Patents

Literature

328results about How to "Small thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

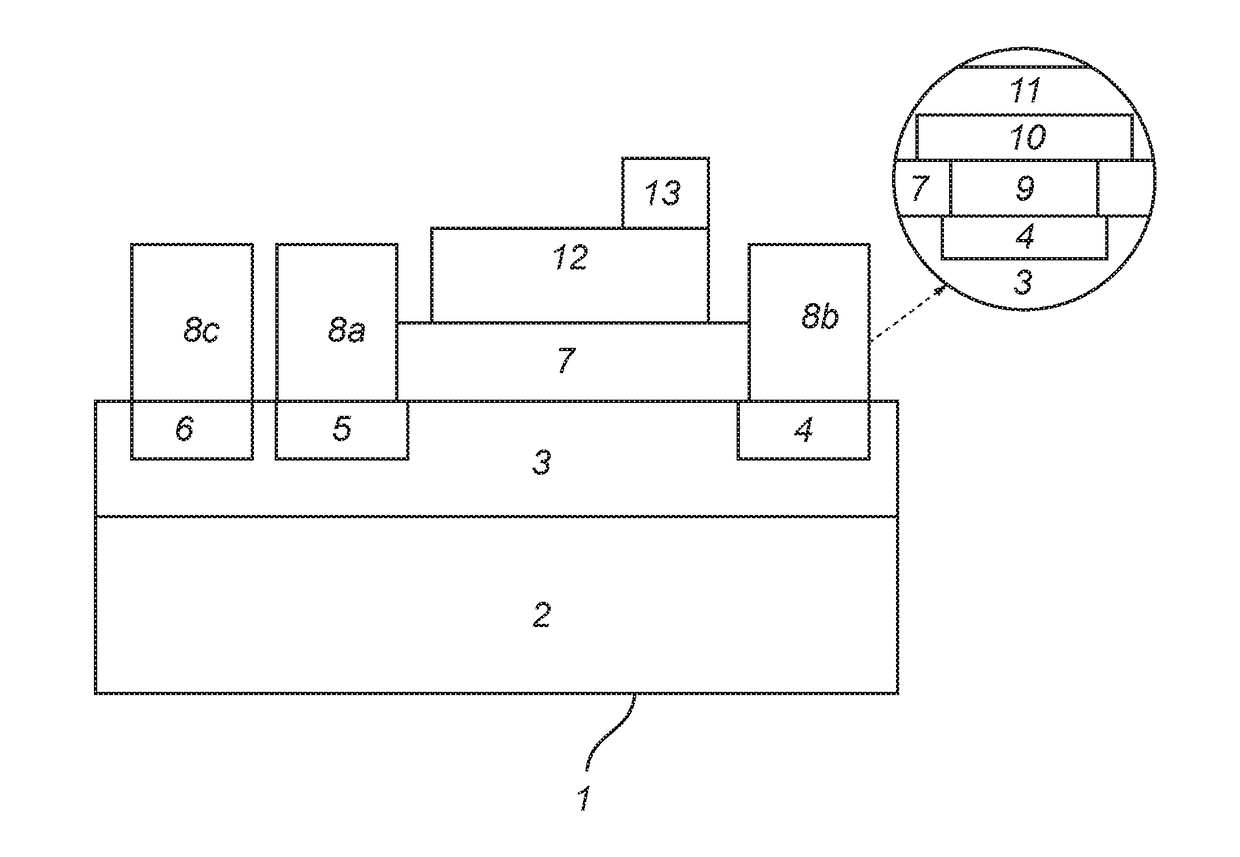

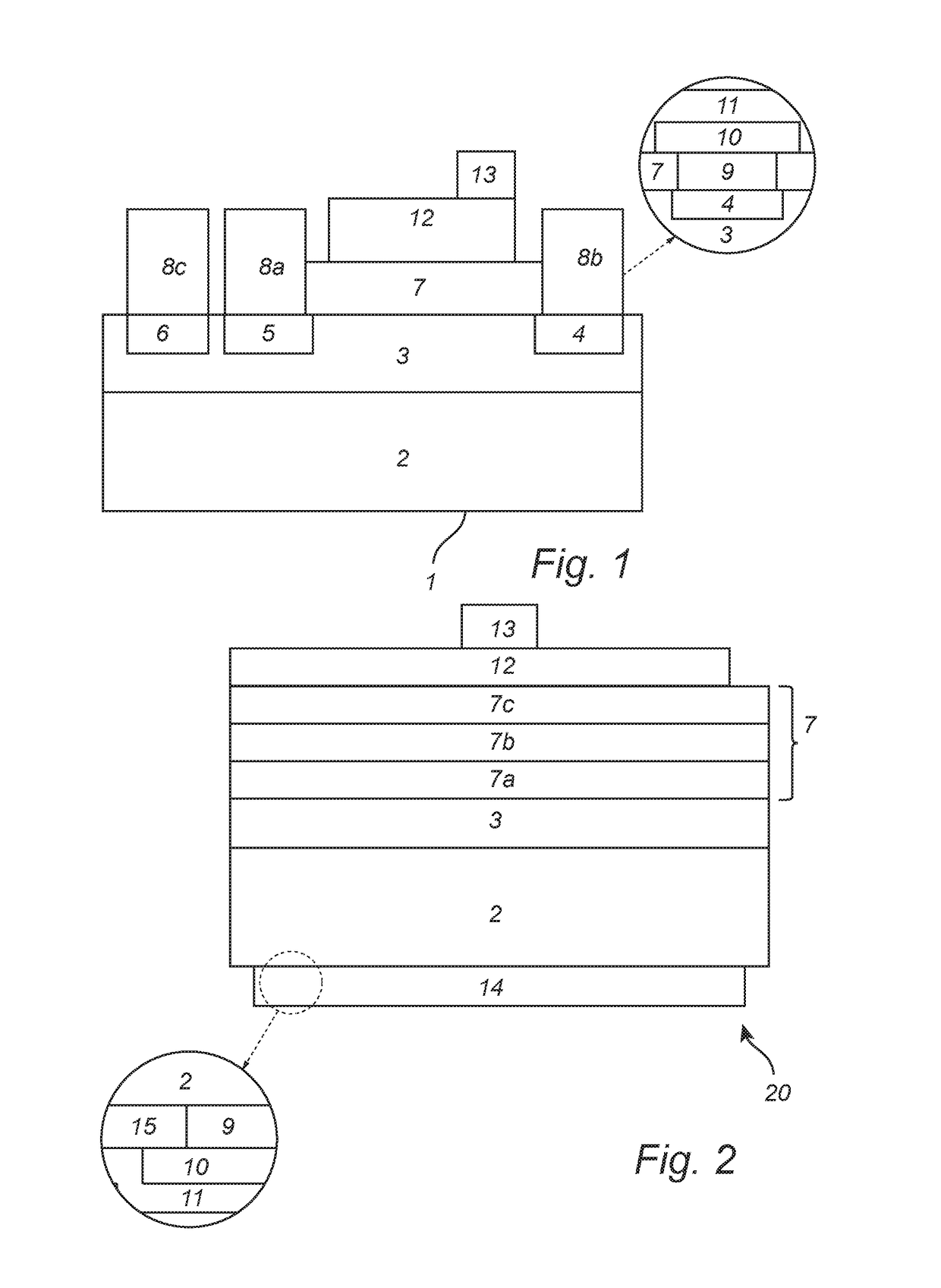

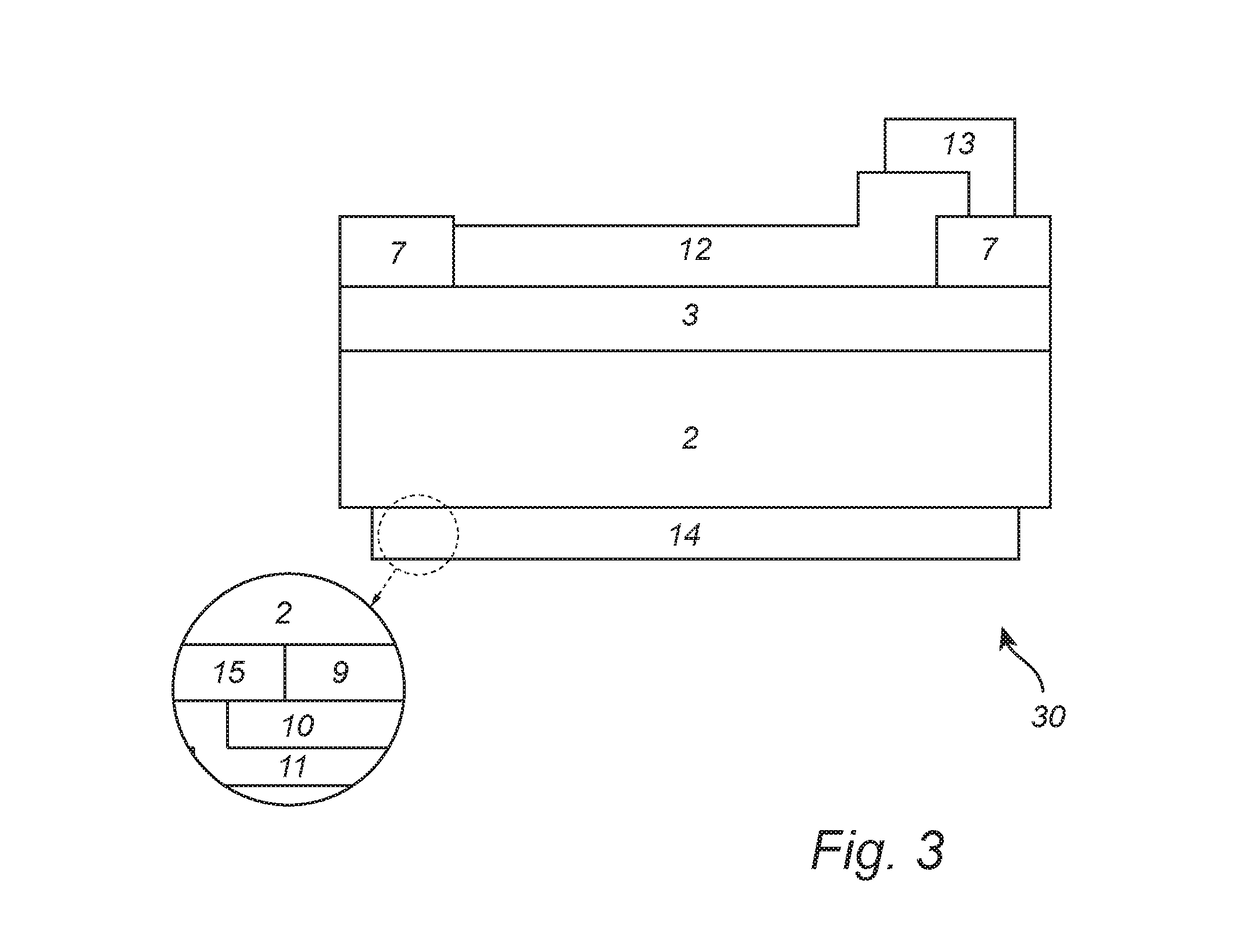

Silicon carbide based field effect gas sensor for high temperature applications

InactiveUS20180011052A1Change electrical propertiesLong-term reliable operationMaterial analysis by electric/magnetic meansSemiconductor/solid-state device manufacturingOhmic contactSemiconductor structure

A field effect gas sensor, for detecting a presence of a gaseous substance in a gas mixture, the field effect gas sensor comprising: a SiC semiconductor structure; an electron insulating layer covering a first portion of the SiC semiconductor structure; a first contact structure at least partly separated from the SiC semiconductor structure by the electron insulating layer; and a second contact structure conductively connected to a second portion of the SiC semiconductor structure, wherein at least one of the electron insulating layer and the first contact structure is configured to interact with the gaseous substance to change an electrical property of the SiC semiconductor structure; and wherein the second contact structure comprises: an ohmic contact layer in direct contact with the second portion of the SiC semiconductor structure; and a barrier layer formed by an electrically conducting mid-transition-metal oxide covering the ohmic contact layer.

Owner:VOLVO CAR CORP

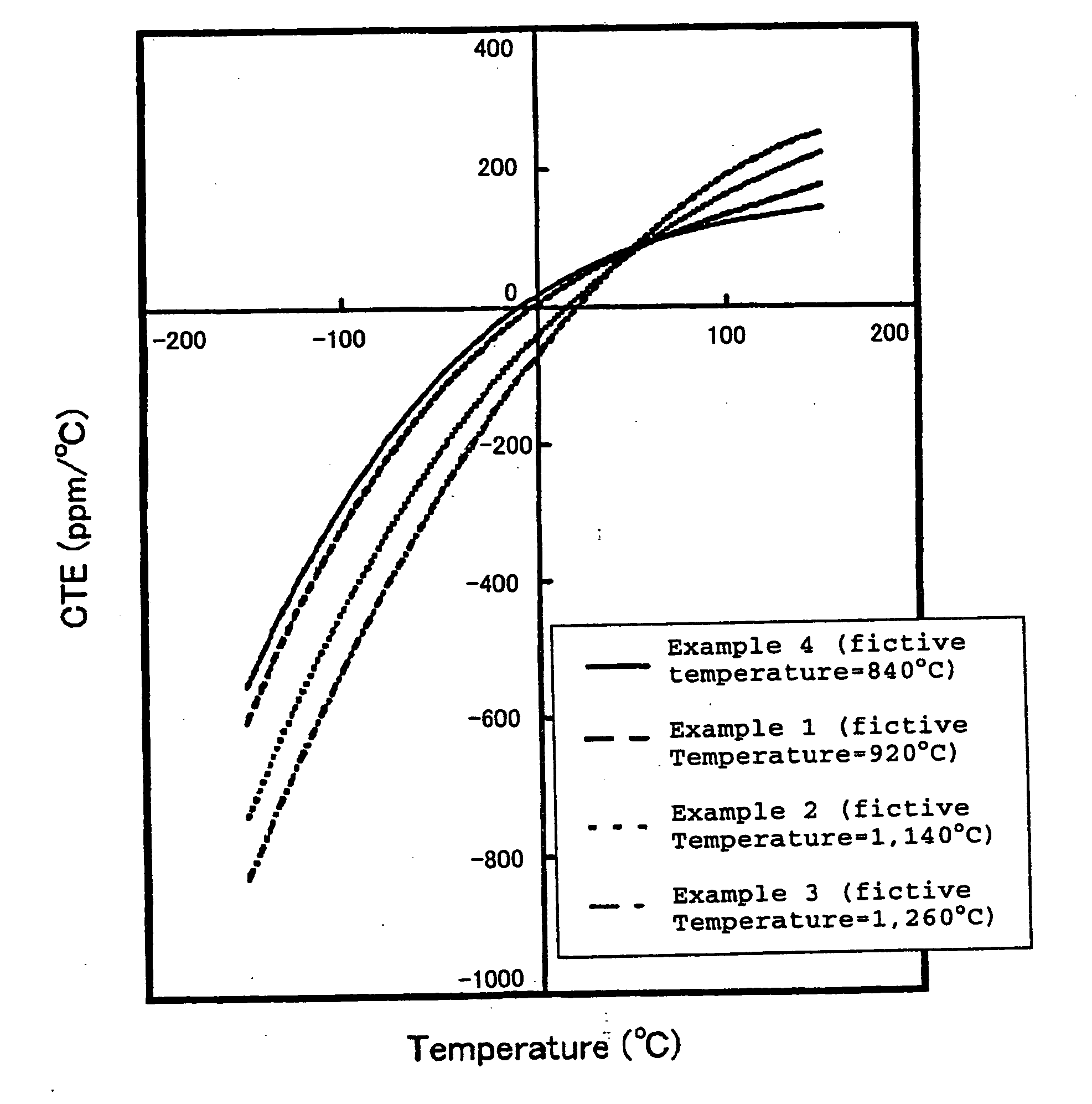

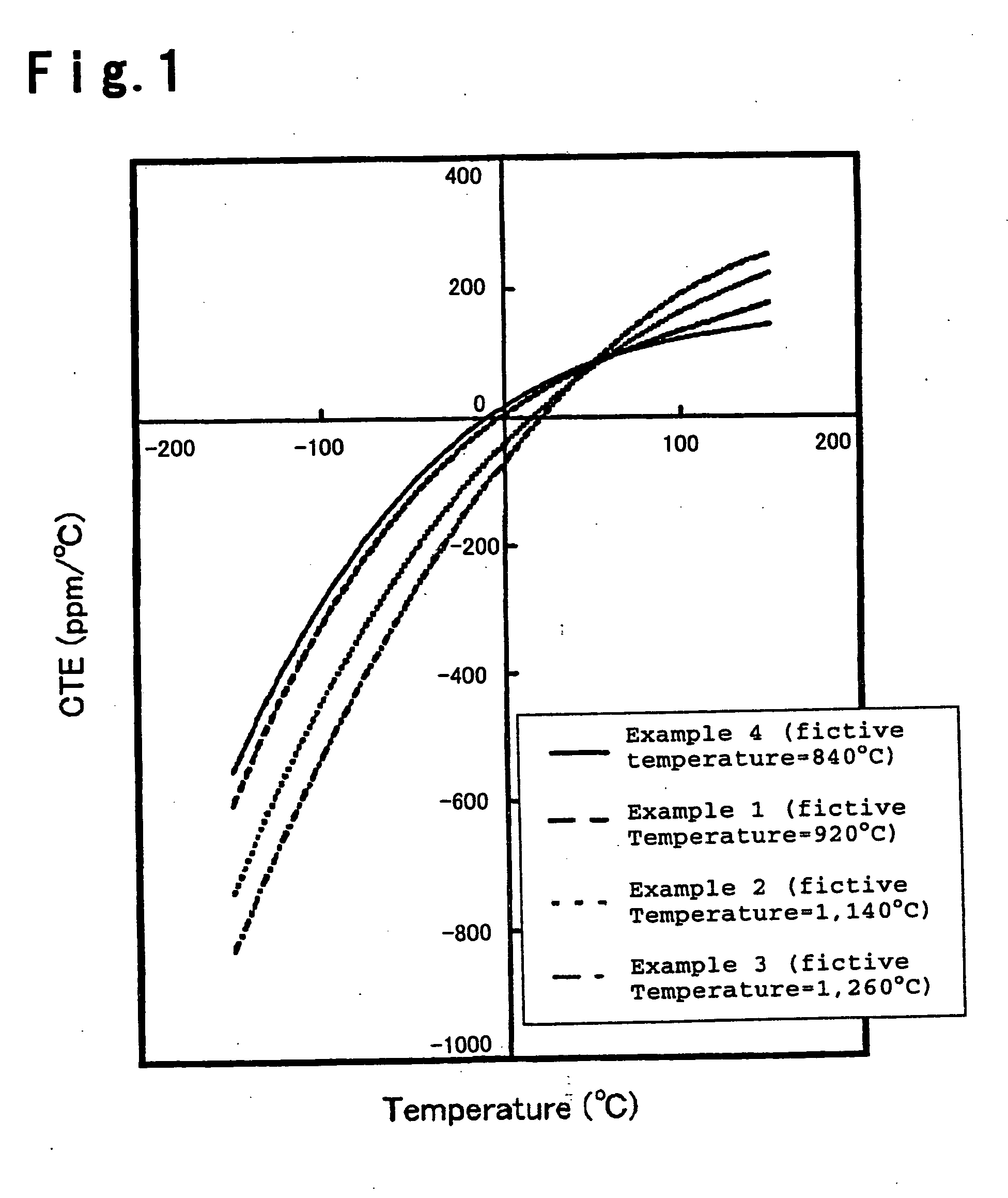

Silica glass containing TiO2 and process for its production

ActiveUS20050245382A1Excellent uniformitySmall thermal expansionSemiconductor/solid-state device manufacturingGlass shaping apparatusTitanium dioxideSilica glass

A silica glass containing TiO2, which has a fictive temperature of at most 1,200° C., an OH group concentration of at most 600 ppm and a coefficient of thermal expansion of 0±200 ppb / ° C. from 0 to 100° C.

