Patents

Literature

34results about How to "Comfortable braking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asbestos-free small mount of metal disk brake lining used in vehicle and manufacture method therefor

The invention discloses a kind of disk brake staff facing used in cars with none asbestos and little metal and the production technology. Its friction material includes bed charge and plus material. The bed charge includes: mineral fiber 35~50%, barite powder 10~20%, heavy calcium carbonate 10-20%, the oil of cashew shell phenol-formaldehyde resin modified 20~30%, flour acrylonitrile butadiene rubber 2~15%. The match of plus material: kaflar fiber 0.1~3%, steel fiber 20~35%, copper fiber 1~5%, particle graphite 6~18%, oil coke blacking 5~15%, the oil of cashew shell friction-type mix 2~8%, sericite in powder 5~10%, antimony trisulfide 0.5~5%, heavy calcium carbonate 2-8%, barite powder 10~20%, flour acrylonitrile butadiene rubber 2~6%, the oil of cashew shell phenol-formaldehyde resin modified 6~15%. After made the bed charge and the plus material weight them in proportion then chill-pressing confectioning and heat pressing confectioning steps and so on and then rivet accessory at last treatment make up the products. It needs low abrasion and has no noise.

Owner:福建冠良汽车配件工业有限公司

Novel brake pad material of truck

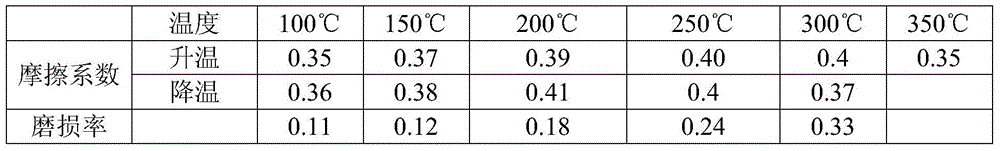

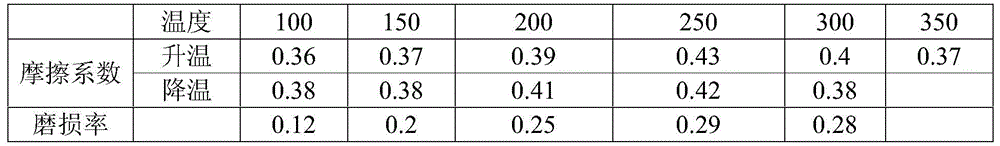

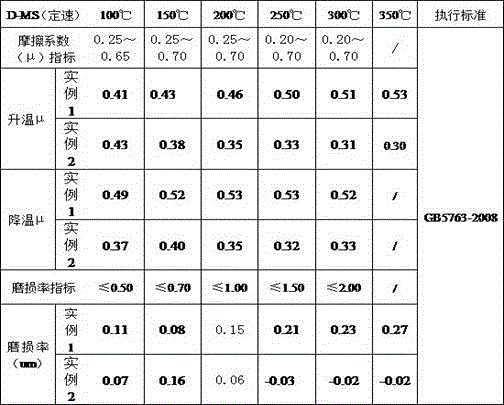

InactiveCN101555399AStable coefficient of frictionStable recovery performanceOther chemical processesFriction liningLow speedEngineering

The invention relates to a frictional material, in particular to a novel brake pad material of truck. The invention provides a novel brake pad material of a truck, wherein the novel brake pad material is used in a dry one-step hot press molding process applied to a nanocopper modified phenolic resin agglutination technology and a parent material modifying and adjusting technology. The raw material mixing ratio of the novel brake pad material is as below: 15%-20% of binder, 30%-50% of framework material, 10%-15% of friction enhancing agent, 5%-10% of anti-friction agent and 20%-30% of filling material. The binder is nanocopper modified phenolic resin, the framework material is mineral fibre and the like, the friction enhancing agent is great-hardness chromium ore power, and the like, the anti-friction agent is low-hardness graphite, and the like, the filling material is BaSO4, coarse whiting, and the like. The novel brake pad material has the advantage that a brake lining has a stable friction factor, stable recovery performance, good heat resistance, no crack performance, low speed sensitivity, good wearability and no braking noise.

Owner:SHANDONG DAWANG XINYI AUTOMOBILE FITTING

Method for preparing brake block by calcium sulfate crystal whisker

InactiveCN101177601AEasy to compressImproved high-temperature heat-fading propertiesOther chemical processesFriction liningAdhesiveAramid

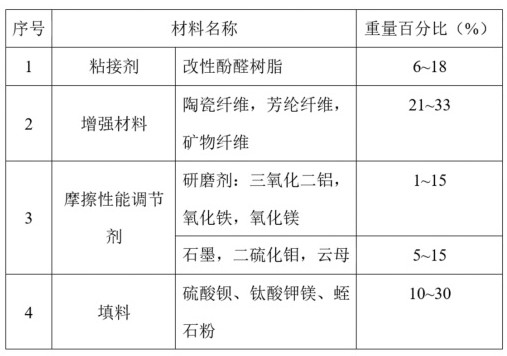

The invention relates to a method of using calcium sulfate whisker in the friction material field to prepare a brake block. The technical proposal of the invention consists of the following materials by weight: 5-18 portions of adhesive which is produced by employing modified phenolic resin; 20-40 portions of strengthening materials which are mixed by one or several of calcium sulfate whisker and one of aramid fiber, steel fiber, ceramic fiber and mineral fiber and glass fiber; 1-15 portions of grinding agent which is compounded by one or several of aluminum oxide , ferric oxide and magnesium oxide; 5-15 portions of lubricant which is compounded by one or several graphite, molybdenum disulfide and mica; and 10-30 portions of fillers which are compounded by one or several barium sulfate, potassium titanate and vermiculite powder. The brake block prepared by the method is able to lower the thermal fading of organics caused by thermal decomposition under high temperature, and has stable friction coefficient; when in use, the brake block has comfortable brake, being quiet, small abrasion and more than 70,000 kilometers of service life.

Owner:信义集团公司

Non-asbestos micro-metal mineral fiber disk type brake block for automobile

InactiveCN104533998ASensitive brakesBrake pads require sensitive brakingOther chemical processesFriction liningAcrylonitrileStearic acid

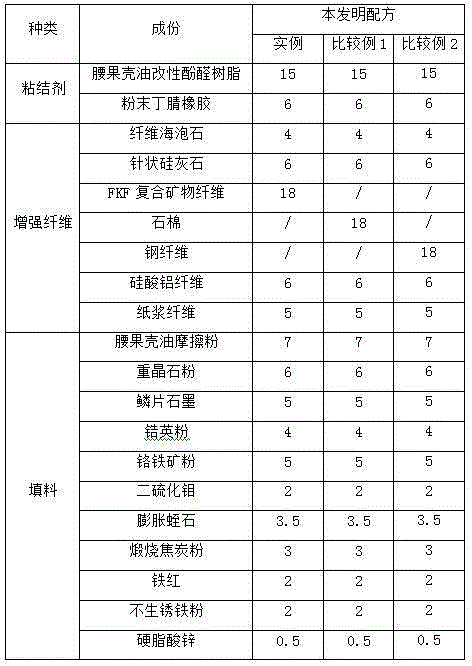

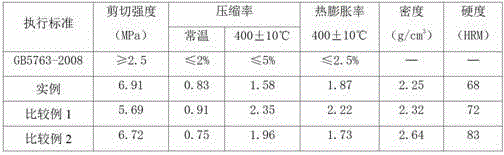

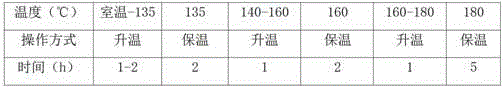

The invention discloses a non-asbestos micro-metal mineral fiber disk type brake block for an automobile. The non-asbestos micro-metal mineral fiber disk type brake block comprises, by weight, 10-20% of cashew nut shell oil modified phenolic resin, 3-8% of powder butadiene-acrylonitrile rubber, 3-8% of fibrous sepiolite, 5-10% of needle-like wollastonite, 15-20% of FKF composite mineral fiber, 5-10% of alumina silicate fiber, 2-6% of paper pulp fiber, 5-10% of cashew nut shell oil friction powder, 5-13% of blanc fixe, 3-15% of crystalline flake graphite, 1-10% of zircon powder, 0.1-0.7% of zinc stearate, 4-7% of chromite ore fines, 1-3% of molybdenum disulfide, 3-6% of expanded vermiculite, 1-5% of calcined coke powder, 1-5% of iron oxide red and 1-6% of rustless iron powder. The production process comprises the steps that the components are pre-mixed and mixed through an automatic mixer, the amount of finally-formed materials is weighted according to the required specification of the disk type brake block, a cold blanket is formed after cooling forming, hot press forming and heat processing are carried out, and the finished product is manufactured through fine machining. The non-asbestos micro-metal mineral fiber automobile disk type brake block has the advantages of being stable in friction abrasion performance, good in mechanical property, excellent in heat recession resisting performance and long in service life.

