Patents

Literature

35results about How to "Improved heat decay performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

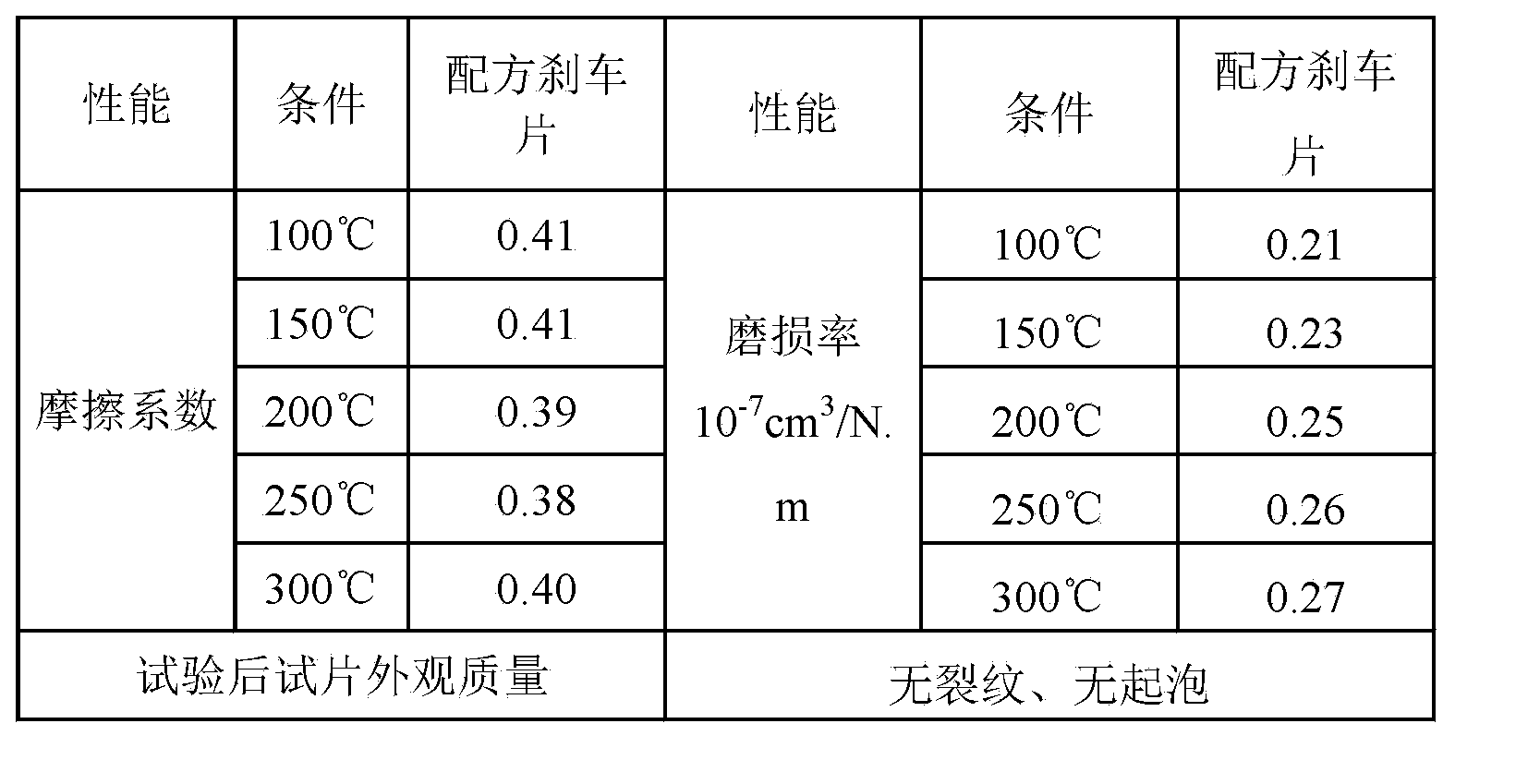

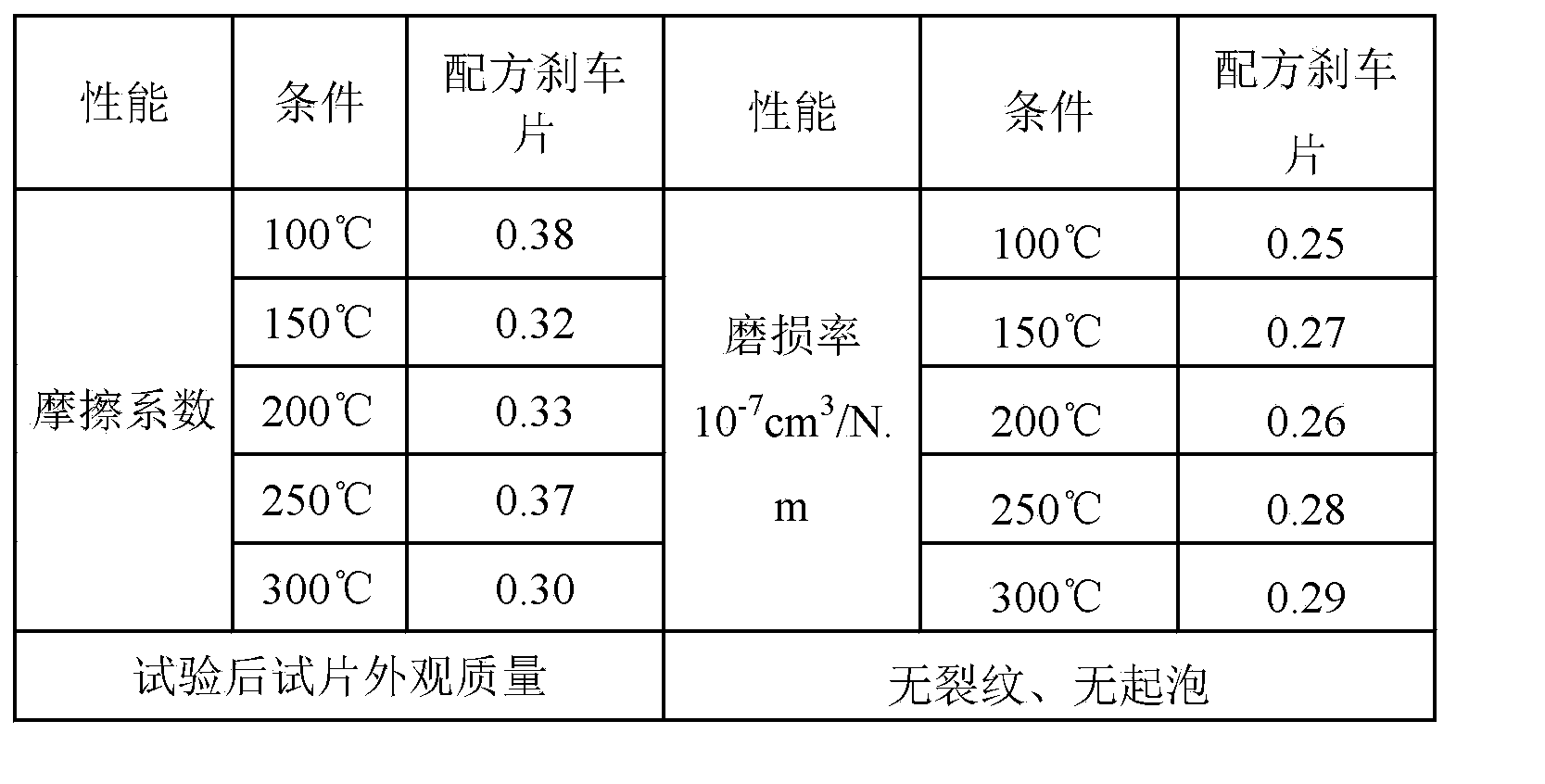

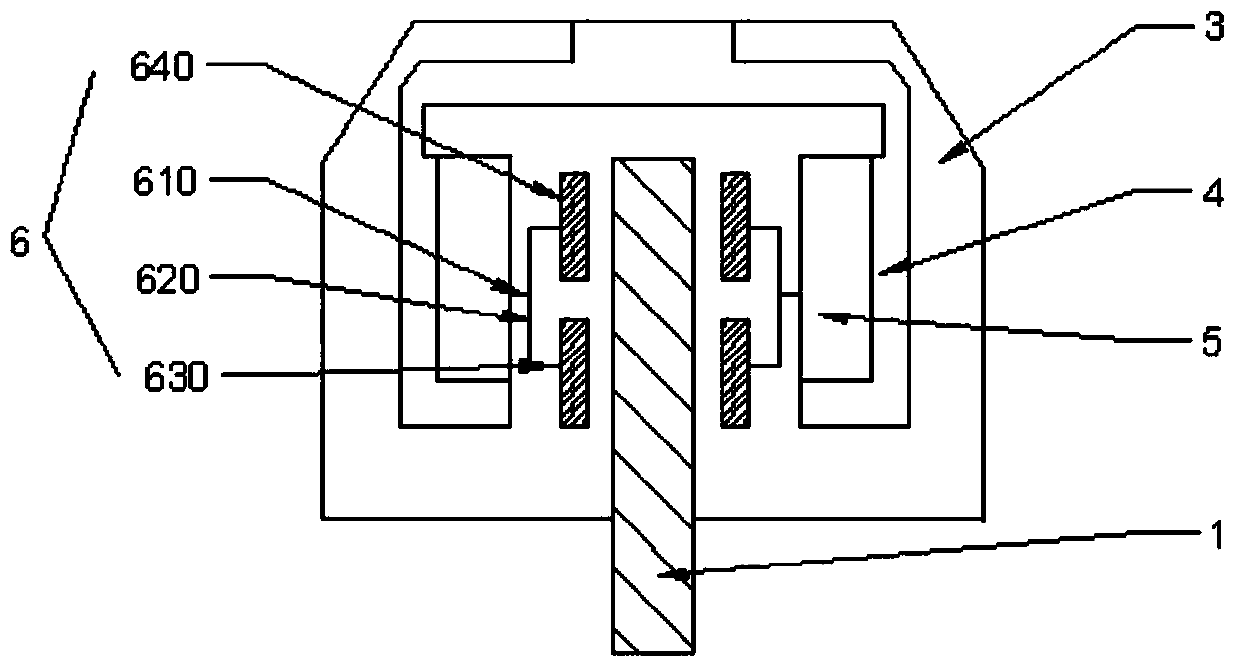

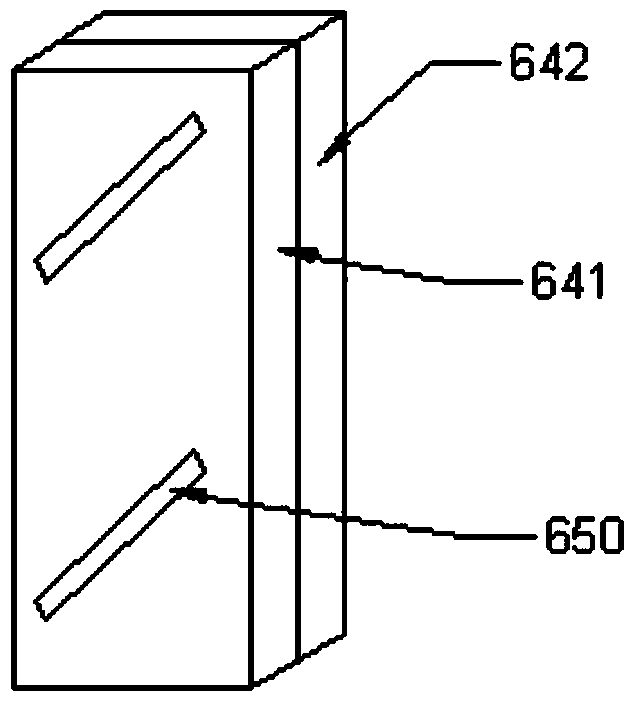

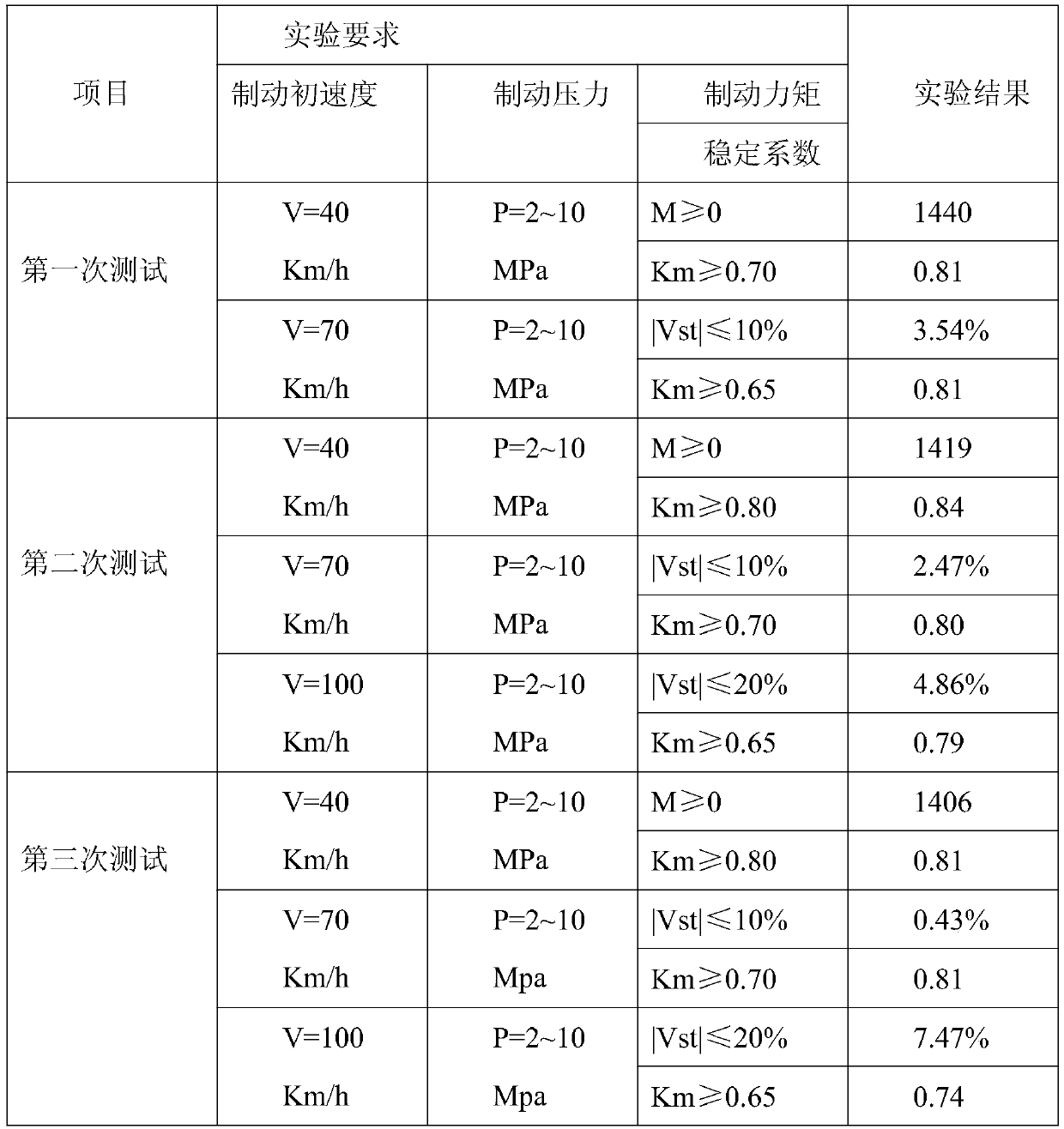

Vibration-damping, denoising and yaw low-speed braking pad and fabrication method thereof

