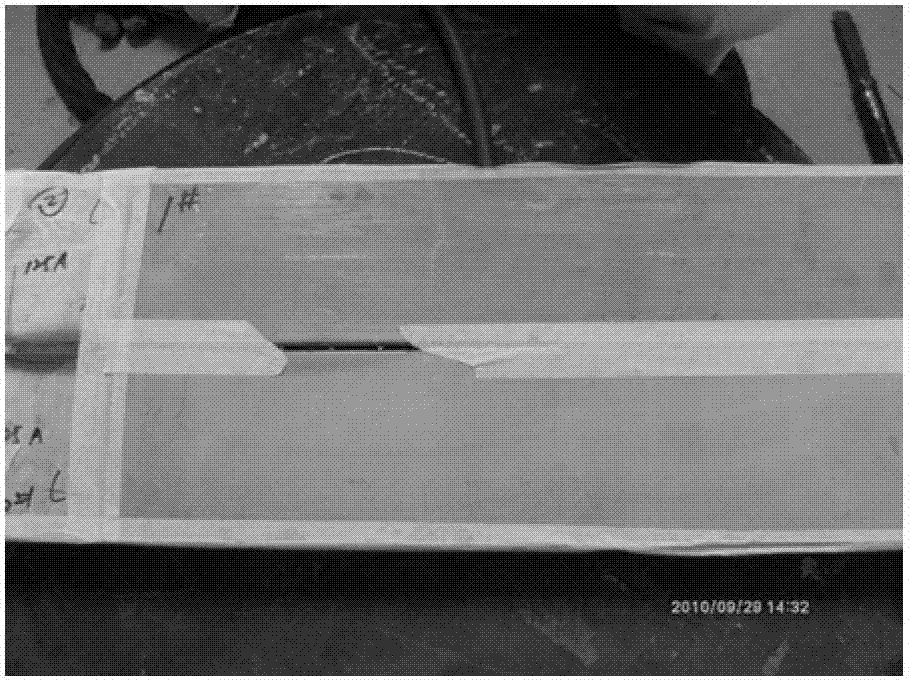

Novel method of resistance spot welding of aluminum base composite material

InactiveCN101623793AEasy to shapeIncrease tensile and shear forceWelding/cutting media/materialsWelding/soldering/cutting articlesElectrical resistance and conductanceWhiskers

The invention discloses a novel method of resistance spot welding of aluminum base composite material. A stainless steel sheet is added between an electrode and aluminum base composite material when resistance spot welding connection is carried out on the aluminum base composite material. When the resistance spot welding connection is performed by adding the stainless steel sheet between the electrode and the aluminum base composite material, the squeeze time is 0.4 to 1 S, the hold time is 0.4 to 1.2 S, the electrode force is 2000 to 3500 N, the welding time is 0.1 to 0.3 S, and the welding current is 1.2 to 1.8 kA. The method has the advantages that when resistance spot welding connection is carried out on the aluminum base composite material, a stainless steel sheet with certain thickness is added between the electrode and the aluminum base composite material, the welding process is simple, reinforced phase particles or crystal whiskers in a joint region are evenly distributed, the tension and shearing force of a resistance spot welding connector is obviously improved, the applicable scope of the welding machine is expanded, and the damage to the resistance spot welding machine equipment is reduced, therefore, the invention is an effective novel technology for resistance spot welding of aluminum base composite material, which has important application value.

Owner:ZHENGZHOU UNIV

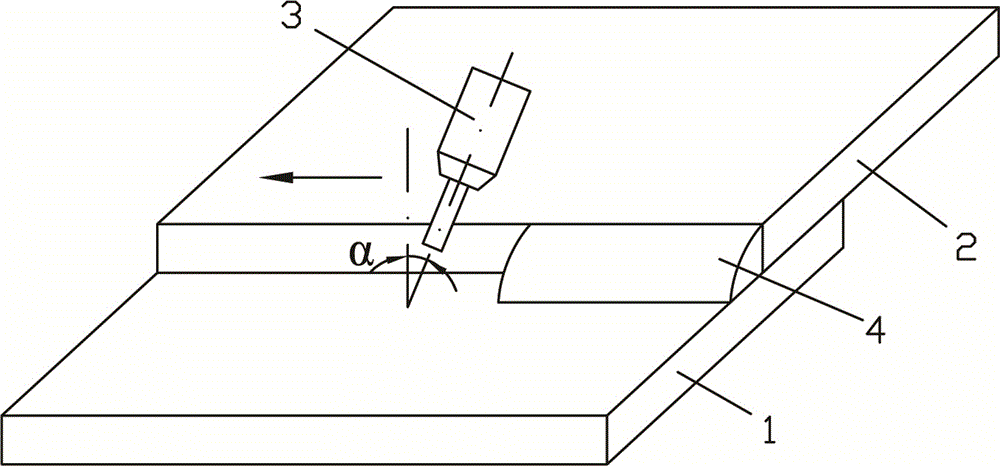

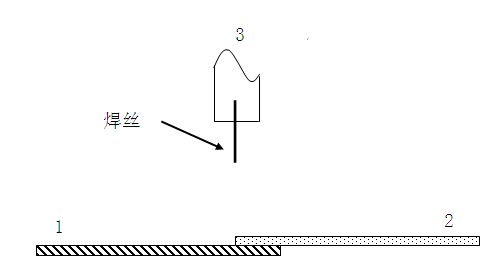

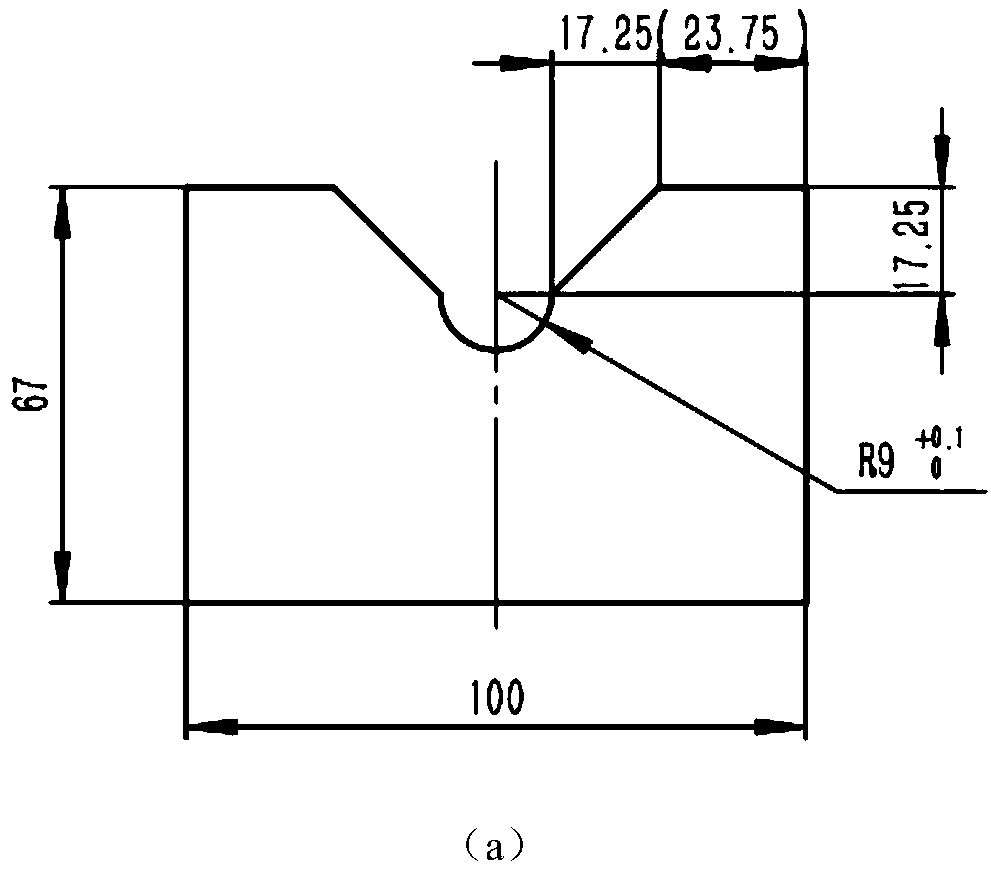

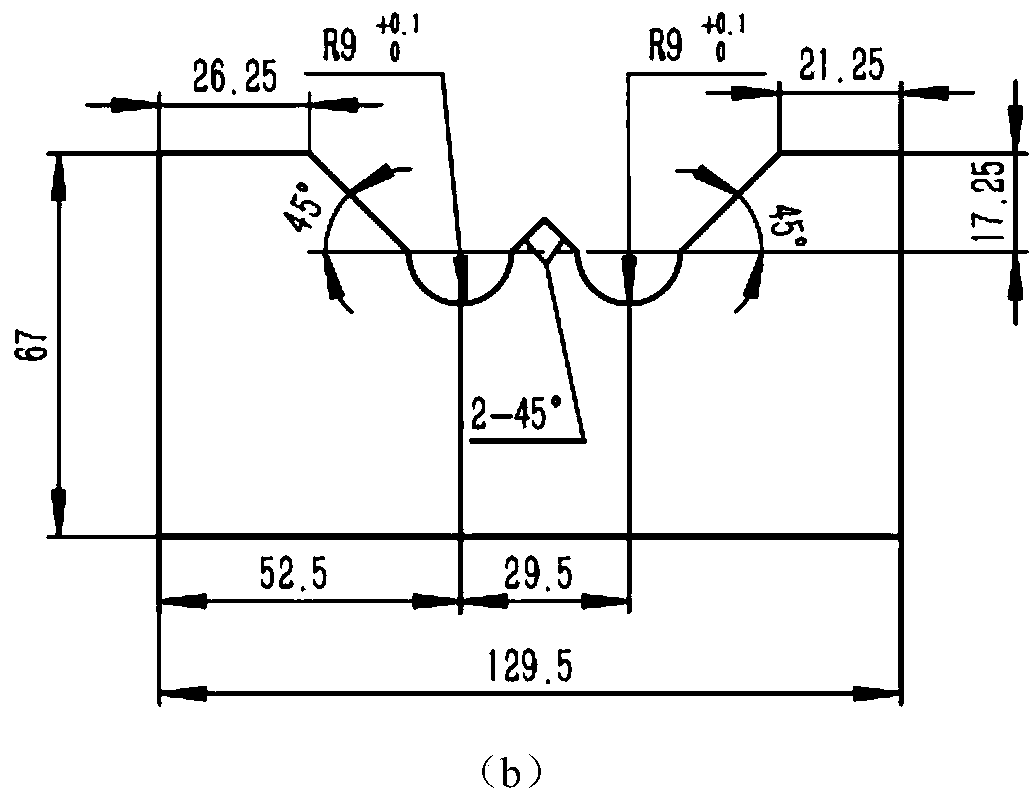

Method for preparing steel-aluminum dissimilar metal overlap joint by adopting CMT technology

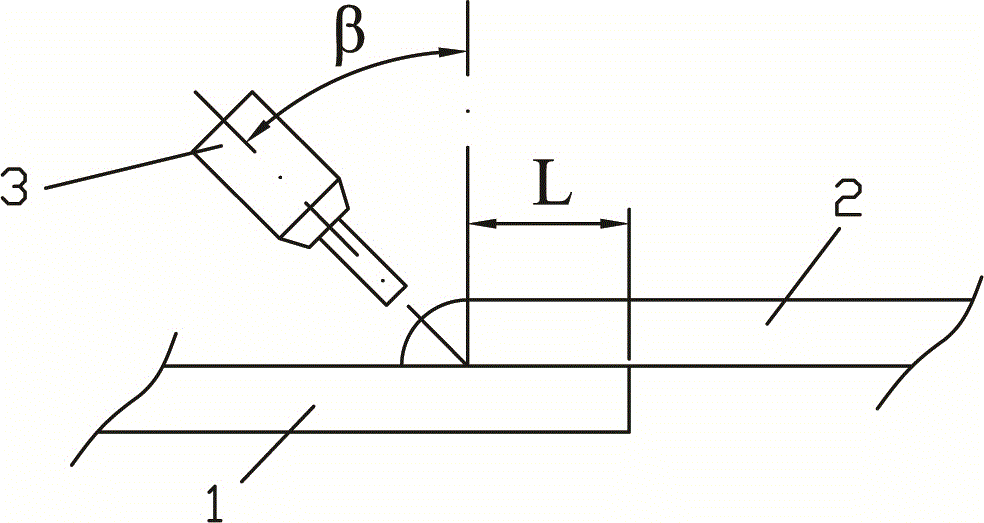

InactiveCN106624281ALow heat inputIncrease heat inputArc welding apparatusWelding/soldering/cutting articlesMetalPerpendicular distance

The invention provides a method for preparing a steel-aluminum dissimilar metal overlap joint by adopting the CMT technology. The method comprises the following steps: an aluminum alloy plate is placed on a galvanized steel plate in an overlap manner and fixed by utilizing a fixture, wherein the overlap amount ranges between 5 mm and 20 mm; and a CMT welding machine is utilized, a welding gun is inclined towards the aluminum alloy plate to form an angle of 1-45 degrees with the vertical direction, the welding gun is inclined towards the forward direction by 5-30 degrees, the perpendicular distance between the welding gun and the galvanized steel plate is 10-20 mm, and the welding speed is 0.4-1.0 m / min. According to the method provided by the invention, the CMT technology is improved based on an original MIG welding power source, thereby converting molten droplet transfer into cold metal transfer, and reducing the metal spatter when the heat input during a welding process is reduced; and accordingly, the method is very suitable for welding of the aluminum alloy plate and the galvanized steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