Owner:福建冠良汽车配件工业有限公司

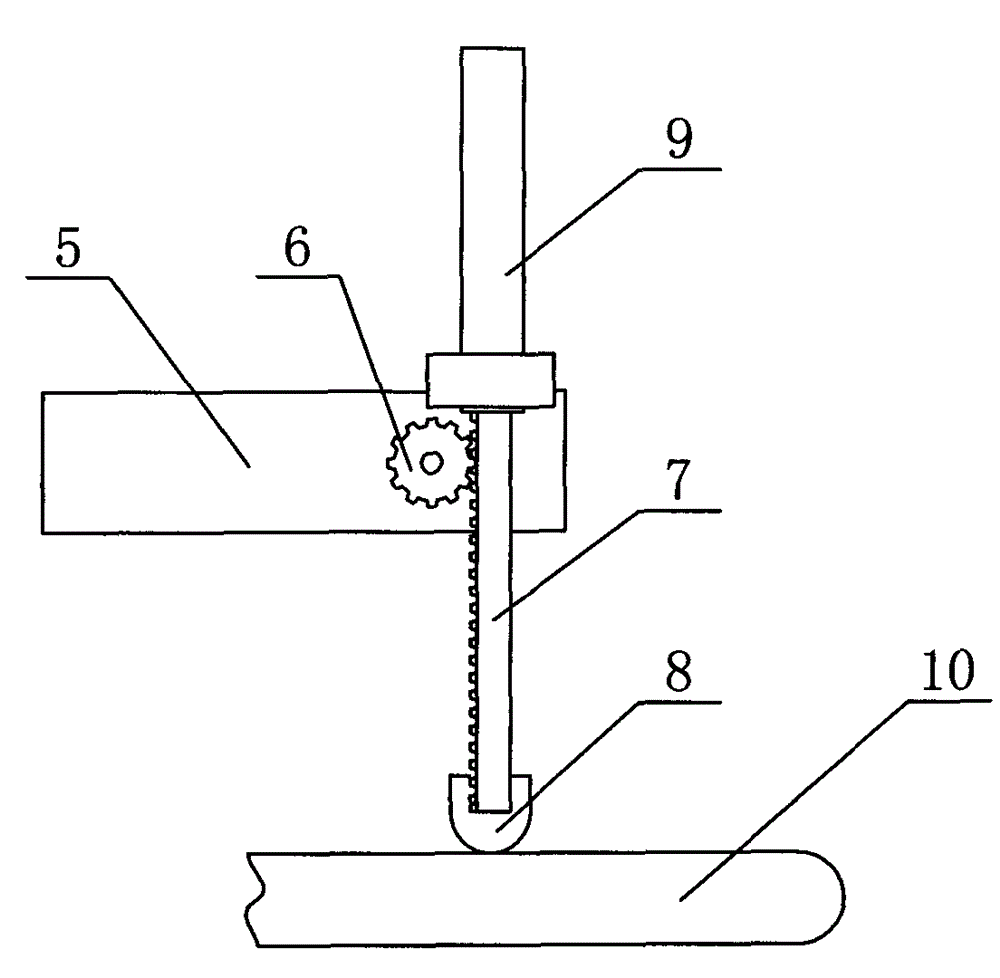

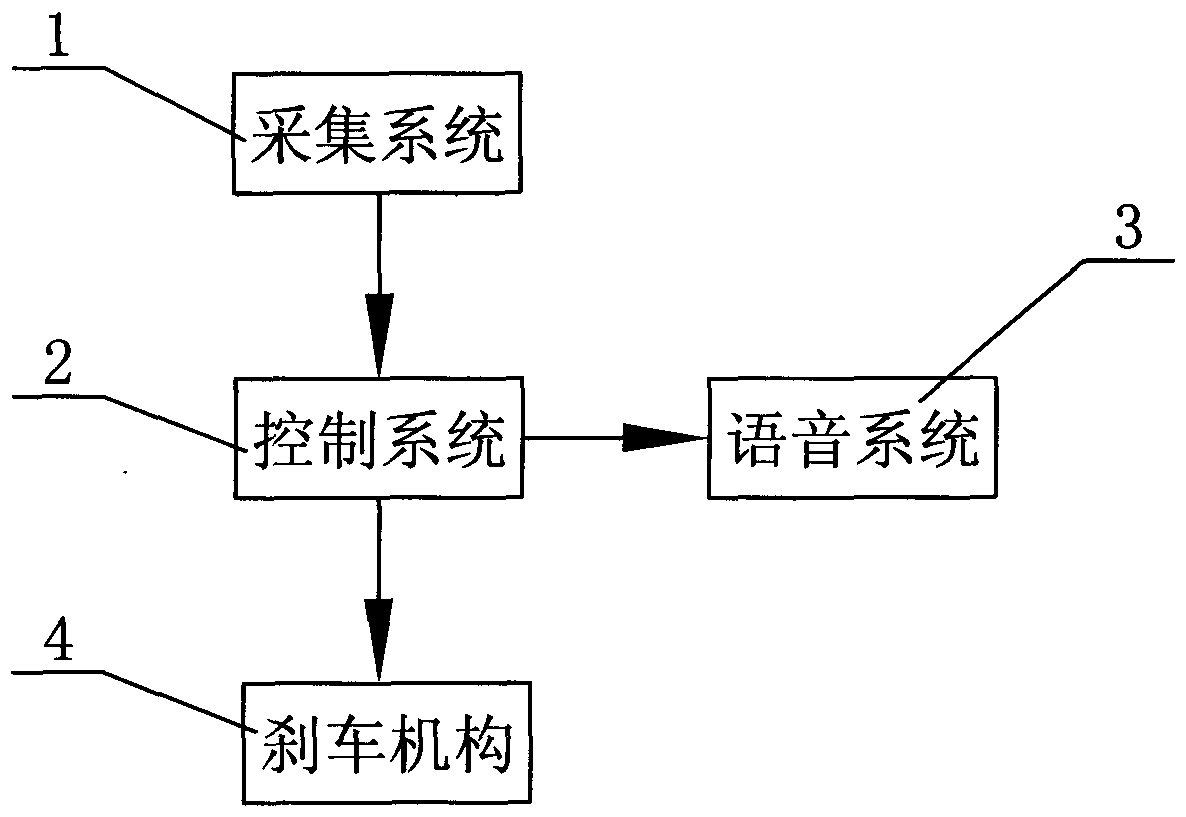

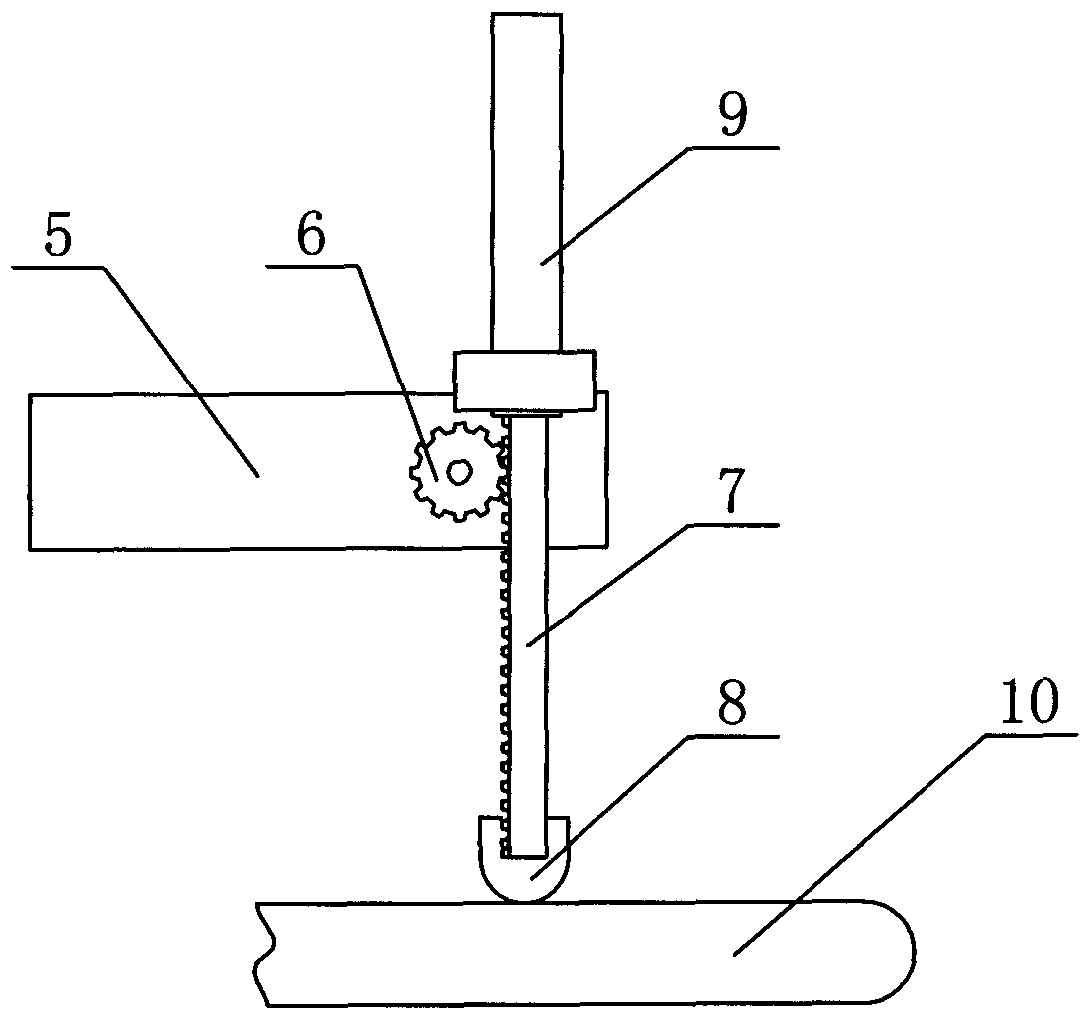

Vehicle reversing anti-collision system

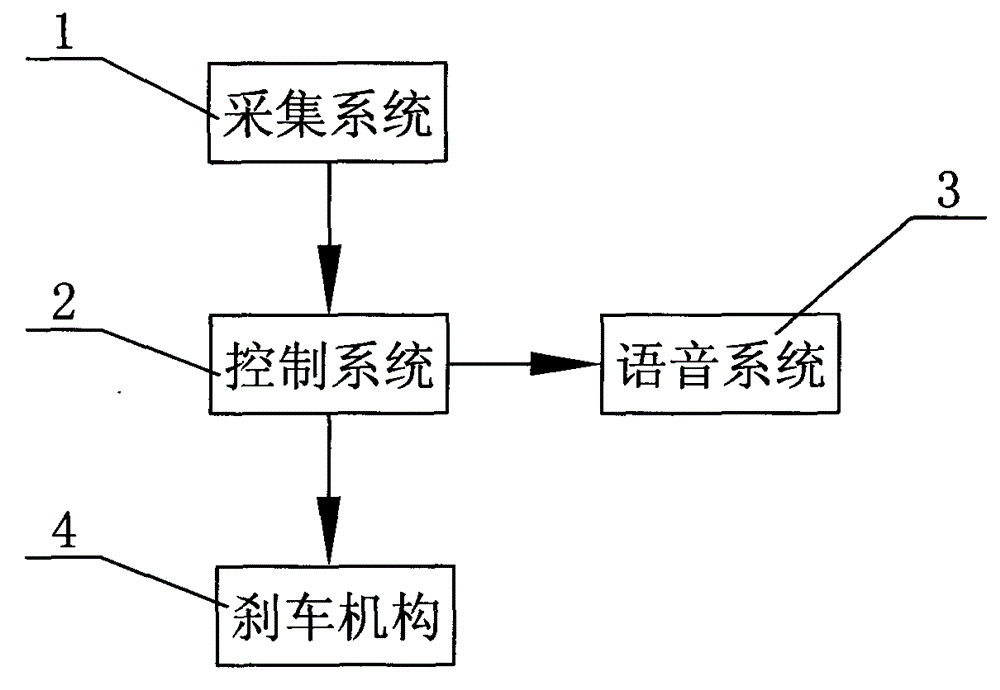

ActiveCN104802781AAvoid crashesImprove maneuverabilityAcoustic signal devicesAutomatic initiationsCar drivingCollision system

The invention relates to a vehicle reversing anti-collision system, which comprises a collection system, a control system, a voice system and a brake mechanism; the collection system is arranged at the tail of a vehicle; the control system is arranged in a trunk of the vehicle; the voice system is arranged at a multimedia chamber of the vehicle; the brake mechanism is arranged under an instrument panel of a driving cab of the vehicle and corresponds to a vehicle brake pedal. An ultrasonic principle is used, an ultrasonic sensor is additionally arranged at the tail of the vehicle, the distance between a reversed vehicle and an obstacle is automatically measured by the ultrasonic sensor, and then a driver is prompted. Meanwhile, according to the distance between the reversed vehicle and the obstacle, an automatic brake device is controlled to automatically brake, so the reversed driven vehicle is automatically alarmed and braked, occurrence of vehicle collision accidents is effectively prevented, the operability of the vehicle is improved and vehicle safety is ensured.

Owner:王柳坤

Copper-free carbon-based friction material

InactiveCN102585767AImprove heat resistanceImprove recession resistanceOther chemical processesCarbon fibersAdhesive

The invention relates to the technical field of preparation of friction materials in the automobile industry field and provides a material for improving heat resistance and recession-proofness of a friction material. A copper-free carbon-based friction material comprises the following components in percentage by weight: 7-18 percent of adhesive, 5-15 percent of friction performance modifier, 20-33 percent of reinforcing material and 10-30 percent of stuffing; the adhesive is compound modified phenolic resin; the reinforcing material is carbon fiber, aramid fiber, mineral fiber or glass fiber; the friction performance modifier is a grinding agent including aluminium oxide, ferric oxide and magnesium oxide; the friction performance modifier further comprises graphite, molybdenum disulfide and mica with weight percentage of 5-15%; and the stuffing comprises barium sulfate, potassium titanate and vermiculite powder. A brake pad produced by using the material disclosed by the invention has the advantages of no heat recession at high temperature, stable friction coefficient, small abrasion of products, comfortable braking in use and no noise.

