Disc brake assembly

A technology of disc brakes and brake discs, applied in the direction of brake types, brake components, gear transmission mechanisms, etc., can solve the problems of high manufacturing cost, consumption, and consumption design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

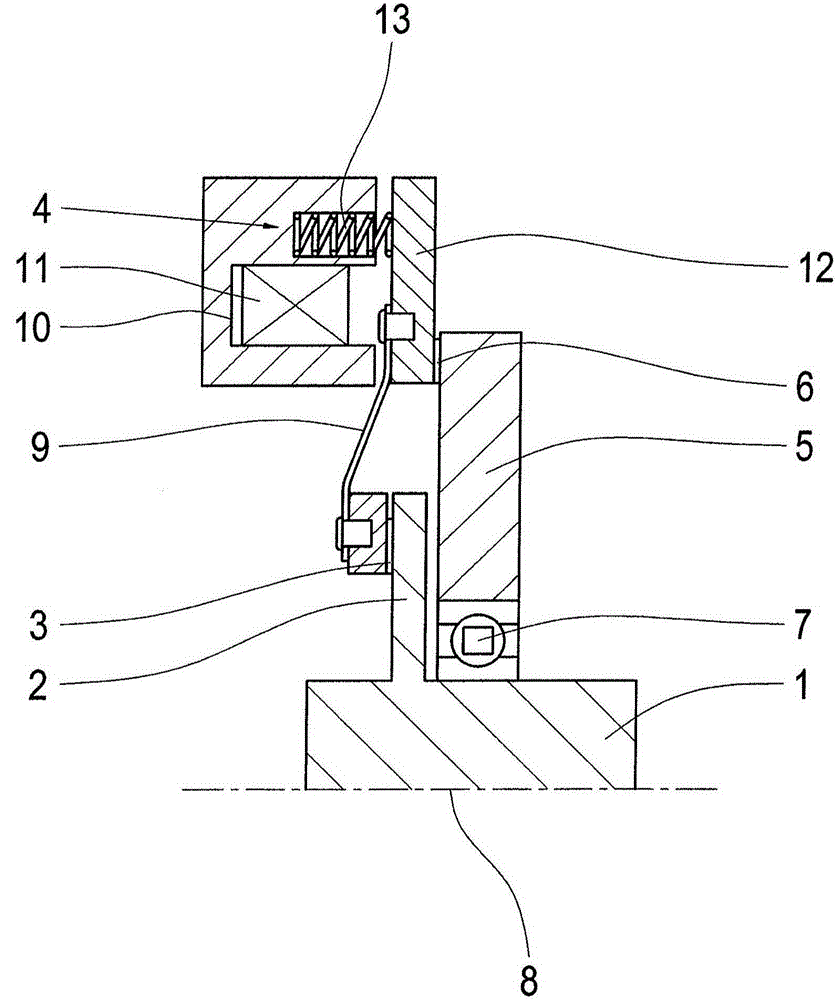

[0016] In the embodiment variant shown, a single-sided brake is shown. However, it is conceivable to use double-sided brakes or multi-disk brakes. Independent of the corresponding brake design used, this type of brake has the advantage that maintenance-free operation is ensured over the entire service life of the drive system.

[0017] The disc brake mechanism or disc brake is used to apply a predetermined braking torque depending on the direction of rotation in order to decelerate the shaft 1 . The disc brake mechanism comprises a first brake disc 2 connected in a rotationally fixed manner to the shaft 1 and at least one associated first friction surface 3 , which can be activated via a brake actuating device 4 for applying a desired braking torque. Connection (Wirkverbindung).

[0018] According to the invention it is provided that at least one second brake disk 5 is provided with at least one second friction surface 6 , wherein the braking torque transmittable to the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com