ActiveCN103256325AStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

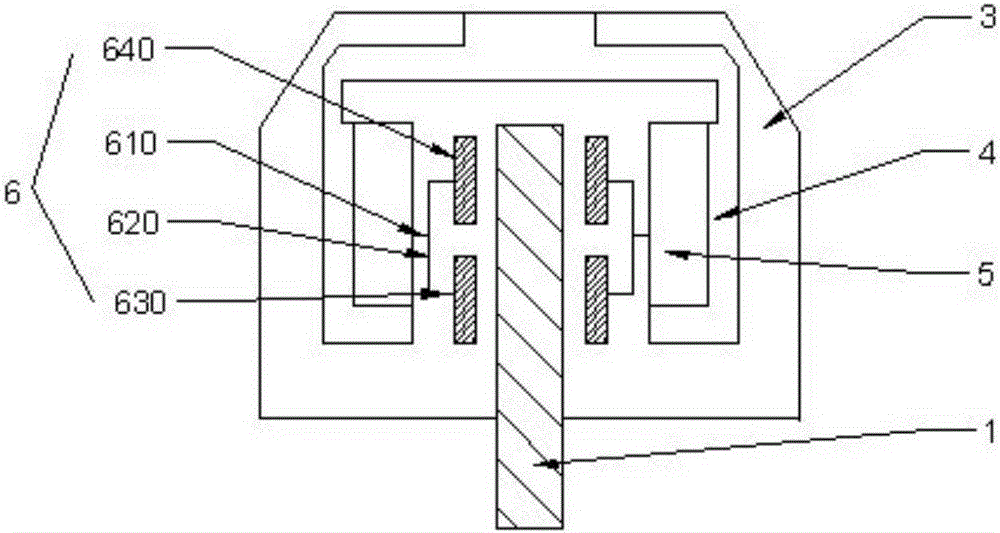

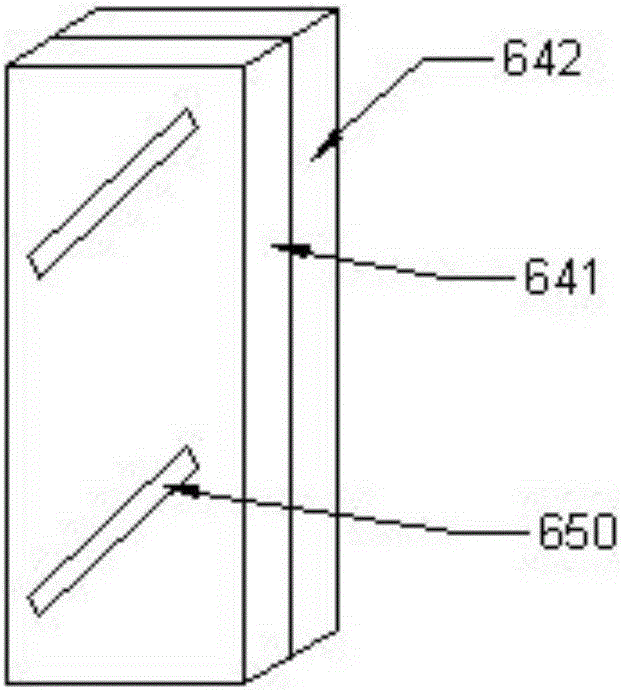

Emergent brake device for vehicle

ActiveCN105240424AImprove securityReduce spacingAxially engaging brakesBrake actuating mechanismsEngineeringBrake pad

The invention discloses an emergent brake device for a vehicle; left and right two brake frames are arranged in a brake clamp of the brake device, wherein the brake frames comprise a first cross bar, a first vertical rod, two brake rods and two brake pieces; one end of the first cross bar is fixedly connected to a brake block; the center of the first vertical rod is vertically connected to the other end of the first cross bar; one ends of the two brake rods are fixedly connected to one end of the first vertical rod; the two brake pieces are respectively and correspondingly fixed at the other ends of the two brake rods; and the brake pieces are perpendicular to the corresponding brake rods. Through the arrangement of the brake frames in the emergent brake device for the vehicle, when the vehicle is emergently braked, if one of the brake pieces is failed, the friction brake of the rest brake piece still can be used, the safety of the vehicle is improved; and meanwhile, the use level of brake oil can be decreased, and the energy is saved.

Owner:海宁经开产业园区开发建设有限公司

Preparation method for lanthanide modified brake pad of mining truck

InactiveCN103436222AImprove heat decayReduce wear rateOther chemical processesFriction liningFiberLanthanide

The invention discloses a preparation method for a lanthanide modified brake pad of a mining truck. The brake pad is prepared through taking lanthanide oxides, reinforcing fibers, binding agent, conditioning agent and filling powder as the principle additive raw materials and adopting the procedures of mixing, cold pressing, hot pressing and heat treatment for modification. The product prepared through the method has the advantages of high temperature resistance, good heat fading performance, stable friction coefficient, excellent braking performance, good abrasion resistance, long service life, low braking noise, and good conformance to environmental protection requirements, and can completely satisfy the specific requirements of high deadweight tonnage, large braking torque, high braking frequency and great calorific value for the mining truck.

Owner:BAOTOU DACHUAN MACHINERY SCI & TECH

Apocynum venetum fiber doped high environmentally-friendly type ceramic saloon car brake pad and preparation method thereof

ActiveCN102329475AStable coefficient of frictionReduce wearFriction liningAdditive ingredientApocynum venetum

The invention relates to a ceramic saloon car brake pad which comprises the following ingredient components: modified phenolic resin, ceramic fiber, gelatin-spraying aluminum silicate fiber, aramid fiber, apocynum venetum fiber, red copper fiber, graphite, potassium hexatitanate whisker and BaSO4, wherein before being used, apocynum venetum needs to be subjected to modification as follows: the apocynum venetum fiber soaked by water is put in a NaOH solution for alkali treatment, then the apocynum venetum fiber subjected to alkali treatment is put in a high-pressure container for pressure maintaining treatment, and finally, fire retardant treatment is carried out on the surface of the apocynum venetum fiber. The invention also provides a preparation method of the ceramic saloon car brake pad. The apocynum venetum fiber doped saloon car brake pad has the advantages of stable frictional factor, high temperature resistance, small antithesis abrasion, good abrasive resistance and corrosion resistance, small heat-fading property, small noise, good comfortableness, environmental friendliness, thereby being an ideal substitute material of an asbestos-free organic based brake pad.

