Patents

Literature

108results about How to "Increase friction torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

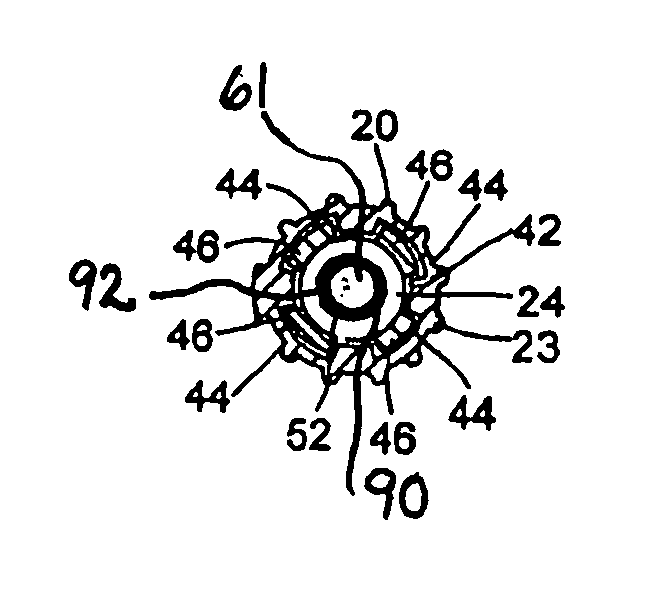

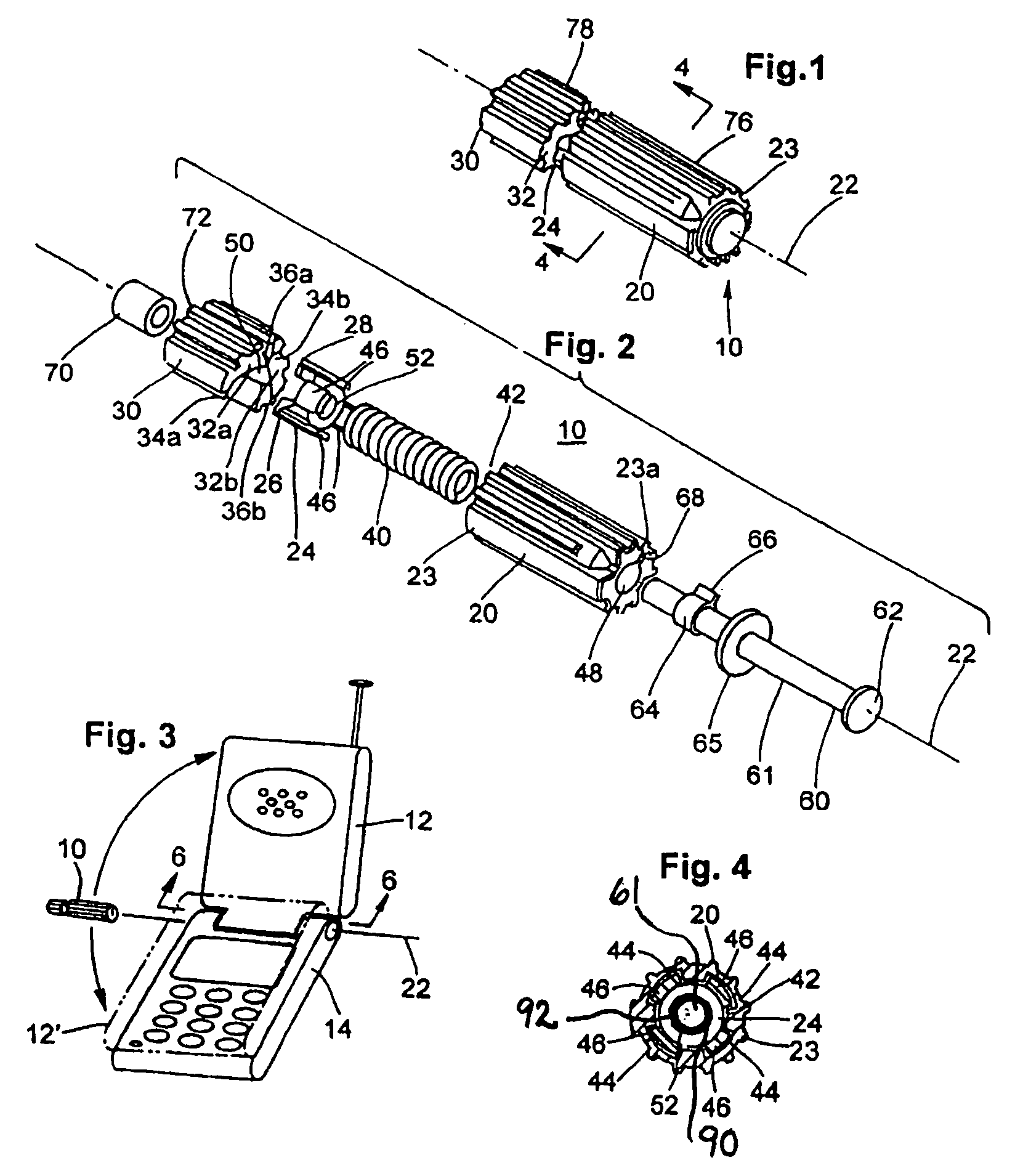

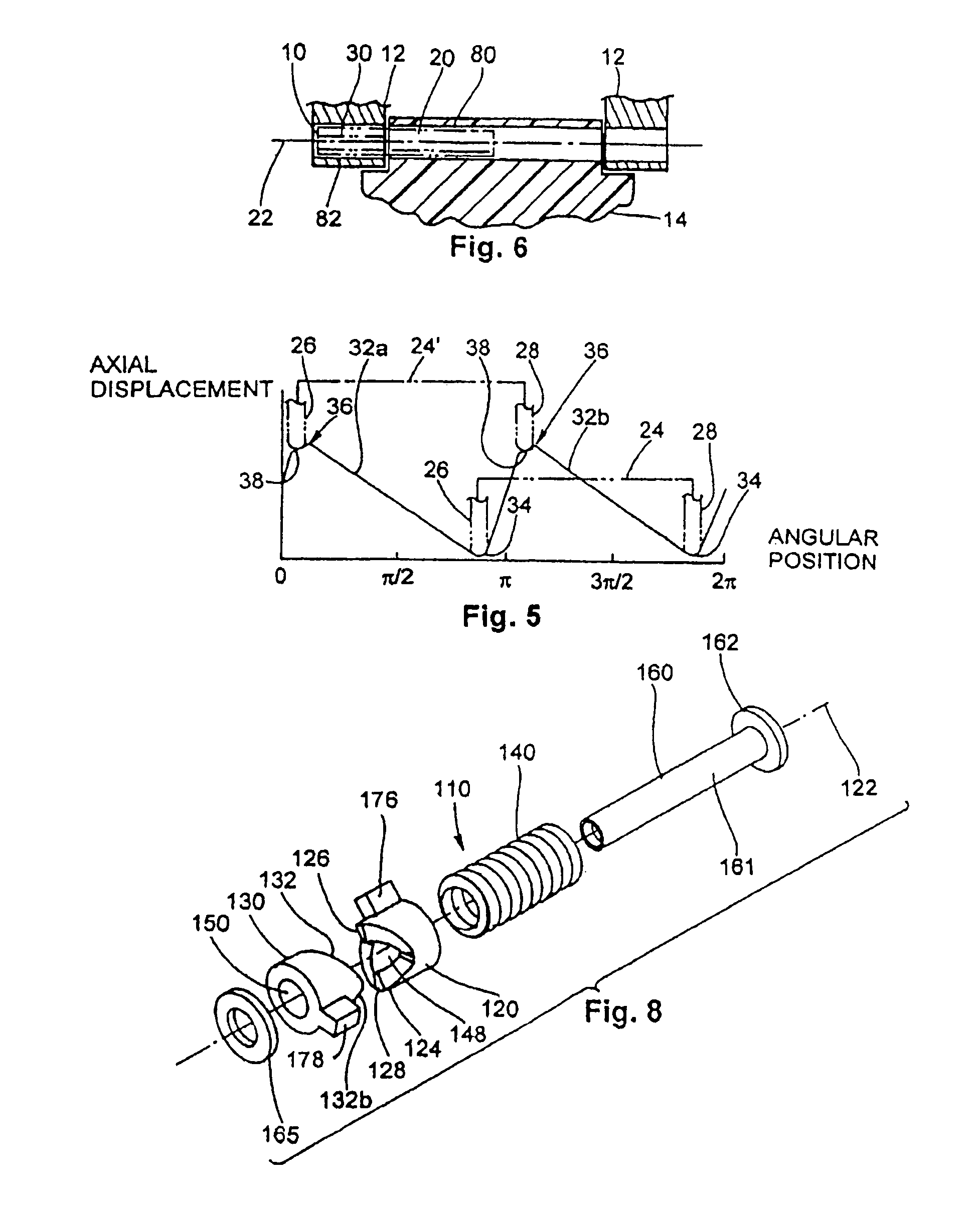

Bistable hinge with dampening mechanism

ActiveUS7065834B2Travel delayIncrease friction torqueInterconnection arrangementsDigital data processing detailsMechanical engineeringHinge angle

Owner:SOUTHCO

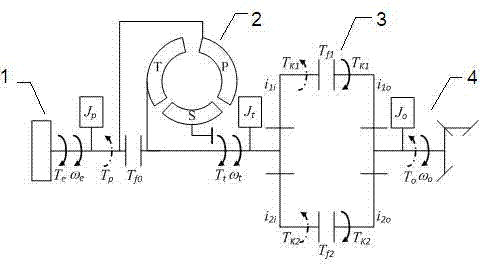

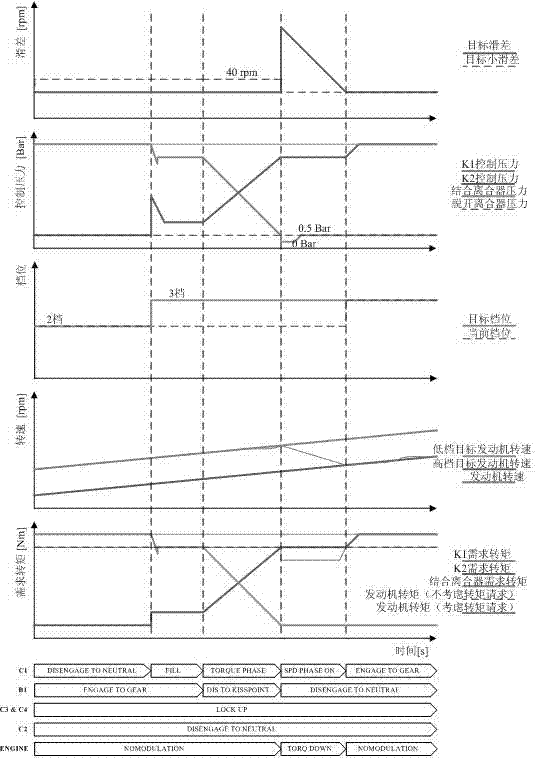

Gear-shifting control method for automatic hydraulic speed changer

ActiveCN103671898AControl torque variationCombined with softGearing controlAutomatic transmissionControl theory

The invention discloses a gear-shifting control method for an automatic hydraulic speed changer. The gear-shifting control method comprises the steps that in the one-time gear shifting process, only one clutch is started, the other clutch is combined, the torque exchanging process is carried out between the two movement clutches, oil pressure is controlled through the combination of the clutch controlling step and the separated clutch controlling step, and the flexible clutch combination is guaranteed by adjusting the K1 and K2 control pressure in the gear shifting process. The engine torque changing is controlled, and easy, efficient and smooth gear shifting controlling of the automatic hydraulic speed changer is achieved. The test carried out under the full accelerator aperture and other limiting conditions such as gear lifting and gear jumping and reducing in a low-gear gear area shows that the control method can meet the requirements for gear shifting quality of forward torque gear lifting, forward torque gear reducing, negative torque gear lifting and negative toque gear reducing.

Owner:SHENGRUI TRANSMISSION

Disk brake

InactiveUS7461725B2Reduce weightReliable functionAxially engaging brakesBrake actuating mechanismsCalipersBrake pad

A disk brake includes a brake disk with a preferred rotational direction, with a first brake pad with a first center of gravity on a first side of the brake disk, a second brake pad with a second center of gravity on a second side of the brake disk, and a caliper for transmitting the braking forces produced by the second brake pad to the first side of the brake disk. The second center of gravity is offset from the first center of gravity by a predetermined distance in the direction toward the side of the brake disk that trails when the disk is rotating in its preferred direction.

Owner:WABCO EURO BVBA SPRL

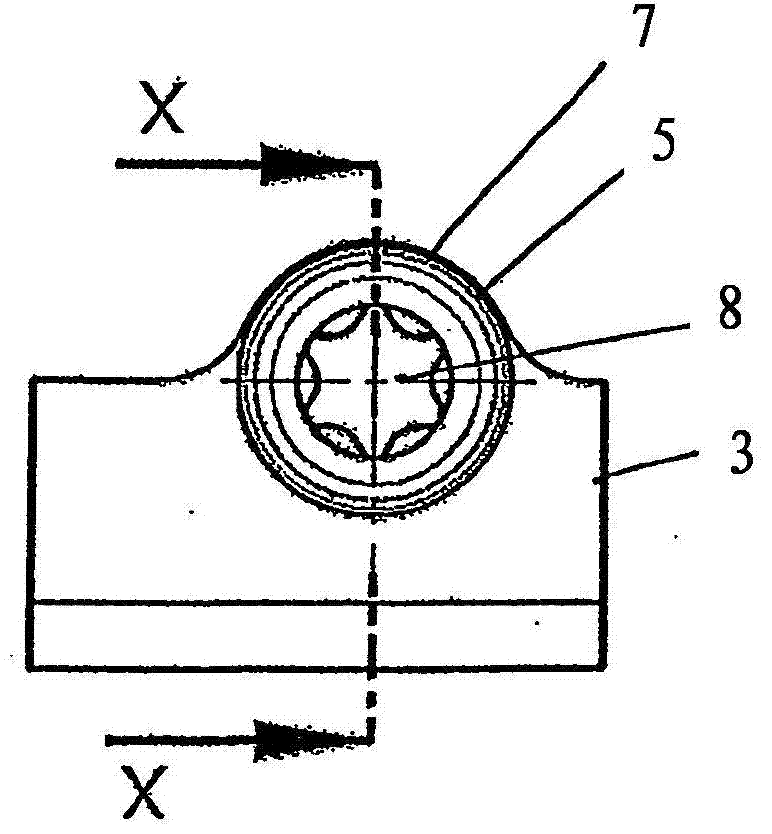

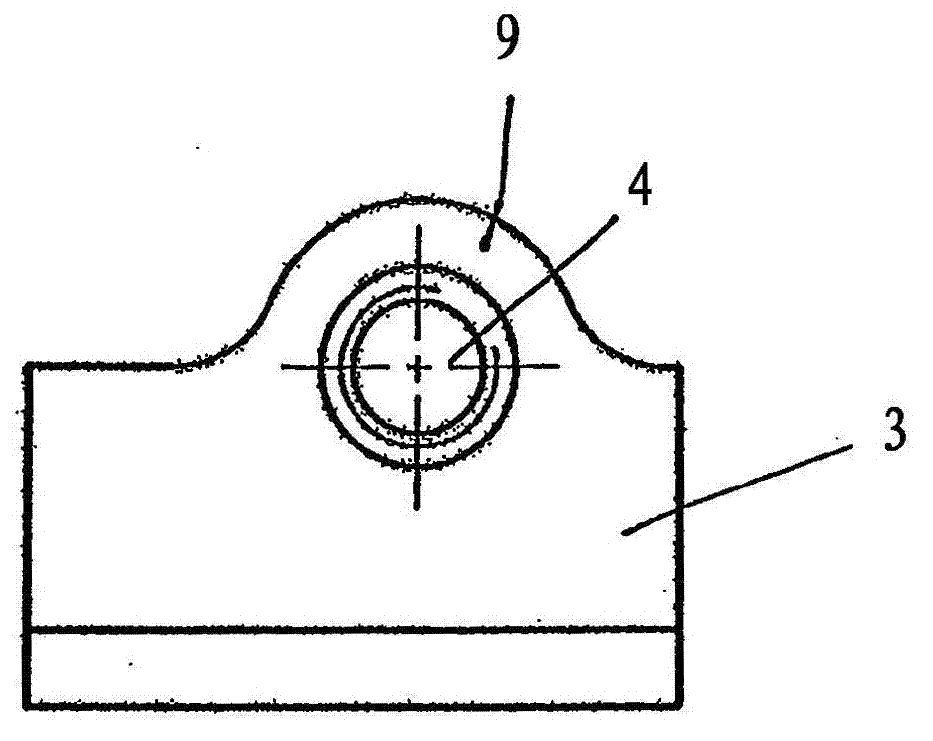

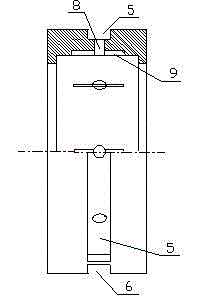

Bare weight two-stage friction-type lower side bearing

ActiveCN101830235AIncrease contactFit closelyBogiesBogie-underframe connectionsFrictional coefficientTruck

The invention relates to a bare weight two-stage friction-type lower side bearing which comprises an inner seat of the side bearing and an outer sleeve of the side bearing which are sleeved and matched with each other, wherein a pressing block of the inner seat of the side bearing is arranged at the upper part of the inner seat of the side bearing; a heavy-load friction plate is arranged at the top part of the pressing block of the inner seat of the side bearing; a pressing plate of the outer sleeve of the side bearing is arranged at the upper part of the outer sleeve of the side bearing; a non-load friction plate is arranged at the top part of the pressing plate of the outer sleeve of the side bearing; the friction factor muk of the non-load friction plate is greater than the friction factor muz of the heavy-load friction plate; an elastic element for controlling the vertical position relation between the inner seat of the side bearing and the outer sleeve of the side bearing is arranged between the inner seat of the side bearing and the outer sleeve of the side bearing; and the mechanical property of the elastic element enables the non-load friction plate and the heavy-load friction plate to meet the following position relation: in an empty car state, the horizontal position of the non-load friction plate is higher than the that of the heavy-load friction plate, and in a heavy car state, the horizontal position of the non-load friction plate is flush with that of the heavy-load friction plate. A railway freight car bogie assembled with the lower side bearing has higher critical speed in the no-load state and better curve negotiation capacity in the heavy-load state.

Owner:CRRC YANGTZE CO LTD

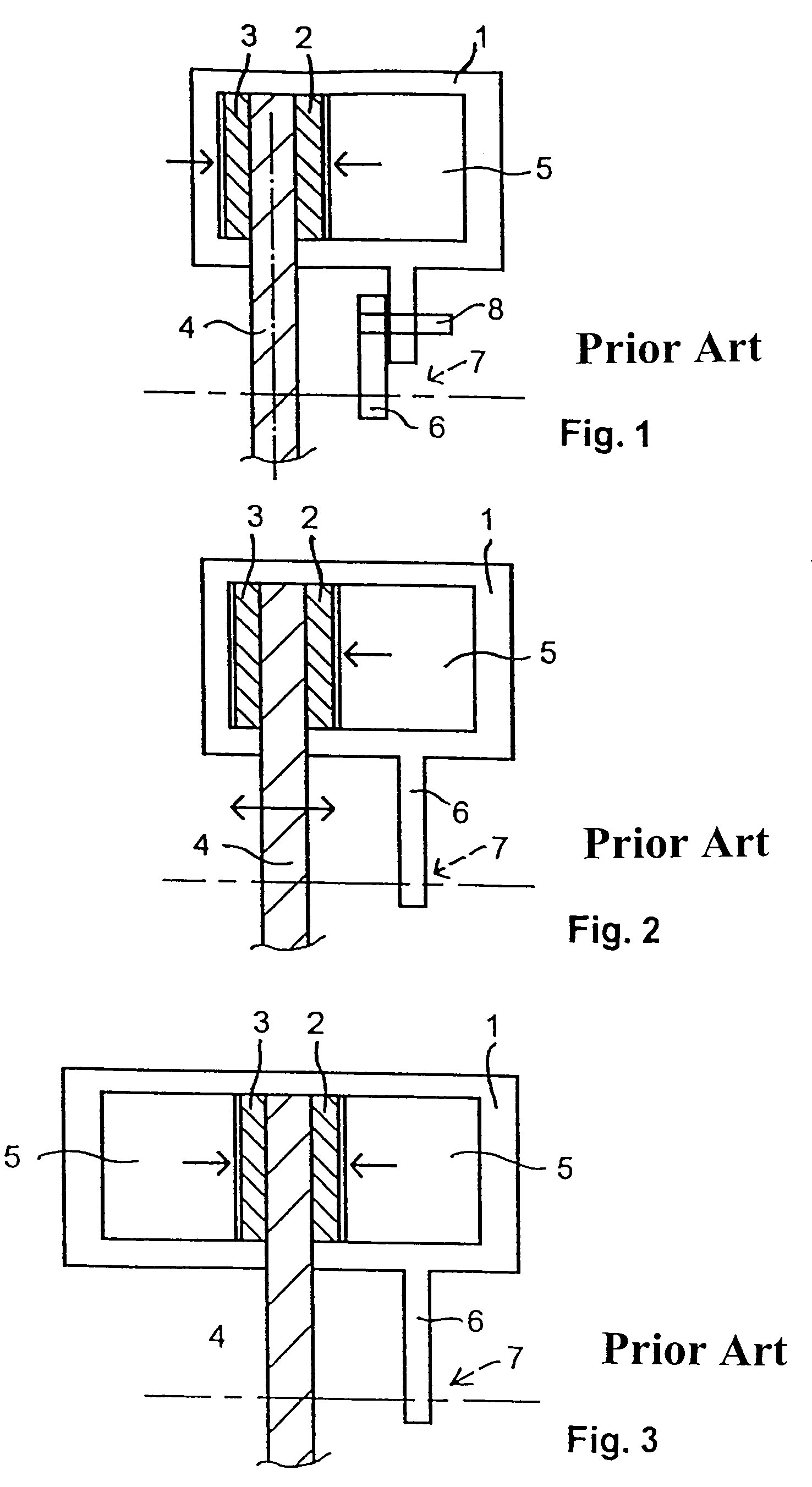

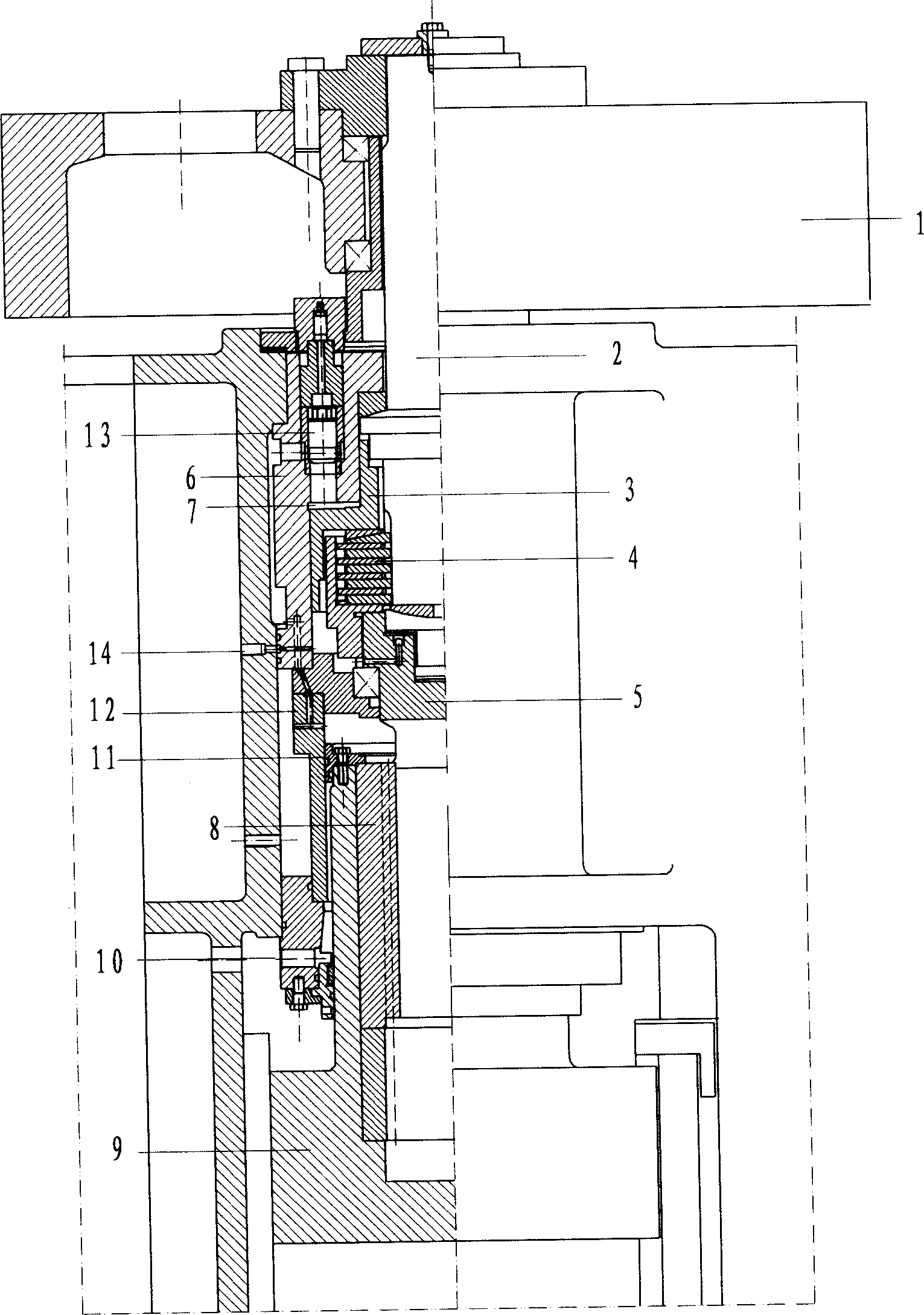

Synchronizer having three pyramidal faces

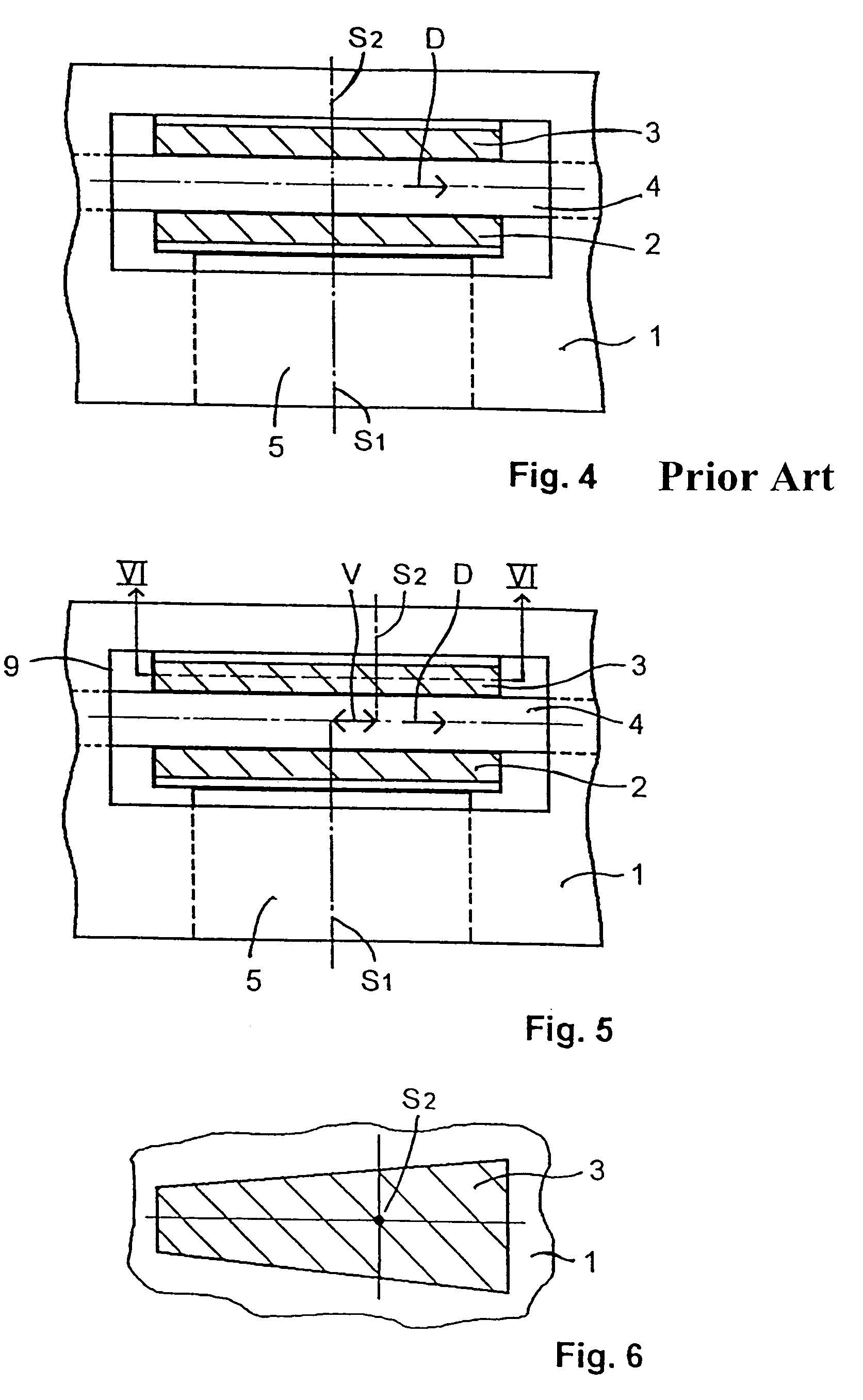

InactiveCN1544824AIncrease friction torqueReduce shift forceMechanical actuated clutchesGearing detailsEngineering3d surfaces

The invention is a 3D surface synchronizer, belonging to automobile driving device field, including: two-stage gear, inner conical ring, outer conical ring, medium ring, synchronizer spring, tooth case, gear hub, slide block, one-stage gear, first groove, slide block groove, and second groove, where inner conical ring, outer conical ring and medium ring are set in sequence from inside to outside to compose a friction ring on the gear, the inner conical ring is covered on the conical surface of the gear, the medium ring covered on the inner conical ring and the outer conical covered the medium ring, the medium ring is connected with the two-stage gear and one-stage gear by the grooves on the stage tooth, the slide groove is on the inner wall of the tooth case, the whole slide block is inserted in the groove of the gear hub, two synchronizer springs tightly adhere to two sides of the gear hub, respectively, and the outer conical ring is set with groove at the big end. It largely enhances synchronous torque, thus shortens synchronous time and widens the working range of the synchronizer, etc.

