Ore crushing dedusting system

A dust removal device and ore crushing technology, applied in grain processing, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as endangering the health of personnel on the job site, blocking the operation of mechanical equipment, polluting the working environment of the site, and reducing equipment cleaning and maintenance costs, equipment investment is small, and the effect of optimizing the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

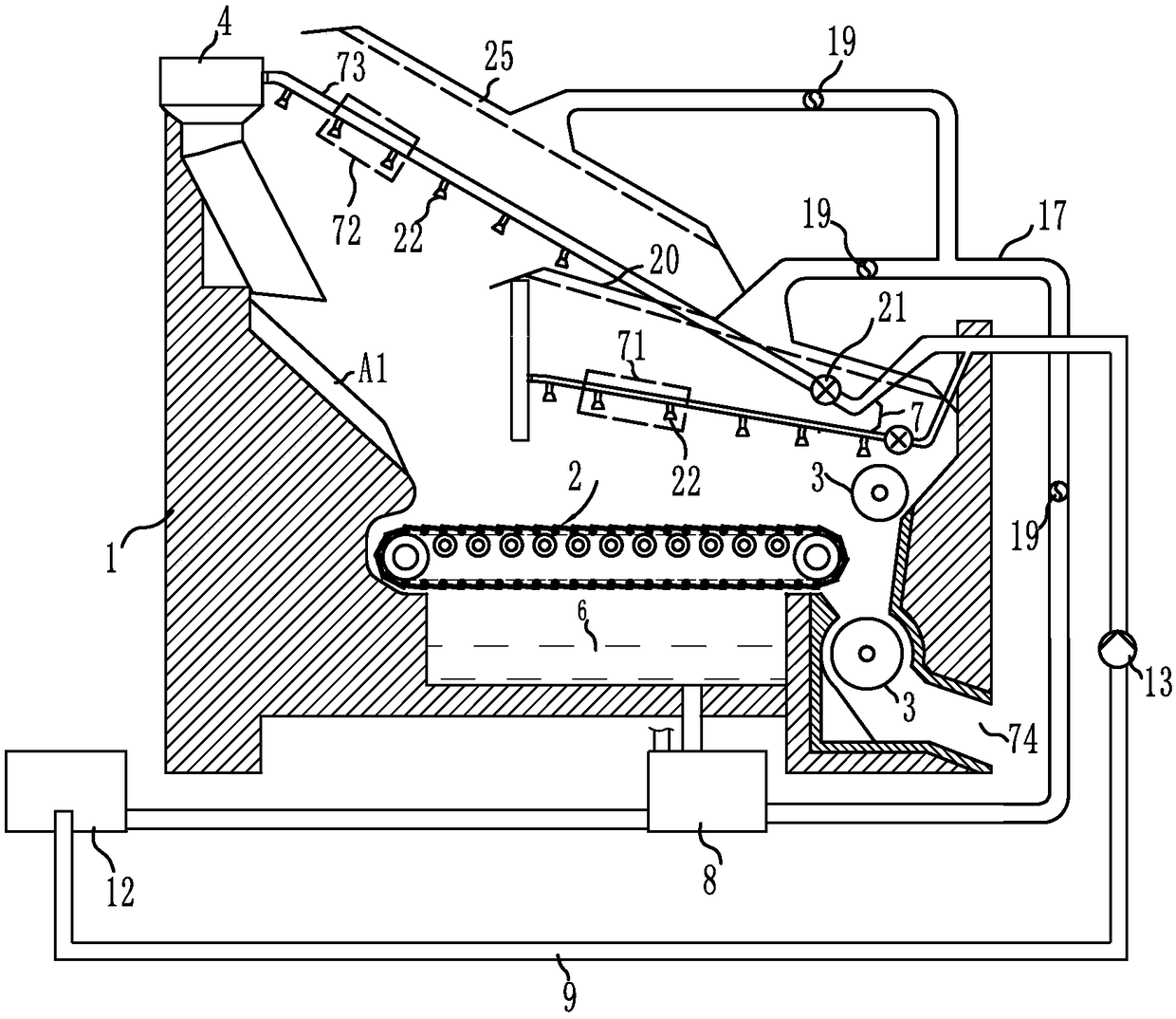

[0026] Embodiment 1: refer to figure 1 with figure 2

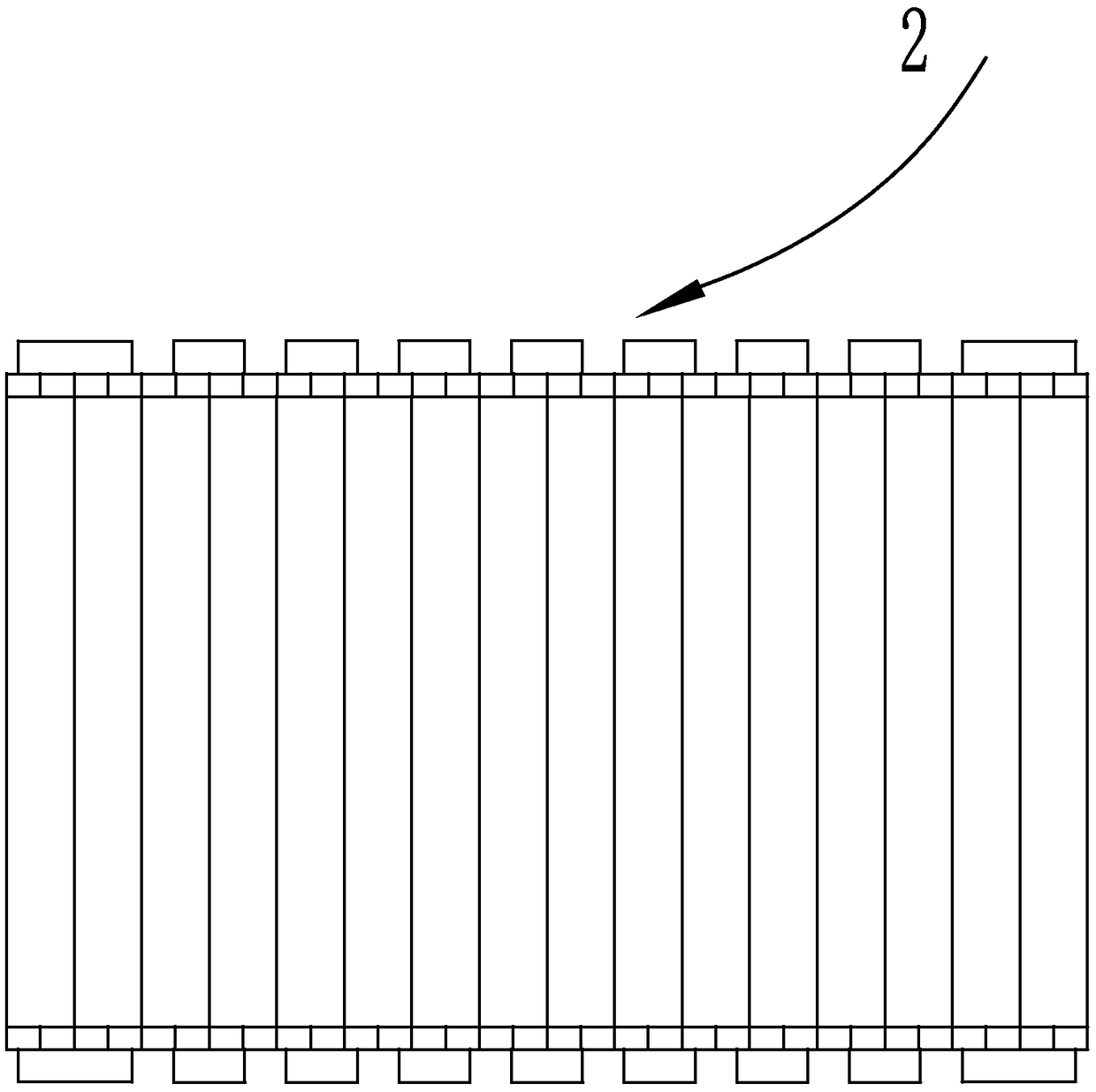

[0027] An ore crushing and dedusting device, mainly composed of a base 1, a transmission device 2, a crusher 3, a feed port 4 and a discharge port 74;

[0028] The conveying device 2 is set on the base 1, the feeding port 4 is set on the base 1 and close to the input end of the conveying device 2, an inclined slideway A1 is set between the feeding port 4 and the conveying device 2, and the crusher 3 is set on the base 1 and close to the output end of the conveying device 2, the discharge port 74 is set at the discharge end of the crusher 3; a water collection tank 6, a water spray device 7, a clean water tank 12 and a sewage tank 8 are also provided;

[0029] The sump 6 is arranged at the lower part of the conveying device 2, and the sump 6 communicates with the sewage tank 8 through a connecting pipe;

[0030] The water spray device 7 is fixed on the base 1 and communicates with the clean water tank 12 through the wat...

Embodiment 2

[0032] Embodiment 2: refer to figure 1 with figure 2

[0033] Compared with Embodiment 1, the difference is that a dust collection hood is also provided, and the dust collection hood includes No. 1 dust collection hood 20, No. 2 dust collection hood 25 and gas collection pipe 17, wherein No. 1 dust collection hood 20 is arranged on a Above the No. water spraying part 71, the No. 2 dust collecting cover 25 is arranged above the No. 2 water spraying part 72; the No. 1 dust collecting cover 20 and the No. 2 dust collecting cover 25 communicate with the sewage tank 8 through the air collecting pipe 17, and the air collecting pipe 17 pipelines are provided with a negative pressure fan 19.

[0034] The dust that is not removed in time by wet method is collected by No. 2 dust collection cover 25 and enters the return air pipe 17b; the dust generated during the ore crushing process is concentrated at the output end of the conveyor 2, and at this time, No. 1 water spraying part 71 c...