Owner:JIANGSU ANJIE AUTO PARTS

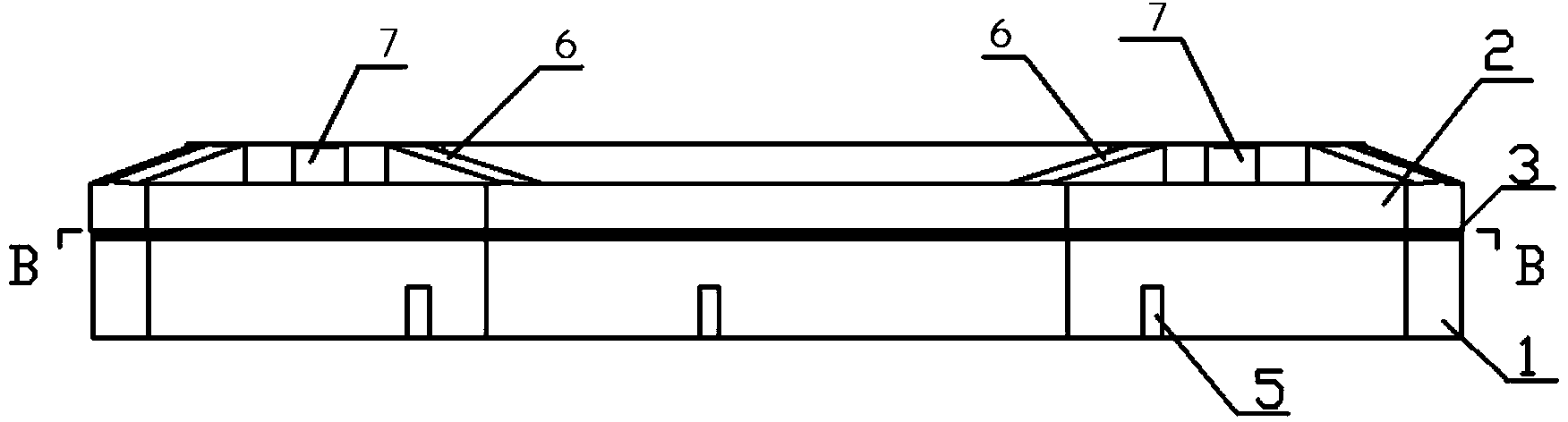

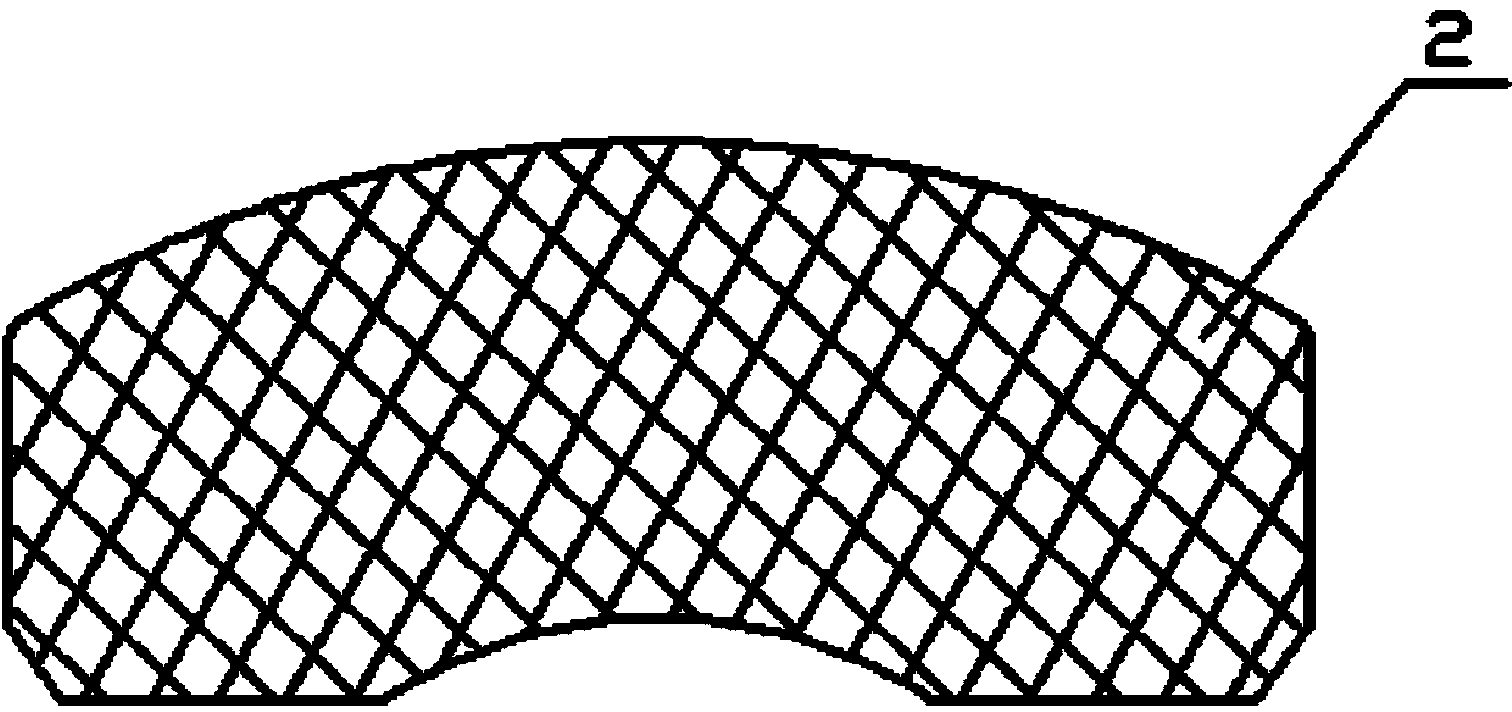

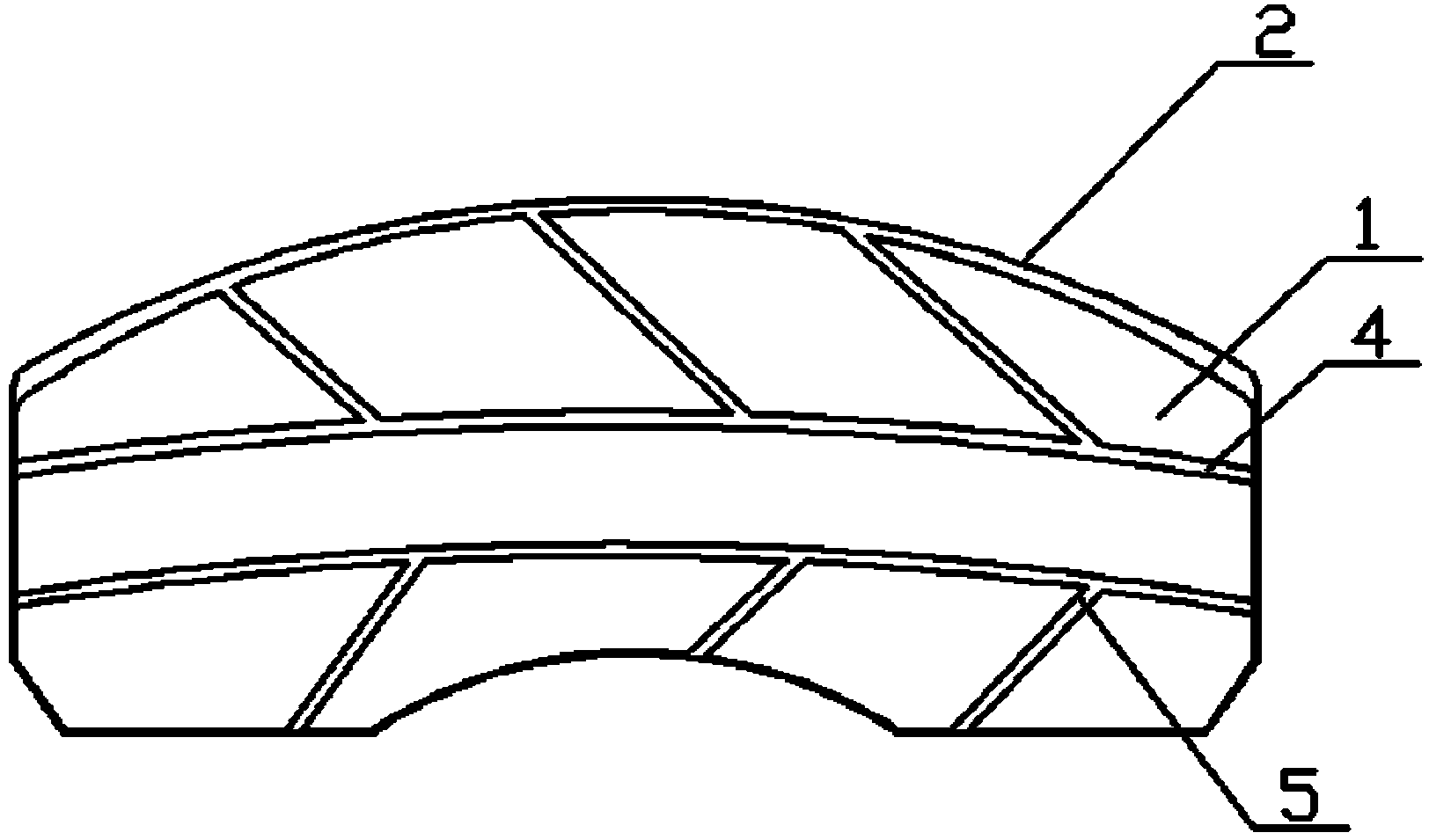

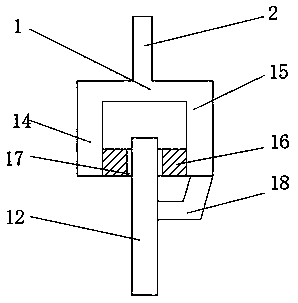

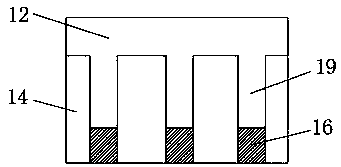

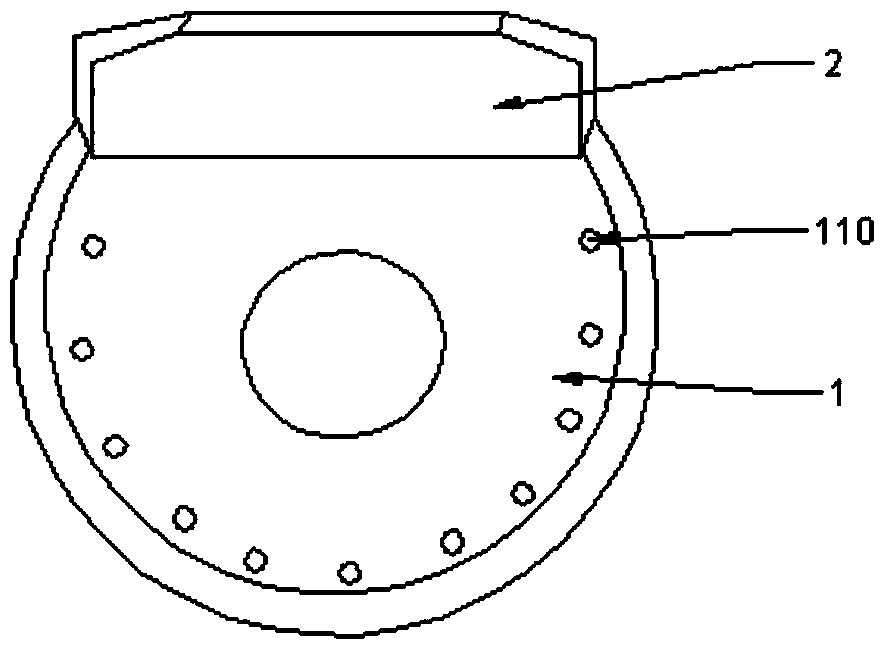

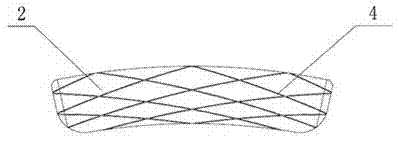

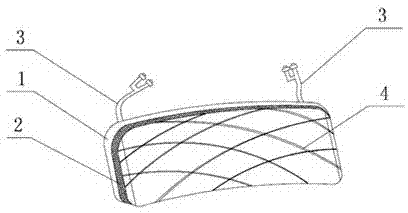

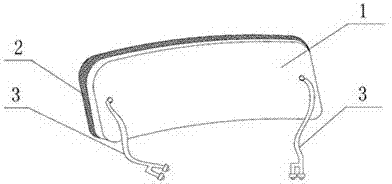

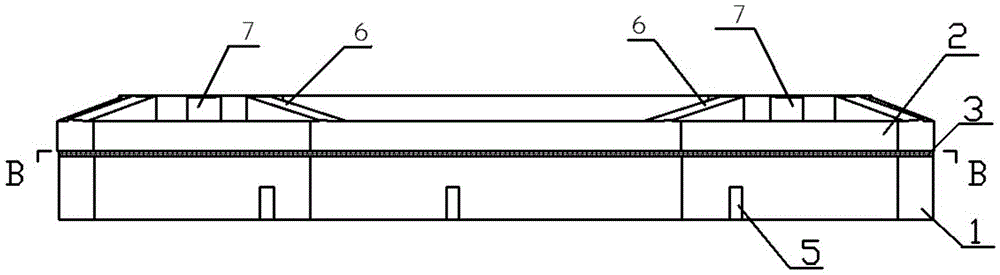

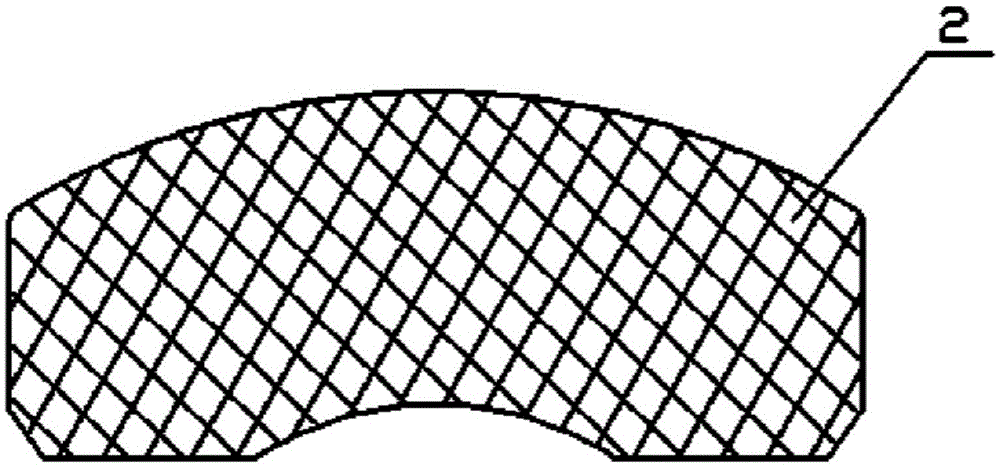

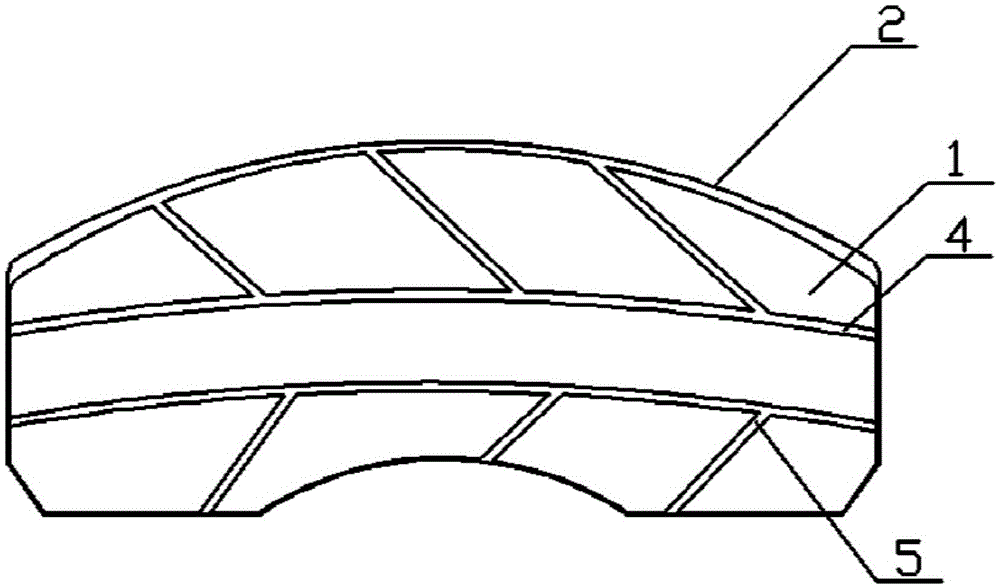

Brake pad for disc brake

ActiveCN103883653AReduce brake noiseReduce vibrationBraking elementsFriction liningEngineeringNoise suppression

The invention discloses a brake pad for a disc brake. The brake pad comprises a friction layer and a steel backing layer, the steel backing layer is positioned above the friction layer and adhered to the same through a metal binding agent, a braking face of the friction layer is provided with a plurality of arc grooves which are distributed transversely and penetrate through the friction layer, and skewed slots which are distributed obliquely, longitudinally and uniformly and lead to the edge of the friction layer are formed in the outer sides of the arc grooves on two sides. A layer of rhombus net grooves is graved on a face, fitting with the friction layer, of the steel backing layer. Two cylindrical bosses are symmetrically arranged on the upper surface of the steel backing layer, and the outer edges of the bosses are provided with asterisk-shaped reinforcing ribs. The brake pad for the disc brake has the advantages of vibration reduction, noise suppression, long service life, high stability, good heat effect, high safety, effectiveness in improvement of safety of the brake and good application prospect.

Owner:JIANGSU HENGLI BRAKE MFG +1

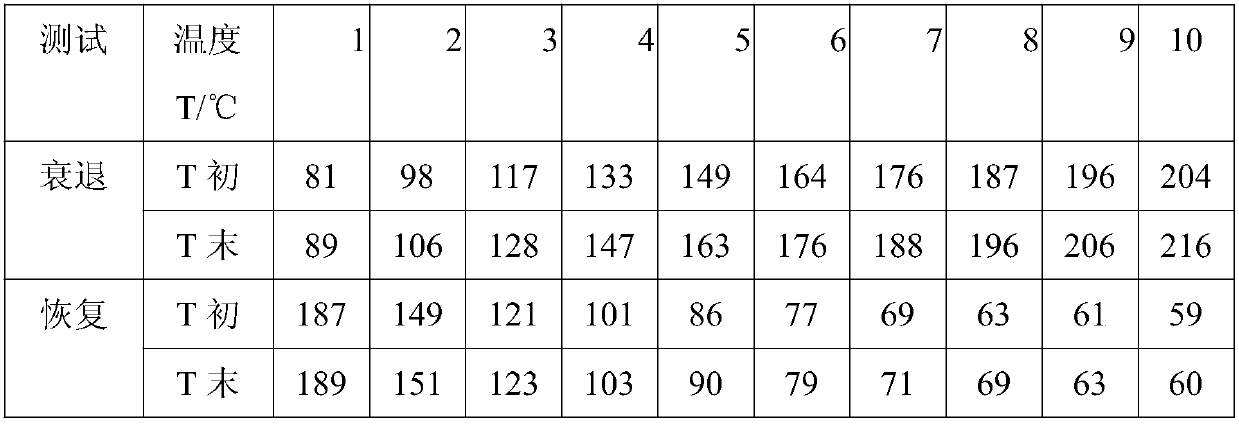

Ceramic high-performance disc brake pad for bus and manufacturing method thereof

InactiveCN103629281AImproved heat decay performancePromote recoveryOther chemical processesFriction liningFiberGlass fiber

The invention discloses a ceramic high-performance disc brake pad for a bus. The disc brake pad comprises, by weight, 14-18% of modified phenolic resin, 18-23% of a fabric material, 50-60% of filler and 8-10% of ceramic fibers, wherein the ceramic fibers are made of at least two of common aluminum silicate fibers, high-alumina aluminum silicate fibers, aluminum silicate fibers containing chromium oxide, aluminum silicate fibers containing zirconium oxide, aluminum silicate fibers containing boron oxide, polycrystalline alumina fibers and polycrystalline mullite; the fabric material is composed of one or more kinds in mineral fibers, glass fibers and paper fibers. The invention further discloses a manufacturing method of the ceramic high-performance disc brake pad for the bus. The ceramic high-performance disc brake pad for the bus is stable in high-temperature friction coefficient, good in abrasion resistance, simple in manufacturing method and low in cost.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

