Composite additive manufacturing method of conformal cooling die

A conformal cooling and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of poor shape regularity of the upper arm of the cavity, rough inner wall, and low precision of the mold surface, so as to improve cooling performance, large heat source radius, cost and The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

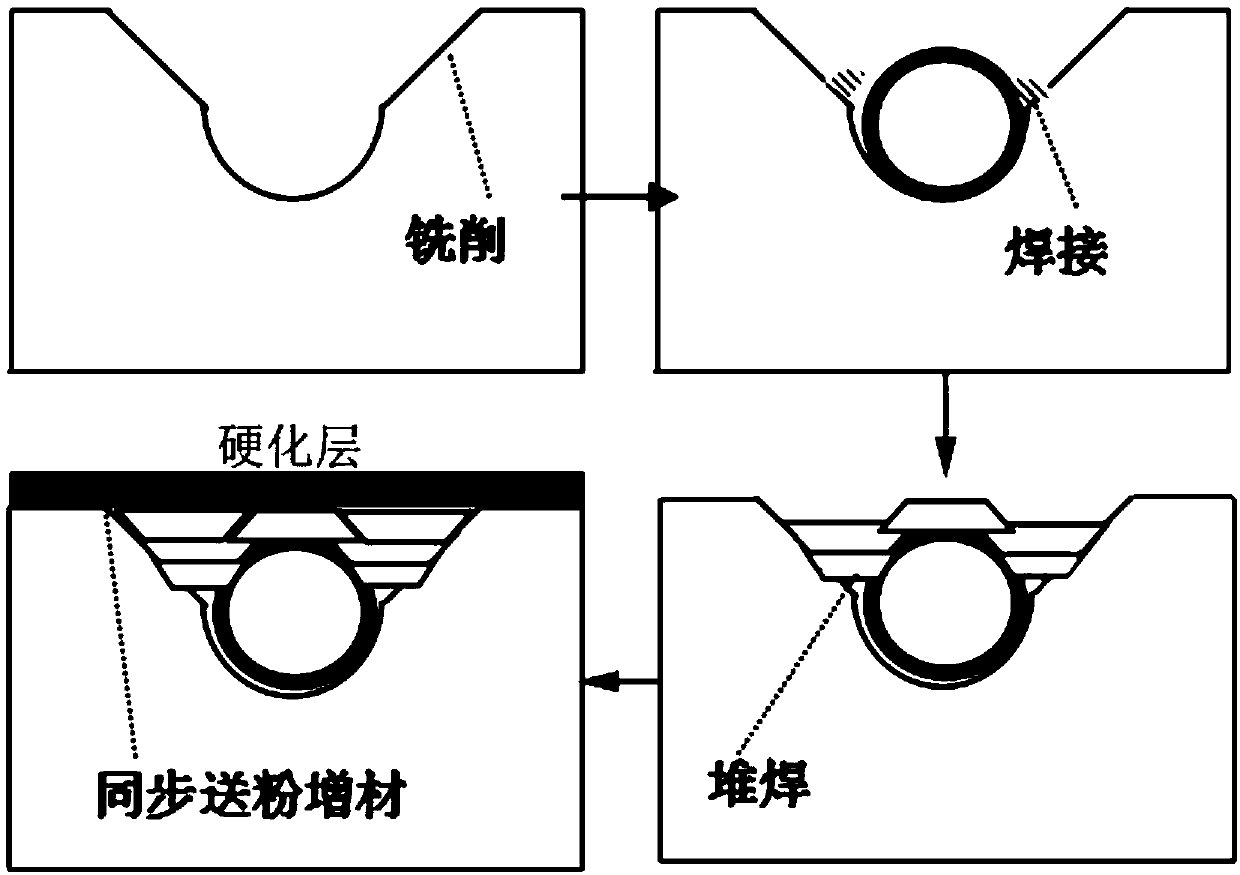

[0027] figure 1 It is a schematic diagram of the process flow of the present invention. The process mainly includes four processes of milling semicircular grooves and grooves on the substrate, welding positioning of pipes, surfacing filling, and laser synchronous powder feeding for additive manufacturing of the surface layer.