Embodiment 3

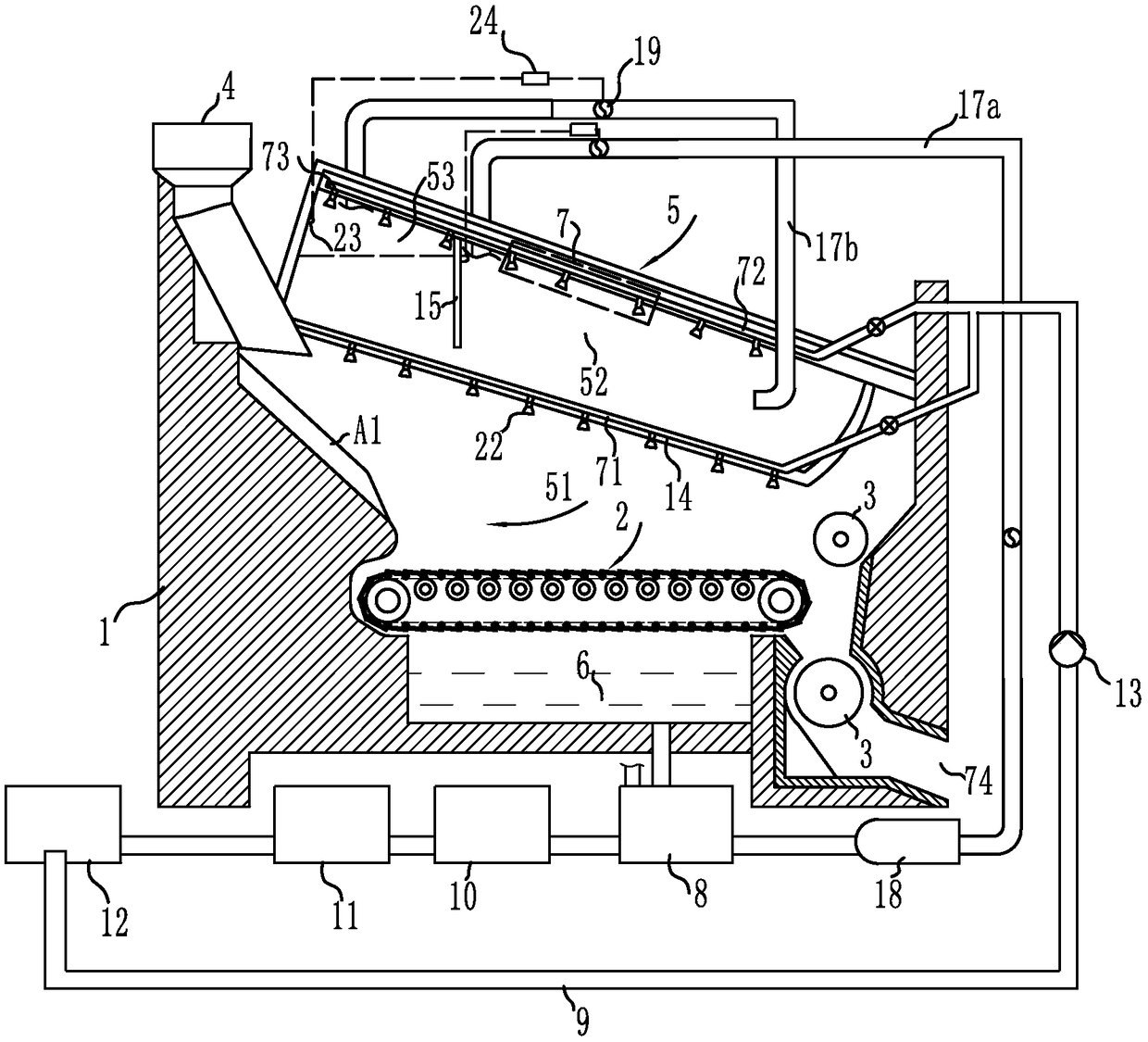

[0035] Embodiment 3: refer to image 3 with Figure 4

[0036]Compared with Embodiment 1, the difference is that the ore crushing and dedusting device also includes a dedusting chamber 5, which is obliquely arranged on the base 1, and the middle part of the dedusting chamber 5 is horizontally provided with a blocking plate 14, on which there are There are through holes 141, and the dust removal chamber 5 is vertically provided with a baffle plate 15. There is a certain gap between the block plate 14 and the baffle plate 15, and the block plate 14 and the baffle plate 15 divide the dust removal chamber 5 into a No. 1 dust removal chamber. 51. No. 2 dust removal chamber 52 and No. 3 dust removal chamber 53; said No. 1 dust removal chamber 51, No. 2 dust removal chamber 52 and No. 3 dust removal chamber 53 communicate with the sewage tank 8 through the air collecting pipe 17, and one end of the return air pipe 17b is connected to the third dust removal chamber. No. dust removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com