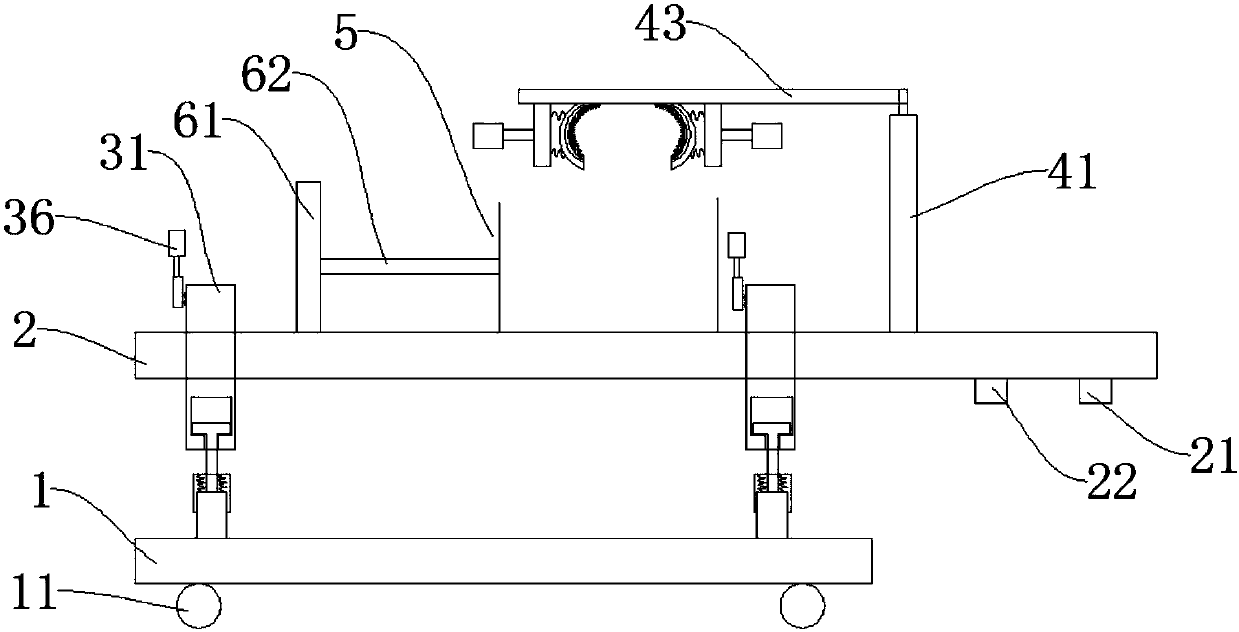

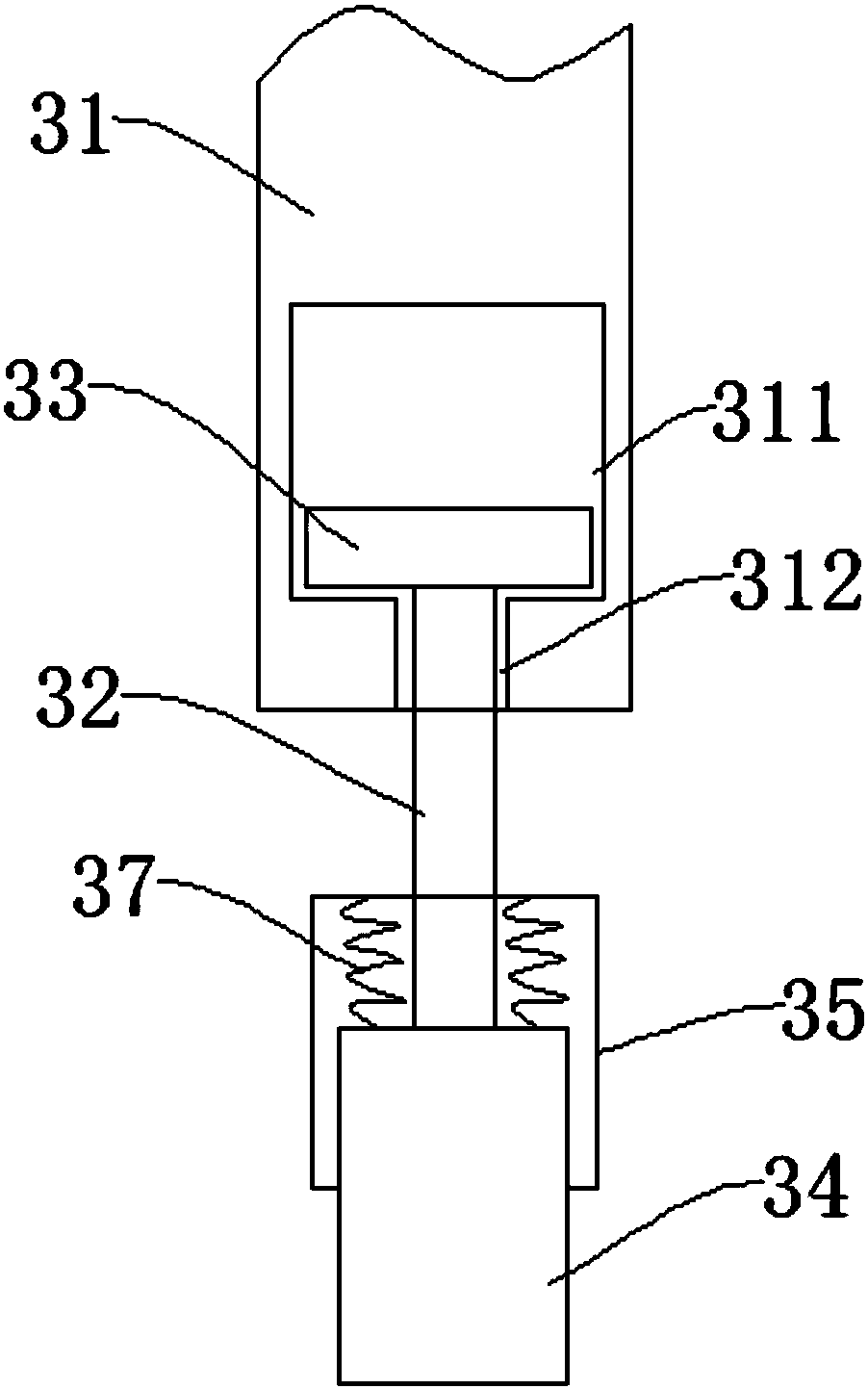

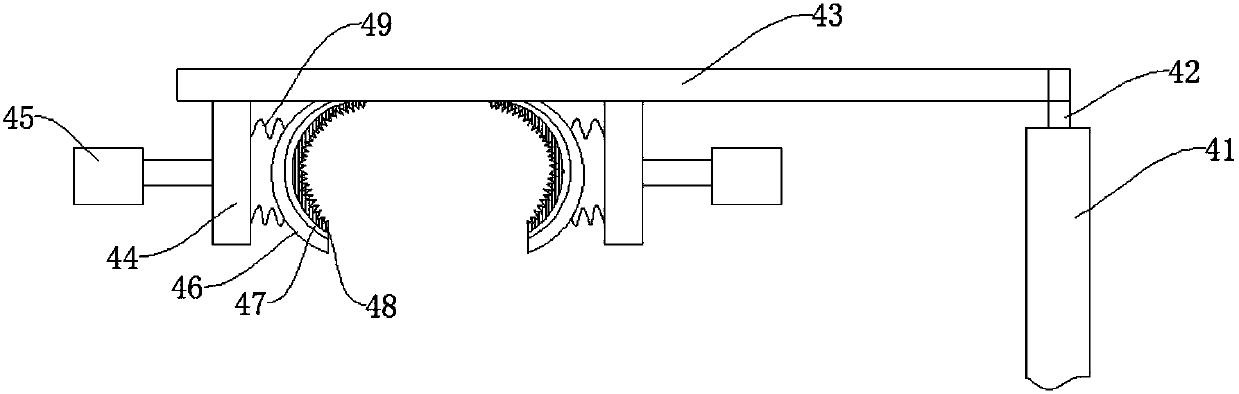

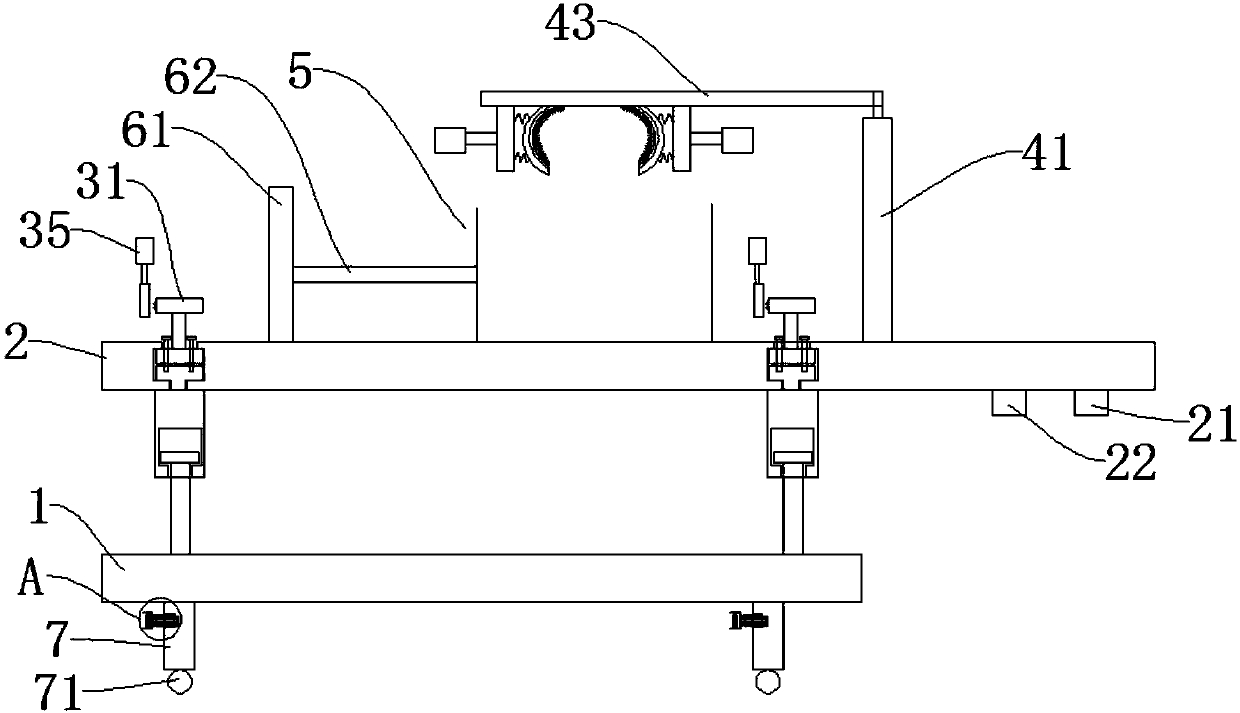

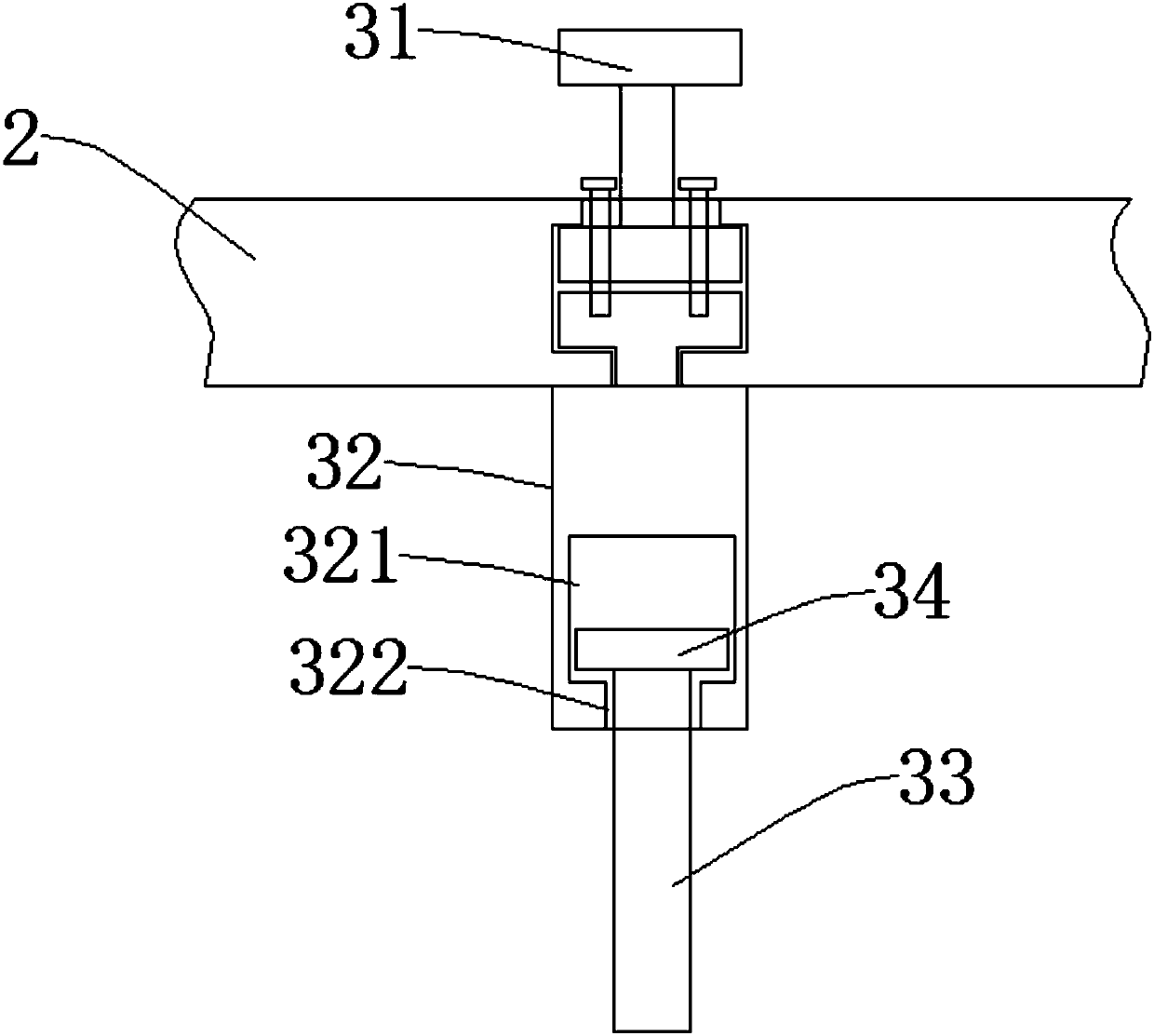

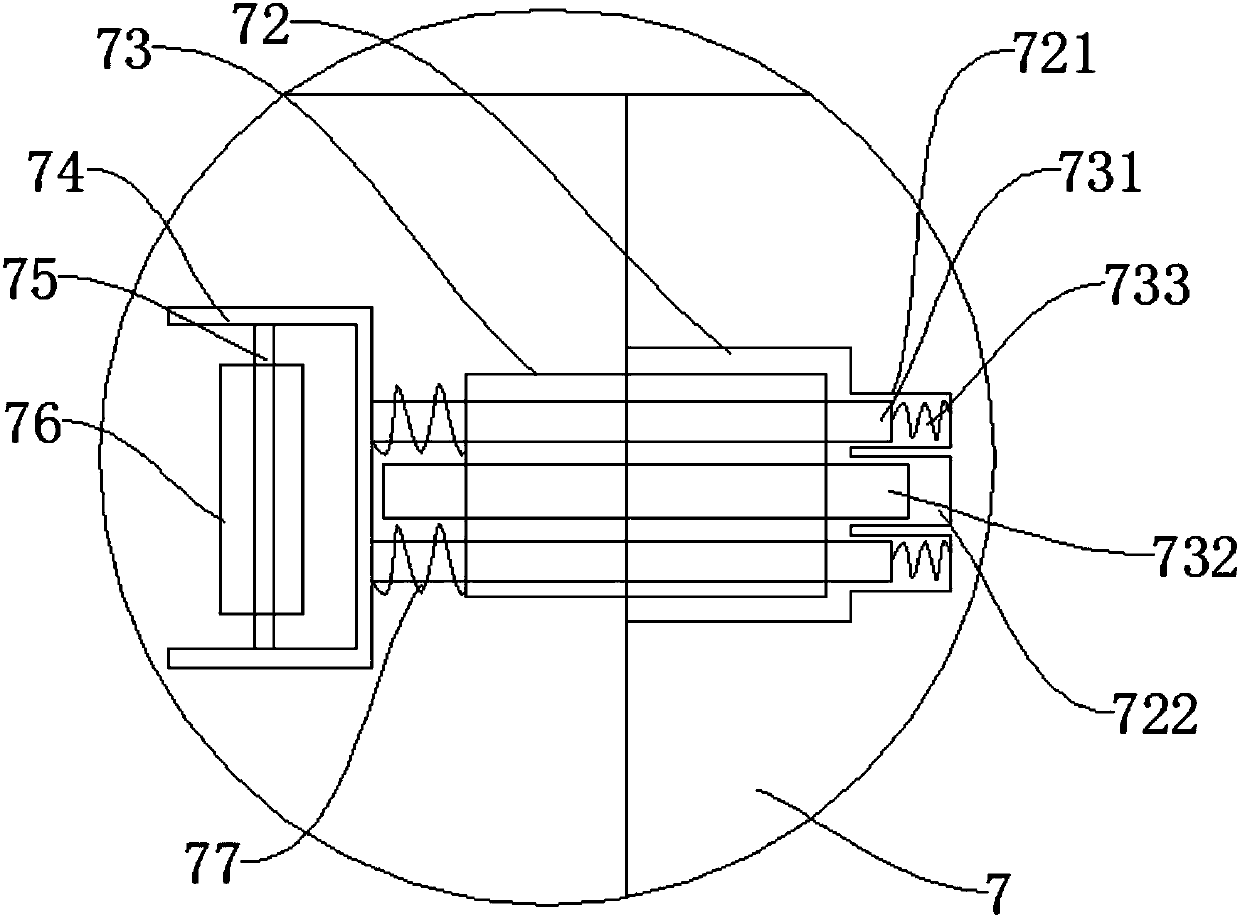

Plastic bucket conveying robot

The invention discloses a plastic bucket conveying robot. The robot comprises a working table, a base and two telescopic structures; a telescopic stand column is arranged on the upper surface of the working table, a fixed column is arranged on the upper end face of the stand column, a beam sleeve with one end provided with a punched hole is arranged outside the fixed column in a sleeving mode, a beam can rotate around the fixed column, two grabbing plates are arranged on the lower end face of the beam in the length direction in a spaced mode, and a material box is arranged below the beam; multiple driving wheels are arranged on the lower end face of the base; the telescopic structures are arranged between the base and the working table in the length direction of the base. The plastic bucket conveying robot can grab a plastic bucket, grabbing is stable, walking in the conveying process is stable, and the height is adjustable.