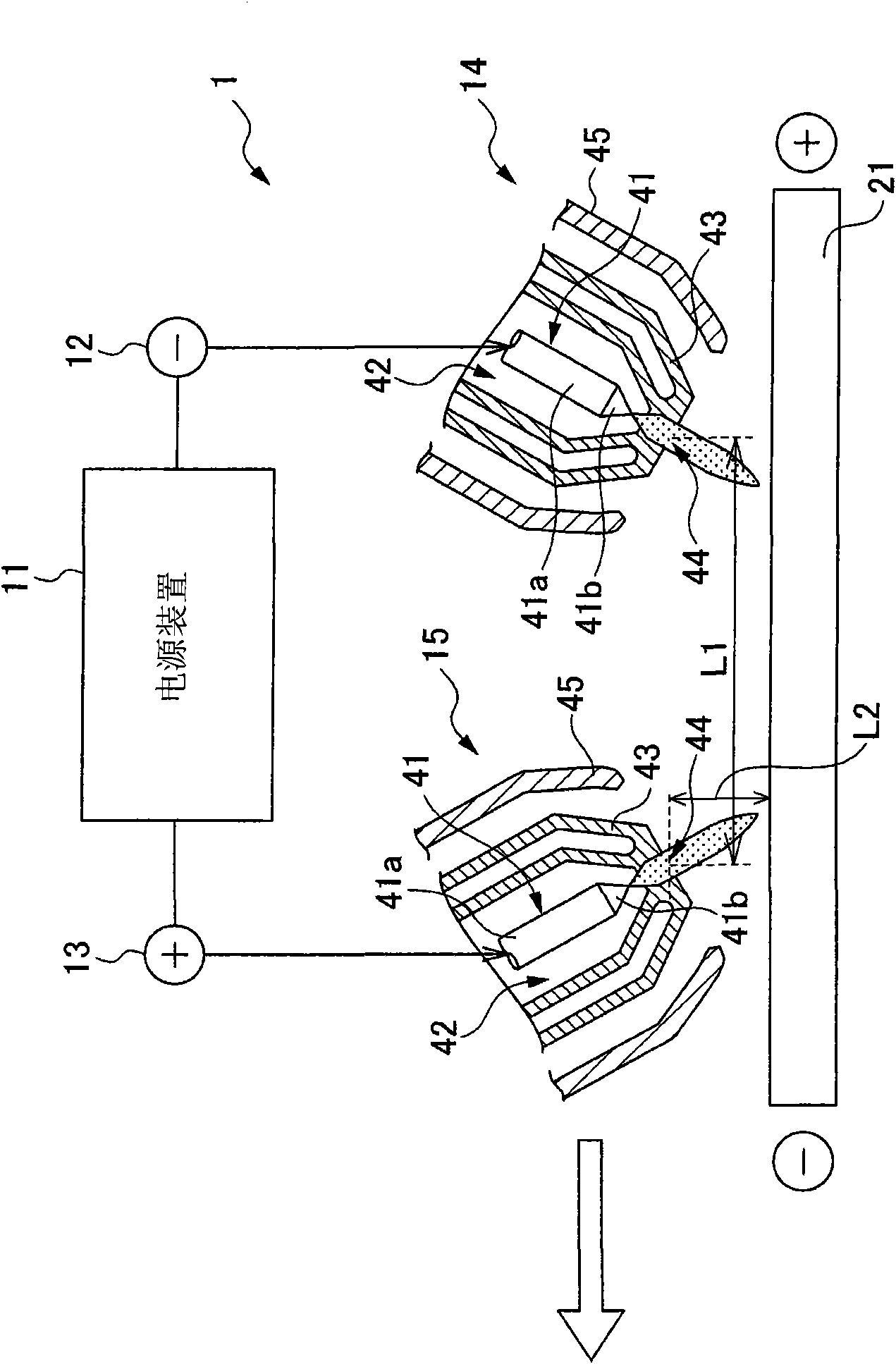

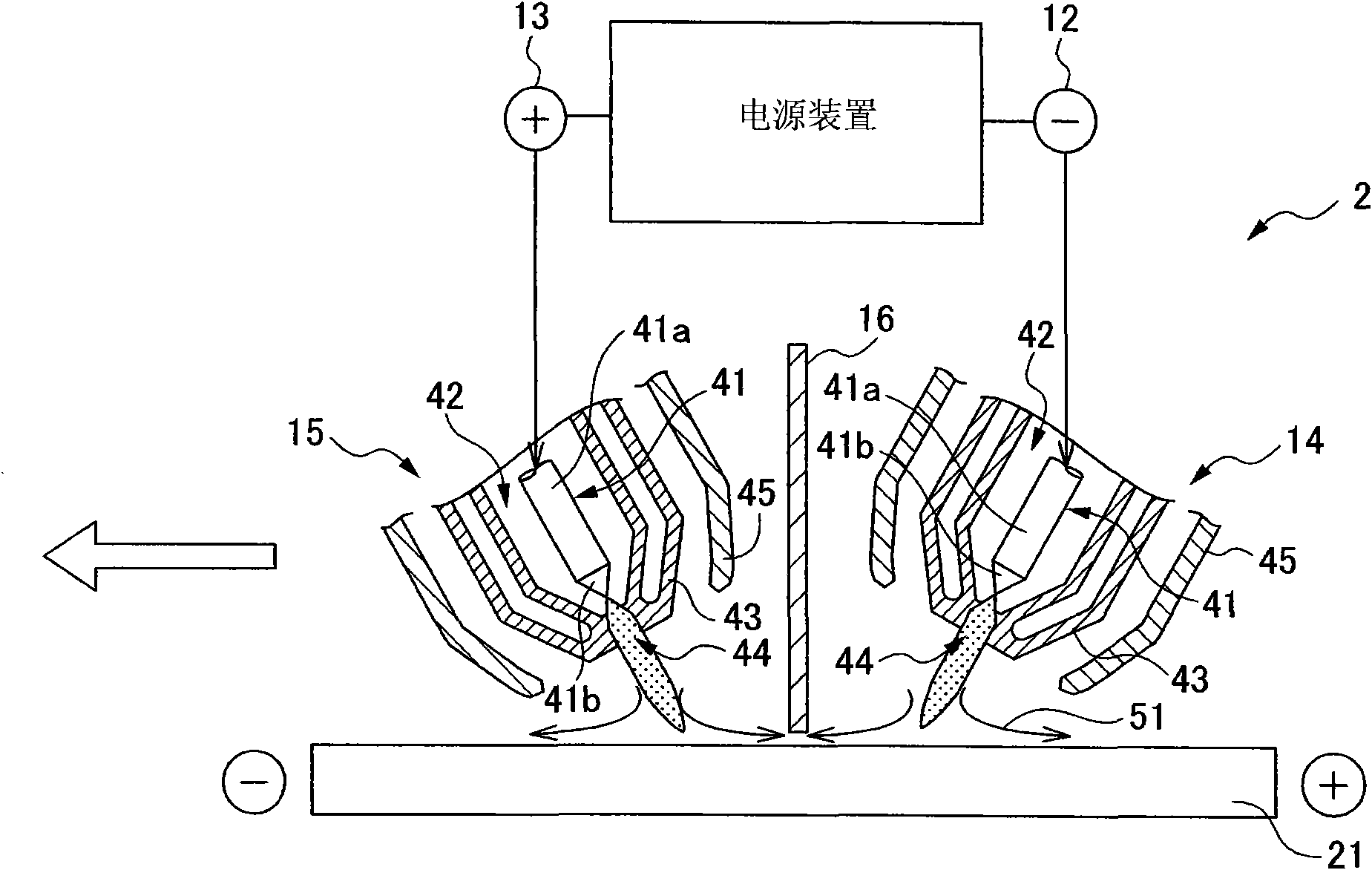

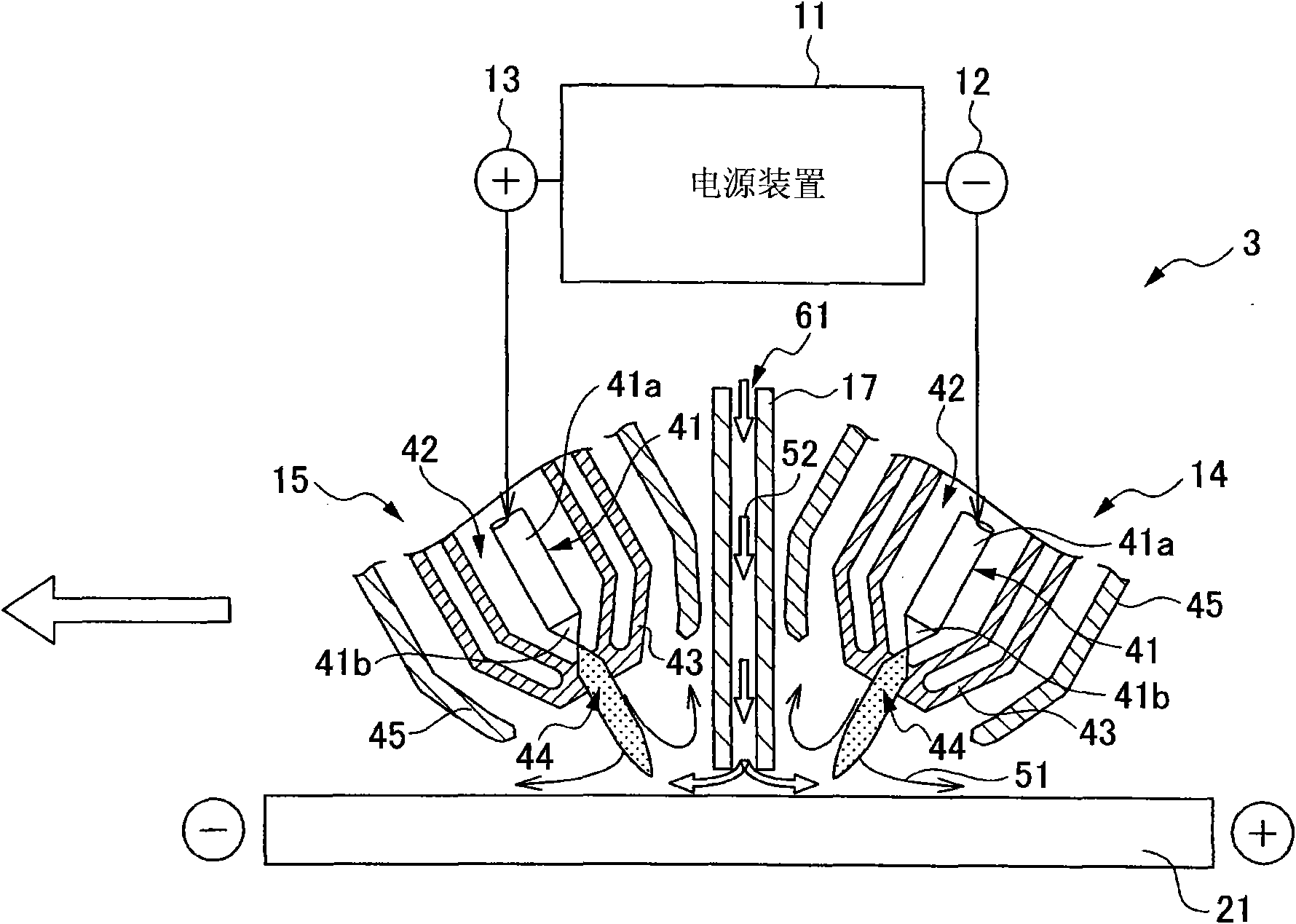

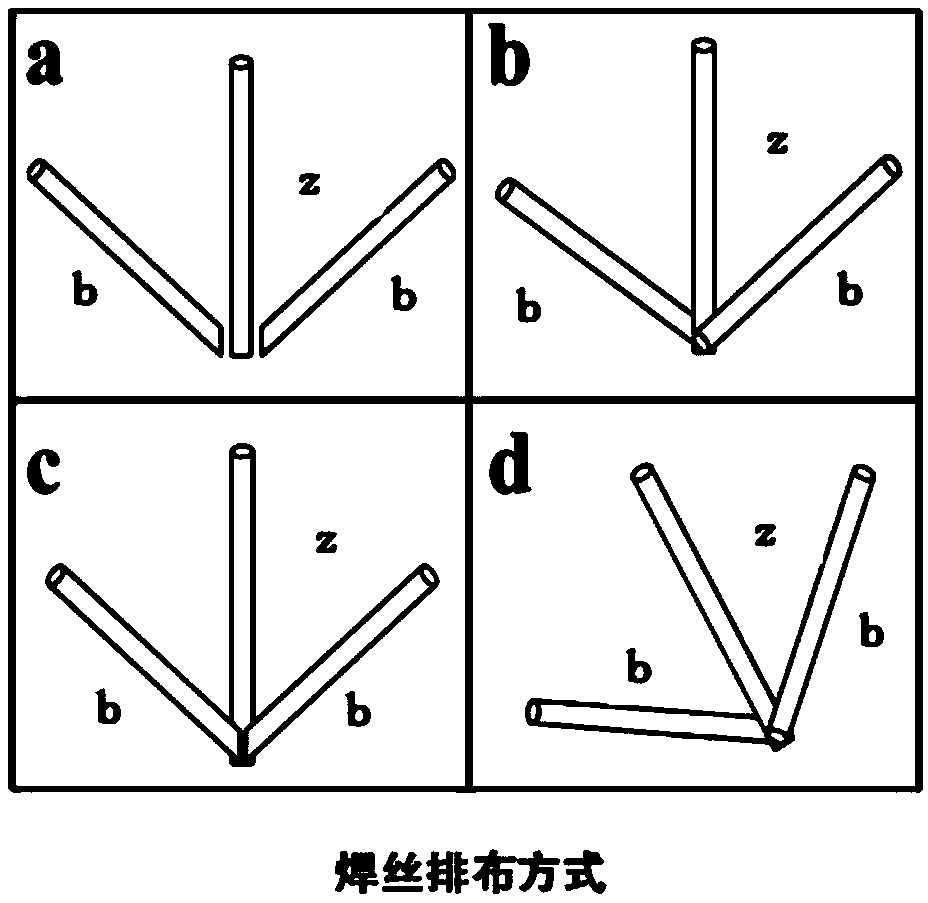

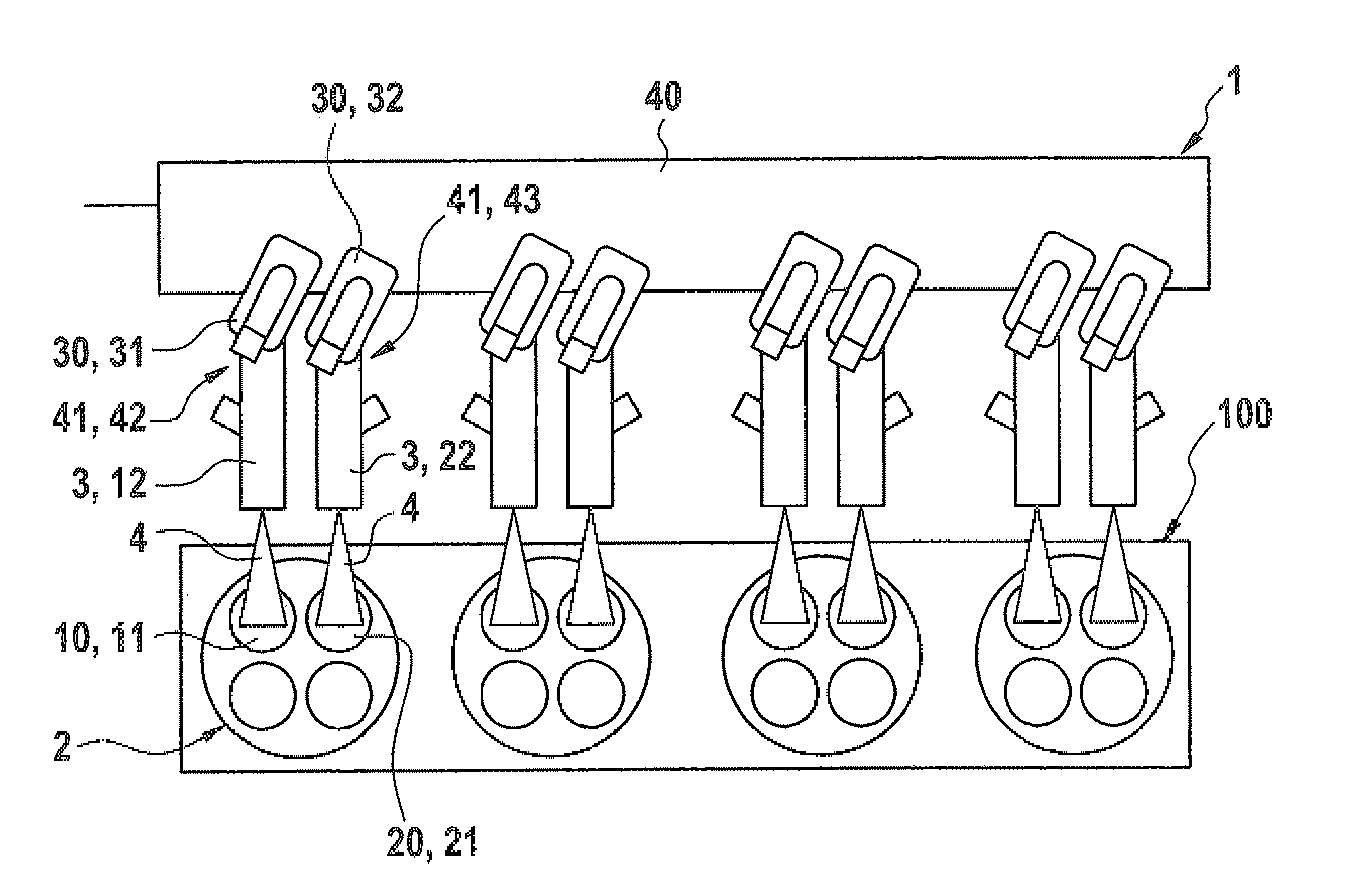

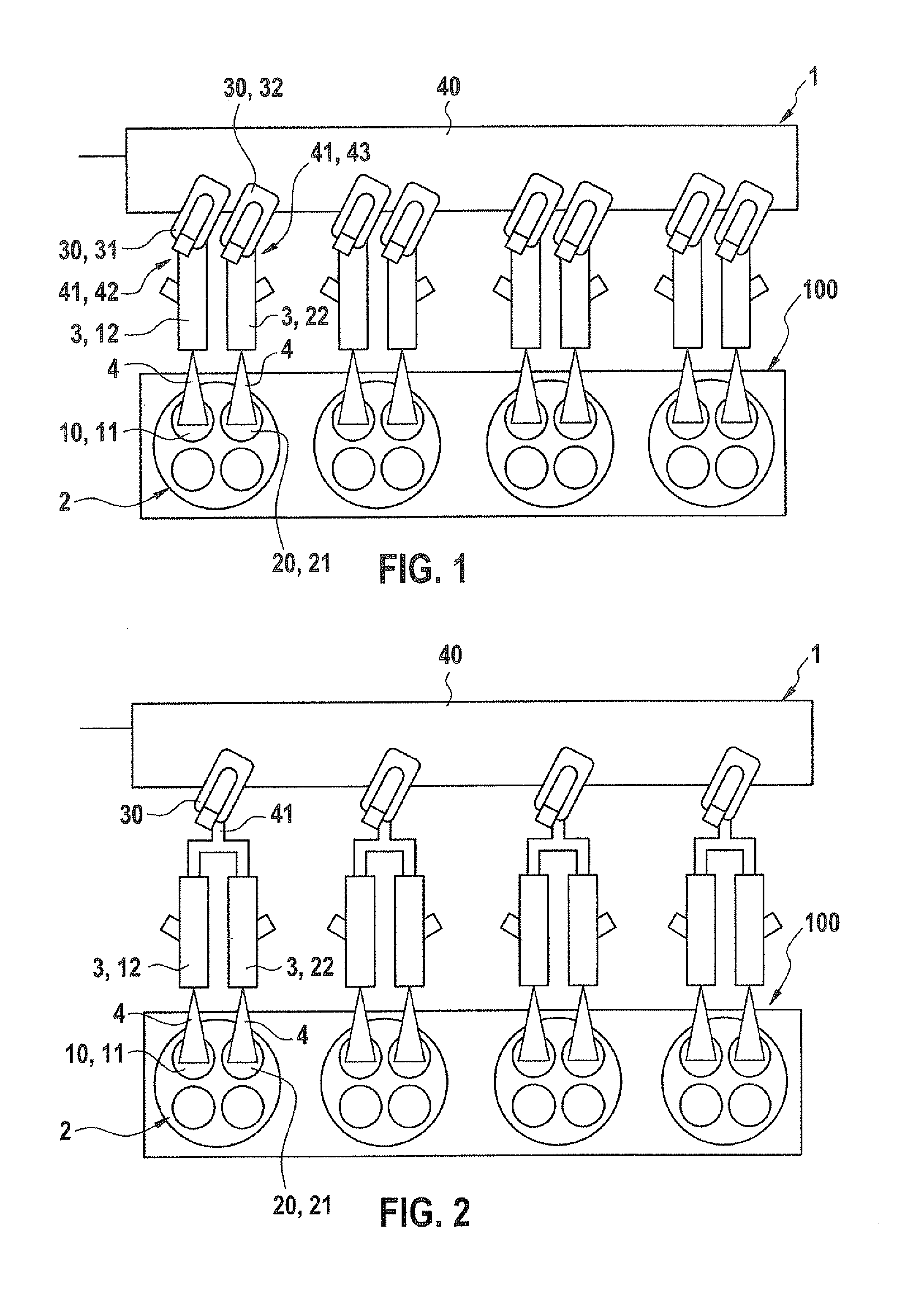

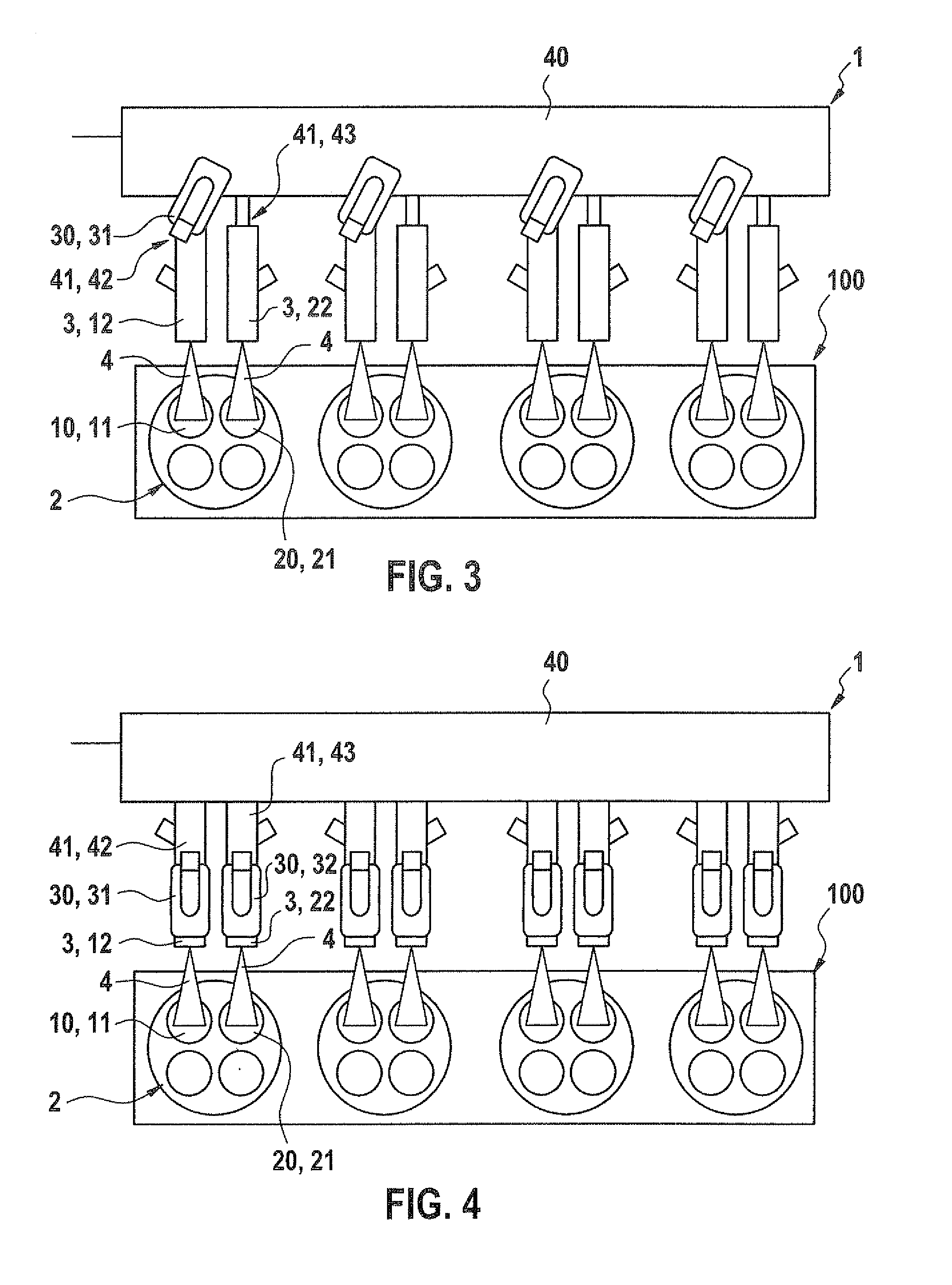

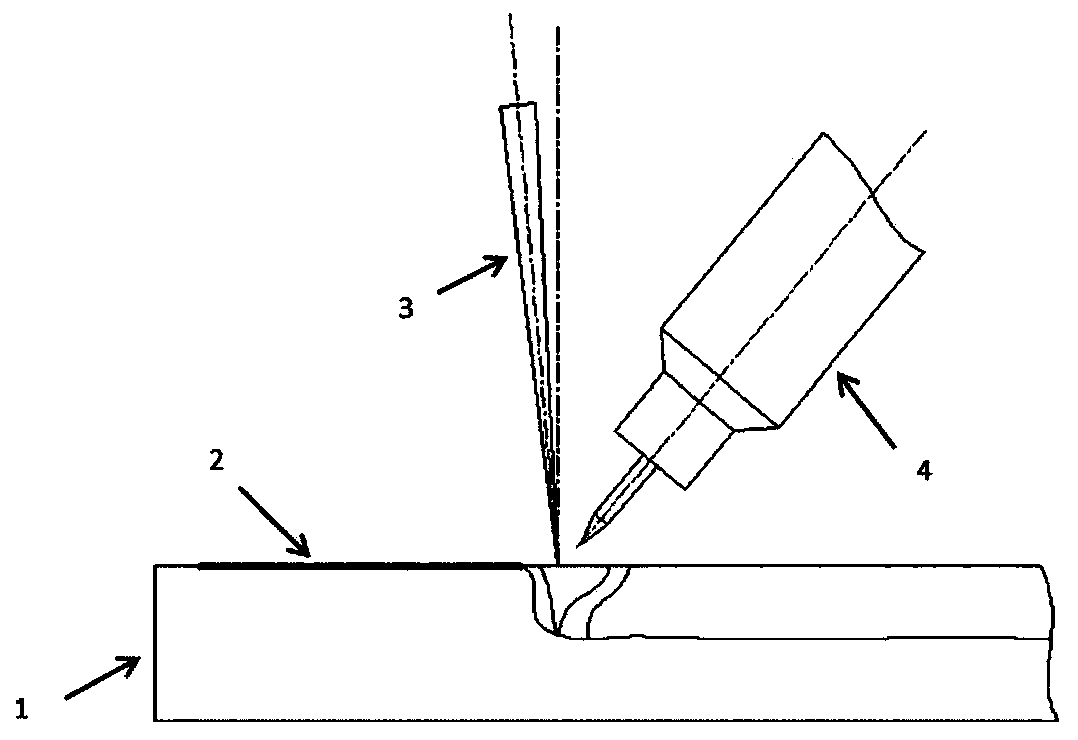

Two-electrode arc welding device and two-electrode arc welding method

InactiveCN102126066AAvoid arcingIncrease heat inputArc welding apparatusPlasma welding apparatusTorchElectric potential

A two-electrode arc welding device and two-electrode arc welding method are provided for performing welding with improved penetration performance using two non-consumable electrodes. In a two-electrode arc welding device 1, a power-supply unit 11 outputs a straight-polarity voltage and a reverse-polarity voltage, which has a different electrical potential than the straight-polarity voltage. The straight-polarity voltage output from the power-supply unit 11 is applied to a non-consumable electrode 41 of a straight-polarity arc torch 14, whereby an arc is formed. The reverse-polarity voltage output from the power-supply unit 11 is applied to a non-consumable electrode 41 of a straight-polarity arc torch 15, whereby an arc is formed. An arc spacing distance L1, which is a distance between the ends of both the straight-polarity arc torch 14 and the reverse-polarity arc torch 15, is set to be at least a minimum distance at which an arc will not occur therebetween (arc spacing critical distance).

