Preparation method for lanthanide modified brake pad of mining truck

A brake pad and modification technology, applied in the field of friction material preparation, can solve problems such as environmental pollution around the workplace, and achieve the effects of improving thermal fading performance, less wear, and reducing noise

Inactive Publication Date: 2013-12-11

BAOTOU DACHUAN MACHINERY SCI & TECH

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0032] The present invention will be described in detail below in combination with specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

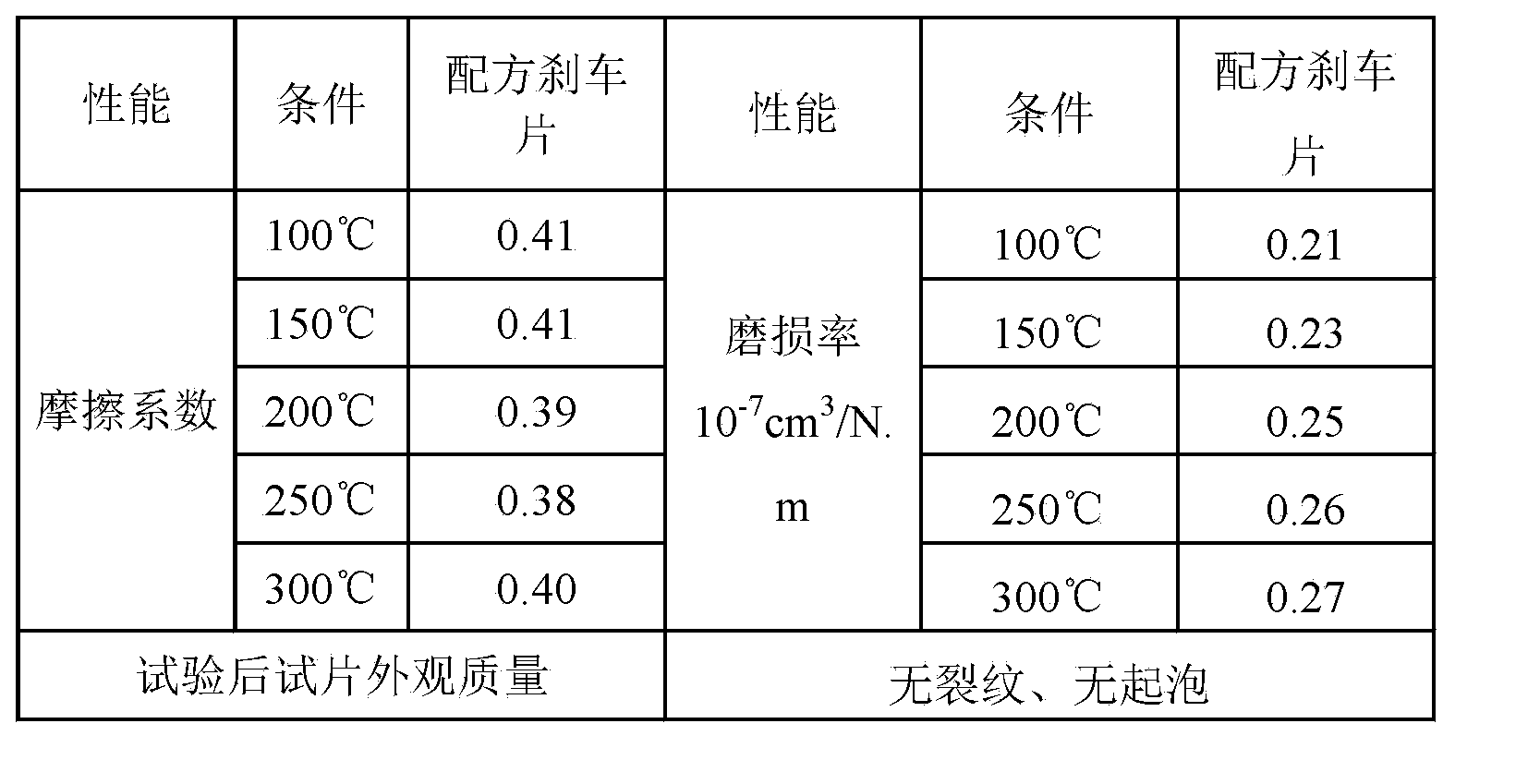

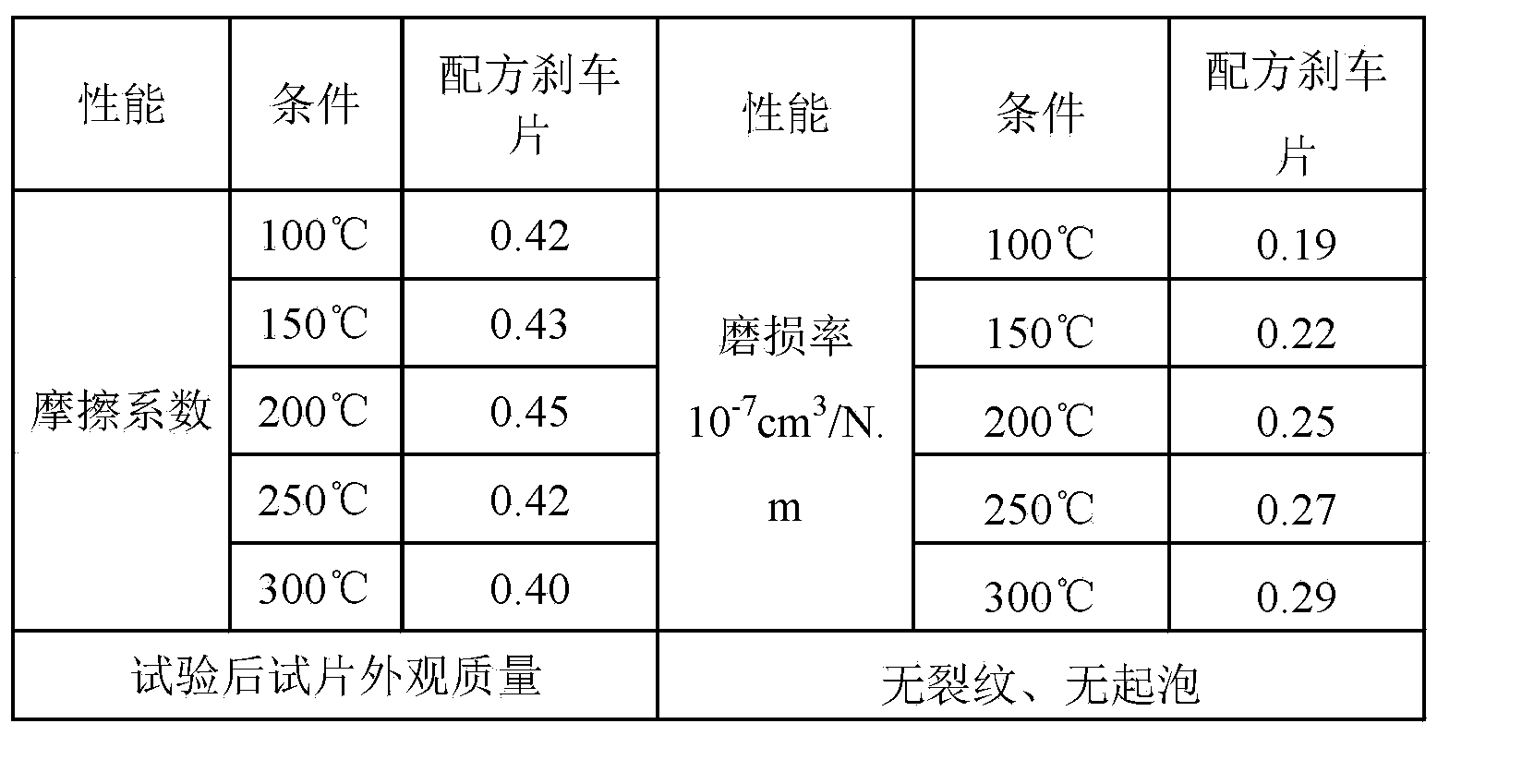

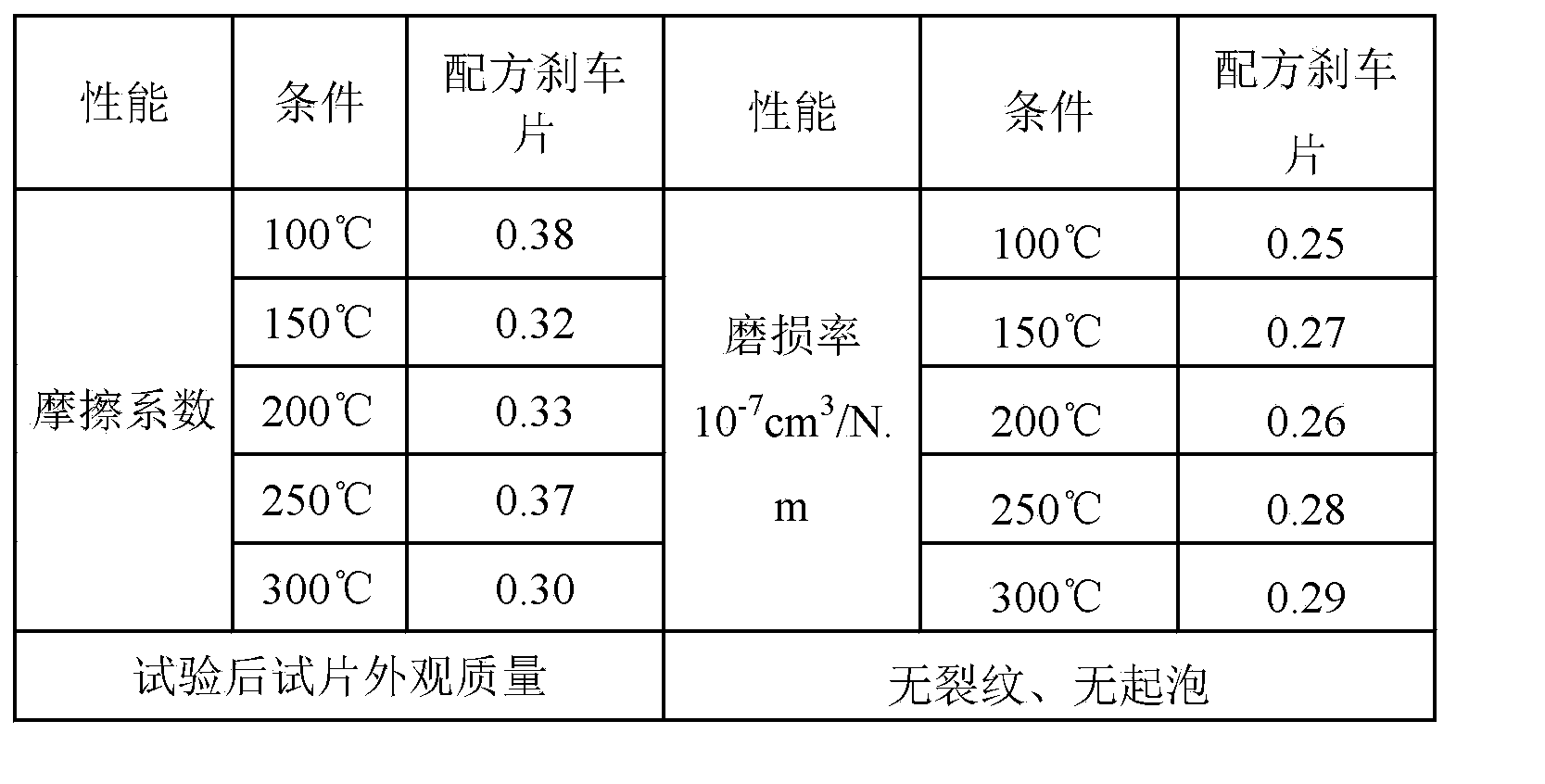

The invention discloses a preparation method for a lanthanide modified brake pad of a mining truck. The brake pad is prepared through taking lanthanide oxides, reinforcing fibers, binding agent, conditioning agent and