Ceramic-based high-temperature-resistant brake pad and preparation method thereof

A technology for brake pads and high temperature resistance, applied in the field of ceramic-based high temperature resistant brake pads and their preparation, can solve the problems of falling ash, high noise, poor braking comfort, affecting driving safety, etc., so as to improve safety performance and improve structural strength. , The effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The ceramic-based high-temperature-resistant brake pad described in this embodiment is prepared from a binder, a reinforcing fiber, a friction modifier and a filler; wherein, the binder includes resin and rubber powder; the reinforcing fiber includes mineral fiber , aramid fibers, potassium titanate whiskers; the friction modifier includes graphite, chromite powder, zircon powder, antimony sulfide, molybdenum disulfide, tin sulfide, aluminum oxide; the filler is barium sulfate, carbonic acid calcium.

[0024] The parts by weight of various raw materials in the ceramic-based high-temperature resistant brake pad are:

[0025]

[0026]

Embodiment 2

[0028] The ceramic-based high-temperature-resistant brake pad described in this embodiment is prepared from a binder, a reinforcing fiber, a friction modifier and a filler; wherein, the binder includes resin and rubber powder; the reinforcing fiber includes mineral fiber , aramid fibers, potassium titanate whiskers; the friction modifier includes graphite, chromite powder, zircon powder, antimony sulfide, molybdenum disulfide, tin sulfide, aluminum oxide; the filler is barium sulfate, carbonic acid calcium.

[0029] The parts by weight of various raw materials in the ceramic-based high-temperature resistant brake pad are:

[0030]

Embodiment 3

[0032] The ceramic-based high-temperature-resistant brake pad described in this embodiment is prepared from a binder, a reinforcing fiber, a friction modifier and a filler; wherein, the binder includes resin and rubber powder; the reinforcing fiber includes mineral fiber , aramid fibers, potassium titanate whiskers; the friction modifier includes graphite, chromite powder, zircon powder, antimony sulfide, molybdenum disulfide, tin sulfide, aluminum oxide; the filler is barium sulfate, carbonic acid calcium.

[0033] The parts by weight of various raw materials in the ceramic-based high-temperature resistant brake pad are:

[0034]

[0035] The preparation method of the ceramic-based high-temperature resistant brake pad of the present invention comprises the following steps:

[0036] 1. Ingredients: Weigh various raw materials according to the raw material formula;

[0037] 2. Mixing: Put various raw materials into the mixer, mix for 5-10 minutes, and make cold blocks;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