Owner:LIUZHOU FUNENG ROBOT DEV CO LTD

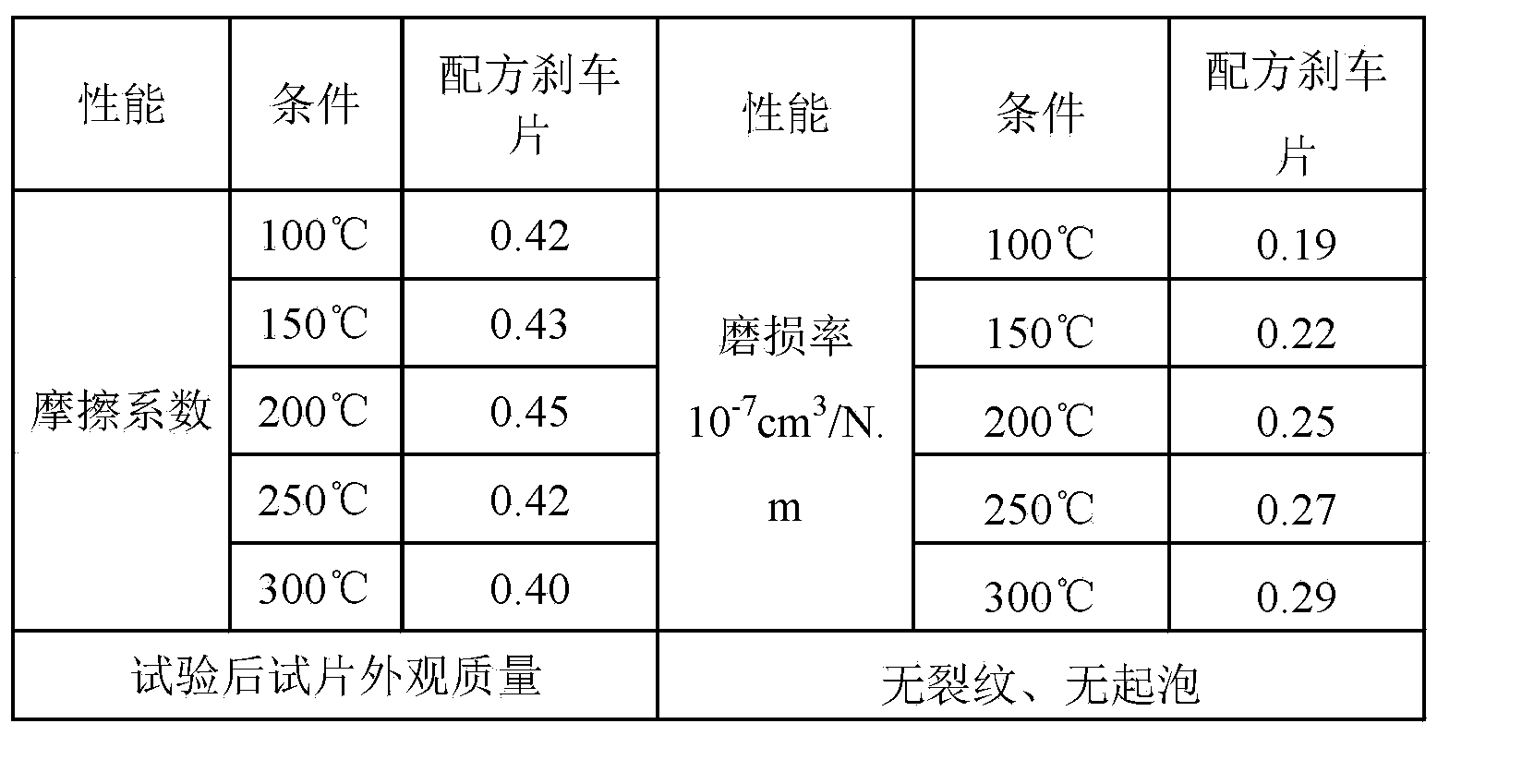

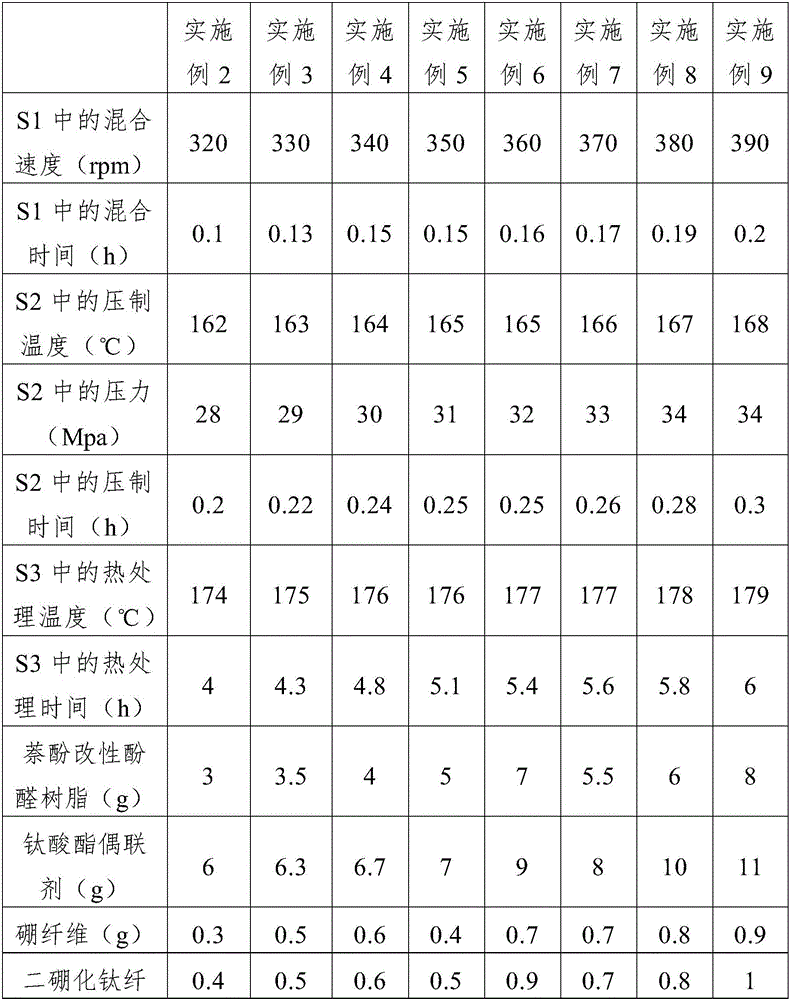

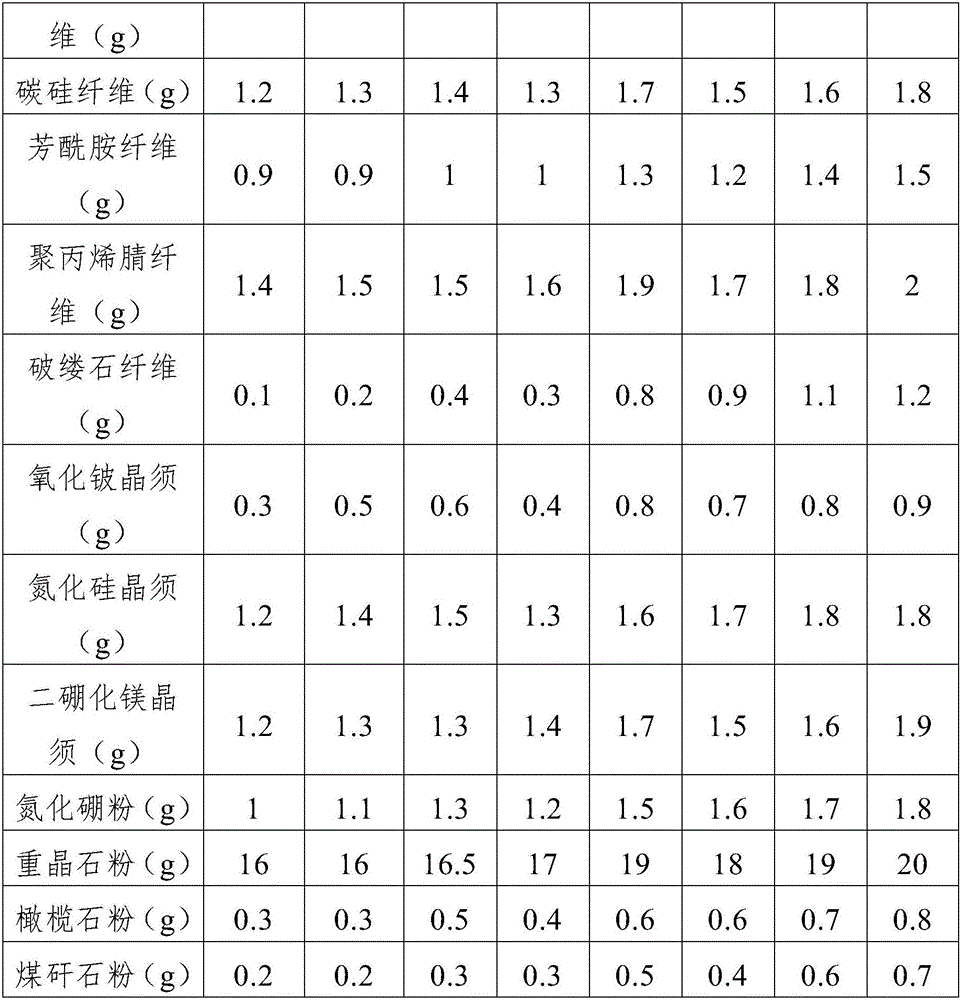

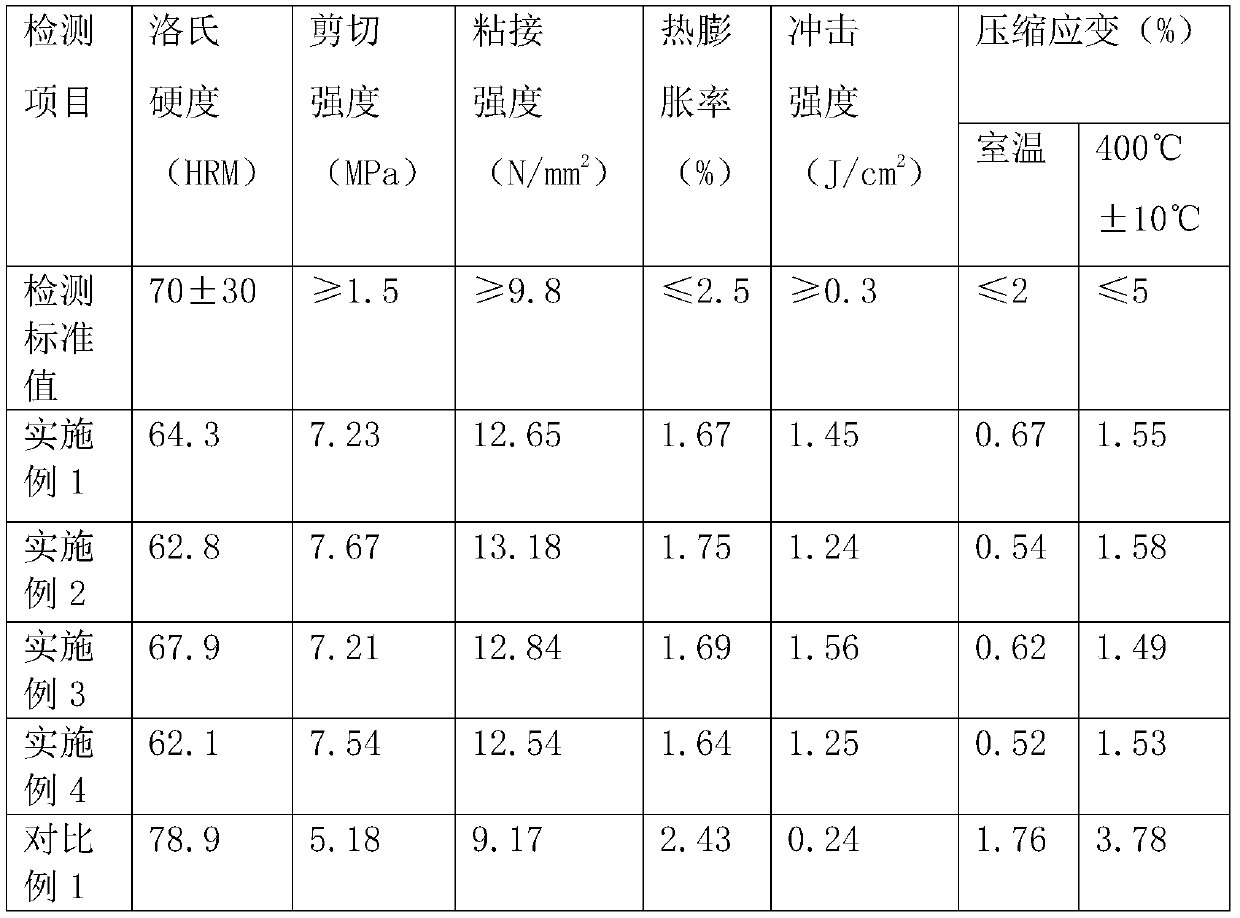

Friction material for brake pad, brake pad and brake pad preparation method

ActiveCN106763367AGood heat decay performanceImprove friction performanceOther chemical processesFriction liningCoal gangueSilicon nitride

The invention relates to the technical field of brake pads, in particular to a friction material for a brake pad, the brake pad and a brake pad preparation method. The friction material for the brake pad consists of the raw materials of: naphthol modified phenolic resin, titanate coupling agent, boron fiber, titanium diboride fiber, carbon silicon fiber, aromatic amide fiber, polyacrylonitrile fiber, Polvshi fiber, beryllium oxide whisker, silicon nitride whisker, boride whisker, boron nitride powder, barite powder, olive stone powder and coal gangue powder. The brake pad is manufactured by the friction material for the brake pad and a back plate. The brake pad preparation method comprises the steps of: pressing the friction material for the brake pad with the back plate, heat treatment, and size machining. The brake pad has the advantages of longer life, more comfortable braking, higher safety and more stable friction coefficient. The brake pad preparation method is simple in process.