Owner:SAIC MOTOR

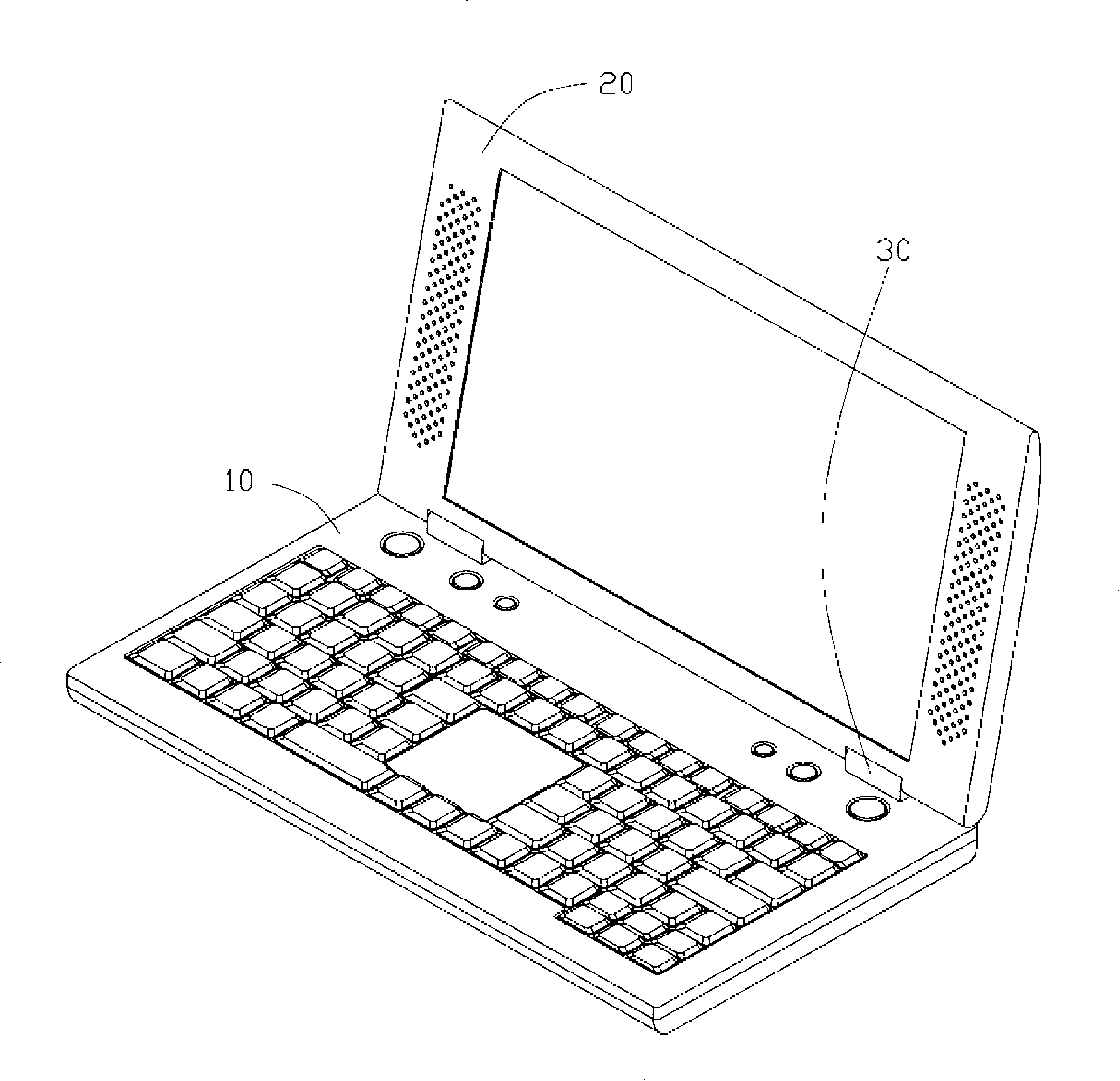

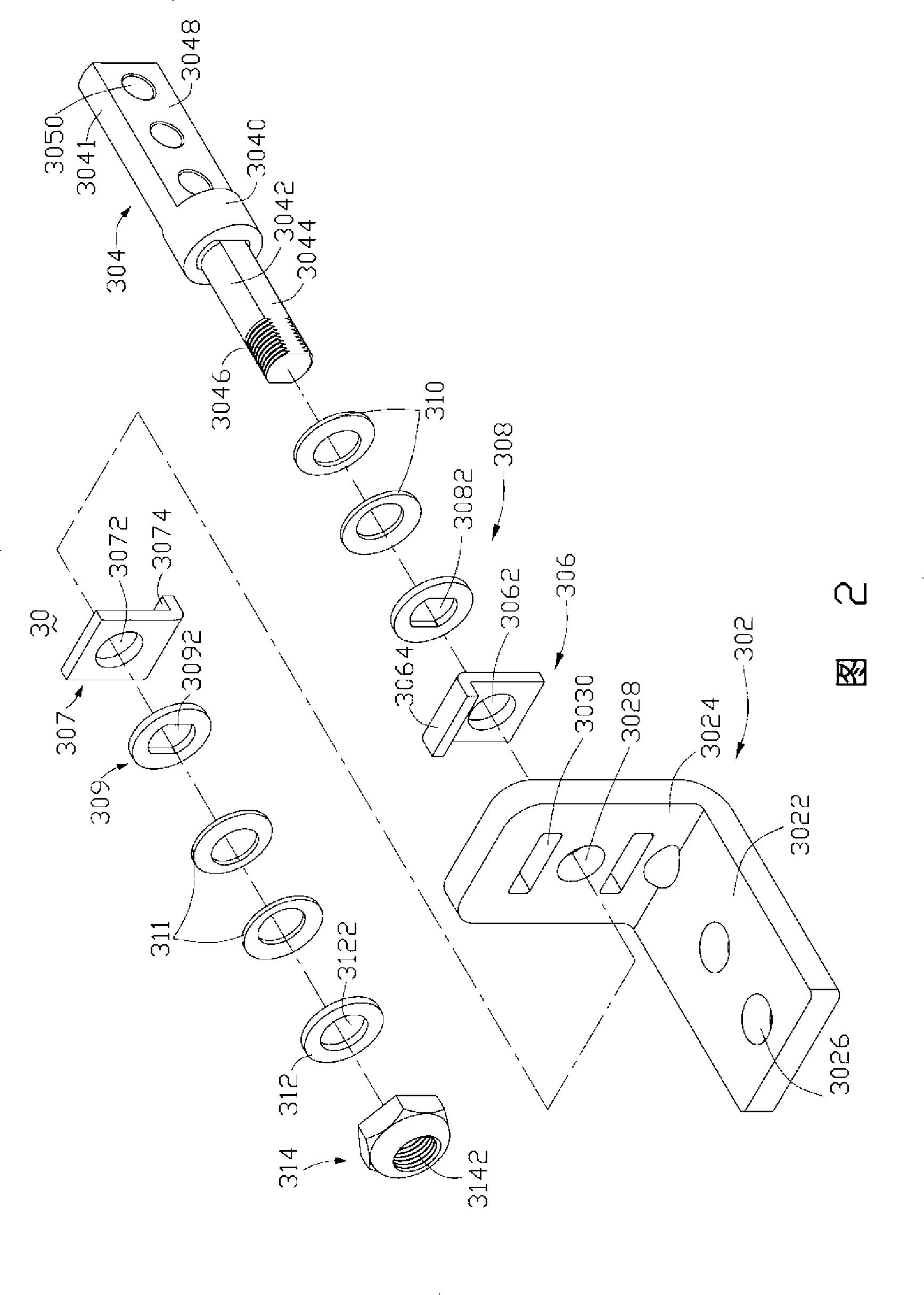

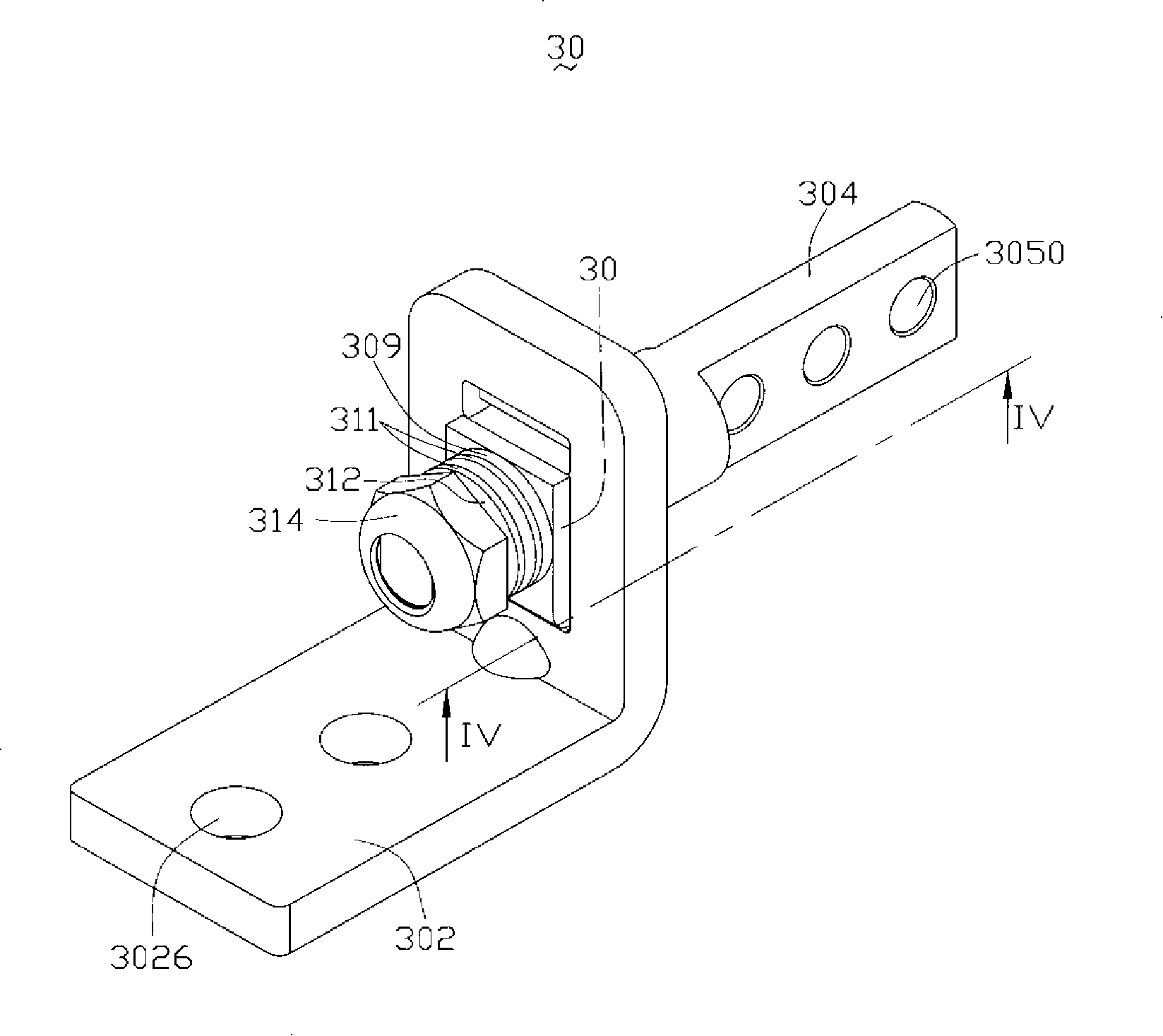

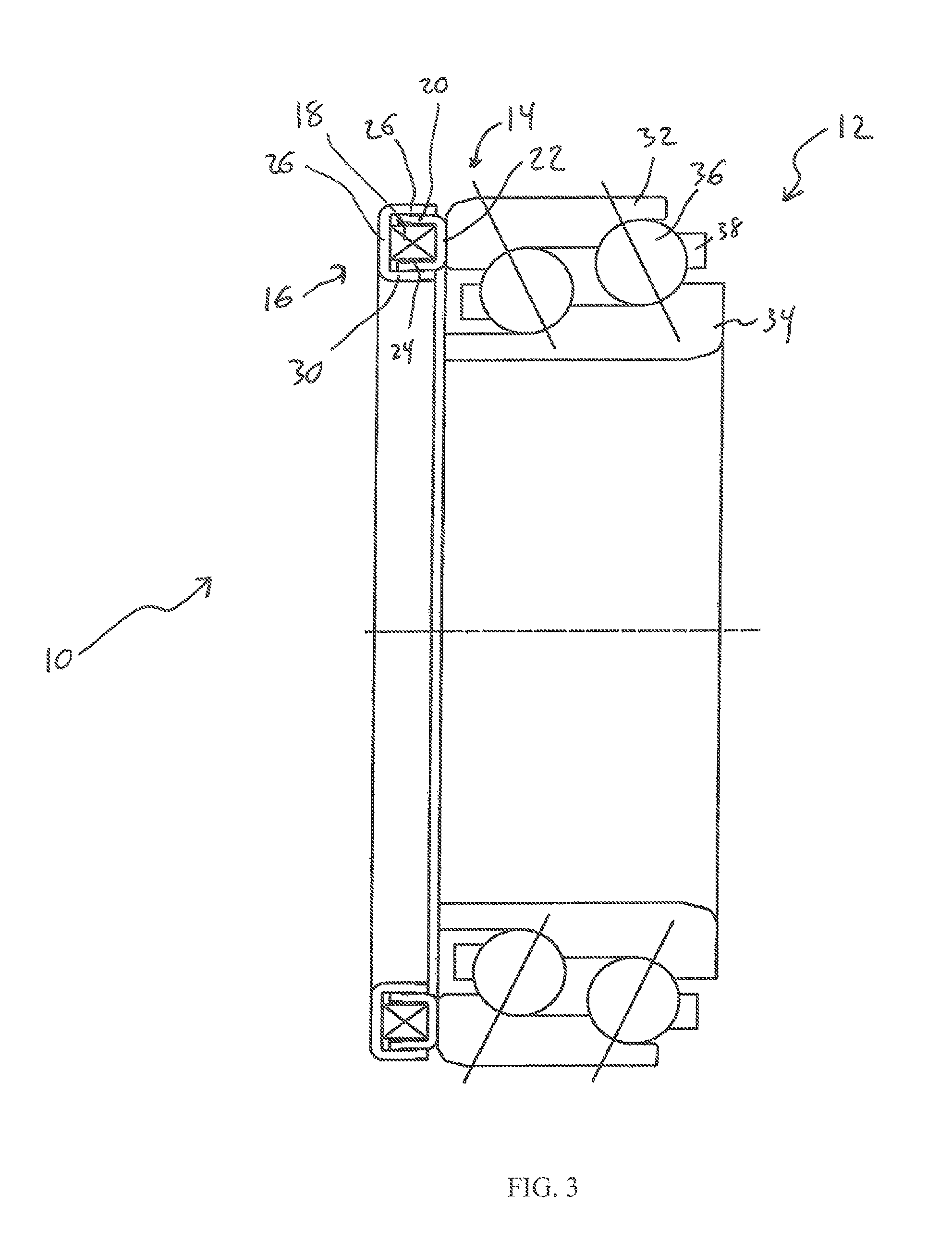

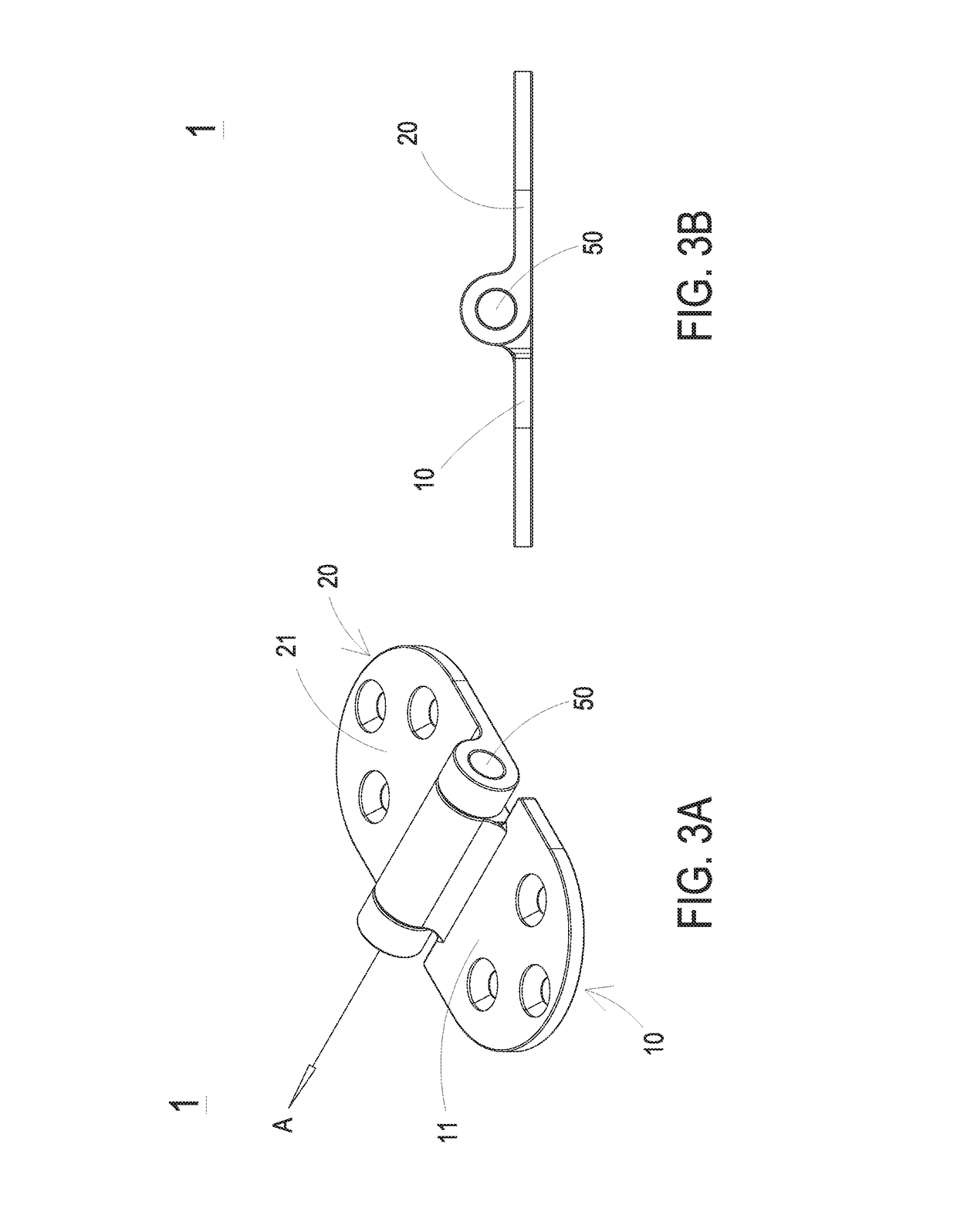

Hinge mechanism

InactiveCN101201078AIncrease friction torqueWing accessoriesDetails for portable computersFriction torqueElastic component

The invention discloses a hinge structure, which is suitable for electronic devices such as the notebook computer comprising two components. The invention comprises a support, a rotation axis, two movable friction plates, two fixed wear plates, an elastic component and a locking firmware. One movable friction plate and one fixed wear plate are arranged at one side of the support and the other movable friction plate and the other fixed wear plate are arranged at the other side of the support. In addition, each movable friction plate is arranged closely to the corresponding fixed wear plate. The elastic component is sheathed on a rotation axis to provide axial force. The movable friction plates are sheathed on the rotation axis and can not rotate. The support and the fixed wear plates are sheathed on the rotation axis rotatablely. The locking firmware is arranged at one end of the rotation axis to prevent the support, the fixed wear plates, the movable friction plates and the elastic component from dropping off the rotation axis. One movable friction plate and one fixed wear plate are respectively arranged at the two sides of the support of the hinge structure; thereby double-faced friction is formed at the two sides of the support, which can increase friction torque effectively.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

