Braking device of electric block

A braking device and electric hoist technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of broken workers, reduced braking performance of the braking mechanism of the reducer, and easy damage to the scene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

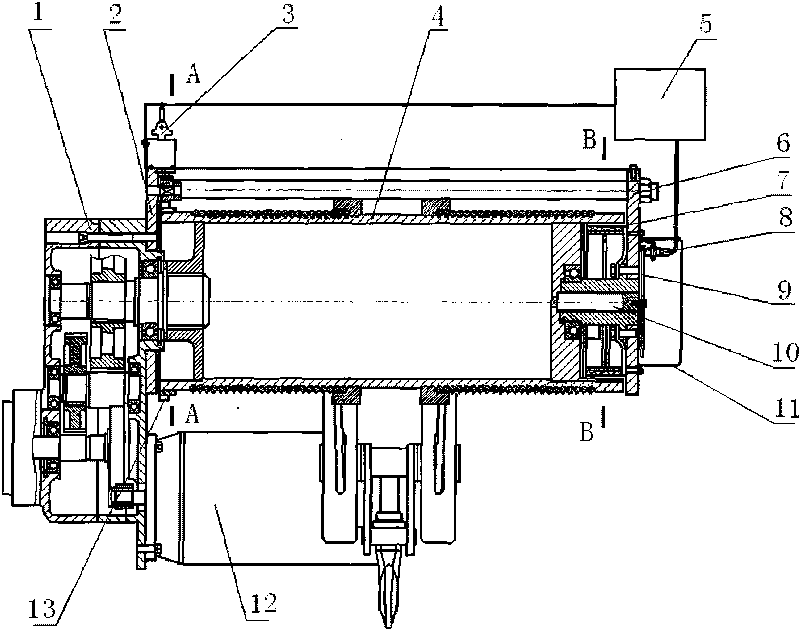

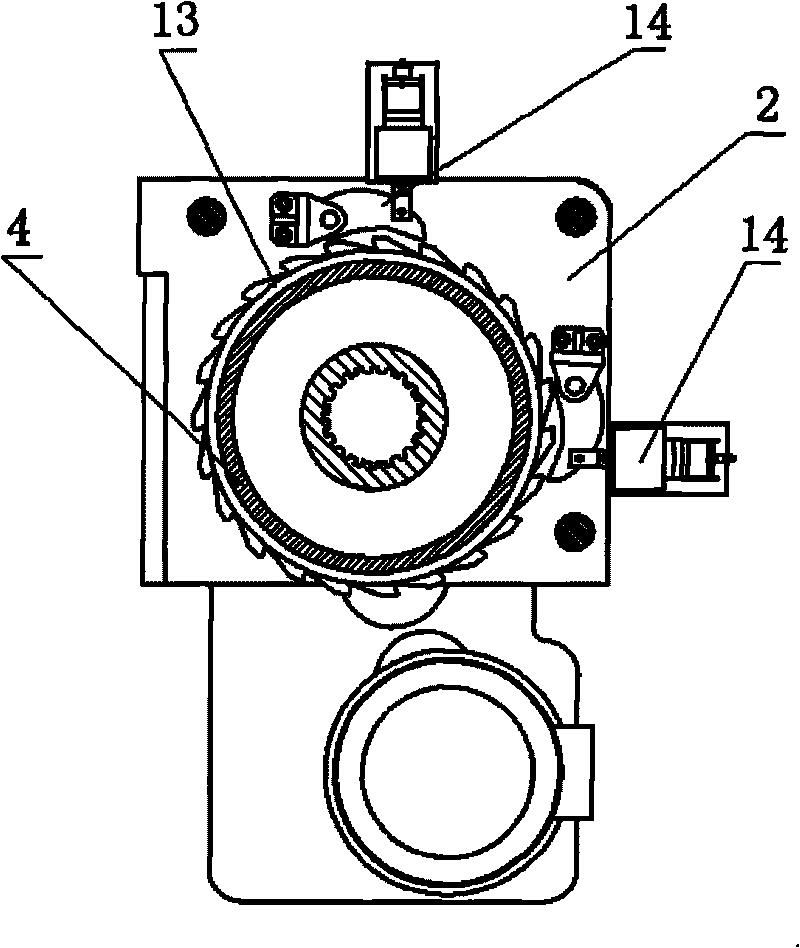

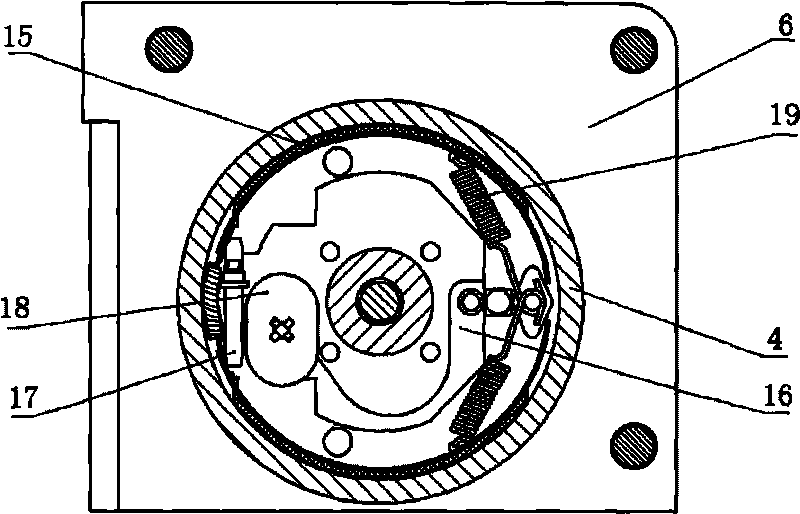

[0014] Such as figure 1 , figure 2 , image 3 As shown, an electric hoist braking device is composed of a motor braking mechanism, a reducer braking mechanism and a drum forced braking mechanism. The drum forced braking mechanism includes a speed sensor connected to the extension end of the drum output shaft 10 Disk 9, the speed sensor 8 of the speed induction disk 9 rotating speed of perception speed sensor 8, the speed electric control part 5 that links to each other with speed sensor 8, ratchet 13, the ratchet mechanism 3 that is controlled by the speed electric control part 5, protective cover 11 and by The rotating speed electric control part 5 controls the action of the drum brake 7, the ratchet 13 is fixedly connected to the opposite end of the speed induction disk 9 of the reel 4, and has a gap with the motor 12, the position of the ratchet mechanism 3 is adapted to the ratchet 13, and the speed There is a space between the induction disk 9 and the reel bearing supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com