Owner:信义集团公司

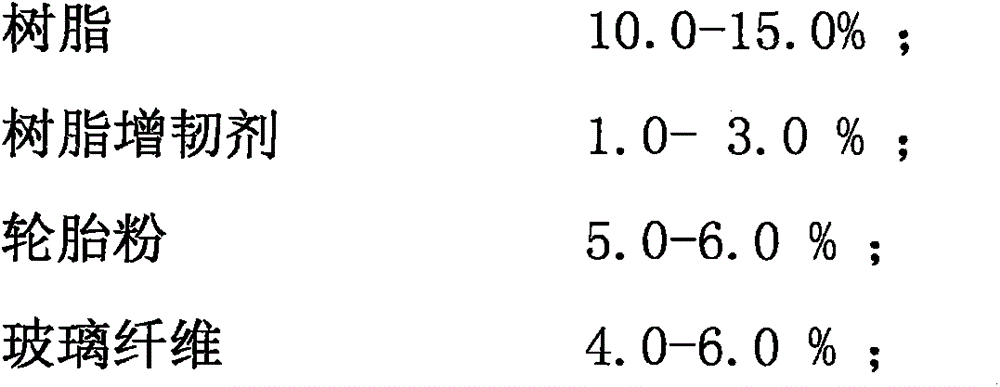

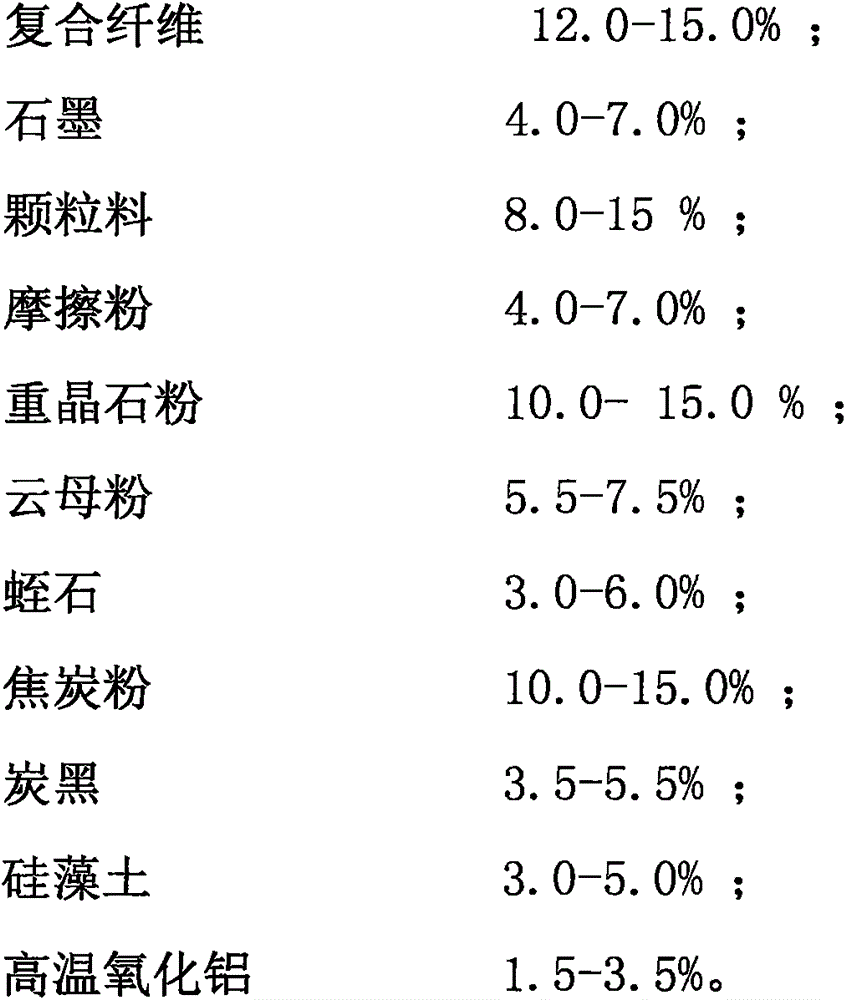

Environment-friendly noise-free brake block and processing method thereof

InactiveCN103351844ANo pollutionSuitable for useOther chemical processesFriction liningFiberEnvironmental resistance

The invention discloses an environment-friendly noise-free brake block and a processing method thereof. The brake block is produced from resin, a resin flexibilizer, tire powder, glass fibers, composite fibers, graphite, granules, frictional powder, baryte powder, mica powder, vermiculite, coke blacking, carbon black, diatomite and high-temperature aluminium oxide. The environment-friendly noise-free brake block has the advantages that no asbestos, heavy metals and compounds are contained so that no dust falls after braking and no asbestos dust is generated to pollute environment and result in cancer, lots of soft raw materials such as flexible granules, and moreover, organic frictional powder and organic rubber powder are added, and simultaneously, inorganic packing such as coke and vermiculite of porous loose structure is added, so that the brake block is comfortable to brake without noise and thereby especially suitable for urban buses.

Owner:耿琪国

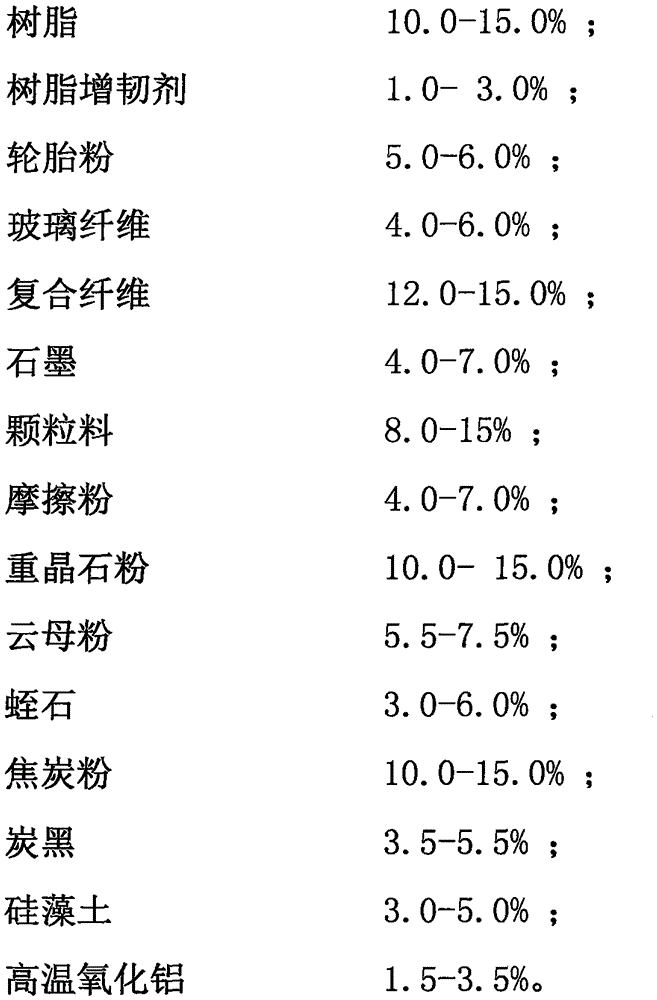

Novel environment-friendly noise-free brake pad and machining method thereof

InactiveCN105387107ANo pollutionSuitable for useOther chemical processesFriction liningFiberUrban bus

The invention discloses a novel environment-friendly noise-free brake pad and a machining method thereof. The brake pad is made of resin, a resin flexibilizer, tire powder, glass fibers, composite fibers, graphite, granules, friction powder, baryta powder, mica powder, vermiculite, powdered coke, carbon black, kieselguhr and high-temperature aluminum oxide. The novel environment-friendly noise-free brake pad has the beneficial effects that the brake pad does not contain asbestos or heavy metal or compounds, fallen dust is avoided after braking, and environment pollution and cancers are avoided as no asbestos powder is generated; a large quantity of the soft materials such as the flexible granules, the organic friction powder and the organic rubber powder are added, and the inorganic filler such as the porous coke of a loose structure and the vermiculite is also added, so that a user feels comfortable during braking, noise is avoided, and the brake pad is particularly suitable for urban buses.

Owner:QINGDAO LIBO AUTO PARTS PRECISION CASTING

High-performance composite brake disc material

InactiveCN104893256AImprove thermal conductivityEnhanced interface bindingFriction liningMicrosphereWear resistant

The invention discloses a high-performance composite brake disc material, the wear resistant material comprises the following raw materials: bisphenol a novolac epoxy resin, diaminodiphenyl sulfone, hollow microspheres, a lubricant, a silane coupling agent, diamine, an imidazoles compound, an anti-oxidant, chloroprene rubber powder, alumina and reinforced fibers. The reinforced fibers can be a mixture of zylonite fiber, aramid fiber, cotton fiber and ramie fiber; the interface combination of fiber and particles in the materials is good, and the fiber and particles in the materials enable synergistic interaction with antimonony oxide and graphite, generation of thermal decomposition, heat attenuation and heat cracks phenomena can be effectively reduced, thermal conductivity of the materials is good, heat generated when brake friction is carried out can be timely radiated, brake disc surface temperature can be rapidly reduced, high temperature heat attenuation is reduced, hollow microspheres, the lubricant, the silane coupling agent and the enhance fiber are specific, friction coefficient of the wear resistant materials can be enhanced by intermolecular cooperation of the substances, and stability of the friction coefficient can be improved simultaneously.