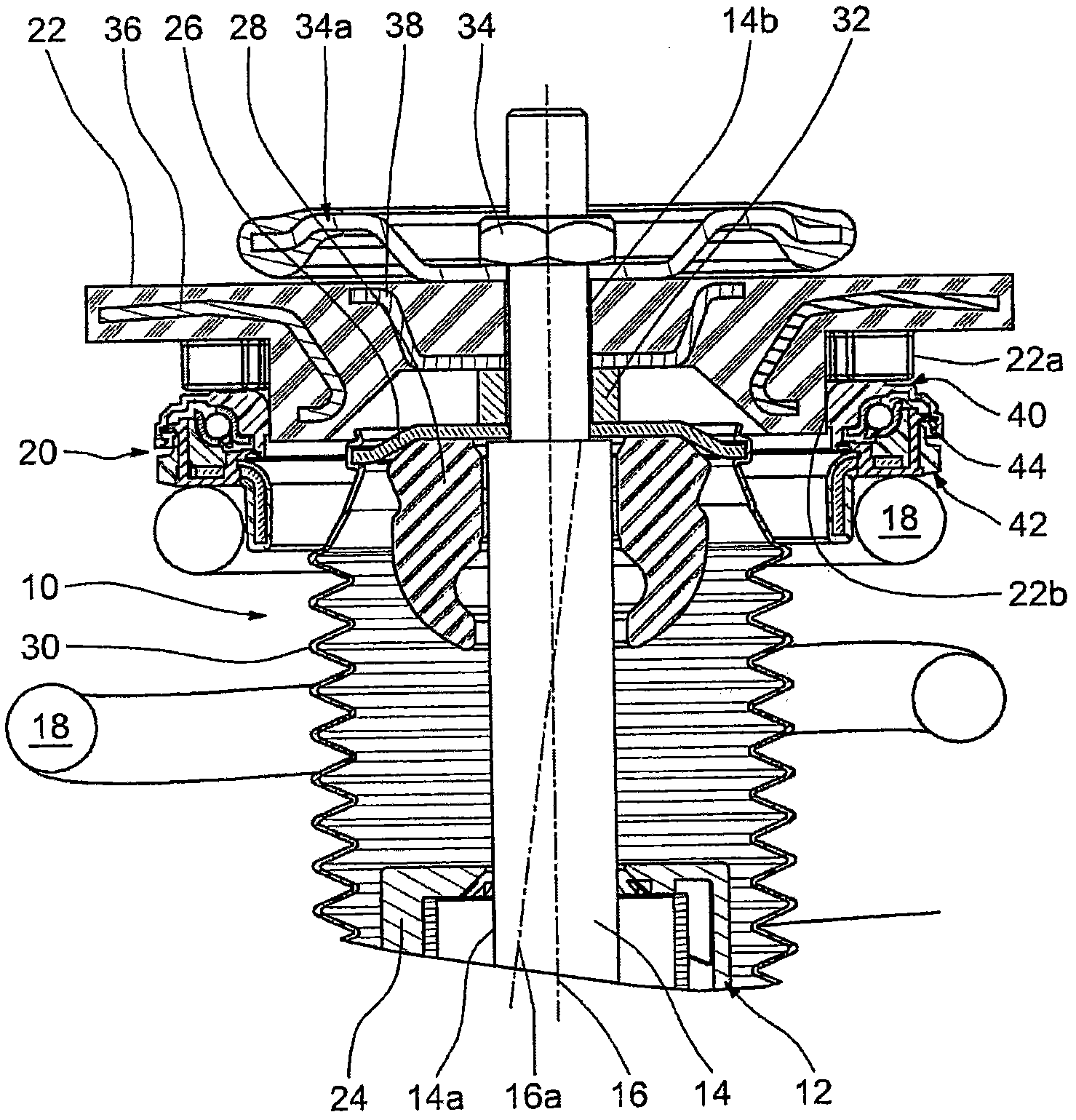

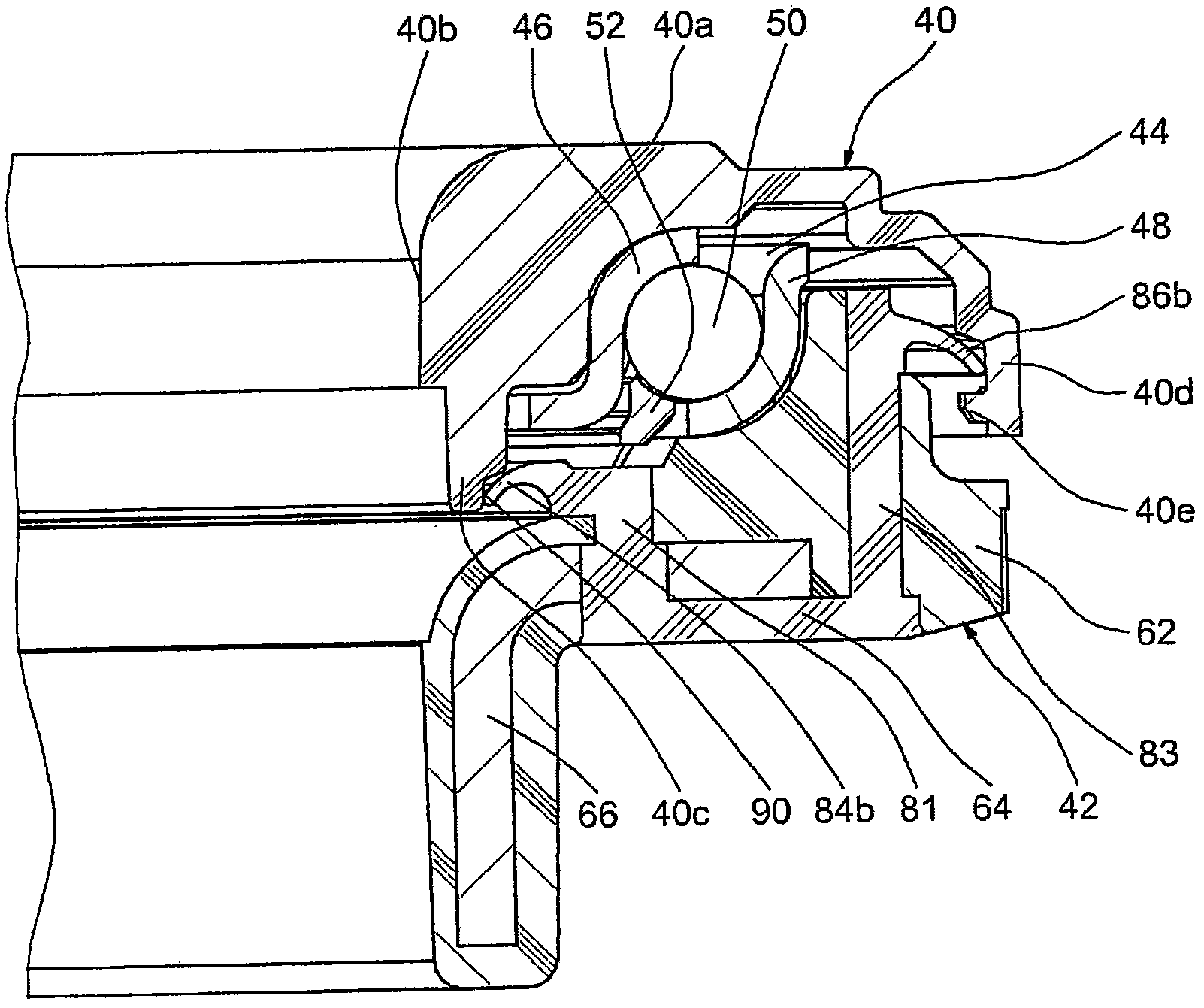

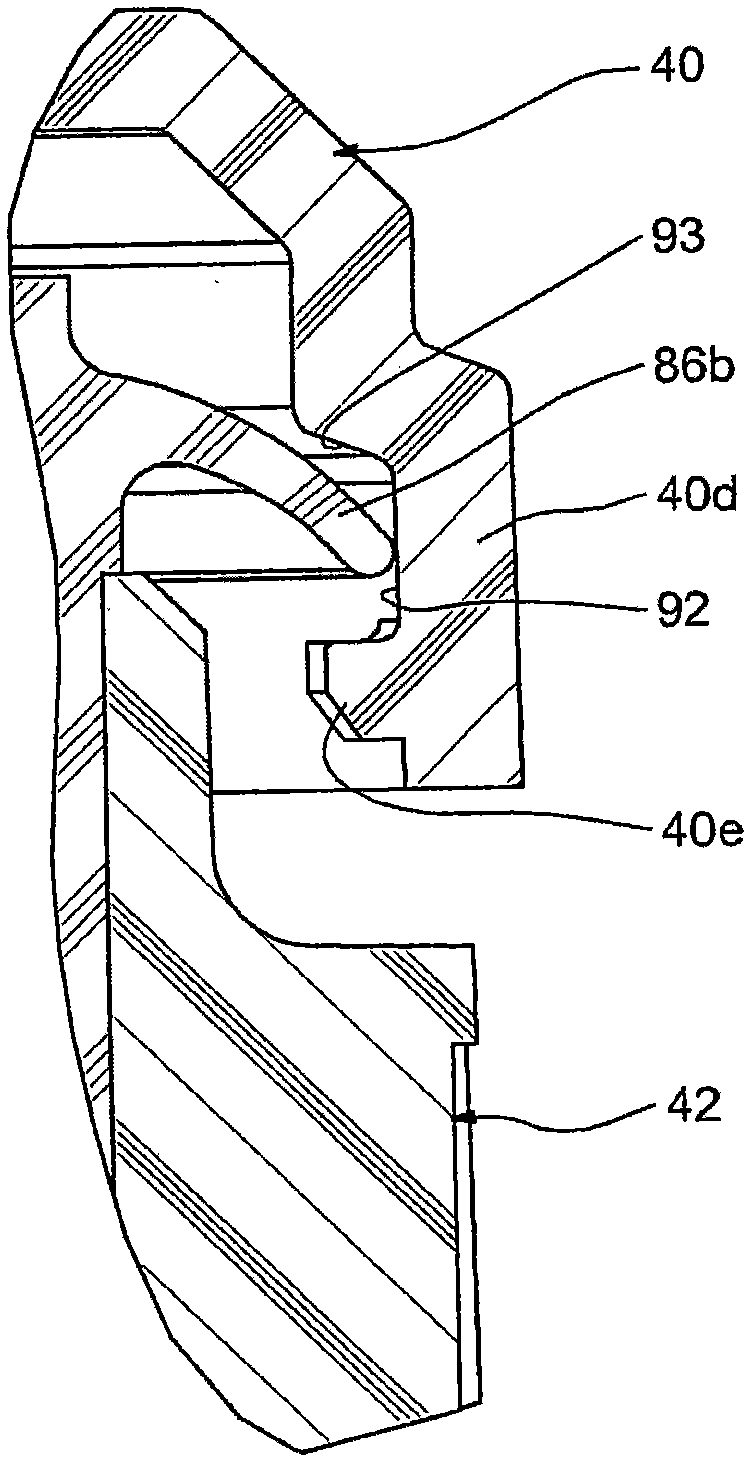

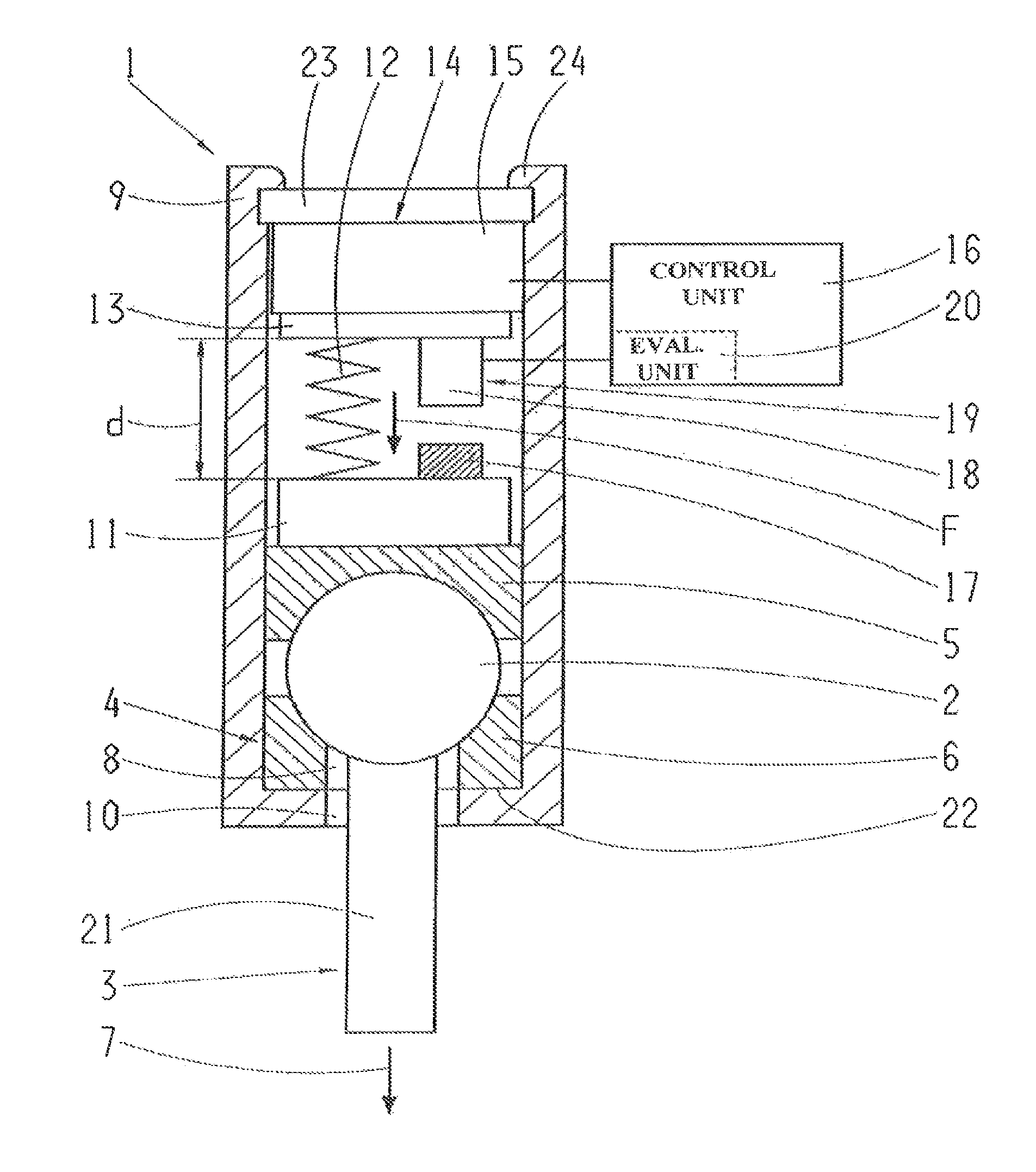

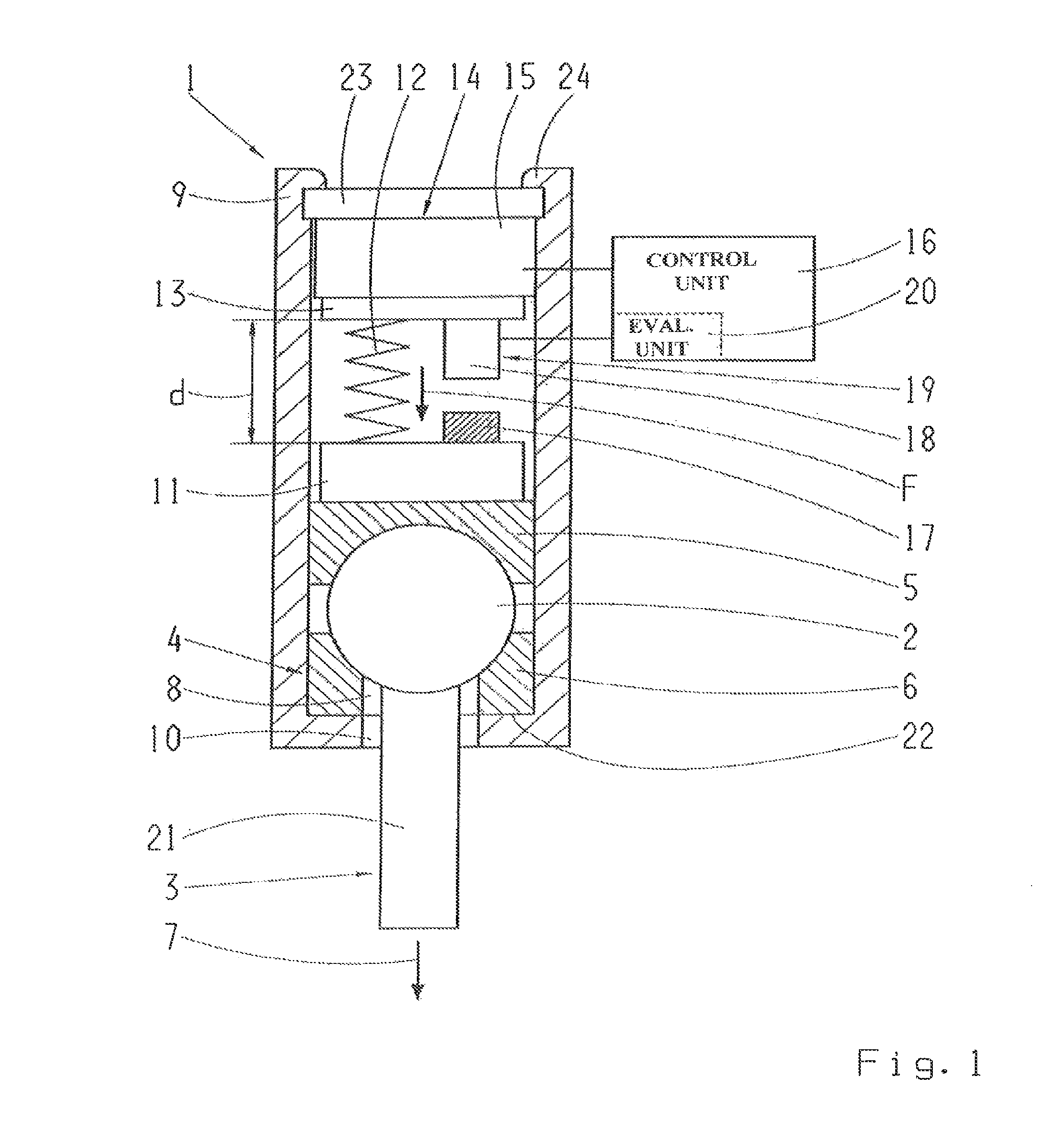

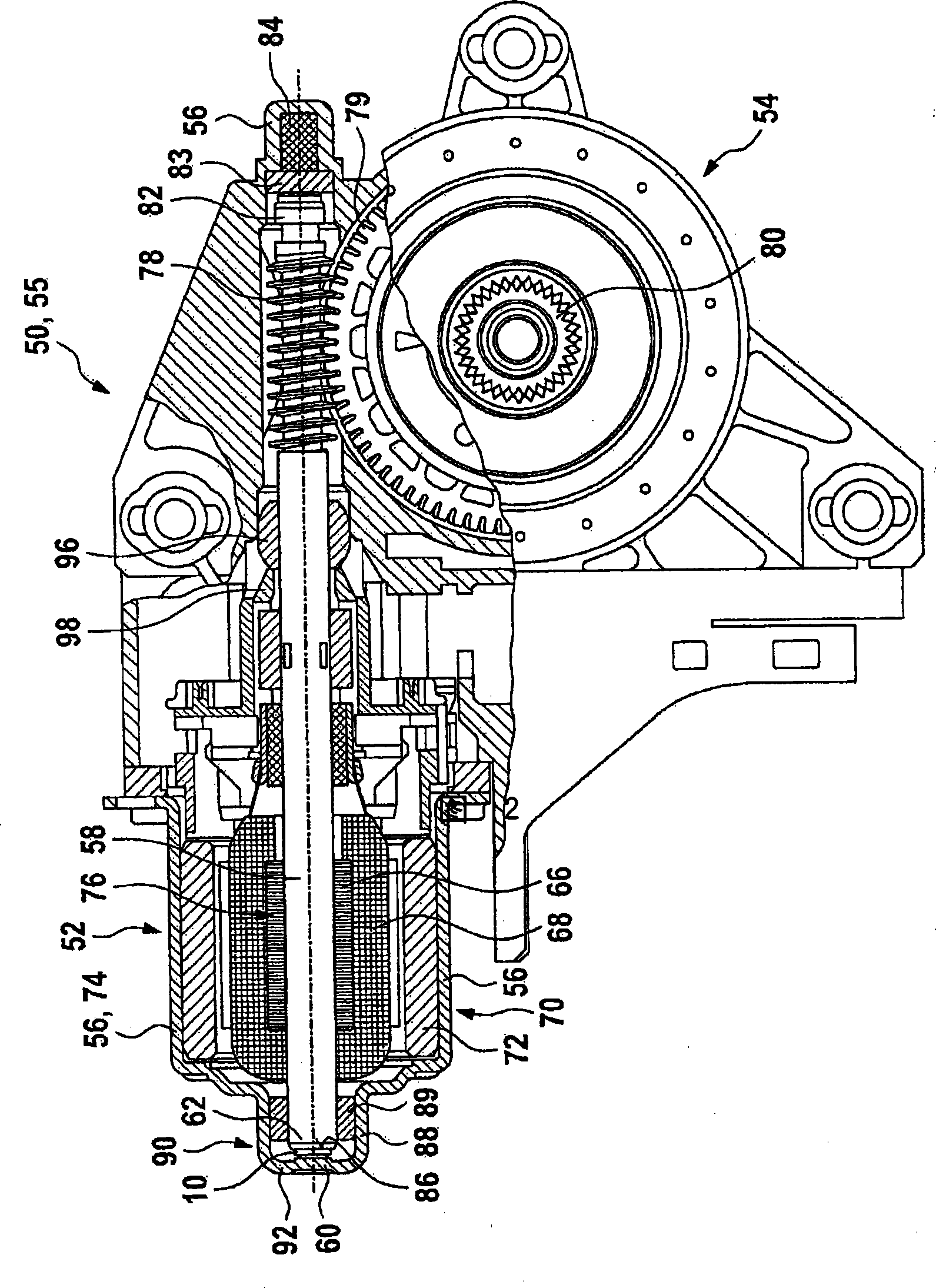

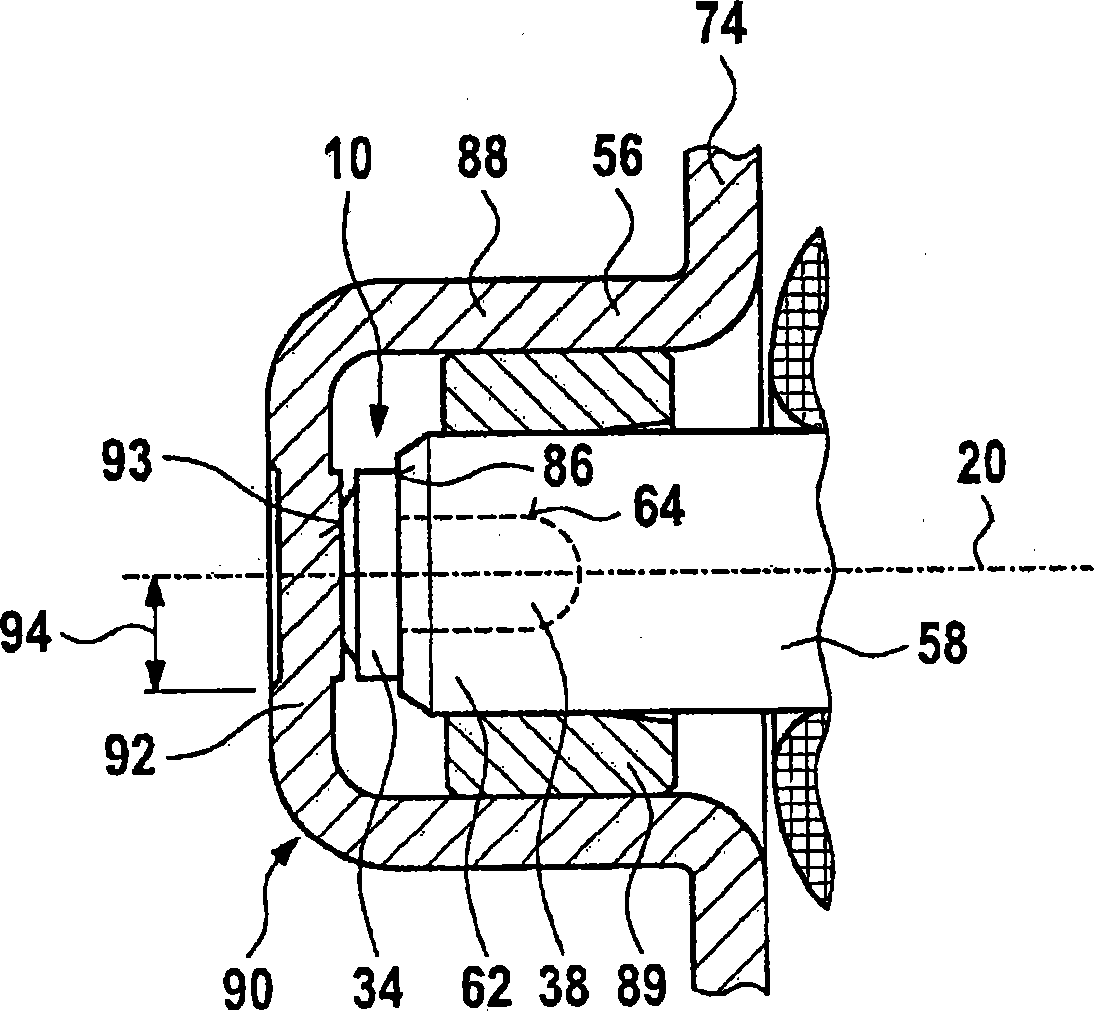

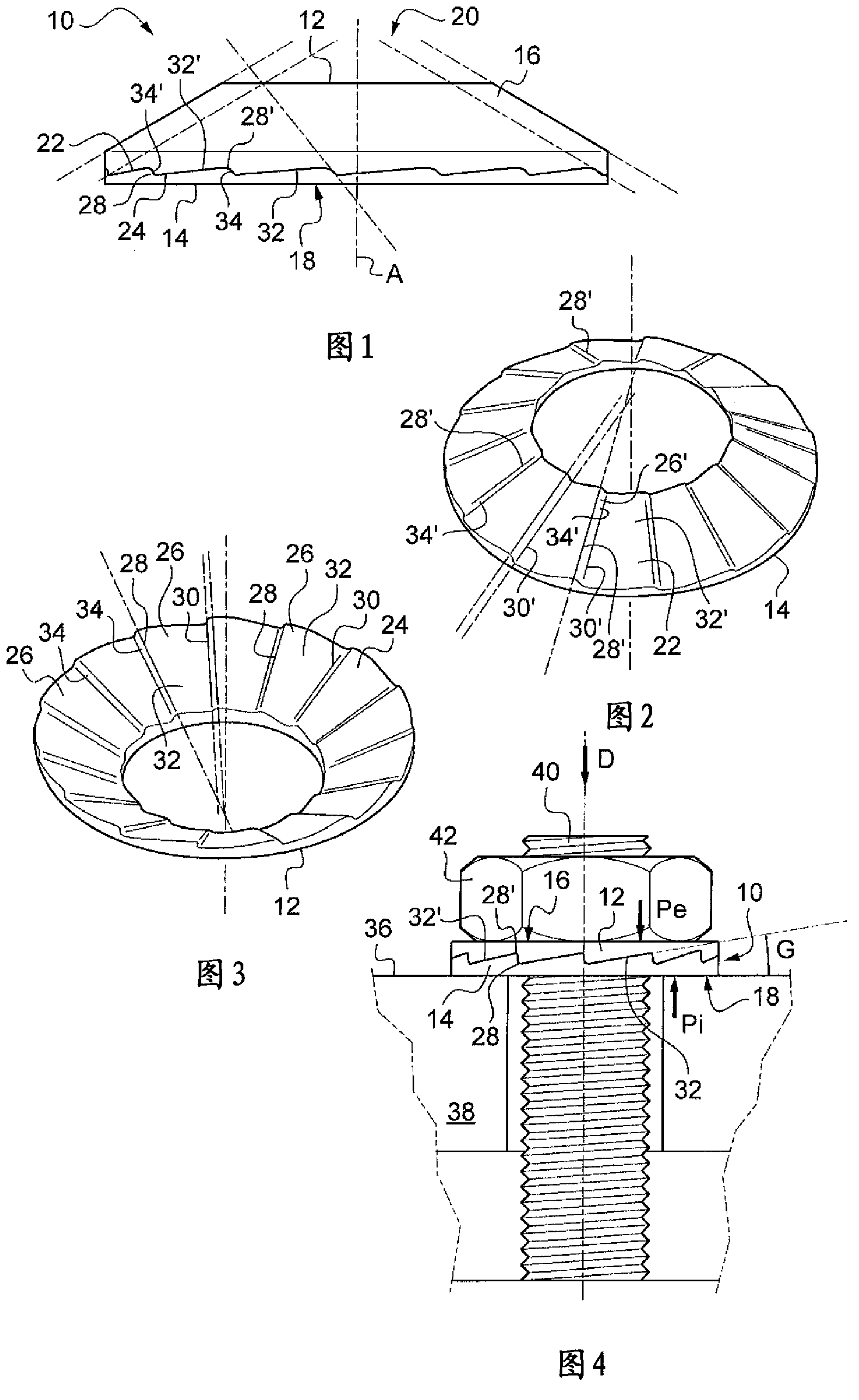

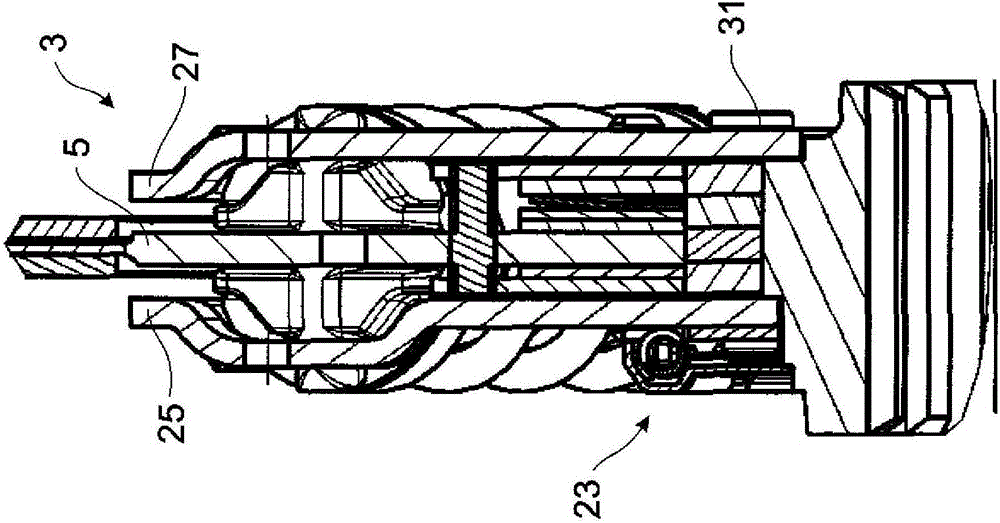

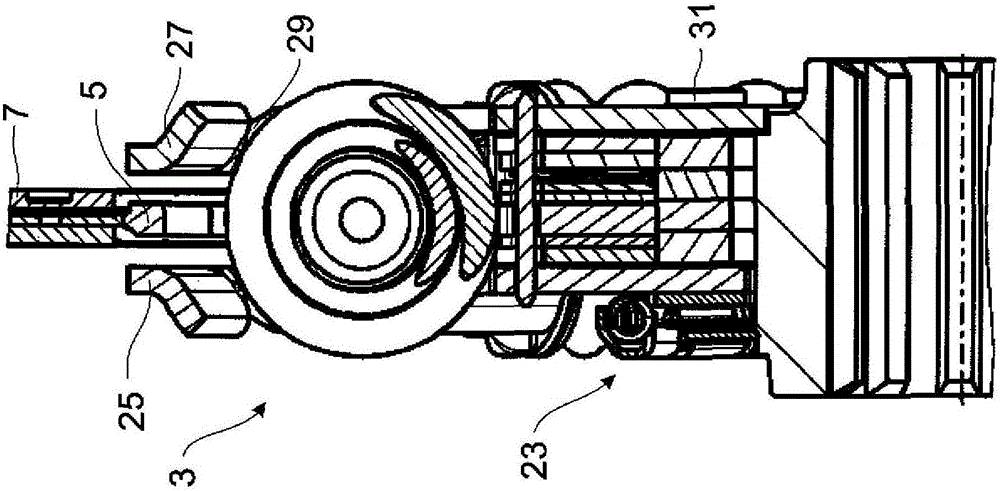

Suspension bump stop and strut device

InactiveCN102046404AImprove sealing propertiesIncrease friction torqueBall bearingsHigh internal friction springsRolling-element bearingEngineering

The suspension bump stop device comprises a rolling bearing (44) that forms an axial bump stop, equipped with an upper ring (46), with a lower ring (48) and with a plurality of rolling elements positioned between the rings, the upper and lower rings being supported respectively by an upper cup (40) and a lower cup (42), the lower cup forming a bearing means for a suspension spring (18), at least one sealing lip being provided on one of the cups so that it bears against a bearing surface portion of the other cup. The bearing surface portion is substantially cylindrical, the sealing lip being directed downwards away from the rolling bearing and bearing with radial interference against the said surface portion, the said substantially cylindrical surface portion being connected towards the top to a shoulder against which the lip can bear if the two cups become radially eccentric relative to one another.

Owner:AB SKF

Extruder

ActiveUS20150045182A1Reduce revolutionIncrease air pressureToothed gearingsDynamo-electric brake controlClutchControl theory

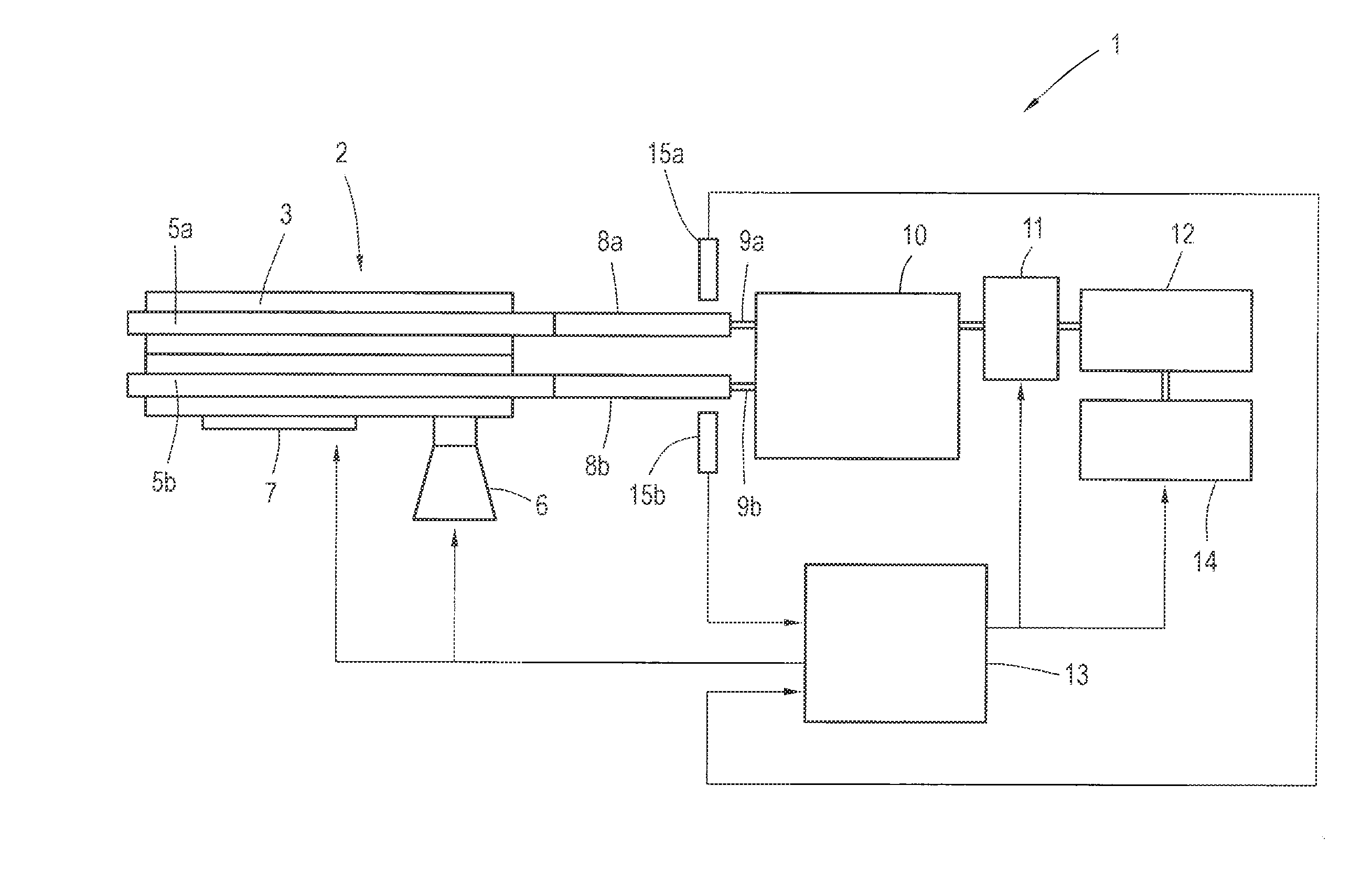

An extruder having an operative unit composed of a cylinder and at least two screw shafts which are rotatably accommodated therein, a gear unit having at least two output shafts, wherein each output shaft, via a connecting element, is connected in a rotationally fixed manner to one screw shaft, a motor which drives the gear unit and is coupled to the gear unit via a clutch, and a controller installation, wherein each connecting element or each output shaft is assigned a separate measuring installation for determining the applied torque, wherein the measuring installations communicate with the controller installation which, depending on the individual determined torques, controls the clutch which is implemented as a switchable clutch, wherein the controller installation is configured for opening the clutch both when a determined torque exceeds a torque limit value and also when the difference between the two determined torques exceeds a limit value.

Owner:LEISTRITZ EXTRUSIONSTECHN

On track maintainable low-power consumption high-reliability space brake

InactiveCN102128222AReduce power consumptionEnables on-orbit debuggingAxially engaging brakesBrake actuating mechanismsMechanical engineeringElectromagnetic coil

The invention discloses an on track maintainable low-power consumption high-reliability space brake, which relates to a space brake. The invention aims to solve the problems of low reliability, high power consumption and incapability of on track maintenance for the existing space brake. A duplex-winding redundant magnet coil provided by the invention is installed in a circular groove; an air gap adjusting sleeve cylinder is sleeved on a connecting shafting; an armature friction plate is connected with a brake shell through a plurality of spring guide rods and a nut; a brake spring is sleeved on each spring guide rod; a large brake gear is fixedly sleeved on the connecting shafting; the end surface of a friction plate boss is in contact with the end surface of a gear boss; a gear shaft is penetrated on a brake cover; the inner shaft end of the gear shaft is provided with a small gear; a spring pressing cover is positioned at the outer side of the brake cover and is fixedly sleeved on the gear shaft; a manual spring is sleeved on the gear shaft; and when the brake works, the small gear is separated from the large brake gear, and when the brake is maintained, the small gear is meshed with the large brake gear. The on track maintainable low-power consumption high-reliability space brake is used for space service equipment.