Owner:FOSHAN JIAMULE TECH CO LTD

Novel rare earth compound type brake pad and preparation method thereof

InactiveCN103644224AReduce coefficient of frictionImproved heat decay performanceOther chemical processesBraking membersFiberRare earth

The invention discloses a novel rare earth compound type brake pad. The novel rare earth compound type brake pad comprises, by weight, 14-18% of modified phenolic resin, 25-30% of fiber materials, 25-35% of filling materials and 25-35% of rear earth materials, wherein the rear earth materials are composed of one or more kinds of lanthanum oxide, cerium oxide and praseodymium oxide, and the fiber materials are composed of one or more kinds of mineral fibers, glass fibers and paper fibers. The invention further discloses a preparation method of the novel rare earth compound type brake pad. The novel rare earth compound type brake pad is good in high-temperature resistance, excellent in abrasion resistance and large in impact resistance, and the preparation method is simple and low in cost.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Multifunctional grinding dust granules for car brake pad and preparation method thereof

InactiveCN105715718AEnable recyclingImproved heat decay performanceOther chemical processesFriction liningFiberCarbon fibers

The invention relates to multifunctional grinding dust granules for a car brake pad and a preparation method thereof. The method includes the following steps that 40-50 parts of grinding dust, 10-15 parts of NACF fibers, 10-15 parts of calcium carbonate whiskers, 10-15 parts of diatomaceous earth, 10-15 parts of cryolite, 15-20 parts of magnetite powder, 1-2 parts of antimony sulfide, 5-10 parts of barium sulfate, 3-5 parts of lithopone, 3-5 parts of crystalline flake graphite, 20-25 parts of potassium hexatitanate whiskers, 8-15 parts of F826 adhesives, 20-36 parts of spherical white vermiculite, 4-6 parts of nitrile butadiene rubber powder, 25-30 parts of aluminium silicate hollow spheres, 15-20 parts of sepiolite fibers, 8-15 parts of expanded graphite, 5-8 parts of tyre powder, 25-30 parts of carbon fibers and 15-20 parts of porous iron powder are mixed evenly, put into smelting equipment to be smelted and plastified, and smashed into the granules with the grain size being 8-20 meshes, so that the multifunctional grinding dust granules are obtained. The multifunctional grinding dust granules and the preparation method thereof have the advantages that the grinding dust can be recycled, the heat fading performance of a friction plate is improved, the working noise of the friction plate is low, the heat conductivity of the friction plate is good, the abrasion resistance of the friction plate is enhanced, and the service life of the brake pad is prolonged.

Owner:HENGYANG ANPIN AUTOMOBILE FITTINGS

Novel brake pad

ActiveCN104110455AImproved heat decay performancePromote recoveryOther chemical processesFriction liningAccelerantPhenol formaldehyde resin

The invention discloses a novel brake pad. The novel brake pad is obtained through the steps of weighing raw materials, namely, modified phenolic resin, fiber type raw material, filling type material and novel nitrile rubber powder, wherein the novel nitrile rubber powder is composed of a nitrile rubber powder body, sulphur, accelerants DM and carbon black, the fiber type raw material is composed of one or more of mineral fiber, glass fiber, steel fiber and wood fiber, and the filling type material is composed of one or more of graphite, barite, frictional powder and bauxite; uniformly mixing the modified phenolic resin and the filling type material, adding the novel nitrile rubber powder and the fiber type raw material to be uniformly mixed into a mixture, sending the obtained mixture and a brake pad back plate coated with rubber into the pressing process, conducting cold pressing to form a finished blank, controlling the pressure intensity to be within the range of 21MPa to 26MPa, conducting hot pressing and forming, controlling the temperature to be within the range of 143 DEG C to 151 DEG C, and obtaining the novel brake pad. The novel brake pad is high in high temperature resistance, excellent in abrasion resistance and high in anti-impact strength, and the blank manufactured through cold pressing and preforming has high strength and can be conveniently transported.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Highly abrasion resistant brake pad and preparation method thereof

InactiveCN103644229AImprove buffering effectImprove wear resistanceOther chemical processesFriction liningFiberGlass fiber

The invention discloses a highly abrasion resistant brake pad which comprises, by weight, 13-16% of modified phenolic resin, 28-33% of fiber materials, 45-55% of filling materials and 3-6% of Sinkiang white vermiculite, wherein the fiber materials are composed of one or more of mineral fibers, glass fibers and paper fibers. The invention further discloses a preparation method of the highly abrasion resistant brake pad. The highly abrasion resistant brake pad is stable in high-temperature friction coefficient and good in abrasion resistance, and the preparation method is simple, low in cost and suitable for Yunan, Guizhou and Sichuan regions and other regions with high mountains, steep roads and large brake loads.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

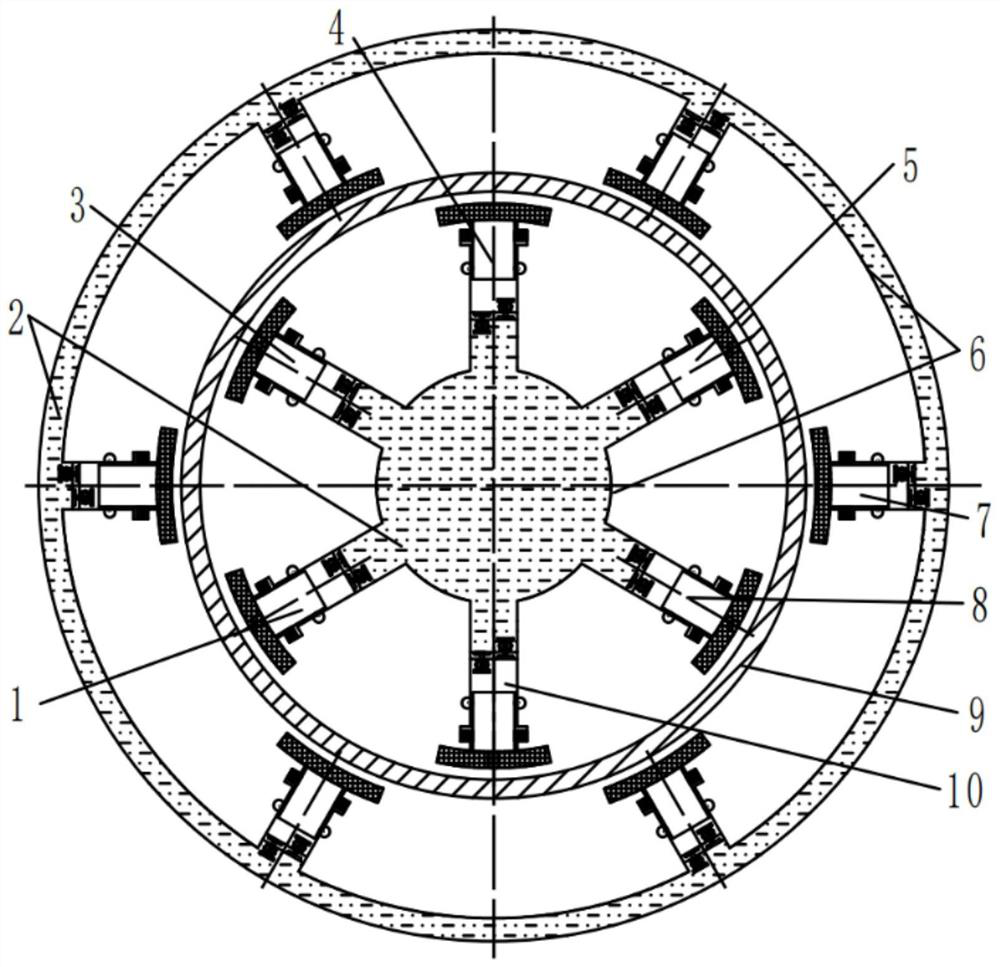

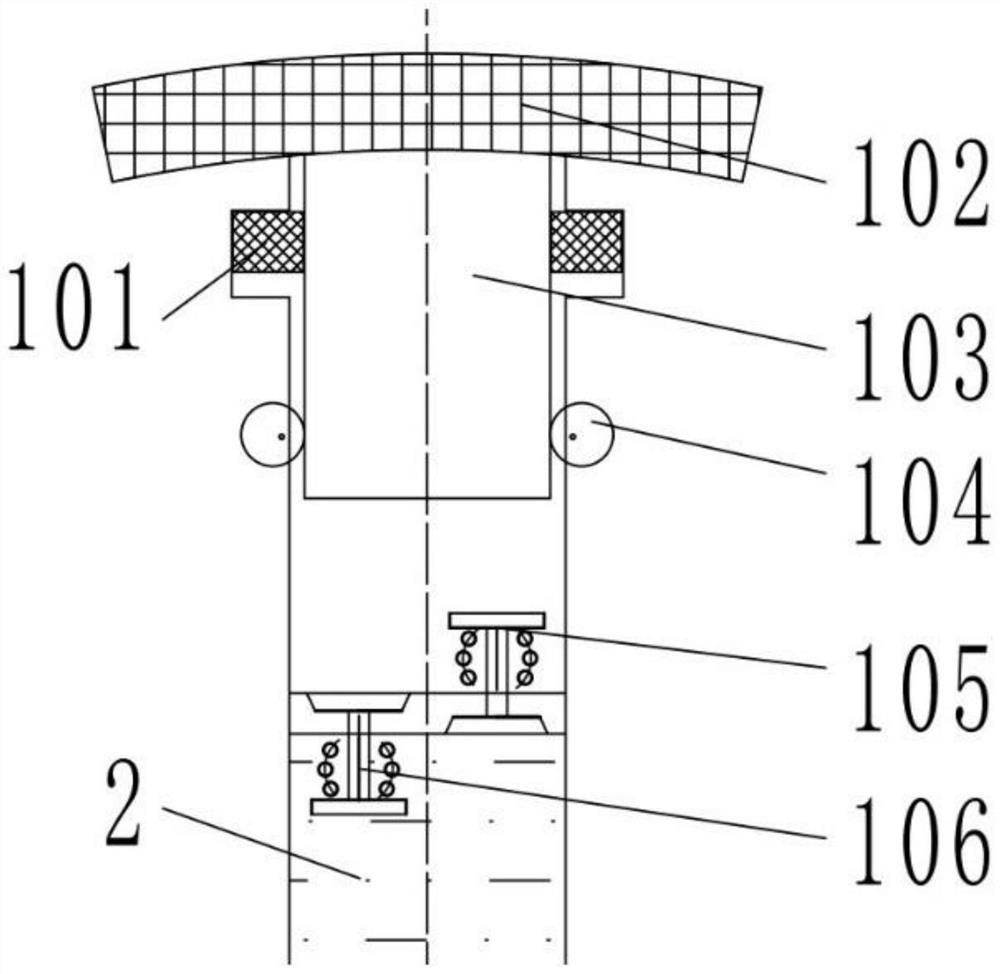

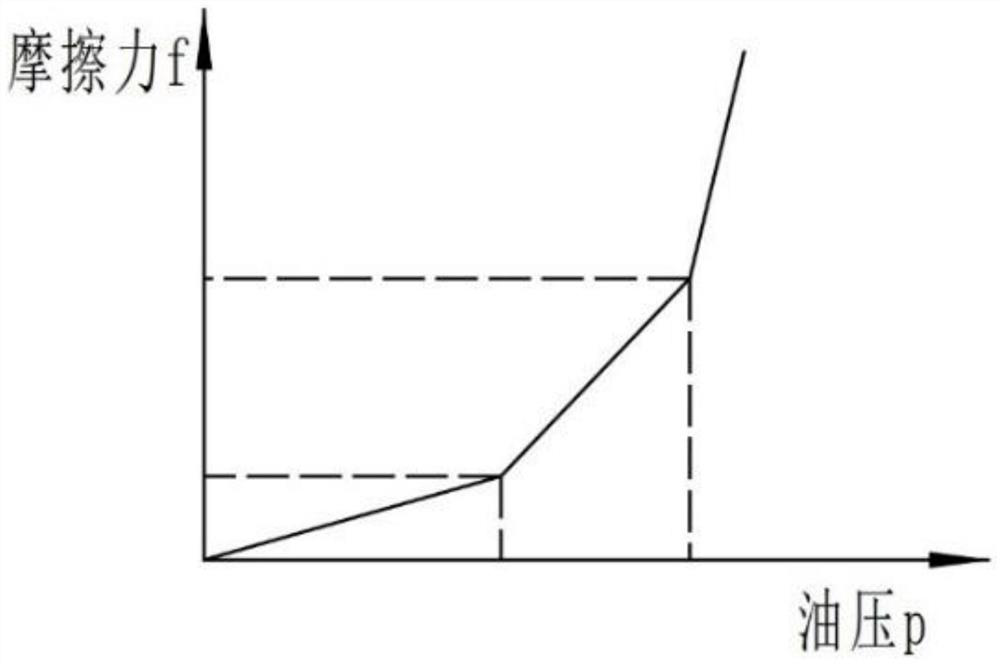

Multi-brake-shoe drum brake and working method

PendingCN113124072AIncrease contact areaGood heat decayBraking membersCombination drum brakesDrum brakePiston

The invention discloses a multi-brake-shoe drum brake and a working method. The multi-brake-shoe drum brake comprises internal expansion type brake mechanisms, a brake bottom plate, external bundling type brake mechanisms and a brake drum. The inner expansion type brake mechanisms and the outer bundling type brake mechanisms both comprise a rectangular sealing ring and a piston, an annular groove is formed in the inner wall of the brake bottom plate, the rectangular sealing rings are embedded into the annular groove, friction plates are installed at the top ends of the pistons, the outer side of a hydraulic brake wheel cylinder is connected with an oil pipeline, the oil pipeline is filled with oil, and the oil pipeline communicates with an inner cavity of the brake bottom plate. Partition plates are installed at the positions, on one sides of the pistons, in the brake bottom plate, the oil and the pistons are located on the two sides of the partition plates correspondingly, and one-way valves and back pressure valves are installed on the partition plates. According to the multi-brake-shoe drum brake and the working method, the brake drum is tightly pressed by using the internal expansion type brake mechanisms and the external bundling type brake mechanisms, and friction force is applied; and meanwhile, through the plurality of groups of back pressure valves with different opening pressures and the friction plates with different friction coefficients, the plurality of groups of internal expansion type brake mechanisms and external bundling type brake mechanisms can act in sequence.

Owner:江苏开沃汽车有限公司

Anti-oscillation plastic bucket conveying robot

InactiveCN107585556ANot easy to dropIncrease frictionControl devices for conveyorsSupporting framesDrive wheelEngineering

The invention discloses an anti-oscillation plastic bucket conveying robot. The anti-oscillation plastic bucket conveying robot comprises a base, a working table and two telescopic structures, whereinsupporting columns are mounted on the four corners of the lower end surface of the base, and a driving wheel is arranged at the lower end of each supporting column; a telescopic standing column is arranged on the upper surface of the working table, a fixing column is arranged on the upper end surface of the standing column, a cross beam with a through hole formed in one end portion is arranged outside the fixing column in a sleeving mode, the cross beam can rotate around the fixing column, two grabbing plates are arranged on the lower end surface of the cross beam in the length direction at intervals, and a material box is arranged below the cross beam; each telescopic structure is arranged between the base and the working table in the length direction of the base, and each telescopic structure comprises a first rotating rod, a second rotating rod and an I-shaped connecting part. The anti-oscillation plastic bucket conveying robot can stably grab a plastic bucket and stably travel inthe conveying process, and external collision can be prevented.

