Copper-free nano ceramic brake pad

A brake pad, copper nano technology, applied in the field of copper-free nano ceramic brake pads, to achieve the effect of no noise, low product wear and comfortable braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

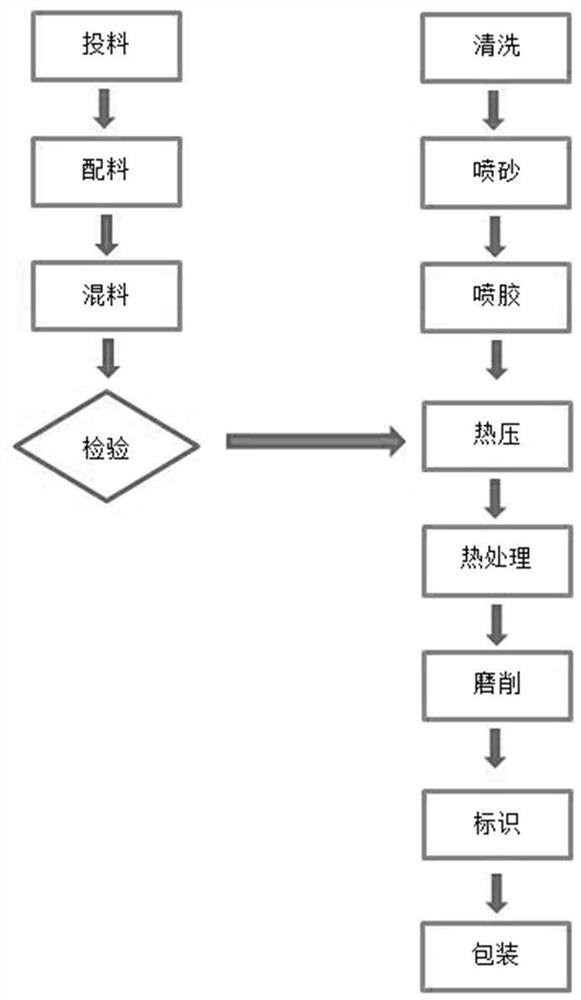

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

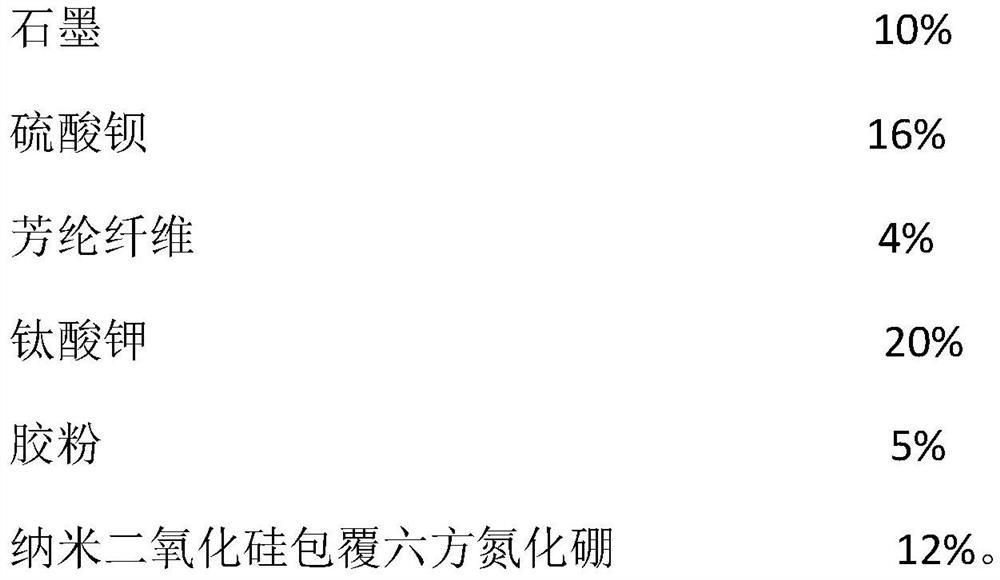

[0011] A copper-free nano ceramic brake pad, comprising phenolic resin, mineral fiber, iron oxide, graphite, barium sulfate, aramid fiber, potassium titanate, rubber powder and nano silicon dioxide coated hexagonal boron nitride, the brake The weight percent of sheet component is:

[0012]

[0013]

[0014] The nano silicon dioxide coated hexagonal boron nitride is spherical.

[0015] A copper-free nano-ceramic brake pad. Spherical nano-silica coated hexagonal boron nitride is introduced into the friction material as a friction performance modifier. When braking, the surface layer of nano-silica and graphite and other lubricants work together to maintain friction. The coefficient is stable, and the transfer film is completed. As the braking temperature rises, the graphite gradually loses its lubricity, while the cladding layer opens, and a new transfer film is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com