Owner:HARBIN INST OF TECH

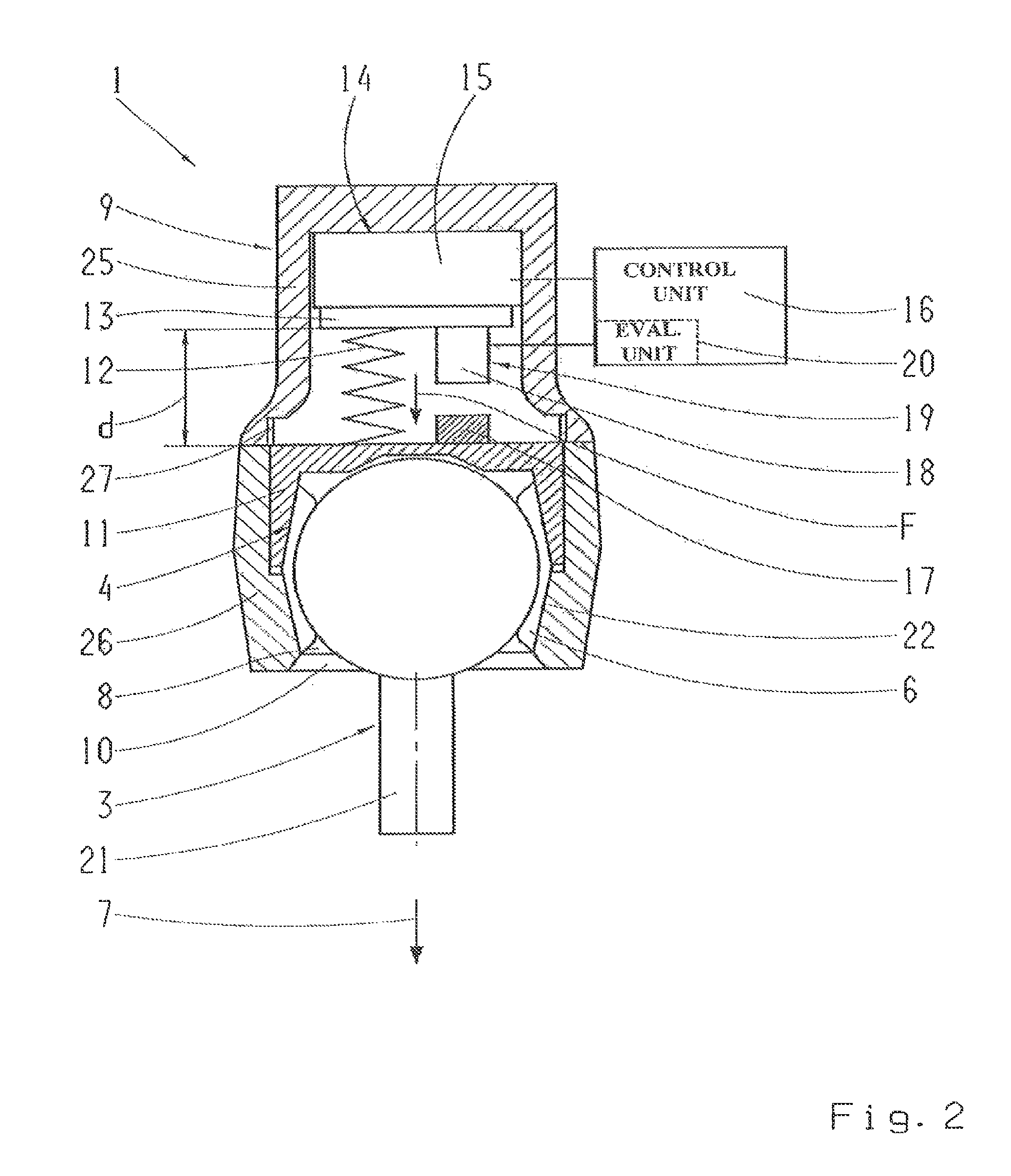

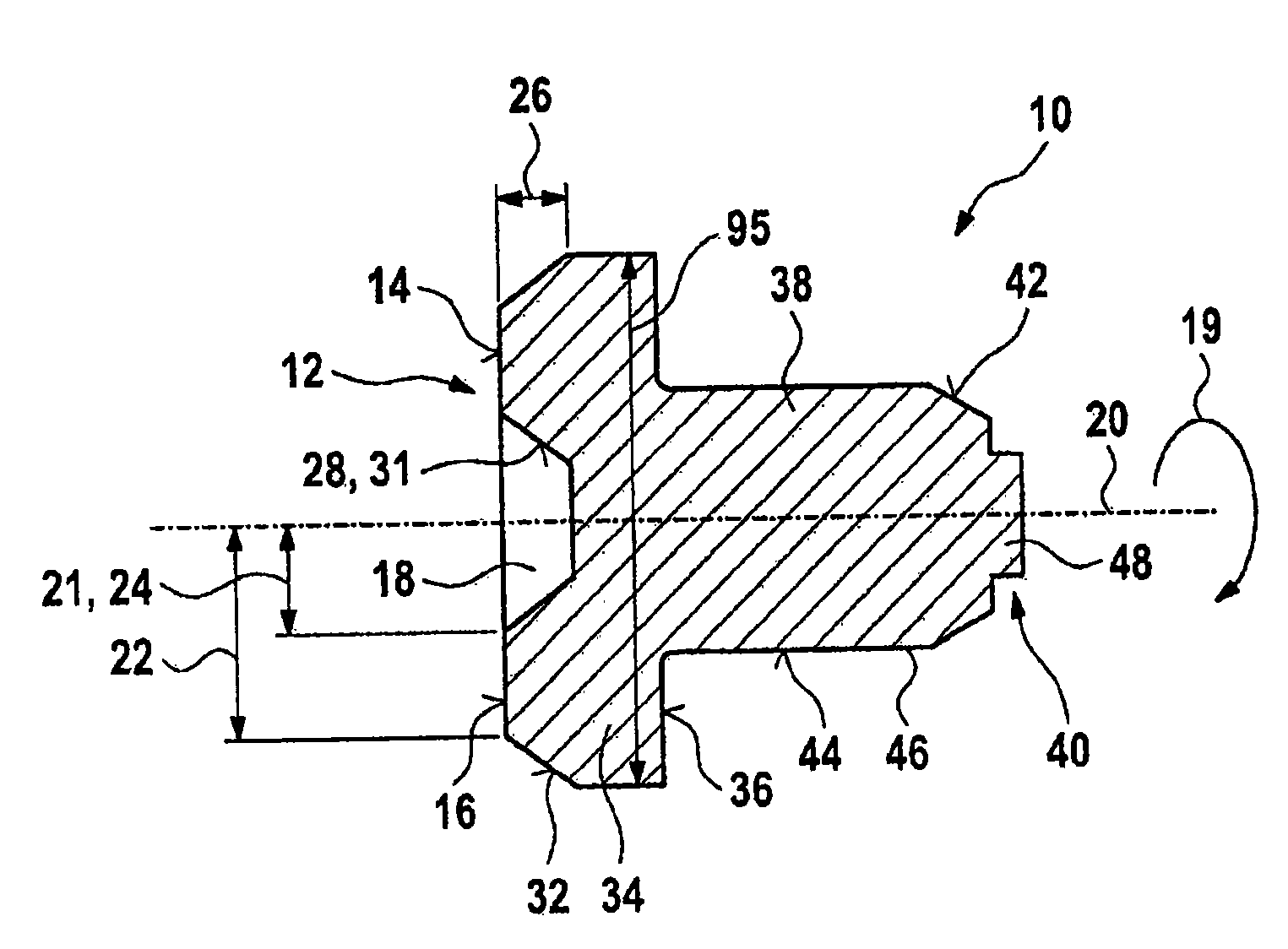

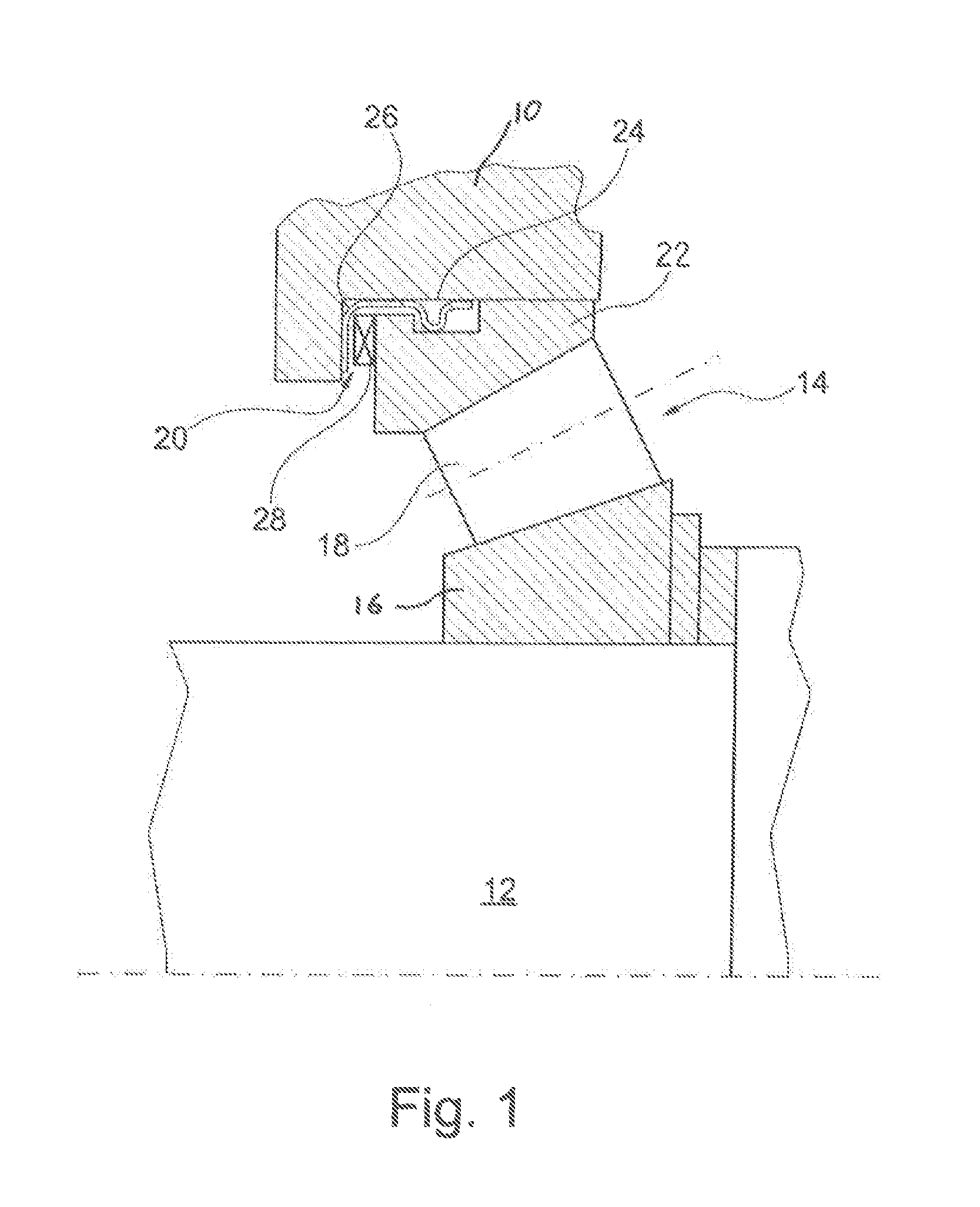

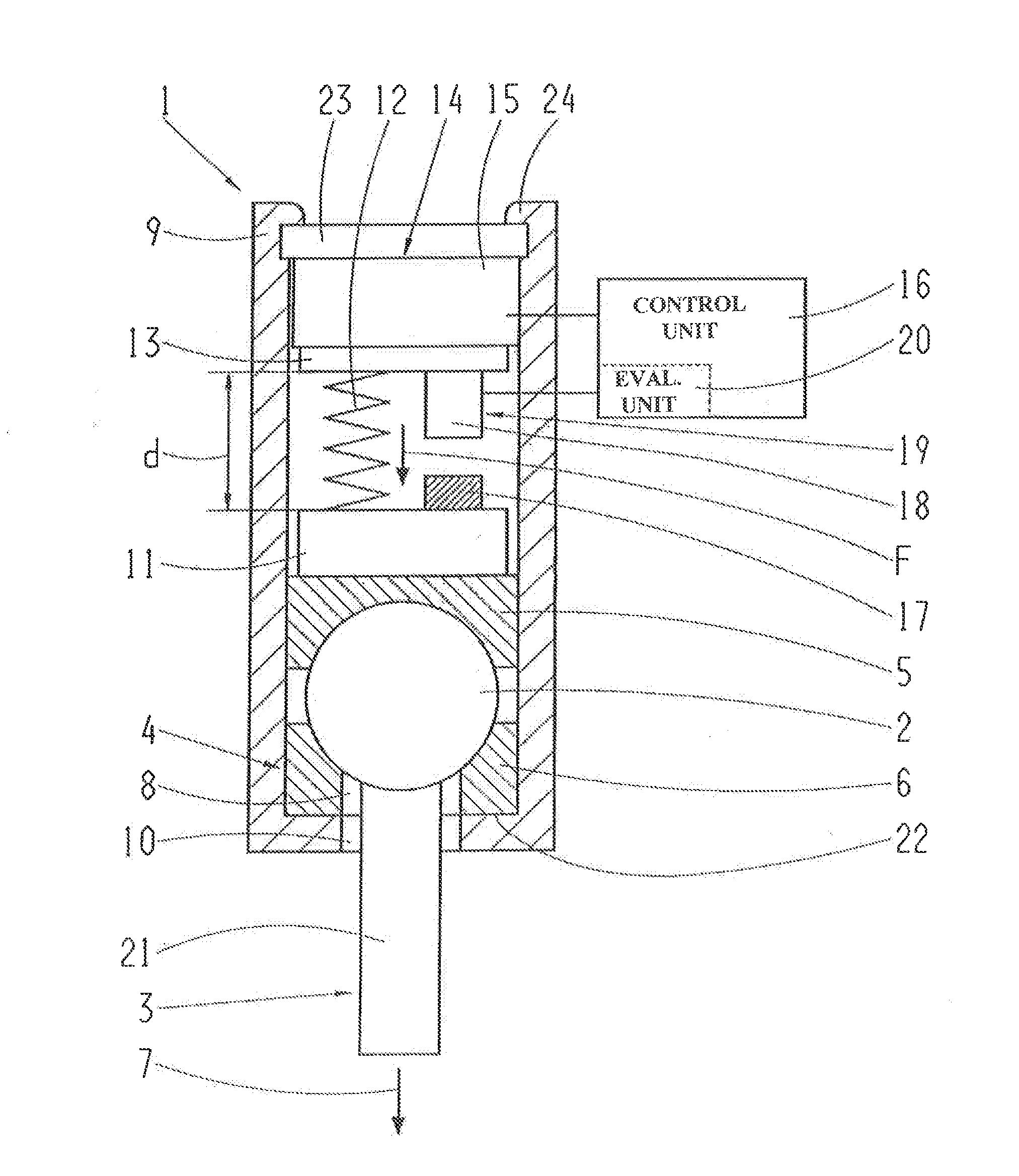

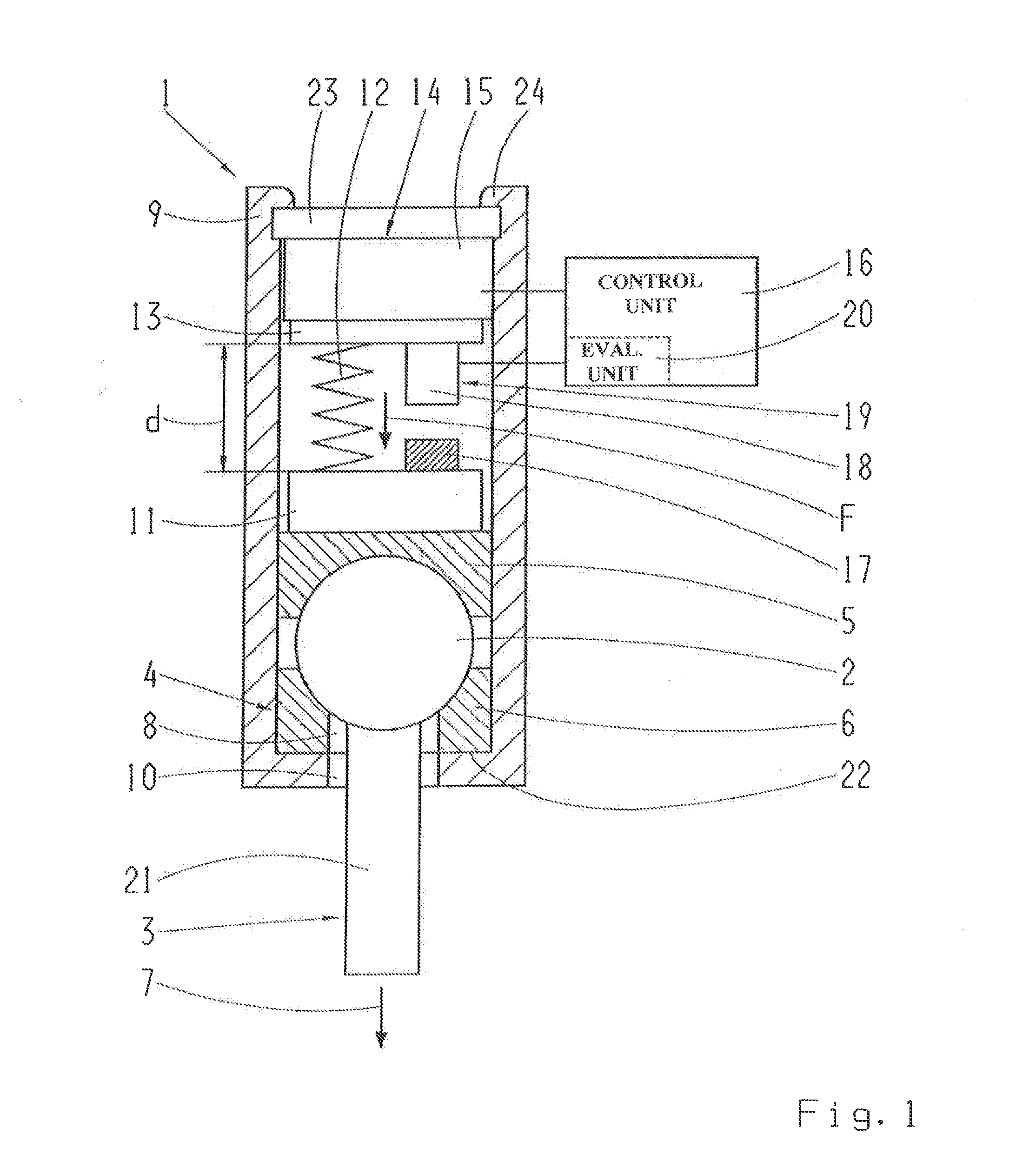

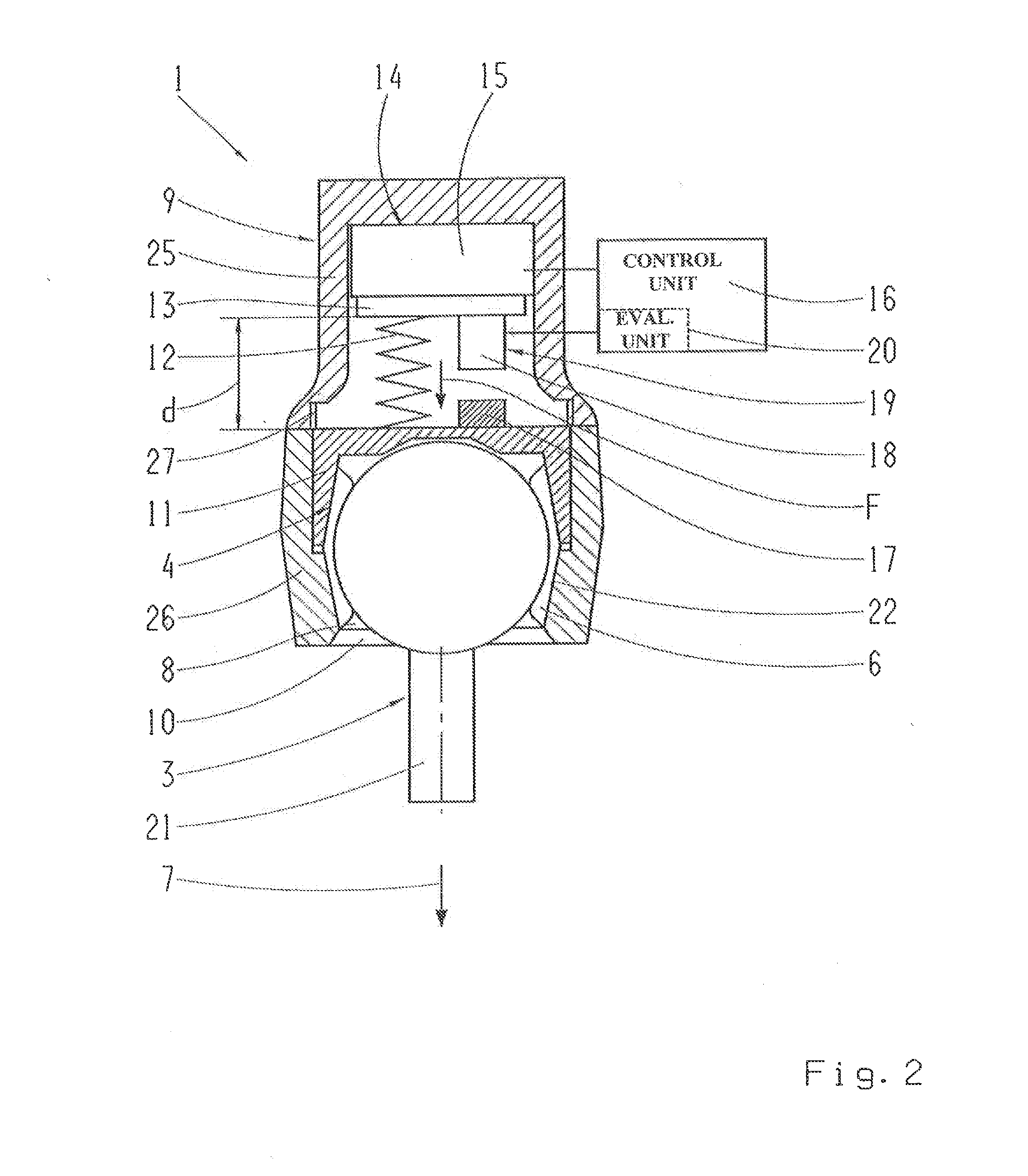

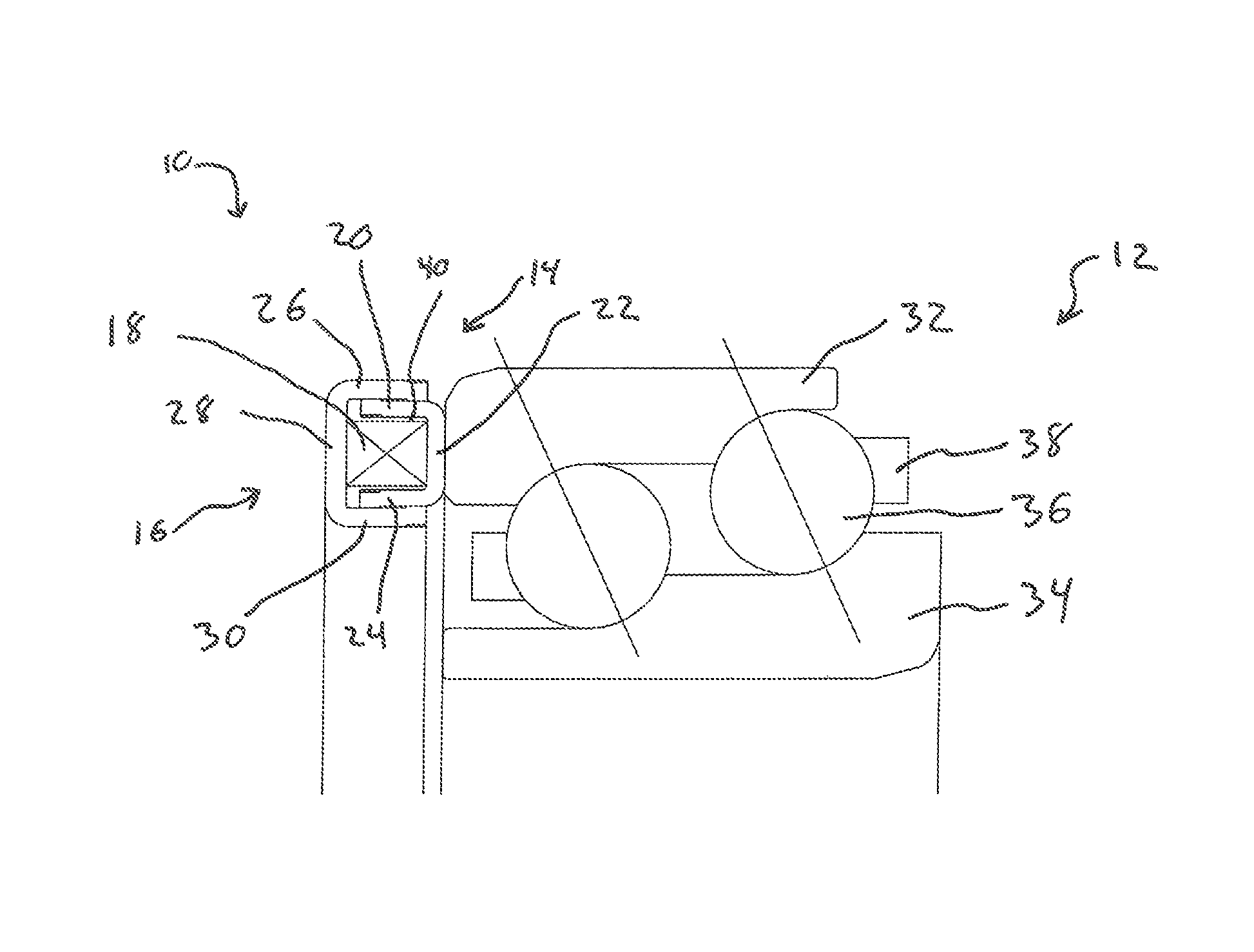

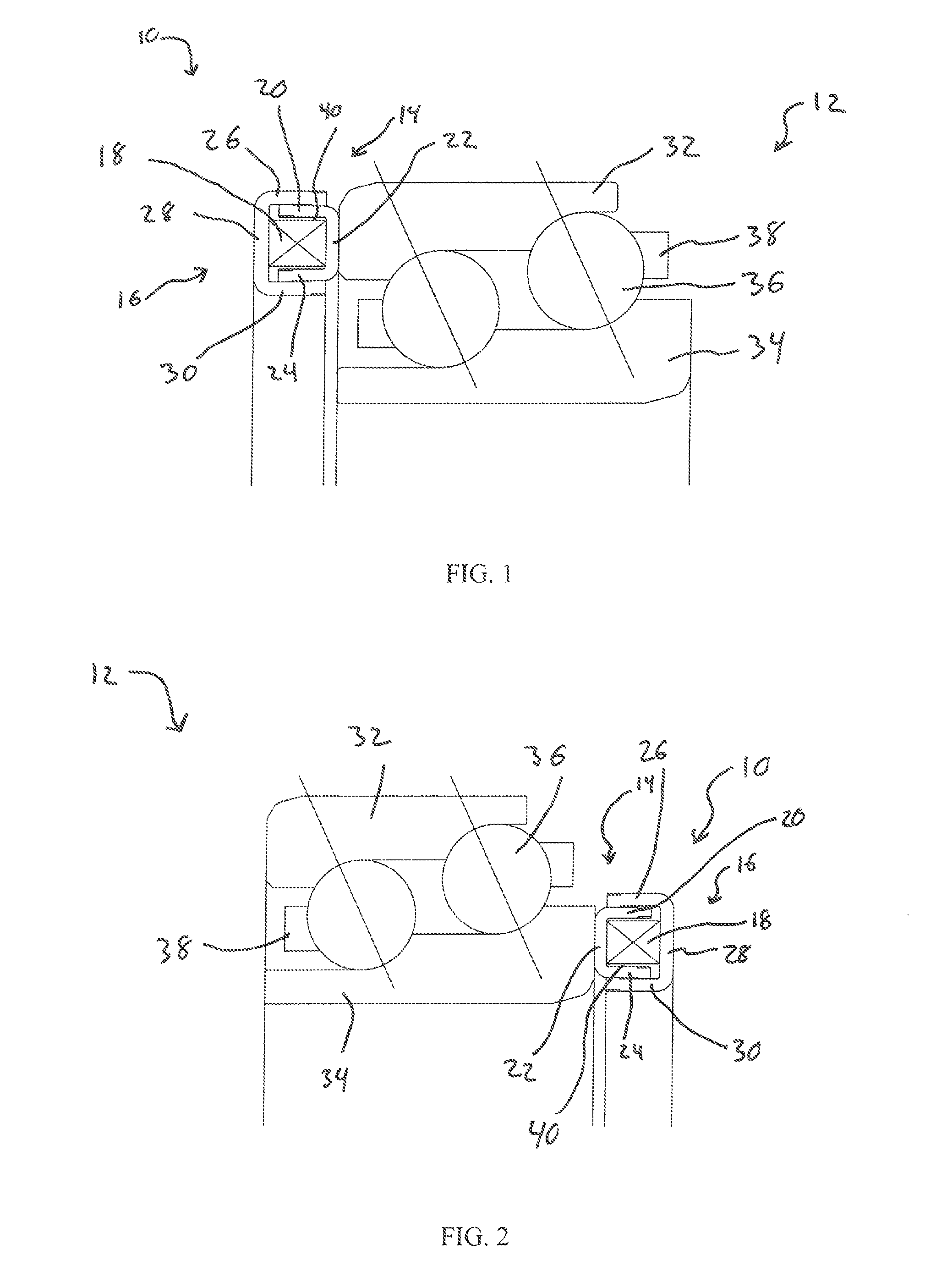

Ball and socket joint for a vehicle

A ball joint for a vehicle, with a ball pin that has a joint ball, a joint housing that encloses the joint ball and is provided with a pin opening, in which the joint ball of the ball pin is fitted and able to move. The ball pin extends out of the joint housing through the pin opening. An actuator can press a pressure element, in an axial direction, against the joint housing in such a manner that pressure can be exerted by the joint housing and the pressure element onto the joint ball. The actuator acts upon a spring which acts upon the pressure element. The length of the spring can be measured by a displacement sensor.

Owner:ZF FRIEDRICHSHAFEN AG

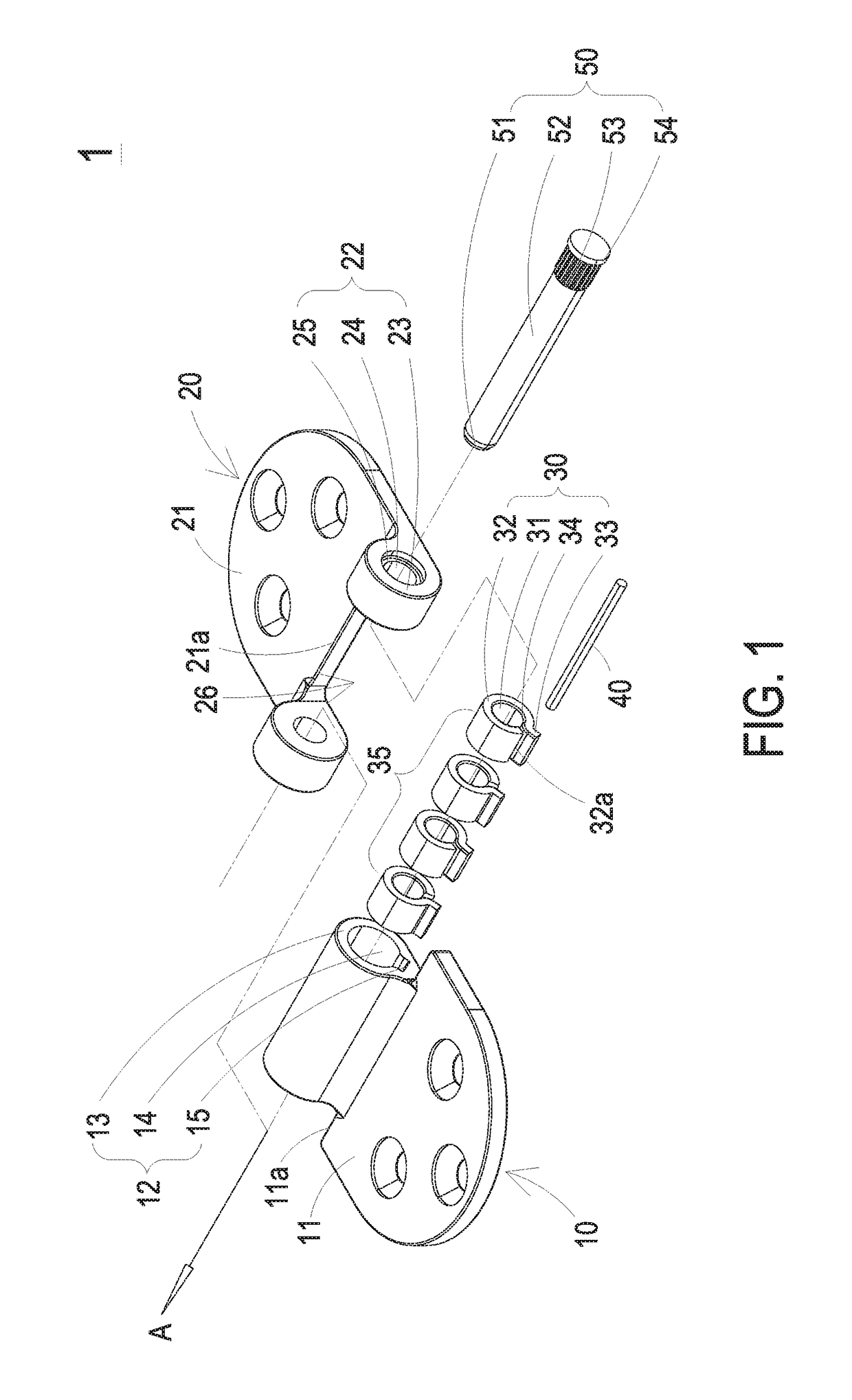

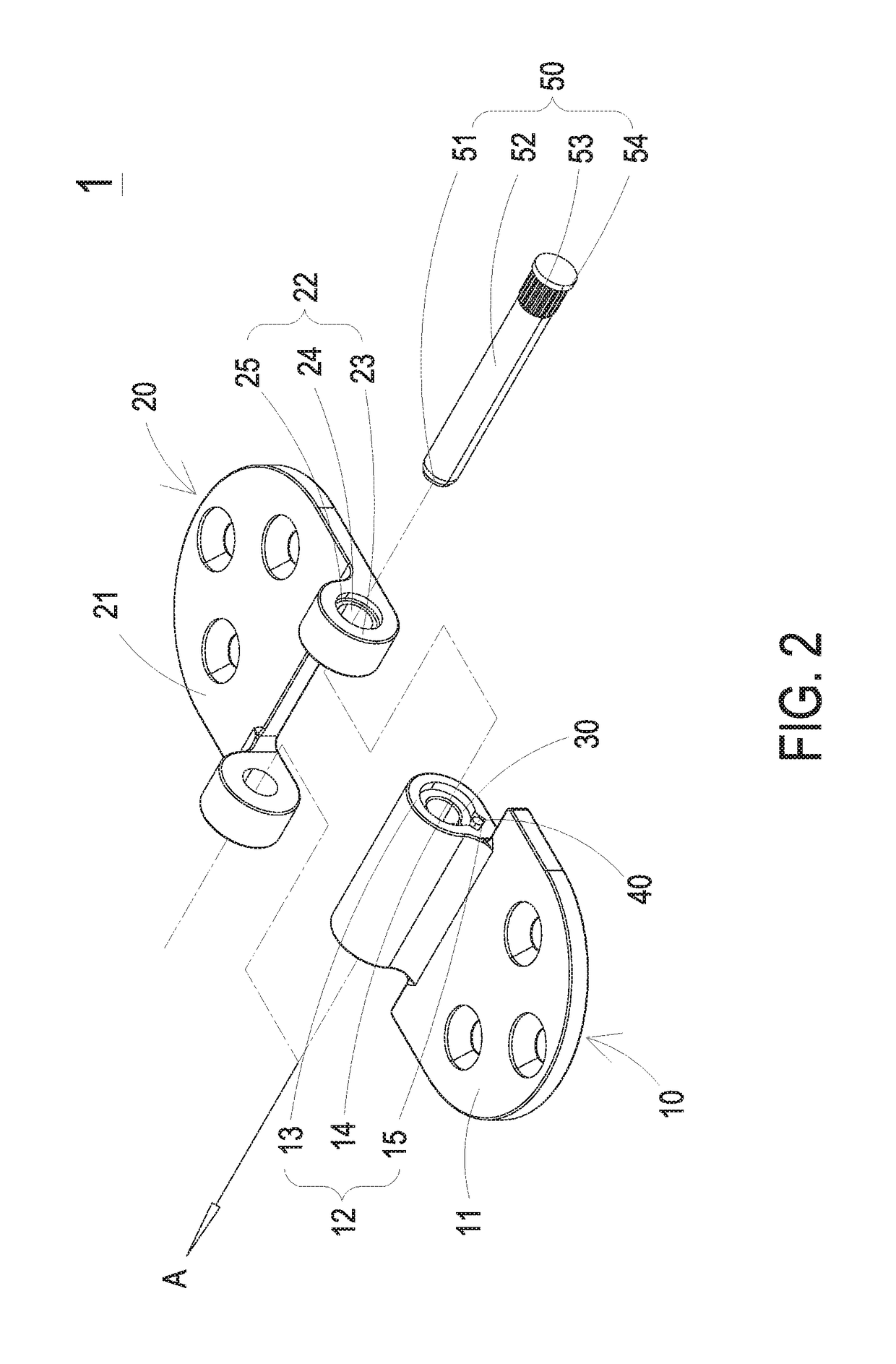

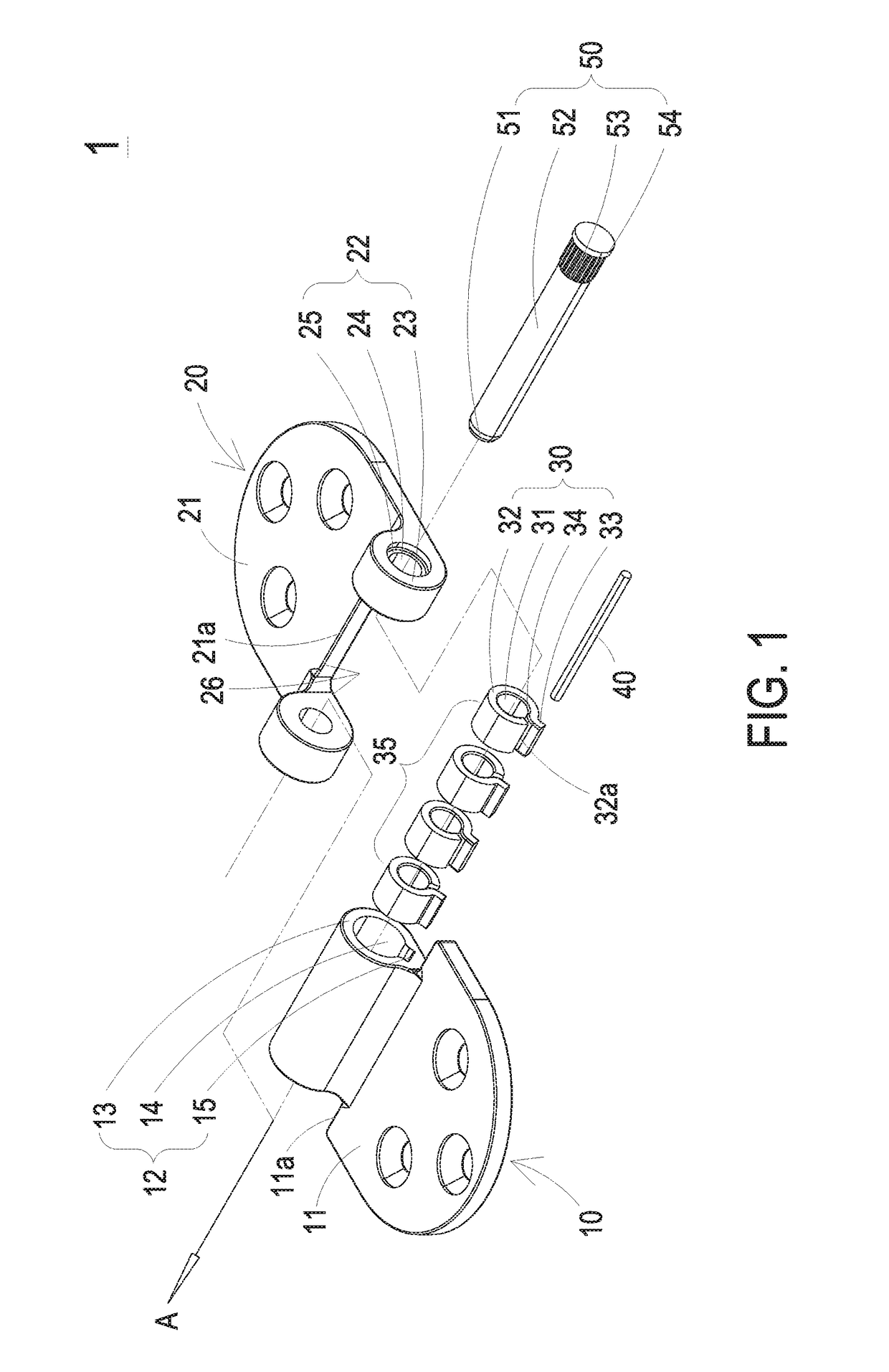

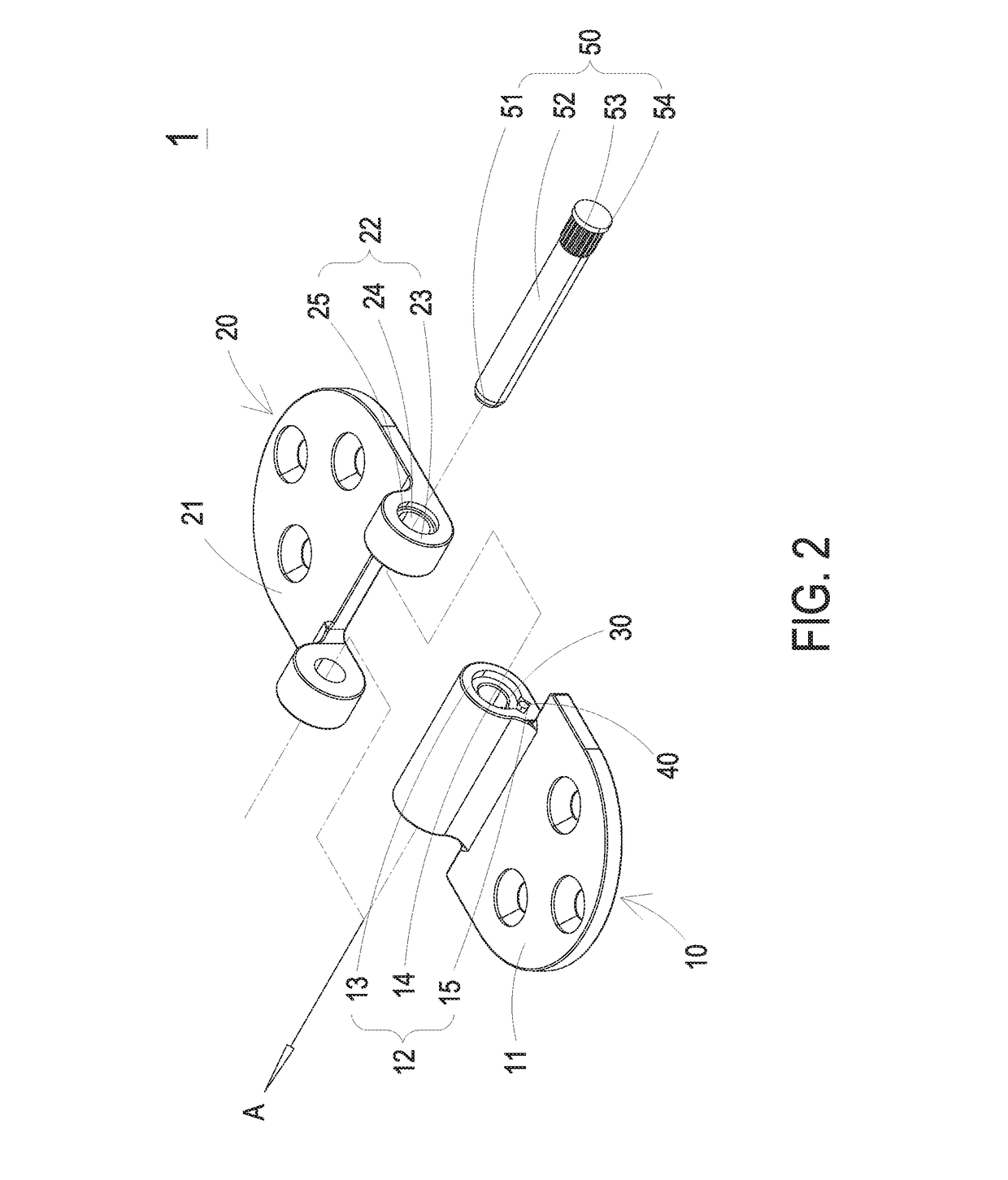

Adjustable positioning hinge with high torsional friction and assembling method thereof

ActiveUS20190040665A1High torsional frictionEasy to assembleWing accessoriesHingesMechanical engineeringEngineering

Owner:JEAN WEN FONG

Thrust mushroom-shaped part and motor with the thrust mushroom-shaped part

InactiveCN104141680AEliminate central touch pointsReduce wearShaftsBearing componentsClassical mechanicsElectric machinery

A thrust mushroom-shaped part (10) used for axially supporting a rotor shaft (58) of a motor (50) is provided. The thrust mushroom-shaped part (10) is provided with an end face (12). A thrust surface (14) is configured on the end face and functions together with a matching face (60) of the motor (50) in an installation state. The thrust surface (14) is configured to be an annular shape. The motor is also provided by the invention and is provided with the thrust mushroom-shaped part (10).