Owner:HONDA MOTOR CO LTD

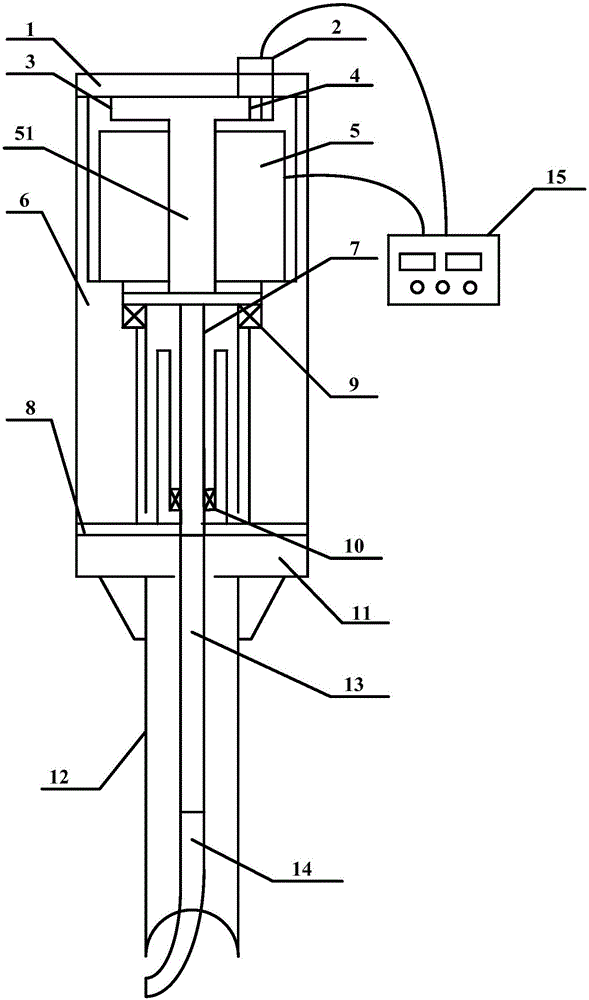

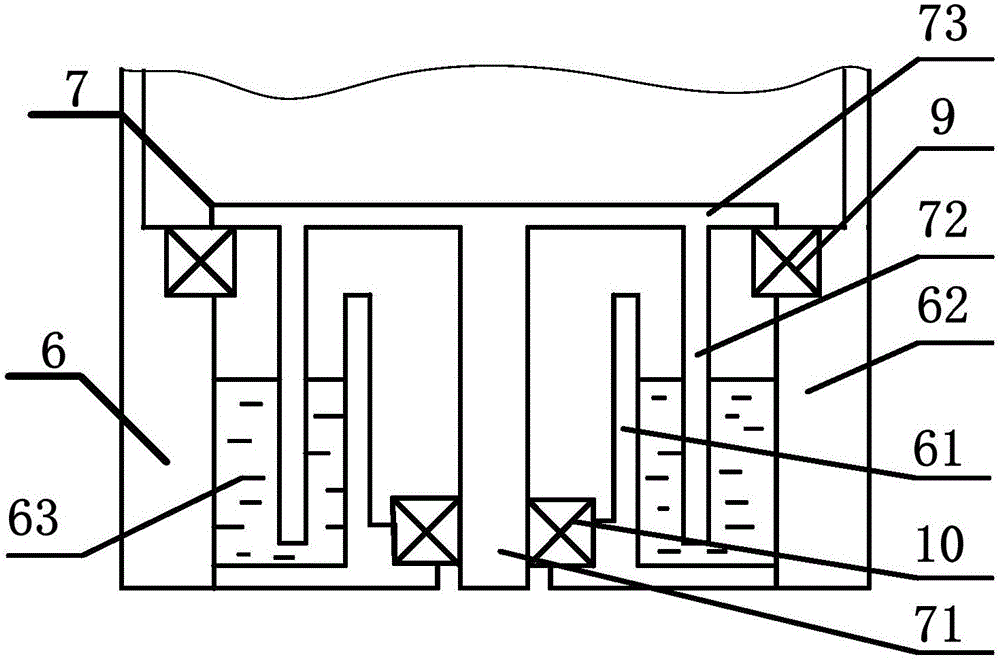

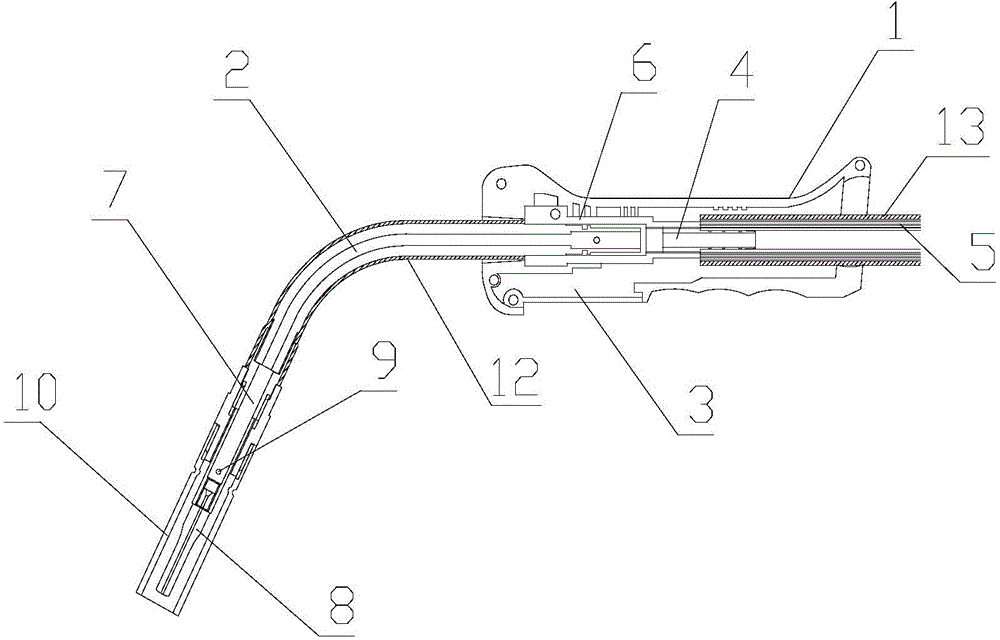

Rotary swing type welding torch and welding method

InactiveCN106180994AEasy to set upIncrease heat inputCooled electrode holdersElectrode accessoriesEngineeringWelding torch

The invention provides a rotary swing type welding torch. The rotary swing type welding torch comprises a current contact nozzle, a rotary swing driving mechanism and a control device, wherein the control device is connected with the rotary swing driving mechanism so as to control the rotary swing driving mechanism to move, and the movement output end of the rotary swing driving mechanism is connected with the current contact nozzle so as to adjust the position of the current contact nozzle and / or enable the current contact nozzle to make rotary swing movement according to preset swing parameters. According to the rotary swing type welding torch, two operating modes of swing and rotation can be realized, so that heat input to the side wall of a groove can be increased by virtue of electric arc swing, and the problem of poor fusion of the side wall and the bottom of the groove during narrow gap welding of large-thickness plates is solved. The invention further provides a welding method.

Owner:HARBIN INST OF TECH AT WEIHAI

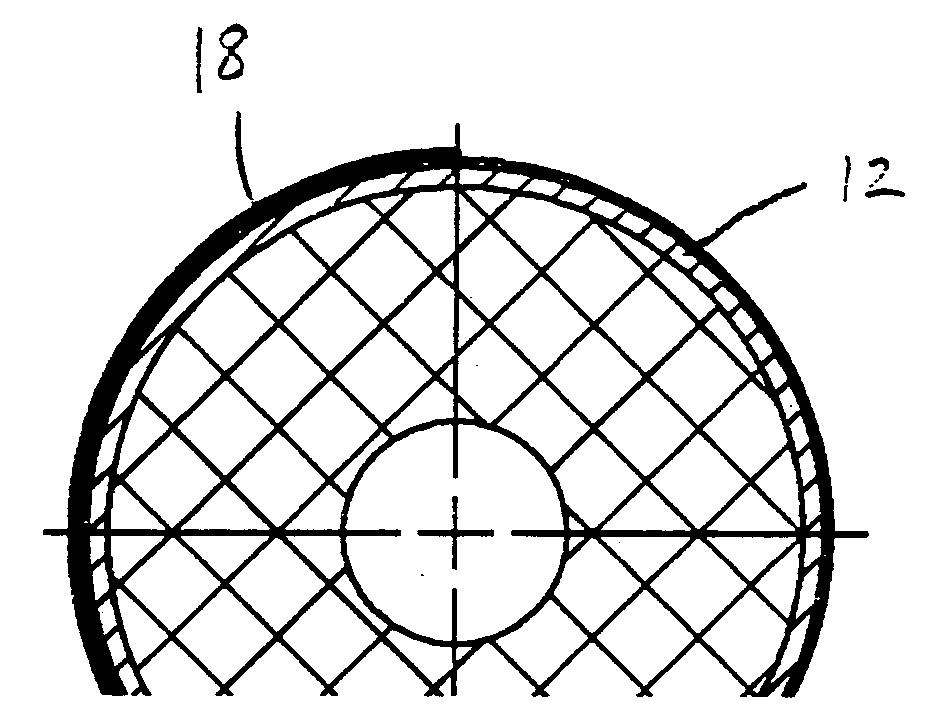

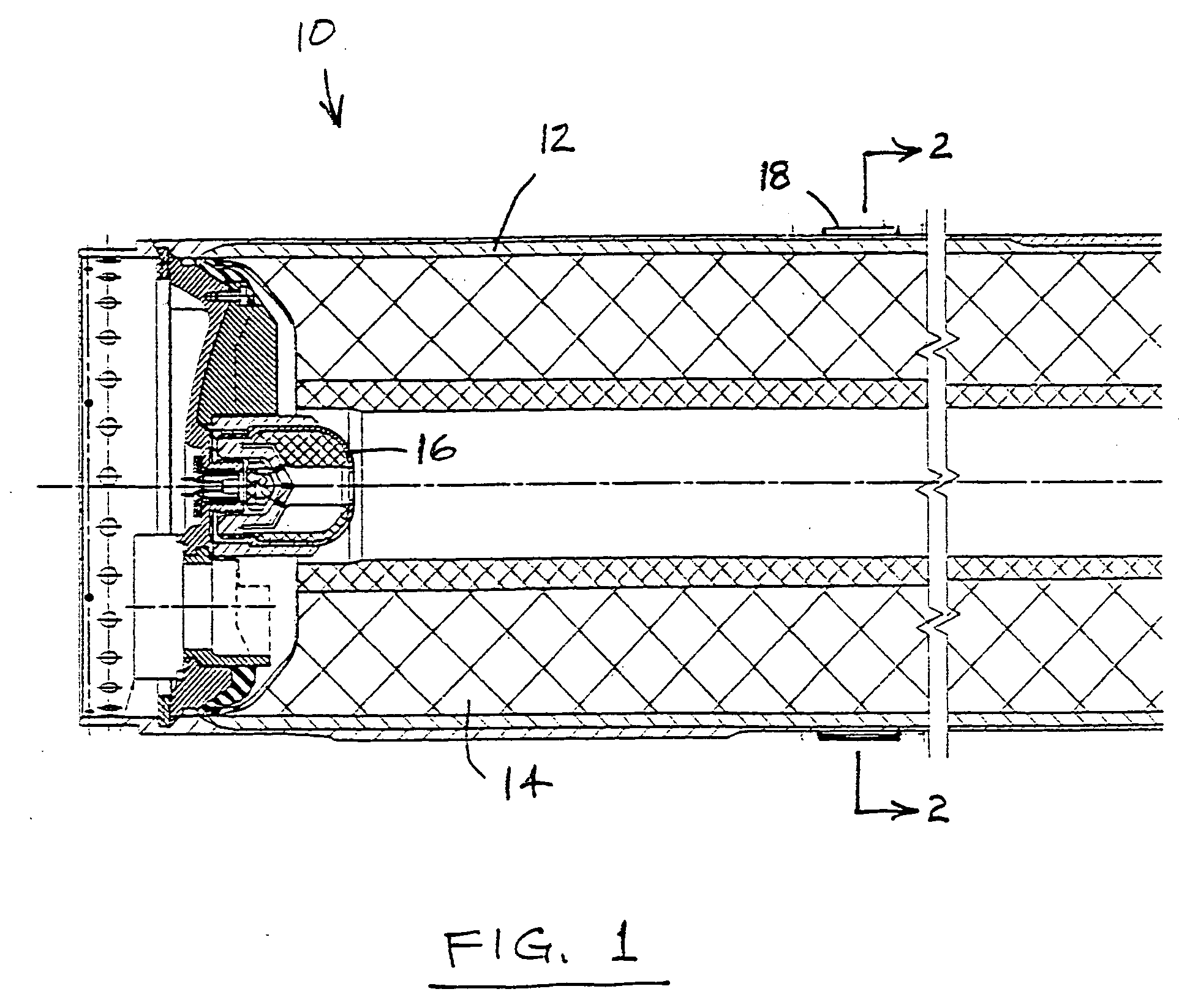

Apparatus and method for passive venting of rocket motor or ordnance case

InactiveUS20050193917A1Increase heat inputAmmunition projectilesHand grenadesExplosive materialPropellant

Passive venting apparatus and method for a rocket motor or ordnance device containing propellant or explosive material enclosed in a case, which presents an explosion hazard when subjected to external heat. A combustible strip is secured to the exterior surface of the case and is constructed to burn and generate sufficient heat when exposed to predetermined external heat to weaken the adjacent portion of the case and effect rupture of the case to vent interior gases therein prior to autoignition of the propellant or explosive.

Owner:AEROJET GENERAL CORP

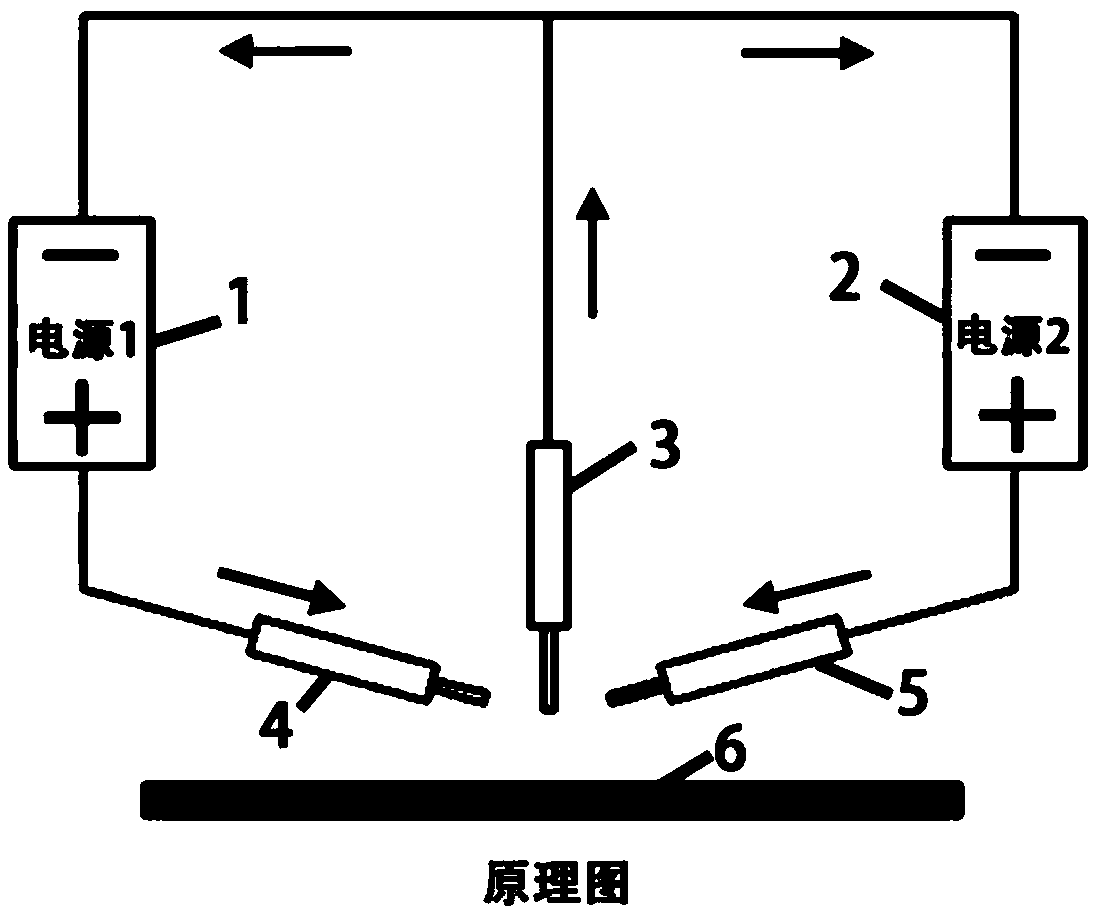

Three-wire gas shielded indirect arc welding method, device and application of method

ActiveCN109079287AIncrease heat inputHigh deposition coefficientArc welding apparatusWelding/soldering/cutting articlesEngineeringVolumetric Mass Density