Owner:CHONGQING JIAOTONG UNIVERSITY

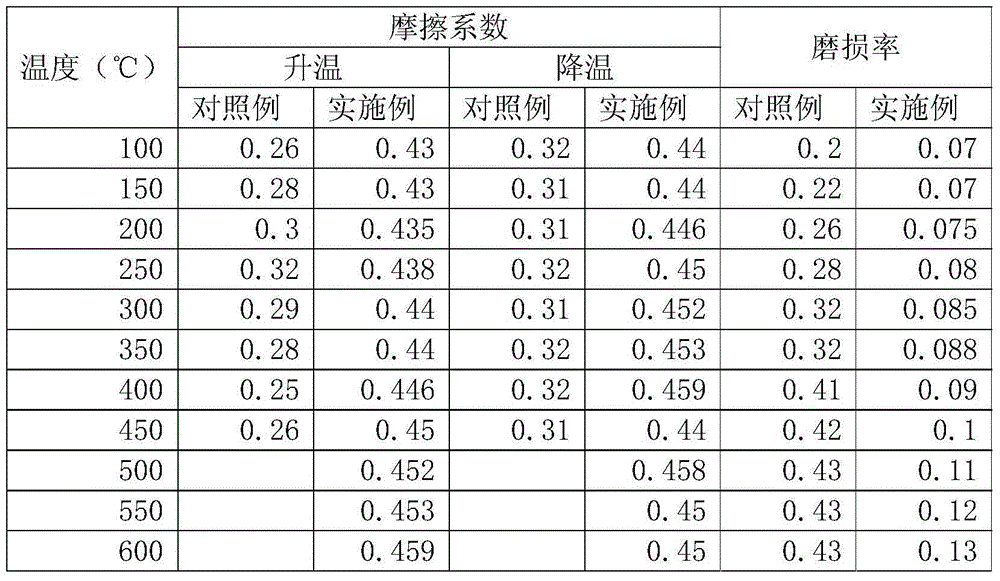

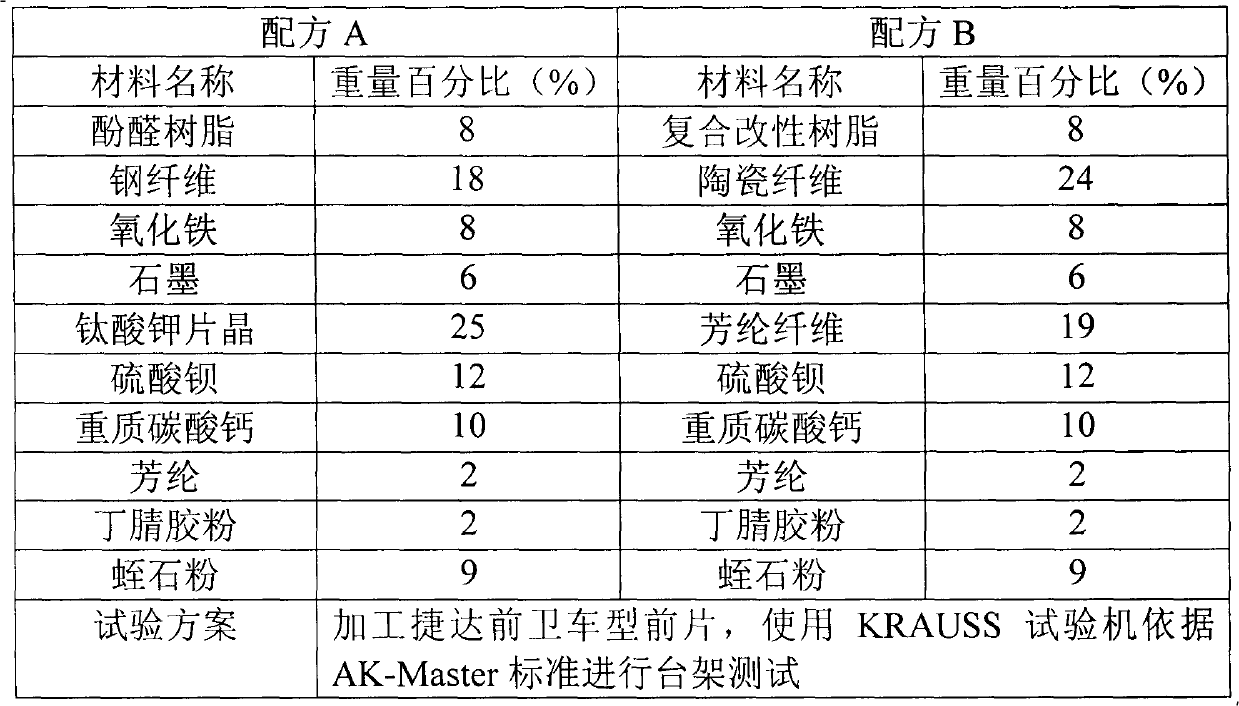

Method for preparing brake pad by utilizing ceramic fiber

The invention relates to a preparation method of a friction material in the field of automobile industry and provides a formula for preparing a brake pad, which can improve heat resistance and fading resistance of the friction material. The formula comprises an adhesive, a reinforcing material, a friction performance regulating agent and a filling material, wherein the adhesive is of compound modified phenolic resin, and the percentage by weight of the adhesive is 5-18%; the reinforcing material is of the ceramic fiber and aramid fiber, and the percentage by weight of the reinforcing material is 20-30%; the friction performance regulating agent comprises a grinding agent, graphite, molybdenum disulfide and mica, the grinding agent comprises aluminum oxide, ferric oxide and magnesium oxide, the percentage by weight of the grinding agent is 1-15%, and the graphite, the molybdenum disulfide and the mica account for 5-15% by weight in total; and the filling material comprises barium sulfate, potassium titanate and vermiculite powder. The brake pad produced by adopting the formula disclosed by the invention, heat fading phenomenon can be avoided at high temperature, the friction coefficient is stable, the abrasion of a product is small, the brake is comfortable during the using process, the noise can be avoided, and the service life can be up to above 70000km.

Owner:东营宝丰汽车配件有限公司

Wear-resistant material for brake block of heavy duty automobile

InactiveCN104788906ASolve the real problemLong processOther chemical processesCross-linkCarbon fibers

The invention discloses a wear-resistant material for a brake block of a heavy duty automobile. The wear-resistant material comprises raw materials as follows: bisphenol A novolac epoxy resin, diaminodiphenyl sulfone, mineral powder, a lubricant, a cross-linking agent, chloroprene rubber powder, aluminum oxide, cotton fiber, carbon fiber, aramid fiber, sisal fiber, antimonous oxide, graphite and calcium lignosulfonate. The components are compatible, so that the overall performance of the wear-resistant material is effectively guaranteed, the components can make up for defects in performance mutually and can have high performance due to mutual restriction functions, problems of existing brake blocks are solved, high-speed decline and high-temperature decline can be well prevented, and the wear-resistant material has advantages of better stability and long service life.

Owner:CHONGQING JIAOTONG UNIVERSITY

Ceramic-based high-temperature-resistant brake pad and preparation method thereof

PendingCN111442045AReduce ashResistant to high temperature decayOther chemical processesFriction liningVulcanizationAdhesive

The invention relates to the technical field of vehicle brake devices, in particular to a ceramic-based high-temperature-resistant brake pad and a preparation method thereof. The high-temperature-resistant brake pad is prepared from an adhesive, reinforced fibers, a friction performance modifier and filler, wherein the adhesive comprises resin and rubber powder; the reinforced fibers comprise mineral fibers, aramid fibers and potassium titanate whiskers, wherein the friction performance modifier comprises graphite, chromite powder, zirconite powder, antimony sulfide, molybdenum disulfide, tinsulfide and aluminum oxide; and the filler is barium sulfate and calcium carbonate. The ceramic-based high-temperature-resistant brake pad has the advantages of being resistant to high-temperature attenuation, high in emergency braking or high-speed braking friction coefficient, low in ash falling, low in noise, comfortable in braking, capable of meeting the environment-friendly requirement and the like.

Owner:山东金力新材料科技有限公司

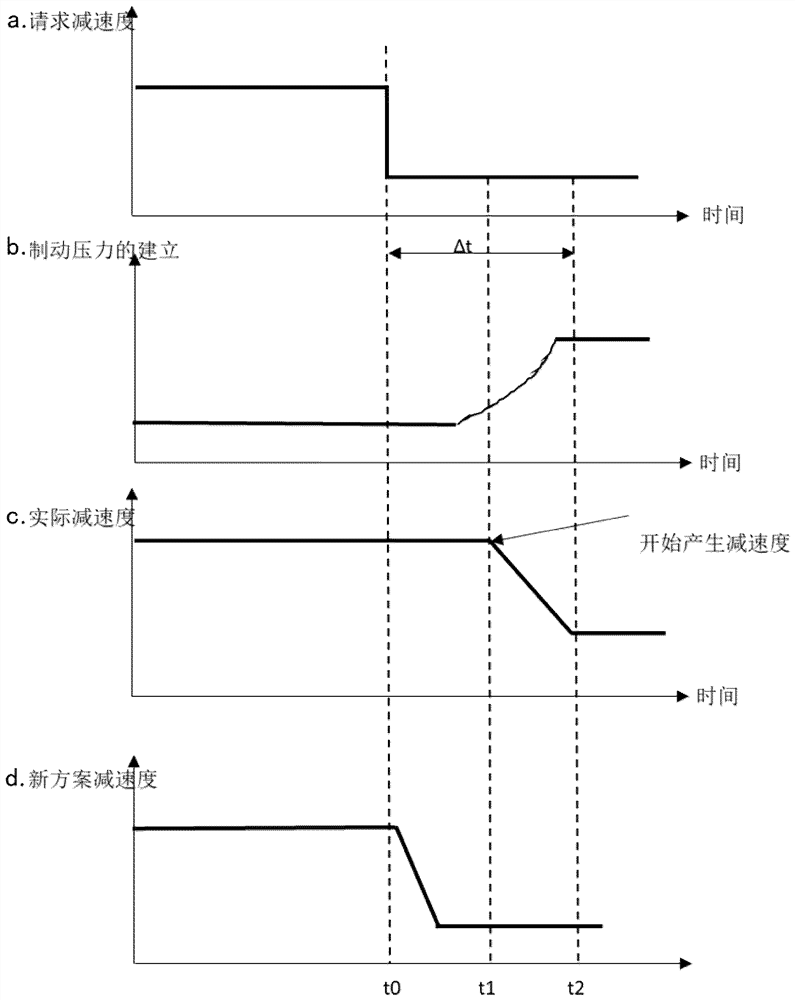

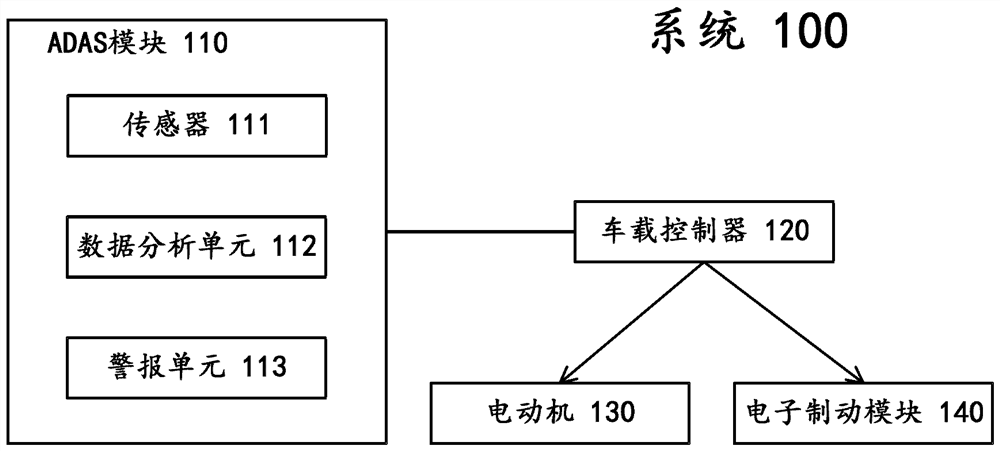

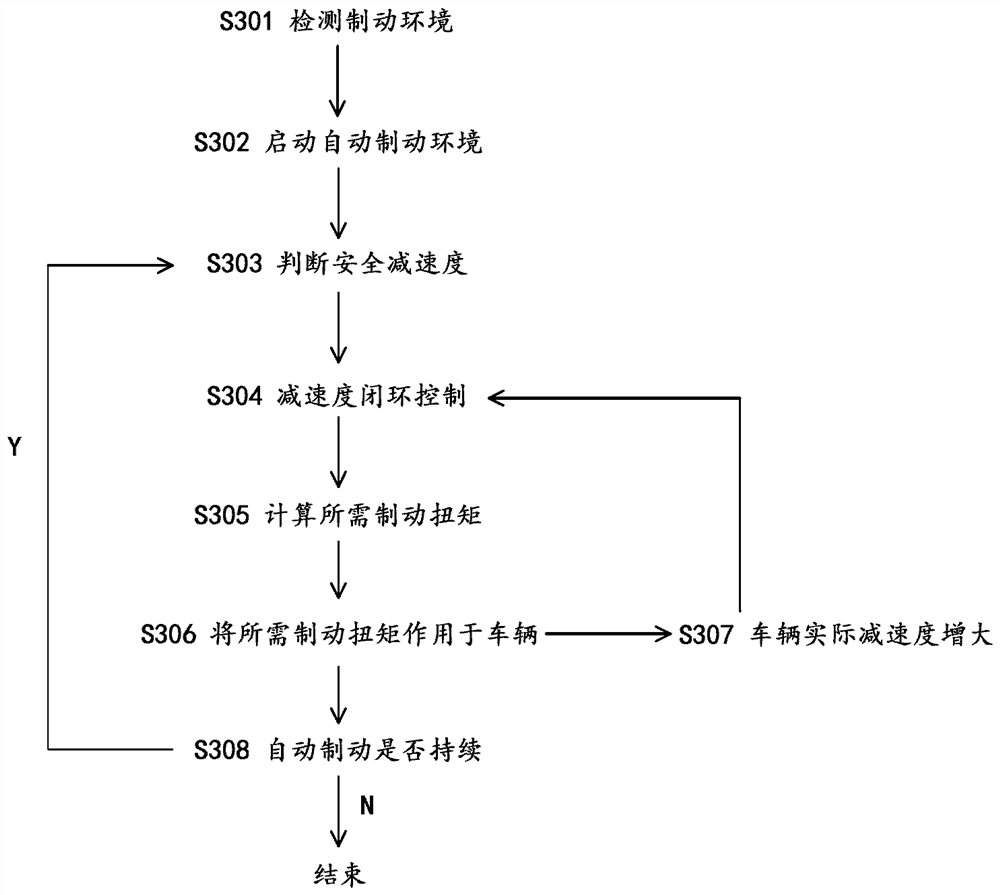

System and method for improving brake delay of intelligent driving vehicle

PendingCN113696863ASecurity impactReduced braking delayAutomatic initiationsBrake safety systemsAutomatic brakingIn vehicle

The invention relates to a method and a system for improving brake delay of an intelligent driving vehicle. The method comprises the following steps that the braking environment of the intelligent driving vehicle is detected; judging whether an automatic braking mode is started or not according to the braking environment; under the condition that the automatic braking mode is started, a reverse towing torque request is sent to a motor, and the intelligent driving vehicle is controlled to conduct reverse towing braking; and in the case where the automatic braking mode is activated, simultaneously sending a braking request and activating the mechanical braking. The system comprises an ADAS module, a vehicle-mounted controller, an electronic braking control module and a motor. The vehicle-mounted controller is configured to send a reverse towing torque request to the motor and control the intelligent driving vehicle to perform reverse towing braking under the condition that an automatic braking mode is started; in the case where the automatic braking mode is activated, simultaneously sending a braking request and activating the mechanical braking.