Owner:ROBERT BOSCH GMBH

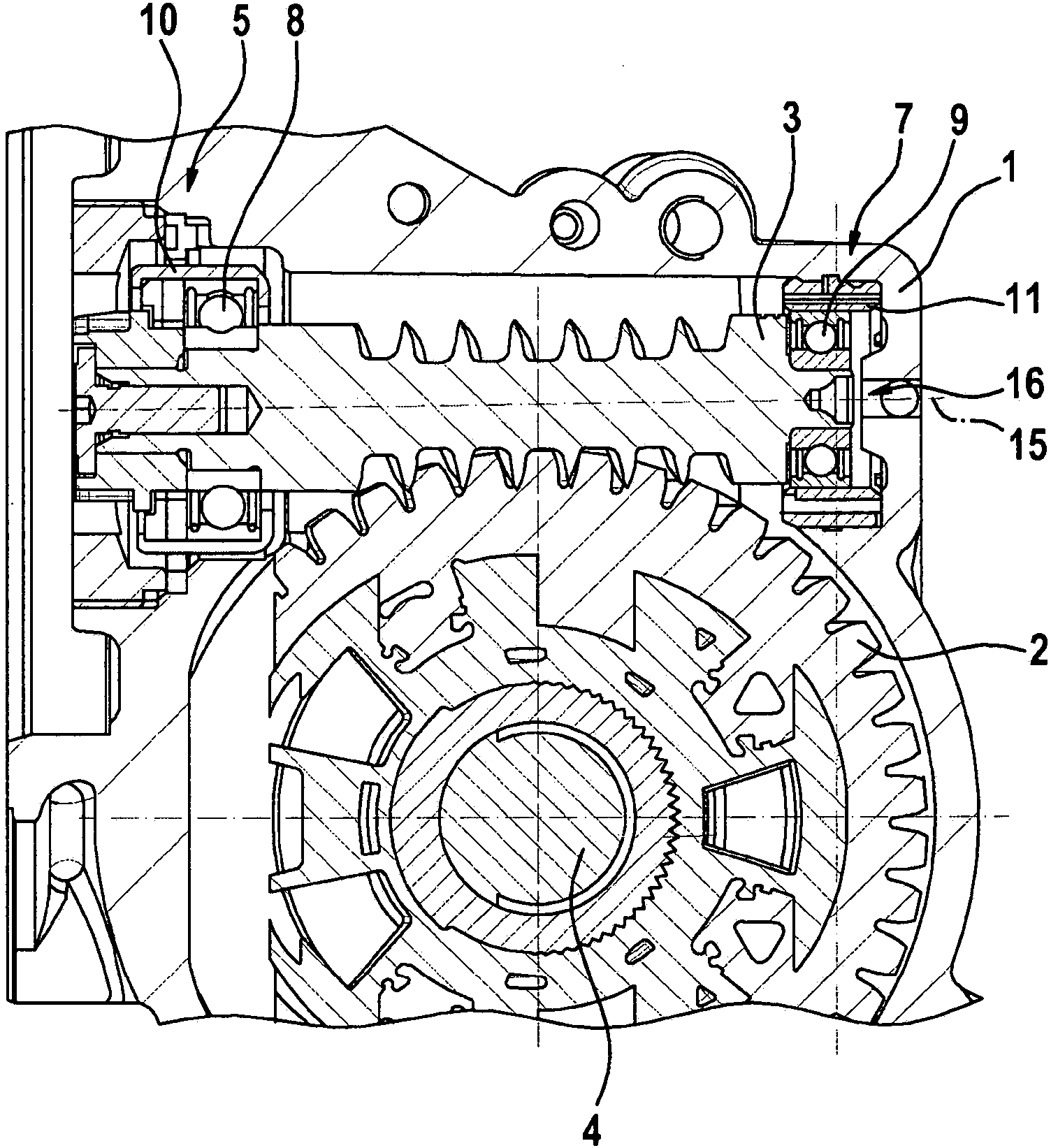

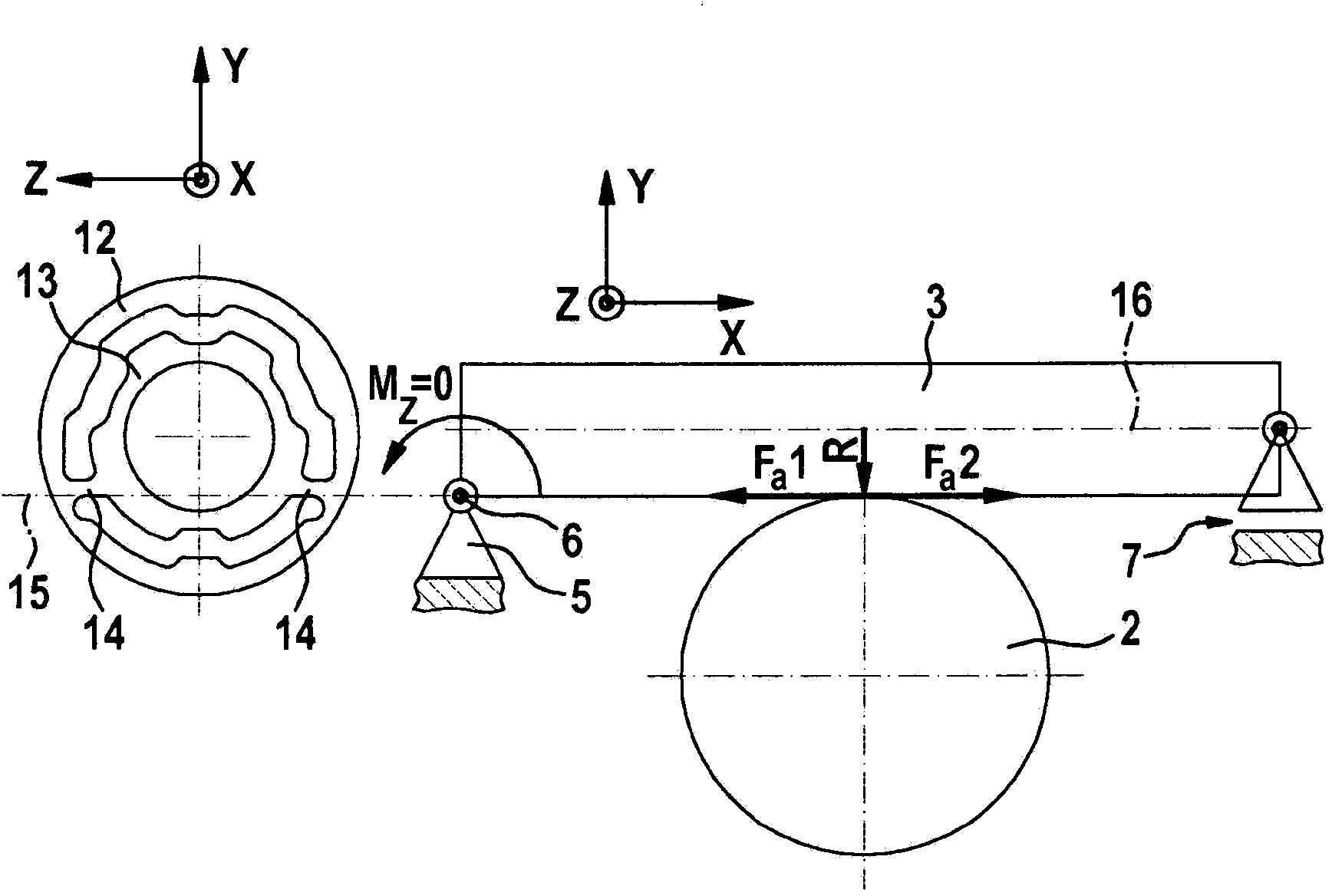

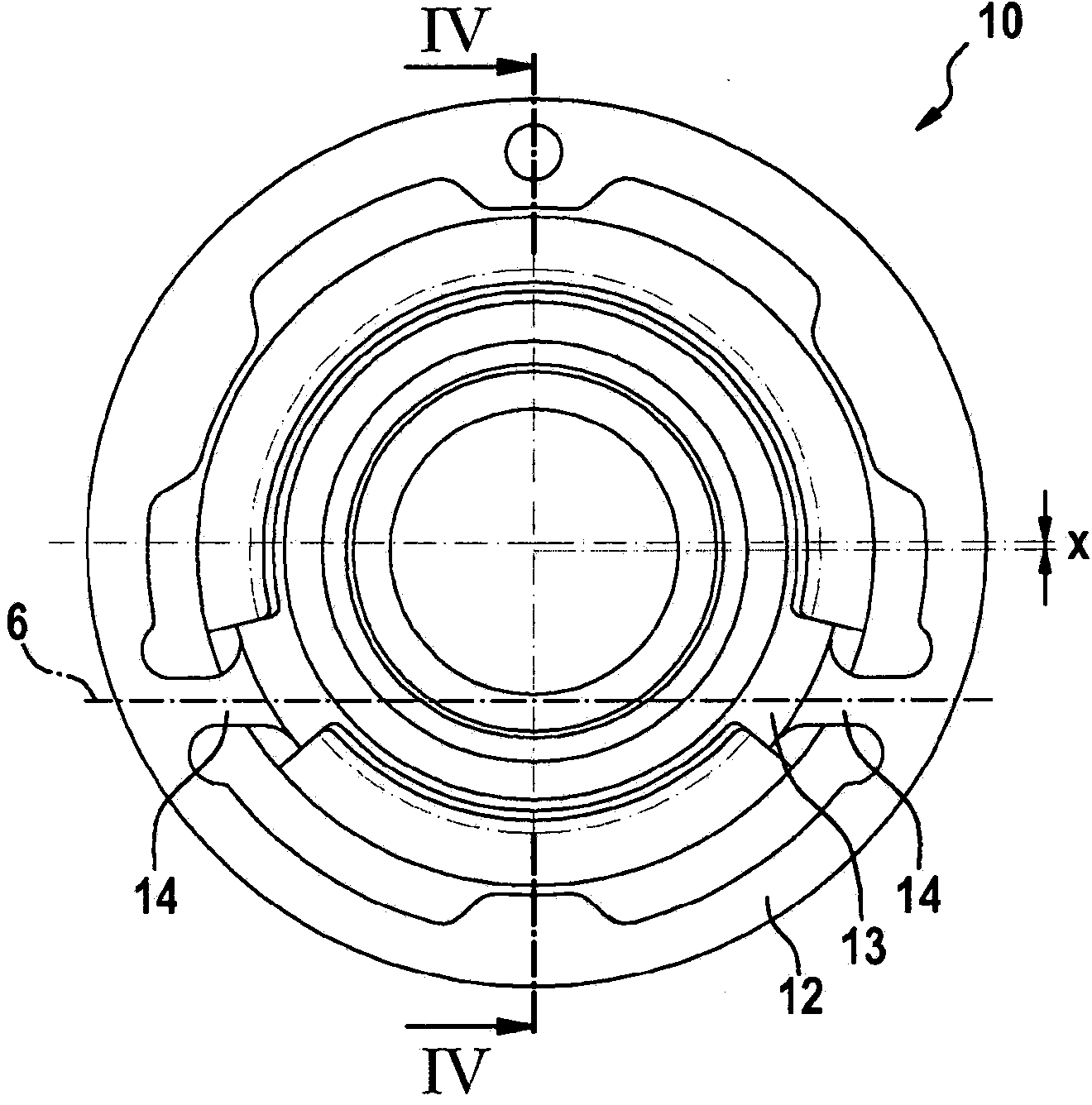

Steering gear

ActiveCN104321239AIncrease friction torqueReduce frictional torqueShaftsMechanical steering gearsEngineeringPinion

A steering gear having a gearwheel (2), having a pinion (3) which meshes with said gearwheel and having a pinion shaft which comprises the pinion (3) and which is mounted so as to be pivotable about a pivot axis (6) perpendicular to the longitudinal axis (16) of the pinion shaft is characterized in that the radial spacing between the pivot axis (6) and the location of toothed engagement (15) between the gearwheel (2) and pinion is smaller than the core radius of the pinion (3).

Owner:ROBERT BOSCH AUTOMOTIVE STEERING

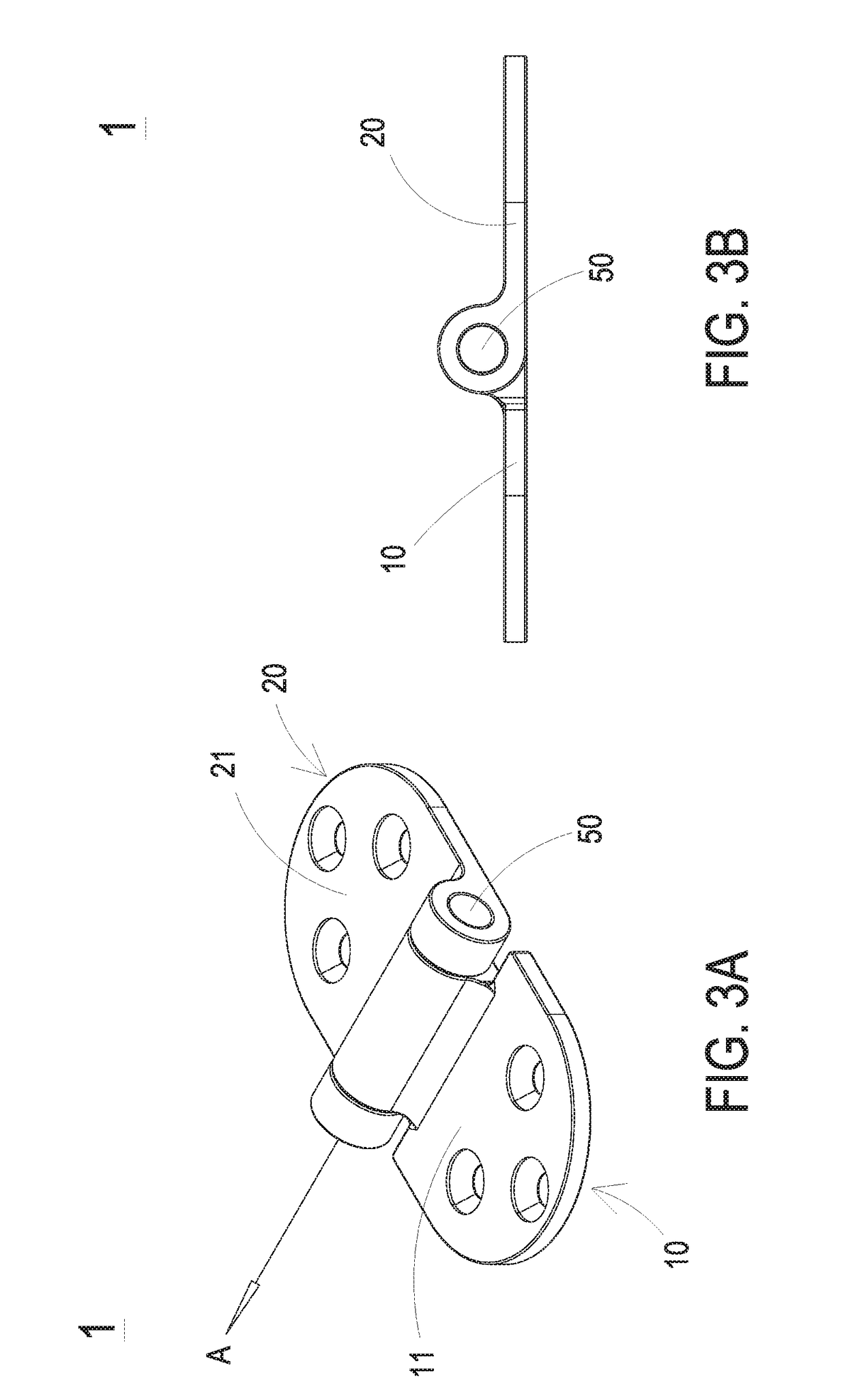

Double-acting lockwasher

The invention relates to a lockwasher which is to be inserted between a bearing element (38) and a screwable element (42), and which includes two rings (12, 14), each of which have an engagement surface (24, 22). Said rings (12, 13), which engage with one another and maintained compressed under axial pressure between said screwable element (42) and said bearing element (38), are capable, when said screwable element is unscrewed, of rotatably engaging with said screwable element (42) and said bearing element (38), respectively, so as to rotate said rings (12, 14) relative to one another, in order to rotatably lock said screwable element (42). According to the invention, said lockwasher (10) is frusto-conical, and said lockwasher (10) is elastically deformable in order to be able to be flattened, forming a spring such that said axial pressure is maintained substantially constant.

Owner:NORD LOCK INT

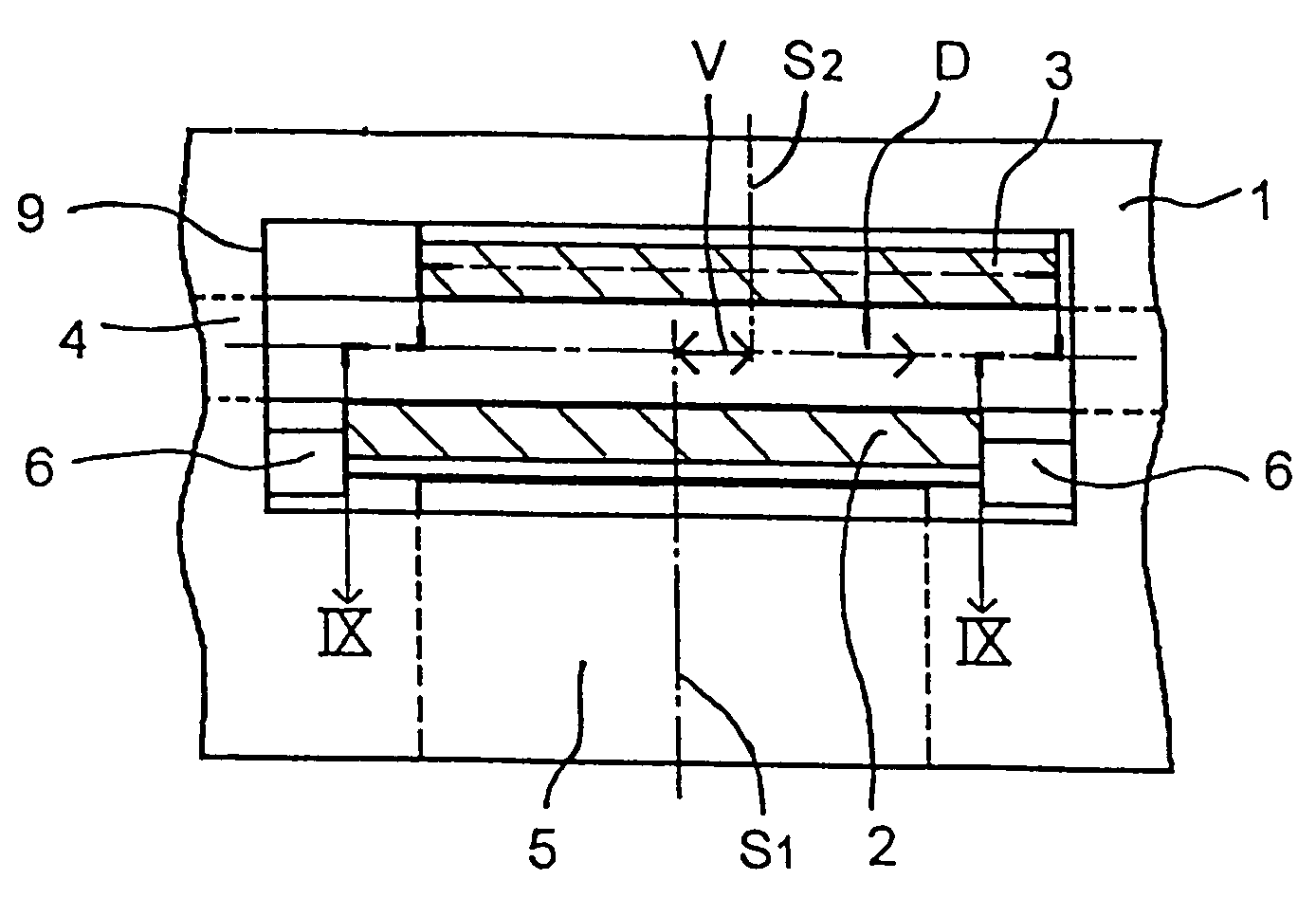

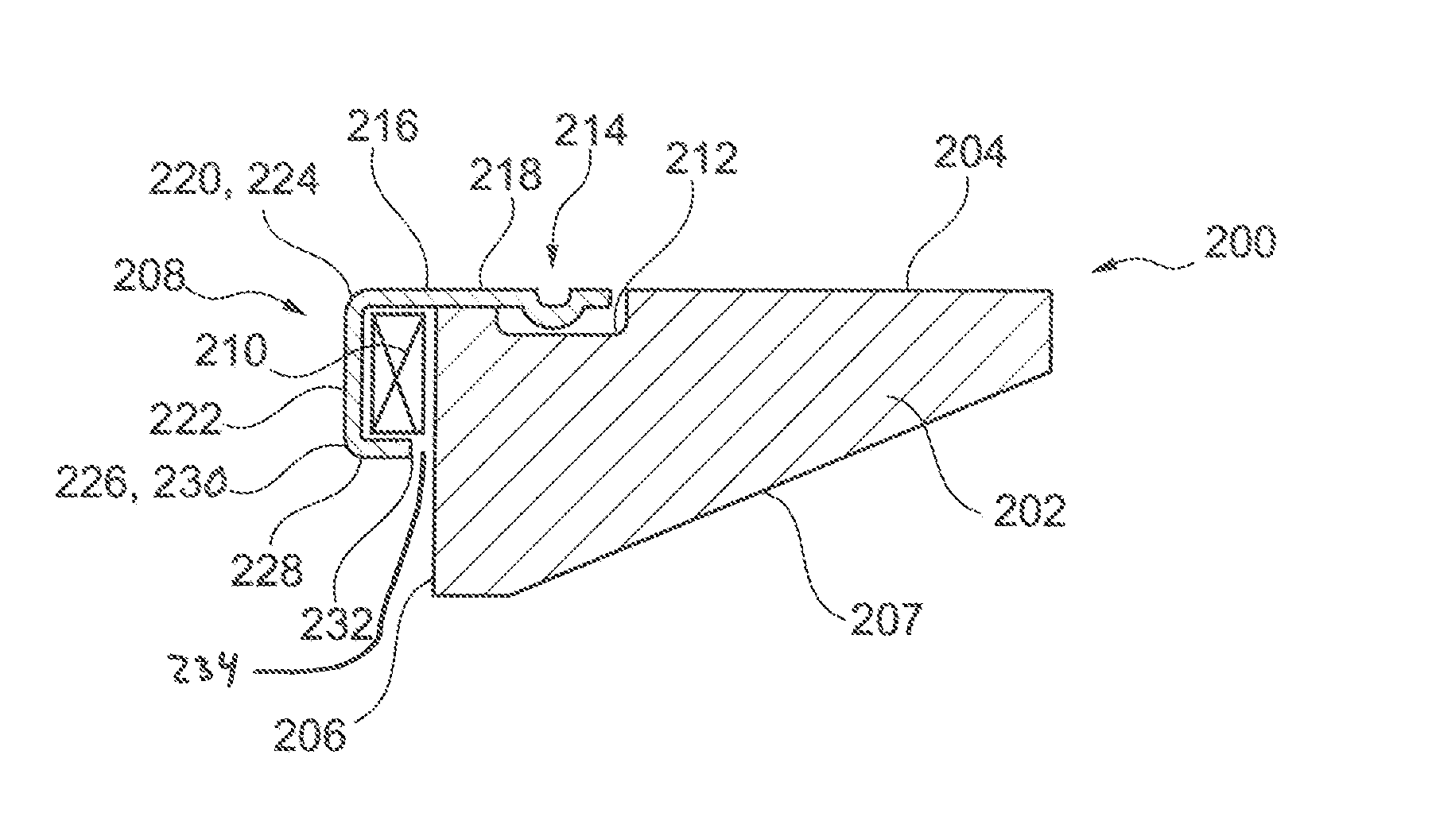

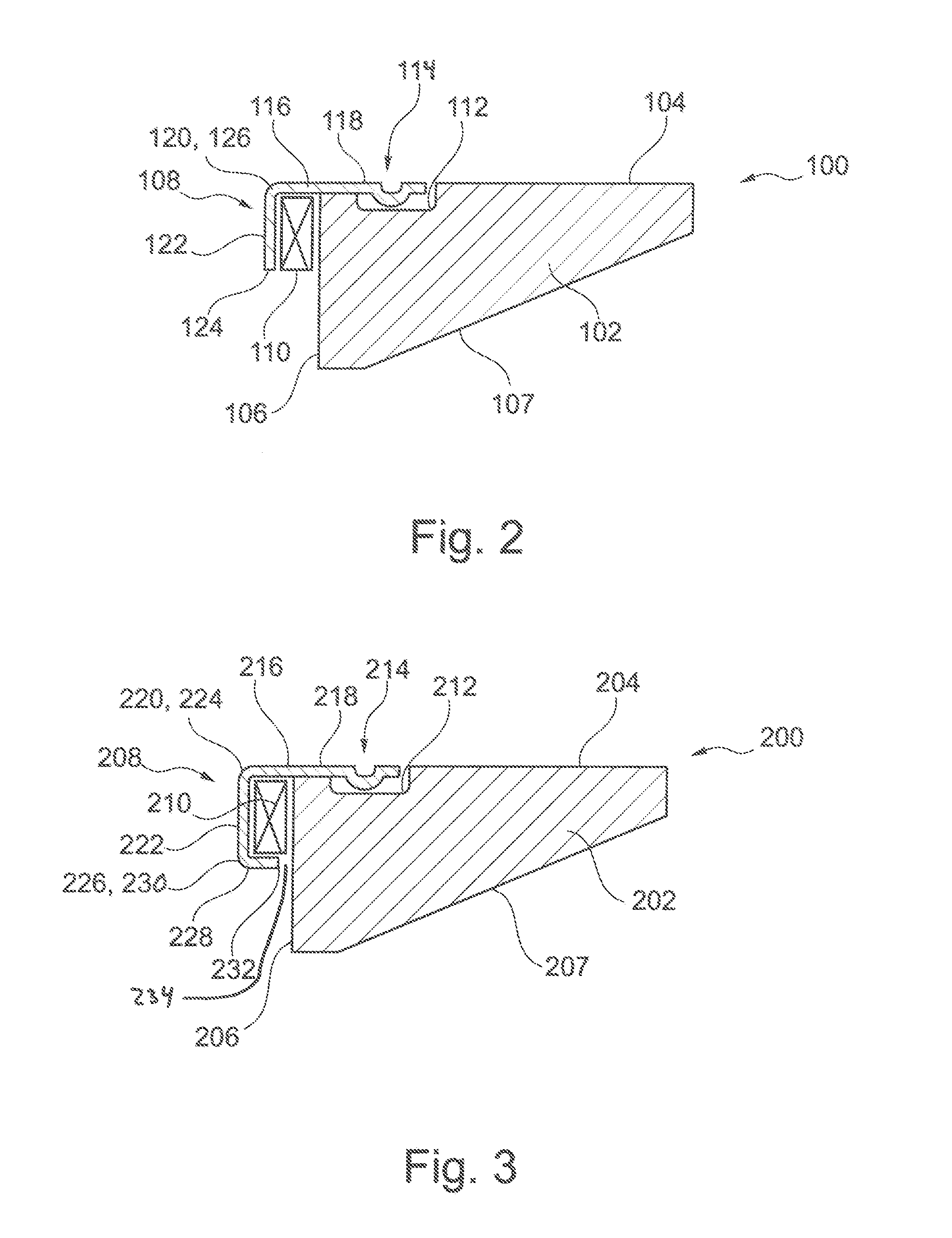

Bearing race with integrated spring

InactiveUS9222508B2Increase friction torqueStiffness of the bearing arrangementRoller bearingsBall bearingsEngineeringHearing perception

A bearing race encapsulation apparatus, which has a spring assembly integrated into a hearing that allows the hearing to compensate for varying expansions and contractions caused by differences in temperature. The bearing race encapsulation apparatus includes an outer bearing ring with an end face and an outer face with a indent formed in the outer face. An encapsulation ring, which has a retention element that is snapped into the indent of the outer bearing ring, a first segment that extends axially outwardly from the retention element, and a second segment that extends radially inwardly from the first segment. A spring is arranged axially between the second segment of the encapsulation ring and the outer bearing ring to compensate for the expansion and contraction.