Owner:DALIAN UNIV OF TECH

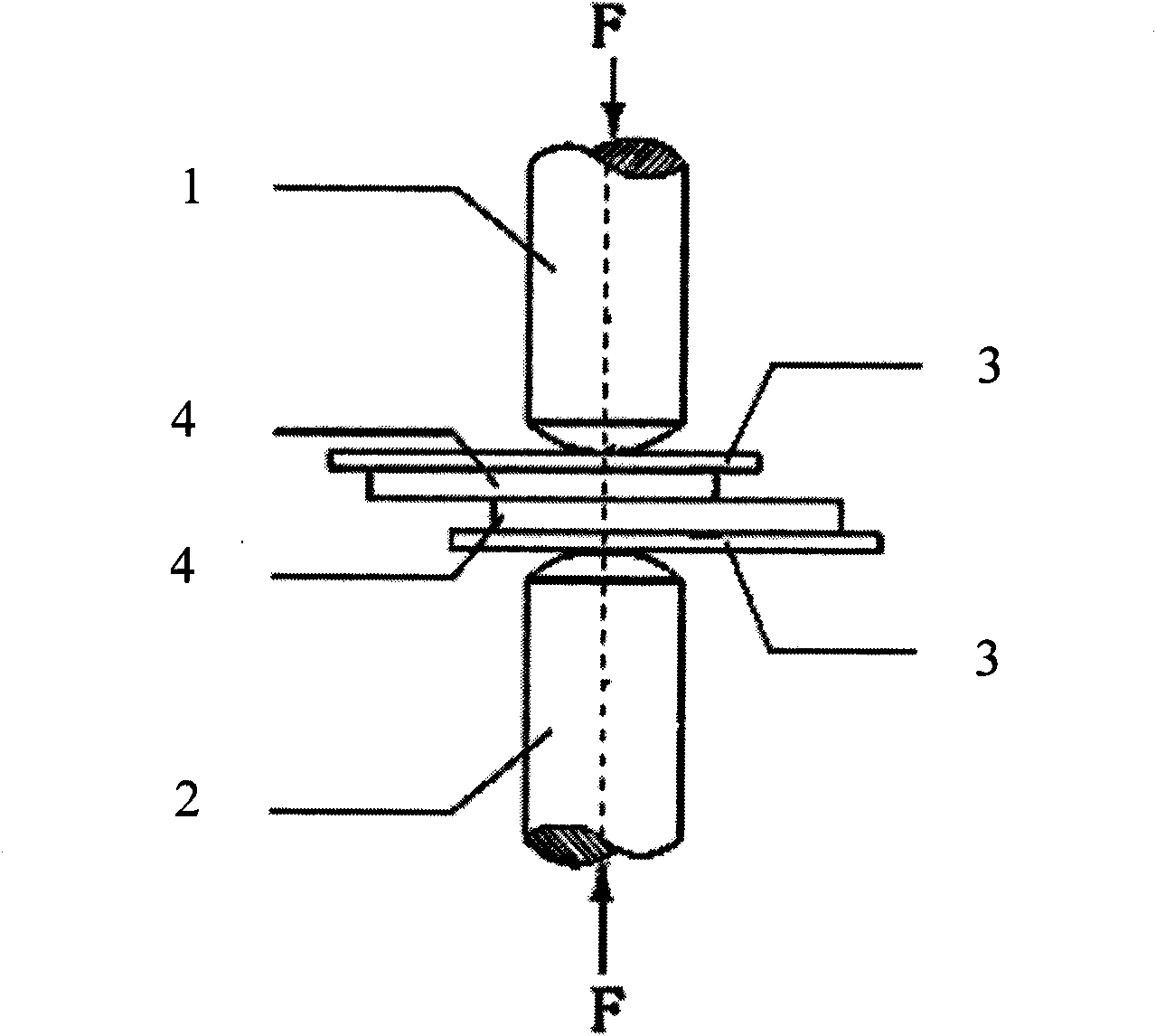

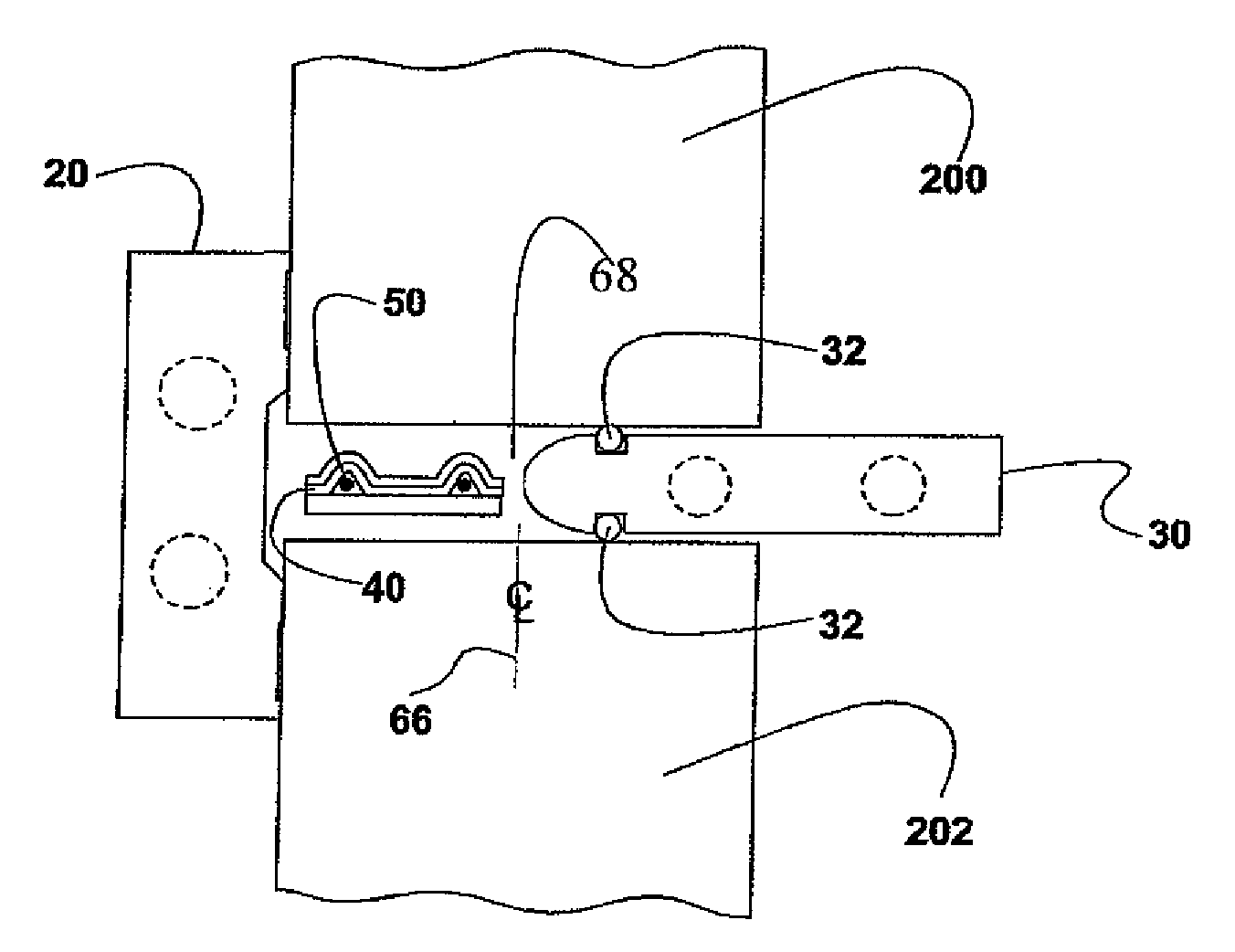

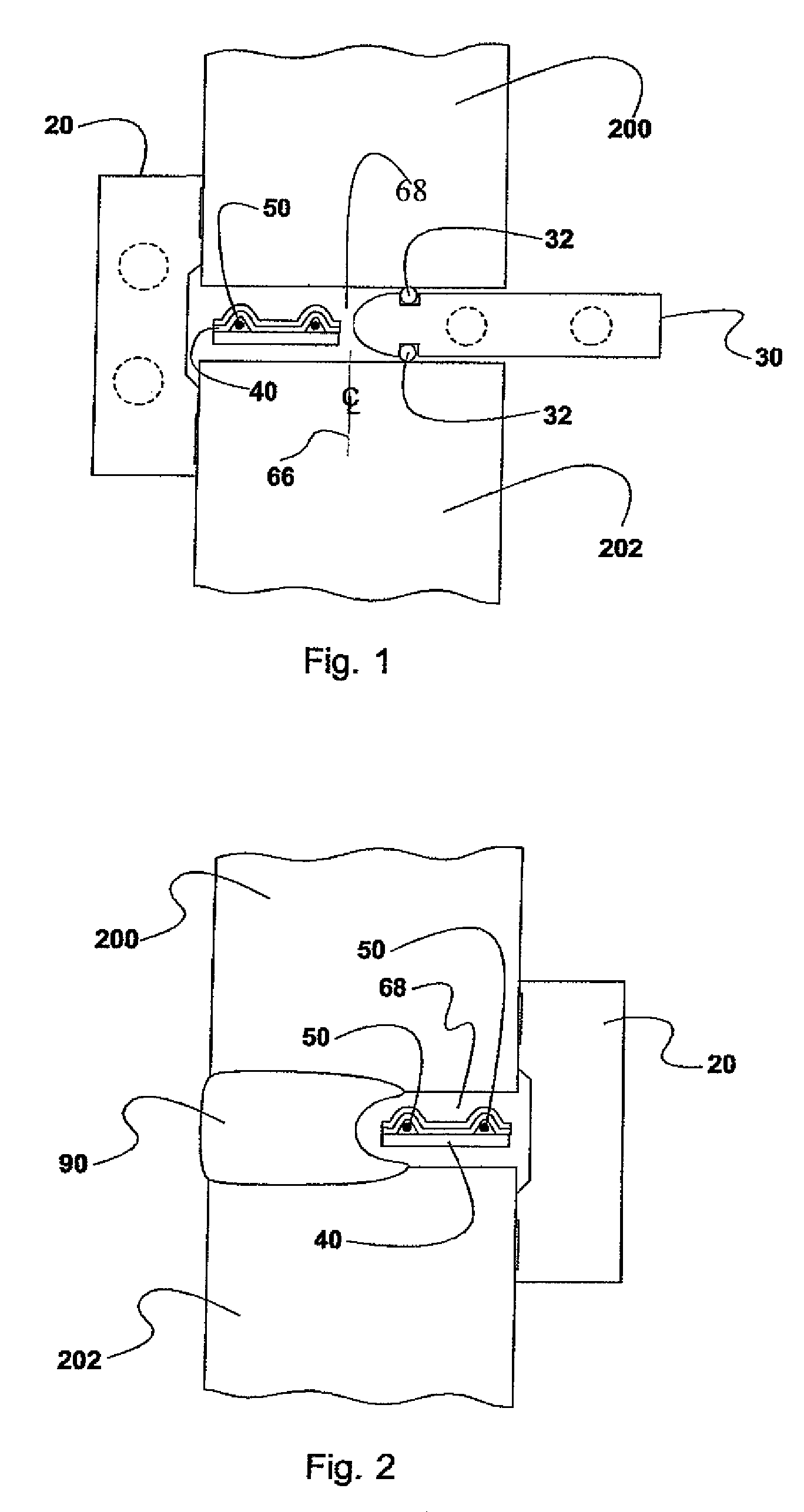

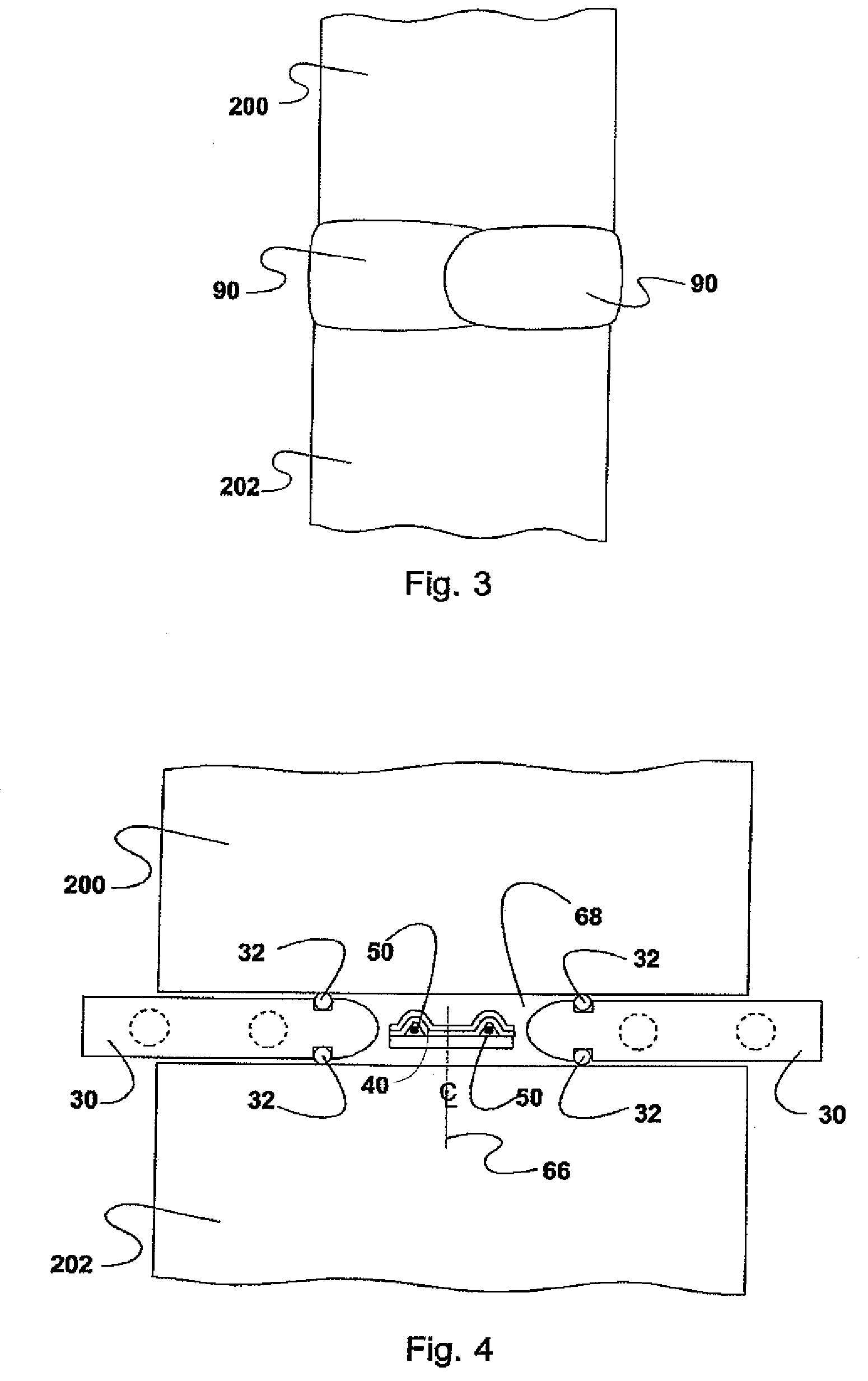

Friction stir welding tool with shoulders having different areas; methods using such tool; product welded with such tool

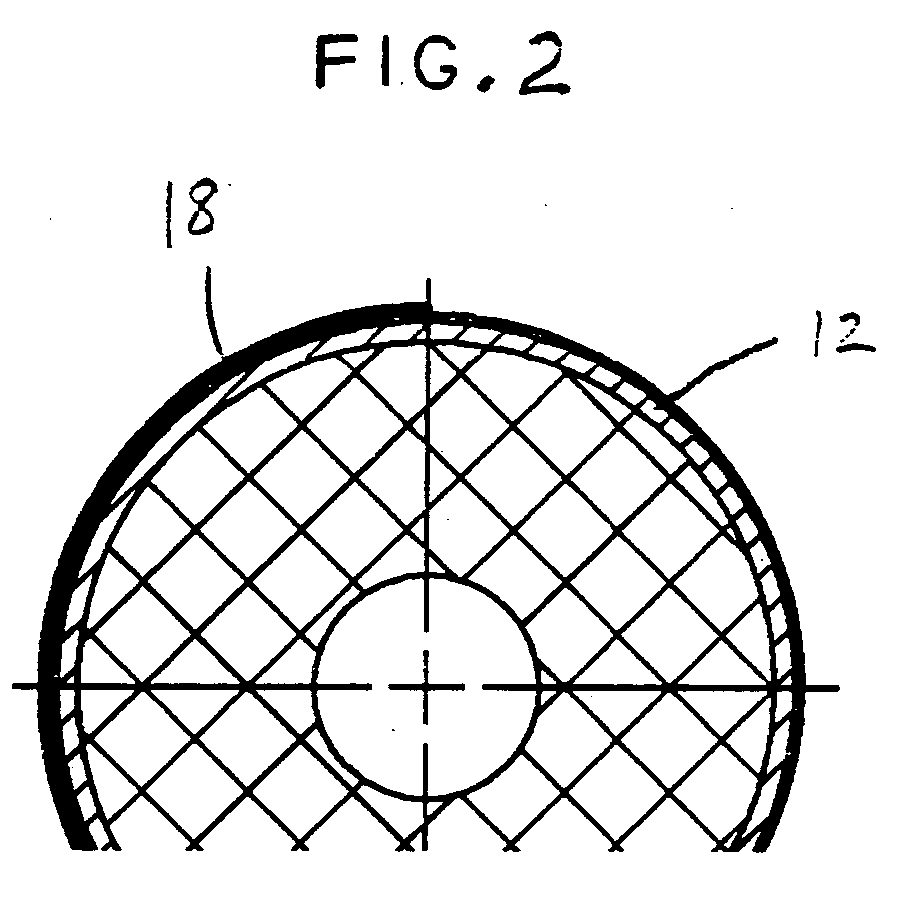

ActiveUS20140119814A1High strengthAvoid bending loadsWelding/cutting auxillary devicesVehicle componentsEngineeringFriction stir welding

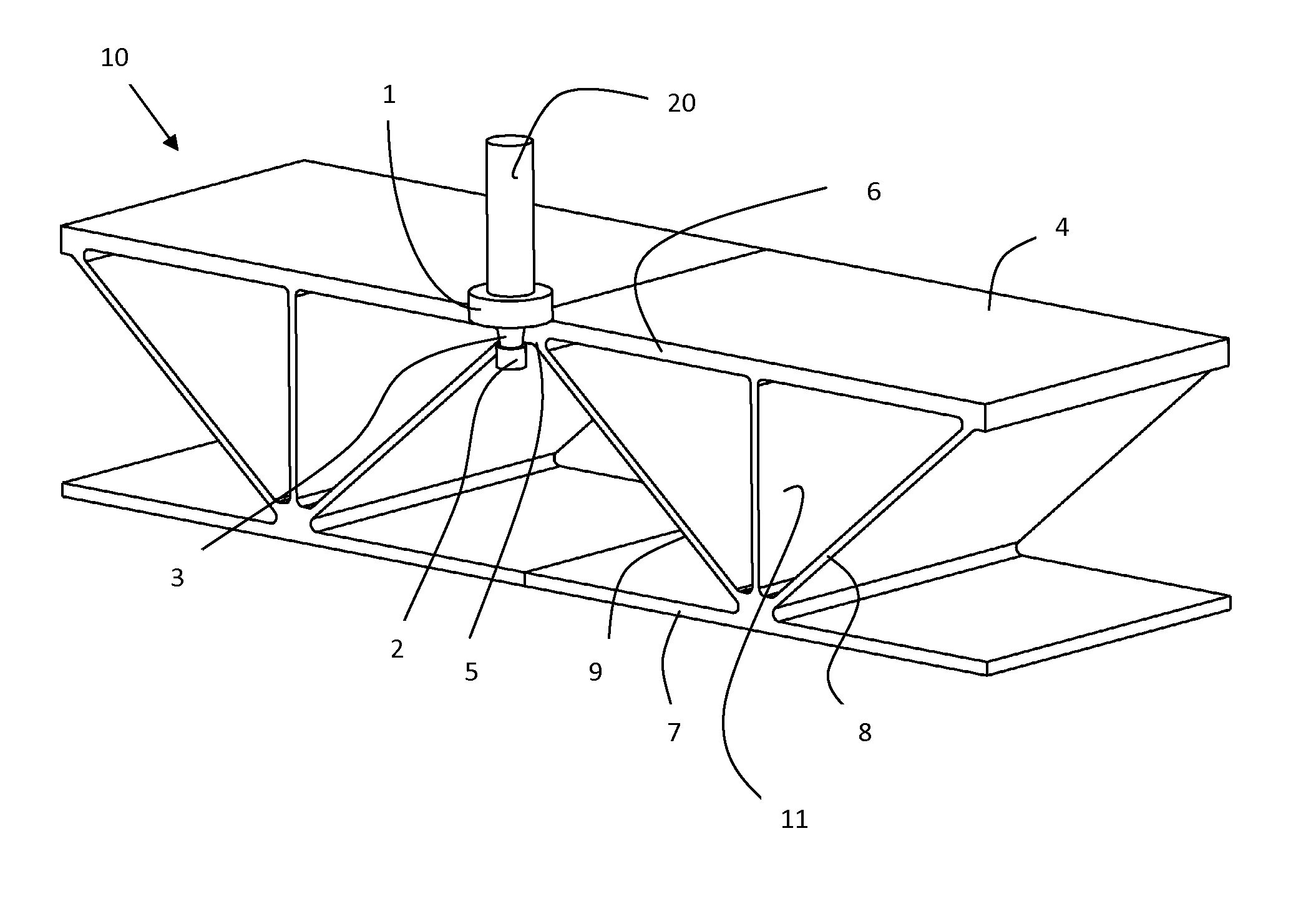

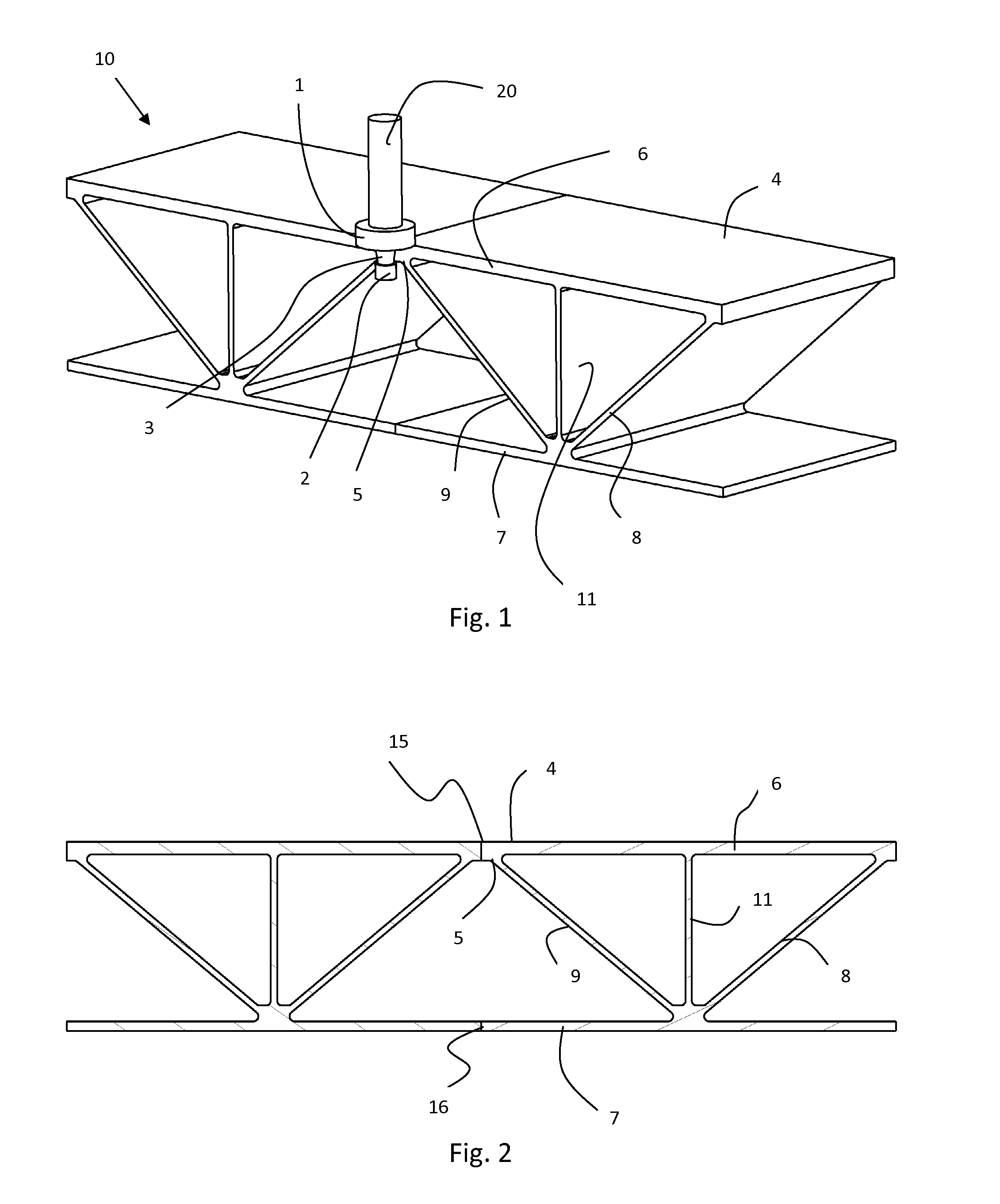

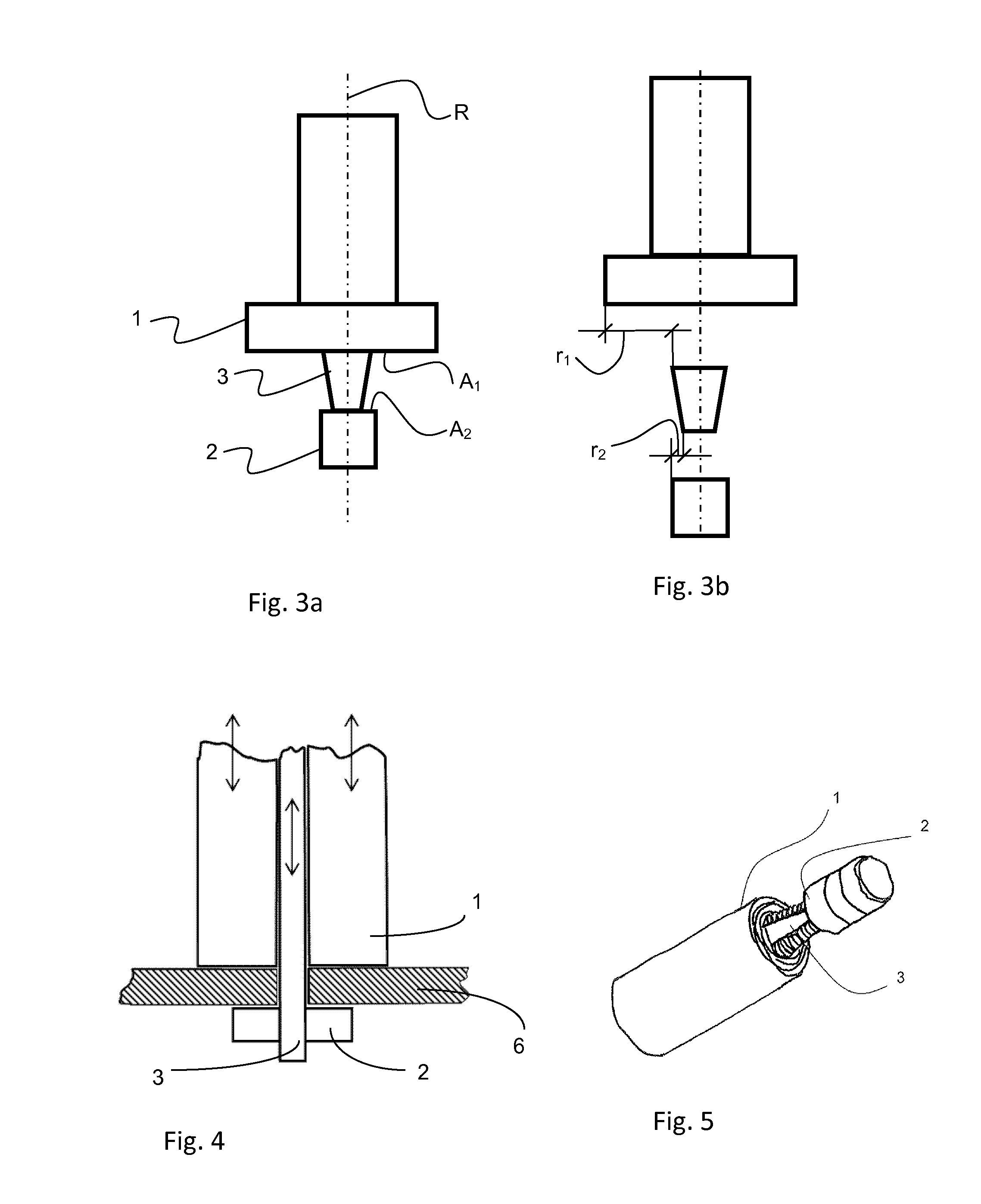

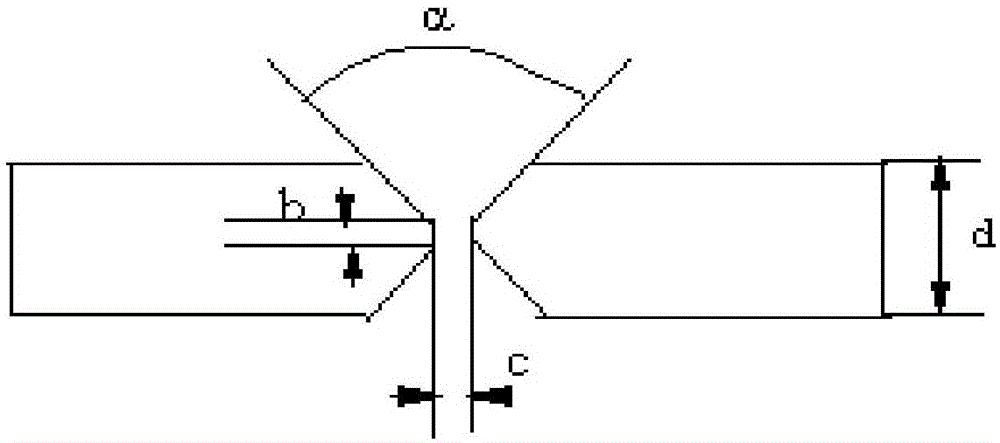

The present application relates to a friction stir welding tool (20) for joining two adjacent work pieces (10), which work pieces comprise portions (6) to be welded and having a narrow space there between on one side, said tool having an axis of rotation, and comprising a first shoulder (1), a second shoulder (2), and a pin (3) arranged so as to connect the first and second shoulders, wherein said first shoulder has a first contact surface for friction heat generation to the work pieces to be joined during welding, said first contact surface having a first contact area, and said second shoulder has a second contact surface for friction heat generation to an opposite surface (5) of the same portions of the work pieces to be joined, said second contact surface having a second contact area, the first and second areas having different sizes, where the first area is a larger sized area than the second area. The application also relates to a method of joining work pieces, a product comprising joined pieces, and the use of such friction stir welding tool.