Owner:SAIC GENERAL MOTORS +1

Ceramic brake pad

InactiveCN106438789ANo brake noiseComfortable brakingOther chemical processesFriction liningSulfideAntimony

The invention relates to a ceramic brake pad, and belongs to the technical field of automobile brake. The ceramic brake pad is prepared from the following components: 1-5 kg of acrylonitrile butadiene rubber powder, 5-10 kg of noise reduction powder, 6-10 kg of resin, 3-8 kg of whiskers, 3-8 kg of brass fiber, 1-4 kg of short fiber, 1-5 kg of frictional powder, 1-4 kg of long fiber, 8-16 kg of ceramic fiber, 3-8 kg of high-temperature barium, 4-9 kg of crystalline flake graphite(-195), 0.5-3 kg of iron, 2-6 kg of petroleum coke, 8-13 kg of ceramic additives, 8-13 kg of wear-resisting powder, 0.5-3 kg of aramid fiber, 1-4 kg of wood fiber, 2-6 kg of ceramic toughening agents, 1-4 kg of antimony sulfide, and 3-8 kg of stabilizers. The ceramic brake pad has the characteristics that a friction disk is not damaged, no brake noise is generated, the temperature resistance is high, the service life is long, and stable braking is realized.

Owner:马乐群

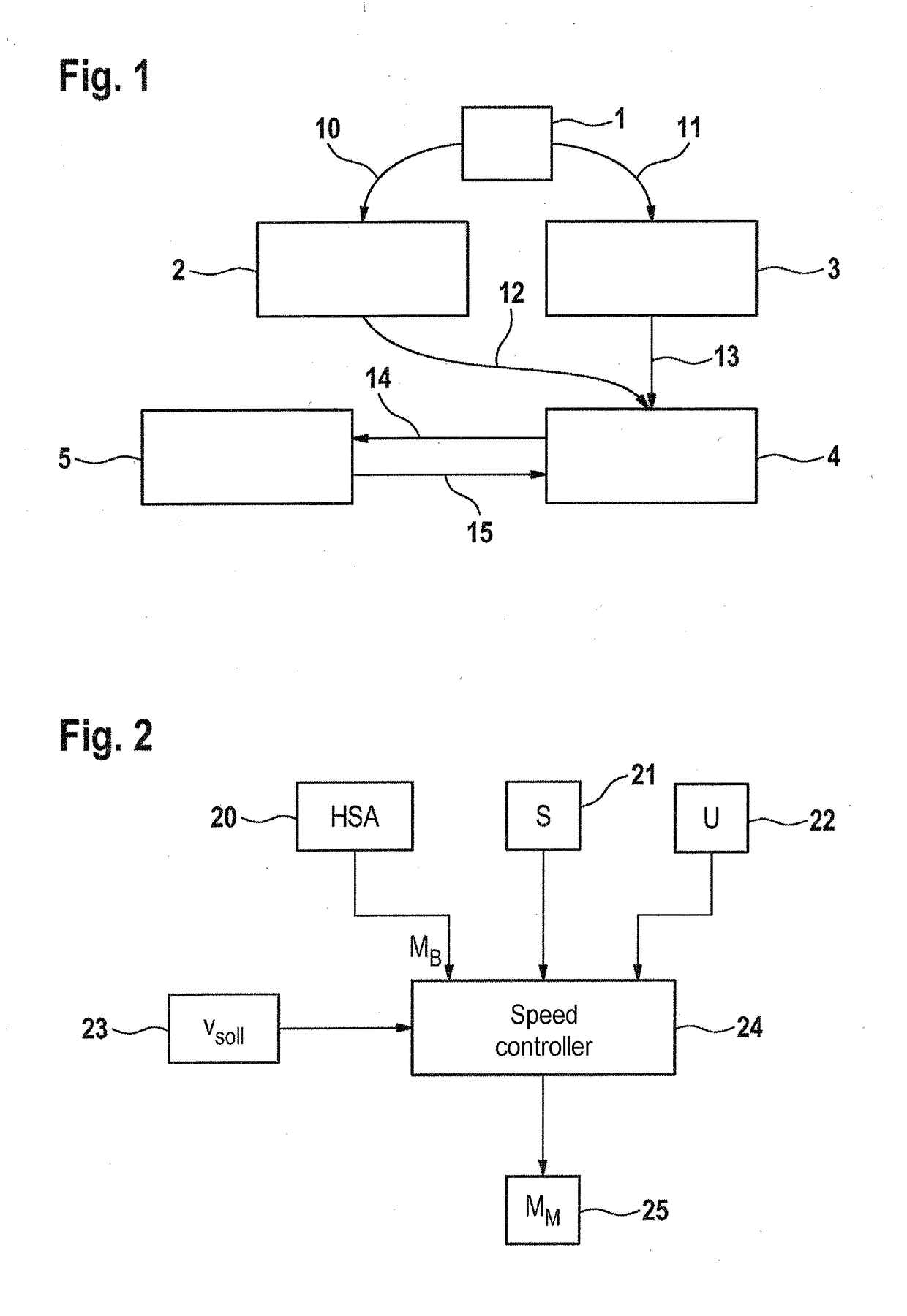

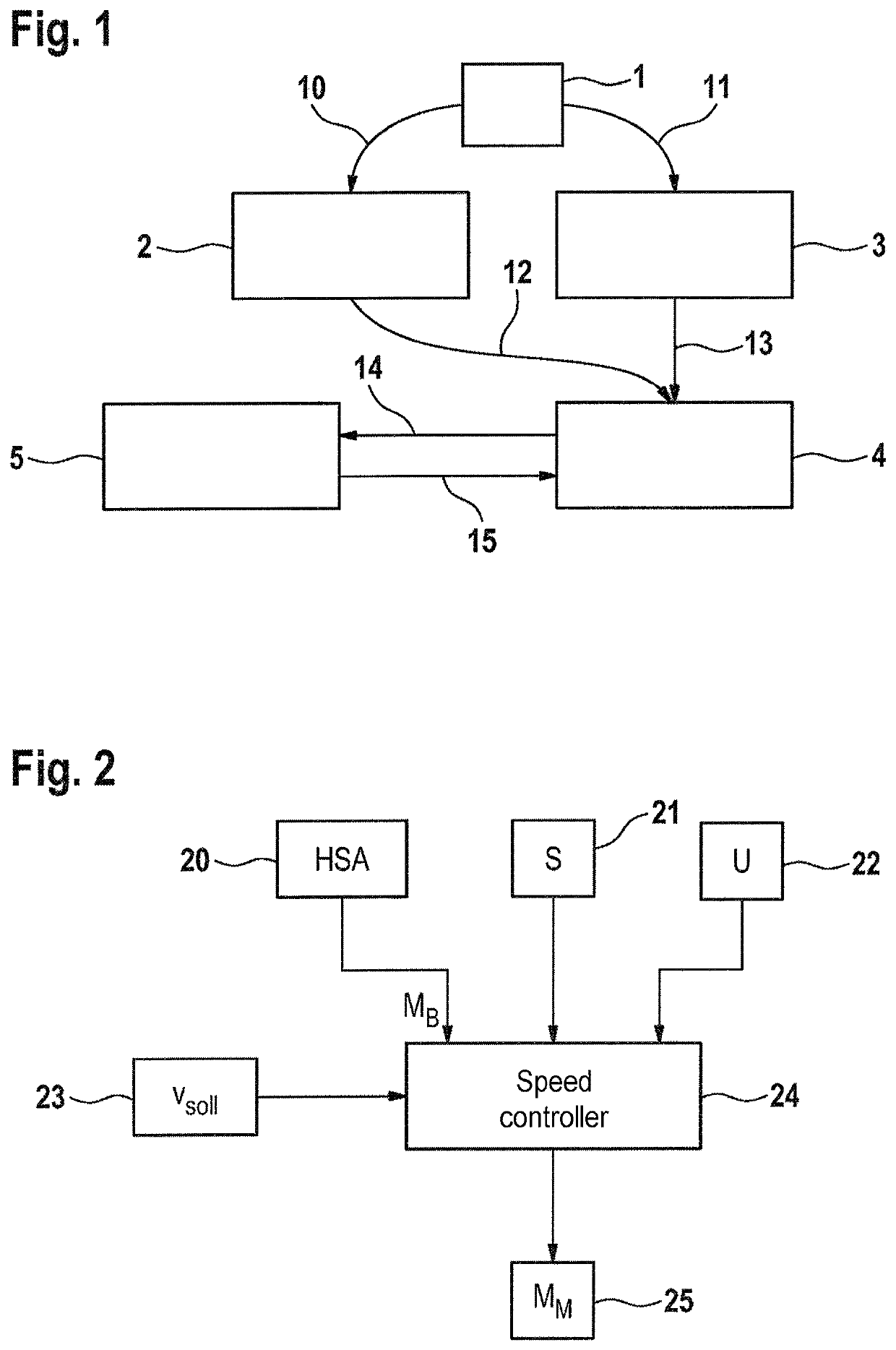

Method for a speed controller

ActiveUS20190084417A1Reduce brake pressureBraking torque reducedVehicle fittingsAutomatic initiationsMobile vehicleControl theory

Owner:CONTINENTAL TEVES AG & CO OHG

Asbestos-free metal-free drum brake lining used in vehicle and manufacture method thereof

The invention discloses a kind of drum brake staff facing used in cars with none asbestos and none metal and the production technology. The component recipes of drum brake staff facing said above are:polyacrylonitrile fiber 1~10%, the oil of cashew shell friction-type mix 2~10%, barite powder 8~20%, heavy calcium carbonate 5-25%, flour acrylonitrile butadiene rubber 2~15%, the mineral fiber 2~6%,the graphite 3~18%, zircon powder 1~10%, the oil of cashew shell phenol-formaldehyde resin modified 10~15%, premix compound 3~15%, glass fiber 2~15%. The production technology is that make the component told above into three times stir mixing and weigh the amount of last formed material with the need of ordinance about the drum brake facing then chill-pressing confectioning forms cool base and then heat pressing confectioning, heat processing and grind on, drill steps and so on then processing make into production. The recipe production is characterized in that: light weight, stabilize coefficient of friction, soft and sensitive braking, and comfort, noiseless and agree the requirement of environmental protection.