filling powder as the principle additive raw materials and adopting the procedures of mixing, cold pressing, hot pressing and heat treatment for modification. The product prepared through the method has the advantages of high temperature resistance, good heat fading performance, stable friction coefficient, excellent braking performance, good abrasion resistance, long service life, low braking noise, and good conformance to environmental protection requirements, and can completely satisfy the specific requirements of high deadweight tonnage, large braking torque, high braking frequency and great calorific value for the mining truck.

Description

technical field [0001] The invention belongs to the technical field of preparation of friction materials, and in particular relates to a preparation method of a mining automobile brake pad modified by lanthanide elements. Background technique [0002] Automobile brake pads were originally made of cotton and leather as substrates, but due to poor heat resistance and poor braking effect, they were replaced by asbestos friction material brake pads. In the 1960s, it was discovered that asbestos material is a strong carcinogenic industrial raw material, and people gradually realized that asbestos is harmful to human health, and then asbestos material brake pads were forced to withdraw from the stage of history. A variety of friction materials such as semi-metal, powder metallurgy, carbon fiber, ceramic fiber and other brake pads have been developed successively at home and abroad. Due to their good performance, they have been widely used in road vehicles and made a certain contri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K3/14F16D69/02C08L61/14C08K13/04C08K3/22C08K7/06C08K3/08C08K3/30C08K3/06C08K3/04C08K3/34C08K3/38

Inventor 李大玉谢璐陈代军钟云汉高瑞芳

Owner BAOTOU DACHUAN MACHINERY SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com