A multi-metal friction material

A friction material and multi-metal technology, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as unstable braking, poor braking performance, and poor high-temperature recovery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

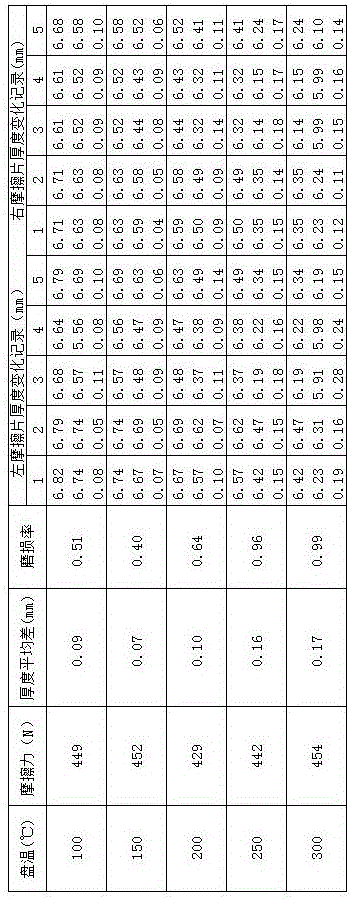

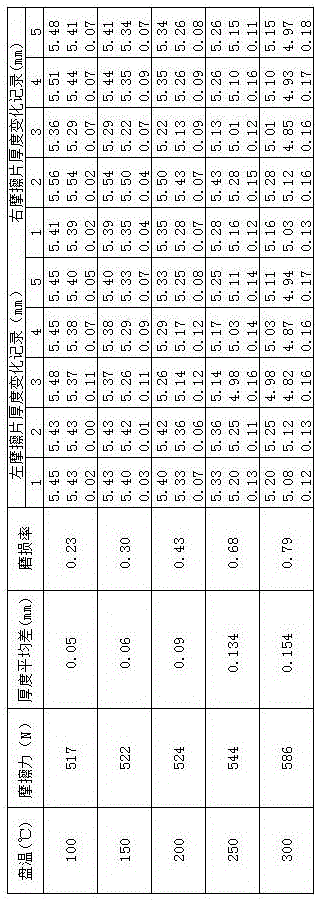

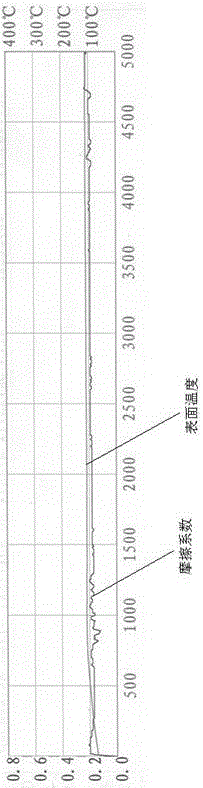

Embodiment 1

[0021] The invention discloses a multi-metal friction material; the multi-metal friction material includes resin, carbon, fiber material, inorganic minerals, and at least two kinds of metal materials; wherein, the resin adopts phenolic resin; the carbon is composed of coke and phosphorus graphite; the fiber material is composed of steel fiber, aramid fiber, wood fiber, Longgang fiber and glass fiber; the inorganic mineral is made of silica fume, feldspar powder and alumina; the metal material Consists of reduced iron powder, and steel fibers in the fibrous material.

[0022] In addition to the constituent raw materials of the above-mentioned friction material, zinc stearate, nitrile rubber powder, barium sulfate and friction powder are added to the above-mentioned multi-metal friction material.

[0023] The weight percentages of raw materials of the above multi-metal friction material are: 10% phenolic resin, 5% coke, 6% graphite flake, 20% steel fiber, 5% aramid fiber, 6% woo...

Embodiment 2

[0030] The invention discloses a multi-metal friction material; the multi-metal friction material includes resin, carbon, fiber material, inorganic minerals, and at least two kinds of metal materials; wherein, the resin adopts phenolic resin; the carbon is made of coke and phosphorus graphite; the fiber material is made of steel fiber, aramid fiber, wood fiber, Longgang fiber and glass fiber; the inorganic mineral is made of silica fume, feldspar powder and alumina; the metal material Consists of reduced iron powder, and steel fibers in the fibrous material.

[0031] In addition to the constituent raw materials of the above-mentioned friction material, zinc stearate, nitrile rubber powder, barium sulfate and friction powder are added to the above-mentioned multi-metal friction material.

[0032]The weight percentages of raw materials of the above multi-metal friction material are: 10% phenolic resin, 8% coke, 8% graphite flake, 16% steel fiber, 7% aramid fiber, 7% wood fiber, ...

Embodiment 3

[0035] The invention discloses a multi-metal friction material; the multi-metal friction material includes resin, carbon, fiber material, inorganic minerals, and at least two metal materials; wherein, the resin is phenolic resin; the carbon is made of carbon black and Phosphorus flake graphite is mixed; the fiber material is made of steel fiber, aramid fiber, wood fiber, Longgang fiber and glass fiber; the inorganic mineral is made of silica fume wool, feldspar powder, alumina and clay; The metal material is composed of reduced iron powder and steel fibers in the fiber material.

[0036] In addition to the constituent raw materials of the above-mentioned friction material, zinc stearate, nitrile rubber powder, barium sulfate and friction powder are added to the above-mentioned multi-metal friction material.

[0037] The weight percent of the raw materials of the above multi-metal friction material is: 10% phenolic resin, 6% carbon black, 6% graphite flake, 20% steel fiber, 5% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com