Small-diameter shaft shoulder stirring head

A stirring head and small-diameter technology, applied in non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as weld hole defects, limited spindle speed, and influence on weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

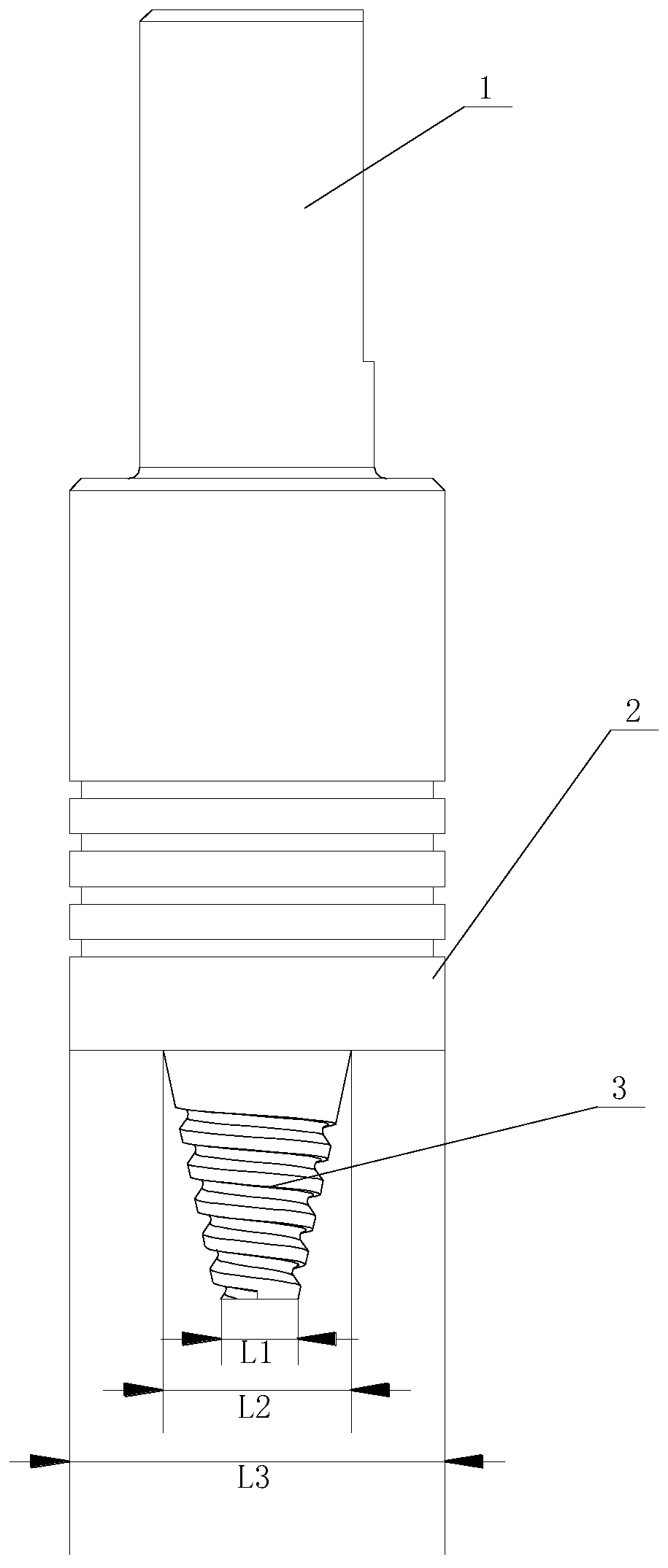

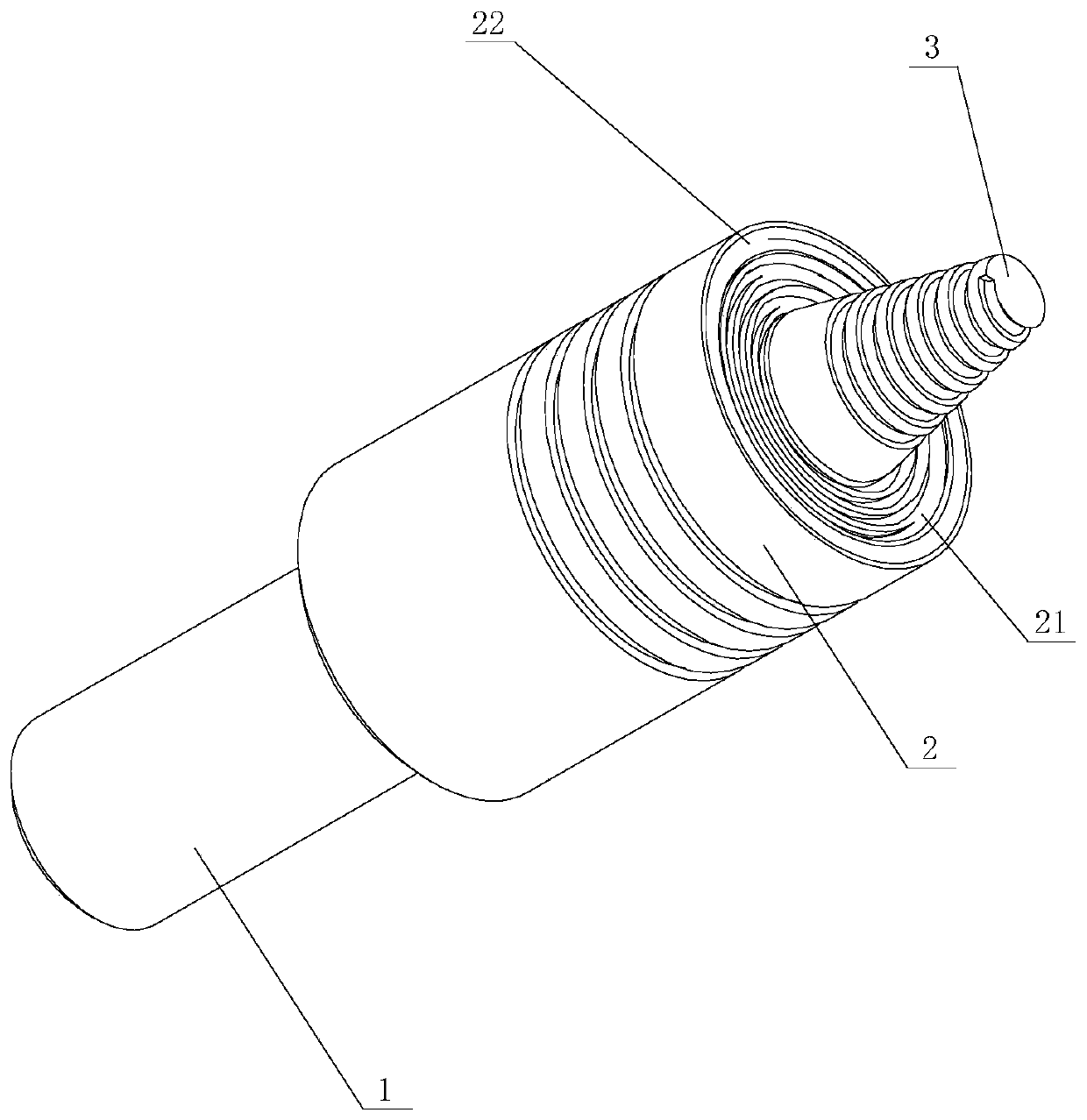

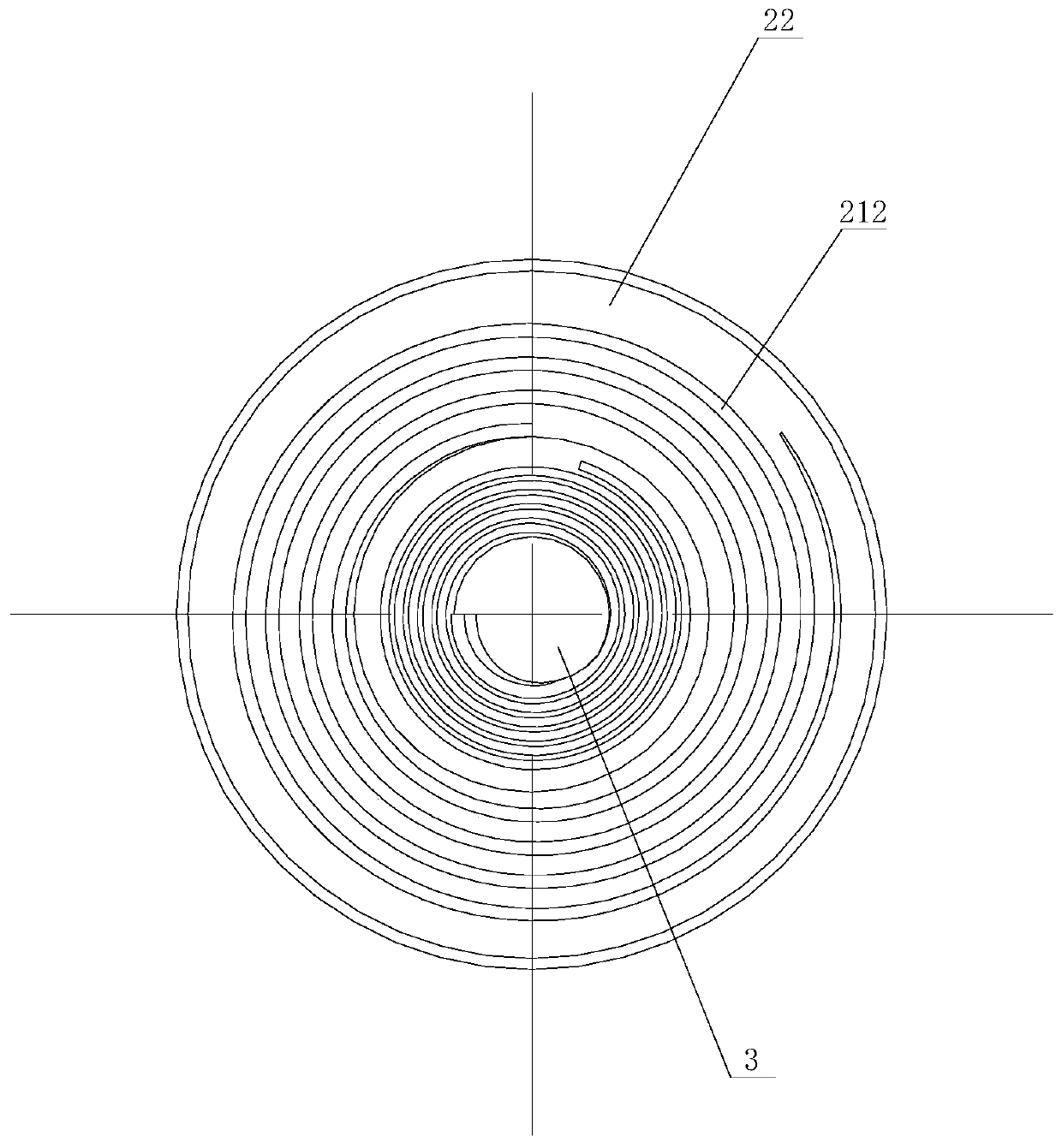

[0064] Such as Figure 1 to Figure 3 As shown, the first embodiment of the small-diameter shoulder stirring head of the present invention includes a clamping part 1, a shaft shoulder part 2 and a stirring needle 3 connected in sequence, and the diameter of the tip part 31 of the stirring needle 3 is defined as L1, and the definition The diameter of the needle base 32 of the stirring needle 3 is L2, and the diameter of the defined shaft shoulder 2 is L3, L1: L2 = 1: 1 ~ 1.7; L2: L3 = 1: 1.8 ~ 2.5; the end face of the shaft shoulder 2 is included