Owner:福建冠良汽车配件工业有限公司

Method for a speed controller

ActiveUS11034240B2Reduce brake pressureBraking torque reducedVehicle fittingsAutomatic initiationsAuto regulationDriver/operator

Owner:CONTINENTAL TEVES AG & CO OHG

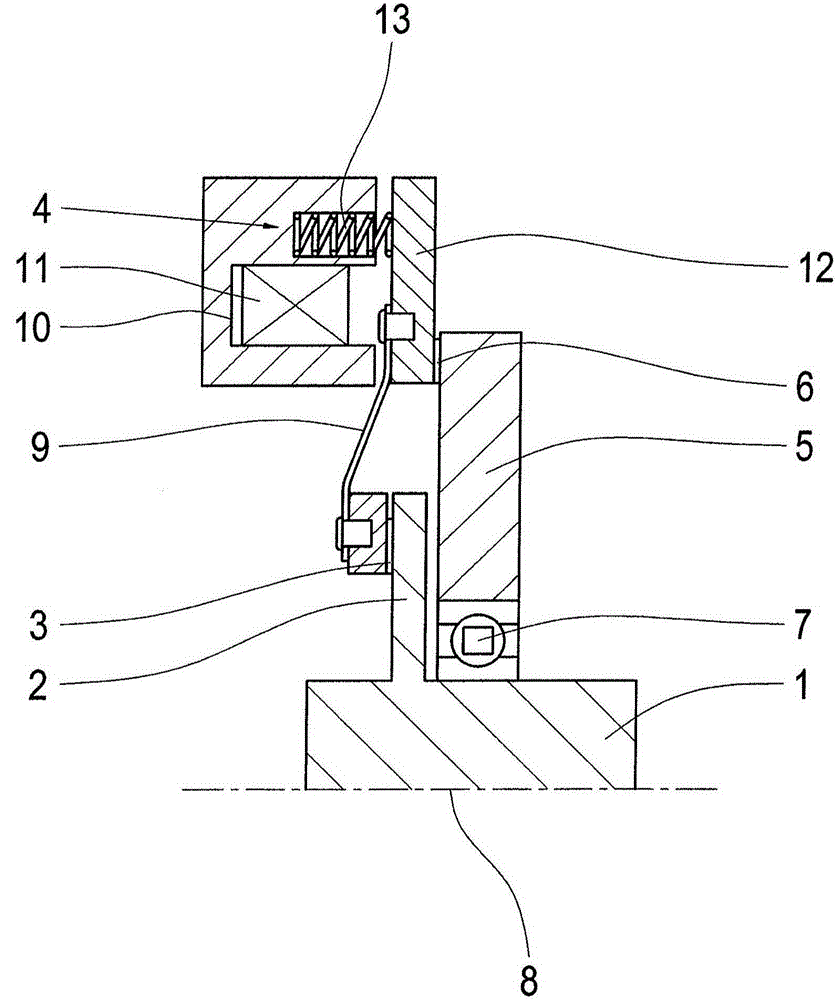

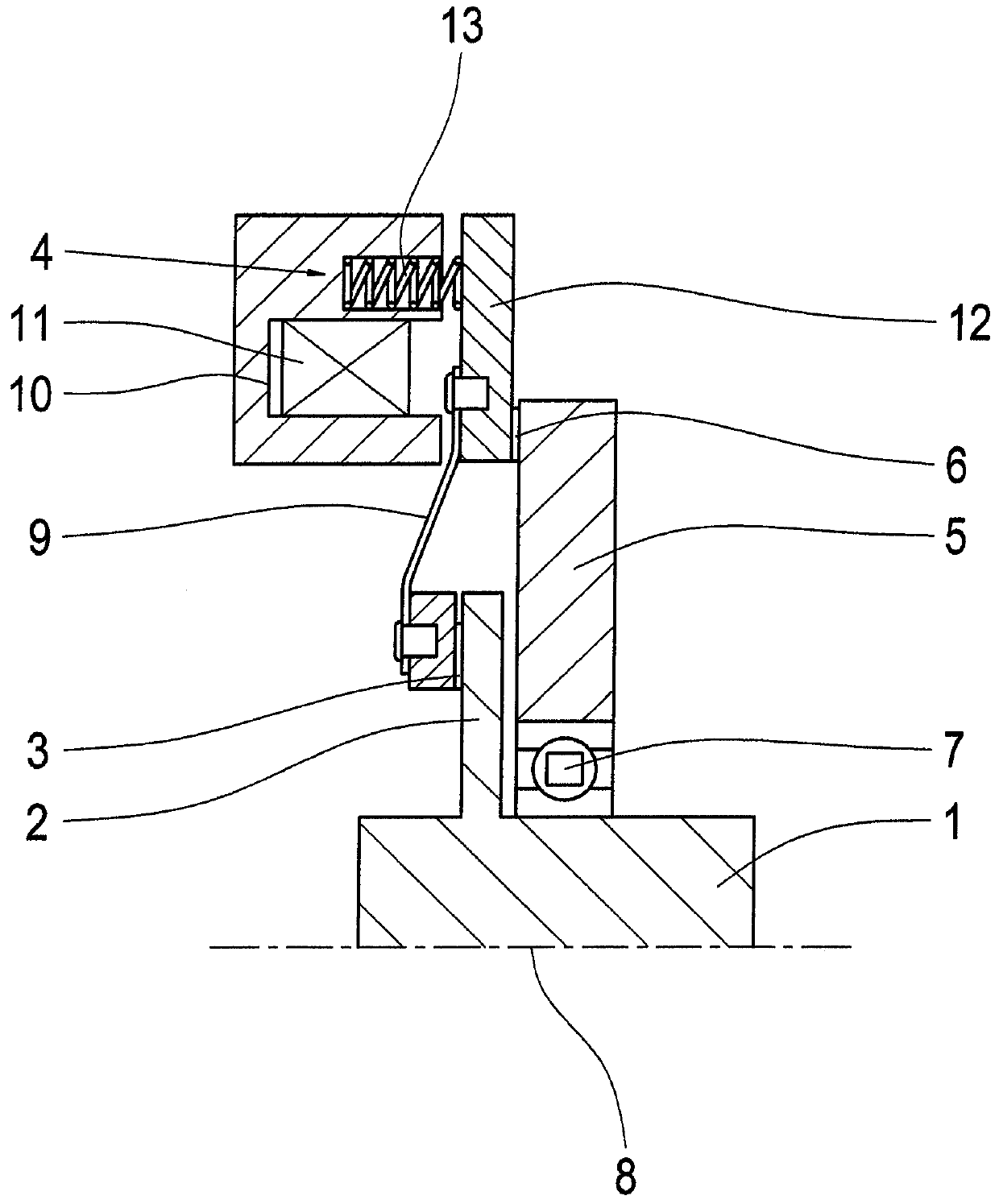

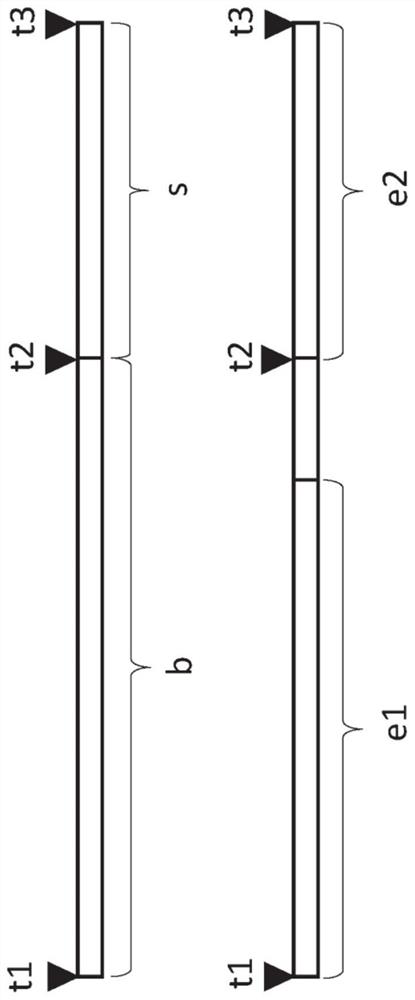

Disc brake assembly

InactiveCN105370766AActive connectionSoft brakingAxially engaging brakesBraking elementsBrake torqueActuator

Disclosed is a disc brake assembly for rotational direction-dependent applying a predetermined braking torque for braking a shaft (1) having a first brake disc (2) and with at least one associated first friction surface (3) in a brake actuator (4) for applying a desired braking torque operative connection can be brought, at least a second brake disc (5) and at least a second friction surface (6) are provided, wherein the on the second brake disc (5) transferable braking torque is dependent on the direction of rotation transmitted to the shaft (1).

Owner:ZF FRIEDRICHSHAFEN AG

disc brake mechanism

InactiveCN105370766BActive connectionSoft brakingAxially engaging brakesBraking elementsEngineeringMechanical engineering

The utility model relates to a disc brake mechanism and automatic escalator disc brake mechanism or automatic walkway disc brake mechanism, disc brake mechanism are used for applying predetermined braking moment according to the rotation direction for make axle (1) slow down, this disc brake mechanism has first brake disc (2) and at least one is attached first friction surface (3), this first brake disc and first friction surface can effectively be connected via braking operating means (4) that are used for applying the braking moment of expectation each other, wherein, is provided with at least one second brake disc (5) and at least one second friction surface (6), wherein, and on the braking moment of transferable to the second brake disc (5) can transmit axle (1) according to the rotation direction.

Owner:ZF FRIEDRICHSHAFEN AG

A kind of preparation method of water-durable brake pad

The invention discloses a water-passing durable type brake pad and a preparation method thereof. The water-passing durable type brake pad comprises raw materials of RK-150 basalt fibers, boron-modified phenolic resin, friction powder, barium sulfate, calcium sulfate whiskers, glass fibers, magnesium hydroxide, magnesium oxide, steel fibers and nitrile butadiene rubber. Through mixing, die-filling,pressurized heating, pulling out of a die, heat treatment, cutting, polishing and drilling, the prepared brake pad is more durable and high in strength, has the relatively stable friction coefficientand is not liable to crack, and the service life of the brake pad is not less than five months.

Owner:海盐欧亚特汽配有限公司

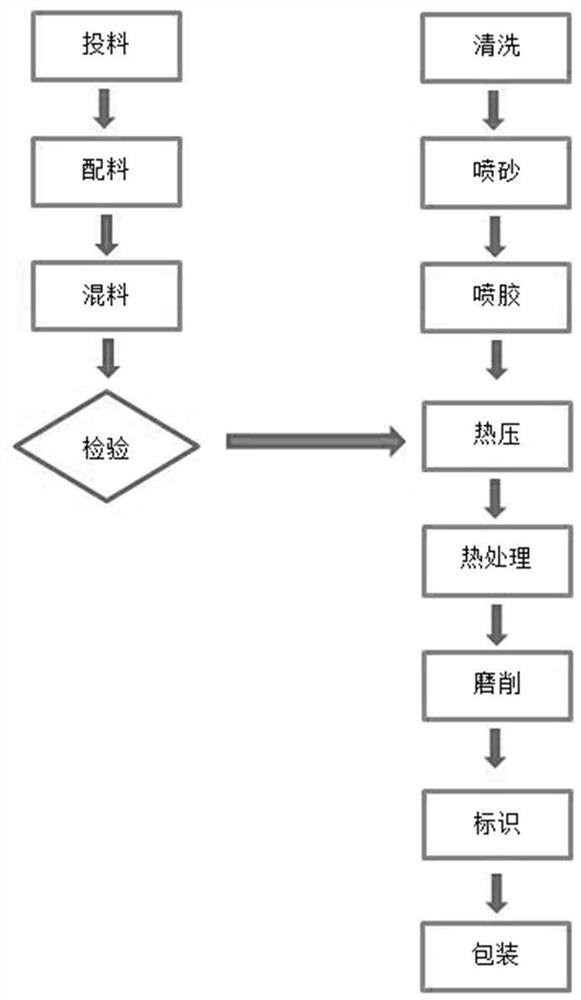

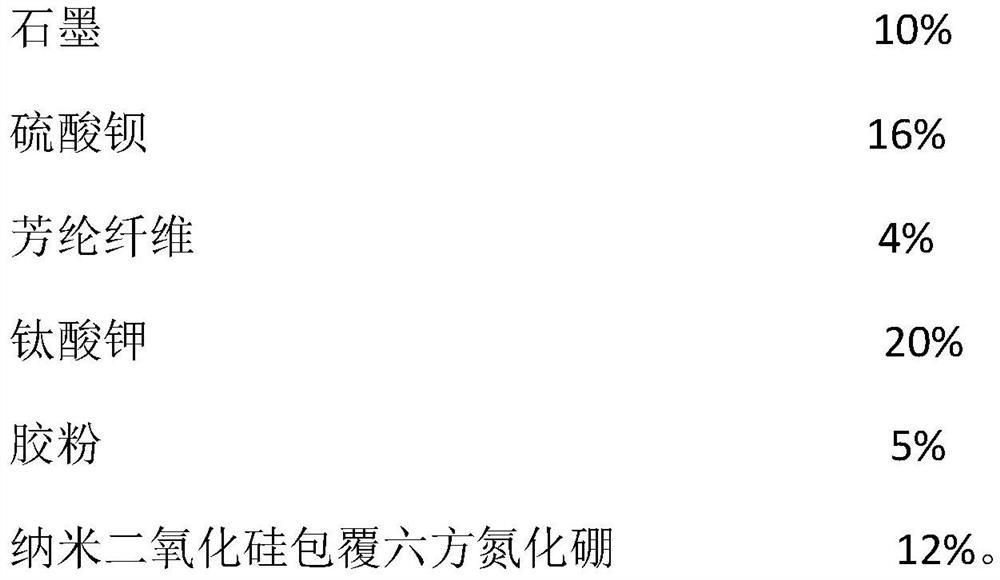

Copper-free nano ceramic brake pad

The invention provides a copper-free nano ceramic brake pad. The brake pad comprises the following components in percentage by weight: 10% of phenolic resin, 17% of mineral fiber, 6% of ferric oxide,10% of graphite, 16% of barium sulfate, 4% of aramid fiber, 20% of potassium titanate, 5% of rubber powder and 12% of nano silicon dioxide coated hexagonal boron nitride. The brake pad has the advantages of being stable in friction coefficient, small in product abrasion, comfortable in braking in the using process and free of noise, and the service life reaches more than 70000 kilometers.