Owner:ASAHI GLASS CO LTD

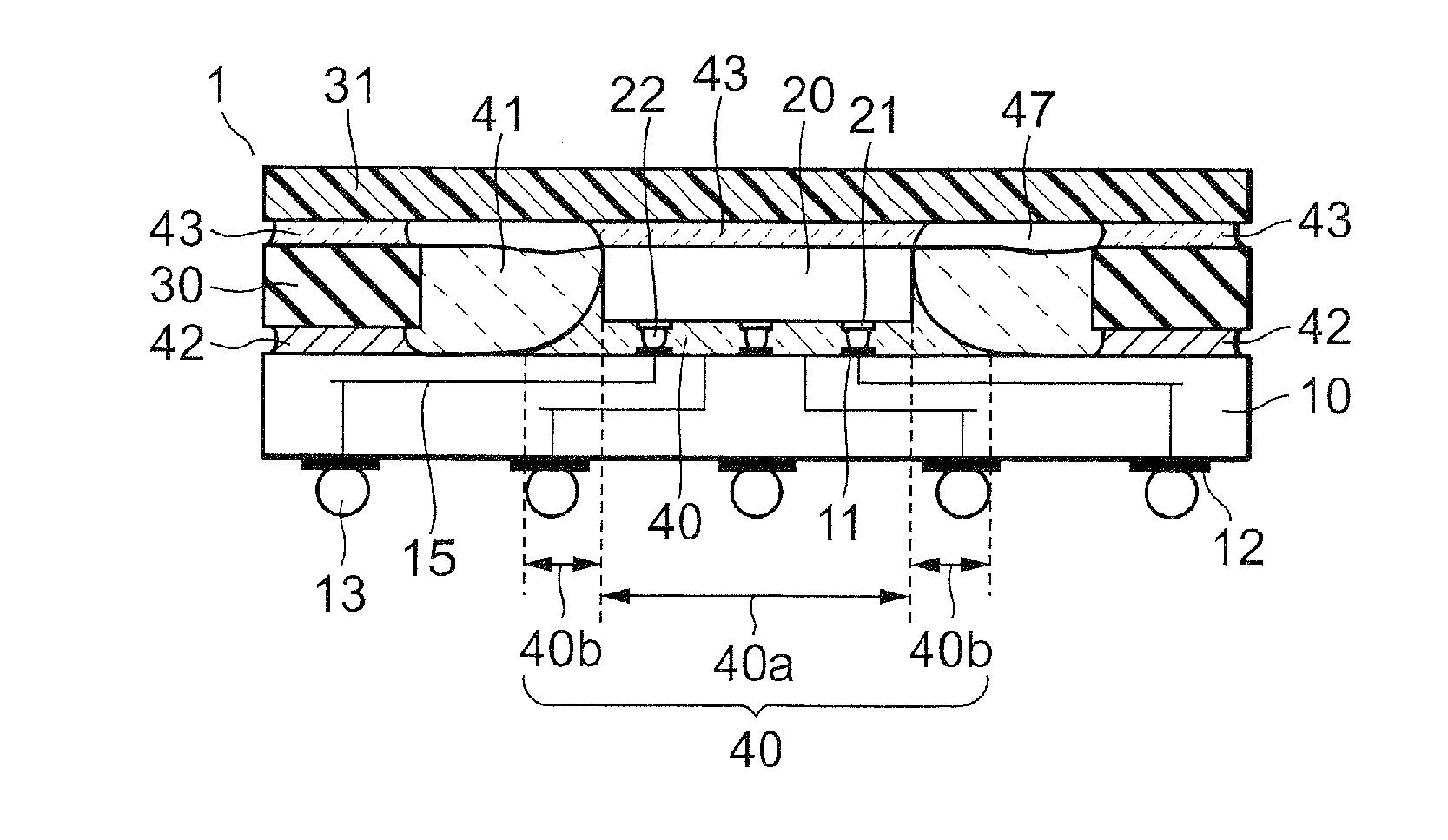

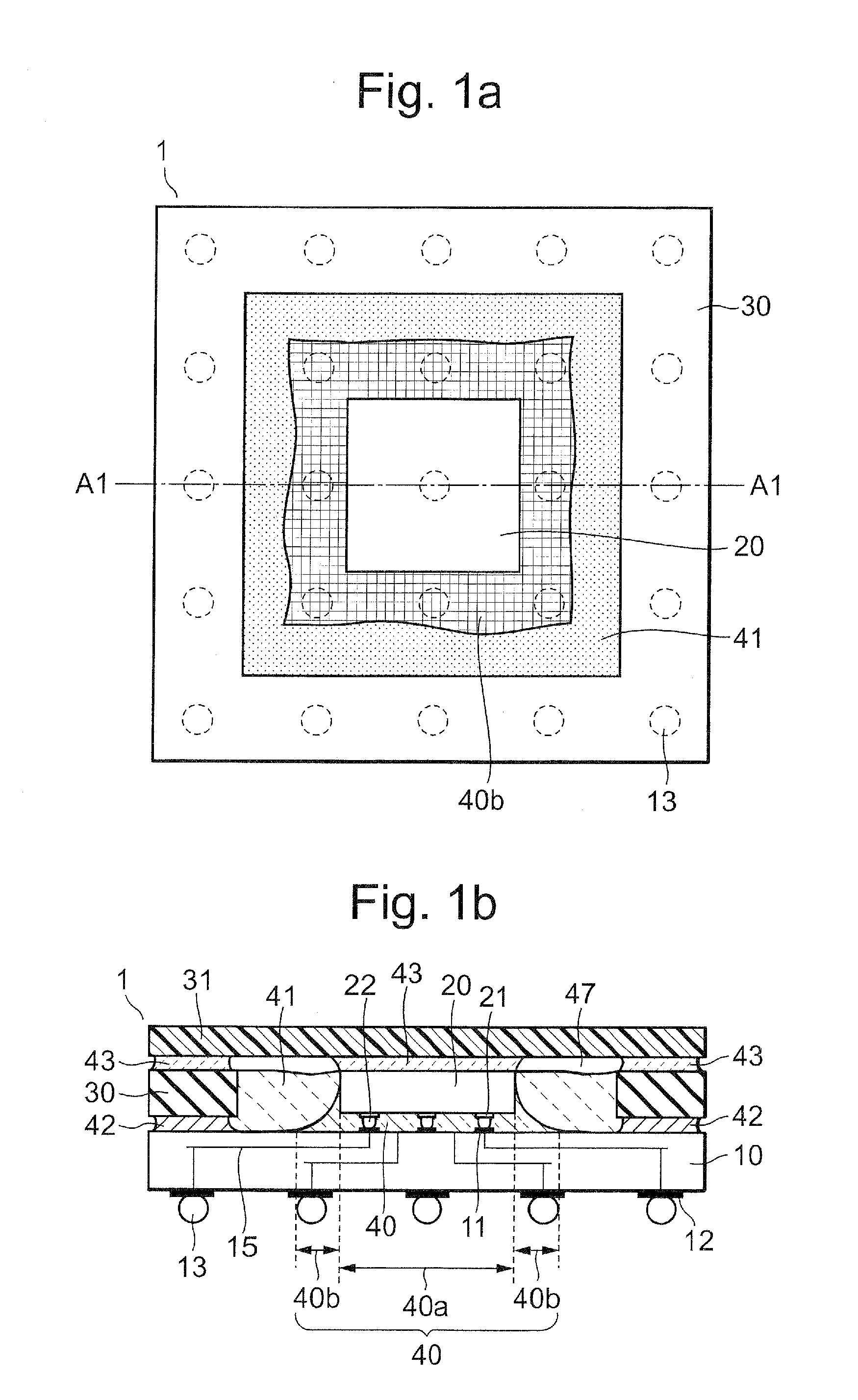

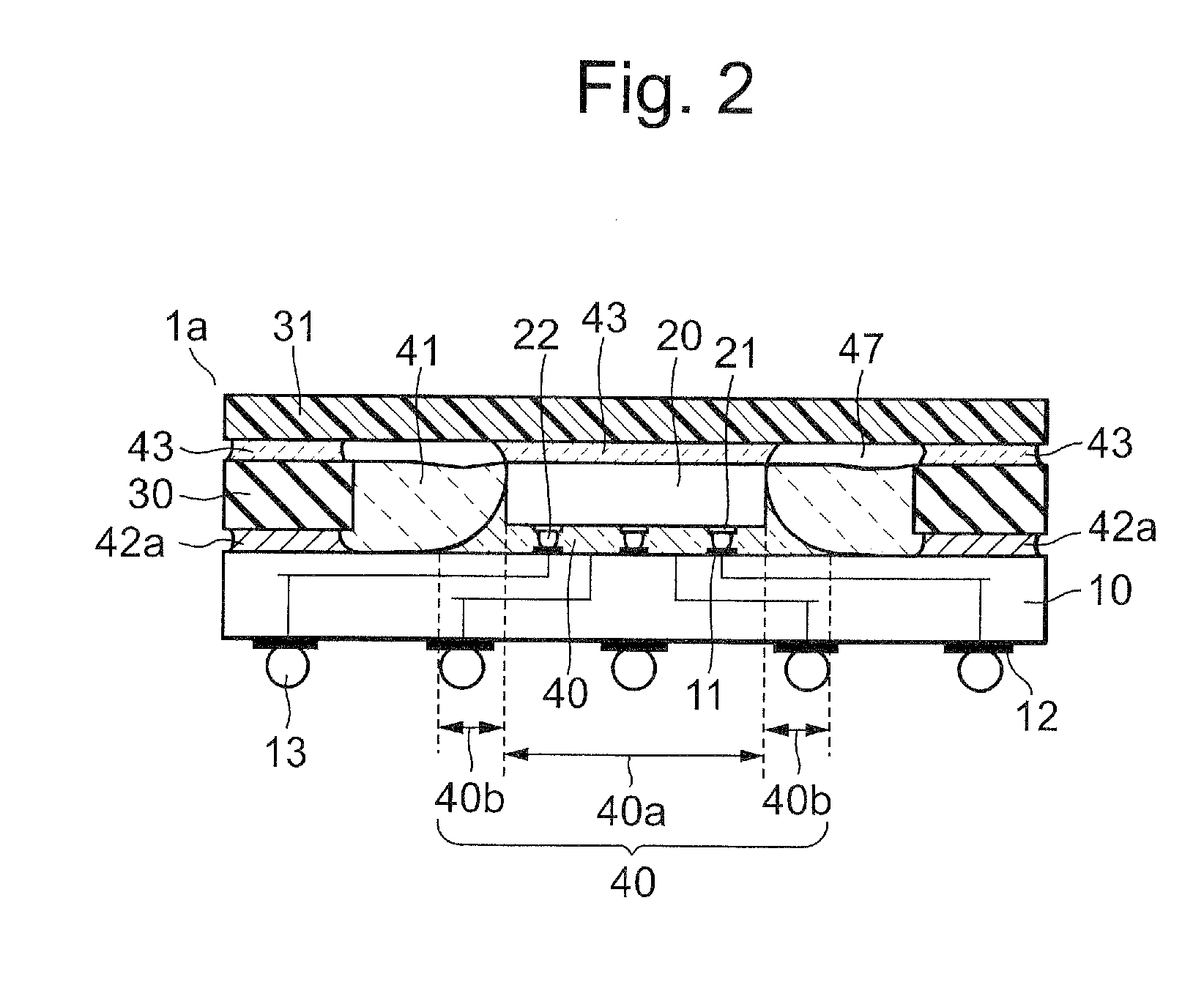

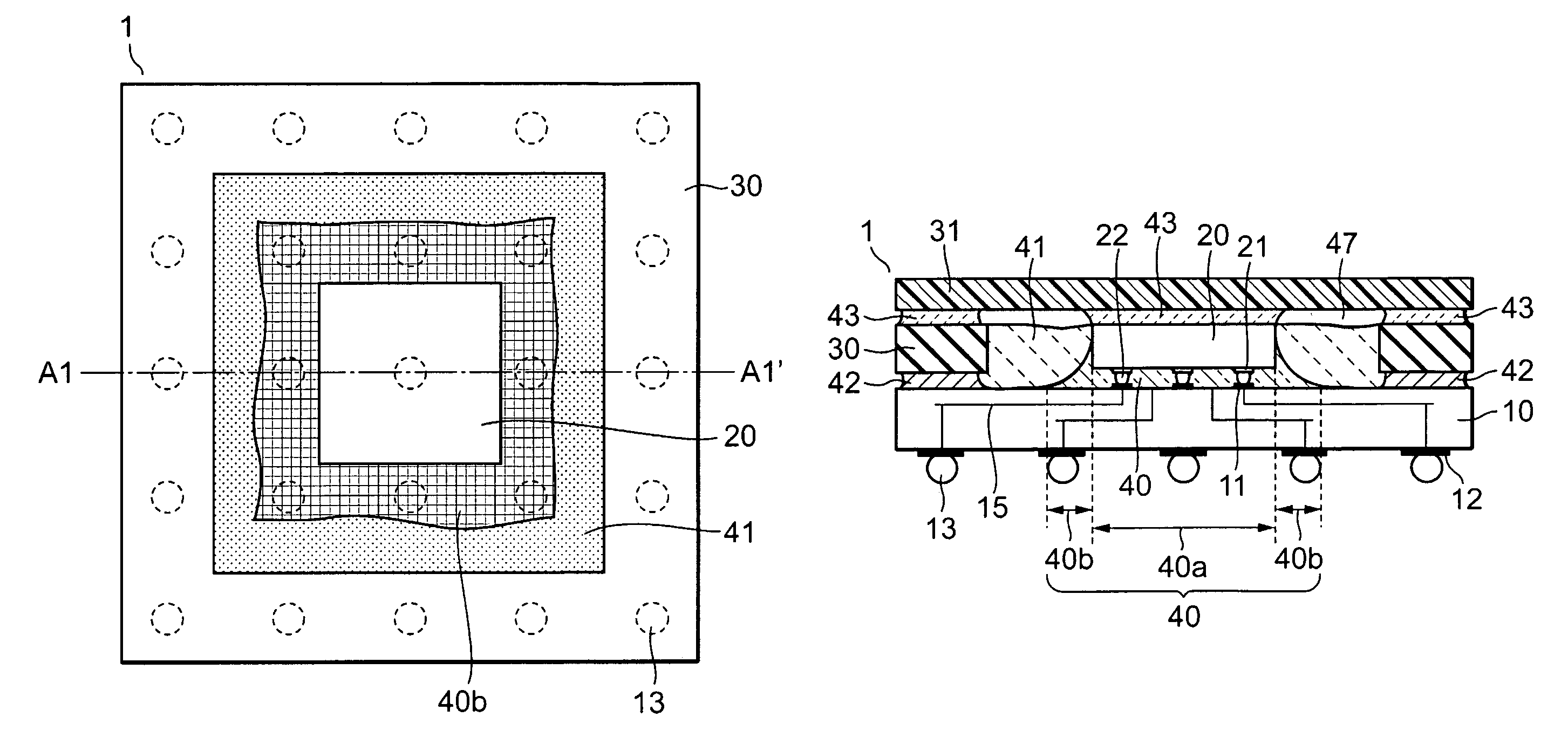

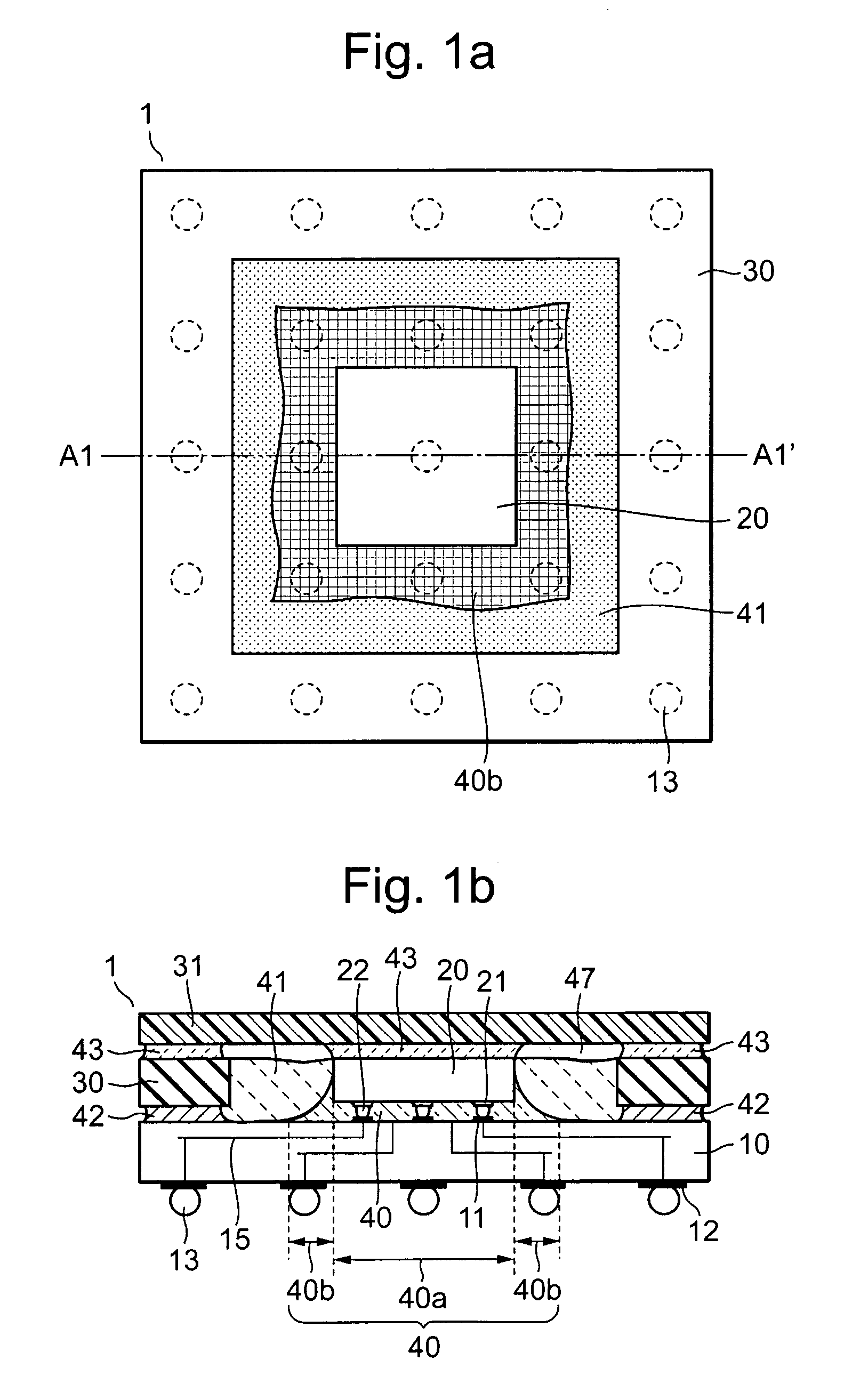

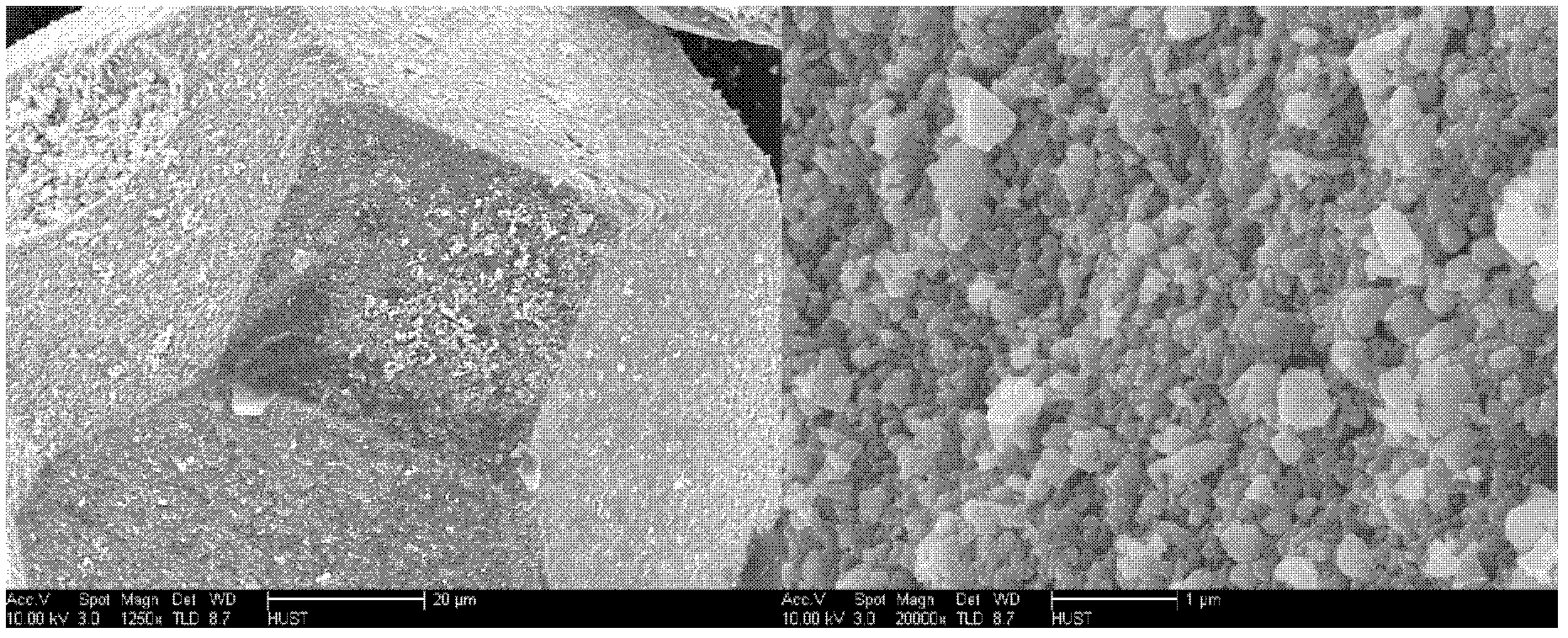

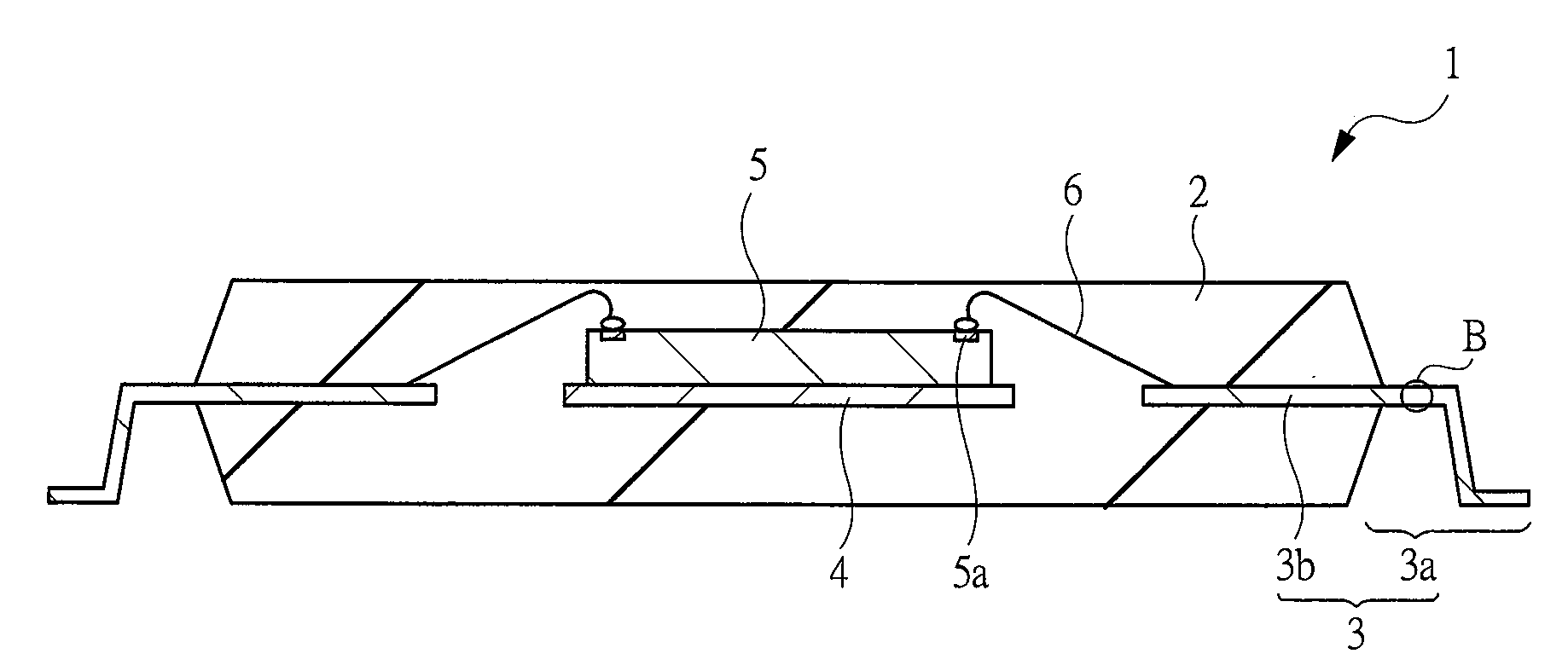

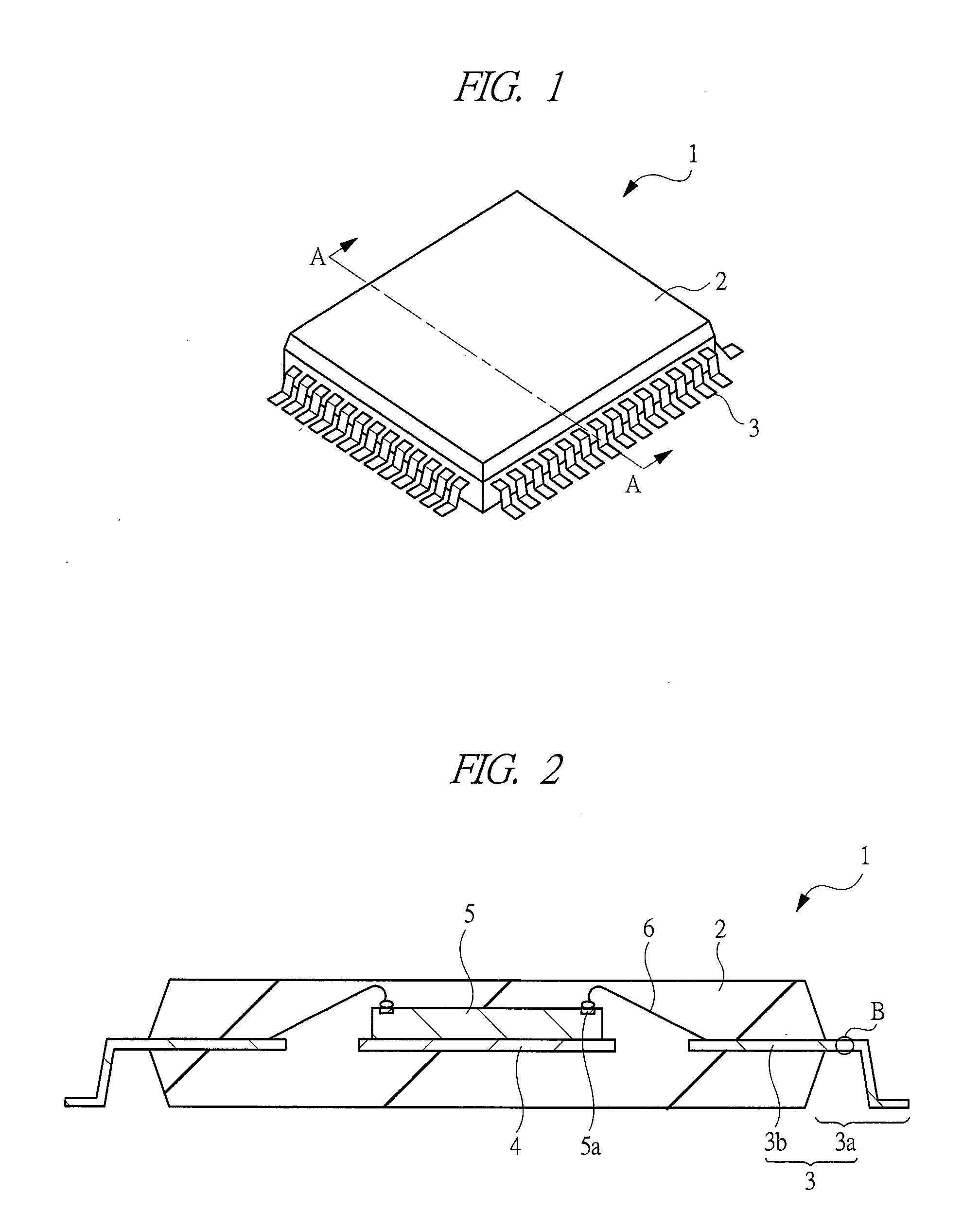

Warp-suppressed semiconductor device

InactiveUS20100230797A1Warpage suppressionLow viscositySemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor chip

A semiconductor device includes: a semiconductor chip mounted on a mounting substrate; a first resin filling a gap between the chip and the substrate; a frame-shaped stiffener surrounding the chip; a first adhesive for bonding the stiffener to the substrate; a lid for covering the stiffener and an area surrounded by the stiffener; and a second resin filling a space between the stiffener and the chip. A thermal expansion coefficient of the second resin is smaller than that of the first resin. The first resin includes an underfill part filling a gap between the chip and the substrate and a fillet part extended from the chip region.

Owner:RENESAS ELECTRONICS CORP

Warp-suppressed semiconductor device

InactiveUS7728440B2Suppression of deformationWarpage suppressionSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor chip

A semiconductor device includes: a semiconductor chip mounted on a mounting substrate; a first resin filling a gap between the chip and the substrate; a frame-shaped stiffener surrounding the chip; a first adhesive for bonding the stiffener to the substrate; a lid for covering the stiffener and an area surrounded by the stiffener; and a second resin filling a space between the stiffener and the chip. A thermal expansion coefficient of the second resin is smaller than that of the first resin. The first resin includes an underfill part filling a gap between the chip and the substrate and a fillet part extended from the chip region.

Owner:RENESAS ELECTRONICS CORP

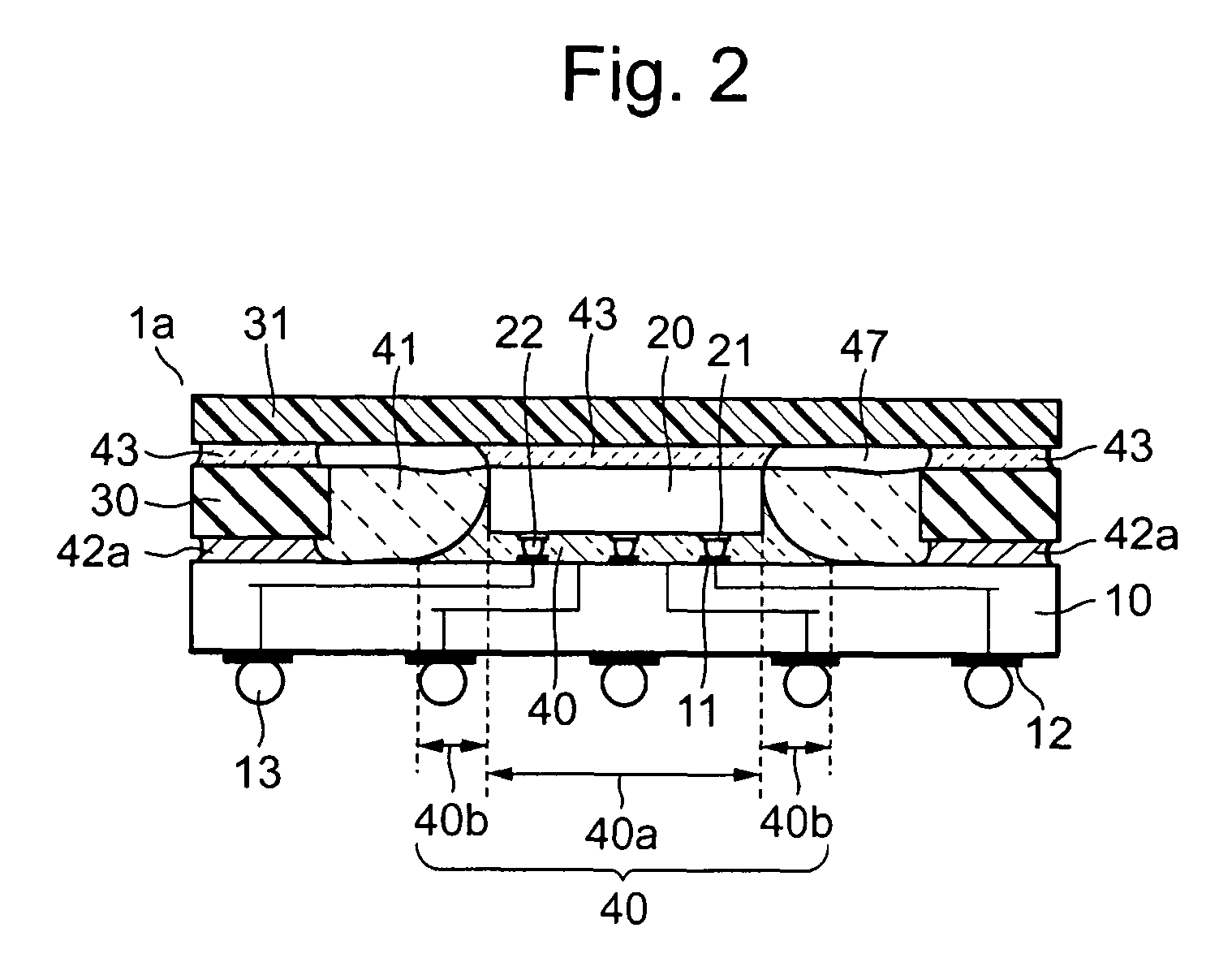

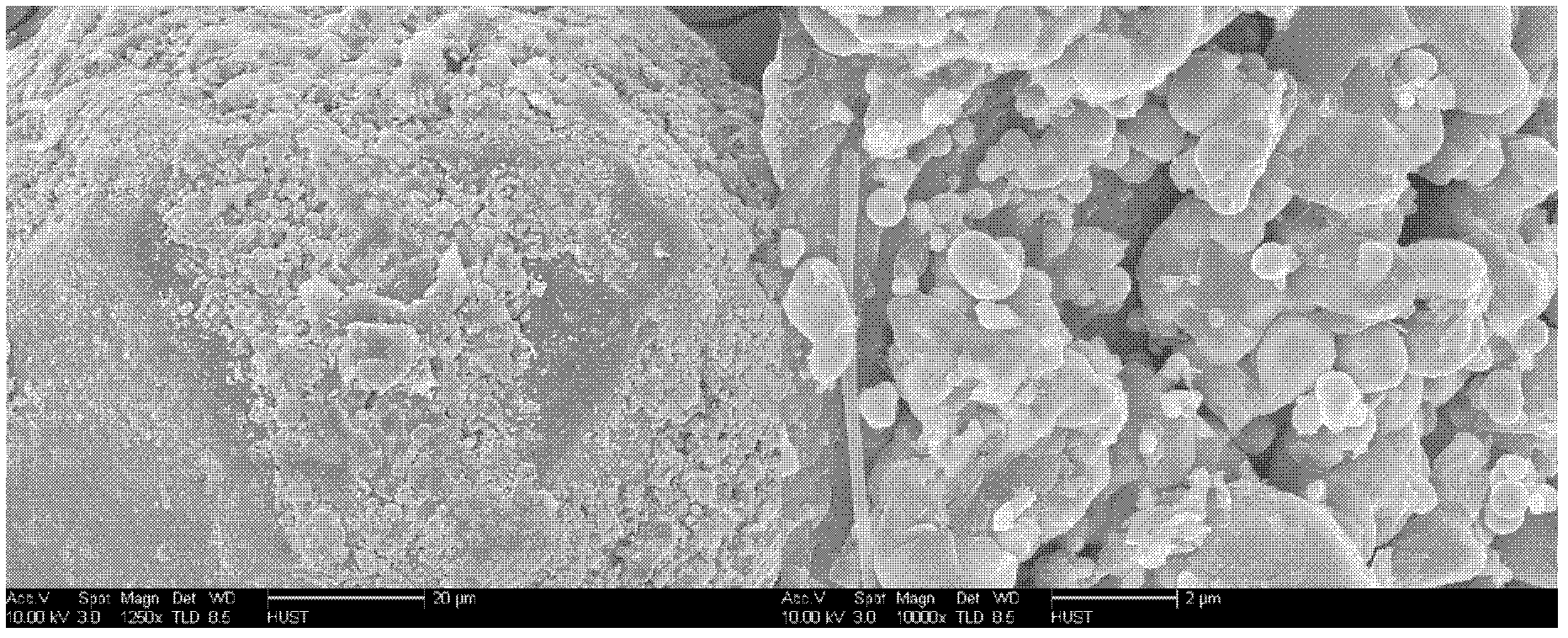

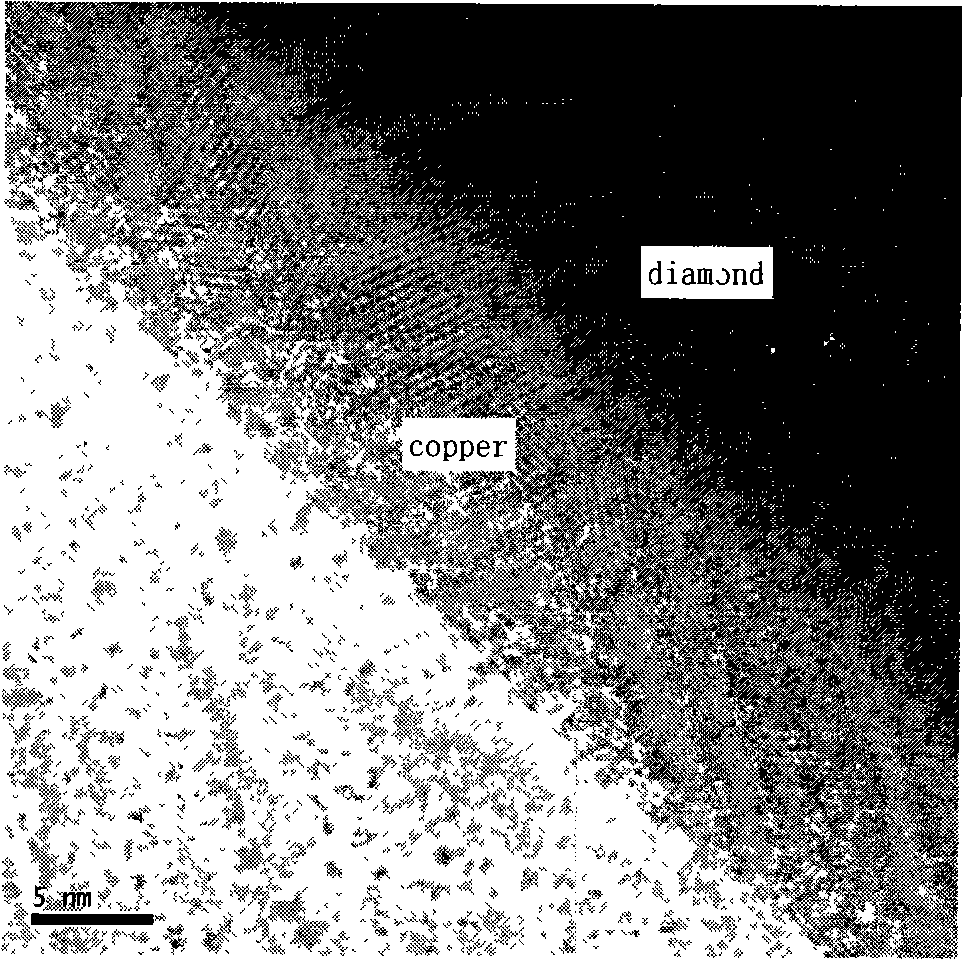

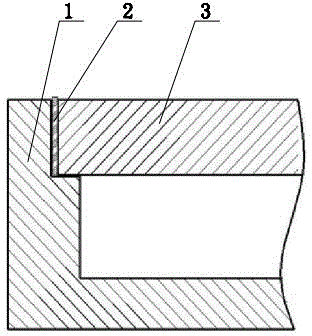

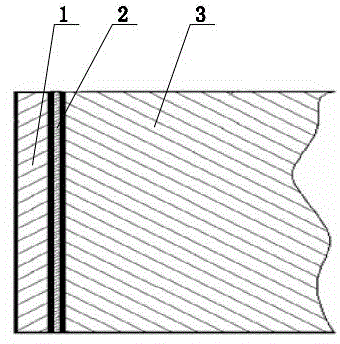

Method for preparing diamond-copper composite material by virtue of metallization of high-temperature blending surface

InactiveCN102383014AImprove wettabilityControllable coefficient of thermal expansionRoom temperatureCarbide