Owner:SAPA

Non-preheating gas shielded welding method for wear-resistant steel plate

ActiveCN105149746AHigh strengthImprove toughnessArc welding apparatusWelding/cutting media/materialsWear resistantSteel plates

The invention discloses a non-preheating gas shielded welding method for a wear-resistant steel plate. The non-preheating gas shielded welding method comprises the following steps: adopting a high-strength wear-resistant steel plate with carbon equivalent greater than 0.48% and hardness level of HBW450; selecting a gas mixture of 20% CO2 and 80% Ar and a GHS70-2 soldering wire; adopting fixed-point welding, not preheating before welding, and controlling a temperature between welding beads of a filling and cosmetic-welding welding seam to 100-150 DEG C; adopting an arc-connected left welding method for backing welding, controlling backing welding current to 150-170 A, welding voltage to 18-22V and welding speed to 10-15cm / min, and guaranteeing good back forming; controlling welding current during interlayer and cosmetic welding to 200-230 A, welding voltage to 25-28 V and welding speed to 20-25cm / min; and controlling thermal input to 16-20kJ / cm. According to the non-preheating gas shielded welding method, a welding joint has relatively high strength, and a welding seam has excellent low-temperature toughness resistance.

Owner:SHANDONG IRON & STEEL CO LTD

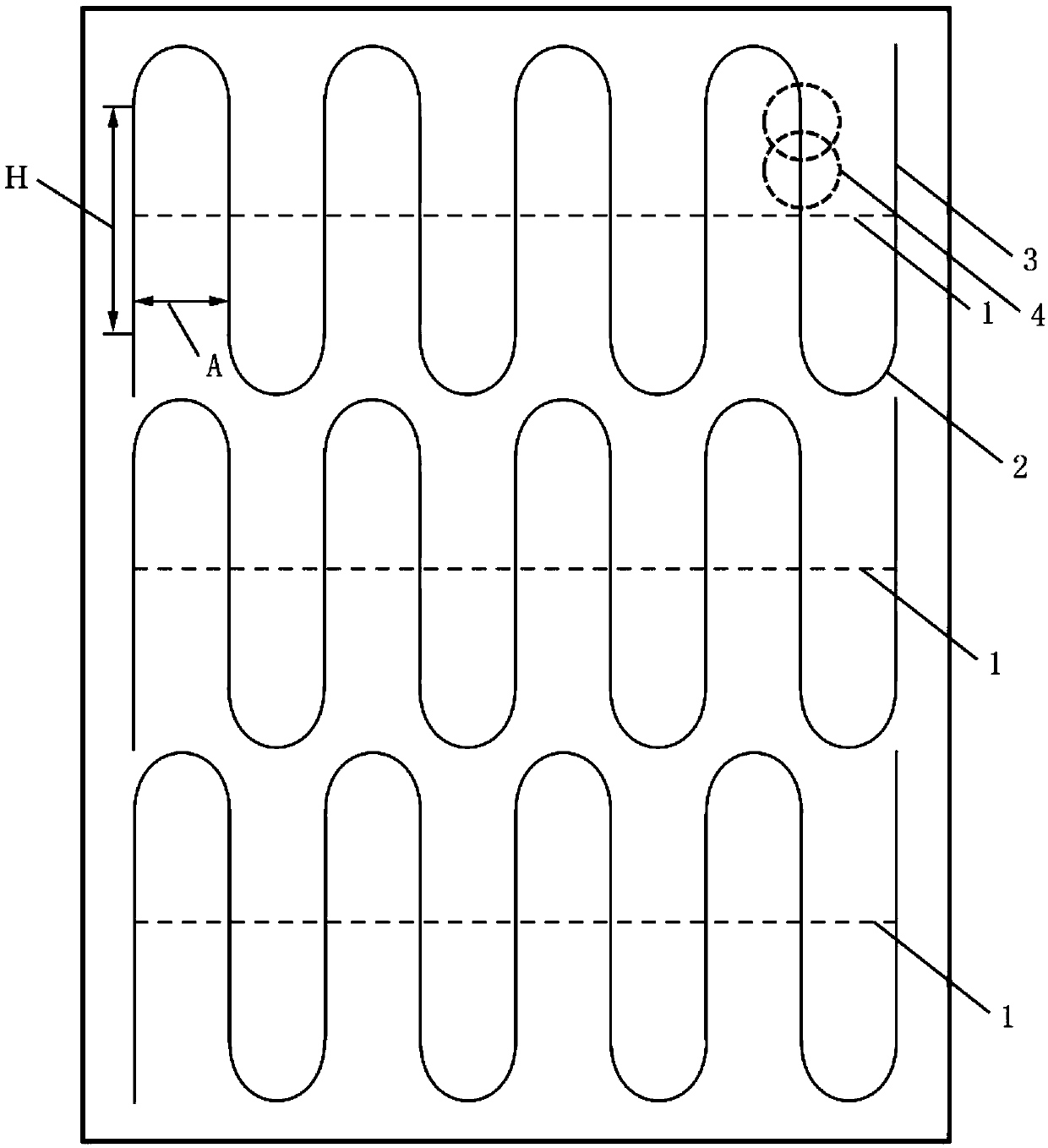

Laser scanning path planning method used for additive-manufacturing three-dimensional object

ActiveCN109648080ASolve the problems of difficult control and low forming efficiencyHigh energyAdditive manufacturing apparatusIncreasing energy efficiencyLight spotHigh energy

The invention discloses a laser scanning path planning used for additive-manufacturing a three-dimensional object. The laser scanning path planning method comprises the following steps: firstly, inputting each layer of slice files of a part model; then, determining a partition datum line according to structural features of a part and user settings, and partitioning each layer of slices of the part; and finally, performing S-shaped scanning planning in each partition, wherein an S-shaped scanning path comprises a datum line, a circular-arc section and a linear section. According to the method disclosed by the invention, S-shaped scanning path planning is performed on sliced files, heat input can be improved in a scanning process, relatively high energy is kept, and the forming quality problem due to the fact that burning loss is caused as thermal stress is too great or scanning speed is low while cold speed is too high during great-width and large-light-spot part processing can be effectively solved. While part quality is improved, skip reduction is realized through circular-arc oscillation, so that the service life of a laser unit is prolonged.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

Process for reforming hydrocarbons

ActiveUS20130345324A1Lower potentialReduce trafficSequential/parallel process reactionsHydroxy compound preparationHeat flowProcess engineering

A process and plant for the production of synthesis gas by a series arrangement of heat exchange reforming and autothermal reforming stages, in which the heat required for the reforming reactions in the heat exchange reforming stage is provided by hot effluent synthesis gas from the autothermal reforming stage. The invention optimizes the operation and control of an arrangement of heat exchange reforming and autothermal reforming stages and involves the introduction of an additional waste heat boiler.

Owner:HALDOR TOPSOE AS

Method for adding a fusible material to a container wall

ActiveUS20100239877A1Additional costProcess be complicateFurnaces without endless corePig casting plantsInduction heaterMetal

A method for adhering a shaped fusible material (6) to a portion of a metallic container wall (2) comprising applying the shaped material to said wall portion in a contacting relationship, heating said wall portion with an induction heater to melt the contacting surface of the shaped fusible material, and cooling the assembly to re-solidify the melted surface of the fusible material; and products of the foregoing method.

Owner:TEMPRA TECH

Injection device and internal combustion engine

ActiveUS20120279472A1Cold start capacityReduce gas emissionsElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

An injection device for an internal combustion engine is proposed having at least one injection valve system for injecting fuel into an intake manifold of the internal combustion engine and at least one heating device for pre-heating fuel injected by the injection valve system, the injection valve system including a first injection valve for injecting fuel in the direction of a first inlet opening of a combustion chamber of the internal combustion engine and a separate, second injection valve for injecting fuel in the direction of a second inlet opening of the combustion chamber.

Owner:ROBERT BOSCH GMBH

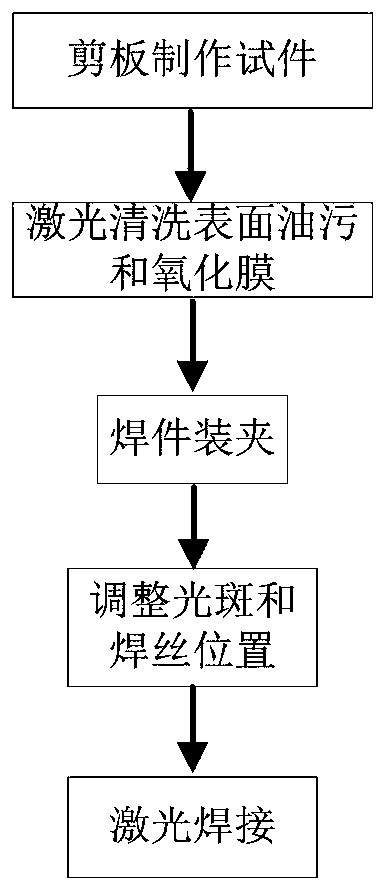

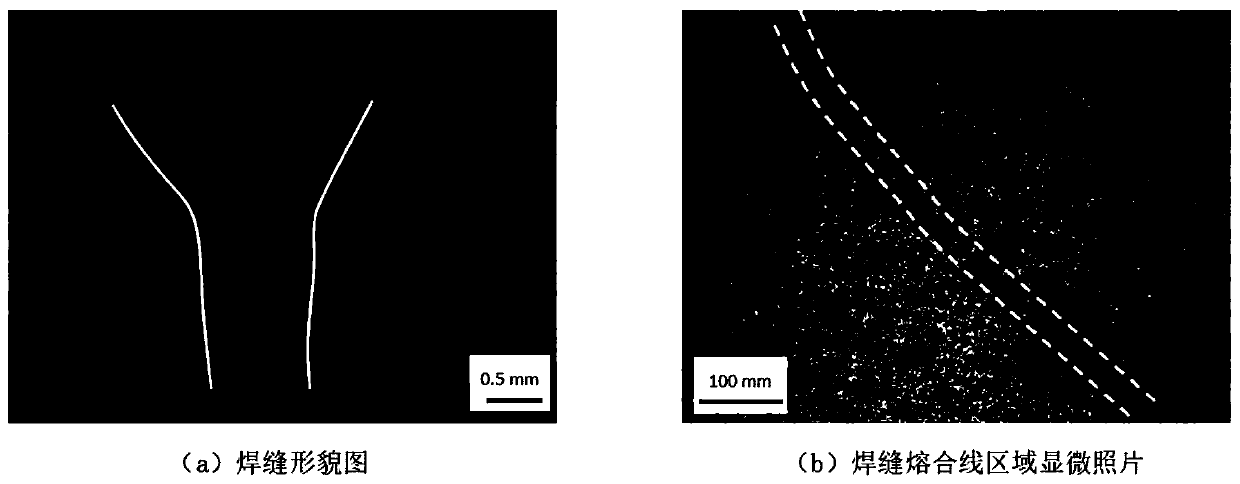

Aluminum alloy laser welding method

InactiveCN110052710AGuaranteed stabilityGeneration of controlCleaning using liquidsWelding/soldering/cutting articlesLiquid metalSpot welding

The invention discloses an aluminum alloy laser welding method. The aluminum alloy laser welding method is used for carrying out aluminum alloy laser welding under the specific laser head angle, wirefeeding angle and specific spot welding wire molten pool position relation, the stability of a molten pool and the timely liquid metal supplement of process air holes during the collapse of key holesare guaranteed, so that the generation of the process air holes is effectively controlled, and meanwhile, the heat input increase caused by the fact that the size of the key holes is added to maintainthe stability of the molten pool is overcome, the deformation is increased, the burning loss of the alloy element is intensified, and the strength of a joint is effectively improved.