Owner:LIUZHOU FUNENG ROBOT DEV CO LTD

Low-resin-based aramid pulp wear-resistant disc brake pad and preparation method thereof

PendingCN113124076AImproved heat decay performanceReduce high temperature wearOther chemical processesFriction liningDisc brakePhenol formaldehyde resin

The invention provides a low-resin-based aramid pulp wear-resistant disc brake pad and a preparation method thereof. The low-resin-based aramid pulp wear-resistant disc brake pad comprises the following materials in percentage by weight: 6-9% of an organic binder, 25-35% of reinforcing material fibers, 10-20% of a friction performance regulator, 25-35% of an anti-wear lubricant, 5-10% of an elastic toughening agent, 5-8% of a high-temperature inorganic binder, 3-8% of a friction increasing agent and 15-30% of a space filler. An aramid pulp hybrid fiber reinforced low-content modified phenolic resin-based brake pad sample is prepared through a mold pressing method, and the formula research and development and the manufacturing technology of the aramid pulp low-resin-based wear-resistant disc brake pad are provided. The disc brake pad designed and prepared through the method has the characteristics of being high in strength, stable in friction coefficient, resistant to high temperature, resistant to abrasion and the like, braking is comfortable in the using process, noise is avoided, dust falling is little, the service life can reach 100 thousand kilometers or above, and the service life of a product is greatly prolonged.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

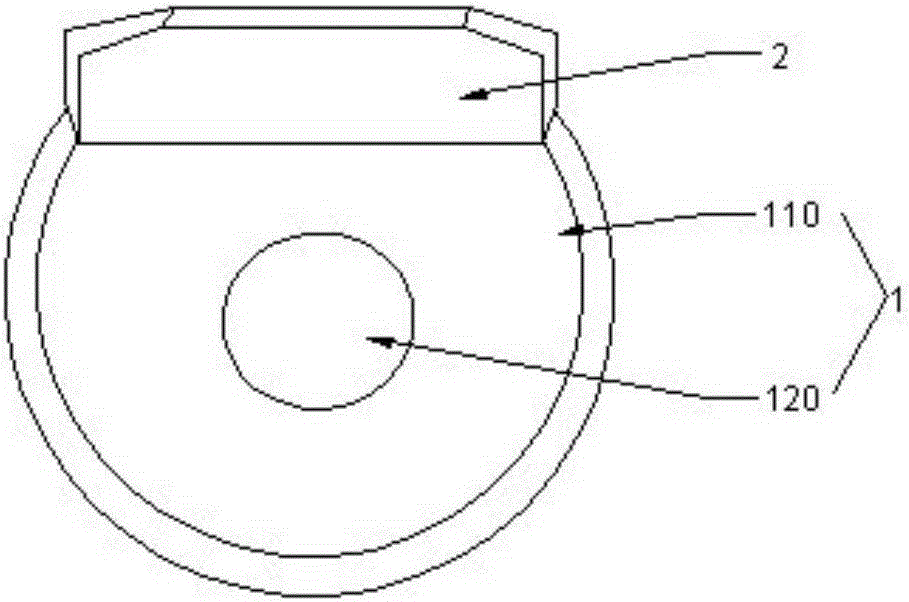

Automotive disk brake with good sealing performance

InactiveCN108869576AReturn in timeExcellent braking effect and stabilityAxially engaging brakesBrake actuating mechanismsHydraulic cylinderEngineering

The invention discloses an automotive disk brake with a good sealing performance. The automotive disk brake comprises a brake seat, a brake fluid guide tube is movably mounted at the upper end of thebrake seat, a pneumatic box is movably mounted at the upper end of the brake fluid guide pipe, a pneumatic piston is arranged in the brake fluid guide pipe, and a sealing pad for enhancing the sealingperformance is arranged between the pneumatic box and the pneumatic piston. A brake fluid flow guide tube is mounted at the upper end of the pneumatic box, a brake hydraulic cylinder is mounted at the upper end of the brake fluid flow guide tube, a pneumatic tube is movably mounted on one side of the pneumatic box, a cylinder is movably mounted on one side, far away from the pneumatic box, of thepneumatic tube, a pushing rod is fixedly mounted in the middle of one side, far away from the pneumatic tube, of the cylinder, and a brake pedal is fixedly mounted on one side, far away from the cylinder, of the pushing rod. In the use process, the automotive disk brake is more stable in brake, brake pressure is uniformly distributed, a brake arm can timely return after brake, a steel disc rubs with a brake pad to make a sound when the brake pad wears out, a driver is reminded to replace the brake pad, and the use process is optimized.

Owner:长兴微羽智能科技股份有限公司

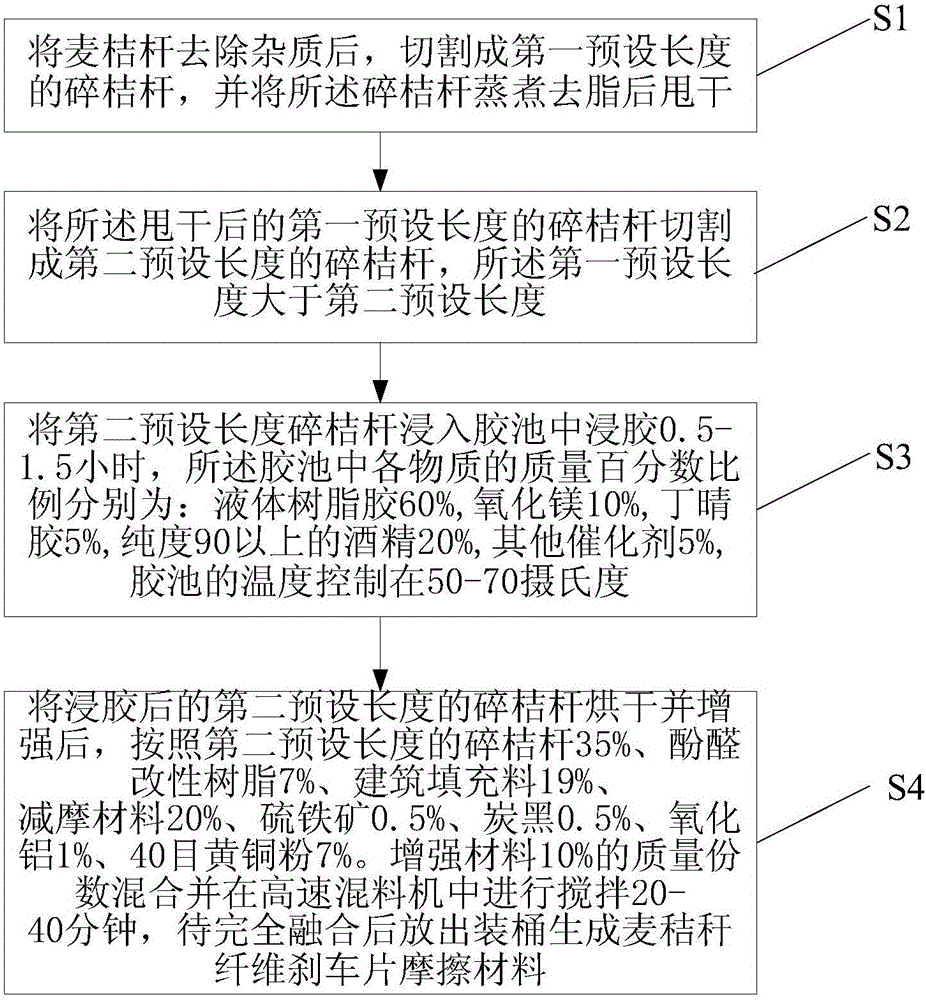

Production technique for wheat straw fiber brake disc friction materials

ActiveCN106090088AImproved heat decay performanceHigh hardnessOther chemical processesFriction liningFiberEngineering

The invention provides a production technique for wheat straw fiber brake disc friction materials. The production technique for the wheat straw fiber brake disc friction materials comprises the steps that wheat straw is cut into broken straw with a first preset length after impurities are removed, and the broken straw is spin-dried after being boiled and degreased; the spin-dried broken straw with the first preset length is cut into broken straw with a second preset length smaller than the first preset length; and the broken straw with the second preset length is placed in a glue pool to be dipped with glue for 0.5-1.5 hours, auxiliary materials are stirred in a high-speed mixer for 20-40 minutes, the mixture is discharged and barreled after being completely molten, and thus the wheat straw fiber brake disc friction materials are produced. The production technique for the wheat straw fiber brake disc friction materials has the advantages that the produced brake disc friction materials are low in noise and good in performance.

Owner:JIANGSU JINMAISUI NEW ENERGY TECH

Particles having noise reduction and high-temperature declining resistance functions and preparation method of particles

InactiveCN105650157AReduce hardnessReduce compactnessOther chemical processesFriction liningFiberAdhesive

The invention discloses particles having noise reduction and high-temperature declining resistance functions and a preparation method of the particles. A formula adopted in the method comprises 12 parts of NACF fibers by weight, 10 parts of spherical white vermiculite by weight, 12 parts of hollow aluminium silicate spheres by weight, 7 parts of cryolite by weight, 15 parts of magnetite powder by weight, 1 part of butadiene-acrylonitrile rubber powder by weight, 1 part of antimony sulfide by weight, 7 parts of barium sulfate by weight and 8 parts of an F826 adhesive by weight. A preparation technology of the particles comprises steps as follows: raw materials are evenly mixed as per the formula and placed into a double-roll rubber open mill for smelting, the raw materials are fused and plasticized, finally, plasticized materials are crushed to form particles with the particle size ranging from 8 meshes to 20 meshes, and the particles are obtained. The particles have the good sound absorption characteristic, the hardness and the compactness of friction plates can be effectively reduced, the friction plates absorb produced noise during working, the heat fading performance of the friction plates is improved, the friction coefficient of the friction plates at the high temperature is increased, and the high-temperature brake stability of automobiles is guaranteed.

Owner:HENGYANG ANPIN AUTOMOBILE FITTINGS

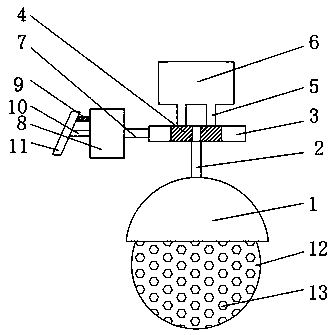

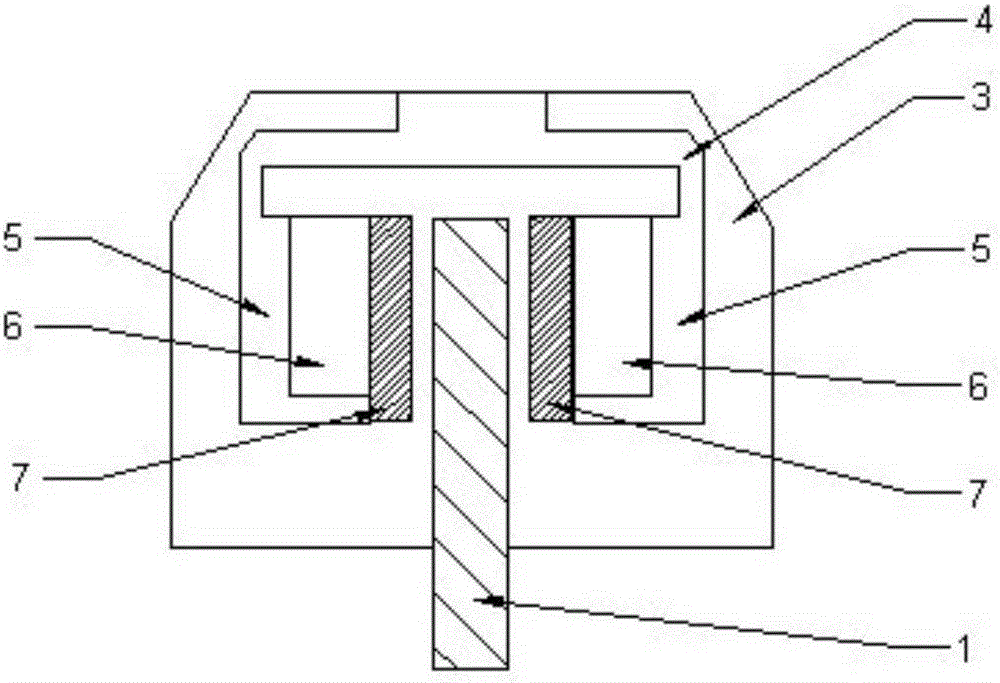

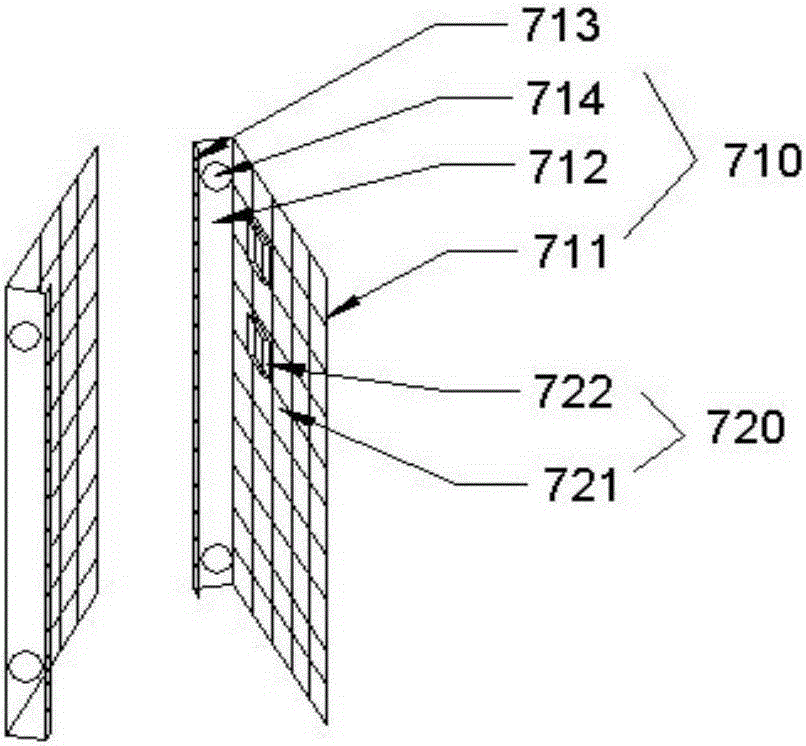

Safe braking device for automobile

The invention discloses a safe braking device for an automobile, wherein a braking pad in the braking device comprises a metal frame and frictional layers; and the metal frame of the braking pad comprises a central plate, a first plate body and a second plate body. According to the safe braking device for the automobile, the first plate body and the second plate body achieve combined action and can lock a braking disc better during braking; the frictional layers are arranged on both the central plate and the second plate body, so that braking can be carried out more quickly; holes formed in the first plate body facilitate heat dissipation of the braking pad, and slip is not prone to happen; epoxide resin modified by polytetrafluoroethylene, silicon carbide and the like serve as raw materials of the frictional layer, so that the heat-fading performance of the braking pad is excellent, and excellent heat resistance is achieved.