in The stirring zone 21 close to the stirring needle 3 in the radial direction and the envelope zone 22 far away from the stirring needle 3, the envelope zone 22 is set as a gentle surface for wrapping together and forging plastic metal, and the stirring zone 21 is provided with a surface for increasing the frictional moment non-concentric circle structure. In this structure, the small-diameter shoulder stirring head is adopted. Accord...

Embodiment 2

[0070] Such as Figure 4 As shown, in the second embodiment of the small-diameter shoulder stirring head of the present invention, the stirring head is basically the same as that of Embodiment 1, the only difference is that in this embodiment, the groove 212 is set as an open-loop type formed by a curve curved groove. The open-loop curved groove can increase the stirring and heat production effect of the stirring zone 21 .

[0071] In this embodiment, the open-loop curved groove is in the form of a continuous single groove. The friction force is increased, and the weld metal in the enveloping area 22 is periodically impacted, which is beneficial to reducing the metal oxide film.

Embodiment 3

[0073] Such as Figure 5 As shown, the third embodiment of the small-diameter shoulder stirring head of the present invention is basically the same as that of embodiment 1, the only difference being that in this embodiment, the open-loop curved grooves are in the form of separate multi-grooves. The friction force is increased, and the weld metal in the enveloping area 22 is periodically impacted, which is beneficial to reducing the metal oxide film.

[0074] In this embodiment, a concentric circle structure is provided between the gentle surface and the non-concentric circle structure. The concentric circle structure can increase the enveloping effect under the condition of radial flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com