Owner:JIANGSU JICUI ADVANCED METAL MATERIAL RES INST CO LTD

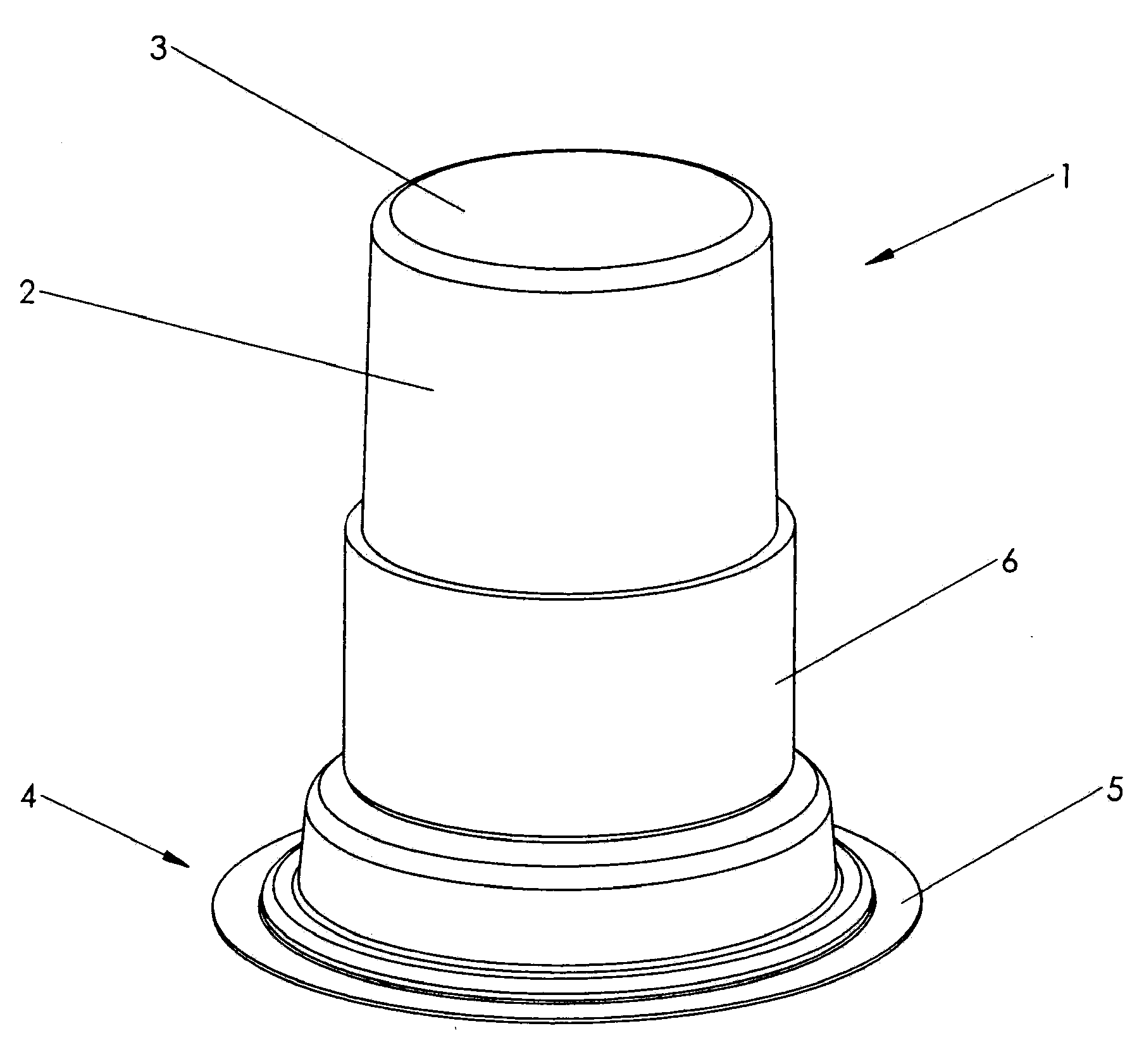

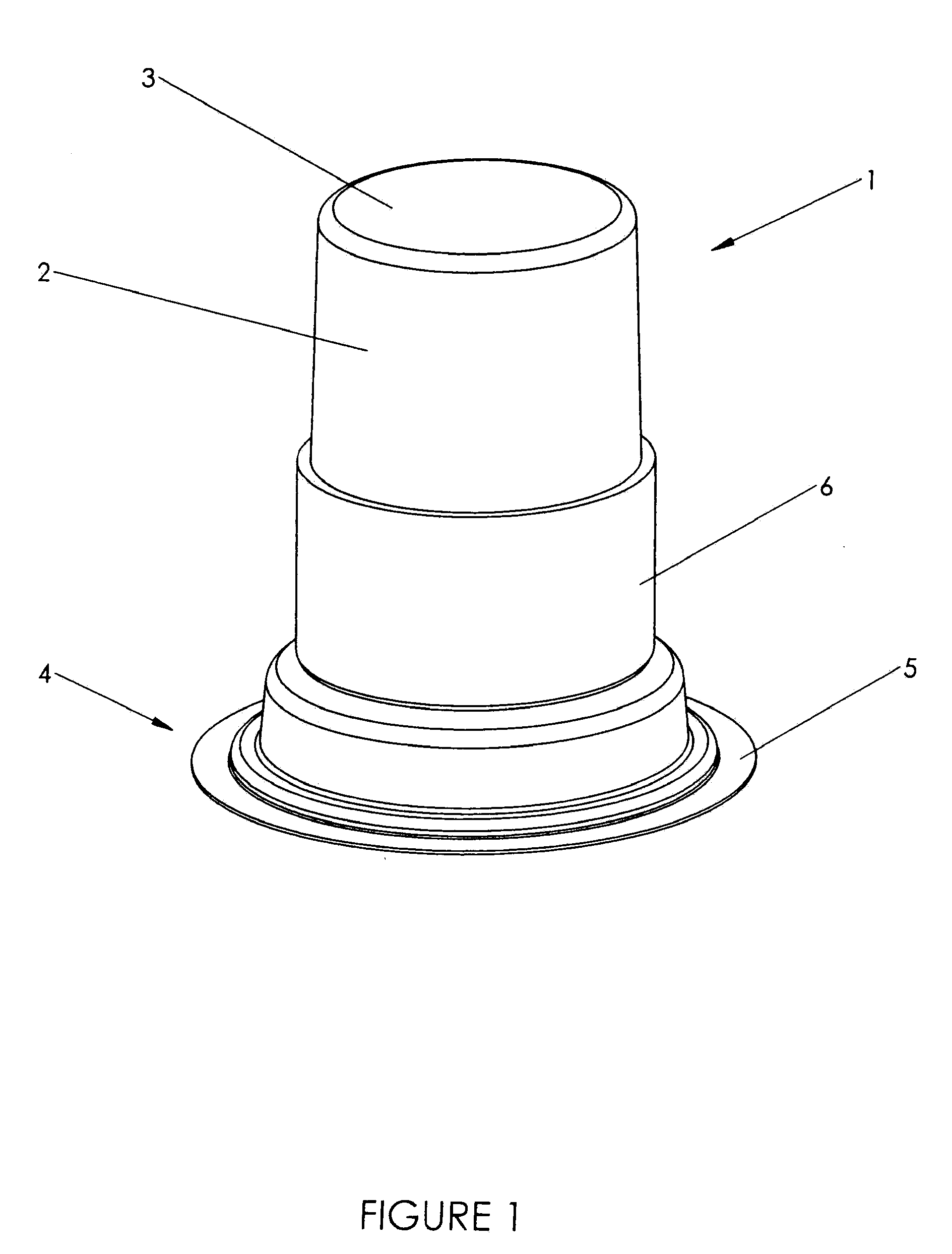

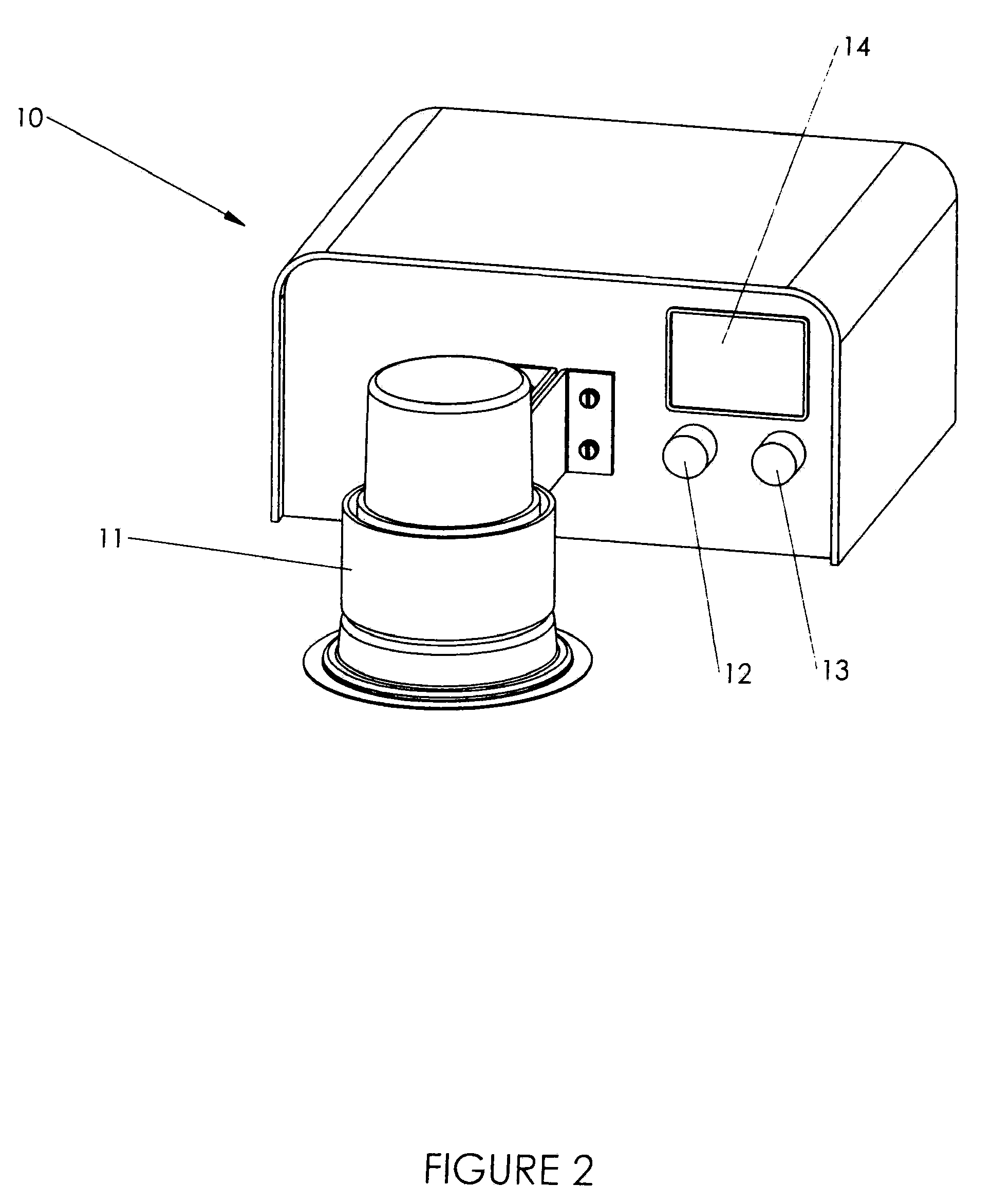

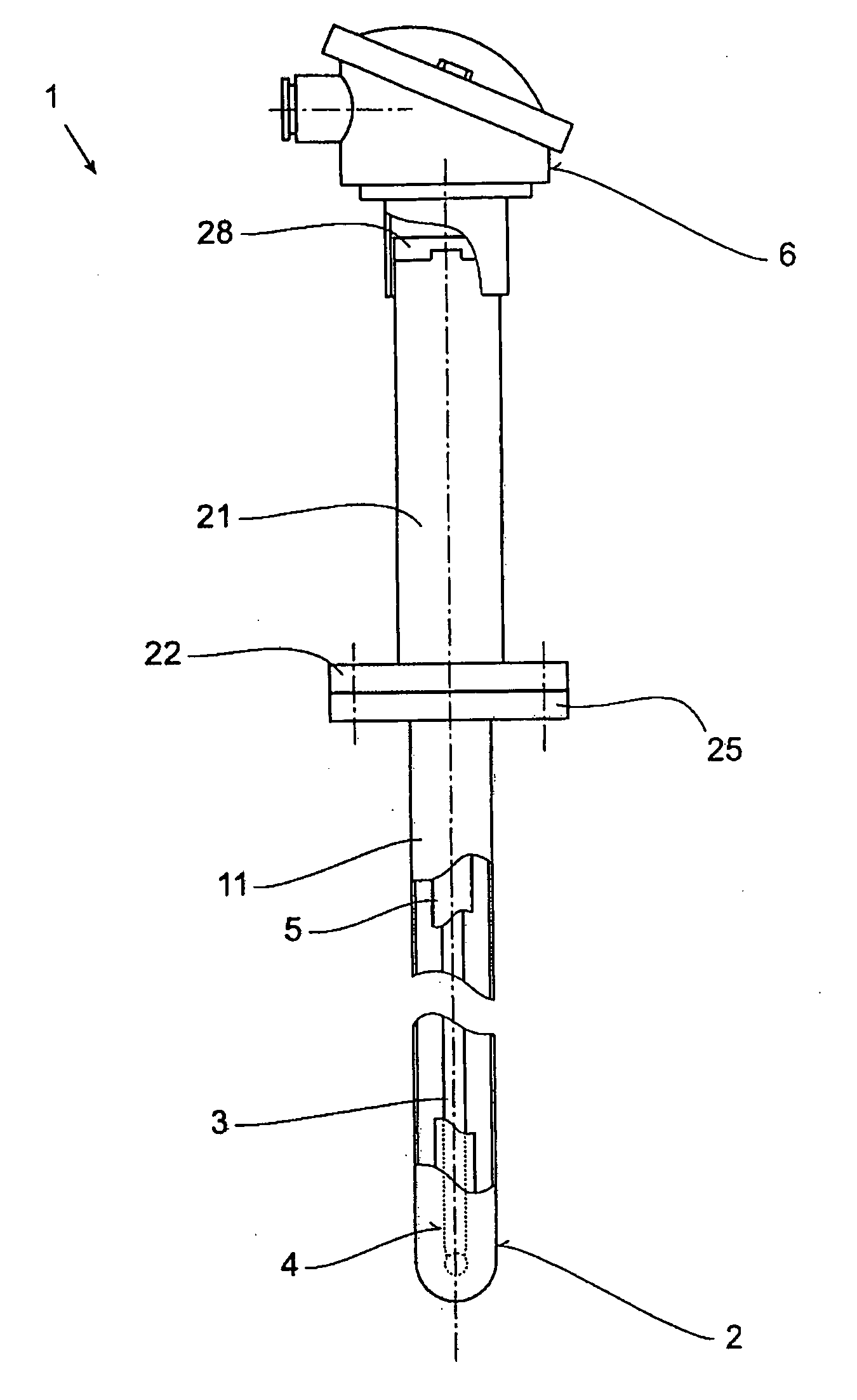

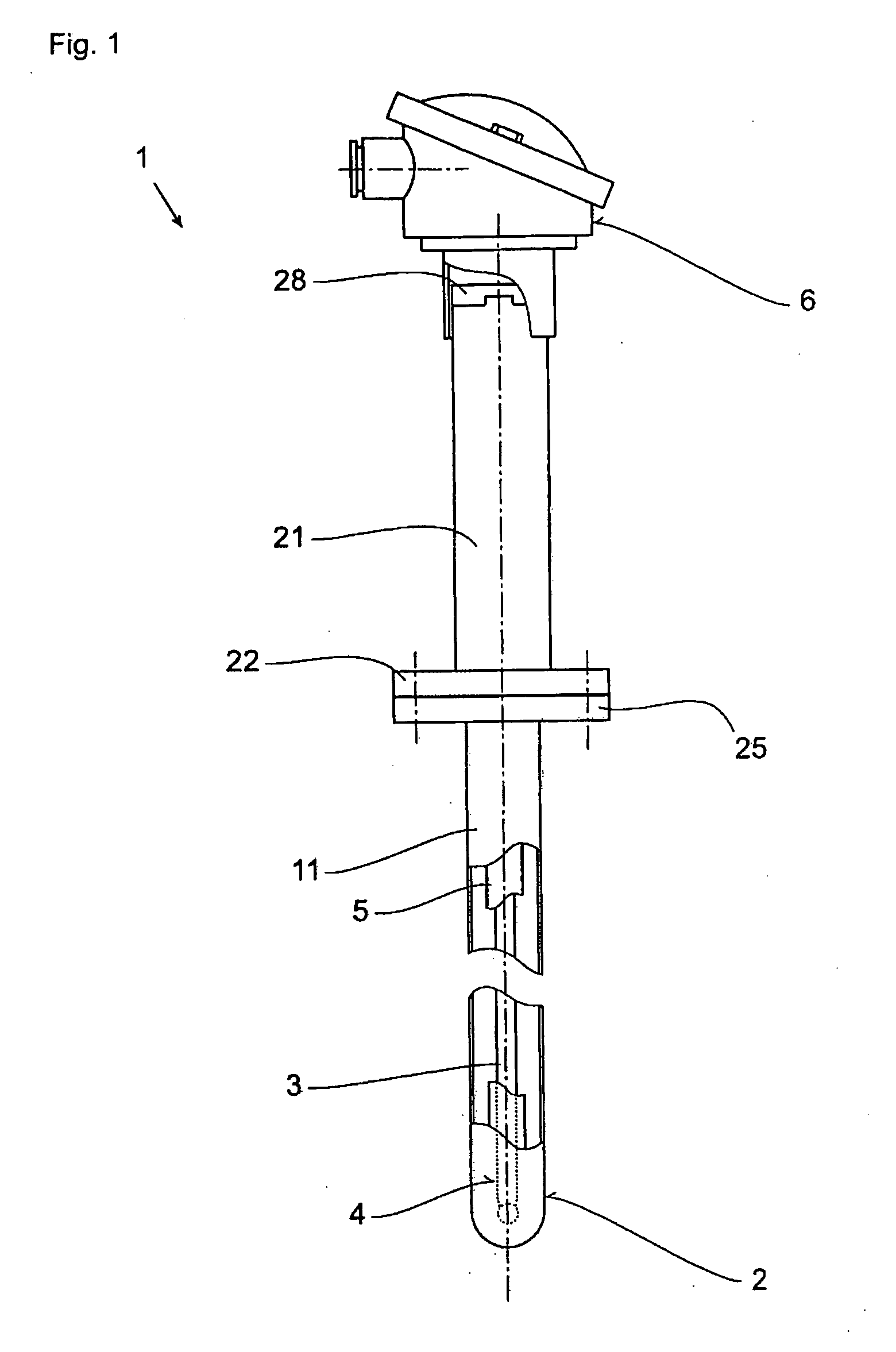

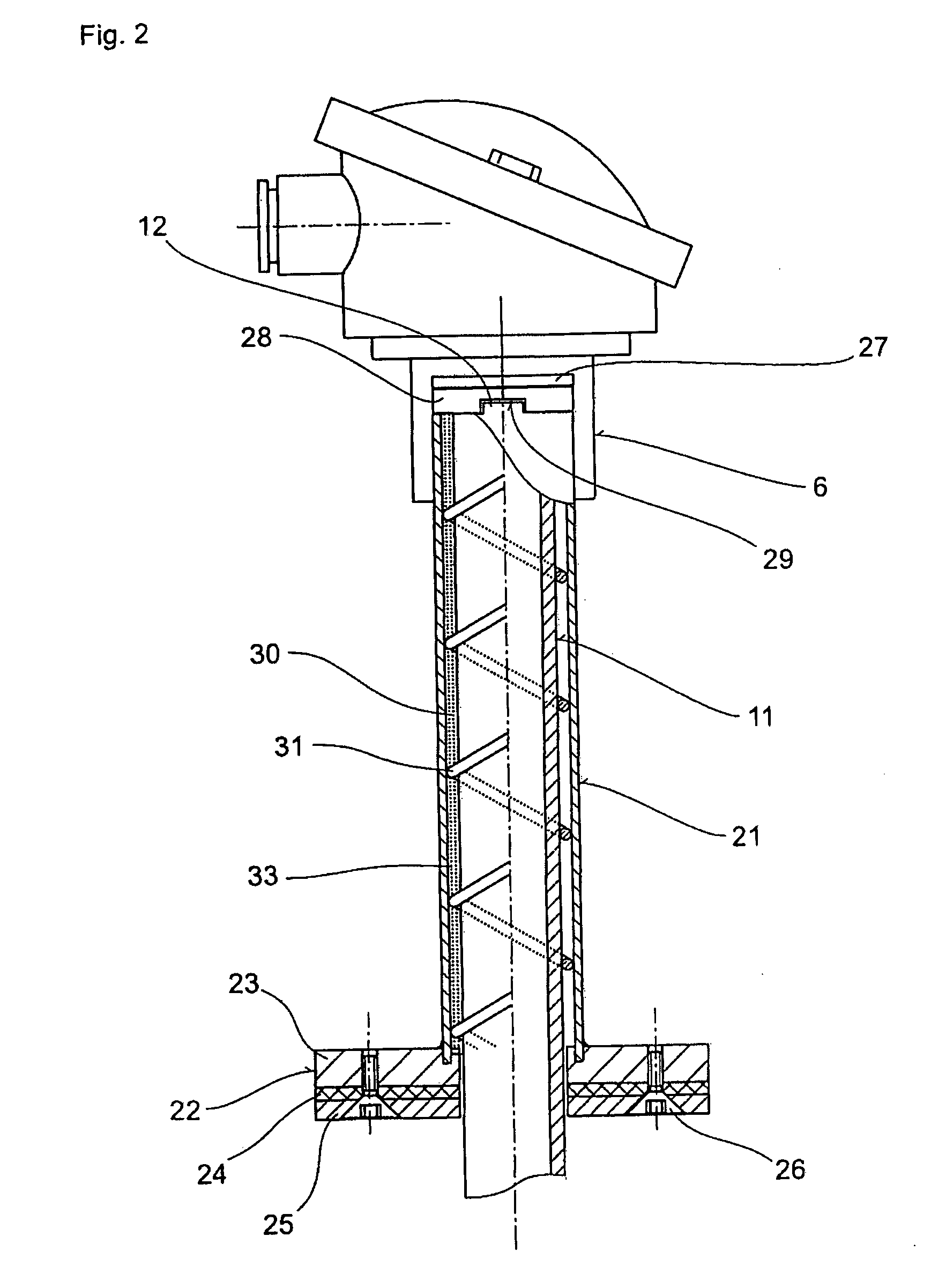

Thermoelement

ActiveUS20110292968A1Stable structureIncrease heat inputThermometer detailsThermometers using electric/magnetic elementsThermal insulationEngineering

A thermoelement (1) for measuring the temperature in gaseous or fluid media by means of one or more thermocouples (4) comprising wires of different metals welded together which give off a resulting electrical voltage when heated and are configured as a measuring insert (2) arranged in an insulating rod (3) disposed in a heat-resistant protective tube (11) that can be connected to a connection head (6), the protective tube being wholly or partially surrounded by a holding tube (21). To prevent a high input of heat which has an unfavourable effect on a temperature measurement, the holding tube (21) is supported against the protective tube (11) at a radial distance from the protective tube (11), and a heat-resistant trace (31) and optionally an insulating material (33) are inserted between the protective tube (11) and the holding tube (21), and the holding tube (21) is attached to the connection head (6) and / or the protective tube (11) in one or both end areas and is provided with thermal insulation.

Owner:INNOVATHERM PROF DR LEISENBERG

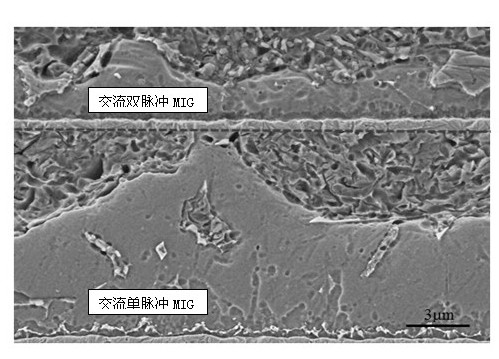

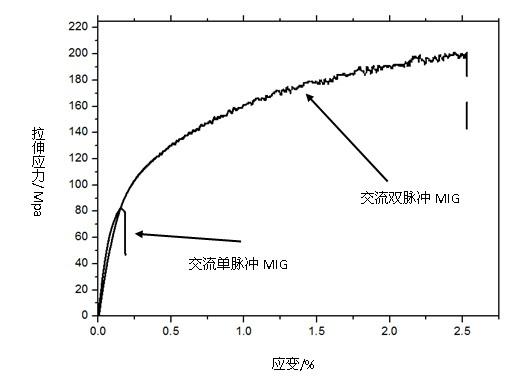

Alternating-current double-pulse MIG (Metal-Inert Gas) welding method for dissimilar metal welding of iron and aluminium

InactiveCN102626815ALow heat inputReduce in quantityArc welding apparatusWelding/soldering/cutting articlesAlternating currentMechanical property

The invention discloses a novel alternating-current double-pulse MIG (Metal-Inert Gas) welding method for dissimilar metals of iron and aluminium. The alternating-current MIG welding enables a base metal to be in a state with continuous change between a positive electrode and a negative electrode by power control, so that the heat input of the base metal in the welding process can be reduced, the thickness of fragile compounds between the metals of iron and aluminium can be reduced, and the mechanical property of welding joints is improved. Simultaneously, the alternating-current double-pulse MIG welding applies two types of pulses with different frequencies (one is high and the other is low) to current in the welding process; and due to the oscillation action of the double-pulse mode on a molten pool, the quantity of gas holes in an aluminium welding seam is reduced; and fish scales are formed on the surface of the welding seam, and the mechanical property of the dissimilar metal joints of iron and aluminium is effectively improved.