Owner:海宁经开产业园区开发建设有限公司

Hydraulic disc brake lining and preparation method thereof

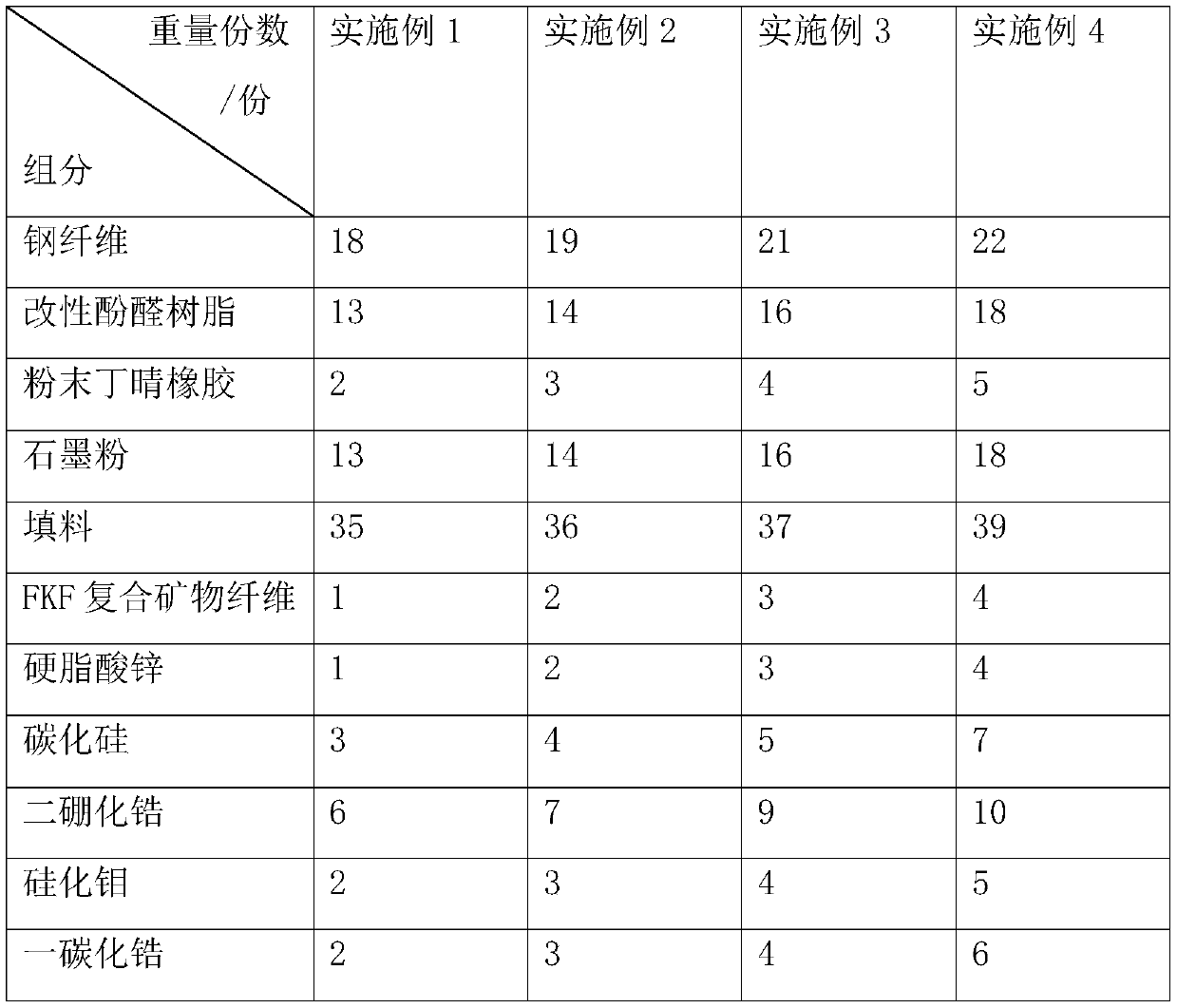

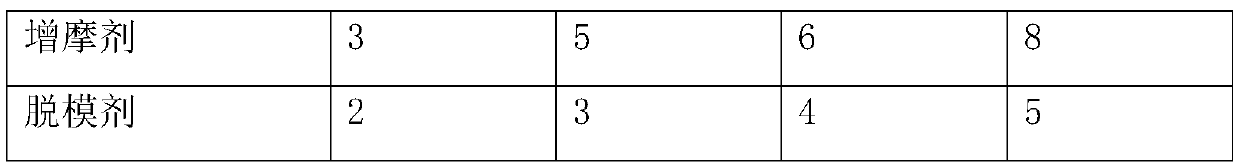

ActiveCN109185372BPrevent oxidationImprove heat resistanceOther chemical processesFriction liningEngineeringStearic acid

The invention discloses a hydraulic disc brake lining and a preparation method thereof. The hydraulic disc brake lining comprises the following components of, by weight, 18-22 parts of steel fibers, 13-18 parts of modified phenolic resin, 2-5 parts of powdery nitrile rubber, 13-18 parts of graphite powder, 35-39 parts of filler, 1-4 parts of FKF composite mineral fiber, 1-4 parts of zinc stearate,3-7 parts of silicon carbide, 6-10 parts of zirconium diboride, 2-5 parts of molybdenum silicide and 2-6 parts of zirconium carbide. The preparation method comprises the following steps that S1, primary mixing and material proportioning and preparing are performed; S2, secondary mixing and material proportioning and preparing are performed; S3, pre-forming is performed; S4, hot-pressing forming is performed; S5, heat treatment is performed; and S6, a product subjected to heat treatment undergoes grinding and drilling, and then is prepared into a finished product through machining. The hydraulic disc brake lining has the advantages of being good in heat resistance, water resistance and high temperature heat fade resistance, and capable of improving the high-temperature brake friction coefficient; and the preparation method has the advantages of being high in preparation precision and more accurate in size.

Owner:海宁易达自动化设备有限公司

A kind of wear-resistant brake pad and preparation method thereof

ActiveCN103644228BImproved heat decay performancePromote recoveryOther chemical processesFriction liningGlass fiberFiber

The invention discloses a wear-resistant brake pad. The wear-resistant brake pad comprises, by weight, 13-16% of modified phenolic resin, 28-33% of fiber materials, 45-55% of filler materials and 1.5-3% of sulfide, wherein the sulfide is formed by one or more of antimony sulfide, molybdenum disulfide and zinc sulfide, and the fiber materials are formed by one or more of mineral fibers, glass fibers and paper fibers. The invention further discloses a preparation method of the wear-resistant brake pad. According to the wear-resistant brake pad and the preparation method of the wear-resistant brake pad, the wear-resistant brake pad is stable in high-temperature friction coefficient and good in wear resistance, the preparation method is simple, the cost is low, and the wear-resistant brake pad and the preparation method of the wear-resistant brake pad are applicable to mountainous and humid areas of the Central America and the like.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Heat recession-resistant friction material and preparation method thereof

InactiveCN105713560AImproved heat decay performanceIncrease coefficient of frictionOther chemical processesFriction liningFiberAdhesive

The invention relates to a heat recession-resistant friction material. The heat recession-resistant friction material comprises the following components in parts by weight: 25-35 parts of NACF fiber, 15-20 parts of cryolite, 30-35 parts of magnetite powder, 3-6 parts of antimony sulfide, and 8-15 parts of an adhesive. A preparation method comprises the followings steps: S01, burdening the components in parts by weight; S02, uniformly mixing the components, placing the mixed components in melting equipment for melting the components and plasticizing the components; and S03, placing the plasticized components for crushing the components to obtain the granular product. The heat recession-resistant friction material is doped into a friction plate according to a certain proportion, so that the heat recession performance of the friction plate can be improved, friction coefficient of the friction plate at high temperature can be increased, and high temperature braking stability of the automobile can be guaranteed.

Owner:HENGYANG ANPIN AUTOMOBILE FITTINGS

Emergency brake device for automobile

ActiveCN105240424BImprove securityReduce spacingAxially engaging brakesBrake actuating mechanismsEngineeringBrake pad

Owner:海宁经开产业园区开发建设有限公司

Vibration-reducing noise-reducing yaw low-speed brake pad and manufacturing method thereof

ActiveCN103256325BStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

a brake pad

ActiveCN104110455BImproved heat decay performancePromote recoveryOther chemical processesFriction liningMaterials scienceRaw material

The invention discloses a novel brake pad. The novel brake pad is obtained through the steps of weighing raw materials, namely, modified phenolic resin, fiber type raw material, filling type material and novel nitrile rubber powder, wherein the novel nitrile rubber powder is composed of a nitrile rubber powder body, sulphur, accelerants DM and carbon black, the fiber type raw material is composed of one or more of mineral fiber, glass fiber, steel fiber and wood fiber, and the filling type material is composed of one or more of graphite, barite, frictional powder and bauxite; uniformly mixing the modified phenolic resin and the filling type material, adding the novel nitrile rubber powder and the fiber type raw material to be uniformly mixed into a mixture, sending the obtained mixture and a brake pad back plate coated with rubber into the pressing process, conducting cold pressing to form a finished blank, controlling the pressure intensity to be within the range of 21MPa to 26MPa, conducting hot pressing and forming, controlling the temperature to be within the range of 143 DEG C to 151 DEG C, and obtaining the novel brake pad. The novel brake pad is high in high temperature resistance, excellent in abrasion resistance and high in anti-impact strength, and the blank manufactured through cold pressing and preforming has high strength and can be conveniently transported.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

A cement-containing non-asbestos brake pad and preparation method thereof

A disclosed cement-containing asbestos-free brake disc comprises the raw materials in percent by weight: 14-18% of modified phenolic resin, 28-33% of a fiber material, 40-50% of a filling material and 3-9% of cement, wherein the fiber material is composed of one or more of mineral fiber, glass fiber and paper fiber, cement is composed of one or more of portland cement, ordinary portland cement, slag portland cement, portland-pozzolana cement, portland fly-ash cement, composite portland cement, medium-heat portland cement, low-heat portland slag cement and white portland cement. The invention also discloses a preparation method of the cement-containing asbestos-free brake disc. The cement-containing asbestos-free brake disc is high in impact strength and good in high-temperature wear resistance; and the preparation method of the cement-containing asbestos-free brake disc is simple and relatively low in cost.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Apocynum venetum fiber doped high environmentally-friendly type ceramic saloon car brake pad and preparation method thereof

ActiveCN102329475BStable coefficient of frictionReduce wearFriction liningOrganic baseAdditive ingredient

The invention relates to a ceramic saloon car brake pad which comprises the following ingredient components: modified phenolic resin, ceramic fiber, gelatin-spraying aluminum silicate fiber, aramid fiber, apocynum venetum fiber, red copper fiber, graphite, potassium hexatitanate whisker and BaSO4, wherein before being used, apocynum venetum needs to be subjected to modification as follows: the apocynum venetum fiber soaked by water is put in a NaOH solution for alkali treatment, then the apocynum venetum fiber subjected to alkali treatment is put in a high-pressure container for pressure maintaining treatment, and finally, fire retardant treatment is carried out on the surface of the apocynum venetum fiber. The invention also provides a preparation method of the ceramic saloon car brake pad. The apocynum venetum fiber doped saloon car brake pad has the advantages of stable frictional factor, high temperature resistance, small antithesis abrasion, good abrasive resistance and corrosionresistance, small heat-fading property, small noise, good comfortableness, environmental friendliness, thereby being an ideal substitute material of an asbestos-free organic based brake pad.

Owner:JIANGSU ANJIE AUTO PARTS

A kind of method adopting basalt fiber to prepare automobile brake pad

ActiveCN106949179BImprove performanceExtended service lifeOther chemical processesFriction liningPolymer scienceCarbon fibers

The invention relates to a method of preparing an automobile brake pad by adopting basalt fiber. The method comprises the following steps: butadiene nitrile rubber modified phenolic resin, surface modified basalt superfine fiber, acicular wollastonite fiber and carbon fiber are added to a material mixing machine and are mixed; then crystalline flake graphite, artificial graphite particles, chromite powder, feldspar powder, dolomite powder, fluorite powder, calcium carbonate powder, mica, nano ZnO, butadiene nitrile rubber and wollastonite are sequentially added to the material mixing machine and mix is carried out; a mixture is placed in a brake pad mould, and hot pressing and demoulding are carried out; a hot pressed material after the demoulding is subjected to grading heat treatment; and a discharged brake pad is subjected to follow-up treatment and packing. The automobile brake pad prepared by the method has a stable friction coefficient and a low wear rate, and further has high heat resistance and heat-aging resistance.

Owner:HUANGSHI JINZHAOYANG POWDER MATERIALS

A brake pad for disc brakes

ActiveCN103883653BReduce brake noiseReduce vibrationBraking elementsFriction liningEngineeringNoise suppression

The invention discloses a brake pad for a disc brake. The brake pad comprises a friction layer and a steel backing layer, the steel backing layer is positioned above the friction layer and adhered to the same through a metal binding agent, a braking face of the friction layer is provided with a plurality of arc grooves which are distributed transversely and penetrate through the friction layer, and skewed slots which are distributed obliquely, longitudinally and uniformly and lead to the edge of the friction layer are formed in the outer sides of the arc grooves on two sides. A layer of rhombus net grooves is graved on a face, fitting with the friction layer, of the steel backing layer. Two cylindrical bosses are symmetrically arranged on the upper surface of the steel backing layer, and the outer edges of the bosses are provided with asterisk-shaped reinforcing ribs. The brake pad for the disc brake has the advantages of vibration reduction, noise suppression, long service life, high stability, good heat effect, high safety, effectiveness in improvement of safety of the brake and good application prospect.

Owner:JIANGSU HENGLI BRAKE MFG +1

Granules with high-temperature decay-resistant function and large porosity and preparation method of granules

InactiveCN105650172AImproved heat decay performanceIncrease coefficient of frictionOther chemical processesFriction liningFiberPorosity

The invention provides granules with a high-temperature decay-resistant function and large porosity and a preparation method of the granules. Formulas used in the method are as follows: NACF fibers, cryolite, magnetite powder, kieselguhr, barium sulfate, antimony sulfide, fibrous sepiolite, white vermiculite, expanded graphite, tire powder and an F826 adhesive. A preparation technology comprises the following steps: evenly mixing raw materials according to the formulas; feeding into a double-roll rubber open mill for smelting, and fusing and plasticizing the raw materials; and finally pulverizing the plasticized materials into granules with grain sizes of 8-20 meshes so as to obtain the product of the invention. The granules can improve thermal decay performance of a friction plate, increase the friction coefficient of the friction plate at high temperature, guarantee stability of high-temperature brake of an automobile, and meanwhile has good sound absorption property and small density and compactness, so that the purposes of reducing brake noises and reducing abrasion of a brake disc are achieved.

Owner:HENGYANG ANPIN AUTOMOBILE FITTINGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com