Owner:SCHAEFFLER TECH AG & CO KG

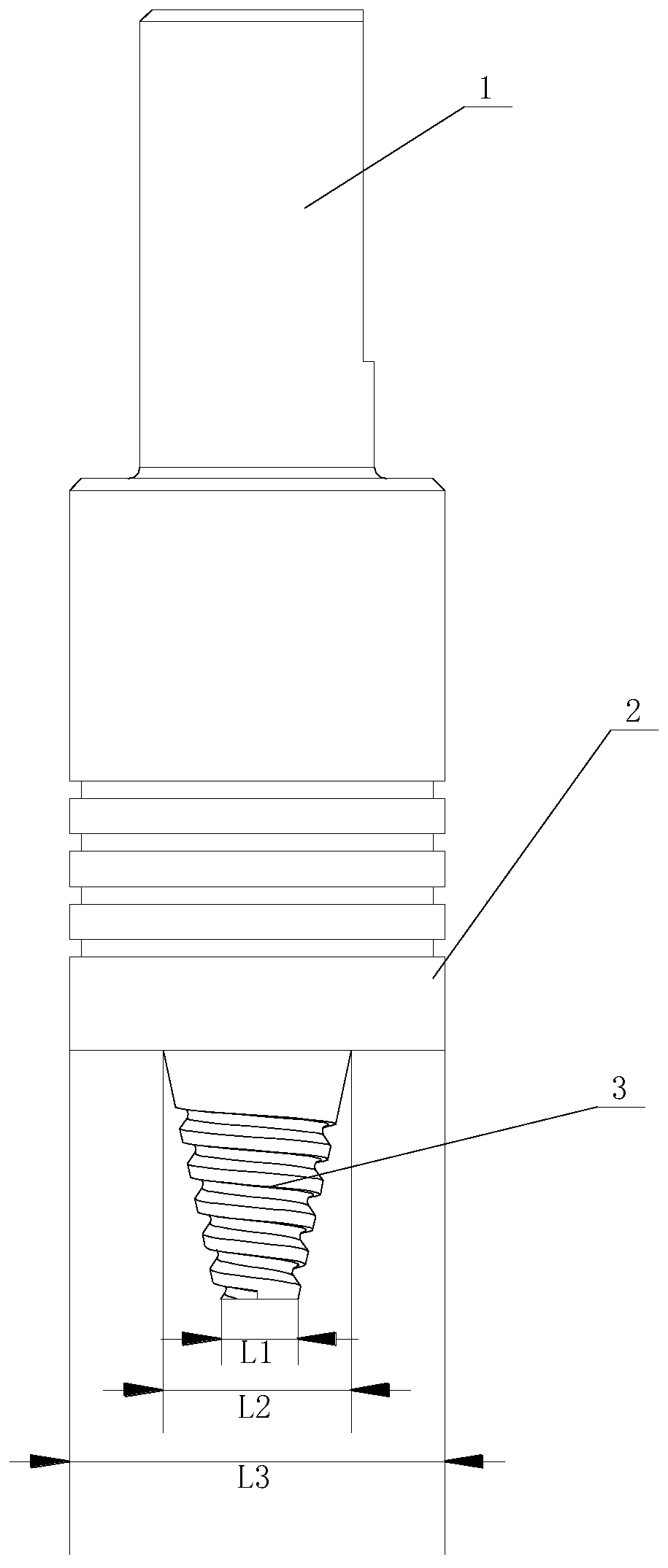

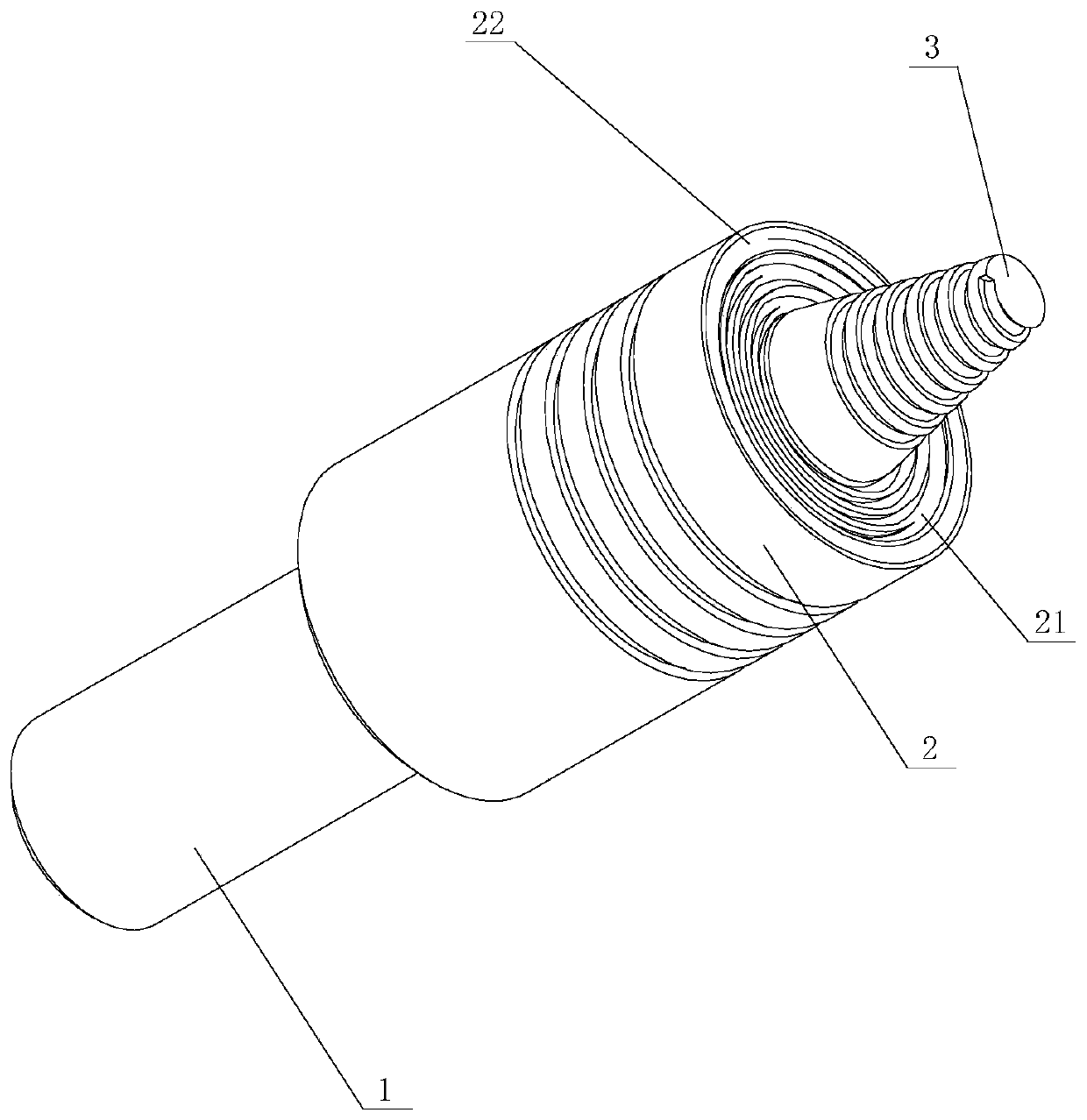

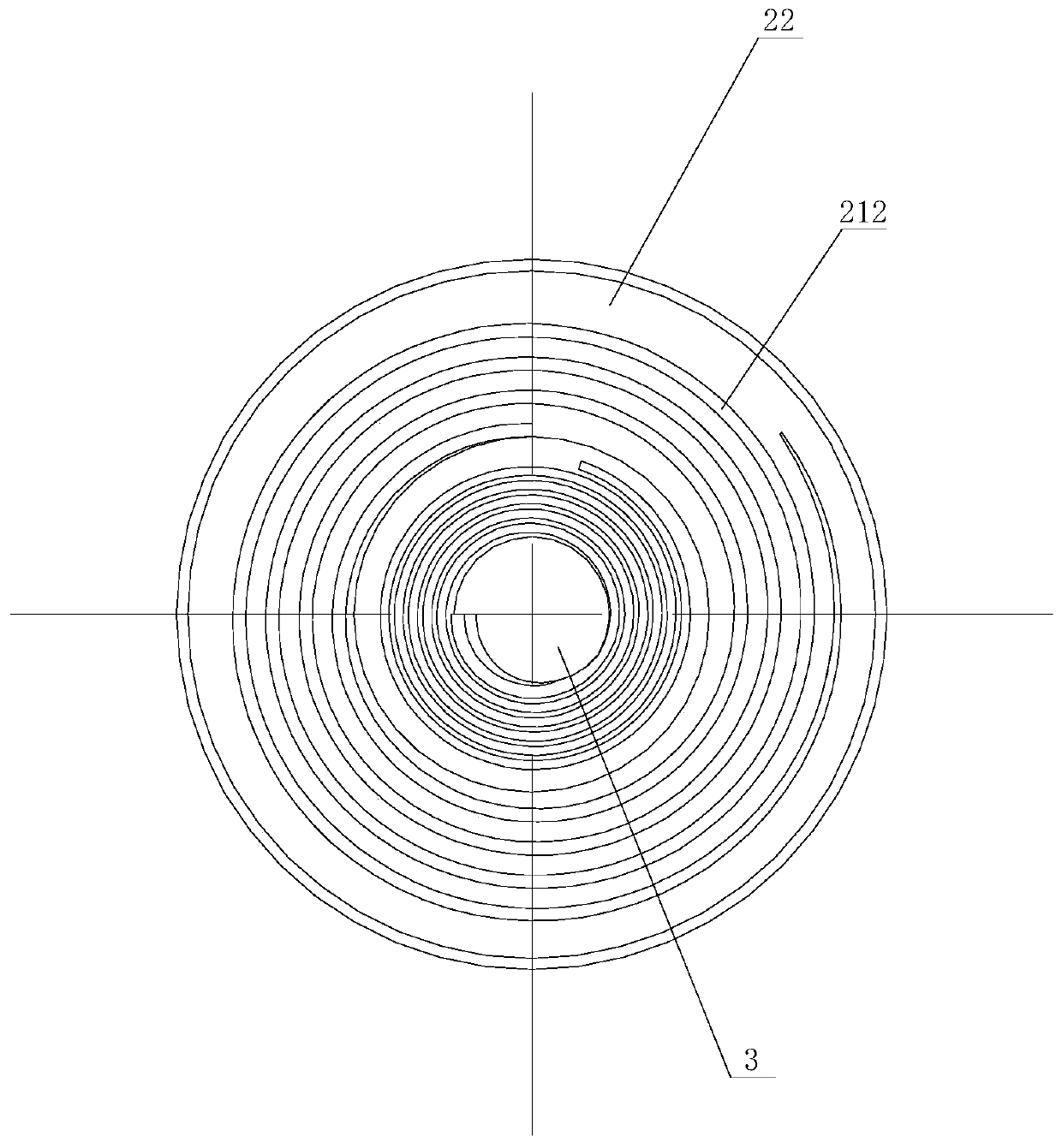

Small-diameter shaft shoulder stirring head

InactiveCN110919161AIncrease heat inputReduce the cross-sectional areaNon-electric welding apparatusFriction torqueEngineering

The invention discloses a small-diameter shaft shoulder stirring head. The small-diameter shaft shoulder stirring head comprises a clamping part, a shaft shoulder part and a stirring needle which aresequentially connected, the diameter of the needle tip part of the stirring needle is defined as L1, the diameter of the needle root part of the stirring needle is defined as L2, the diameter of the shaft shoulder part is defined as L3, the ratio of L1 to L2 is equal to 1 to 1-1.7, the ratio of L2 to L3 is equal to 1 to 1.8-2.5, the end face of the shaft shoulder part comprises a stirring area close to the stirring needle in the radial direction and an envelope area away from the stirring needle, and the stirring area is provided with a non-concentric circle structure for improving the friction torque. The stirring head has the advantages that stirring and heat production effects can be increased, welding defects can be avoided, and the stirring head is suitable for producing narrow-edge welds.

Owner:HUNAN JOINFRONT WELDING TECH

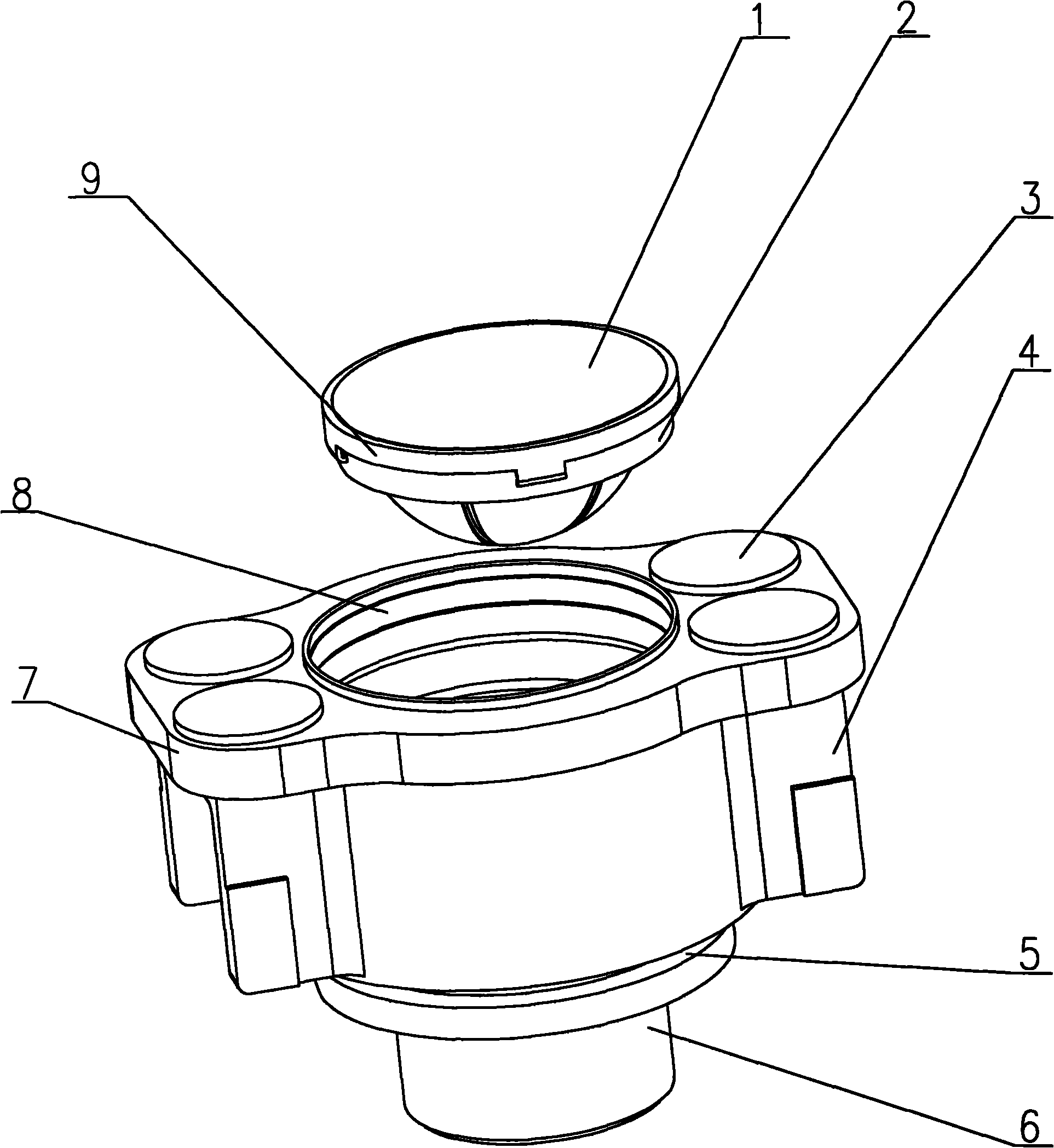

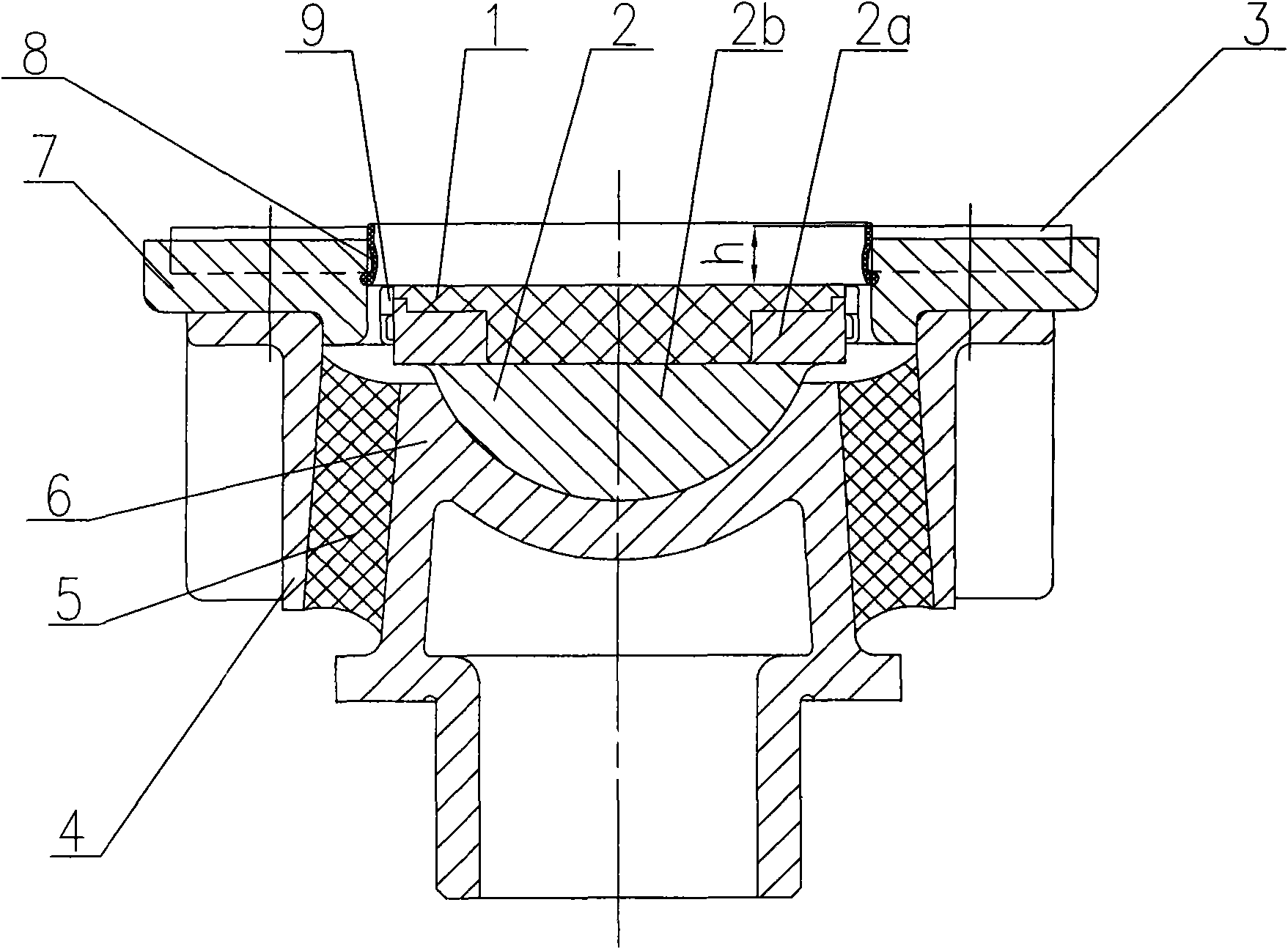

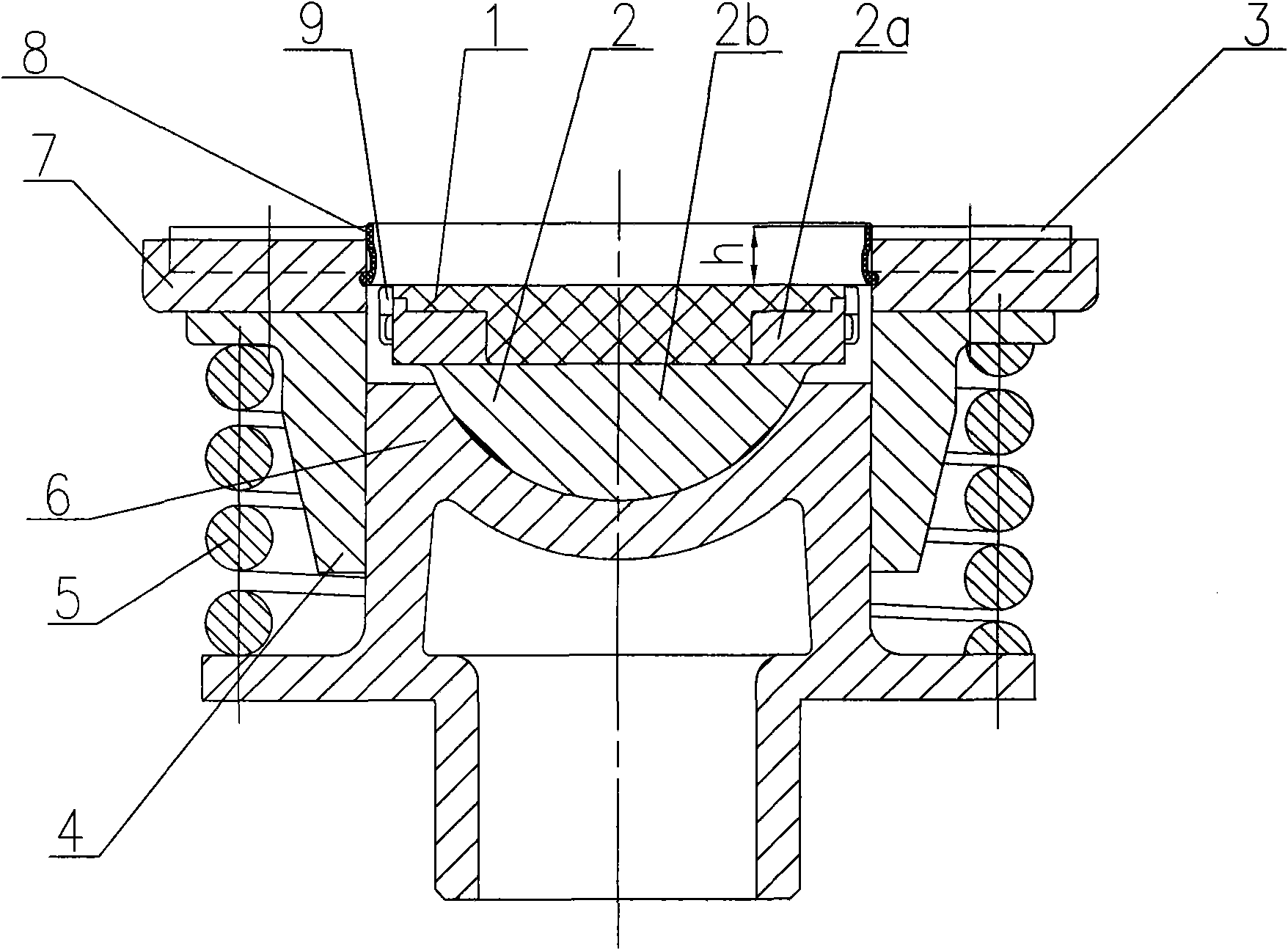

Ball and socket joint for a vehicle

ActiveUS20150098749A1Increase friction torqueEasy to insertPivotal connectionsSliding contact bearingsSacroiliac jointEngineering

Owner:ZF FRIEDRICHSHAFEN AG

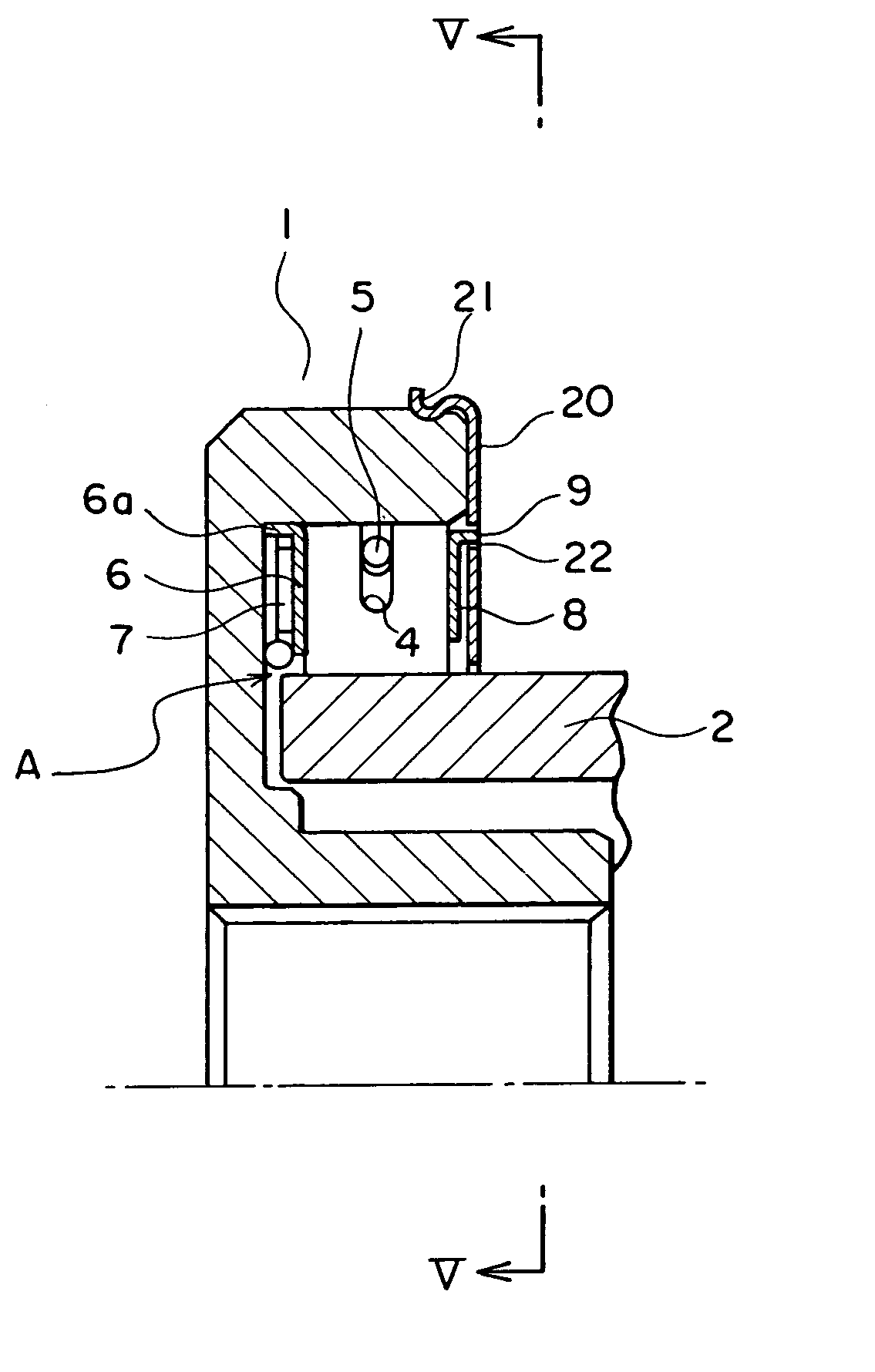

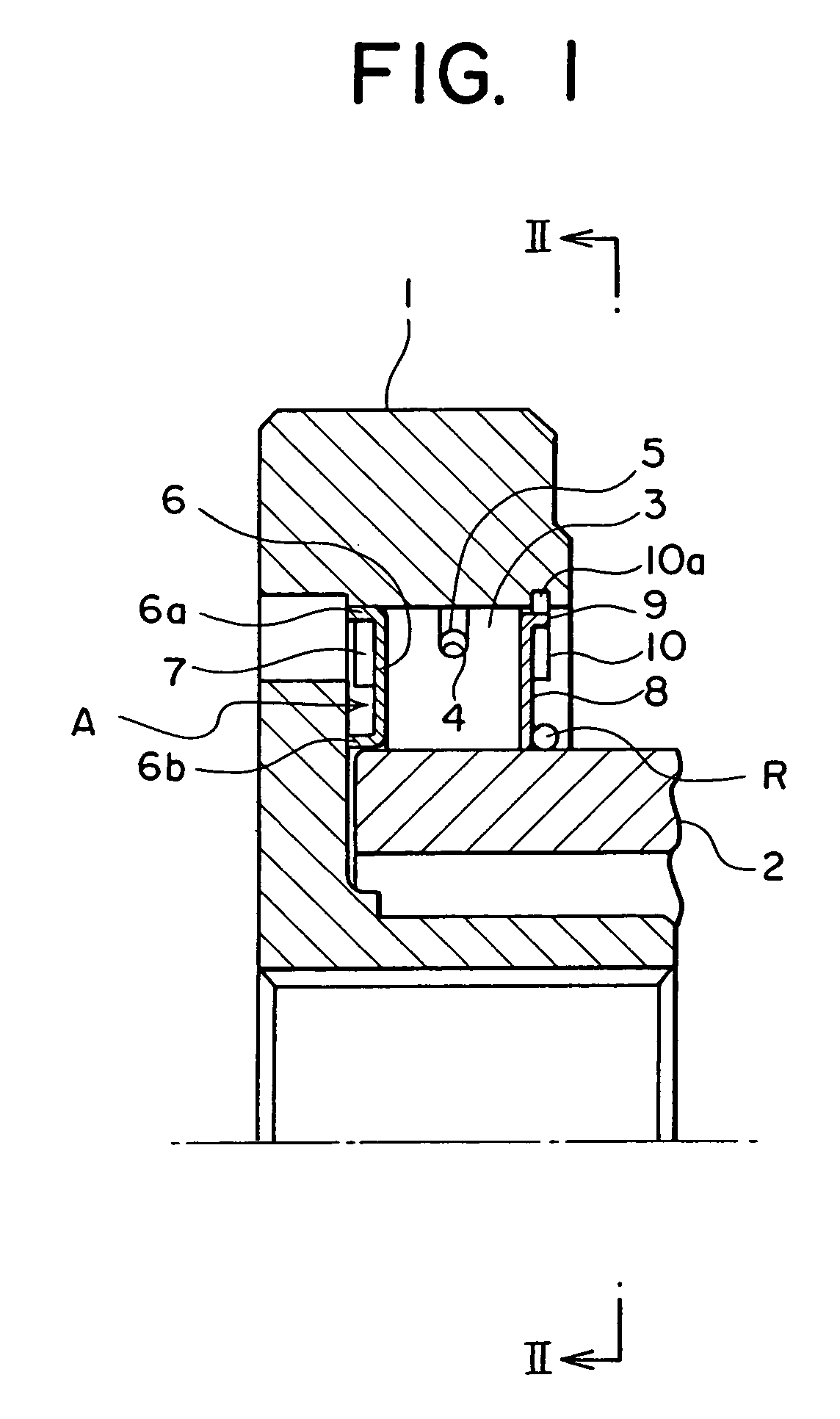

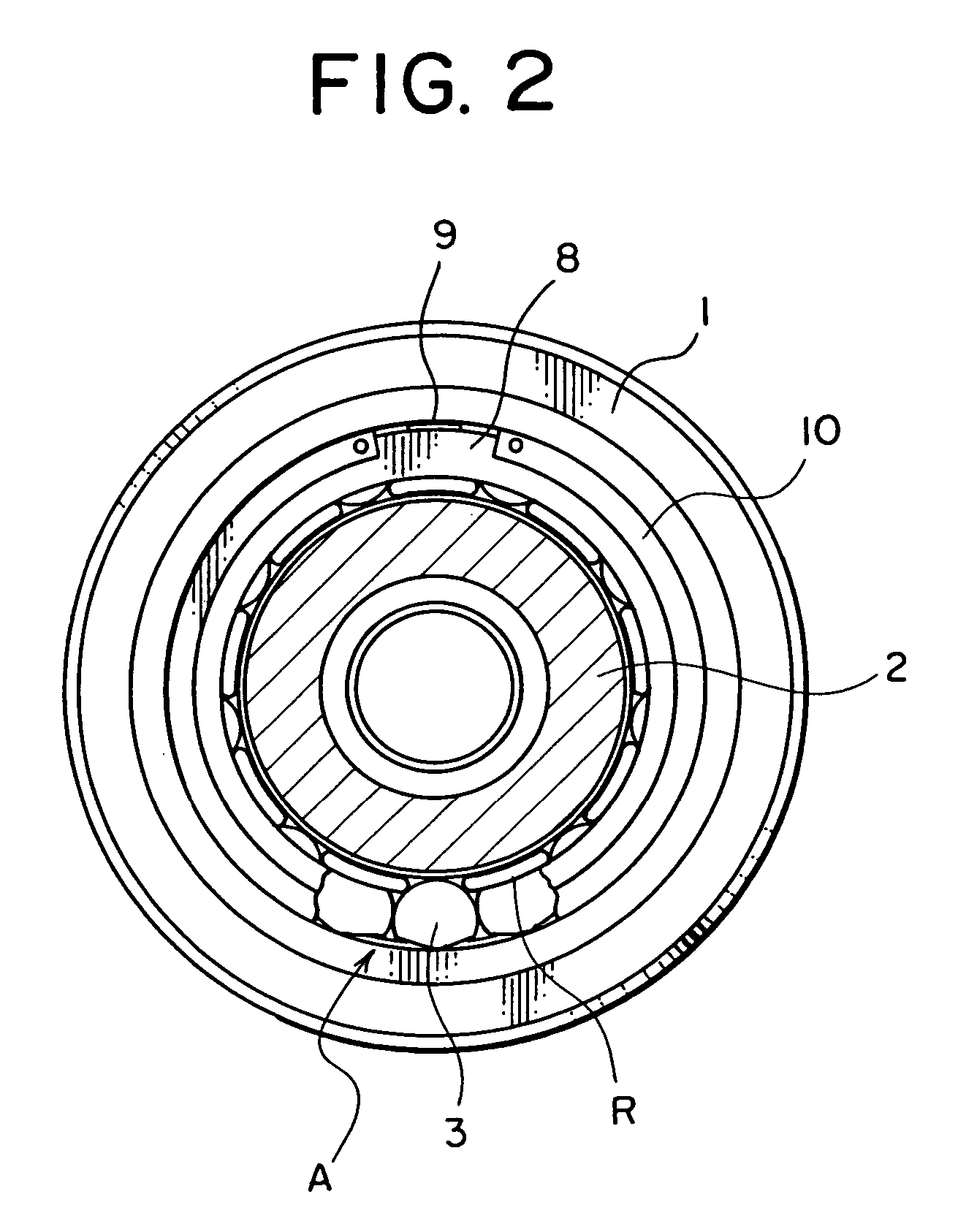

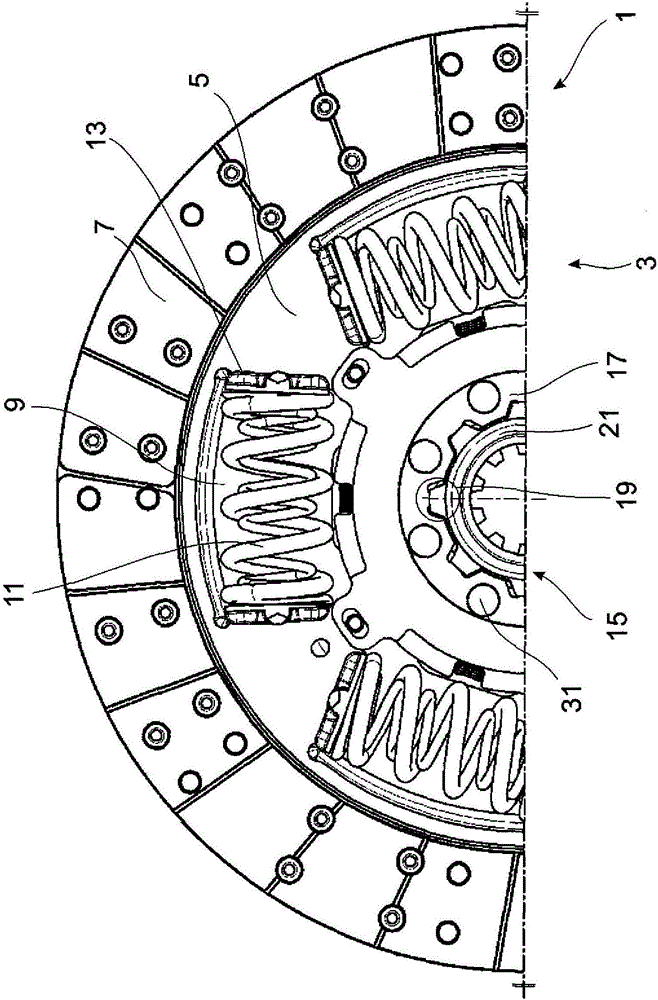

Oneway clutch assembly

InactiveUS7100755B2Increase friction torqueReduce width sizeMechanical actuated clutchesAutomatic clutchesClutchMental detachment

A oneway clutch assembly comprises an outer race and an inner race, torque transmitting members disposed between the outer race and the inner race, a biasing spring for biasing the torque transmitting members, side plates disposed on the both sides of the torque transmitting members in the axial direction thereof, and detachment preventing means for restricting movements of the torque transmitting members, the biasing spring, and the side plates in the axial direction, and being elastically engaged with the outer race or the inner race. One of the side plates is provided with an engagement projection extended in the axial direction and the engagement projection is fitted in the detachment preventing means.

