Friction material for brake pad, brake pad and brake pad preparation method

A friction material and brake pad technology, applied in the field of brake pads, can solve the problems of unstable friction coefficient of brake pads, shortened life of brake pads, poor thermal ablation properties, etc., and achieve excellent thermal decay performance, stable friction coefficient, and friction performance optimization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

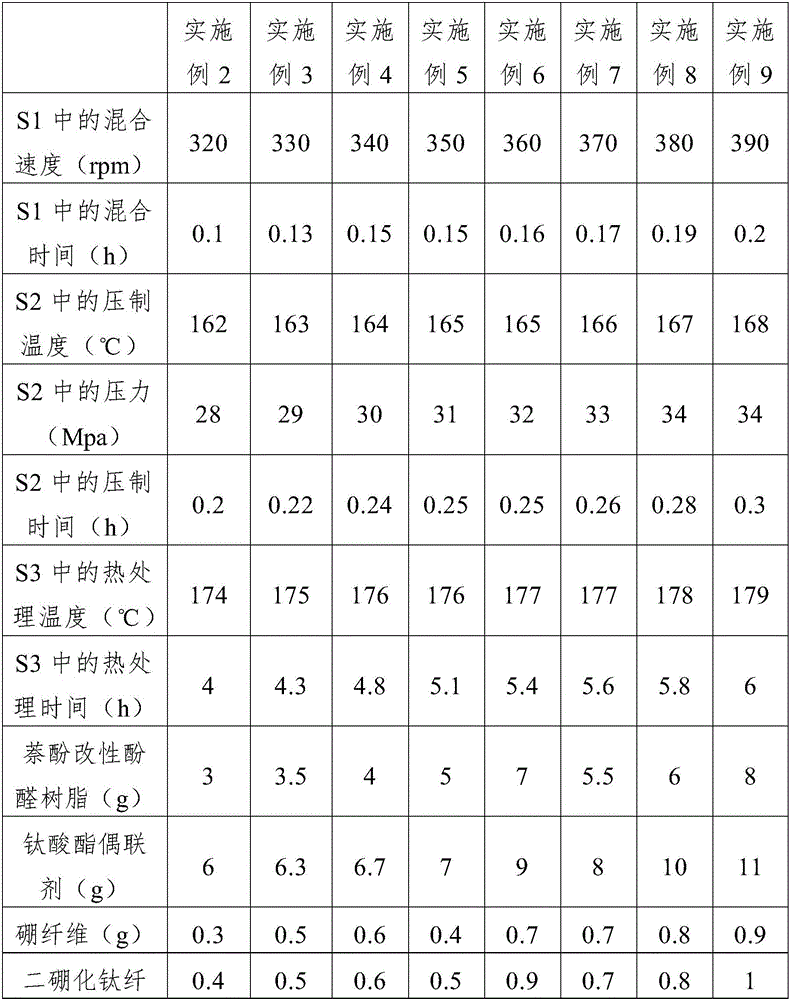

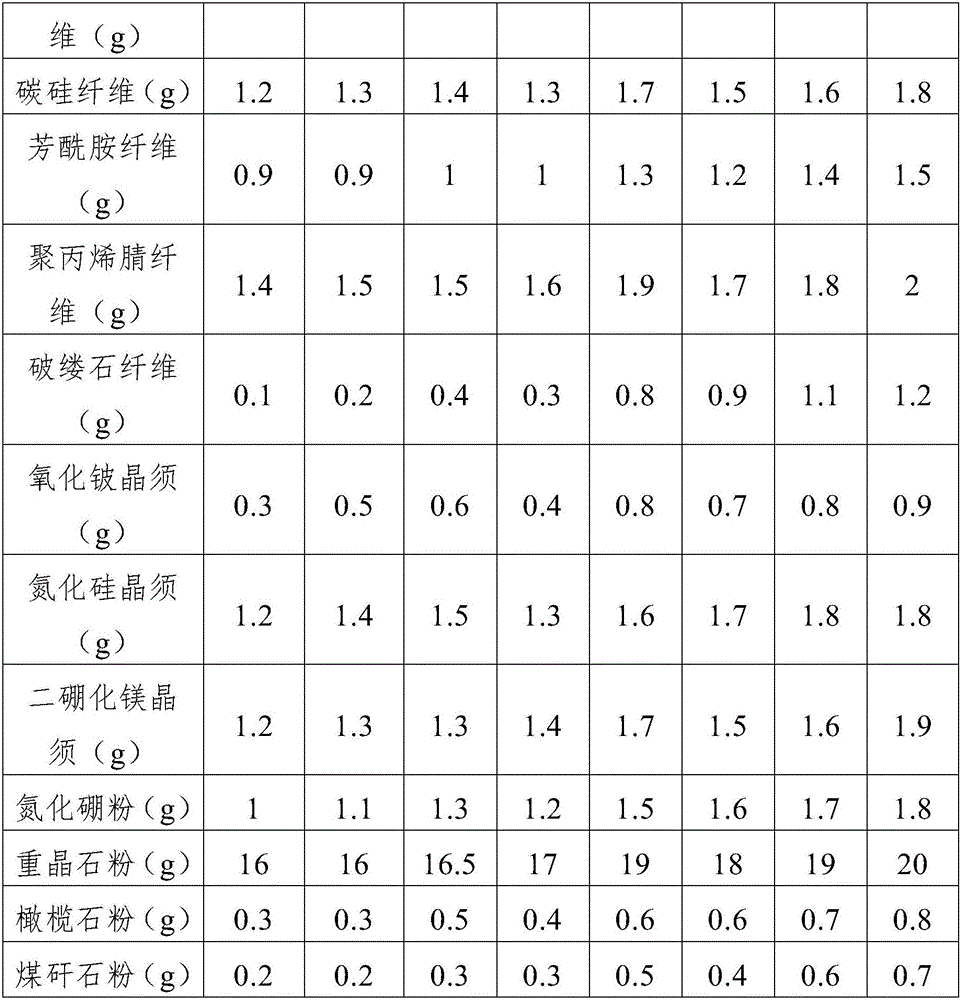

Examples

Embodiment 1

[0047] Select the following raw materials: 6g naphthol modified phenolic resin, 8g titanate coupling agent, 0.5g boron fiber, 0.6g titanium diboride fiber, 1.4g carbon silicon fiber, 1.2g aramid fiber, 1.8g polyacrylonitrile fiber, 0.6g poachite fiber, 0.6g beryllium oxide whisker, 1.4g silicon nitride whisker, 1.6g magnesium diboride whisker, 1.4g boron nitride powder, 18g barite powder, 0.5g olivine powder and 0.4g coal gangue powder.

[0048] Specifically, the brake pad preparation method of this embodiment includes the following steps:

[0049]S1: Select the raw materials of friction material for brake pads of the above quality and mix them to form friction material, the mixing speed is 340rpm, and the mixing time is 0.15h;

[0050] S2: Send the friction material and the back plate of the brake pad into the press for pressing. The pressing temperature is set to 164°C, the pressure is set to 31Mpa, and the pressing time is set to 0.25h to obtain the semi-finished product o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com