The invention belongs to a preparation technique of a copper-based composite material, and discloses a method for preparing a diamond-copper composite material by virtue of metallization of a surface. The method comprises the following steps of: mixing diamond micropowder with copper powder and powder formed by strong carbide elements, wherein the particle size of diamond is 80-300mu m, the content of the strong carbide elements is 1-10wt%, and the mass fraction of the copper powder is 20%-85%; blending the obtained mixed powder for 10-90 minutes at the temperature of 1050-1150 DEG C, and then cooling along with a furnace; sieving to select the powder with the particle size of 80-300 mu m; mixing the mixed powder with the copper powder again, wherein the mass fraction of the copper powderis 40%-95%; quickly heating the mixed powder material to 850-950 DEG C for sintering at the sintering pressure of 30-50MPa; and then, cooling the obtained product to a room temperature along with thefurnace to obtain the diamond-copper composite material. The method for preparing the diamond-copper composite material has the advantages that the operability of the metallization of the surface of the diamond is strong; the process is simple; the wetting property of a matrix and an enhancer in the prepared diamond-copper composite material is improved greatly; and as an electronic encapsulatingmaterial, the composite material has better comprehensive property, wherein the thermal conductivity is up to 672 W / m.K, the thermal expansion is lower than 7.6 mu m / m. DEG C, and the compactness reaches above 96%.

Owner:HUAZHONG UNIV OF SCI & TECH

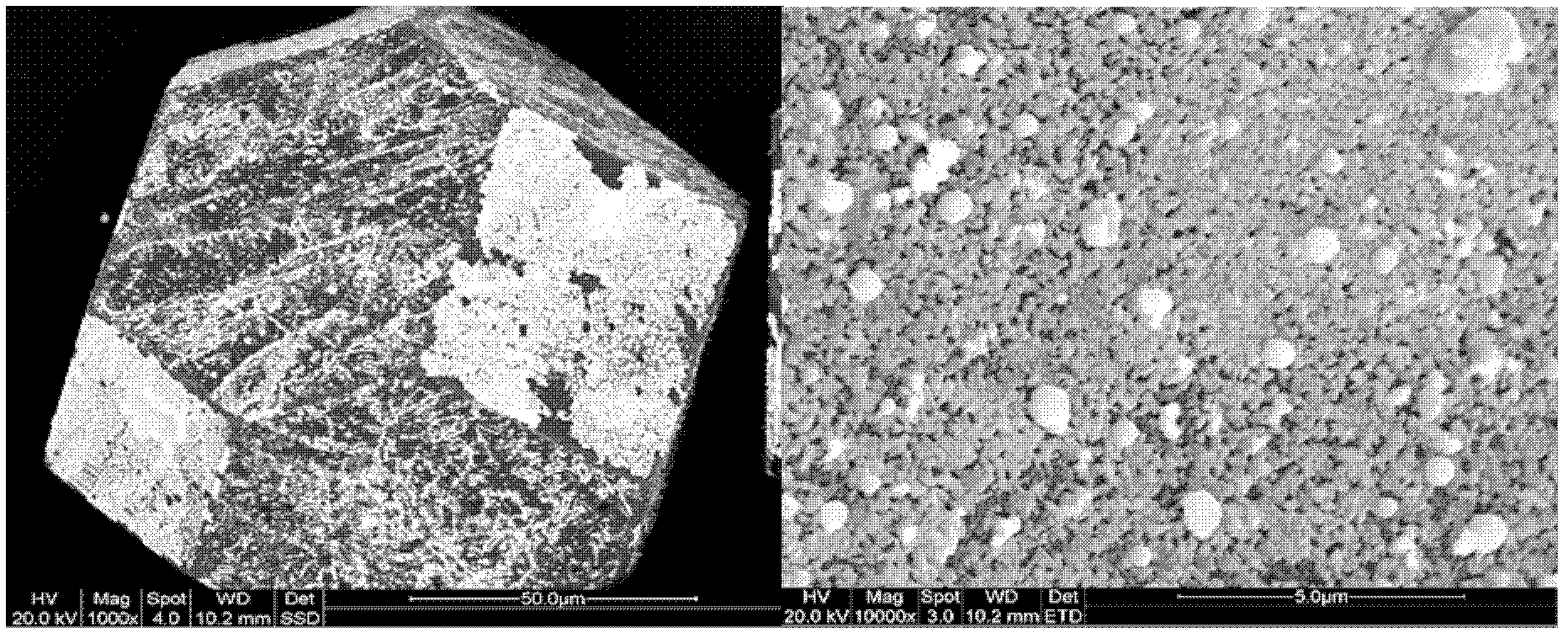

Method for producing diamond reinforced Cu-matrix compound material by surface metallization and chemical deposition

InactiveCN101279366AEasy to operateSimple processLiquid/solution decomposition chemical coatingThermal dilatationChemical plating

The invention relates to a method for preparing diamond enhanced copper-based composite material by surface metallization and chemical deposition, which pertains to the preparation technology of copper-based composite materials. The method comprises that: the chemical copper plating treatment is carried out after the pre-treatment of the surface of a diamond, then the chemical deposition method is used for in situ deposition of copper on the copper-plated diamond, and the diamond enhanced copper-based composite material is obtained by initial pressing, sintering and re-pressing treatment. The method has the advantages that: the metallization operation of the surface of the diamond is better, and the process is simple; the invasion of a matrix and an enhanced body in the prepared diamond enhanced copper-based composite material are greatly improved, the composite material is taken as the electronic packaging material, which has great comprehensive performance, wherein, the thermal conductivity is higher than 400W / m.k, the thermal expansion is lower than 7.9 Mum / m.DEG C, and the density can achieve more than 95 percent.

