Novel method of resistance spot welding of aluminum base composite material

An aluminum-based composite material, resistance spot welding technology, applied in resistance welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problem of high-strength welded joints with large differences in physical properties, thermal conductivity, chemical compatibility, etc. Difficulty, hindering the rapid development of materials and other problems, to achieve the effect of increasing thickness, uniform distribution, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

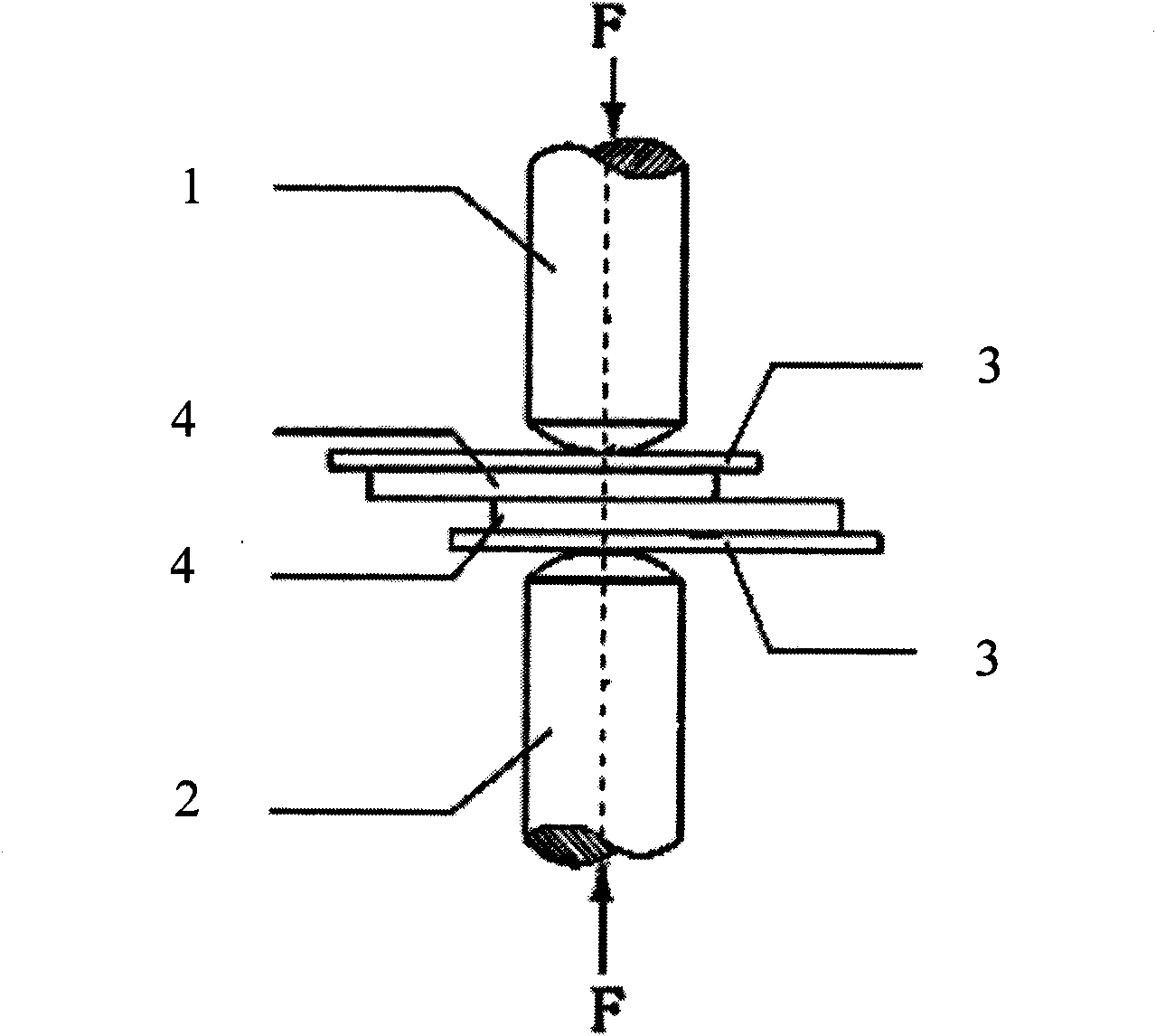

[0028] Example 1: A new method for resistance spot welding of aluminum matrix composites

[0029] New method of resistance spot welding of aluminum matrix composites:

