Synchronizer having three pyramidal faces

A technology of synchronizer and conical surface, which is applied in the direction of clutches, mechanical drive clutches, transmission parts, etc., can solve the problems of shortening synchronization time, difficulty, and failure to shift gears, etc., so as to reduce synchronization time, reduce shifting force, The effect of improved synchronization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

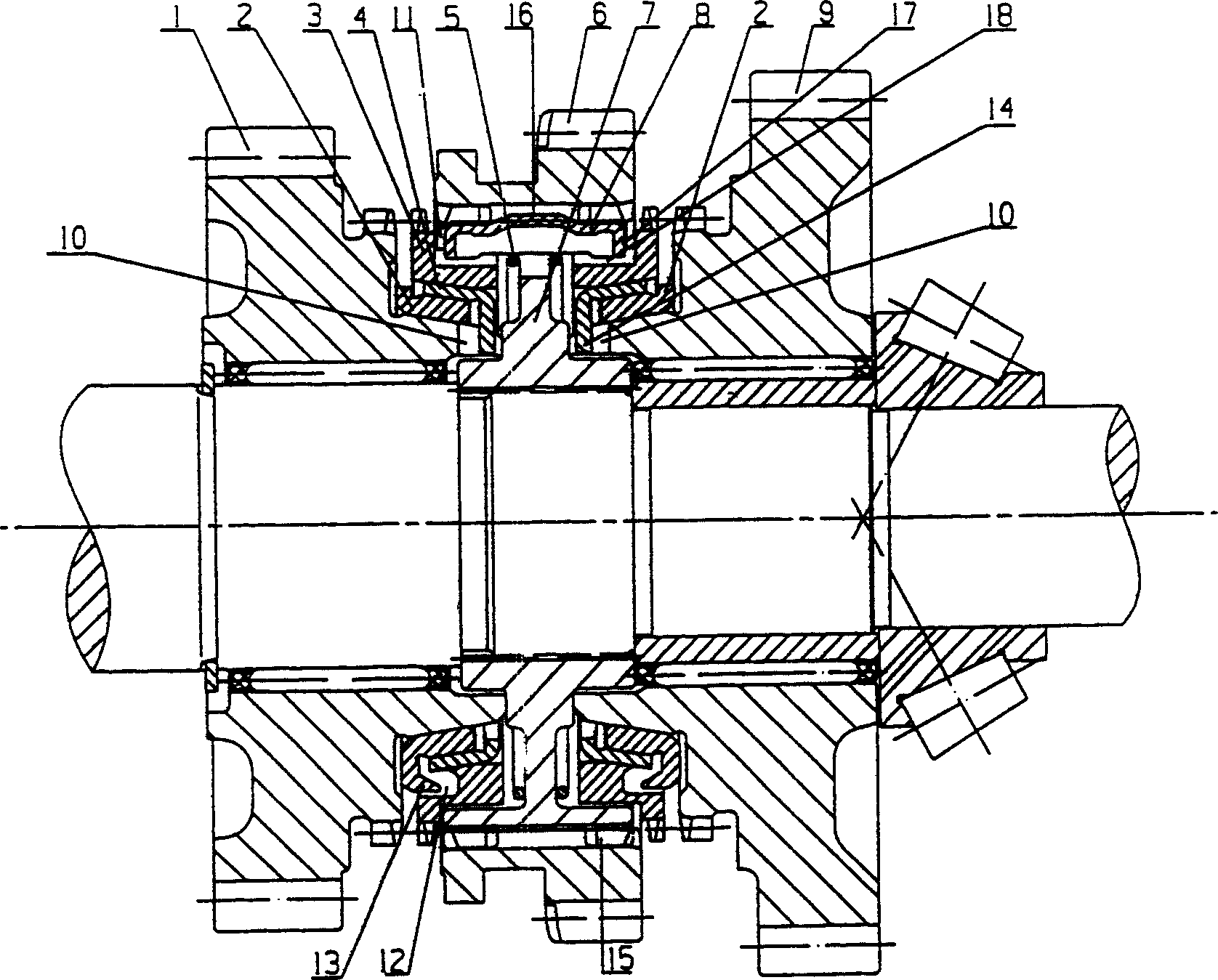

[0012] Such as figure 1 As shown, the present invention includes: second gear gear 1, inner cone ring 2, outer cone ring 3, intermediate ring 4, synchronizer spring 5, tooth sleeve 6, gear hub 7, slider 8, first gear gear 9, first The groove 10, the slider groove 11, and the second groove 12 have a connection relationship: the inner cone ring 2, the intermediate ring 4, and the outer cone ring 3 are sequentially arranged from the inside to the outside to form the friction ring on the gear, and the inner cone ring 2 is empty. Set on the gear cone surface, the intermediate ring 4 is vacantly sleeved on the inner cone ring 2, the outer bevel ring 3 is vacantly sleeved on the intermediate ring 4, and the intermediate ring 4 passes through the first groove 10 on the gear tooth and the second gear 1 , the first gear 9 is connected, the inner wall of the gear sleeve 6 has a slider groove 11, the entire slider 8 is embedded in the groove of the gear hub 7, two synchronizer springs 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com