Owner:TIANJIN UNIV

Thin wall cordierite carrier for ceramic honeycomb catalyst and method for preparing the same

InactiveCN1827217AEasy alignmentSmall expansion coefficientCatalyst carriersCeramicwarePorosityCordierite

The invention relates to the improvement on the ceramic beehive catalyst carrier, especially providing a ceramic beehive catalyst carrier with high mechanical strength and lower expansion parameter and preparing method. The invention is characterized in that: said beehive catalyst carrier is the alumina micro powder in 12-15%WT whose average particle diameter is less than 2 micron; the sheet kaolin and / or clay micro powder in 43-47% whose average particle diameter is less than 2 micron, the sheet steatite micro powder in 33-37% whose average particle diameter is 5-15 micron, and the fuse quartz in 6-12% whose average particle diameter is less than 2 micron to be mixed, molded and baked to attain the cordierite whose total amount is 92-96%, wherein, the Al203, MgO and SiO2 are each in 36-37%, 13.0-14.0% and 50-52%. The invention adds surface active agent in the mixture when in preparation. The prepared beehive cordierite total amount with 600 hole / square inch can reach 92-96%, the expansion parameter can reach 0.8X10-6 / Deg. C (800Deg. C to room temperature), and the factor of porosity can reach 39-40%. The invention can reduce the ignition temperature 25-40Deg. C, and reduce the tail gas discharge of nitrogen oxygen compound and carbon monoxide of vehicle 5-10% to meet the demand of Europe III standard.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY +1

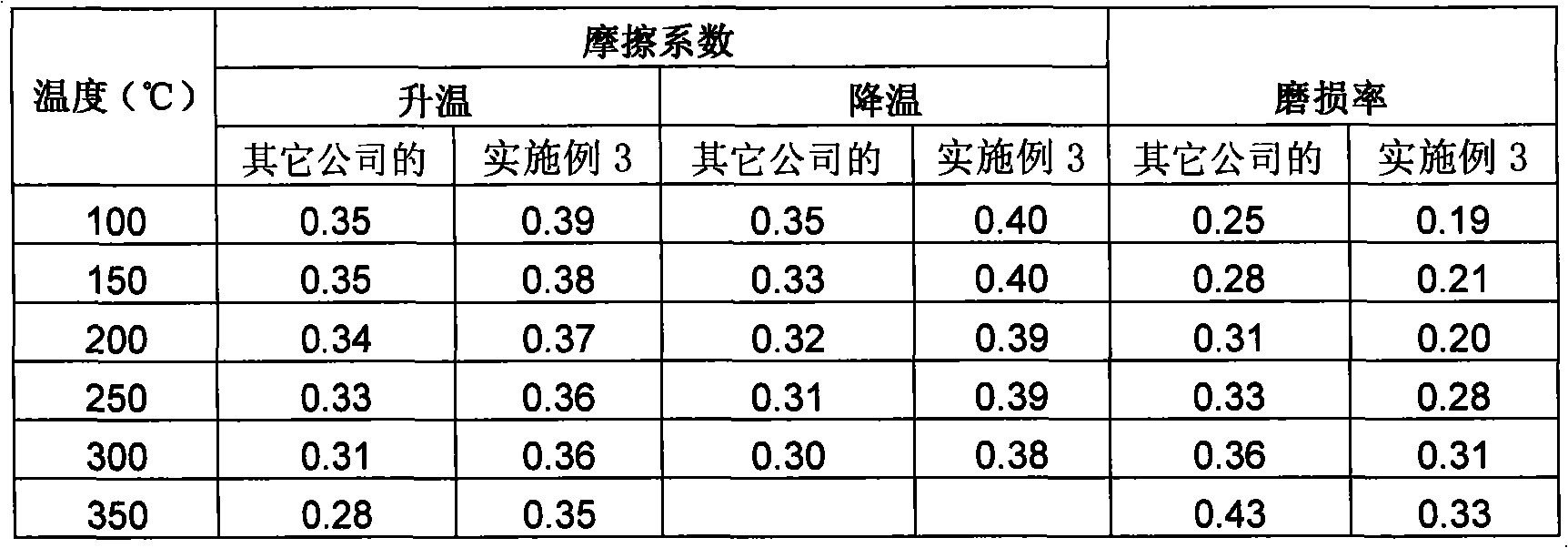

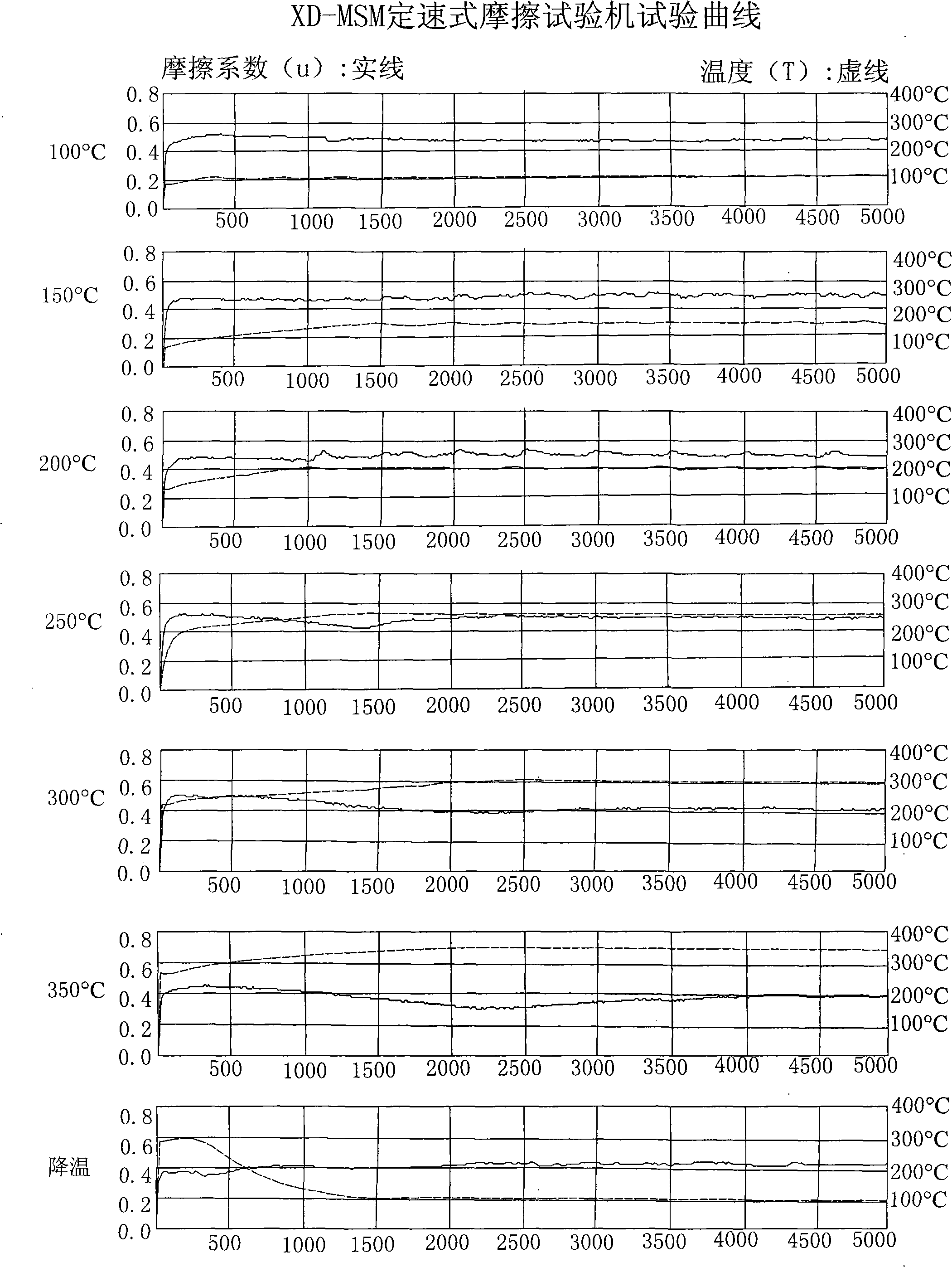

High-performance organic fibre brake pad

ActiveCN101555918AStable coefficient of frictionSmall thermal expansionFriction liningLow noiseCellulose

A high-performance organic fibre brake pad comprises the following components according to weight percentages: 5-9% of cashew nut oil friction powder, 4-8% of chromite, 7-10% of barite, 4-7% of calcined petroleum coke, 3-7% of crystalline flake graphite, 3-6% of sepiolite fibre, 4-7% of ceramic fibre, 1.5-3% of antimony sulphide, 4-7% of red copper fibre, 3-5% of glued aluminium silicate fibre, 1-2% of alumina fibre, 8-11% of vermiculite powder, 9-13% of organosilicone phenol-formaldehyde resin, 1-2% of carbon fibre, 5-7% of bastose, 1-2.5% of wood pulp cellulose, 3-6% of viscose fibre, 6-9% of bamboo carbon fibre, 3-5% of nitrile rubber and 0.3-0.5% of zinc oxide. The invention has the advantages of light weight, strong wear resistance, good flexibility, low noise and long service life, and the like, and the friction performance is stable at operating temperature between 100 DEG C and 450 DEG C.

Owner:摩擦一号制动科技(仙桃)有限公司

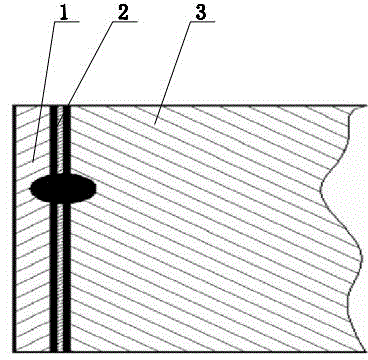

Sealing method for laser filler welding of hybrid integrated circuit package

ActiveCN103331520AImprove sealingMeet various requirements of packagingSemiconductor/solid-state device manufacturingLaser beam welding apparatusCrack freeShielding gas

The invention discloses a sealing method for laser filler welding of hybrid integrated circuit package. The sealing method comprises the following steps: 1, an aluminum alloy casing and an aluminum cover plate are rinsed by using acetone; 2, joints are assembled, a stepped groove is arranged in the aluminum alloy casing, the aluminum alloy cover plate is mounted on the aluminum alloy casing, the aluminum alloy casing and the aluminum alloy cover plate are butted by utilizing a tool, the butting mode is corner joint, and a joint gap is formed at the joints; 3, pre-filler is filled in the joint gap; 4, spot welding is carried out, a Nd:YAG (nipigin-doped: yttrium aluminum garnet) laser is adopted, the relative positions of the aluminum alloy casing, the aluminum alloy cover plate and the pre-filler are fixed, and the spot welding is proceeded in protective gas; 5, the overall welding is carried out, the Nd:YAG laser is adopted, a mouth-shaped welding form is adopted, and the welding process is proceeded in the protective gas. With the adoption of the sealing method, the welding reliability is good, the air-tight seal is good, and the welding seam is attractive and crack-free.

Owner:WUXI HUACE ELECTRONICS SYST

Glass frit free of alkaline, lead and cadmium and its use to produce coloured enamels

The present invention relates to a frit which does not contain base metal, lead or cadmium, the frit is provided with a thermal expansion coefficient alpha of less than 6.5*10-6k-1 at the temperature range from 20 to 300 degree and a transition temperature Tg of less than 550 degree, the frit includes special glass composition or is composed of it. The frit is especially suitable for preparing the low-calcined ceramic pigment which can be used to decorate the low-expending carrier substrate, such as glass and / or devitroceram.

Owner:SCHOTT AG

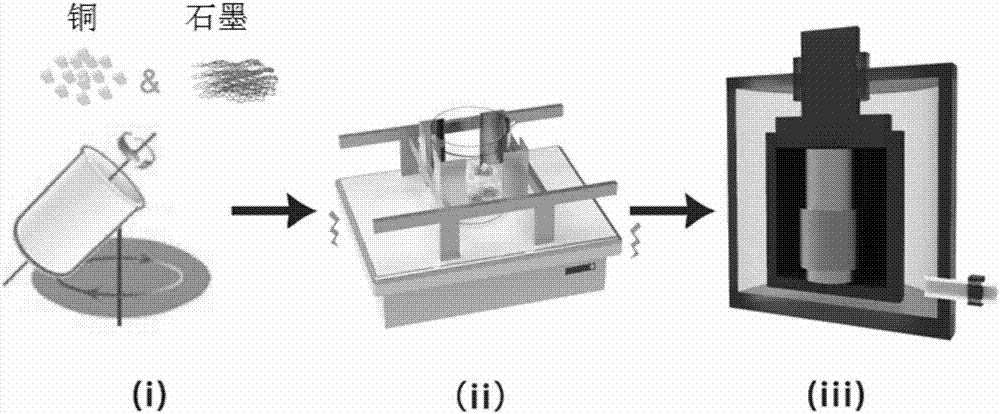

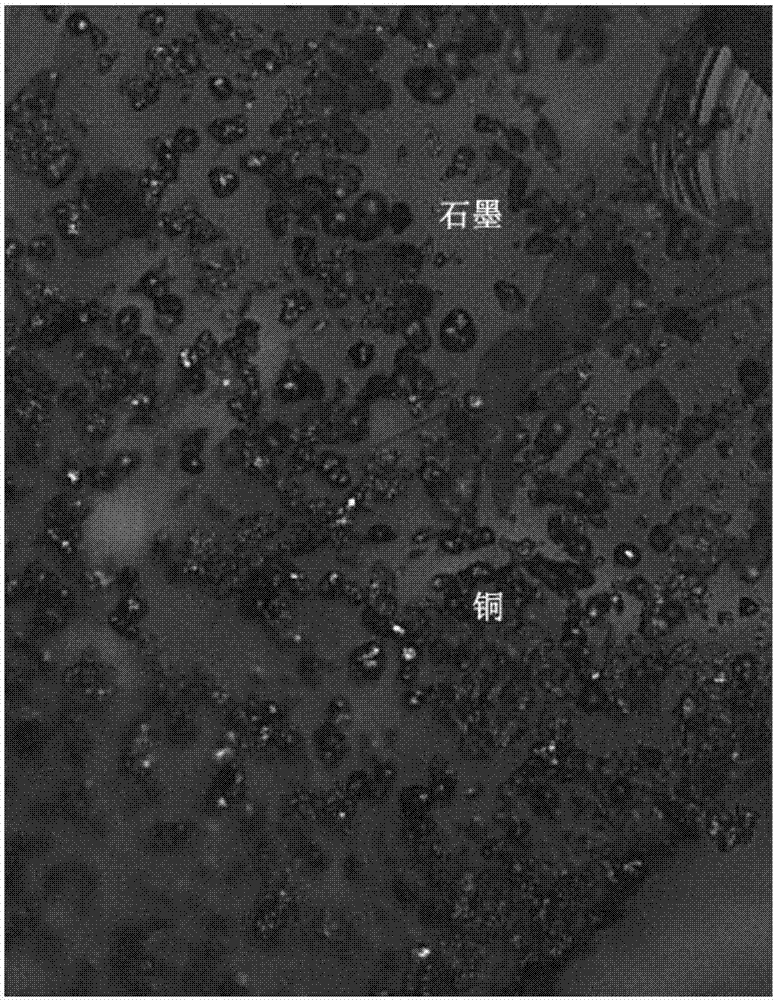

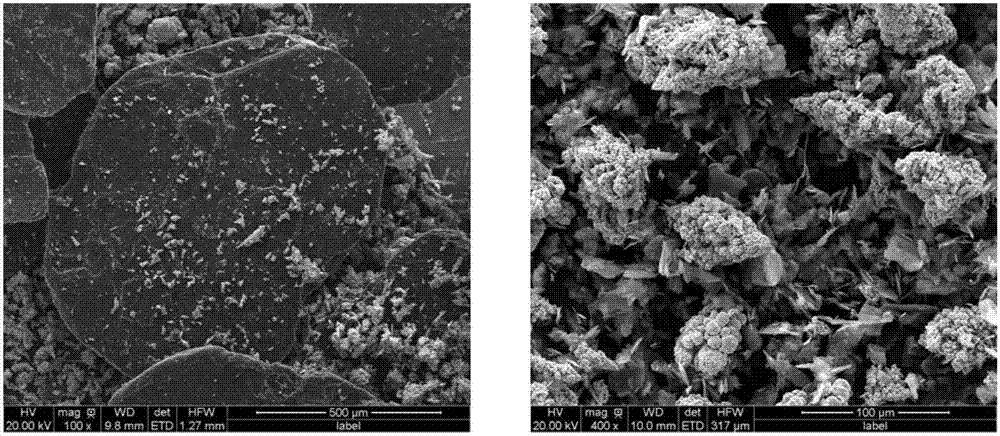

Directed graphite-copper composite material with superhigh thermal conductivity and high strength and preparation method and application thereof

ActiveCN107502767AHigh degree of alignmentHigh bonding strengthTransportation and packagingMetal-working apparatusGraphiteHigh intensity

The invention relates to a directed graphite-copper composite material with superhigh thermal conductivity and high strength and a preparation method and application thereof. Specifically, the composite material is formed by graphite sheet layers and copper layers through hot-pressing sintering, and the graphite sheet layers and the copper layers are arranged in parallel in a directed mode. The ratio of the thermal conductivity of the composite material in the direction parallel to the X-Y direction to the thermal conductivity of the composite material in the direction perpendicular to the X-Y direction is not smaller than 4, the thermal conductivity of the composite material in the direction parallel to the X-Y direction is not smaller than 500 W / m.K, and the X-Y direction is parallel to the graphite sheet layers and the copper layers at the same time. The invention further discloses the preparation method of the composite material. As the graphite sheet layers of the composite material are arranged in the directed mode in the height direction and the copper layers are evenly distributed between the graphite sheet layers, the composite material has quite high thermal conductivity and low coefficient of thermal expansion. The preparation method is simple, low in cost and quite suitable for being popularized on a large scale.

Owner:宁波晨鑫维克工业科技有限公司

Raw materials and preparation method of anti-corrosion mullite brick

The invention discloses raw materials for preparing an anti-corrosion mullite brick, comprising calcium hexaluminate, andalusite, sillimanite, alumina, cordierite, pyrophyllite, kaolin, refractory oxide, foaming agent and binding agent. The preparation method includes the following steps: the sillimanite, alumina, cordierite, pyrophyllite, kaolin, refractory oxide and binding agent are added into a grinding machine to be ground after material preparation, so as to obtain base material; the calcium hexaluminate and andalusite are added into a kollermill to be mixed and milled for 5-10 minutes, water is added until the surface is wetted, so as to obtain particle aggregate, and the base material is added into the kollermill to be mixed, milled and stirred with the particle aggregate, so as to obtain mixture; and water is injected into the mixture and stirring is carried out to form muddy mixture and green brick is obtained, and the green brick is placed into a kiln to be sintered into the anti-corrosion mullite brick finished product. The mullite brick prepared by the raw materials and preparation method has the advantages of low thermal conductivity, good thermal insulation property and strong corrosion resistance.

