Building wall caulking gun

A technology of grooves and walls, applied in the direction of buildings and building structures, can solve the problems of low construction work efficiency, hand damage to the grooves and bags, and large loss of mortar, so as to improve the anti-leakage and frost resistance, Improves overall durability and increases the effect of plumpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

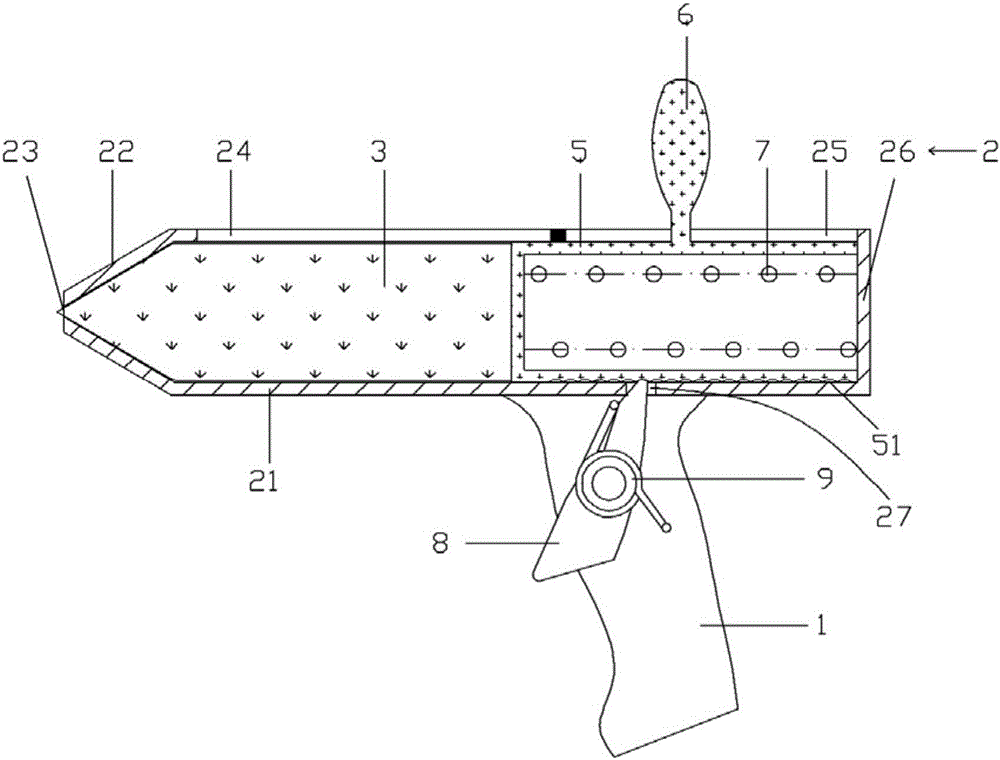

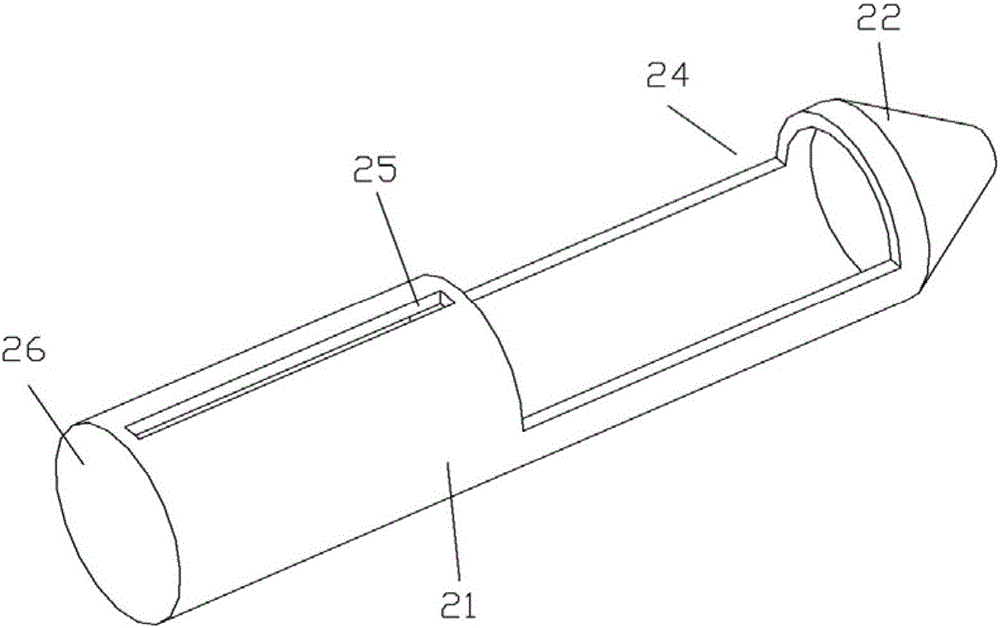

[0018] Example: see Figures 1 to 3 As shown, the building wall ditch gun includes a gun handle 1 and a gun barrel 2, the gun barrel 2 is fixed on the gun handle 1, and the structure of the gun barrel 2 is that a tapered tip is formed on the front end of the cylindrical barrel body 21 