Hydraulic disc brake lining and preparation method thereof

A technology of disc brakes and linings, applied in chemical instruments and methods, friction linings, mechanical equipment, etc., can solve the problems of reduced friction coefficient, poor heat resistance and water resistance, and achieve improved friction coefficient, humidity and water resistance properties, good low-temperature and high-temperature wear-increasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

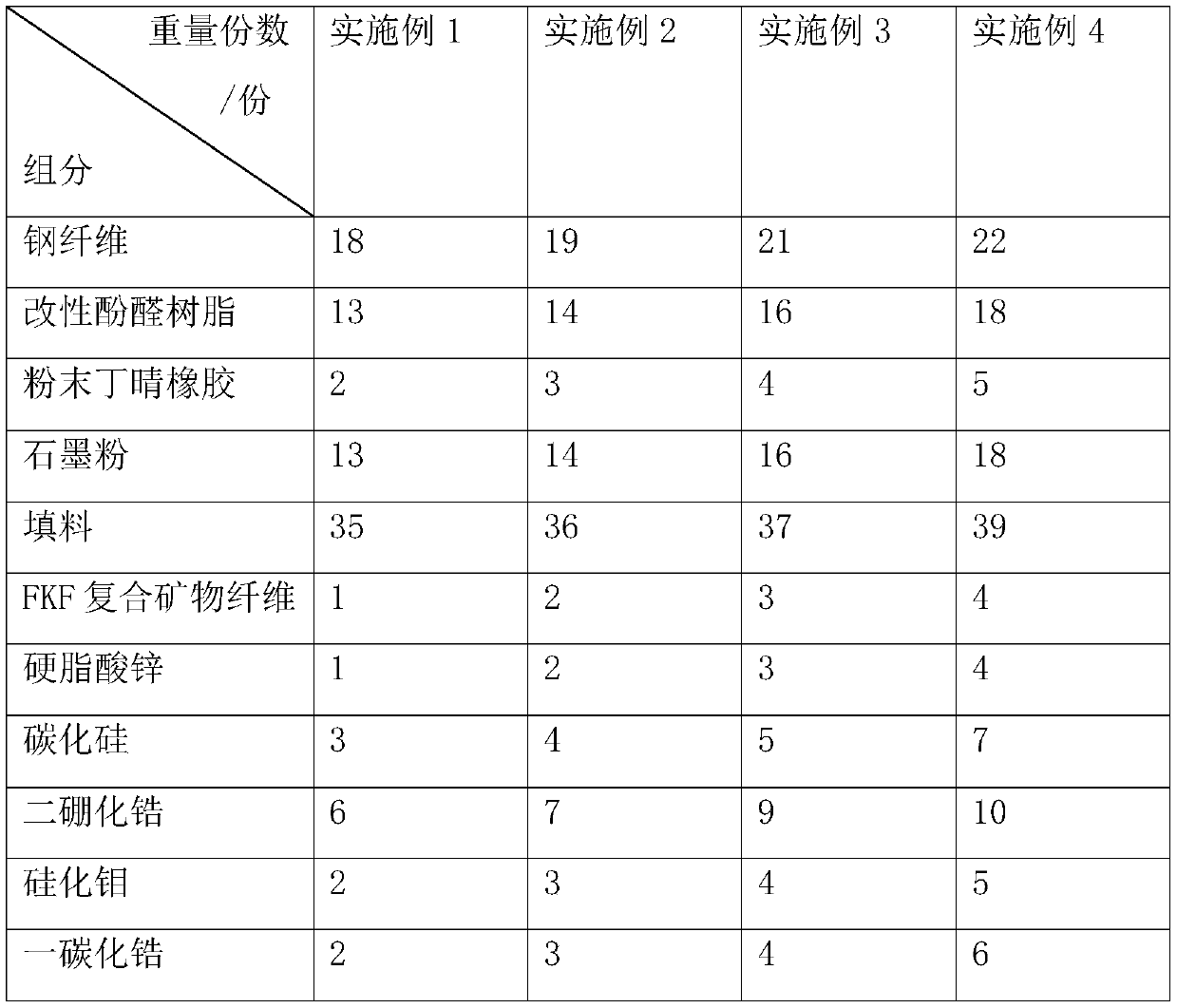

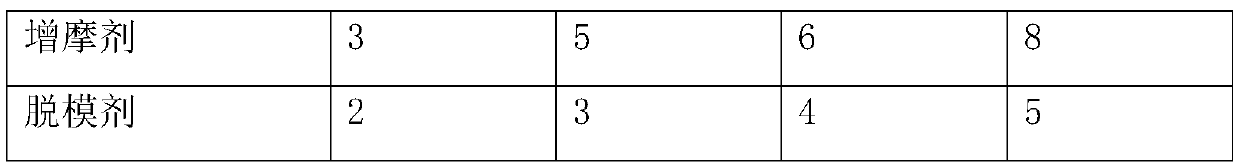

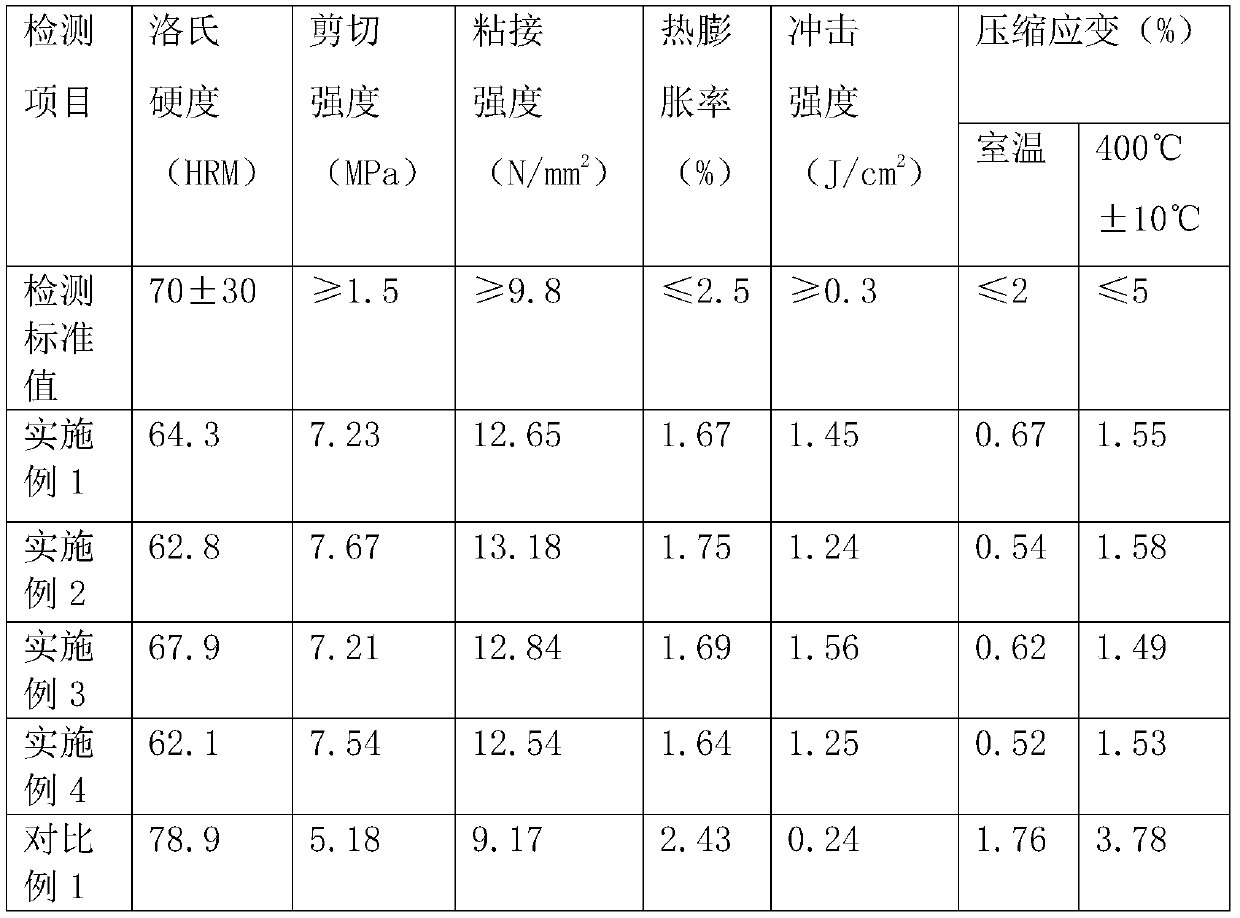

[0044] Embodiment 1: A kind of preparation method of hydraulic disc brake lining, the proportioning ratio of each component in the raw material is shown in Table 1, wherein " part " represents weight part, comprises the following steps:

[0045] S1: Mixing ingredients 1: According to the ratio of raw materials, weigh 1 part of zinc stearate, 18 parts of steel fiber, and 1 part of FKF composite mineral fiber, pour them into the mixer, and stir at a rate of 500r / min. It takes 15 minutes to fully open the fiber and discharge the material for use; the length of the steel fiber is 2nm and the diameter is 0.03mm;