Owner:JIANGSU ZHONGLEI ENERGY SAVING TECH DEV CO LTD

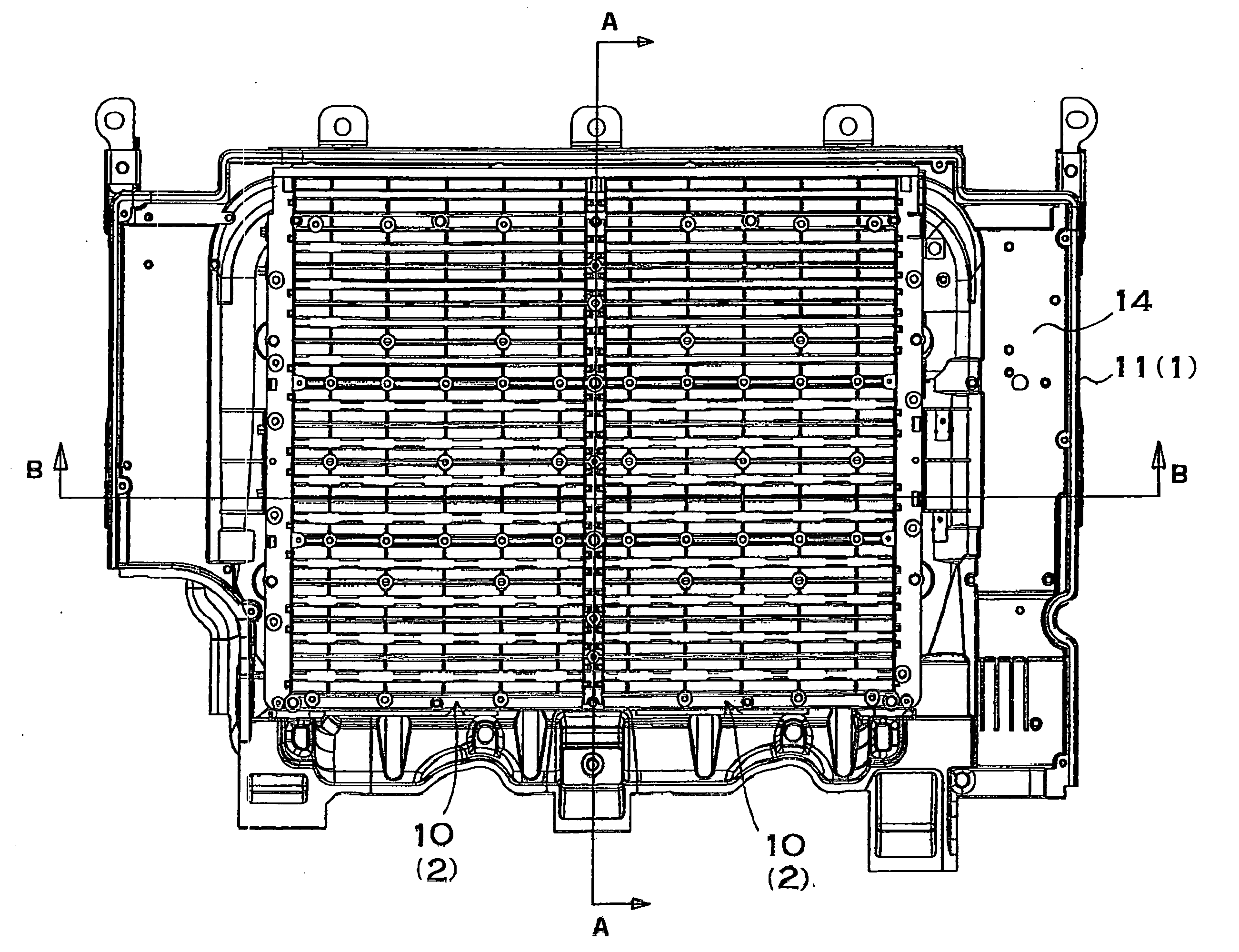

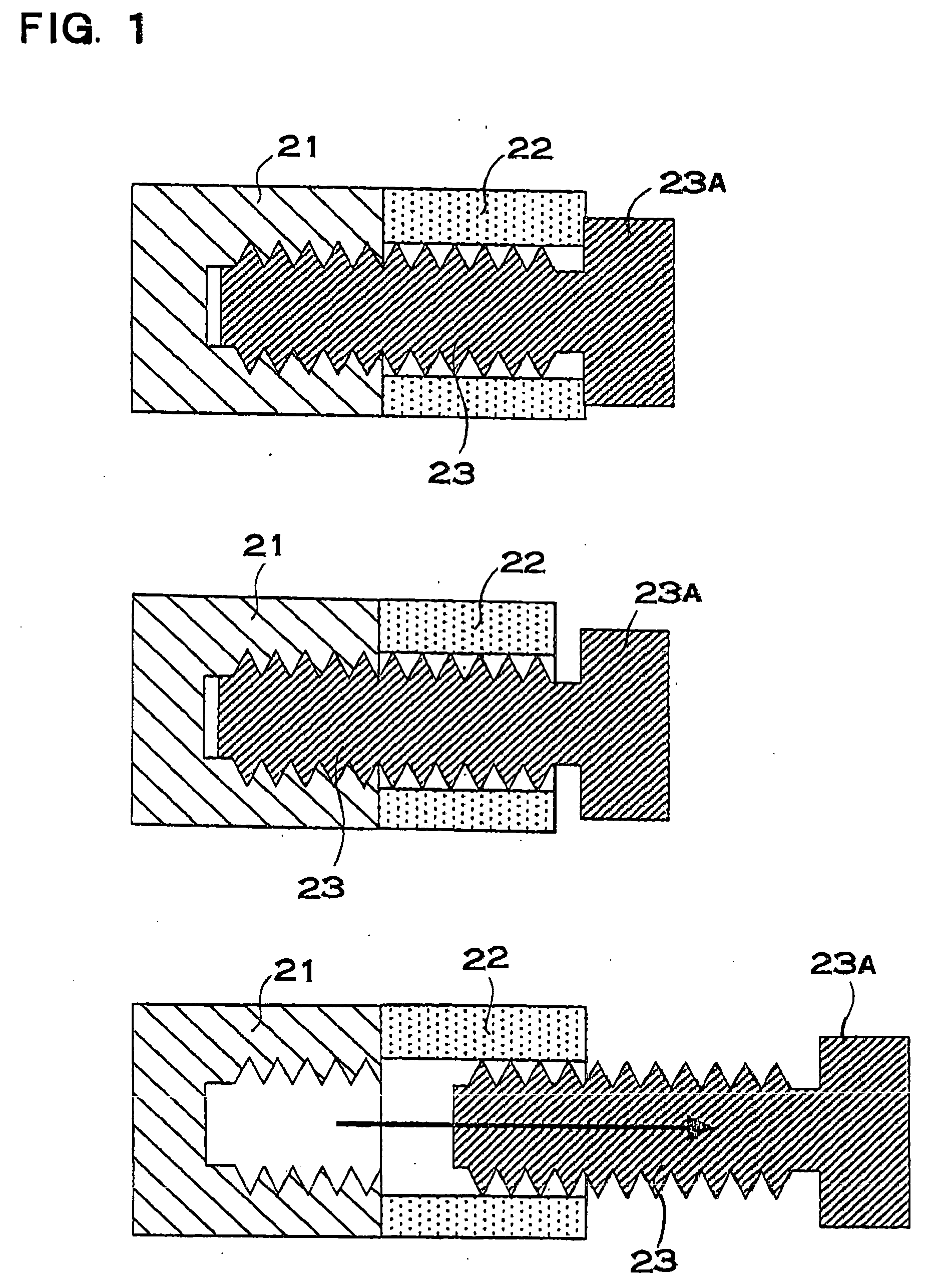

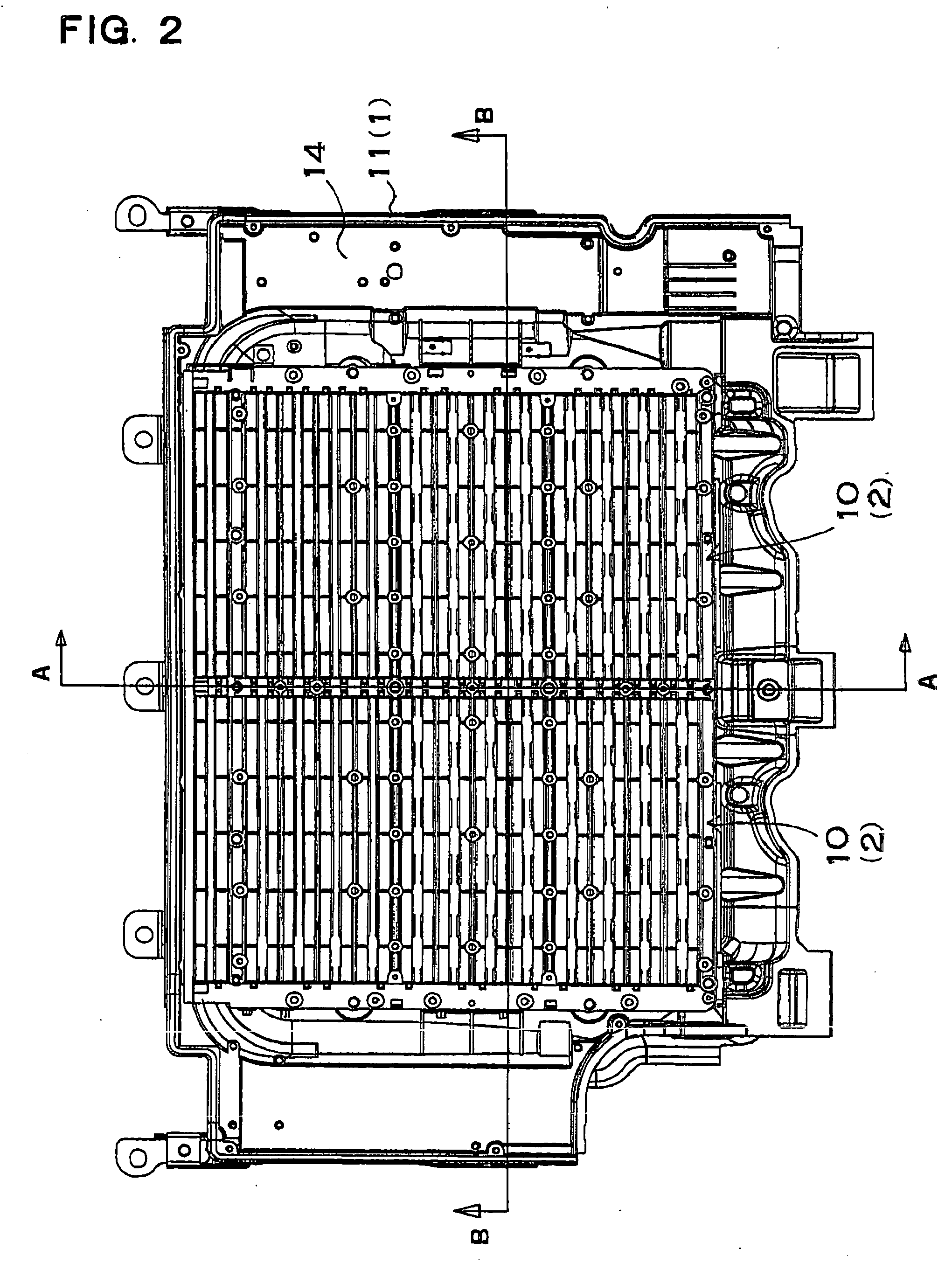

Battery device of vehicle power supply

InactiveUS20070017720A1Simple structureSmall amountElectric/fluid circuitElectrical batteryEngineering

A power device for a vehicle includes a base portion to be mounted on the vehicle, a resin component having a through hole which is to be fixed to the base portion, a metal sleeve inserted through an internal surface of the through hole of the resin component and having a flange on an opposed surface to the base portion, and a metal screw inserted through the metal sleeve inserted in the through hole of the resin component, thereby fixing the resin component to the base portion through the metal sleeve. The base portion has a female screw member into which a tip portion of the metal screw is to be screwed and has a support member provided on an opposed surface to the metal sleeve. In the power device, the metal screw is inserted through the metal sleeve to screw a screw portion on a tip into the female screw member and fixes the metal sleeve to the base portion, thereby securing the resin component to the base portion.

Owner:SANYO ELECTRIC CO LTD

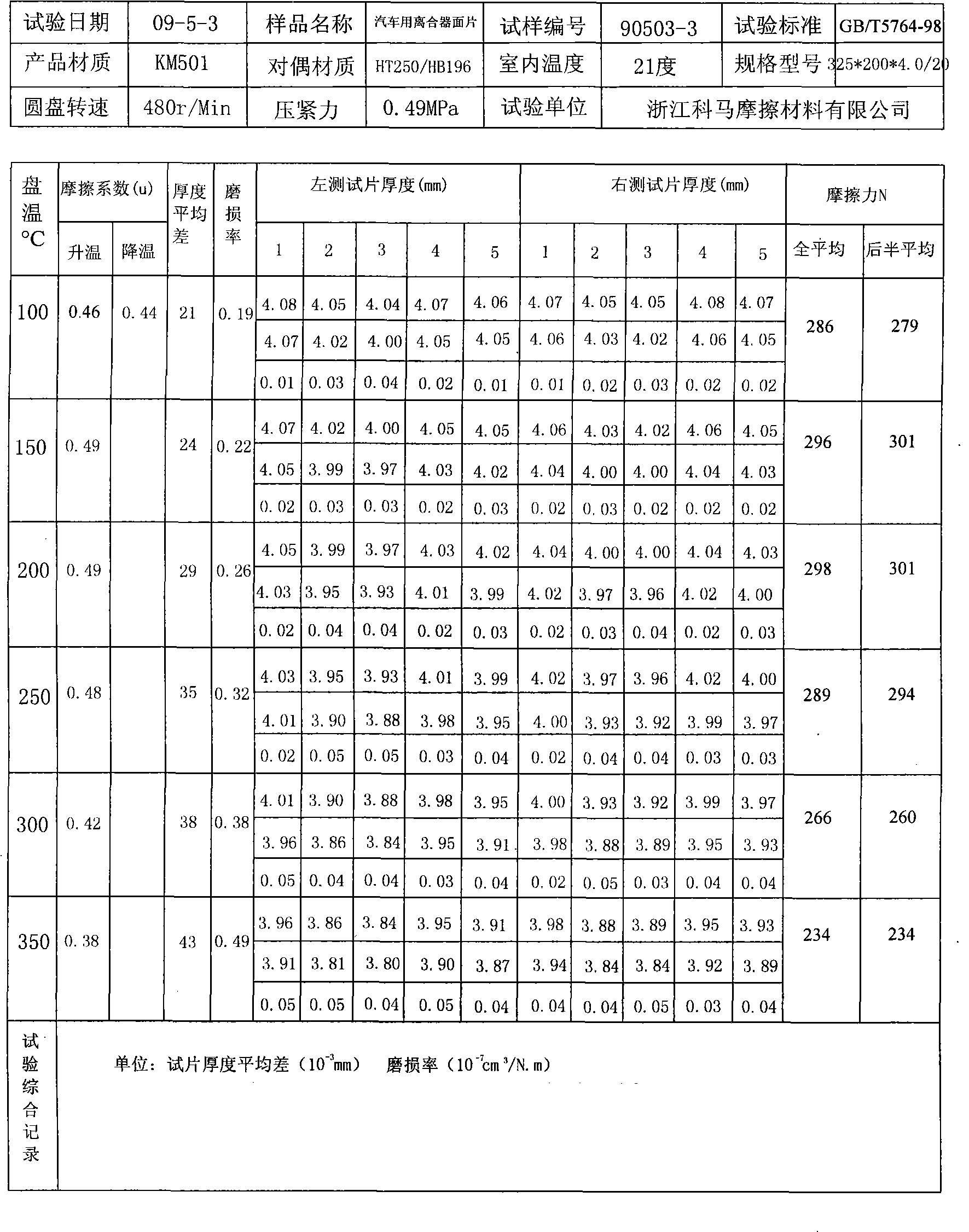

Novel non-rubber winding clutch facing

InactiveCN101792571AReduce coefficient of frictionIncrease coefficient of frictionFriction clutchesFriction liningThermal expansionConductor Coil

The invention provides a novel non-rubber winding clutch facing, which adopts a water soluble phenolic resin as a binding material. The water soluble phenolic resin is prepared by using 100 parts by weight of phenol and 105 to 115 parts by weight of formaldehyde as the raw materials through the condensation reaction under the action of 0.1 to 0.2 part by weight of basic catalyst. The content of solid product obtained after the water soluble phenolic resin is dried accounts for 50 to 55 percent of the weight of the original phenolic resin. The invention uses the water soluble phenolic resin as the novel binder to produce the vehicle clutch facing. The water soluble phenolic resin binder has the advantages of small heat fading, small thermal expansion, higher safety factor and the like, thus, the prepared clutch facing has the advantages of good heat resistance which can reach over 350 DEG C, higher and stable friction coefficient, small heat fading, good wearing resistance and the like, also has the characteristics of stable clutch, particularly smaller thermal expansion and the like, eliminates the flammable and combustible hidden troubles and guarantees the production safety.

Owner:浙江科马摩擦材料股份有限公司

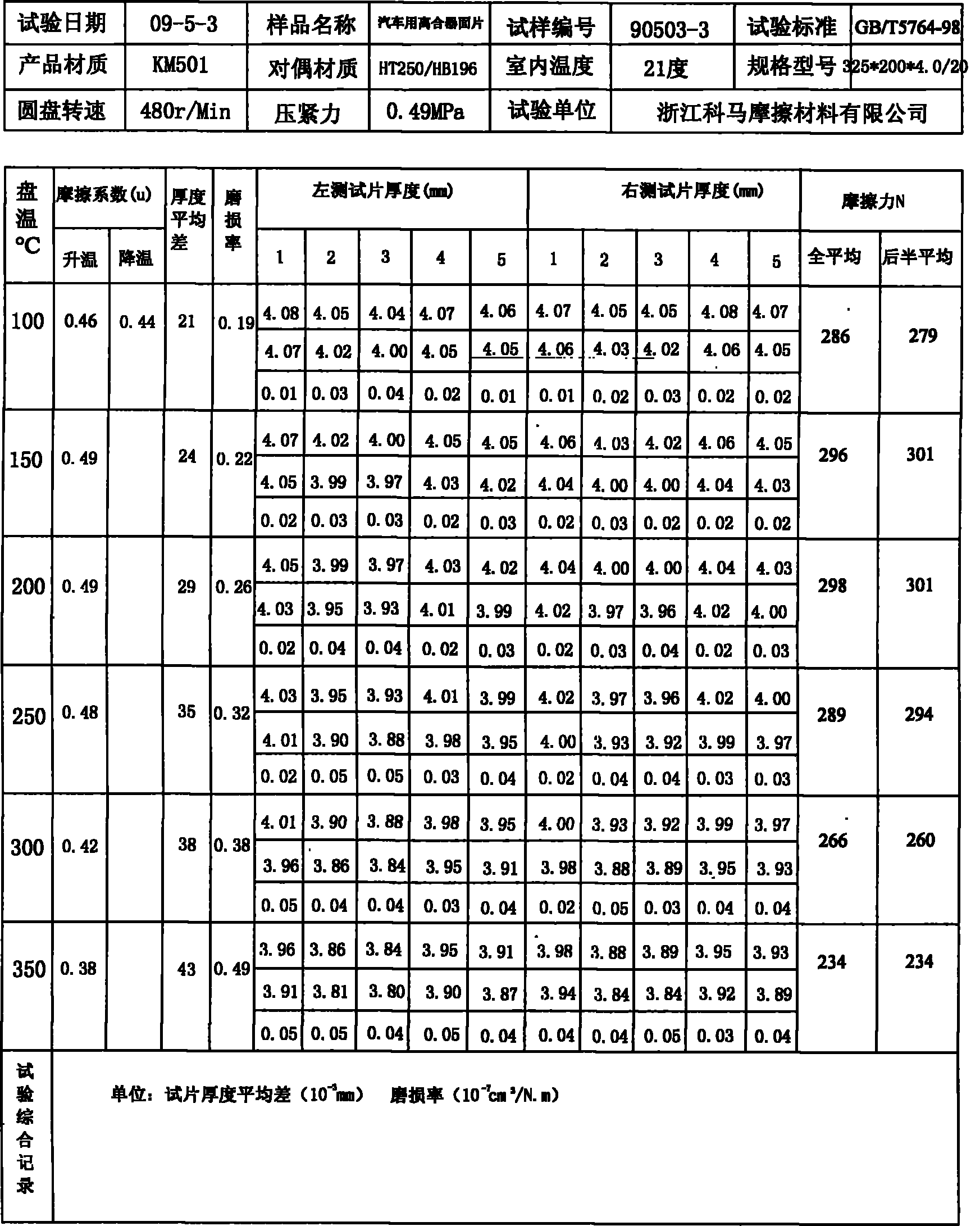

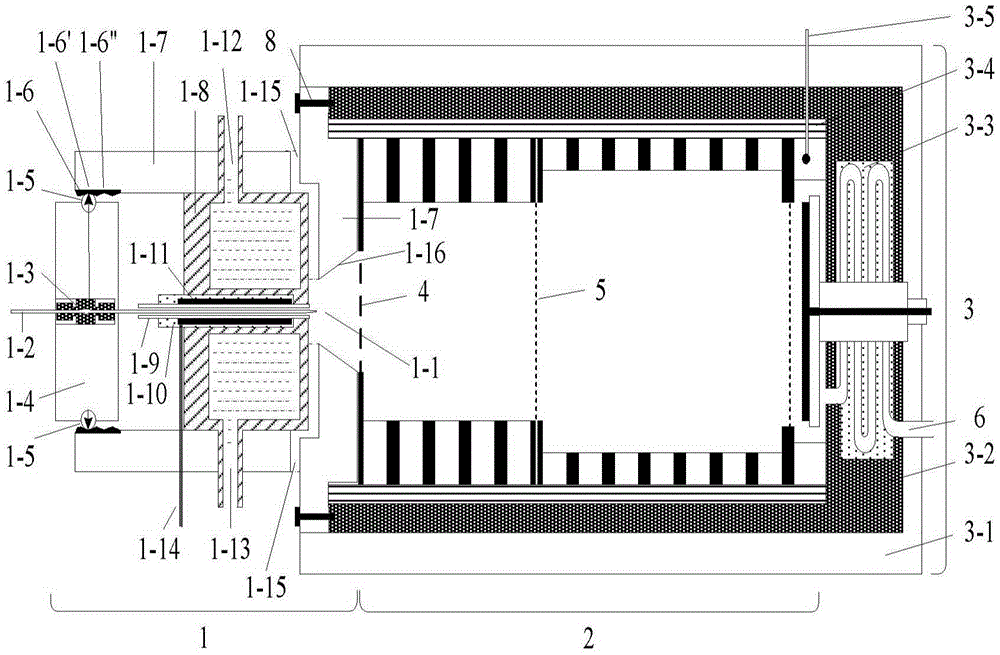

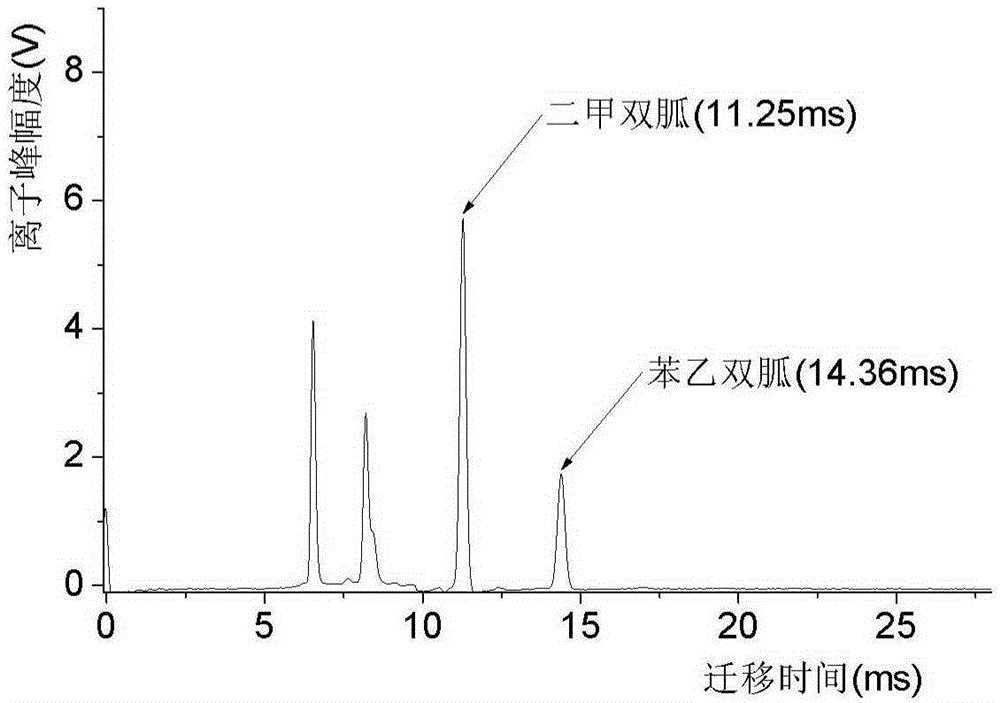

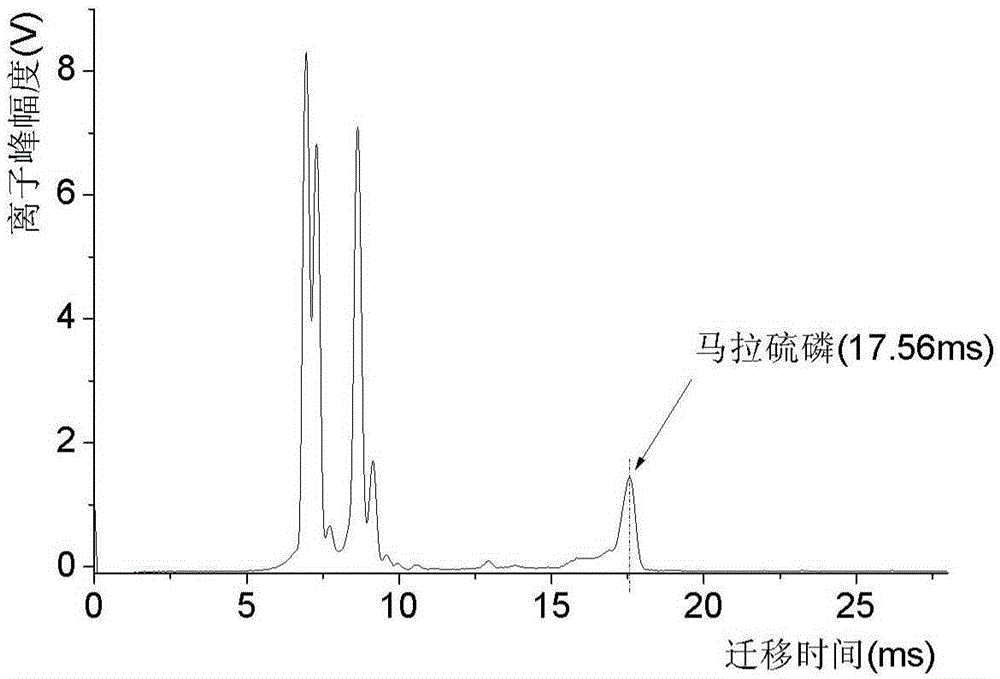

Ion mobility spectrometry employing electrospray/corona discharge dual-mode ion source