Owner:SHANGHAI JIAO TONG UNIV

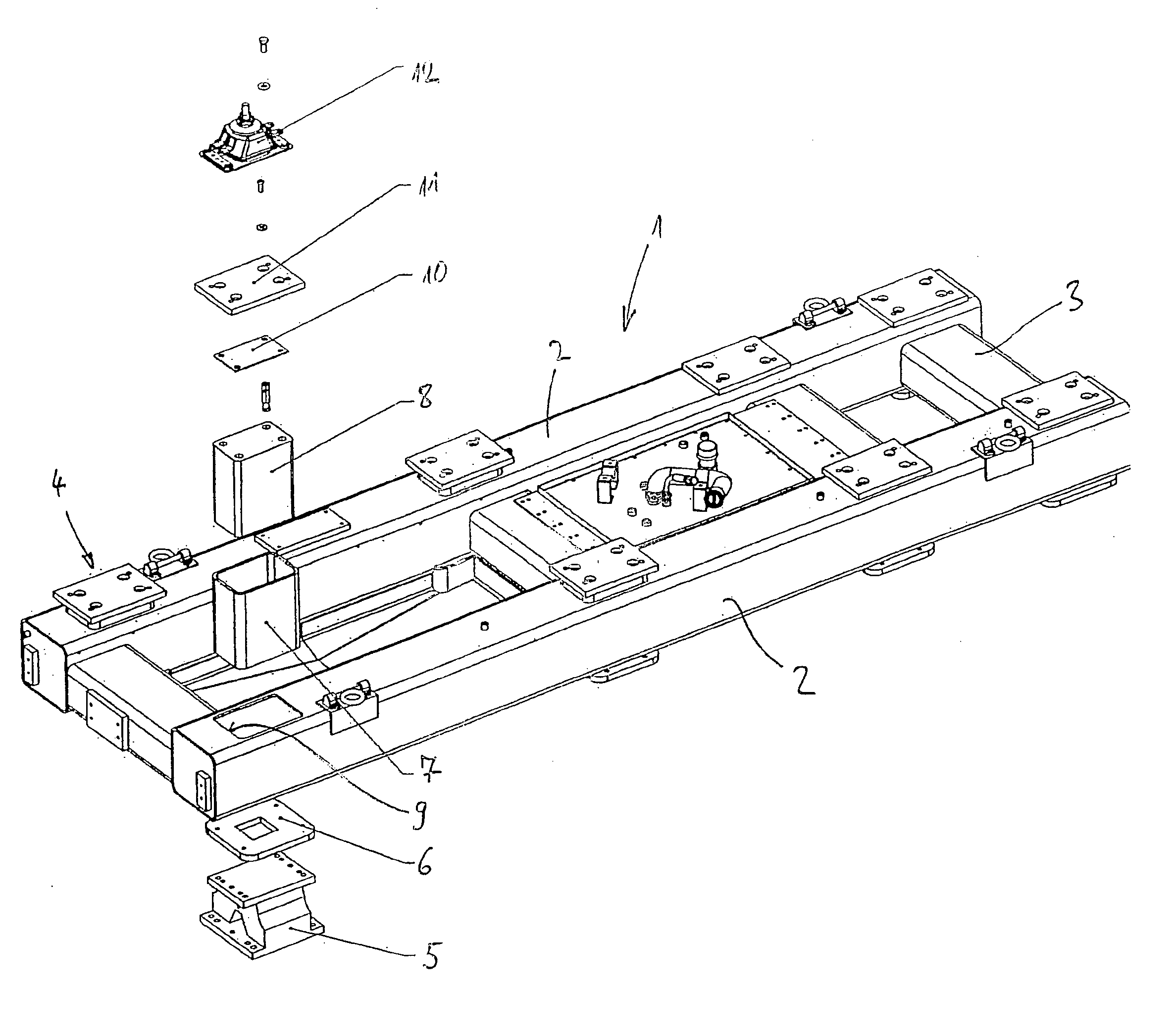

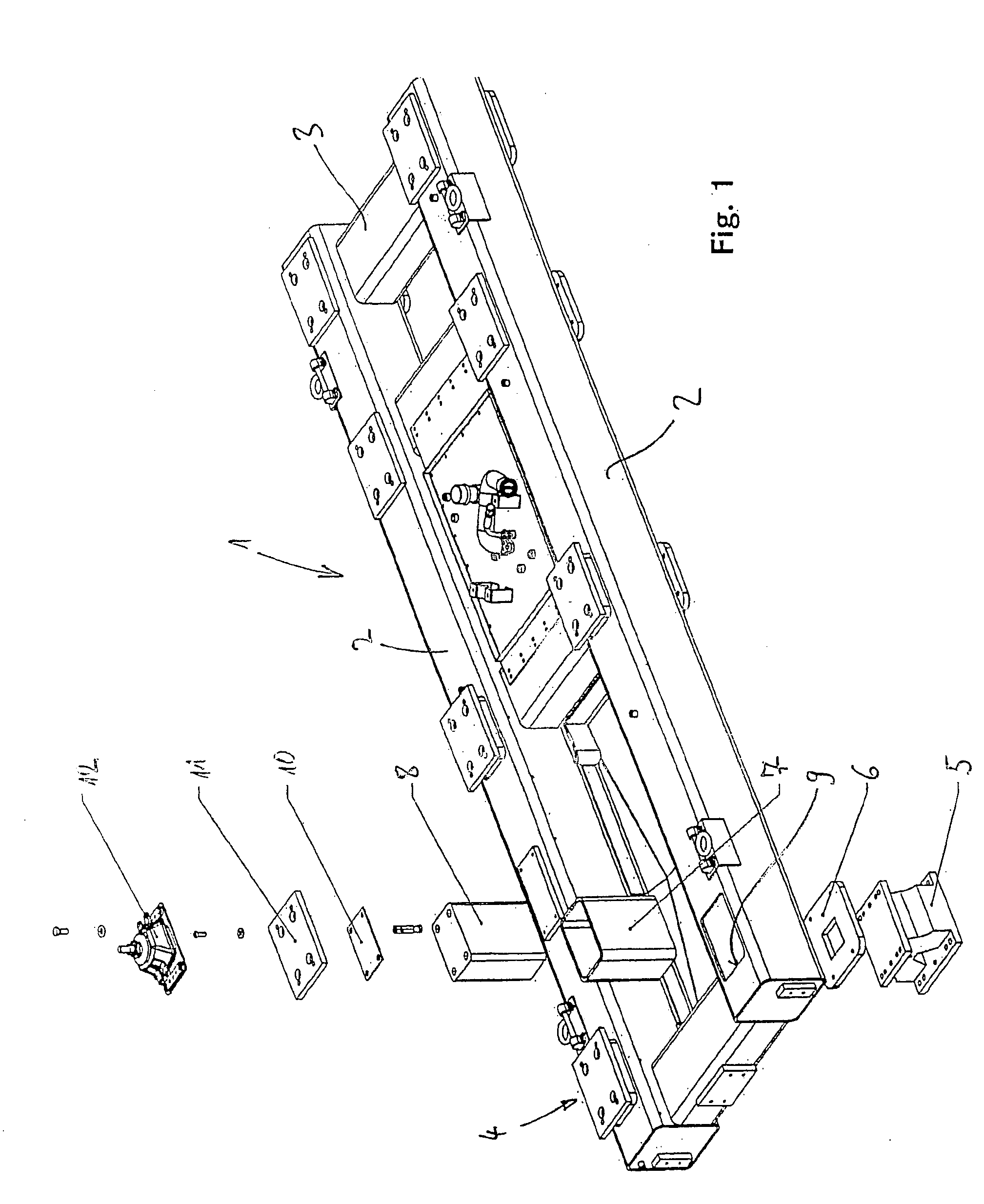

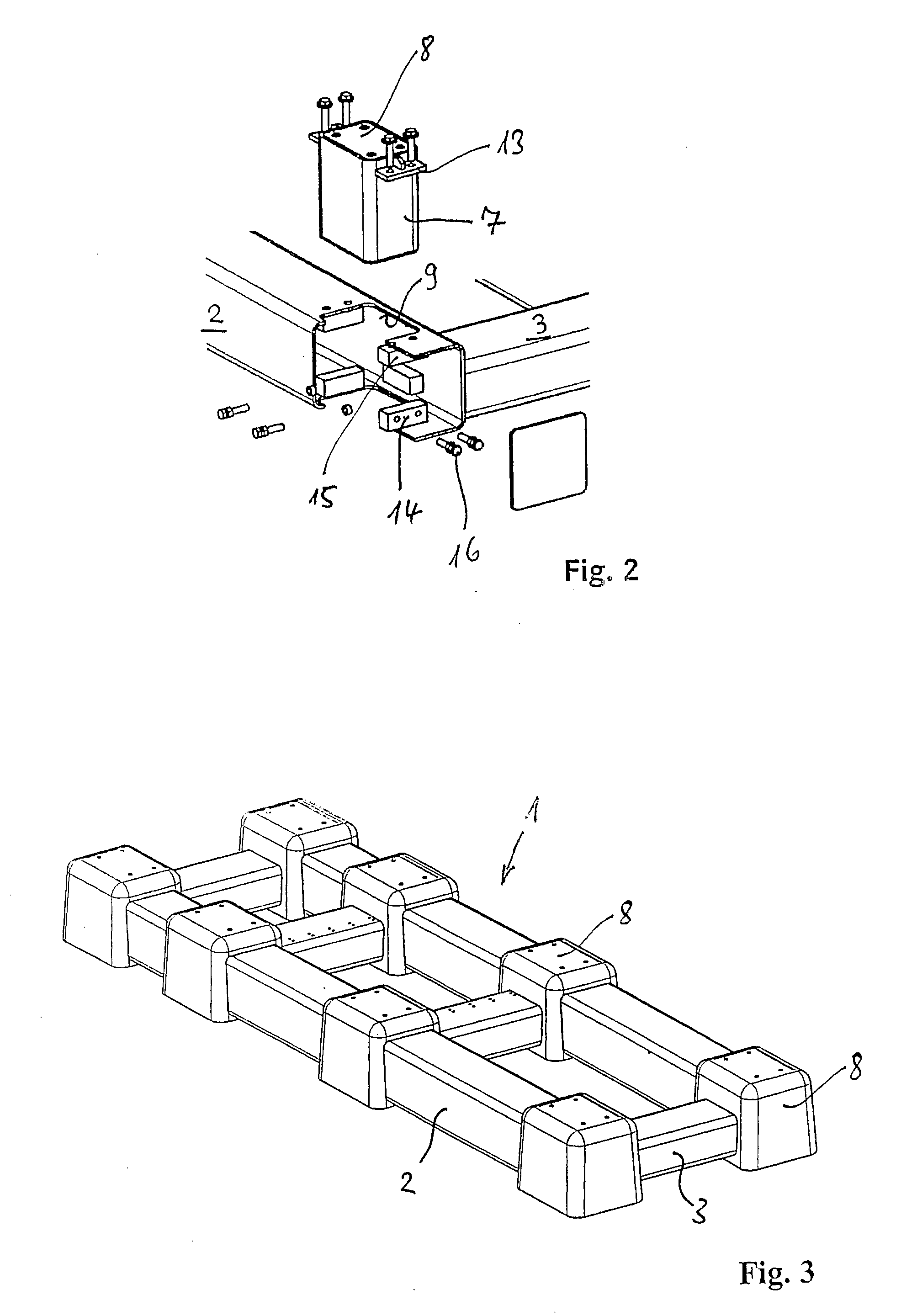

Support frame including longitudinal and transverse beams and method for producing the frame

InactiveUS20050263669A1Effective attenuationSimple and economical mannerStands/trestlesKitchen equipmentUltrasound attenuationBraced frame

In a frame consisting of longitudinal and transverse frame members which are used as bearing units, a frame bearing mount for the frame and an aggregate bearing mount are vertically arranged one upon the other and the frame areas between the frame bearing mounts and the aggregate bearing mounts are made of a vibration absorbing material in the form of blocks so as to provide a lightweight frame in a simple and economical manner and ensure an efficient attenuation of vibrations.

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH

Welding gun for protecting carbon dioxide gas

InactiveCN105312734AImprove insulation performanceUnrestricted operating positionArc welding apparatusShielding gasEngineering

The invention relates to a welding gun for protecting carbon dioxide gas. The welding gun comprises a welding gun base and an elbow pipe body arranged at the front end of the welding gun base, wherein a handle is arranged on the welding gun base; a gas pipe joint is arranged at the tail end of the handle through a gas inlet nut in a sleeving way and is connected with a protective gas inlet; a cable is arranged outside the gas pipe joint; a front gun body is arranged in the welding gun base; a mounting hole is formed in the front gun body; the handle and the elbow pipe body are connected by internal threads and external threads on the elbow pipe body; a connecting rod is arranged at the front end of the elbow pipe body in a sleeving way and is connected with a current contact nozzle; a gas outlet is formed in the front end of the connecting rod; a spray pipe is arranged outside the current contact nozzle in a sleeving way; an insulator for insulating the gun body from the spray pipe is arranged between the connecting rod and the spray pipe. The spray pipe is arranged on the welding gun for protecting the carbon dioxide gas, disclosed by the invention, can be used for protecting gas from dispersing; in addition, the welding gun is good in insulating property and is not limited to an operating position, so that the welding efficiency is greatly improved; the welding gun has the advantages of concentrated electric arc temperature, small heat input, high speed and good protection effect.

Owner:张建生

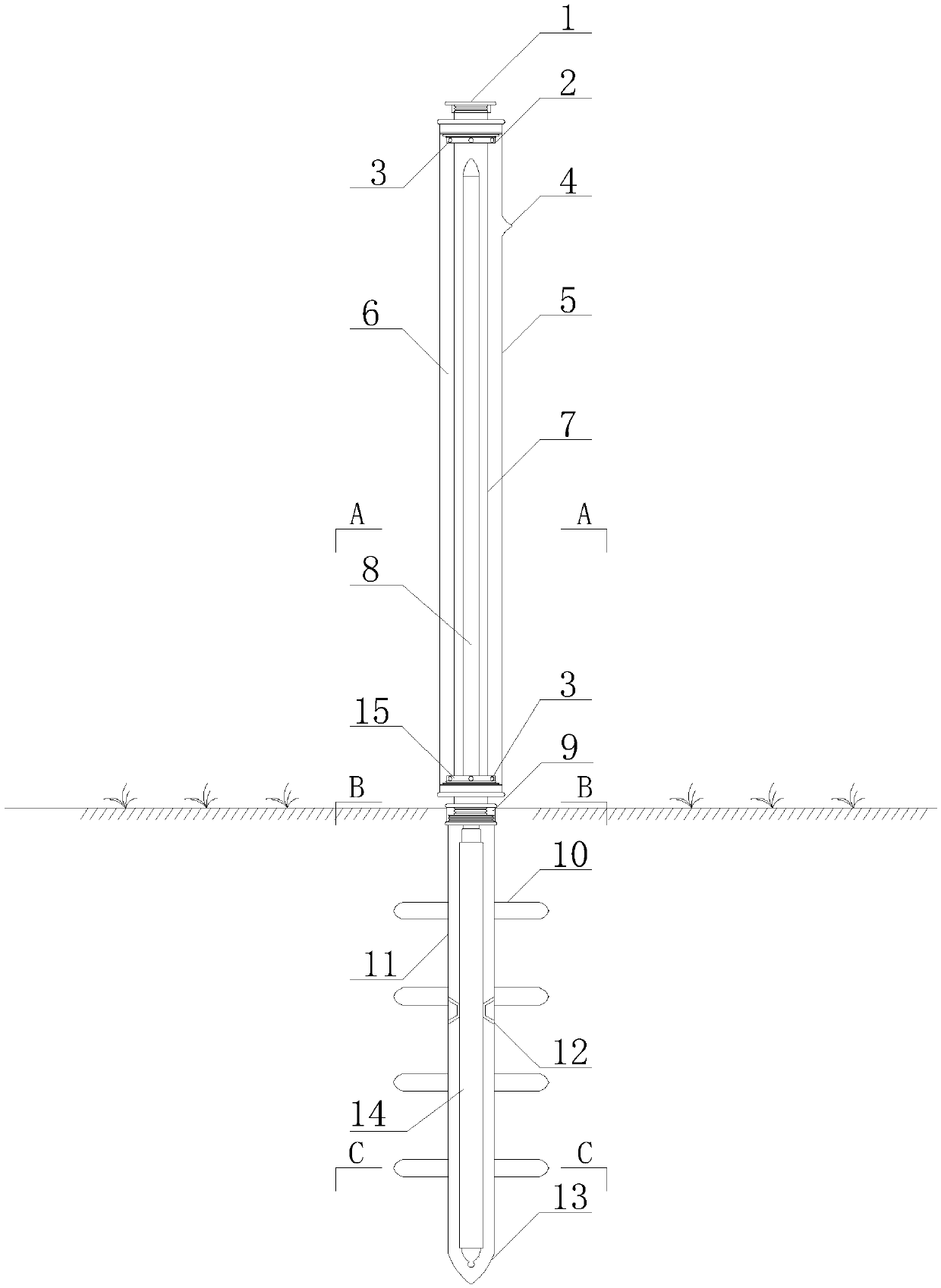

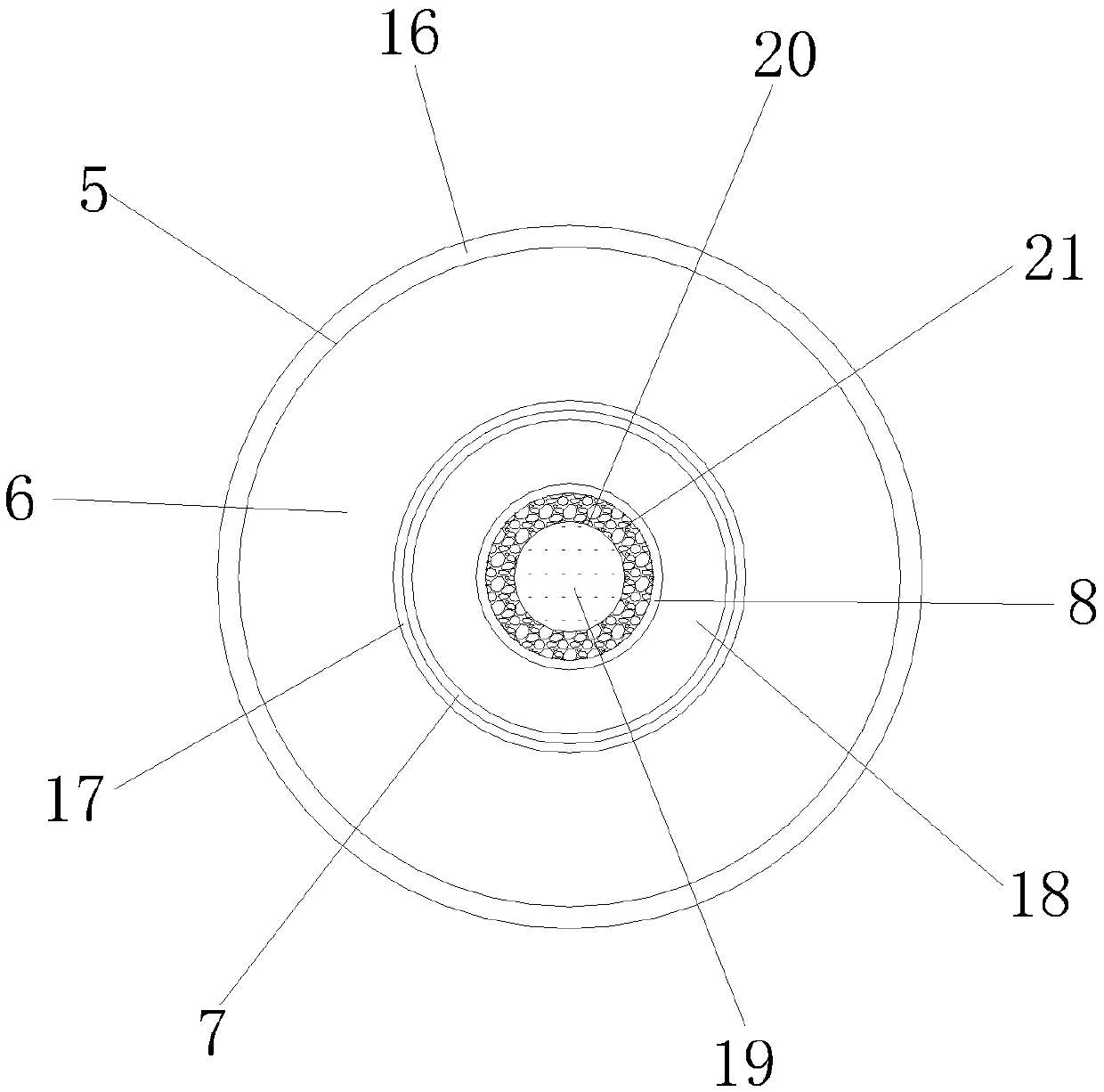

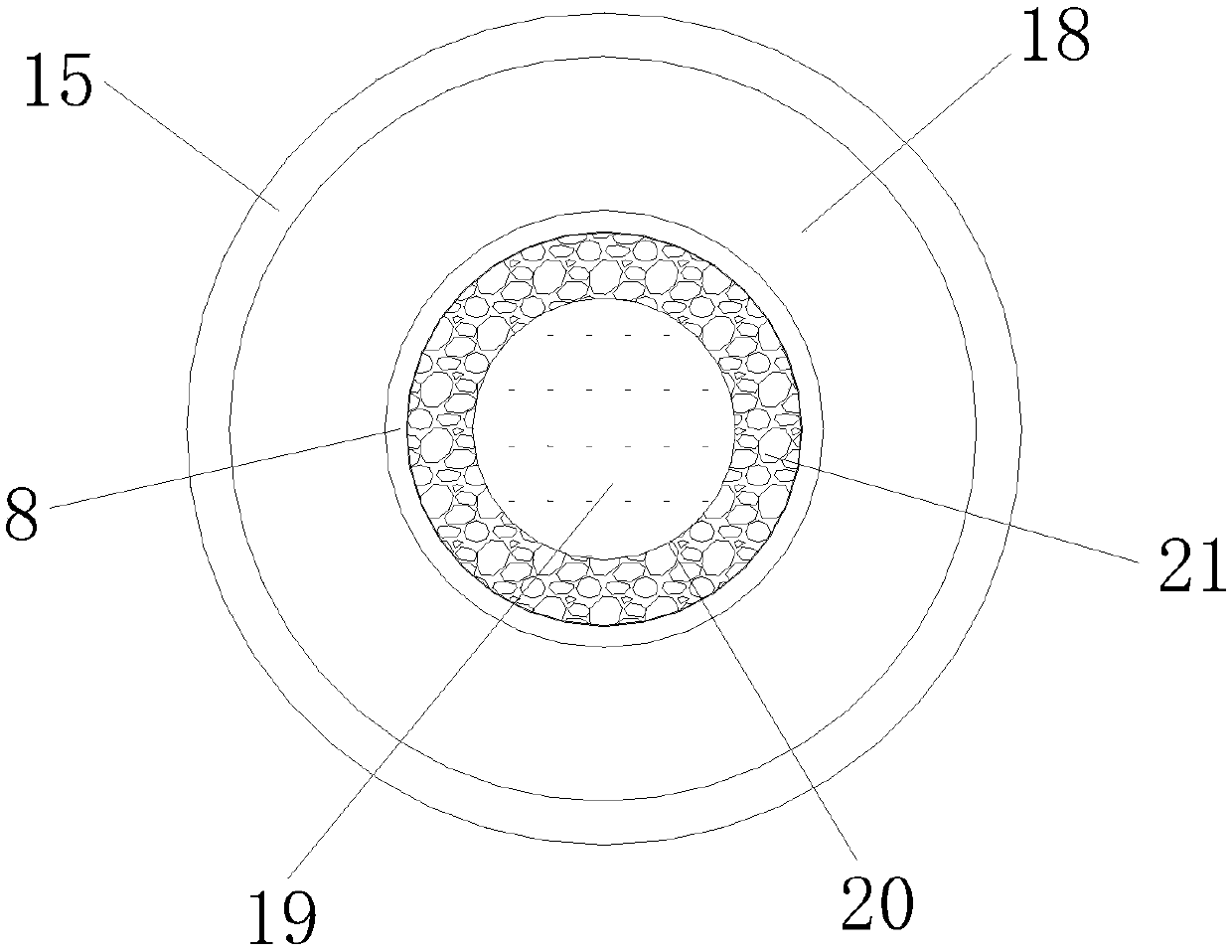

Heat pipe type solar photothermal device aiming at roadbed frost heave and roadbed frost heave prevention method

PendingCN109577126AIncrease heat inputRaise the temperature levelSolar heating energySolar heat collector detailsPhotothermal conversionEngineering

The invention is applicable to the technical field of roadbed engineering construction and maintenance, and provides a heat pipe type solar photothermal device aiming at roadbed frost heave, comprising a photothermal conversion tube, the photothermal conversion tube is sleeved with a light transmission tube, a vacuum cavity is formed between the photothermal conversion tube and the light transmission tube, two ends of the photothermal conversion tube are respectively connected with a first joint and a second joint, and an end cap is arranged on the first joint to form a seal at one end of thephotothermal conversion tube; one end of a thermal dissipation tube is connected with the second joint and is in communication with the photothermal conversion tube, the other end of the thermal dissipation tube is provided with a tapered guide cap, and the inside of the photothermal conversion tube and the inside of the thermal dissipation tube are filled with a first heat transfer medium; a first tube shell is located inside the photothermal conversion tube, a second tube shell is fixed in the inside of the thermal dissipation tube through a bracket, one end of the first tube shell and one end of the second tube shell are connected through a sealing piece, the inside of the first tube shell and the inside of the second tube shell are in conduction, and a second heat transfer medium is infused into the first tube shell and the second tube shell, so as to solve the problem that the effect of the frost heave prevention measures for the roadbed is not ideal.