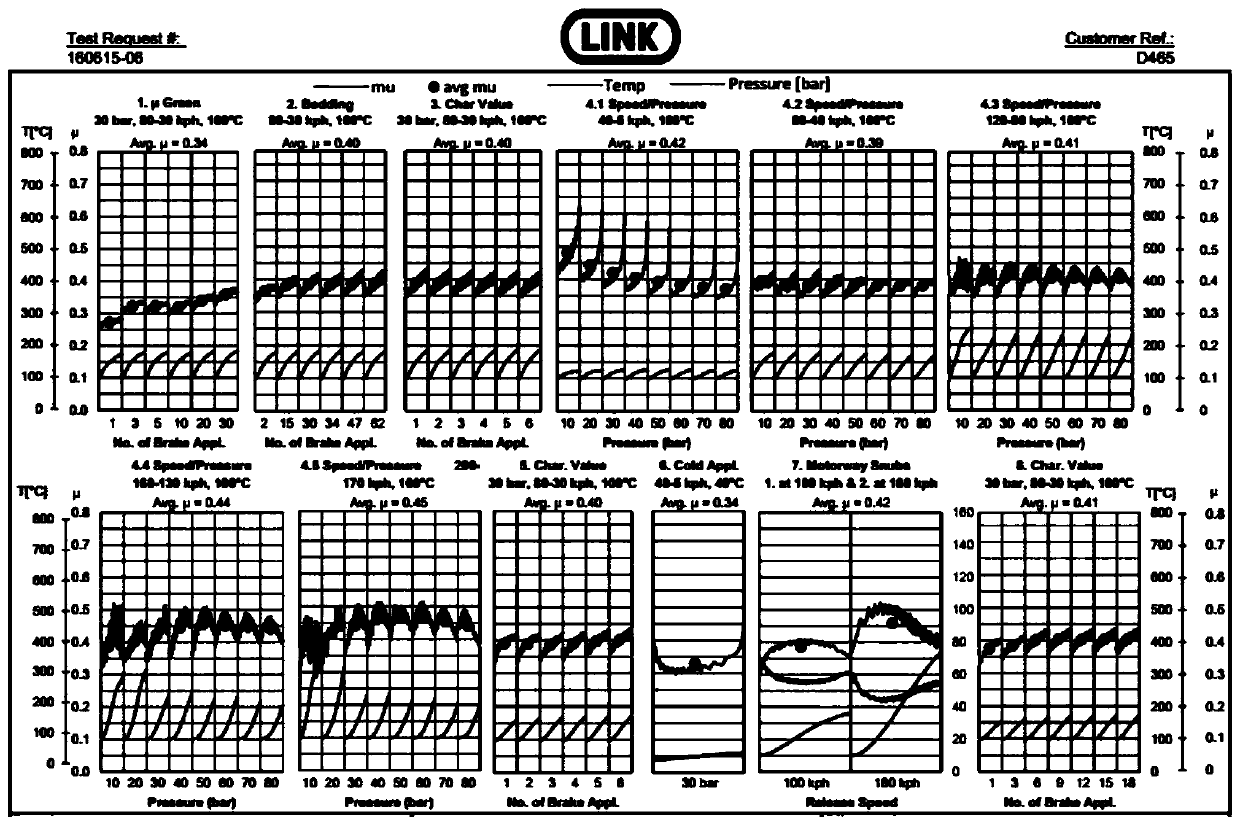

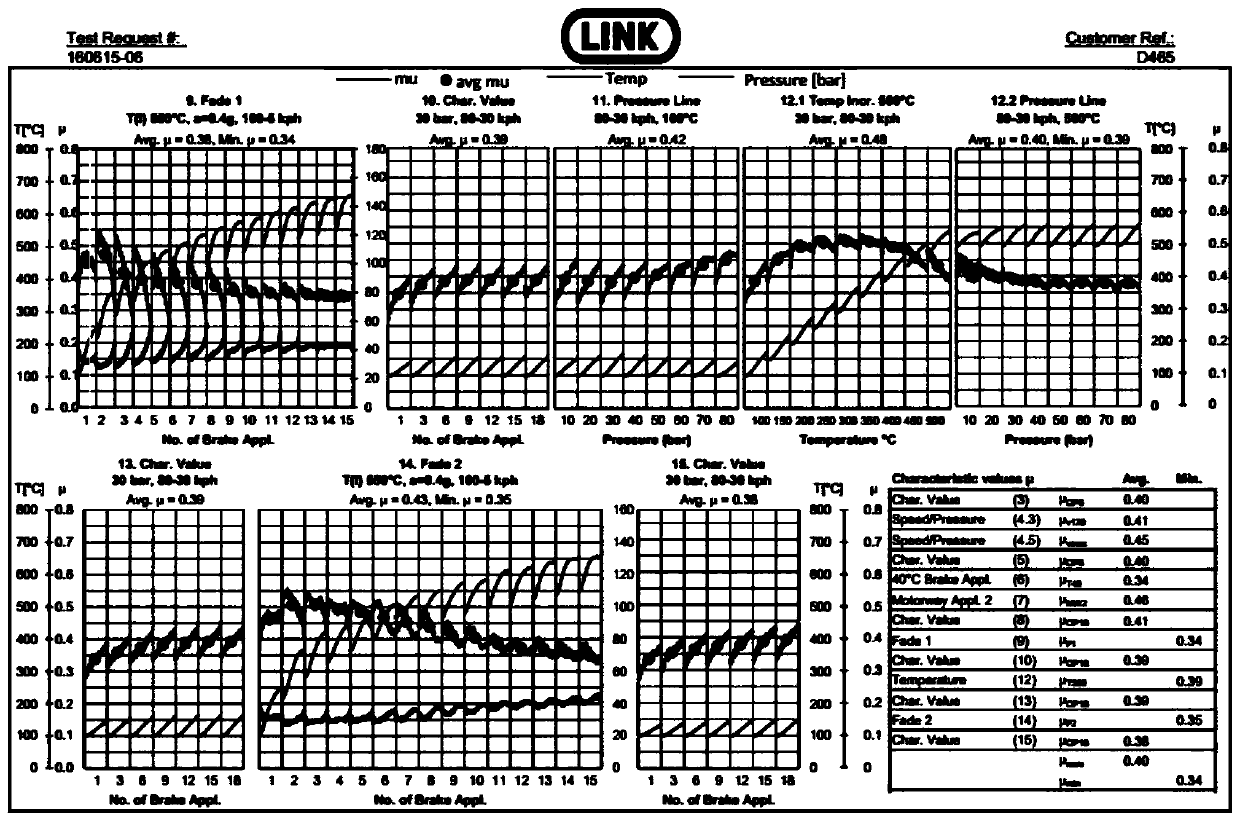

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com