ActiveCN105185686AImprove the ionization effectReduce the effects of ionizationMaterial analysis by electric/magnetic meansIon sources/gunsIon clustersDual mode

The invention discloses an ion mobility spectrometry employing an electrospray / corona discharge dual-mode ion source. Switching of two ionization modes is achieved; and the range of a detectable sample is expanded. An ion source is provided with a liquid-cooling component and a heating film component, which are used for rapidly setting the working temperature of a spray needle, so that different requirements of the two ionization modes on the temperature of the spray needle are met; the flow range of an injected sample is expanded; and the detection sensitivity is improved. A trumpet-shaped space is adopted by an electrospray / corona discharge region between the ion source and a drift tube, so that the atomization efficiency on the sample from low-temperature liquid to a gaseous state is improved; the desolvation effect of the sample is improved; and the sample residue is reduced. The drift tube is manufactured by a metal ceramic sealing technology, so that the connection strength is high; the insulativity and the air tightness are good; and installation together with other components is facilitated. The drift tube and a preheating gas circuit are arranged in a heating cylinder with uniform temperature as a whole, so that the phenomenon of migrating ion cluster diffusion caused by non-uniform temperature of blowback air in a migration area is reduced; and the detection resolution capability is improved.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

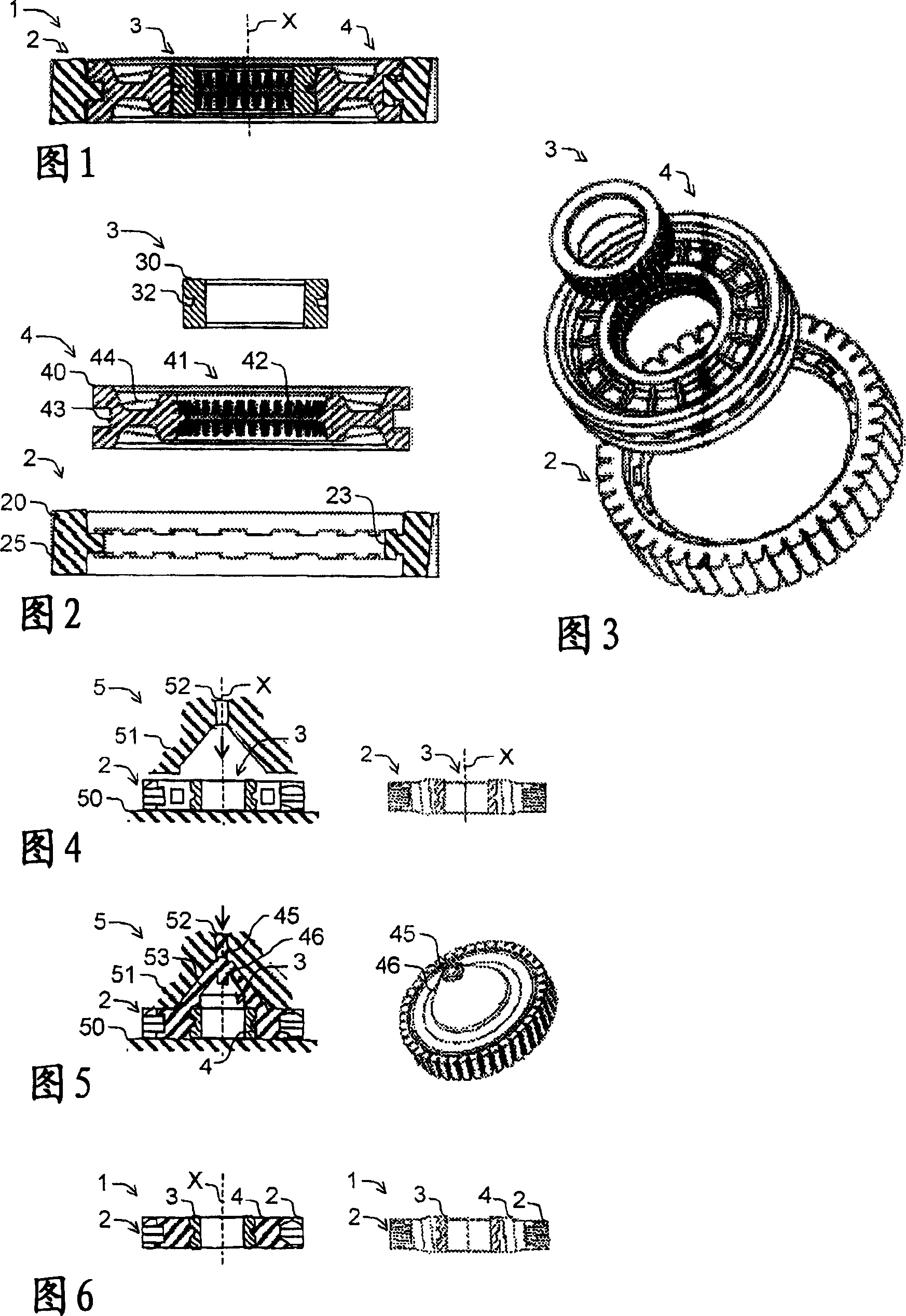

Gearwheel and method for manufacturing a gearwheel

ActiveCN101016944AImprove affordabilitySmall thermal expansionPortable liftingGearing elementsEngineering

Owner:IMS GEAR SE & CO KGAA

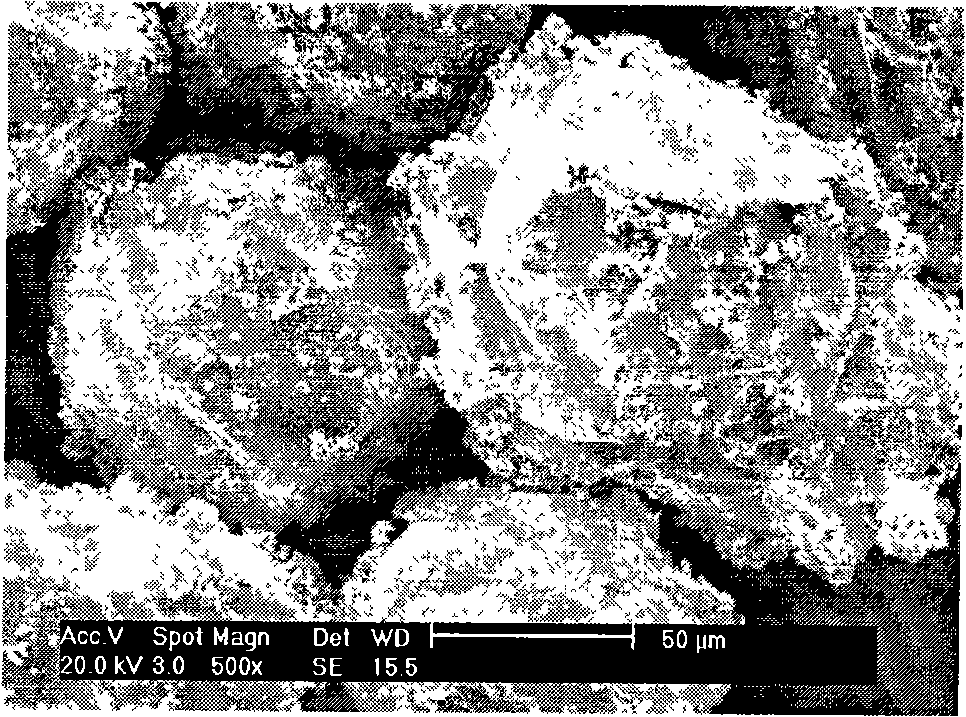

Fused silica ceramic material containing ytterbium oxide and preparation method thereof

The invention relates to a fused silica ceramic material containing ytterbium oxide and a preparation method thereof, belonging to the field of high-temperature structural ceramic materials. The ceramic material is prepared from the following materials by weight percentage: 97% to 99% of fine fused silica powder and 1% to 3% of fine ytterbium oxide powder. The preparation method comprises the following steps: dry-mixing the fine fused silica powder and the fine ytterbium oxide powder; wet-mixing the mixture by adding polyvinyl alcohol solution as binding agent; further sieving, stirring and ageing the mixture to obtain the perform body for molding the green body; molding the green body by a hydraulic press with the molding pressure being higher than or equal to 50MPa; drying and sintering the green body at 1,200 to 1,400 DEG C; and standing for 1 to 3 hours to obtain the fused silica ceramic material containing ytterbium oxide. The invention provides a novel high-temperature structural material for glass melting, ferrous and non-ferrous metallurgy, electronics, military missiles, spacecraft and other fields in China and has wide application prospect and great significance in strengthening the national defense.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Fabrication process of stepped circuit board

InactiveUS20140304977A1Reduce gapSmall coefficientElectronic circuit testingPrinted circuit aspectsCopper platingSolder mask

A fabrication process of a stepped circuit board, comprises the following steps of: A) cutting a circuit board substrate, printing patterns on an inner layer thereof, performing etching, stepped groove grinding, washer milling, brownification and lamination processing on the inner layer, and then drilling holes on an outer layer thereof; B) depositing copper on the outer layer of the circuit board substrate with drilled holes, and then electroplating the entire circuit board substrate; C) performing pattern transfer; D) performing pattern copper plating on the circuit board substrate, and grinding the shape of a connecting piece (SET) on the circuit board substrate, and then etching the outer layer; E) printing a solder mask and texts in a silk-screen manner; F) depositing nickel immersion gold on the entire substrate, then printing characters in a silk-screen manner; and G) testing and inspecting the electrical performance and appearance of a finished board.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Preparation method of heat conduction paster adopting fiber glass mesh as supporting structure

ActiveCN102153955AThe overall thickness is thinGood chemical stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesGlass fiberFiberglass mesh

The invention discloses a preparation method of heat conduction paster, adopting a fiber glass mesh as a supporting structure. The preparation method comprises the steps of dissolving and formulating silicon rubber into silicon rubber solution, and sequentially adding vulcanizer, heat conduction filler and a silane coupling agent to formulate size with medium viscosity and fine coating performance by ultrasonic dispersion and ball-milling uniform mixing; and uniformly coating the size on the pretreated glass fiber mesh and obtaining the heat conduction paster through solvent volatilization, drying, moulding curing and trimming. The heat conduction paster has a high heat conduction rate and a small thermal expansion coefficient, is high in heat stability and soft, meets the requirement on an insulating property, and is convenient to use and disassemble since the surface of the paster has certain viscosity that can be adjusted within a certain range.

Owner:GUANGDONG UNIV OF TECH

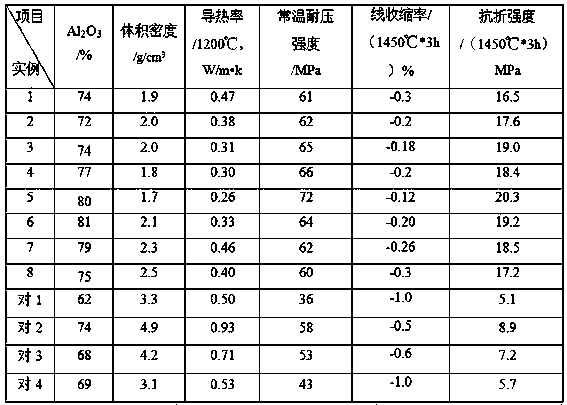

High-alumina refractory castable and preparation method thereof

The invention belongs to the technical field of refractory materials, in particular to a high-alumina refractory castable and a preparation method thereof. The high-alumina refractory castable is prepared from the following raw materials in parts by weight: 50-70 parts of high bauxite, 8-13 parts of andalusite, 11-23 parts of floating bead, 15-20 parts of silicon carbide, 10-15 parts of silicon nitride, 7-12 parts of alpha-Al2O3 micro powder, 3-9 parts of silica-alumina colloid powder, 1-5 parts of attapulgite clay, 10-25 parts of calcium aluminate cement, water reducer and aluminium silicatefiber, wherein the water reducer occupies 0.1-0.3% of total mass of the above raw materials, and the aluminium silicate fiber occupies 0.05-0.12% of total mass of the above raw materials. The high-alumina refractory castable has the advantages of high Al2O3 content, light weight, low heat conductivity and high castable strength.

Owner:黎文泰

Zirconium mullite sagger

The invention provides a zirconium mullite sagger which comprises the following raw materials: natural mullite, tabular corundum, zircon sand, alpha-alumina micro powder, silicon dioxide micro powder, kaolin and a binding agent, wherein the natural mullite consists of mullite granules of which the particle size is within 0.5-1 mm and mullite powder granules of which the particle size is smaller than 0.5 mm; the mass ratio of the mullite granules to the mullite powder granules is (3-4):(6-8); the tabular corundum consists of tabular corundum granules of which the particle size is within 0.1-0.5 mm and tabular corundum powder granules of which the particle size is smaller than 0.1 mm; the mass ratio of the tabular corundum granules to the tabular corundum powder granules is (4-5):(3-4); the particle size of the zircon sand is less than 0.1 mm. The zirconium mullite sagger has the advantages of corrosion resistance and freedom of falling residues, the materials are small in heat capacity and thermal expansion, and the circulation use number is large.

Owner:浙江立鑫高温耐火材料有限公司

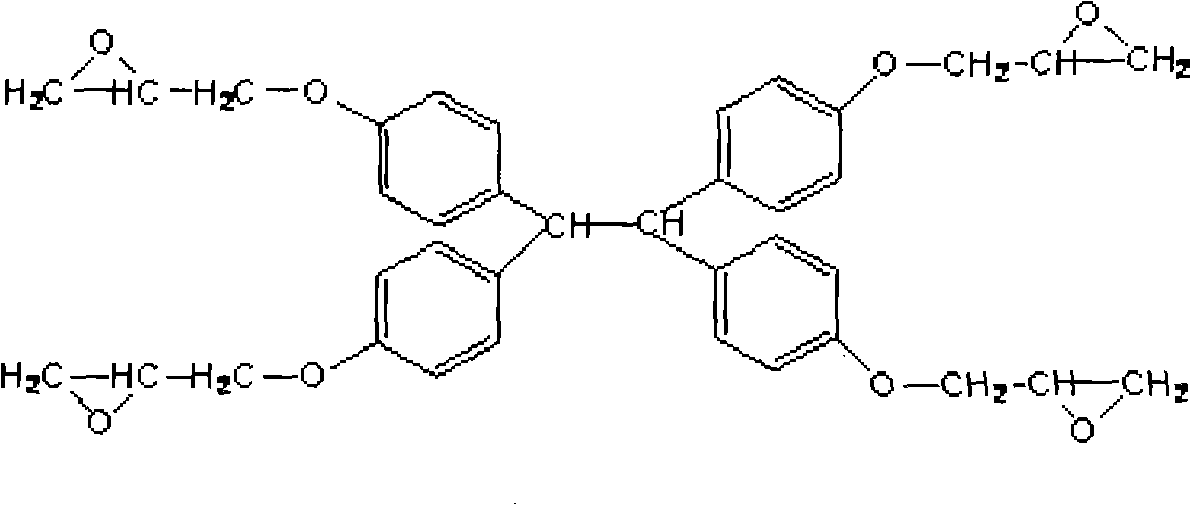

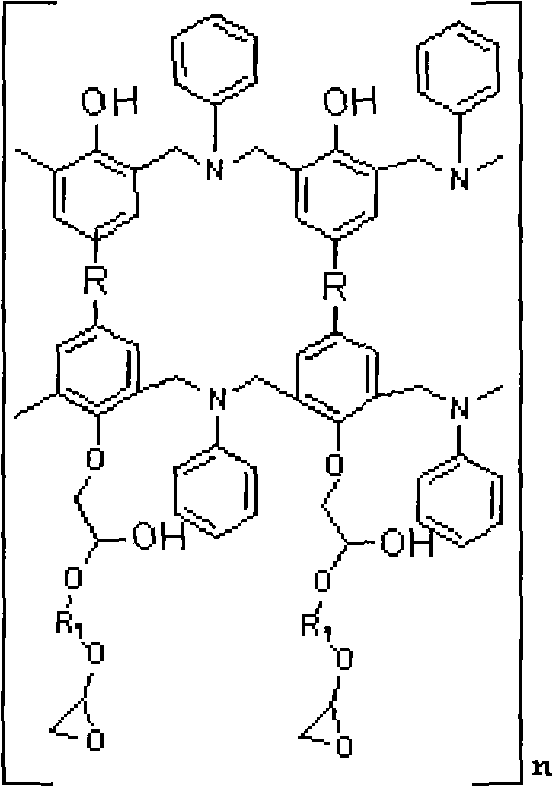

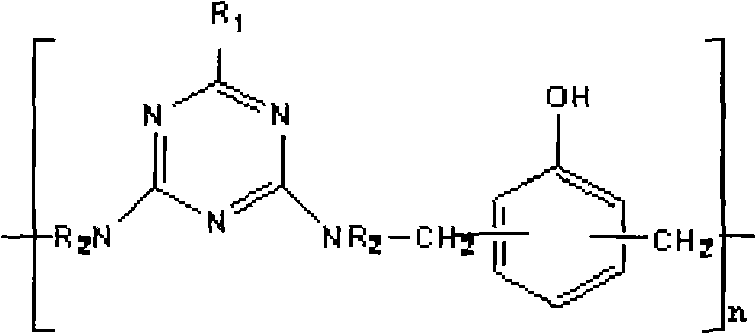

Halogen-phosphorus-free flame retardant epoxy resin composition and application thereof in bonding sheet and copper-clad plate

InactiveCN102093672AIncrease flame retardancySelf-extinguishingCircuit susbtrate materialsMetal layered productsEpoxyThermal expansion

The invention relates to a halogen-phosphorus-free flame retardant epoxy resin composition, which comprises inorganic fillers such as benzoxazine epoxy resin, a modified phenolic resin curing agent, imvite and the like, an inorganic auxiliary flame retardant material and the like, wherein the modified phenolic resin curing agent is nitrogen-containing phenolic resin; a resin condensate system has higher flame retardancy due to the self-extinguishment of the nitrogen-containing phenolic resin during combustion; and the glass-transition temperature of a condensate can be improved further by a unique structure formed by nano-level imvite and condensate molecules, and particularly the condensate has a lower thermal expansion coefficient. The resin composition does not contain halogen and phosphorus elements, and does not generate harmful substances, so a bonding sheet and a copper-clad foil layer, which are produced by the composition, for a printed circuit board have higher heat resistance and flame retardance, and are environmentally-friendly.