Owner:东营宝丰汽车配件有限公司 +1

An environmentally friendly and noiseless brake pad and its processing method

InactiveCN103351844BNo pollutionSuitable for useOther chemical processesFriction liningFiberUrban bus

The invention discloses an environment-friendly noise-free brake block and a processing method thereof. The brake block is produced from resin, a resin flexibilizer, tire powder, glass fibers, composite fibers, graphite, granules, frictional powder, baryte powder, mica powder, vermiculite, coke blacking, carbon black, diatomite and high-temperature aluminium oxide. The environment-friendly noise-free brake block has the advantages that no asbestos, heavy metals and compounds are contained so that no dust falls after braking and no asbestos dust is generated to pollute environment and result in cancer, lots of soft raw materials such as flexible granules, and moreover, organic frictional powder and organic rubber powder are added, and simultaneously, inorganic packing such as coke and vermiculite of porous loose structure is added, so that the brake block is comfortable to brake without noise and thereby especially suitable for urban buses.

Owner:耿琪国

method for controlling a vehicle

ActiveCN111902661BActivating the parking lock functionHang in fastGearing controlControl theoryVehicle brake

A method for controlling a vehicle with an automated shift transmission having a plurality of automatically shiftable driving gears and comprising a first friction clutch on the input side and an output device on the output side , wherein two gears are simultaneously engaged in the parking lock function, namely first and second gear, wherein at least at the first speed of the vehicle according to the requirement (1) for activation of the parking lock function In the range (10), the vehicle brakes (11) are activated in order to bring the vehicle to a stop (3), wherein during braking of the vehicle by means of the vehicle brakes, the first gear (12) is engaged and the vehicle At or near a stop (3), engaging said second gear (7) such that said parking lock function is activated, and a vehicle comprising a control device for carrying out such a method.

Owner:MAGNA PT B V & CO KG

A kind of automobile brake drum and manufacturing method

ActiveCN104745916BReduce the amount of cementiteComfortable brakingBraking drumsBrakeUltimate tensile strength

Belonging to a casting material and the casting method field, the invention discloses an automobile brake drum and a manufacturing method, and relates to a making method for an automobile part brake drum. The automobile brake drum is characterized by being prepared from the following raw materials by weight: 3.00-3.24% of C, 1.6-1.74% of Si, 0.45-0.49% of Mn, 0.05-0.1% of V, 0.1-0.25% of W, 0.38-0.45% of Cr, 0.4-0.7% of Co, and the balance Fe and inevitable impurities. By adopting a twice inoculation manufacturing process, the tensile strength and yield strength can be improved, the mechanical properties exceed ordinary grey cast iron brake drum material HT250, the tensile strength reaches more than 250Mpa, and the hardness HBS value reaches over 200, the wear resistance is good, the friction coefficient is high, and the production cost is low, the method can be used for making automobile brake drums and has broad application prospects. The brake drum product prepared by the method has the advantages of sensitive braking, comfortable and noiseless braking process, no damage to brake drum, and long service life.

Owner:CHONGQING TONGLIANG YUHE IND

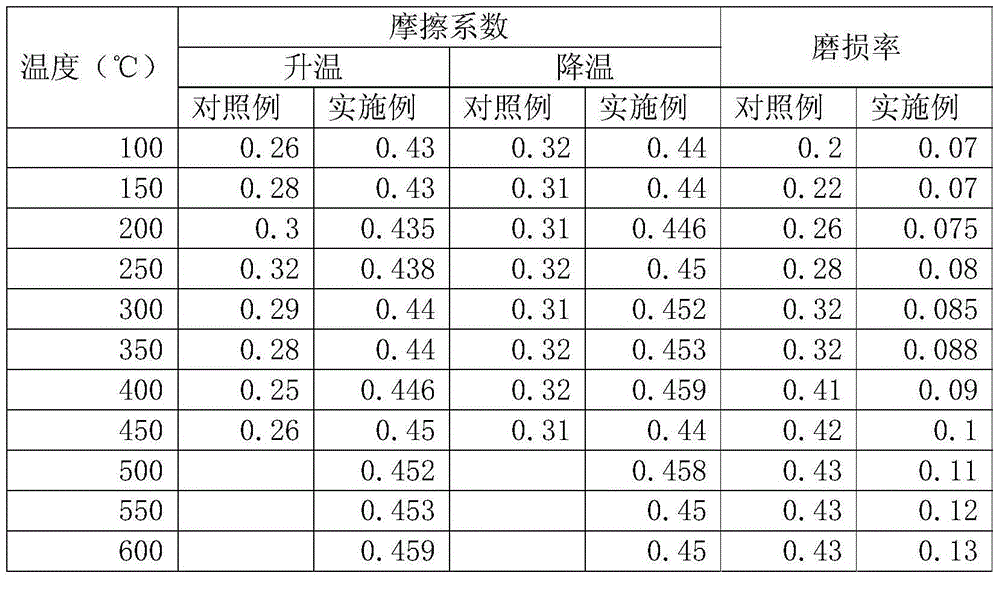

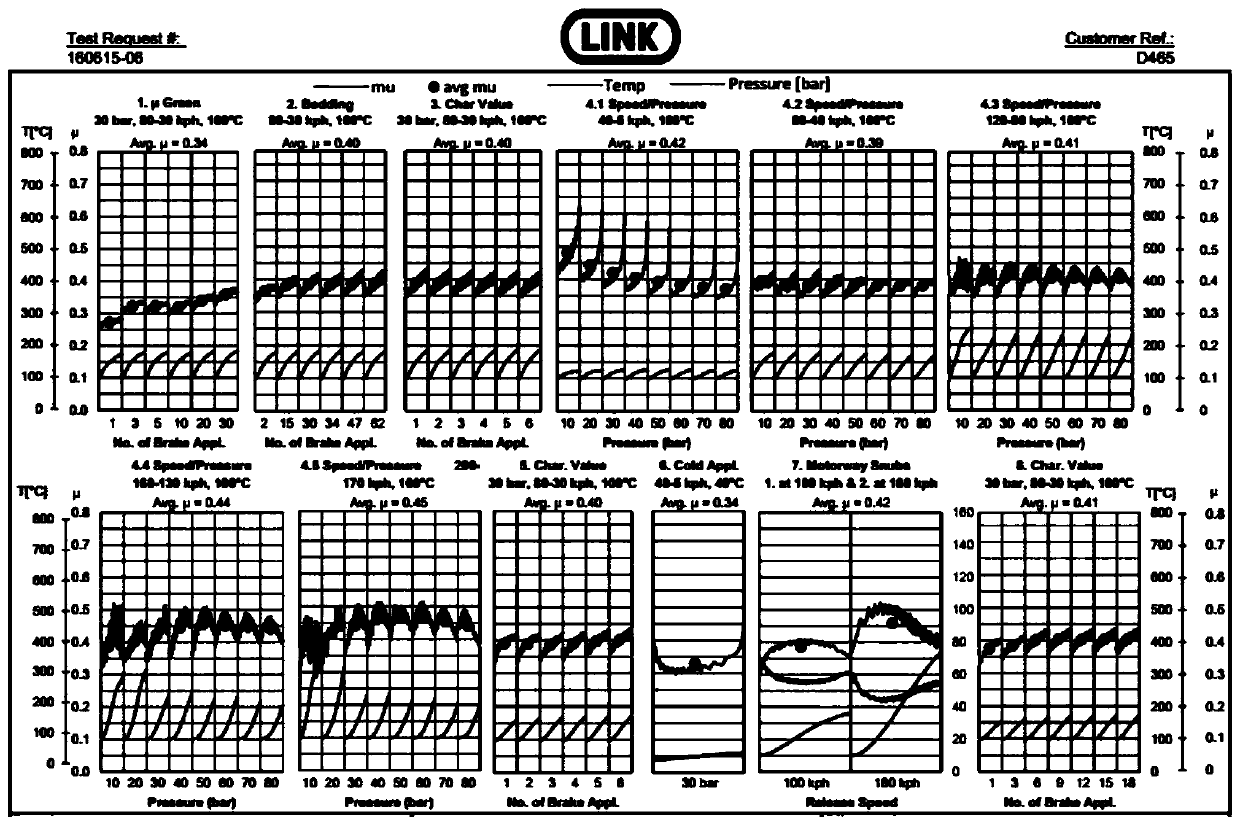

Copper-free ceramic brake pad

PendingCN114001111AChange internal structureImprove practicalityOther chemical processesFriction liningAuto industryAdhesive