Owner:NSK WARNER

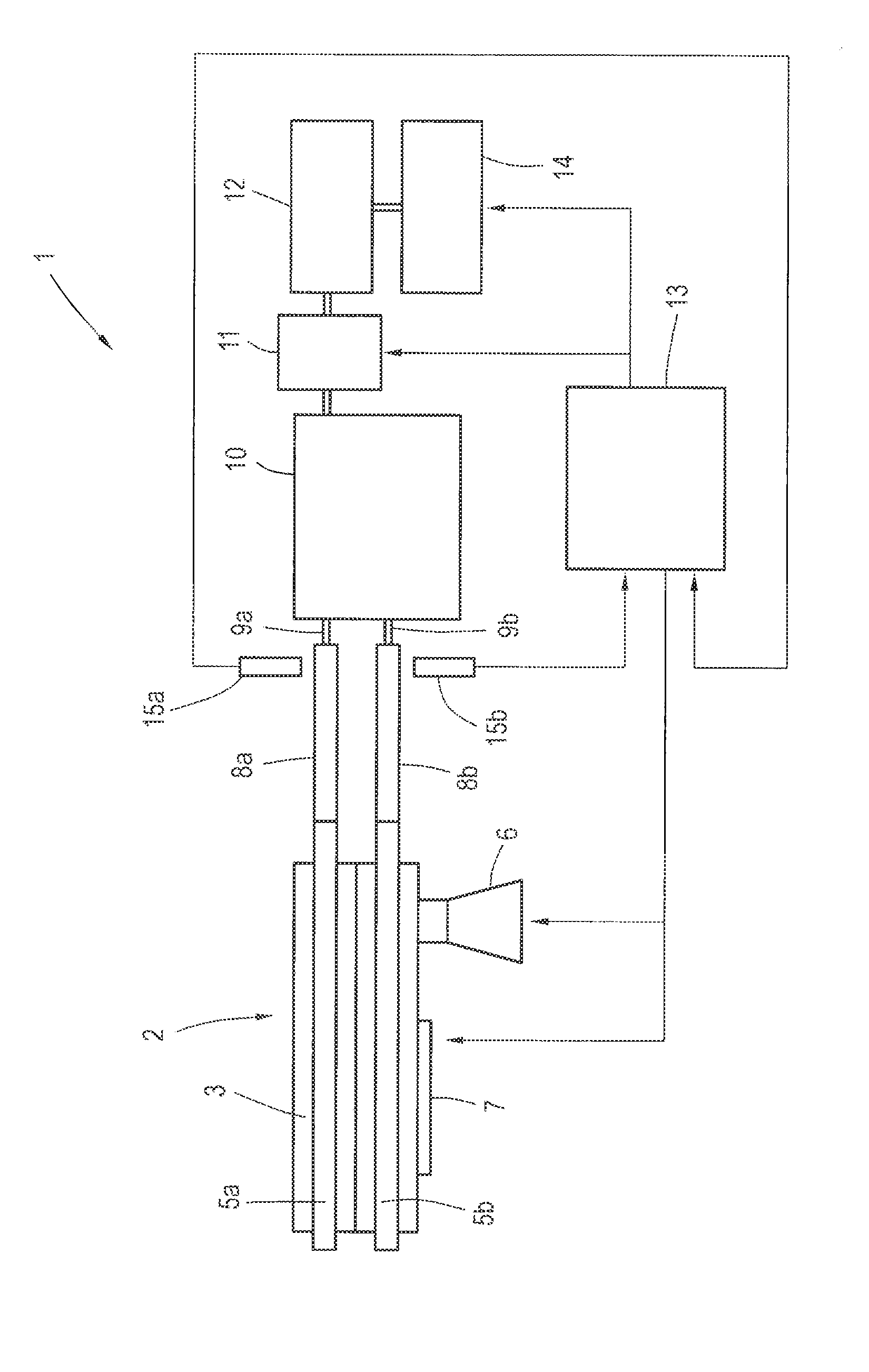

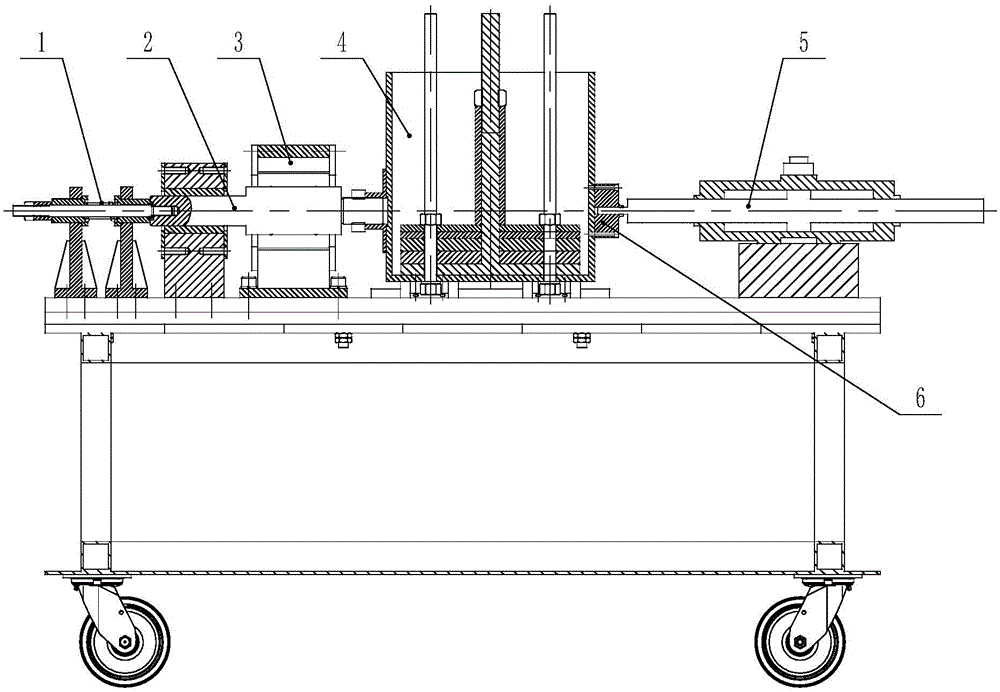

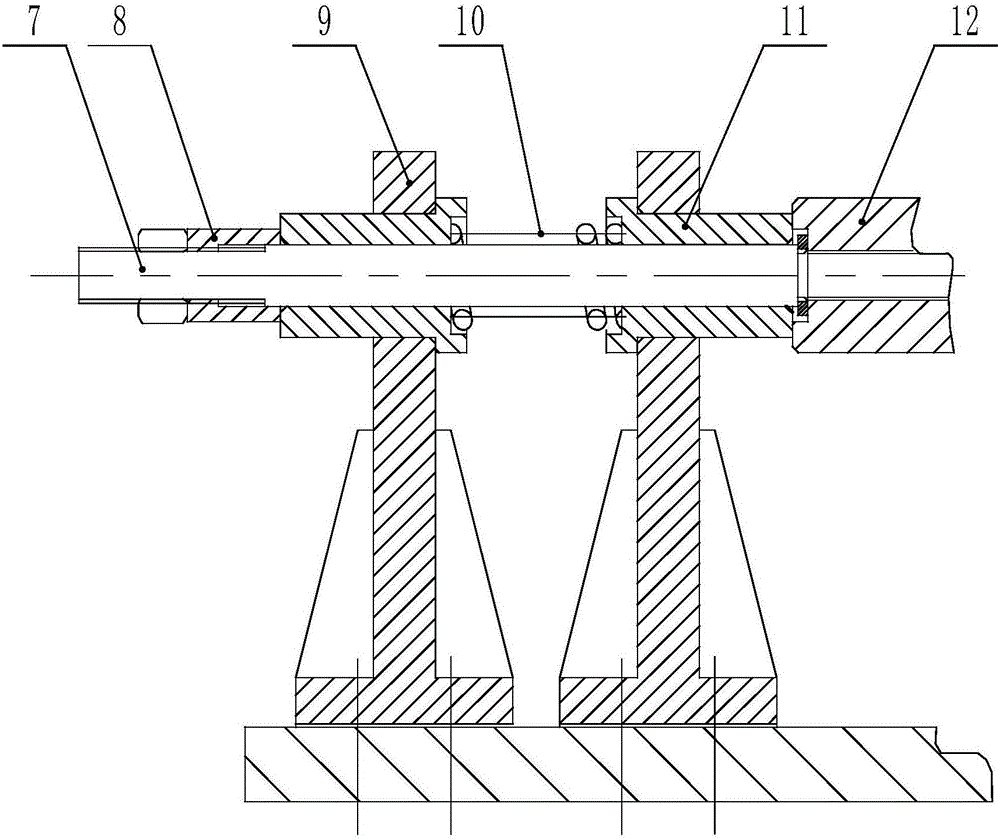

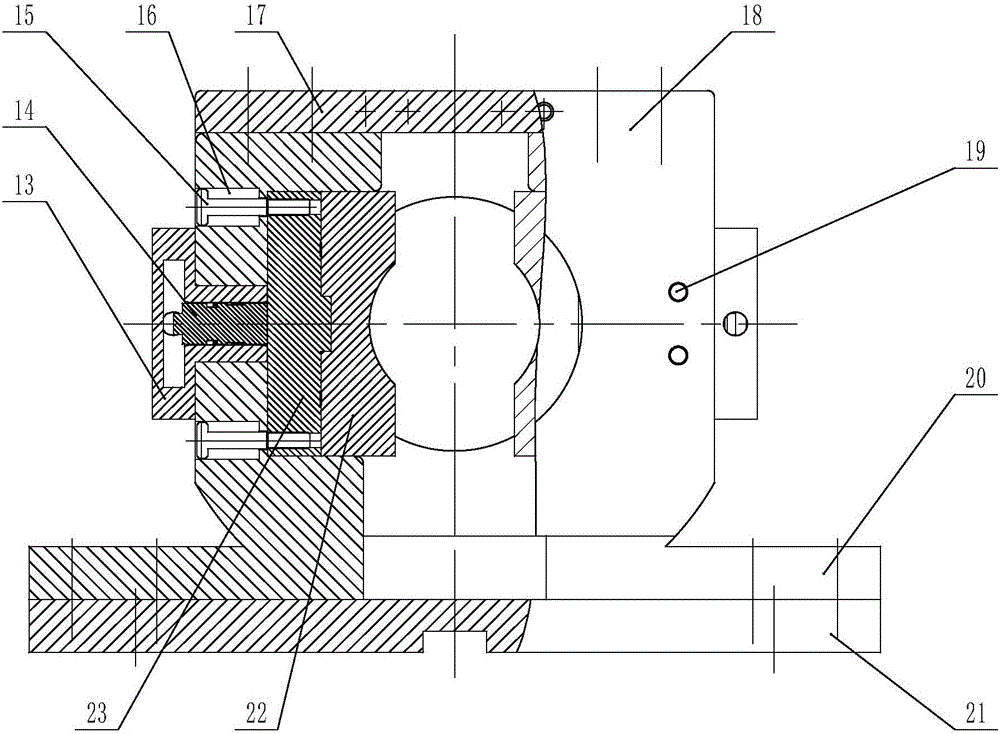

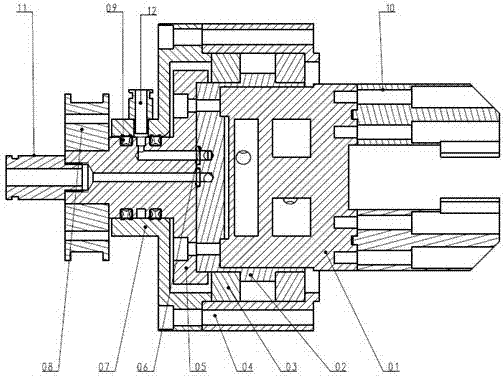

Loading device for testing performance stability of servo valve

InactiveCN106545549AGuaranteed tightnessAvoid offsetFluid-pressure actuator testingServometer circuitsWork periodHydraulic cylinder

The invention provides a loading device for testing performance stability of a servo valve. The loading device comprises an elastic force loading mechanism, a friction force loading mechanism, an inertia force loading mechanism, a tested servo mechanism, a main shaft and a support connection mechanism, wherein the elastic force loading mechanism is in threaded connection with the main shaft through a spring shaft; a friction plate of the friction force loading mechanism is coaxially matched with the main shaft; the left end of the inertia force loading mechanism is in threaded connection with the main shaft, and the right end of the inertia force loading mechanism is connected with a hydraulic cylinder piston rod. The loading device is used for loading the elastic force, the friction force and the inertia force of the servo valve so as to detect stability and reliability of performance of the servo valve under the load condition and particularly detect the zero-position stability of the servo valve; the hydraulic test condition of long-term operation of the servo valve is provided; through test of the product performance under long-term operation condition of the servo valve, the reliability of the product can be improved, so that the reliability of the product in the operation time can be ensured.

Owner:BEIJING JIAOTONG UNIV

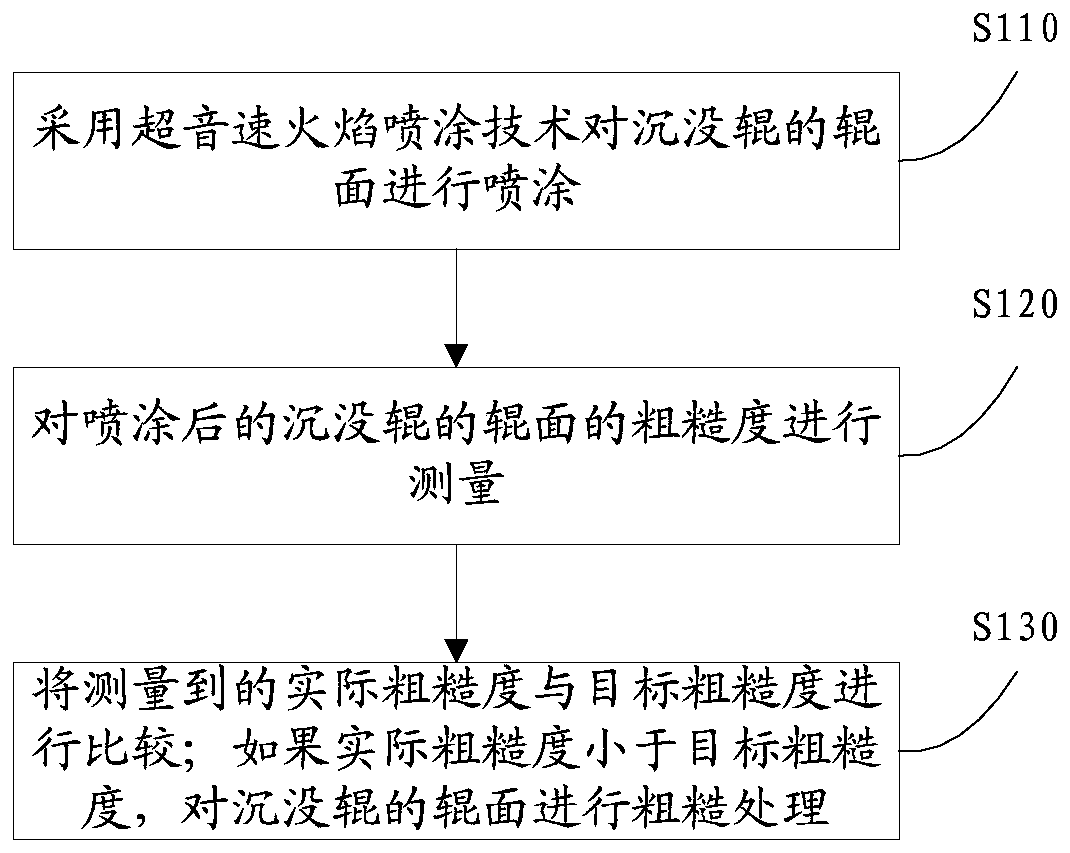

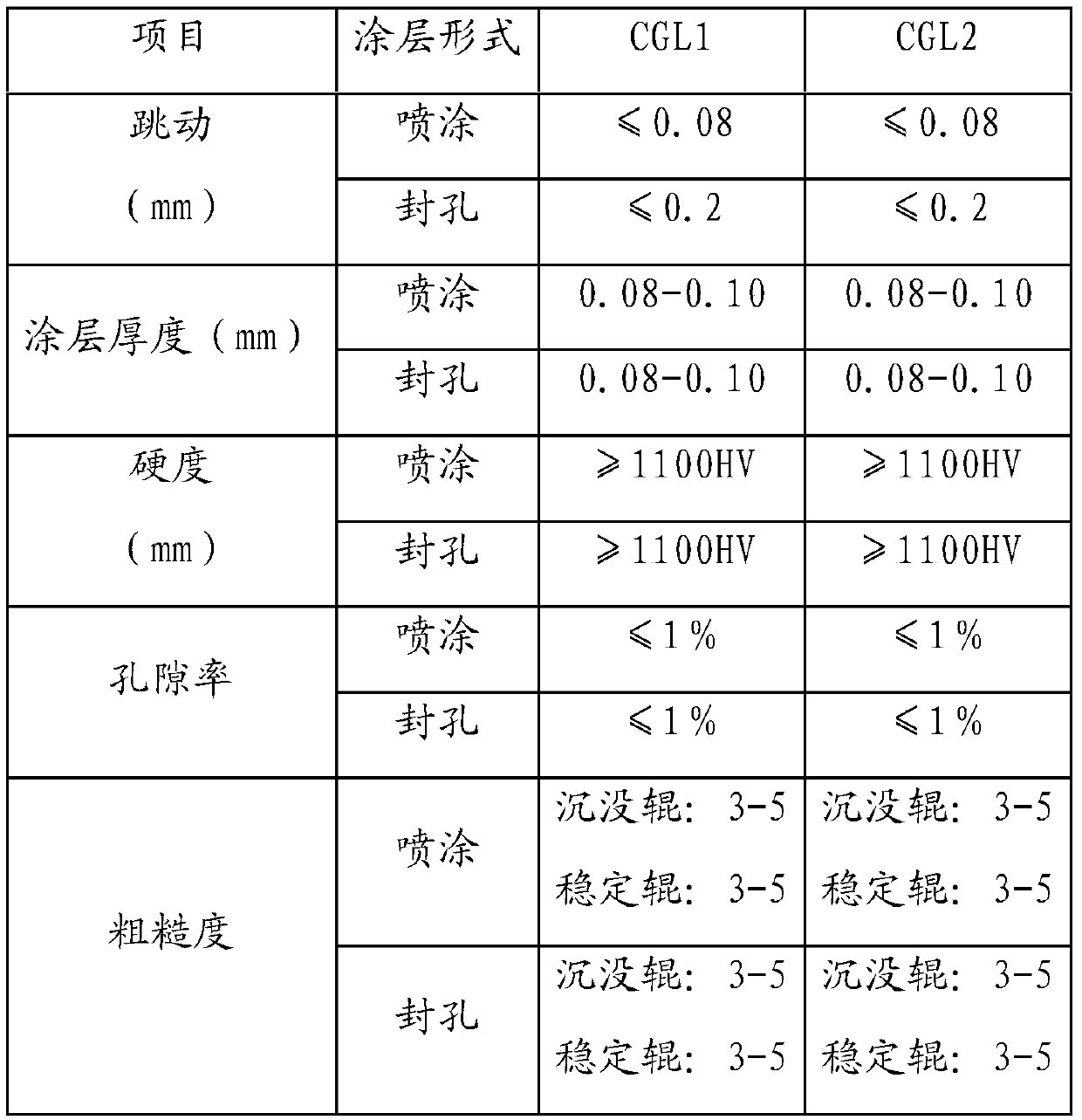

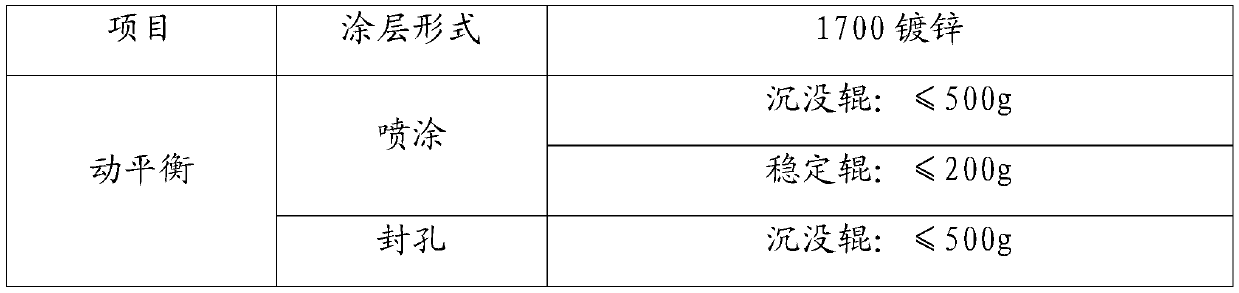

Method of preventing surface of ultra-thin specification hot galvanized plate from being scratched

InactiveCN110747426AGreat driving forceIncrease circumferential forceMolten spray coatingMechanical diameter measurementsStrip steelFriction force

The invention discloses a method of preventing a surface of an ultra-thin specification hot galvanized plate from being scratched. The method comprises the following steps: first, spraying a roll surface of a sink roll by means of a hypersonic flame spraying technique; then measuring roughness of the roll surface of the sprayed sink roll; then comparing the measured actual roughness with target roughness; if the actual roughness is smaller than the target roughness, roughening the roll surface of the sink roll continuously to guarantee that the roughness of the roll surface of the sprayed sinkroll is maintained at a relatively high level of the sink roll, so that the frictional torque of strip steel and the roll surface is increased, and the driving force of the sink roll is further increased, that is, the peripheral force of the sink roll is increased. After the peripheral force is increased, as far as the sink roll of same mass, a roller is easier to rotate, so that the rotating speed difference between the sink roll and the strip steel is reduced, and therefore, scratches caused by speed difference are reduced. The surface quality of the strip steel in a region of a galvanizingprocess section is guaranteed effectively, so that the through plate stability of a region section of a zinc pot is further improved effectively.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Housing cover, in particular plastics oil sump

InactiveCN104214321AAchieve sealingReduce weightCasingsMachines/enginesInternal combustion engineBearing surface

The invention relates to a housing cover made from plastic on an engine housing or gearbox housing made from metal in an internal combustion engine, said housing cover being secured by a plurality of fastening screws (5) against the housing, wherein the housing cover is secured against a bearing surface of the housing by an encircling fastening flange (3) made from plastic, and the fastening flange (3) is provided with penetration openings (4) through which the fastening screws (5) extend into threaded bores (13), which are coaxial with respect thereto, in the housing, wherein the fastening screws (5) are supported by a screw head (7) against the fastening flange (3) directly or with the interposition of a washer, the fastening flange (3) bears without a gap against the bearing surface of the housing, and the fastening screws (5) are secured within the threaded bore (13) against automatic unscrewing.

Owner:IBS FILTRAN KUNST METALLERZEUGNISSE

Ceramic high-performance disc brake pad for bus and manufacturing method thereof

InactiveCN103629281AImproved heat decay performancePromote recoveryOther chemical processesFriction liningFiberGlass fiber

The invention discloses a ceramic high-performance disc brake pad for a bus. The disc brake pad comprises, by weight, 14-18% of modified phenolic resin, 18-23% of a fabric material, 50-60% of filler and 8-10% of ceramic fibers, wherein the ceramic fibers are made of at least two of common aluminum silicate fibers, high-alumina aluminum silicate fibers, aluminum silicate fibers containing chromium oxide, aluminum silicate fibers containing zirconium oxide, aluminum silicate fibers containing boron oxide, polycrystalline alumina fibers and polycrystalline mullite; the fabric material is composed of one or more kinds in mineral fibers, glass fibers and paper fibers. The invention further discloses a manufacturing method of the ceramic high-performance disc brake pad for the bus. The ceramic high-performance disc brake pad for the bus is stable in high-temperature friction coefficient, good in abrasion resistance, simple in manufacturing method and low in cost.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

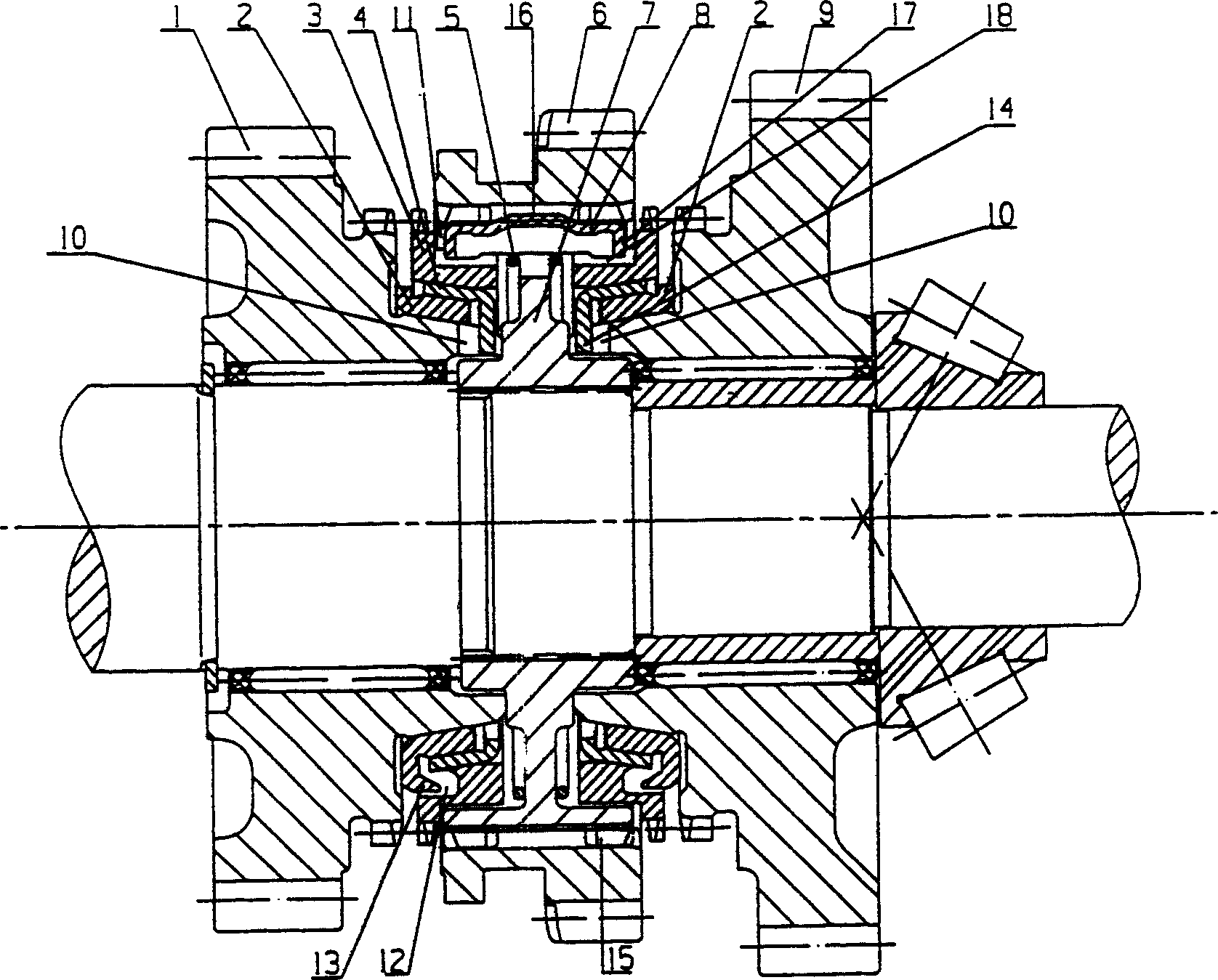

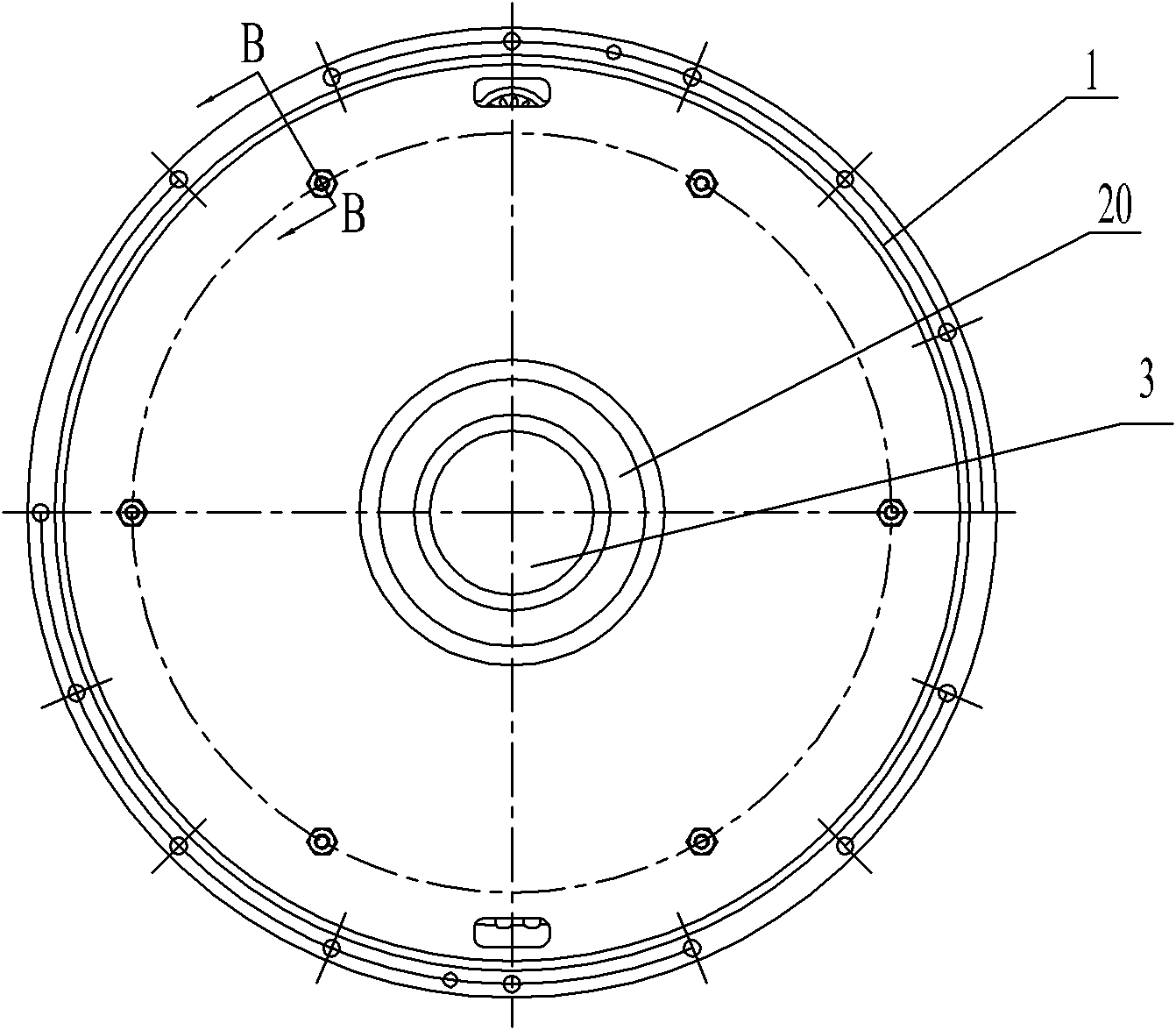

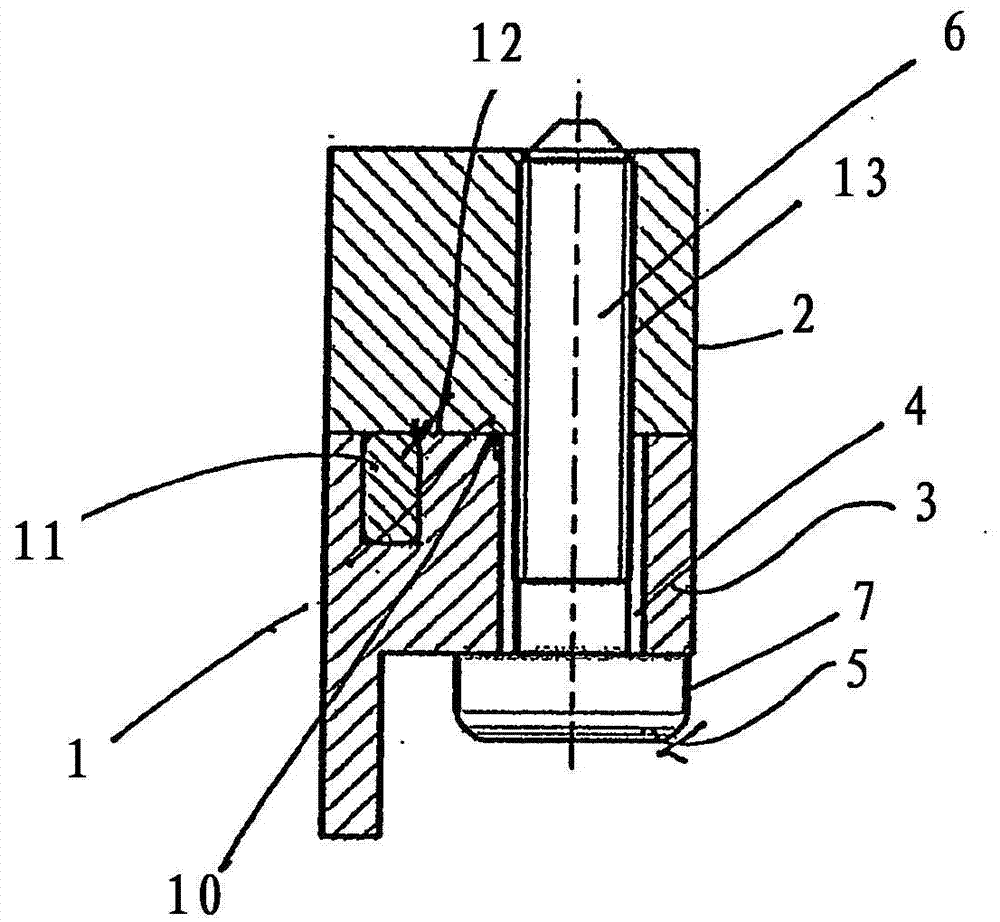

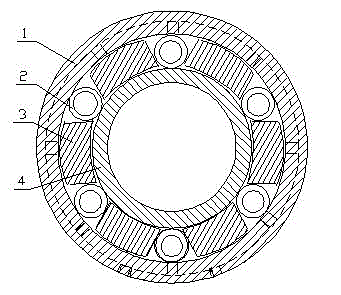

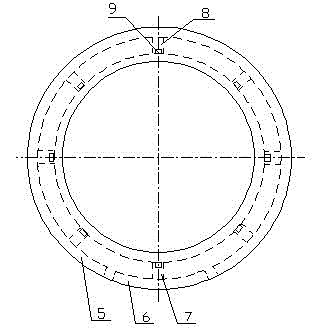

Oil lubricating roll-slide bearing with elastic roller

InactiveCN102494021BIncrease contactIncrease friction torqueRolling contact bearingsBearing componentsRolling-element bearingPre compression