Owner:SHIJIAZHUANG TIEDAO UNIV

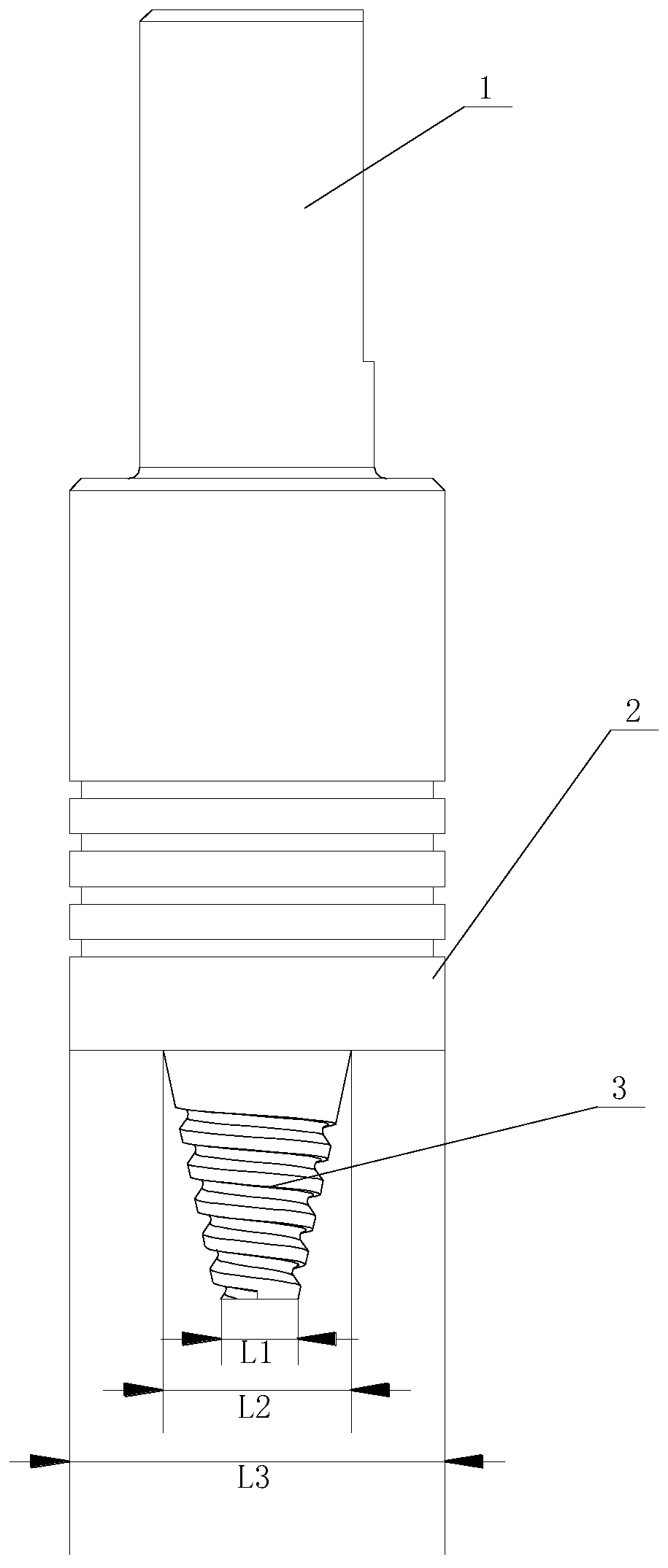

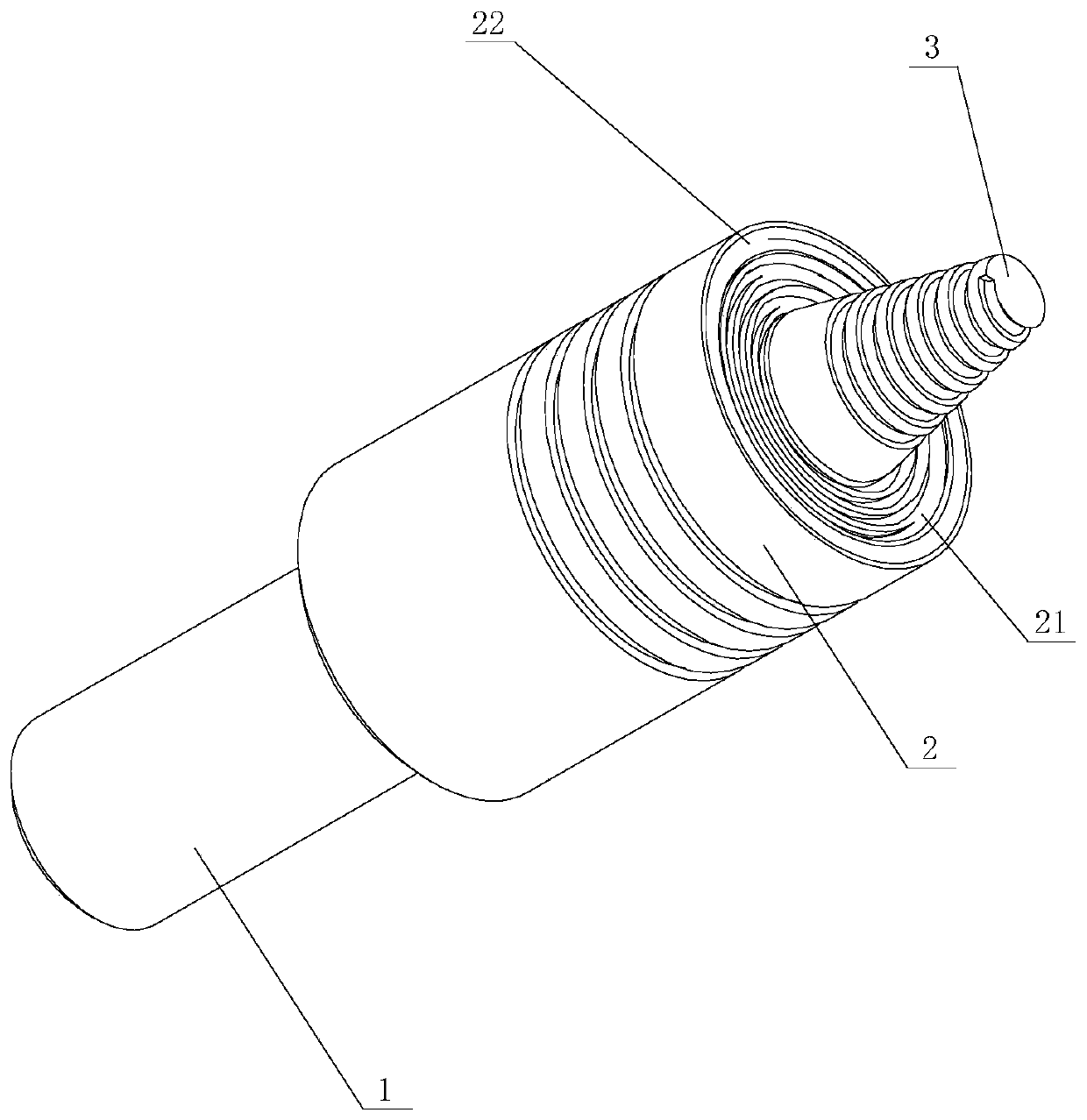

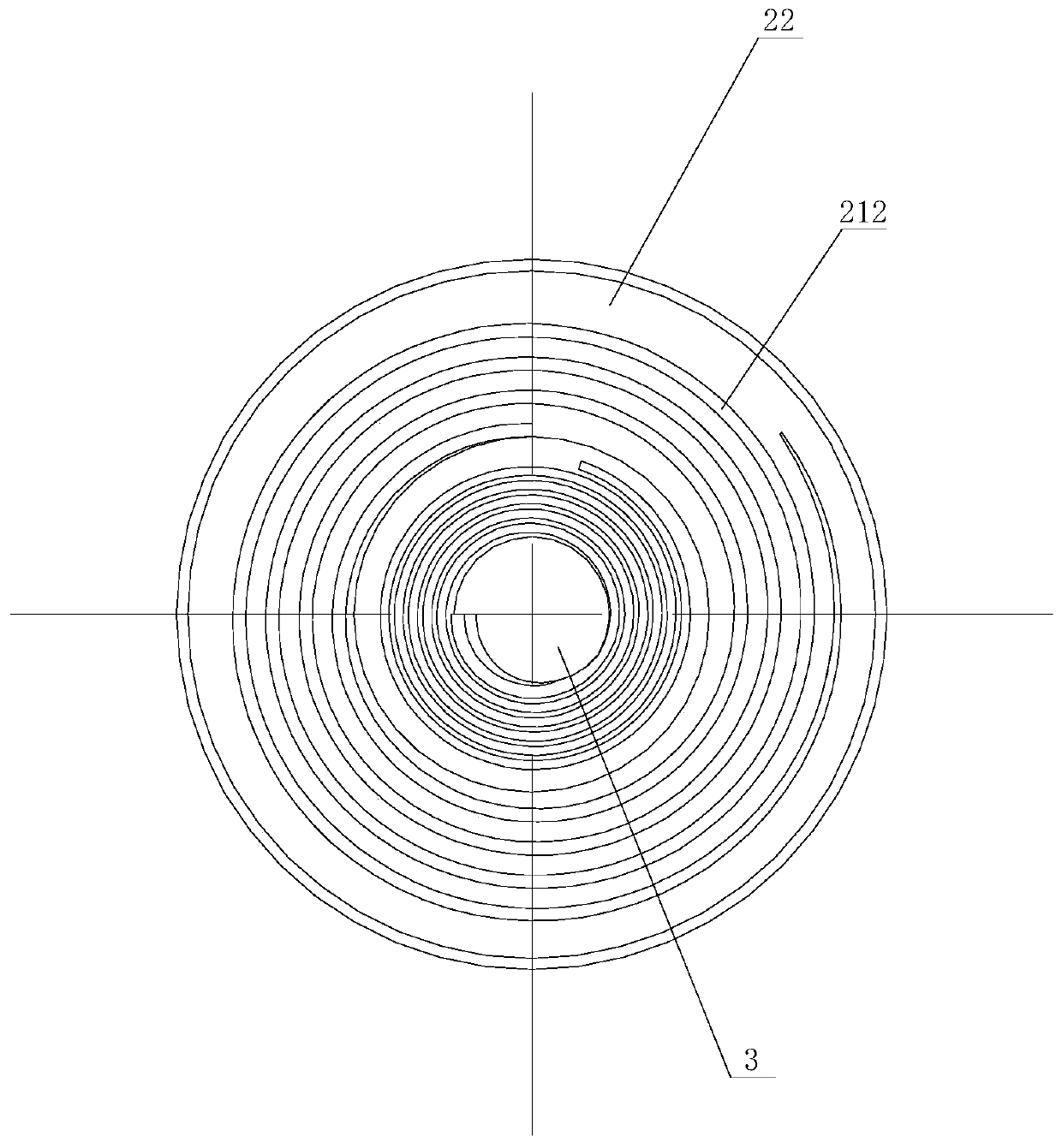

Small-diameter shaft shoulder stirring head

InactiveCN110919161AIncrease heat inputReduce the cross-sectional areaNon-electric welding apparatusFriction torqueEngineering

The invention discloses a small-diameter shaft shoulder stirring head. The small-diameter shaft shoulder stirring head comprises a clamping part, a shaft shoulder part and a stirring needle which aresequentially connected, the diameter of the needle tip part of the stirring needle is defined as L1, the diameter of the needle root part of the stirring needle is defined as L2, the diameter of the shaft shoulder part is defined as L3, the ratio of L1 to L2 is equal to 1 to 1-1.7, the ratio of L2 to L3 is equal to 1 to 1.8-2.5, the end face of the shaft shoulder part comprises a stirring area close to the stirring needle in the radial direction and an envelope area away from the stirring needle, and the stirring area is provided with a non-concentric circle structure for improving the friction torque. The stirring head has the advantages that stirring and heat production effects can be increased, welding defects can be avoided, and the stirring head is suitable for producing narrow-edge welds.

Owner:HUNAN JOINFRONT WELDING TECH

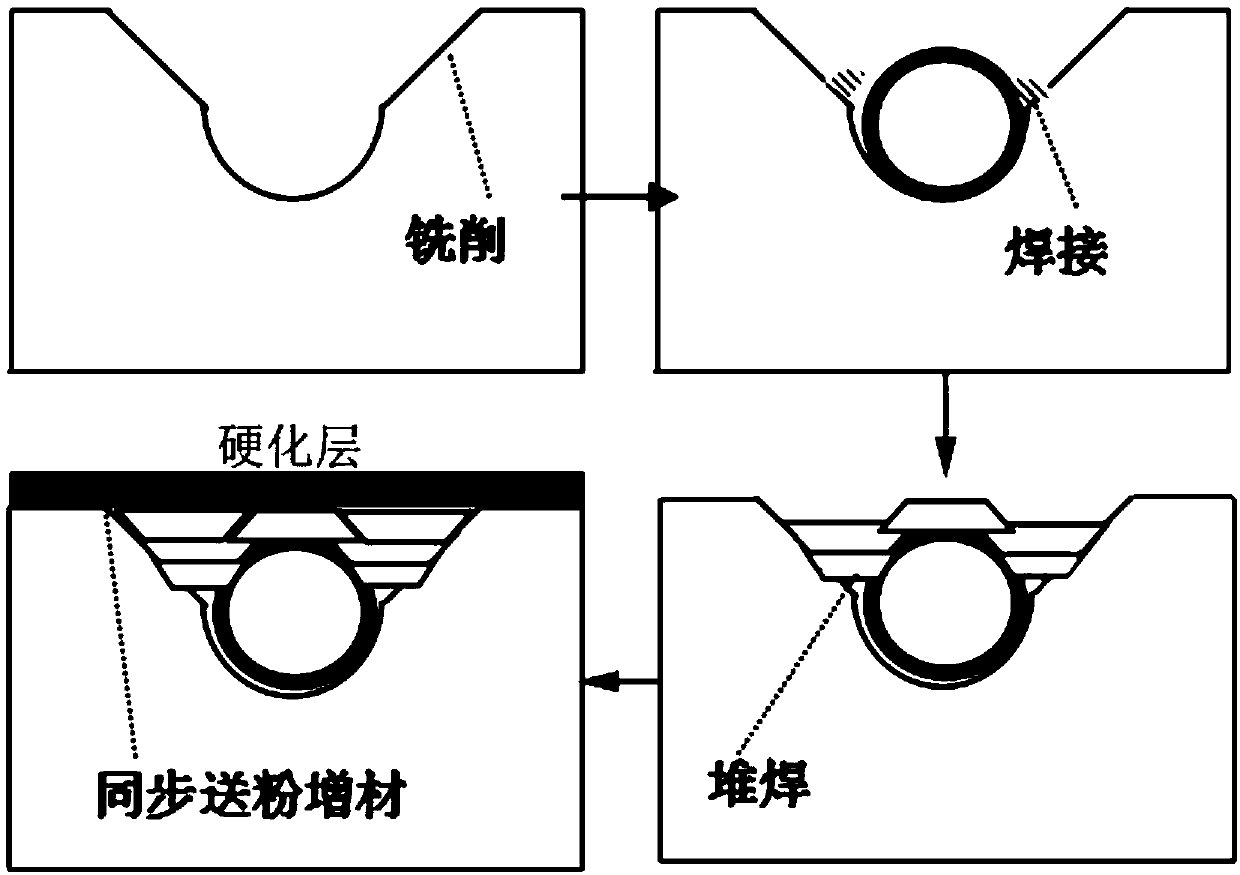

Composite additive manufacturing method of conformal cooling die

ActiveCN110576182AAchieving pose-invariant direct shapingIncrease the additive rateAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlLarge size

The invention discloses a composite additive manufacturing method of a conformal cooling die, and belongs to the field of additive manufacturing. During the manufacturing process of a complex cavity structure, a pipe is adopted as a supporting condition. The composite additive manufacturing method comprises the following steps of at first, machining a circular arc-shaped trough, which is identicalto the external diameter of a cooling pipeline, in a forged base material in a numerical control manner, and forming grooves; placing the pipe in the trough, and performing welding orientation and fixing; swinging an additive manufacturing intermediate layer material in the direction perpendicular to the axial direction of the pipe by adopting a high-efficiency arc surfacing manner; and finally,milling a thick surface of a surfacing layer in a numerical control manner, and adopting a laser synchronous powder feeding process to form a compact and flawless hardened layer. The composite additive manufacturing method adopts a pipe positioning and supporting way, can realize invariable pose direct molding of a runner-containing structure, adopts a surfacing process in the manufacturing process of a large-size intermediate layer material additive, and can remarkably increase the additive speed.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Method for reinforcing welding joint of aluminum/magnesium alloy thick plate by carbon nano pipe

ActiveCN109158736AImprove mechanical propertiesStrong penetrating powerArc welding apparatusWelding/cutting media/materialsCarbon nanotubeMaterials processing

The invention relates to a method for reinforcing a welding joint of an aluminum / magnesium alloy thick plate by a carbon nano pipe, and belongs to the technical field of welding technologies in material machining. A pure aluminum sheath used for wrapping around a mixed powder composed of a carbon nano pipe and an activated rosin flux is used for preparing a novel active welding wire for aluminum / magnesium alloy thick plate welding; the mixed powder comprises the following component, by mass: 0.1%1-2.3% of CNT, 2 to 8-13% of CaF2, 2 to 10-15% of ZnCl2, 10-25% of CaCl2, 2 to 20-25% of SiO2, 2 to20-30% of TiO2 and 10-15% of Te. When the method is used for welding, the welding penetration depth can be not only effectively increased to carry out the aluminum / magnesium alloy thick plate welding, and the carbon nano pipe can be conveyed into the interior of a molten pool, the effects of fine crystal strengthening and dislocation strengthening are achieved in a welding solidification process,and the mechanical property of the welding joint is greatly improved.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

System and method for multi-pass computer controlled narrow-gap electroslag welding applications

A system and method of multi-pass computer controlled narrow-gap Electroslag welding allowing a faster vertical rate of rise at a much lower voltage, and that includes welding selected narrow-gaps within segments of a weld cavity between heavy plate steel workpieces and attendant control of the heat transfer depth penetration from the weld puddle to the workpieces according to a pre-determined profile resulting in a smaller heat affected zone and smaller grain structure in the weld metal.

Owner:ESKANDARI AMIR

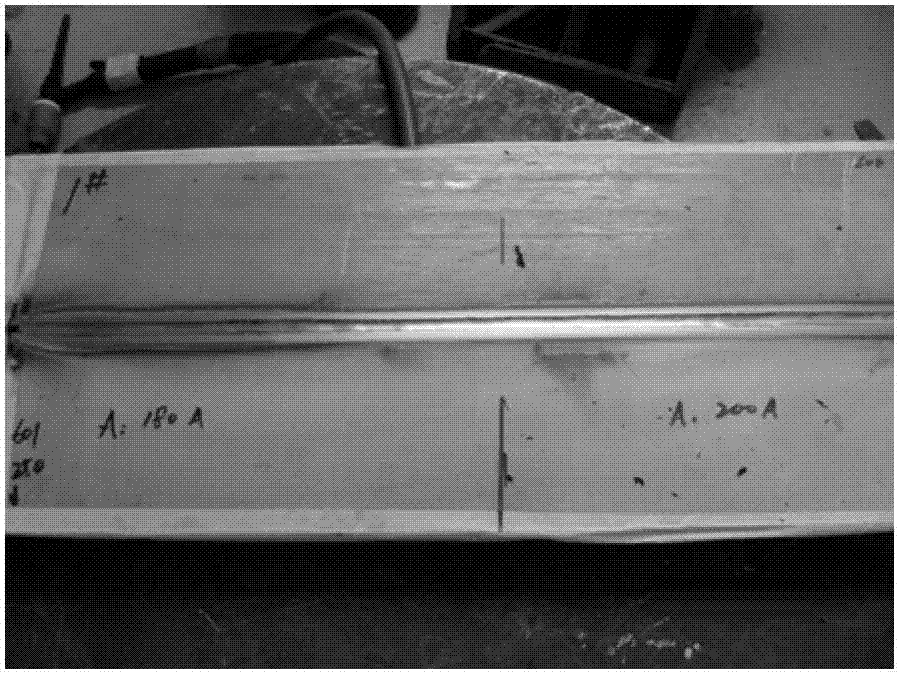

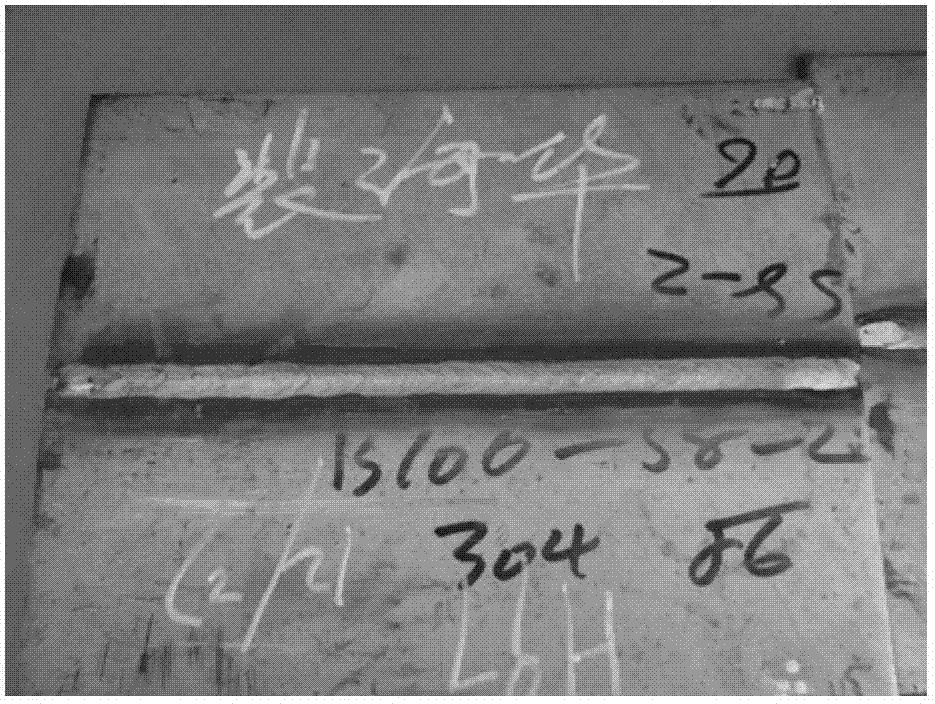

Protective gas for welding stainless steel

The invention discloses a protective gas for welding stainless steel. The protective gas is characterized by being formed by mixing argon and hydrogen, wherein the weight percentage of argon is 95%, and the weight percentage of hydrogen is 5%. The protective gas can be applied to welding the stainless steel, can improve the thermal input of a weld joint, accelerates the welding speed, increases the depth of fusion, improves the wetting degree of a weld bead and widens the sectional area of the weld joint. After hydrogen is added into the argon, the reducing atmosphere is provided for a welding area, so that oxygen and oxide in the weld joint can be removed.

Owner:SHANGHAI YANJIE MECHANICAL ENG CO LTD

High-entropy alloy additive manufacturing device and additive manufacturing method

PendingCN110091035ASimple structureEasy to useElectrode supporting devicesWelding/cutting media/materialsHigh entropy alloysAlternating current

The invention relates to the technical field of high-entropy alloy additive manufacturing, and particularly discloses a high-entropy alloy additive manufacturing device and additive manufacturing method. The high-entropy alloy additive manufacturing device comprises a welding wire clamp used for fixing two welding wires, an alternating-current power source and two wire feeders. The two welding wires are located on the same plane, axes of the two welding wires are crossed, the alternating-current power source is provided with two output ends, the two output ends are connected with a conductivenozzle of one welding wire, the two wire feeders are connected with one welding wire, are located on the ends, close to the conductive nozzle, of the welding wires, and are used for enabling the welding wires to be axially fed, the traditional high-entropy alloy additive manufacturing mode is changed, the high-entropy alloy of the complex structure can be manufactured, in the preparing process, the alternating-current double-wire indirect electric arc welding is used, heat transfer and medium transfer decoupling control is achieved, heat input is controlled within a certain range while the deposition rate is improved, and the device is more efficient and energy-saving.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com