22. The end of the tapered nozzle 22 is formed with a nozzle opening 23, the upper part of the cylinder body 21 is formed with a cylinder body gap 24 and the cylinder body strip hole 25, and the bottom of the cylinder body 21 is formed with a cover 26;

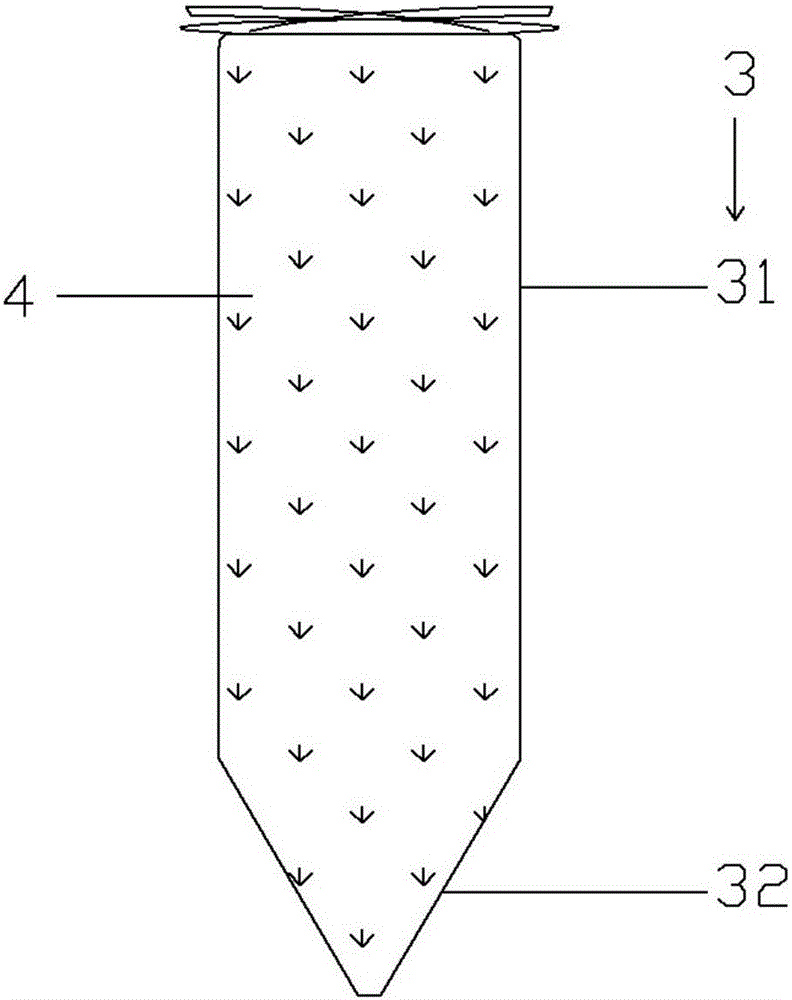

[0019] The structure of the slotted bag 3 is that a tapered pocket 32 is formed at the front end of the cylindrical bag body 31, and the mortar 4 is placed in the slotted bag 3;

[0020] The upper part of the pressure cylinder 5 is fixedly connected with a handle 6, the handle 6 is inserted into the hole 25 of the cylinder body, the right end of the spring 7 is pressed on the cover 26, and the left end is pressed on the pressure cylinder 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com