The invention provides an oil lubricating roll-slide bearing with an elastic roller. The roll-slide bearing consists of an outer ring (1), elastic cylindrical rollers (2), slide blocks (3) and an inner ring (4), wherein the elastic cylindrical roller (2) and the slide block (3) are positioned in a chute between the outer ring (1) and the inner ring (4); the number of the elastic cylindrical rollers (2) equals to that of the slide blocks (3), and the elastic cylindrical rollers (2) and the slide blocks (3) are distributed at intervals; the diameter of the elastic cylindrical roller (2) is more than the thickness of the slide block (3) in the radial direction of the bearing, and the axial length of the elastic cylindrical roller (2) is less than the length of the slide block (3) in the axial direction of the bearing; the elastic cylindrical roller has a certain pre-compression amount in the diameter direction, trace clearances are reserved between the slide blocks (3) and the inner ring (1) and between the slide blocks (3) and the outer ring (4), and the elastic cylindrical rollers (2) are kept to be contacted with the slide blocks (3). The oil lubricating roll-slide bearing is used for reducing the applied stress on the inner and outer rings and the elastic cylindrical roller, has the characteristics of storing and releasing energy and maintaining rolling, and has small abrasion and long service life compared with those of a roll-slide bearing with a corresponding size.

Owner:EAST CHINA JIAOTONG UNIVERSITY

High energy screw press

The present invention is a quick pressure-relieving high-energy screw press for implementing die forging and finish forging process instead of friction press and hot die forging press. Said invented screw press is formed from machine body, motor, pulley, freewheel, screw rod, nut, slide block return system, clutch and its compression system, pressure-relieving system, hydraulic system and circuit system. The pressure-relieving system adopts electromagnetic hydraulic sensor, and the oil pressure in the compression cylinder can be increased with the increment of processing force, and when the oil pressure is reached to the electromagnetic current set value, the electromagnetic hydraulic sensor can act, and can utilize pilot valve and main valve to implement quick pressure relief, the lower cavity of piston is filled with low pressure oil with 0.2 MPa, and between the piston and friction disk and between driving shaft and screw rod the spherical pads are mounted.

Owner:夏天赳 +1

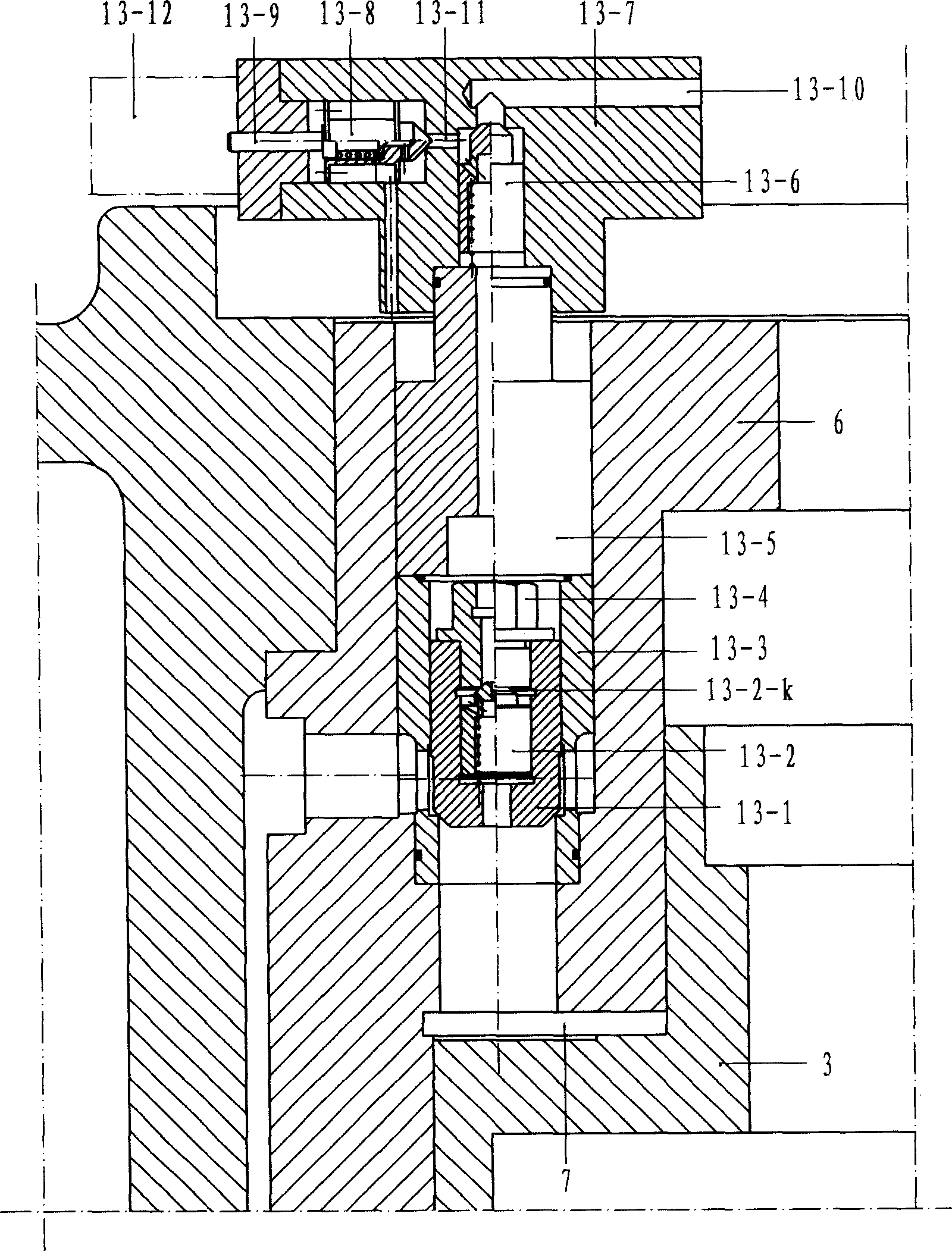

Torsional Damper With Angular-Dependent Friction Damping Device

InactiveCN107524717AIncrease friction torqueIncrease frictionRotating vibration suppressionYielding couplingFriction torqueControl theory

The invention relates to a torsional damper provided with at least one torque input disk and at least one torque output disk. The torque input disc relative to the torque output disc can move in the circumferential direction against the force of at least one spring accumulator; the relative movement is damped by a friction device which generates a smaller frictional torque in a first oscillating angle range than in a second oscillating angle range in that the friction device has at least two mutually rotatable pairs of friction rings, which are activated by the oscillation angle, wherein a first group of friction rings in the circumferential direction are fixed to the torque output part - and a second group of friction rings in the circumferential direction in the first swing angle range are relatively movable to the torque input disk and is mounted to the torque output disk - and in the second swing angle range, the second group of friction rings in the circumferential direction in a driving in the second oscillation angle range, a relative movement takes place in the circumferential direction between the torque output disk and the second friction ring and a relative movement in the circumferential direction between the torque input disk and the first friction ring group.

Owner:ZF FRIEDRICHSHAFEN AG

Thermal compensation element with wave spring

InactiveUS8905643B2Solution to short lifeIncrease preloadRoller bearingsSpringsThermal expansionEngineering

A thermal compensation element which has an inner ring, an outer ring, and a washer. The washer is arranged within the inner ring and the outer ring is mounted over the inner ring, encapsulating the washer, which can be a split wave spring. The inner ring and the outer ring each have retention features to ensure they are retained relative to each other. The thermal compensation, which is positioned between a housing or a shaft, can account for variations in loading and / or temperature that may occur to a bearing and a shaft system when the shaft and an associated component are made of different materials and have different coefficients of thermal expansion by ensuring a proper axial preload is maintained on the bearing.

Owner:SCHAEFFLER TECH AG & CO KG

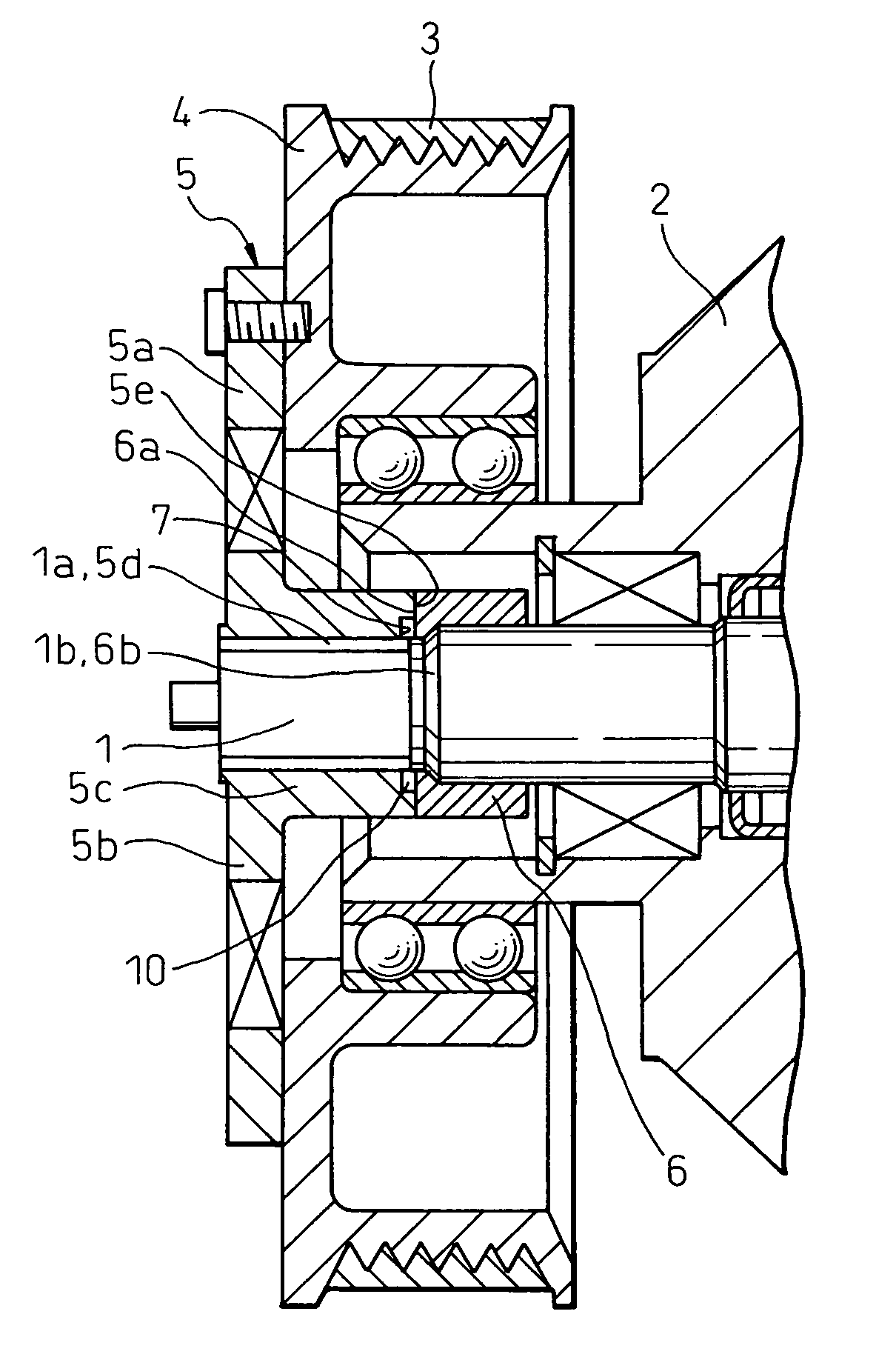

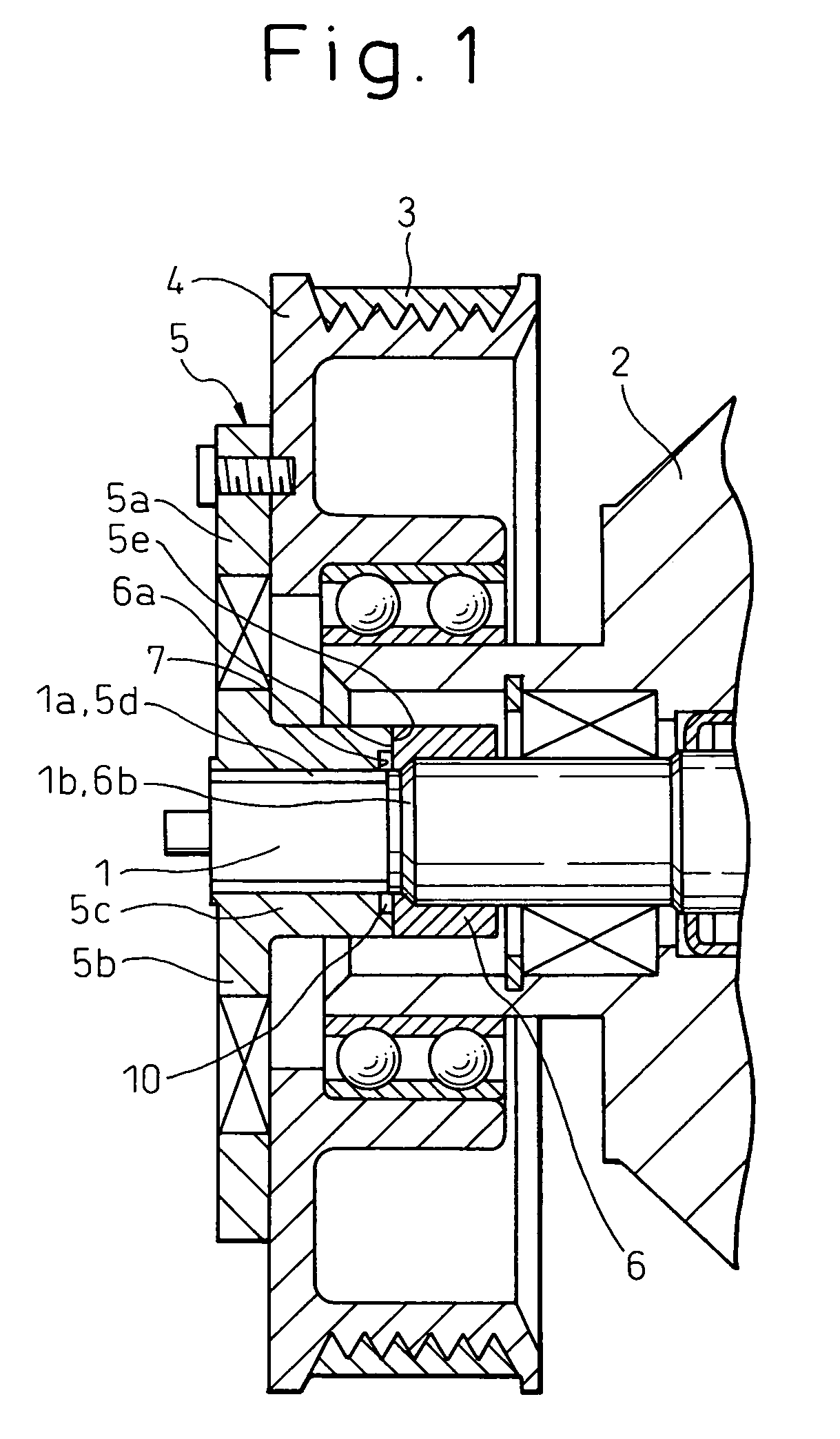

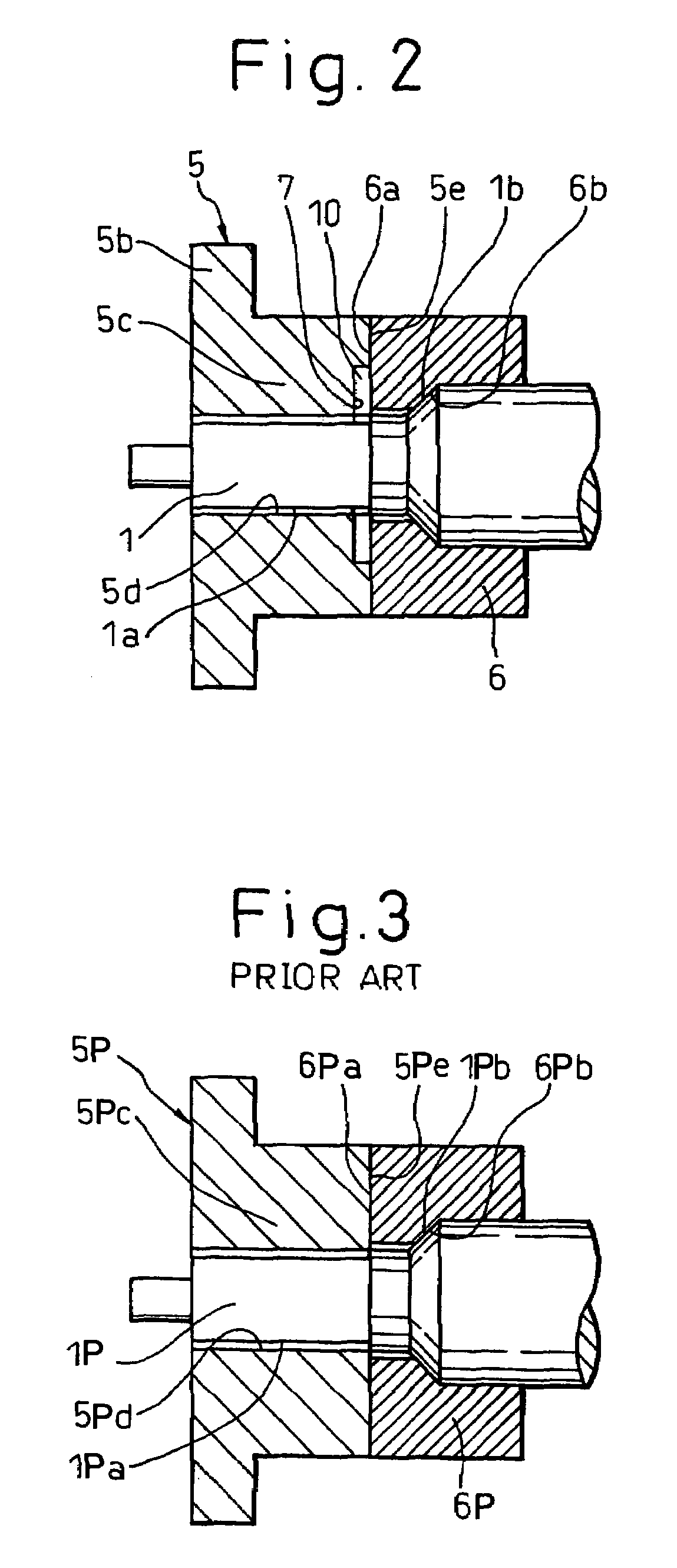

Power transmission mechanism capable of preventing breakage of a rotating shaft

In order to transmit a torque from a hub 5 (rotating body) integrally formed together with a pulley 4 to, for example, a sleeve 6 inserted under pressure into a rotating shaft 1 of a refrigerant compressor 2, end surfaces 5e and 6a, which act as a bearing surface, are brought into frictional contact with each other. An axial pressing force is generated by the engagement of screws 1a and 5d of the rotating shaft 1 and the hub 5. An annular cut-out part 7, etc., is provided to form an annular space 10 in a part of the bearing surface around the rotating shaft 1. Thereby, the equivalent diameter of the bearing surface is increased, a slip is more unlikely to occur on the bearing surface, and it is therefore no longer necessary to apply an excessive pressing force to obtain a large friction torque.

Owner:DENSO CORP

Adjustable positioning hinge with high torsional friction and assembling method thereof

ActiveUS10202791B1Increase frictionEasy to assembleWing accessoriesHingesEngineeringMechanical engineering

Owner:JEAN WEN FONG

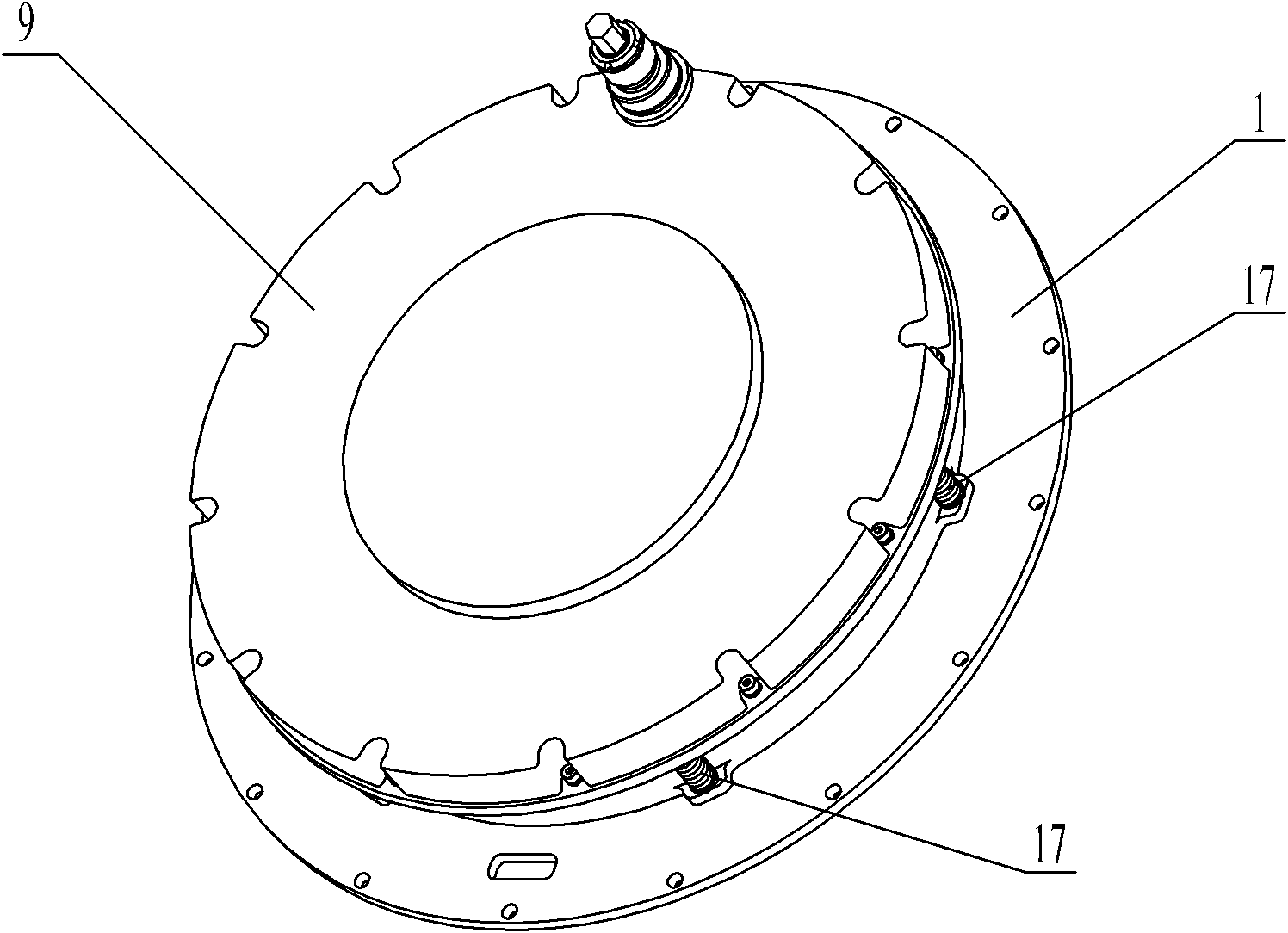

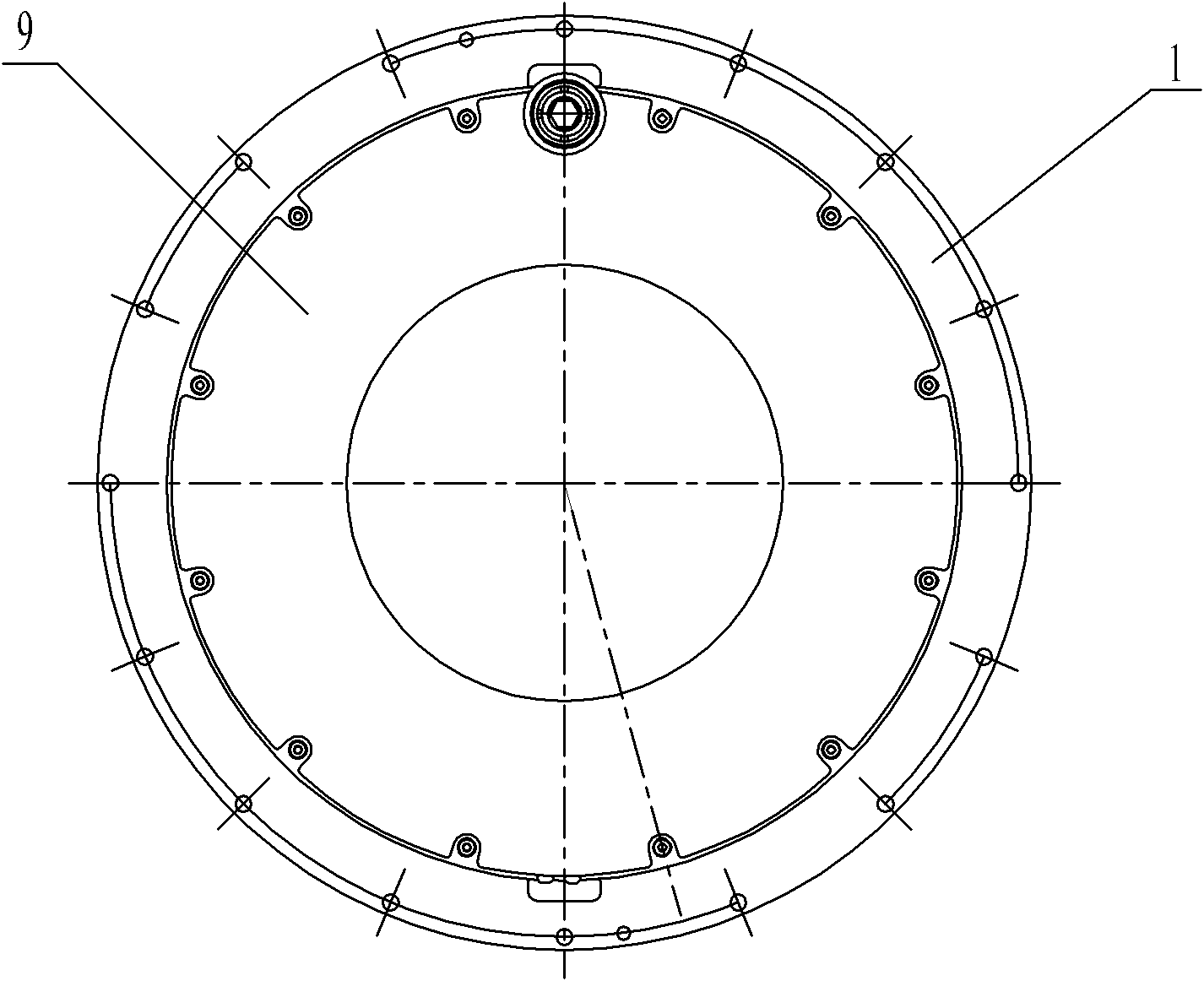

Unlimited rotation automatic clamping mechanism used for full automatic balance correcting equipment

ActiveCN102457143ASmall rotational friction torqueIncrease friction torqueCentering/balancing rotorsFriction torqueEngineering

The invention discloses an unlimited rotation automatic clamping mechanism used for full automatic balance correcting equipment. The clamping mechanism is characterized in that an air claw is fixed in the center hole of an air claw sleeve, the air claw sleeve is fixed on an outer barrel of a rotating mechanism, one end of the air claw is connected with fingers of the air claw, and one end of a rotating shaft is fixed in the air claw sleeve far from the fingers of the air claw; the other end of the rotating shaft is sleeved on a rotating shaft sleeve, two star-type seal rings are utilized to seal the rotating shaft and the rotating shaft sleeve, and the rotating shaft between the two star-type seal rings is provided with an annular air flue; and the rotating shaft sleeve is fixed on the end face of the outer barrel of the rotating mechanism, the rotating shaft positioned outside the rotating shaft sleeve is provided with a synchronous belt pulley, a frictional resistance rotating air joint is arranged in a hole at the other end of the rotating shaft, and a common air joint is arranged on the rotating shaft sleeve. In the invention, a clamping workpiece can carry out unlimited rotation and the rotating friction torque is small, and the clamping mechanism is suitable for automated equipment required to automatically clamp a workpiece to rotate, such as the automatic clamp during circumferential positioning of the workpiece in a full automatic balance correcting machine and the like.

Owner:杭州集智机电股份有限公司

Novel rare earth compound type brake pad and preparation method thereof

InactiveCN103644224AReduce coefficient of frictionImproved heat decay performanceOther chemical processesBraking membersFiberRare earth

The invention discloses a novel rare earth compound type brake pad. The novel rare earth compound type brake pad comprises, by weight, 14-18% of modified phenolic resin, 25-30% of fiber materials, 25-35% of filling materials and 25-35% of rear earth materials, wherein the rear earth materials are composed of one or more kinds of lanthanum oxide, cerium oxide and praseodymium oxide, and the fiber materials are composed of one or more kinds of mineral fibers, glass fibers and paper fibers. The invention further discloses a preparation method of the novel rare earth compound type brake pad. The novel rare earth compound type brake pad is good in high-temperature resistance, excellent in abrasion resistance and large in impact resistance, and the preparation method is simple and low in cost.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com