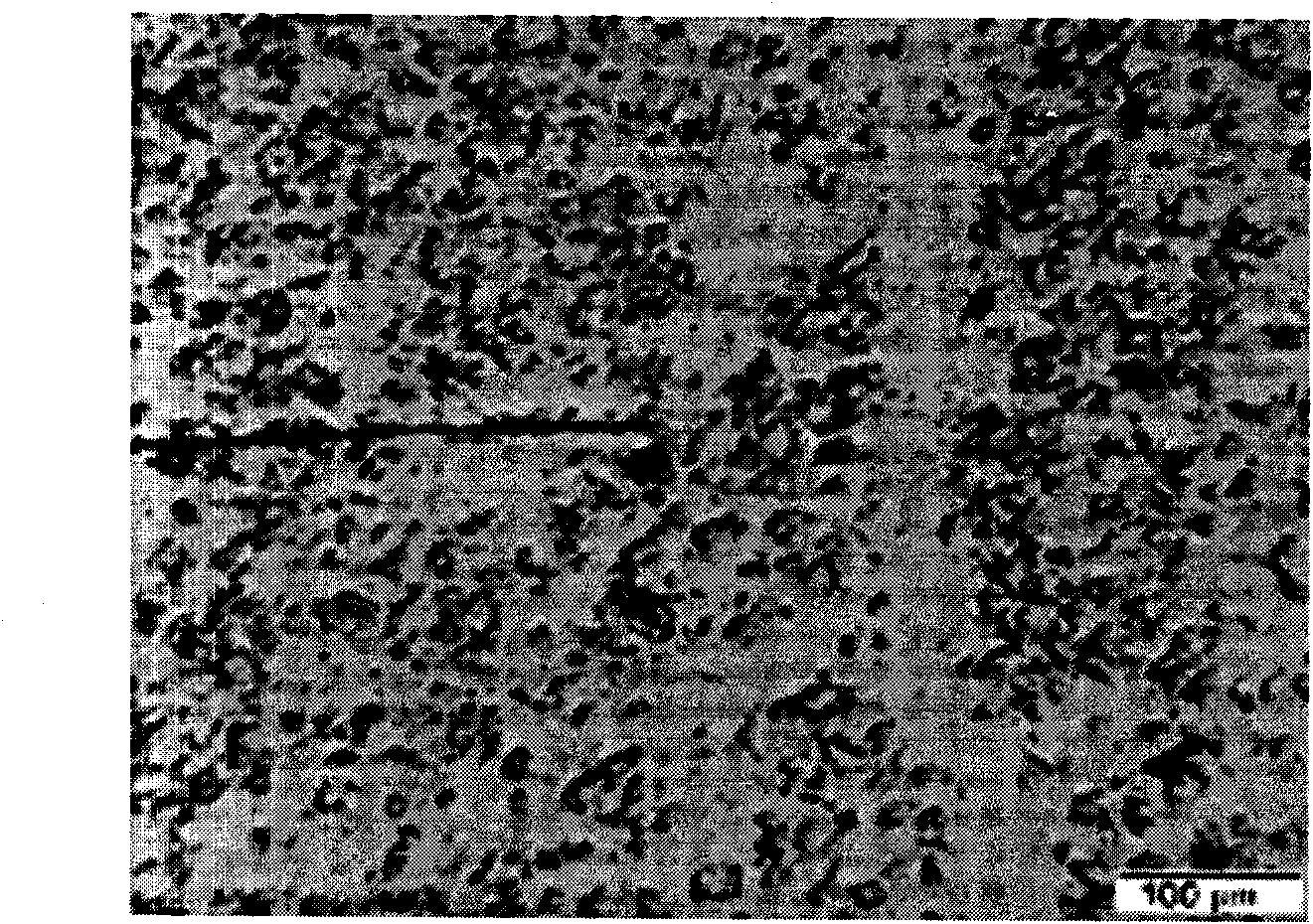

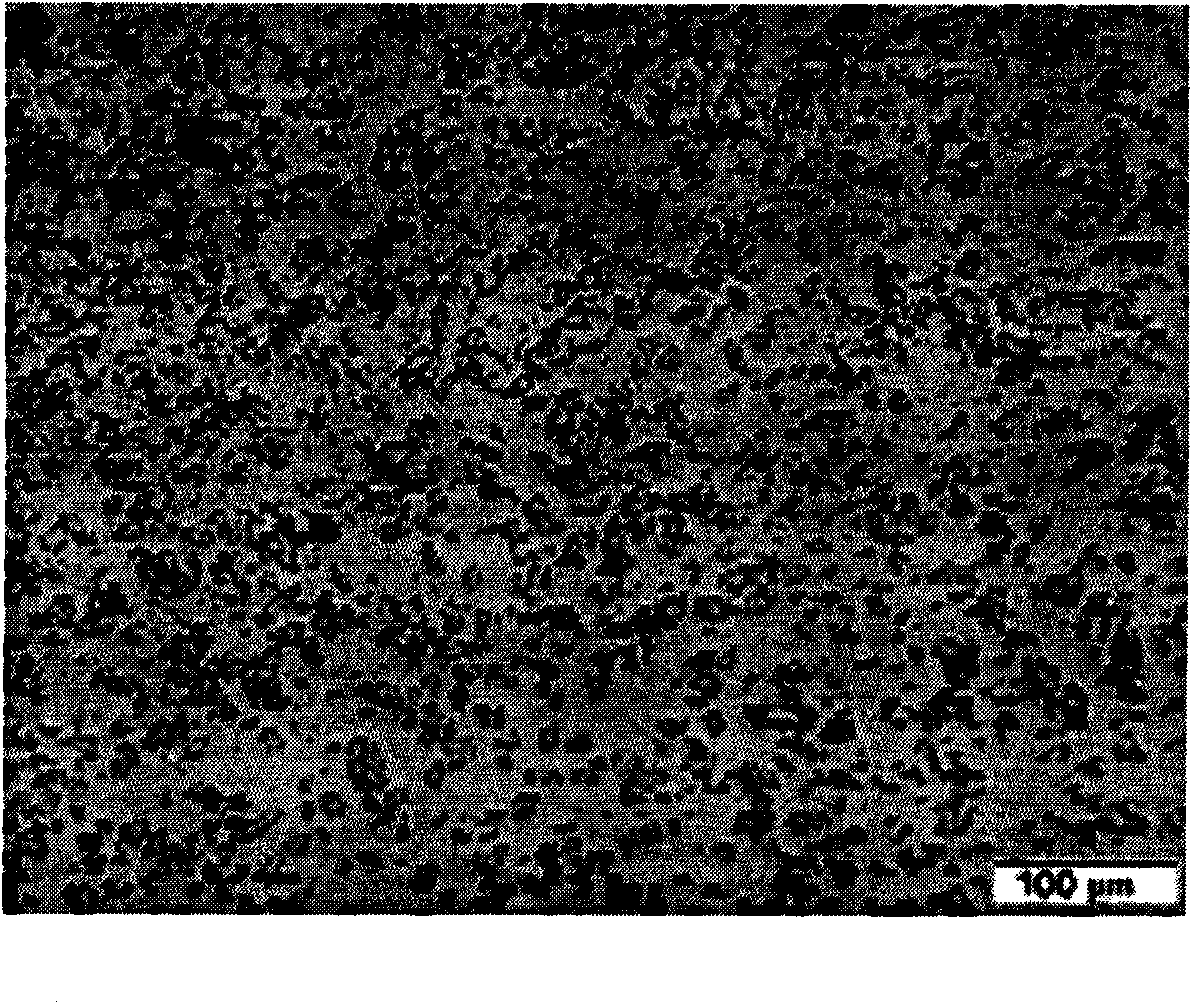

[0030] The matrix of the aluminum-based composite material adopted in the present invention is 2A12 (LY12), and the reinforcing phase is silicon carbide particles; the aluminum-based composite material is used as a plate, with equal thickness on both sides, and its surface and back are polished with sandpaper before resistance spot welding. Remove the surface oxide film, then clean it with acetone and air-dry; the stainless steel sheet used is smooth and flat, and clean it with acetone and air-dry before resistance spot welding; the matrix is 2A12 (LY12) and the reinforcement phase is silicon carbide particles. During resistance spot welding, the thickness of the added stainless steel sheet is 0.12mm (the material composition of the stainless steel sheet is 1Cr18Ni9Ti), the thickness of the welded aluminum ma...

Embodiment 2

[0032] Embodiment two: basically the same as embodiment one, the difference is:

[0033] When performing resistance spot welding on aluminum matrix composite materials, the thickness of the added stainless steel sheet is 0.1mm, the thickness of the welded aluminum matrix composite material plate is 0.7mm, the preloading time is 0.4 seconds, the holding time is 0.4 seconds, and the electrode pressure It is 2000 Newton, the welding time is 0.1 second, and the welding current is 1.2 kA.

Embodiment 3

[0034] Embodiment three: basically the same as embodiment one, the difference is:

[0035] When performing resistance spot welding on aluminum matrix composite materials, the thickness of the added stainless steel sheet is 0.2 mm, the thickness of the welded aluminum matrix composite material plate is 1.5 mm, the pre-compression time is 1 second, the maintenance time is 1.2 seconds, and the electrode pressure It is 3500 Newton, the welding time is 0.3 seconds, and the welding current is 1.8 kA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com