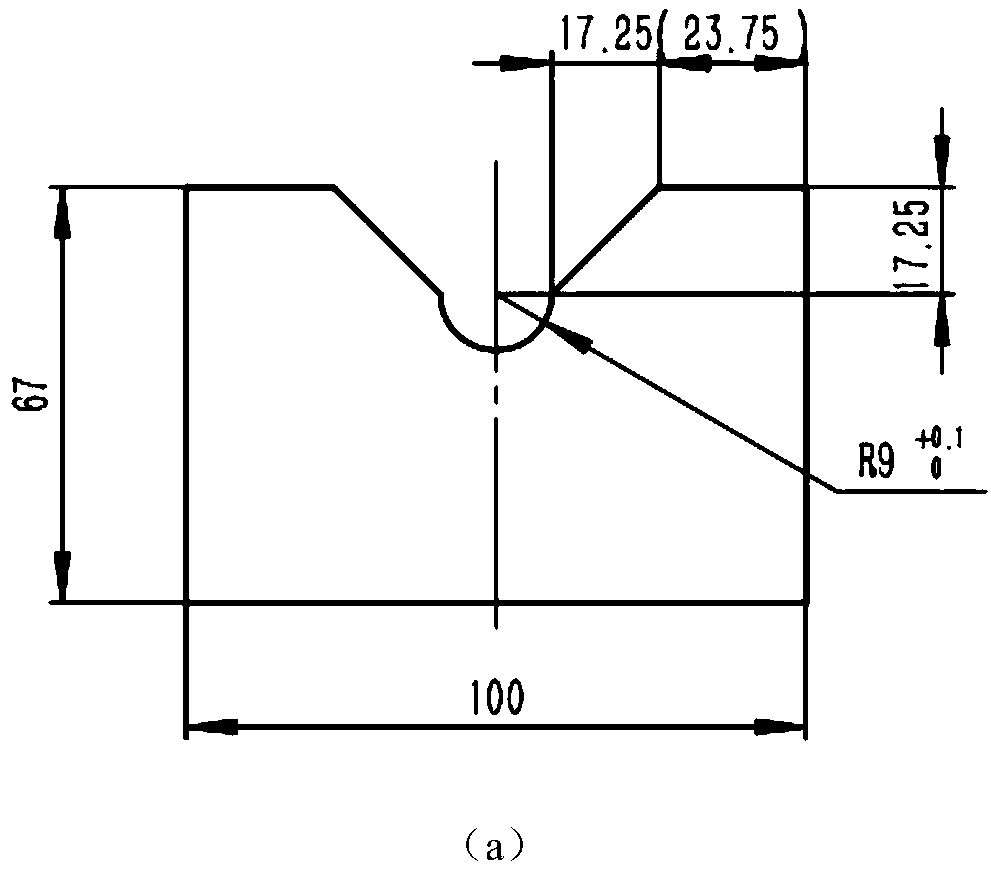

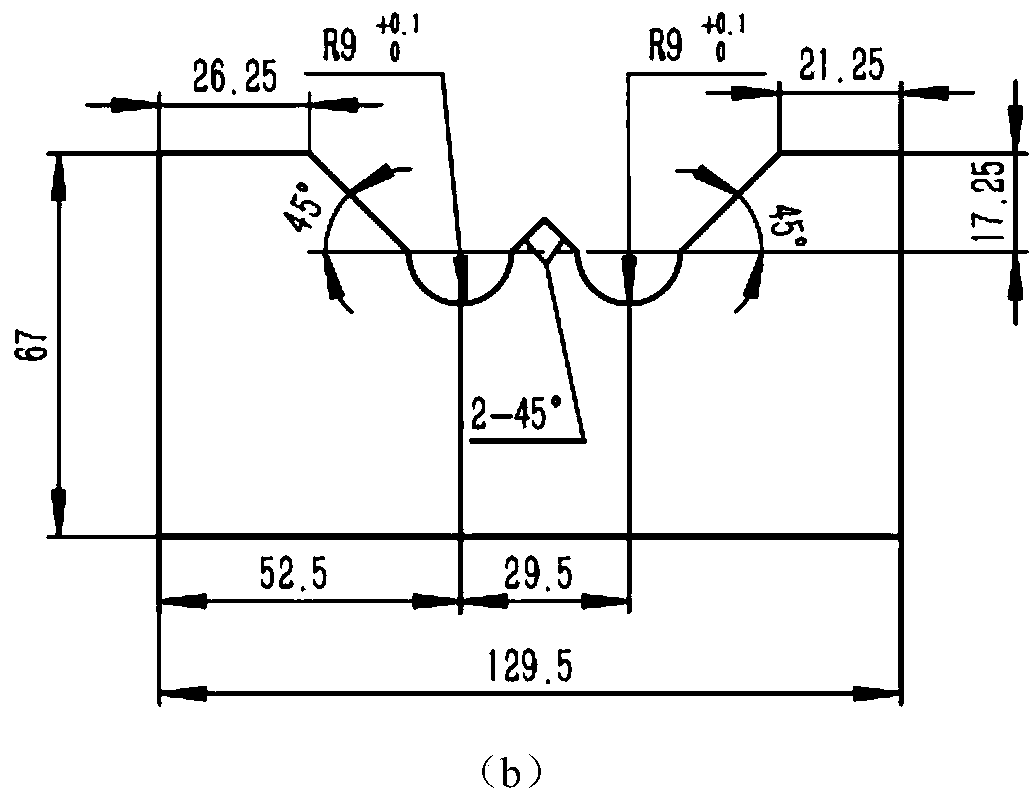

[0028] figure 2 It is the substrate processing groove and groove diagram of the present invention. A semicircular arc with the same diameter as the outer diameter of the cooling pipe is machined on the substrate, and then grooves are made on both sides of the arc. The base material is pre-hardened P20 forged material.

[0029] Place the stainless steel tube or the copper tube in the arc groove, use the fixture to position, and then use the argon arc welding to weld the tube to the base. The stainless steel pipe used in this embodiment is a 316L stainless steel pipe with a wall thickness of 3 mm.

[0030] Then, plasma arc additive manufacturing is used to su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com