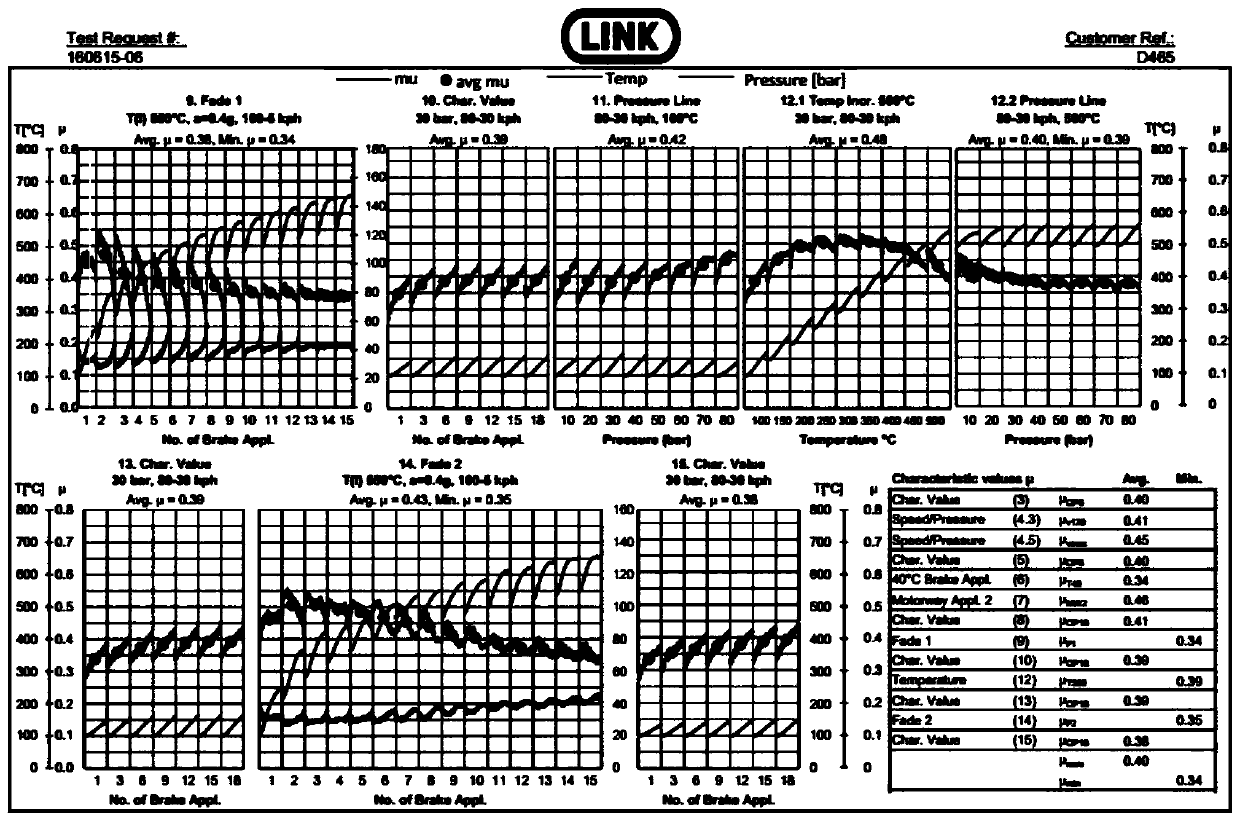

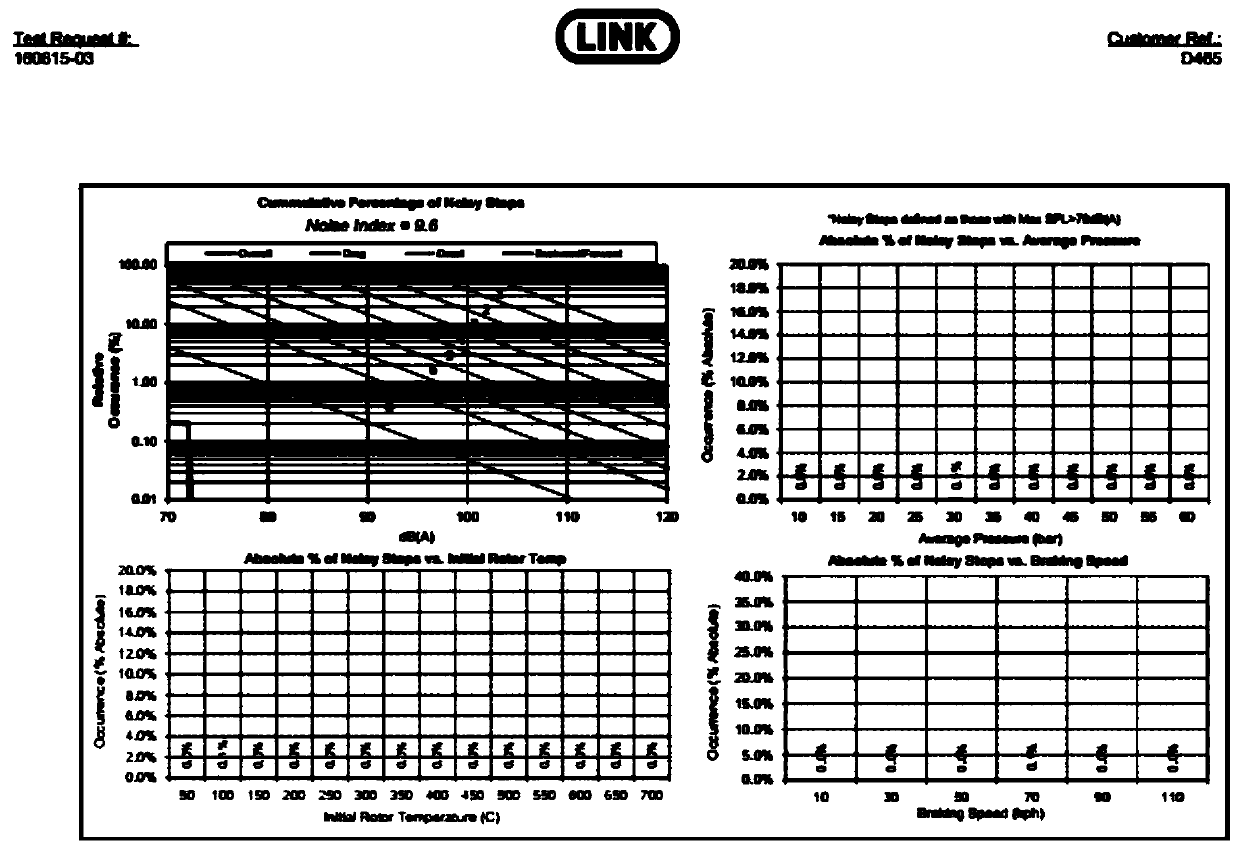

The invention relates to preparation of a friction material in the field of automobile industry, in particular to a copper-free ceramic brake pad, and the friction material of the copper-free ceramic brake pad consists of the following raw materials: an adhesive, a reinforcing material, a friction performance regulator and a filler. The brake pad has the advantages that the friction material formula is designed by utilizing the advantages of good heat resistance, heat stability, water resistance and the like of the ceramic fibers, the internal structure of the material is changed, and the comprehensive practical performance of the brake pad is improved; the brake pad has no heat fading phenomenon at high temperature, the friction coefficient is stable, the product abrasion is small, the brake is comfortable in the use process, no noise is generated, and the service life is more than 70,000 kilometers; and the brake pad is qualified through through the American LINK3900 rack TP2044 standard detection, the car brake pad has the advantages of being stable in safety performance and low in cost, and in addition, and there is no need to improve an existing processing technology, so that the production cost and the transformation cost are greatly saved.

Owner:东营宝丰汽车配件有限公司

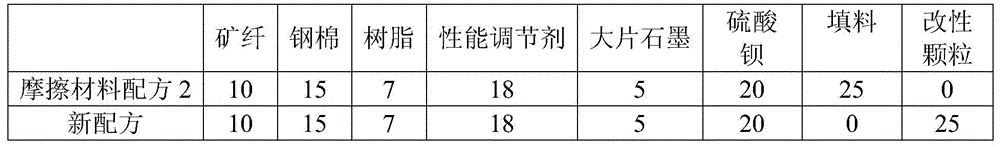

Modified friction particle for friction material and preparation method thereof

The invention relates to modified friction particles for a friction material and a preparation method of the modified friction particles. The modified friction particles are mainly prepared from the following components in percentage by mass: 20-30 percent of aluminum oxide and zirconium dioxide, 20-30 percent of American Parma black powder and Netherland D powder, 10-20 percent of manganese sulfide, zinc sulfide and copper sulfide, 7-15 percent of unexpanded silvery white vermiculite power and graphite, 12-18 percent of butadiene-acrylonitrile rubber and butadiene styrene rubber, 3-5 percent of liquid resin and acrylonitrile-butadiene rubber latex, 5-10 percent of a performance modifying agent and 0.5-1 percent of rubber ingredients. A brake lining manufactured from the friction material containing the modified friction particles disclosed by the invention has high porosity and low hardness; in the test process and the actual application process, the brake lining does not generate noise, has comfortable brake foot sense, can take response quickly, and can reach the service life requirement when used in various severe conditions; after the modified friction particles are used in urban bus brake discs in a large quantity, the service life of the friction material can be over 35000km.

Owner:HANGZHOU UNITED FRICTION MATERIAL

car reversing collision avoidance system

ActiveCN104802781BImprove maneuverabilityEnsure safetyAcoustic signal devicesAutomatic initiationsUltrasonic sensorControl system

The invention relates to a vehicle reversing anti-collision system, which comprises a collection system, a control system, a voice system and a brake mechanism; the collection system is arranged at the tail of a vehicle; the control system is arranged in a trunk of the vehicle; the voice system is arranged at a multimedia chamber of the vehicle; the brake mechanism is arranged under an instrument panel of a driving cab of the vehicle and corresponds to a vehicle brake pedal. An ultrasonic principle is used, an ultrasonic sensor is additionally arranged at the tail of the vehicle, the distance between a reversed vehicle and an obstacle is automatically measured by the ultrasonic sensor, and then a driver is prompted. Meanwhile, according to the distance between the reversed vehicle and the obstacle, an automatic brake device is controlled to automatically brake, so the reversed driven vehicle is automatically alarmed and braked, occurrence of vehicle collision accidents is effectively prevented, the operability of the vehicle is improved and vehicle safety is ensured.

Owner:王柳坤

Method for controlling a vehicle

ActiveCN111902661AActivating the parking lock functionHang in fastGearing controlControl theoryVehicle brake

A method for controlling a vehicle which has an automated manual transmission and a plurality of gears which can be selected in an automated manner and, on the input side, comprises a first friction clutch and, on the output side, comprises an output, wherein two gears are engaged simultaneously in a park lock function, specifically a first gear and a second gear. In response to a request to activate the park lock function (1), a vehicle brake is activated (11) at least in a first speed range (10) of the vehicle in order to bring the vehicle to a standstill (3), the first gear being engaged (12) during braking of the vehicle by means of the vehicle brake and the second gear being engaged (7) when the vehicle (3) is at a standstill or almost at a standstill, such that the park lock functionis activated. The invention also relates to a vehicle comprising a control apparatus for carrying out such a method.

Owner:MAGNA PT B V & CO KG

Asbestos-free micro-metal polycrystalline fiber automotive drum brake linings

ActiveCN104088933BSensitive brakesExtended service lifeOther chemical processesBraking membersMulliteZircon

The invention discloses an asbestos-free micro-metal polycrystalline-fiber drum brake lining for an automobile. The drum brake lining comprises the components as follows: 10-15% of cashew nut shell oil modified phenolic resin, 3-6% of powdered nitrile butadiene rubber, 5-8% of polycrystalline mullite fibers, 10-20% of wood fibers, 2-8% of polyacrylonitrile fibers, 2-10% of cashew nut shell oil friction powder, 5-15% of barite powder, 3-18% of graphite, 1-10% of zircon powder and 16-23% of other filler. A production technology comprises the steps as follows: mixing the components by an automatic mixer, weighing required amounts of finally formed materials according to specifications required by the drum brake lining, performing cold press molding on the materials to form a cold blank, performing hot press molding, heat treatment, grinding and drilling steps, and obtaining a finished product through machining. The formula product has the main characteristics that the drum brake lining is stable in friction coefficient, low in hardness, sensitive in brake, comfortable, free of noises, safe to use, stable, environment-friendly and capable of meeting the environmental protection requirement and meeting various performance requirements required during automobile brake.

Owner:福建冠良汽车配件工业有限公司

Asbestos-free small mount metal disk brake lining used in vehicle and manufacture method therefor

InactiveCN100585210CStable coefficient of frictionReduce wearFriction liningNitrile rubberMining engineering

The invention discloses a kind of disk brake staff facing used in cars with none asbestos and little metal and the production technology. Its friction material includes bed charge and plus material. The bed charge includes: mineral fiber 35~50%, barite powder 10~20%, heavy calcium carbonate 10-20%, the oil of cashew shell phenol-formaldehyde resin modified 20~30%, flour acrylonitrile butadiene rubber 2~15%. The match of plus material: kaflar fiber 0.1~3%, steel fiber 20~35%, copper fiber 1~5%, particle graphite 6~18%, oil coke blacking 5~15%, the oil of cashew shell friction-type mix 2~8%, sericite in powder 5~10%, antimony trisulfide 0.5~5%, heavy calcium carbonate 2-8%, barite powder 10~20%, flour acrylonitrile butadiene rubber 2~6%, the oil of cashew shell phenol-formaldehyde resin modified 6~15%. After made the bed charge and the plus material weight them in proportion then chill-pressing confectioning and heat pressing confectioning steps and so on and then rivet accessory at last treatment make up the products. It needs low abrasion and has no noise.

Owner:福建冠良汽车配件工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com