Owner:力森诺科电子材料(广州)有限公司

High temperature resistant pearlescent pigment and preparation method thereof

ActiveCN104327552AChemically activeSmall thermal expansionInorganic pigment treatmentColor ScaleHot Temperature

The invention relates to a high temperature resistant pearlescent pigment including a synthetic mica substrate, one layer or multi layers of metal oxide layer coating the synthetic mica substrate, and a zirconia high temperature resistant layer coating the metal oxide layer. The high temperature resistant pearlescent pigment using high temperature is up to 1150 DEG C, the high temperature resistant pearlescent pigment can be stably and well dispersed at high temperature, and can be widely used in underglaze color, in-glaze color, overglaze color, enamel, enamel paper transfers, architectural enamel plates, permanent color scales, high temperature resistant paints and other industries, and the usage amount is 0.5 ~ 50% of that of a glaze or a coating.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

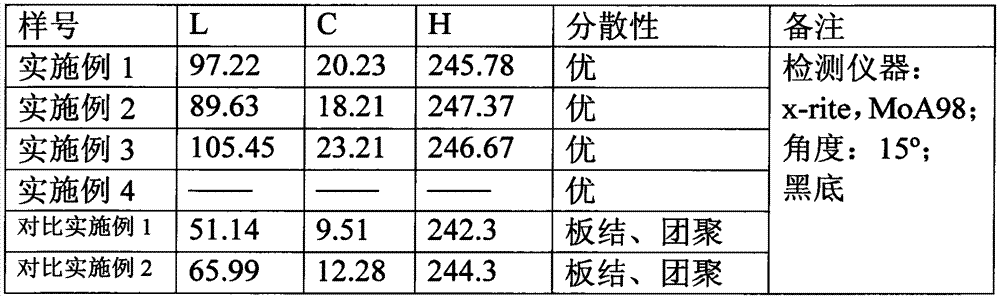

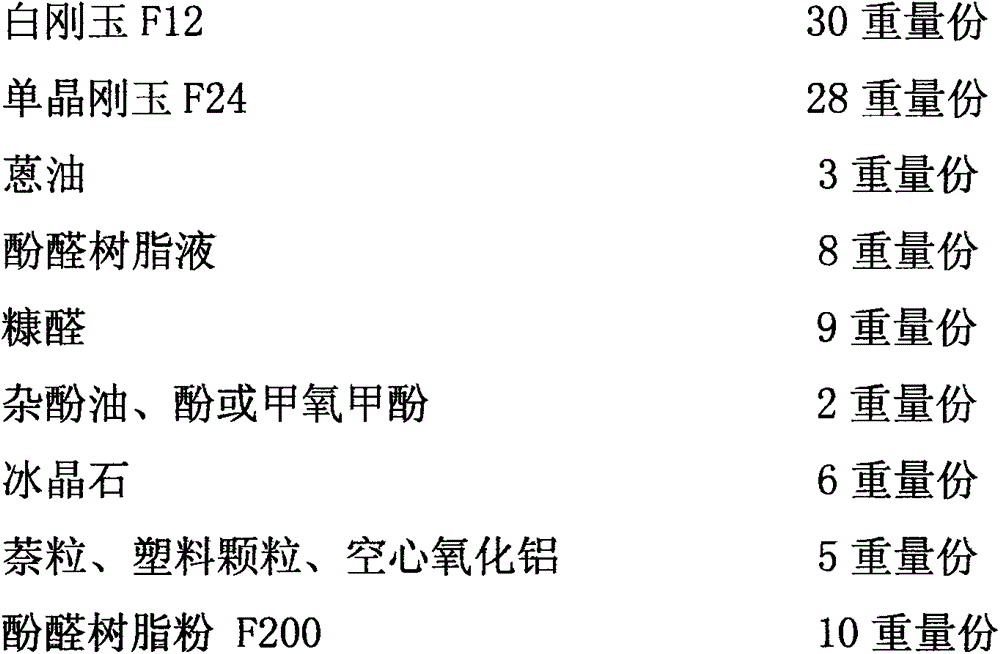

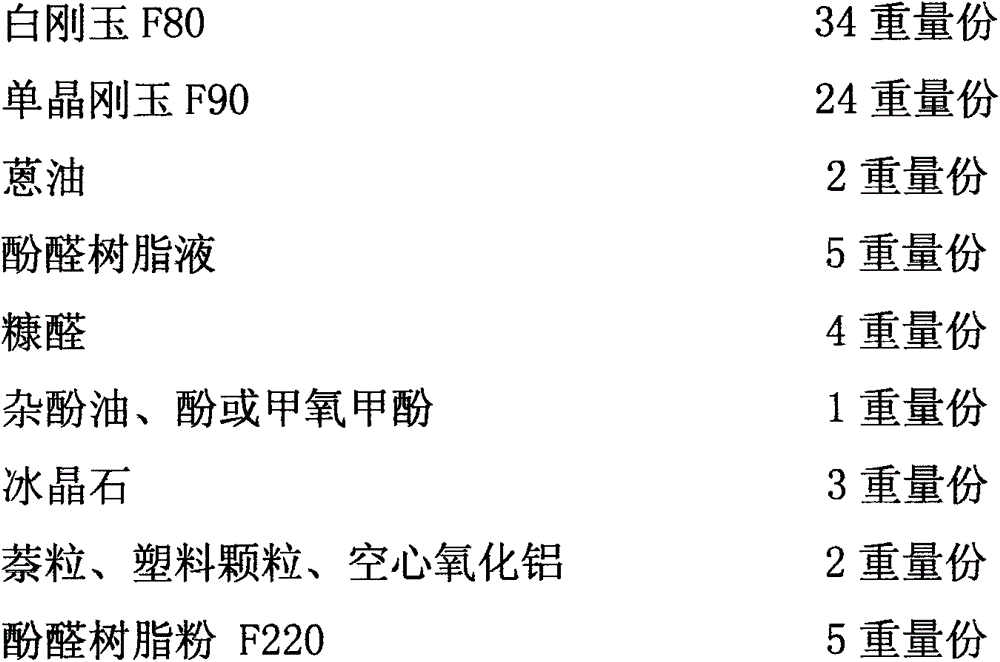

Resin grinding wheel preparation method

ActiveCN104128894AImprove production qualityGood chemical stabilityAbrasion apparatusGrinding devicesWettingPhenols

The invention provides a resin grinding wheel preparation method. A resin grinding wheel is prepared by combining multi-granularity white corundum, monocrystalline fused alumina, anthracene oil and phenolic resin liquid with furfural, kreosote, phenol or kreosol and cryolite, naphthalene grains, plastic particles and hollow alumina filling according to a certain weight ratio. By implementing the method, powder cannot be wrapped by wet materials in the process of mixing of materials, and influence on quality of a resin grinding wheel product due to the fact that the materials are not dispersed and cake is avoided. In addition, a certain weight part of silicon carbide is added in raw materials of mixed grinding materials, and grinding wheel cutting pieces different in performance can be acquired by controlling proportioning content of a silicon carbide grinding material, mixed white corundum and monocrystalline fused alumina and adjusting content of a wetting agent and phenolic resin powder within a certain range.

Owner:NINGBO DAHUA GRINDING WHEEL

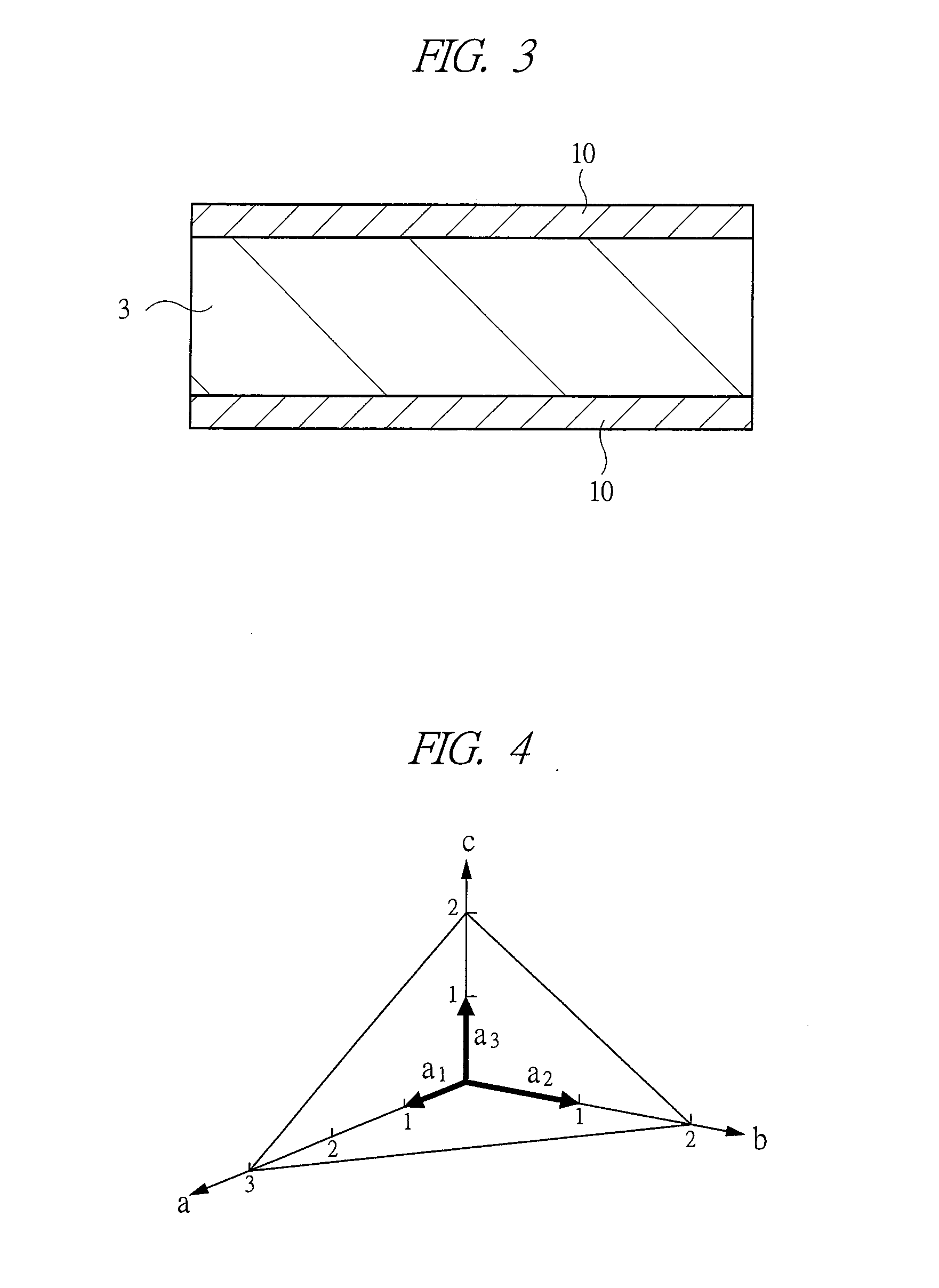

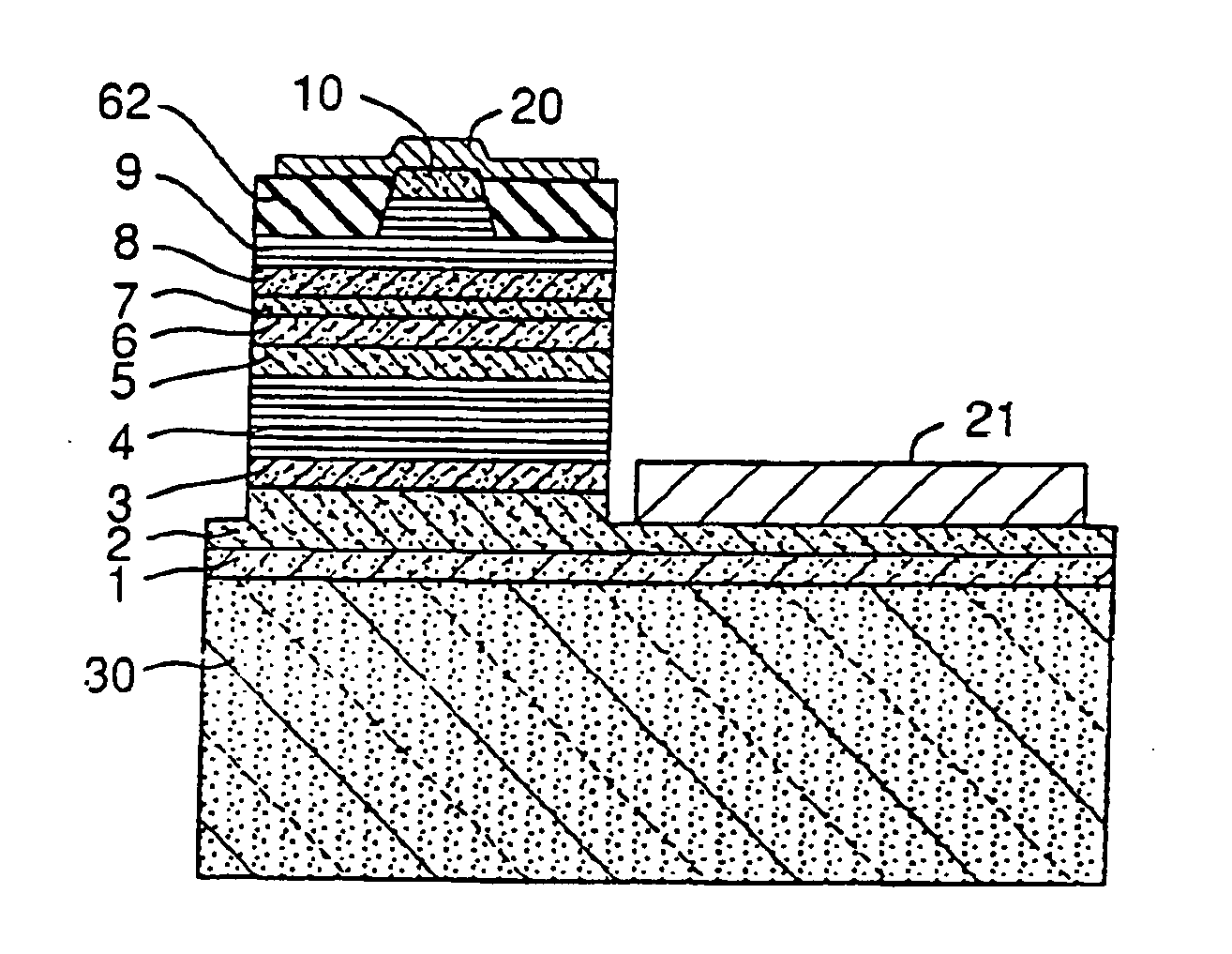

Semiconductor device and its fabrication process

InactiveUS20090108420A1Improve wettabilityPrevent oxidation and corrosionSemiconductor/solid-state device detailsSolid-state devicesThermal expansionPlane orientation

A technique capable of preventing whiskers which are generated in a plating film formed on the surface of each of leads of a semiconductor device is provided. Particularly, a technique capable of preventing generation of whiskers in a plating film containing tin as a primary material and not containing lead is provided. The plating film formed on the surface of the lead is formed so that a particular plane orientation among plane orientations of tin constituting the plating film is parallel to the surface of the lead. Specifically, the plating film is formed so that the (001) plane of tin is parallel to the surface of the lead. Thus, the coefficient of thermal expansion of tin constituting the plating film can be made to be lower than a coefficient of thermal expansion of the copper constituting the lead.

Owner:RENESAS ELECTRONICS CORP

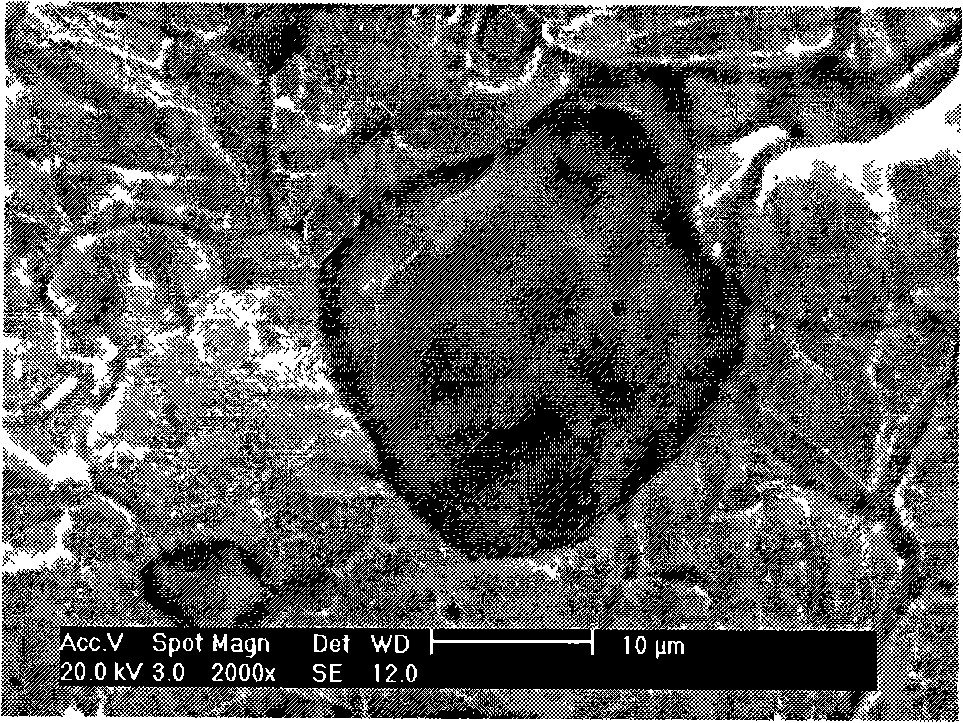

Low-friction-factor silicon carbide ceramic sealing element and preparation method thereof

ActiveCN102030533AReduce coefficient of frictionGuaranteed mechanical propertiesTetramethylammonium hydroxidePolyvinyl alcohol

The invention discloses a low-friction-factor silicon carbide ceramic sealing element which is prepared from a main raw material, polyvinyl alcohol and tetramethyl ammonium hydroxide, wherein the main raw material comprises 65-75% of silicon carbide, 5-10% of boron nitride, 5-10% of fluoridized graphite, 5-10% of molybdenum disulfide and 10% of yttrium aluminium garnet; the polyvinyl alcohol accounts for 2.5-3.5 wt% of the main raw material; and the tetramethyl ammonium hydroxide accounts for 1.5-2.5 wt% of the main raw material. The preparation method comprises the following steps: (1) carrying out ball milling to mix the main raw material, polyvinyl alcohol, tetramethyl ammonium hydroxide and deionized water; (2) carrying out spray granulation on the obtained slurry; (3) putting the obtained granules in a mold, and carrying out dry pressing for primary molding; and (4) carrying out pressureless liquid-phase sintering on the obtained blank to obtain the low-friction-factor silicon carbide ceramic sealing element. The sealing element has the advantages of low friction factor, favorable thermal properties and favorable mechanical properties.