[0046] S2: Mixing ingredients 2: According to the ratio of raw materials, weigh 13 parts of nitrile modified phenolic resin, 2 parts of powdered nitrile rubber, 13 parts of graphite powder, 35 parts of filler, 3 parts of silicon carbide, 6 parts of zirconium diboride, Put 2 parts of molybdenum silicide, 2 parts of zirconium carbide, 3 parts of diatomaceous earth and 2 par...

Embodiment 2

[0055] Embodiment 2: A preparation method of a hydraulic disc brake lining, the proportioning ratio of each component in the raw material is shown in Table 1, wherein "parts" represent parts by weight, comprising the following steps:

[0056] S1: Mixing ingredients 1: According to the ratio of raw materials, weigh 2 parts of zinc stearate, 19 parts of steel fiber, and 2 parts of FKF composite mineral fiber, pour them into the mixer, and stir at a rate of 600r / min. It takes 17 minutes to fully open the fiber and discharge the material for use; the length of the steel fiber is 3nm and the diameter is 0.07mm;

[0057] S2: Mixing ingredients 2: According to the ratio of raw materials, weigh 14 parts of cashew nut shell oil modified phenolic resin, 3 parts of powdered nitrile rubber, 14 parts of graphite powder, 36 parts of filler, 4 parts of silicon carbide, and 7 parts of zirconium diboride , 3 parts of molybdenum silicide, 3 parts of zirconium carbide, 5 parts of mica powder and...

Embodiment 3

[0063] Embodiment 3: A preparation method of a hydraulic disc brake lining, the ratio of each component in the raw material is shown in Table 1, wherein "parts" represent parts by weight, comprising the following steps:

[0064] S1: Mixing ingredients 1: According to the ratio of raw materials, weigh 3 parts of zinc stearate, 21 parts of steel fiber, and 3 parts of FKF composite mineral fiber, pour them into the mixer, and stir at a rate of 700r / min. It takes 18 minutes to fully open the fiber and discharge the material for use; the length of the steel fiber is 4nm and the diameter is 0.11mm;

[0065] S2: Mixing ingredients 2: According to the ratio of raw materials, weigh 16 parts of boric acid modified phenolic resin, 4 parts of powdered nitrile rubber, 16 parts of graphite powder, 37 parts of filler, 5 parts of silicon carbide, 9 parts of zirconium diboride, 4 parts 1 part of molybdenum silicide, 4 parts of zirconium carbide, 7 parts of zirconium silicate and 4 parts of rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com