Owner:ZHEJIANG UNIV

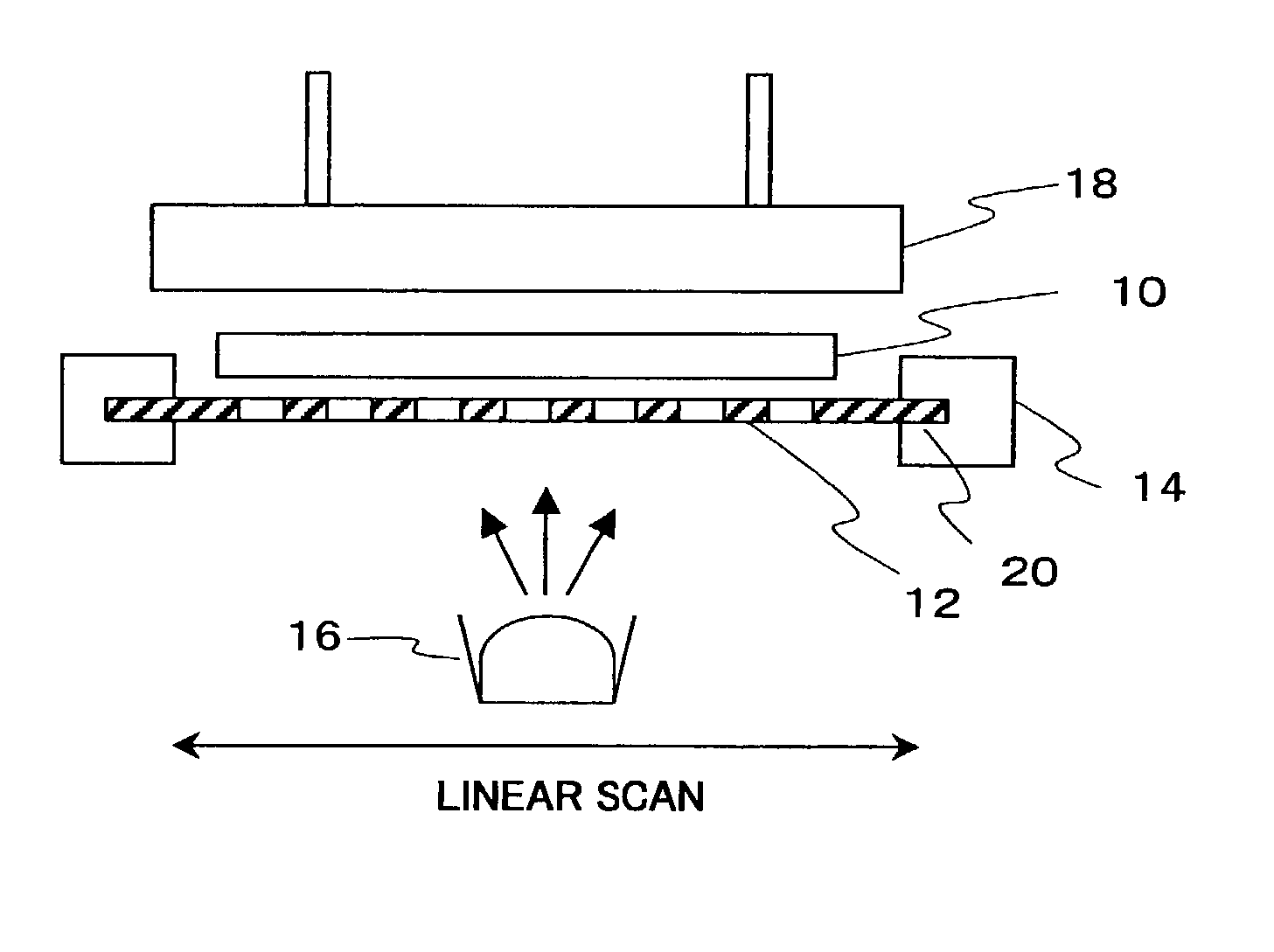

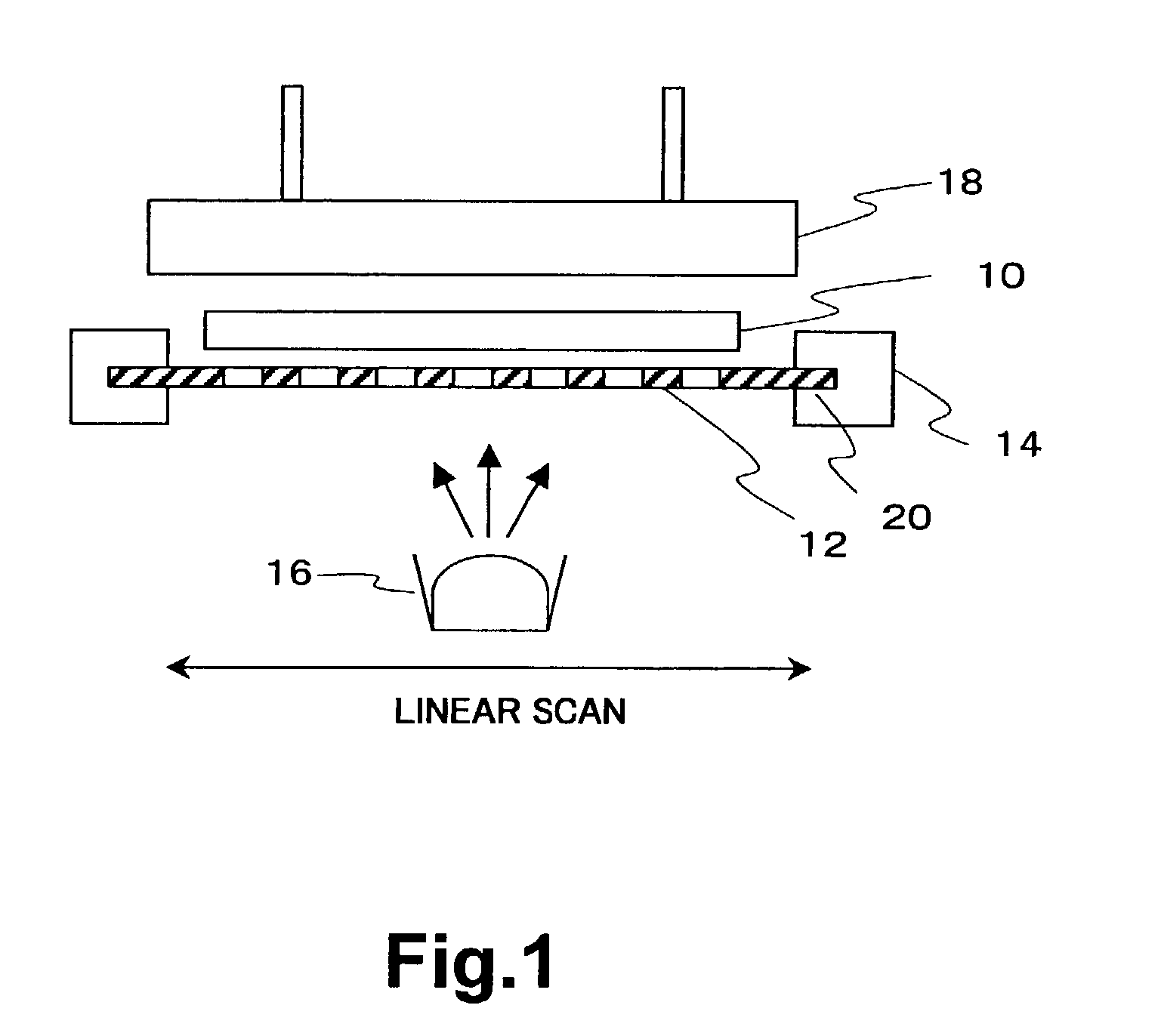

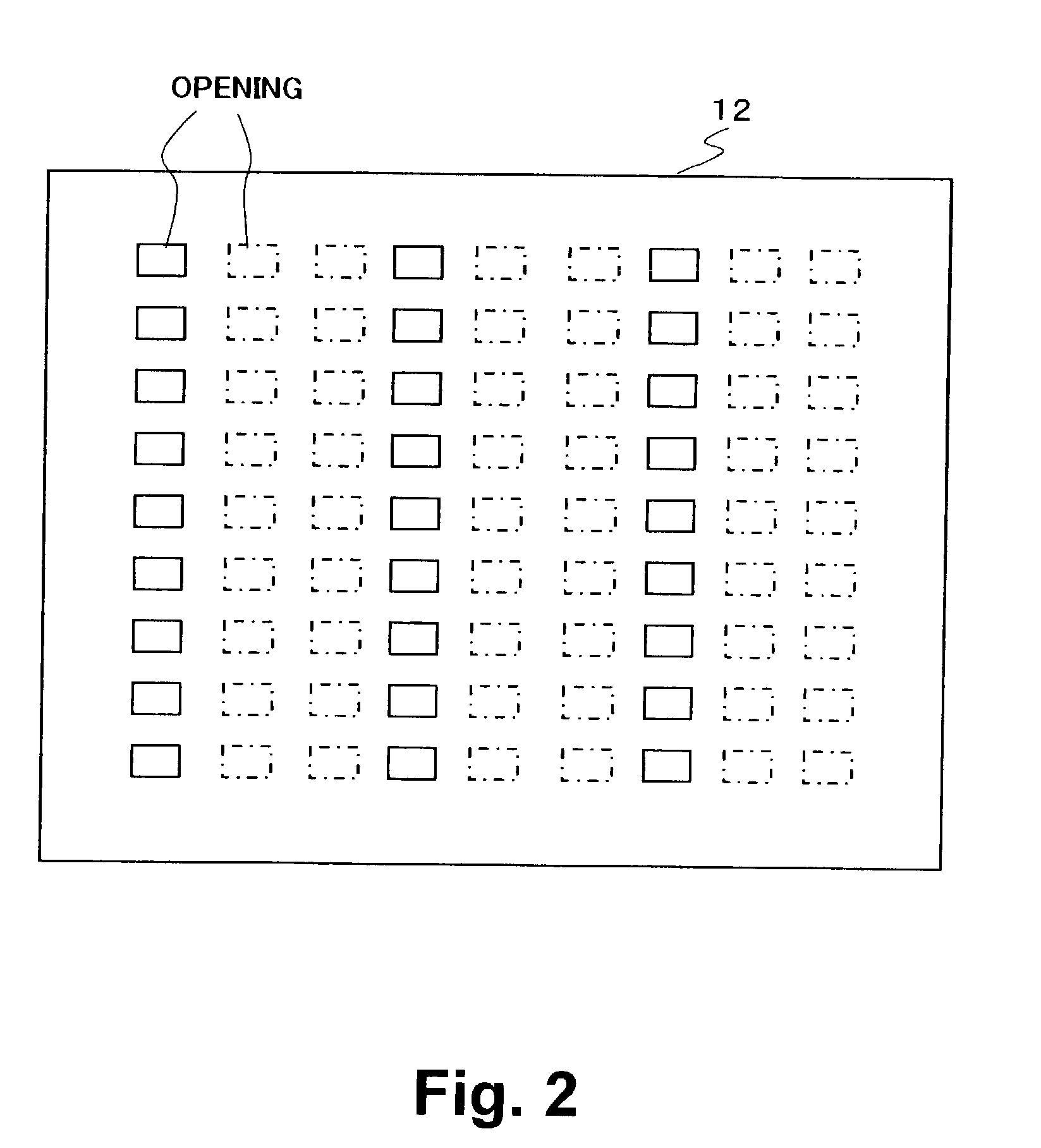

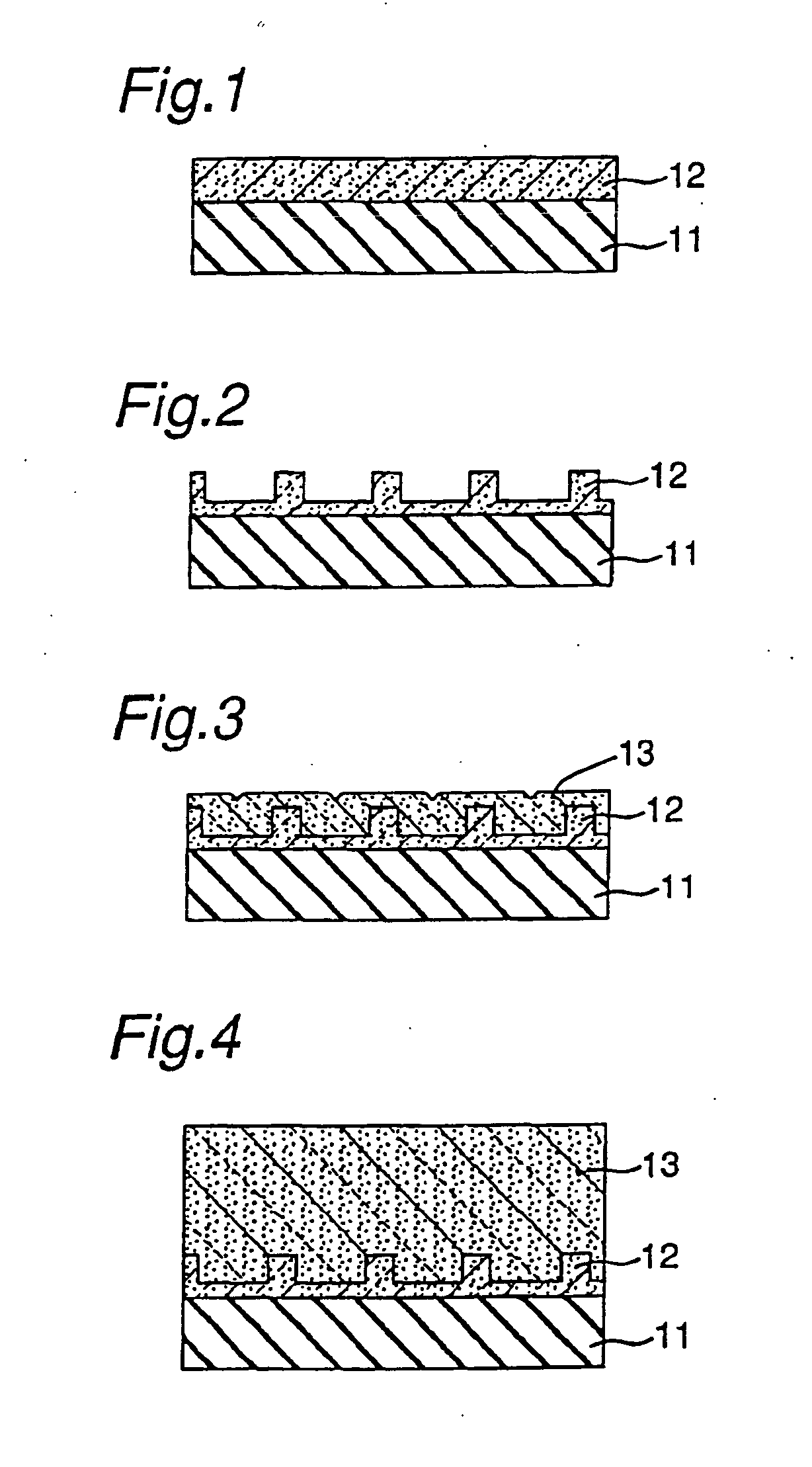

Method for manufacturing electroluminescence display panel and evaporation mask

InactiveUS20030044516A1Reduce thermal deformationImprove the display effectElectroluminescent light sourcesVacuum evaporation coatingThermal coefficientEvaporation

An evaporation mask onto which an opening is formed for selectively allowing passage of an evaporation substance from an evaporation source onto a glass substrate to form an evaporation layer of an electroluminescence element in a predetermined pattern is placed between an evaporation source and a glass substrate and evaporation is performed. As a material for the evaporation mask, a material having a thermal expansion coefficient 160% or smaller of the thermal coefficient of glass is employed so as to minimize the thermal deformation of the evaporation mask which is closer the evaporation source and temperature of which is increased, to thereby improve the evaporation patterning precision.

Owner:SANYO ELECTRIC CO LTD

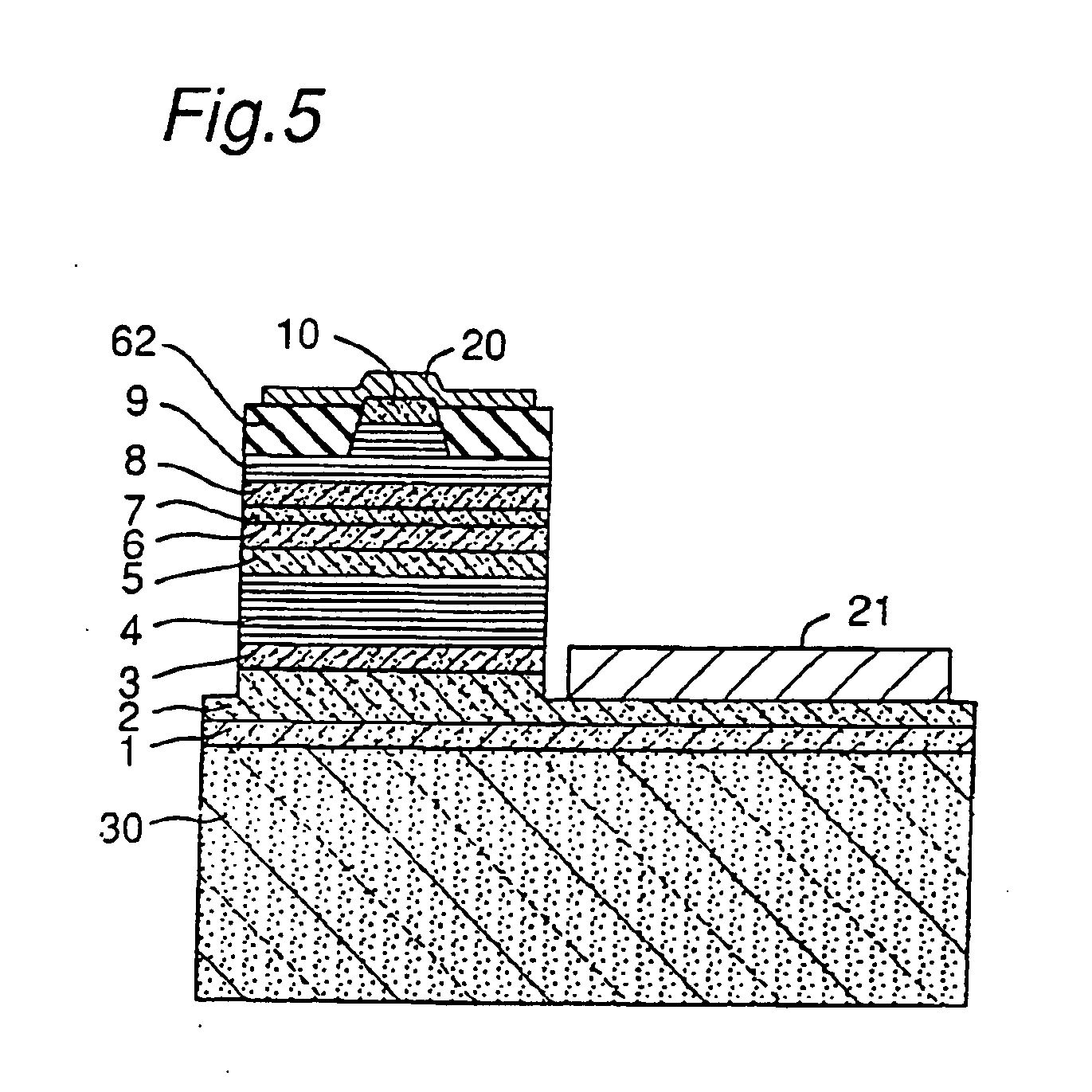

Nitride semiconductor device and manufacturing method thereof

InactiveUS20050054132A1Easy to operateAvoid breakingPolycrystalline material growthLaser detailsDevice formThermal expansion

A nitride semiconductor device includes a GaN substrate having a single-crystal GaN layer at least on its surface and plurality of device-forming layers made of nitride semiconductor. The device-forming layer contacting the GaN substrate has a coefficient of thermal expansion smaller than that of GaN, so that a compressive strain is applied to the device-forming layer. This result in prevention of crack forming in the device-forming layers, and a lifetime characteristics of the nitride semiconductor device is improved.

Owner:NICHIA CORP

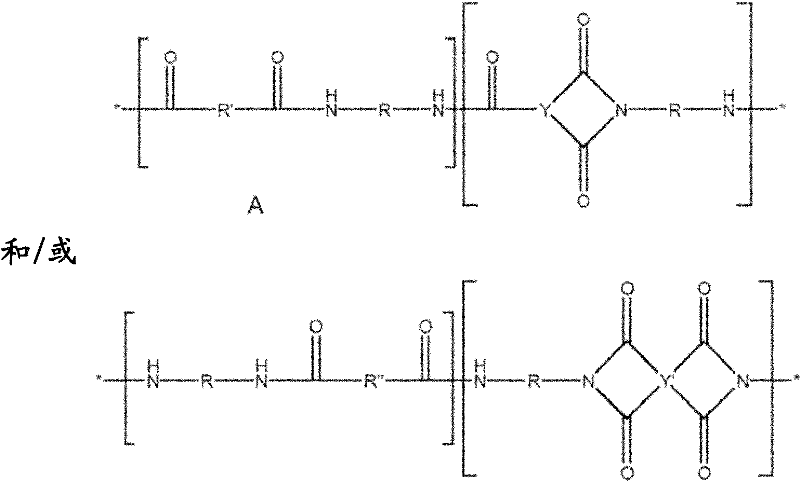

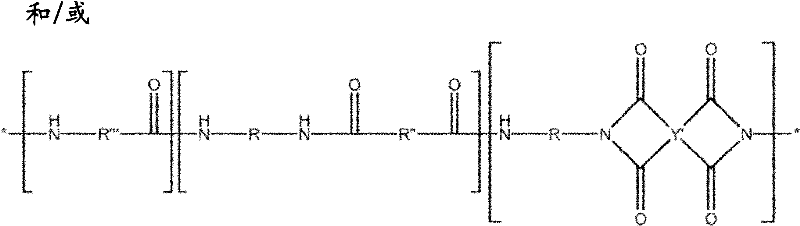

Process for preparing a polyamideimide, a polyamideimide and composition comprising this polyamideimide

The present invention relates to a process for preparing a semi-aromatic polyamideimide, and also to a polyamideimide and to a composition based on a thermoplastic matrix, comprising a polyamideimide. The invention relates more particularly to a process for preparing a polyamideimide by melt polymerization of at least one organic compound having carboxyl groups, of at least one diamine compound and optionally at least one diacid compound.

Owner:RHODIA OPERATIONS SAS

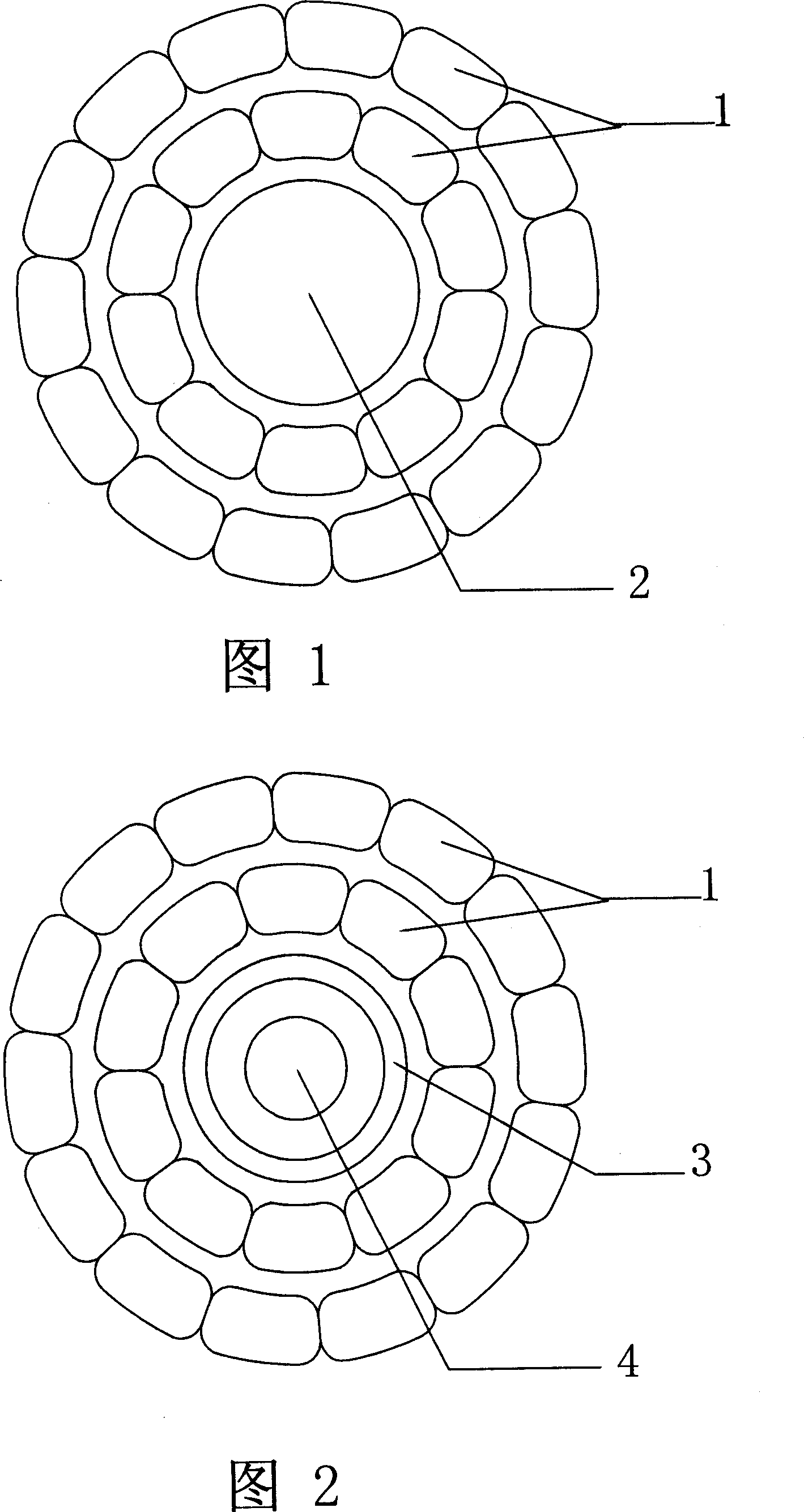

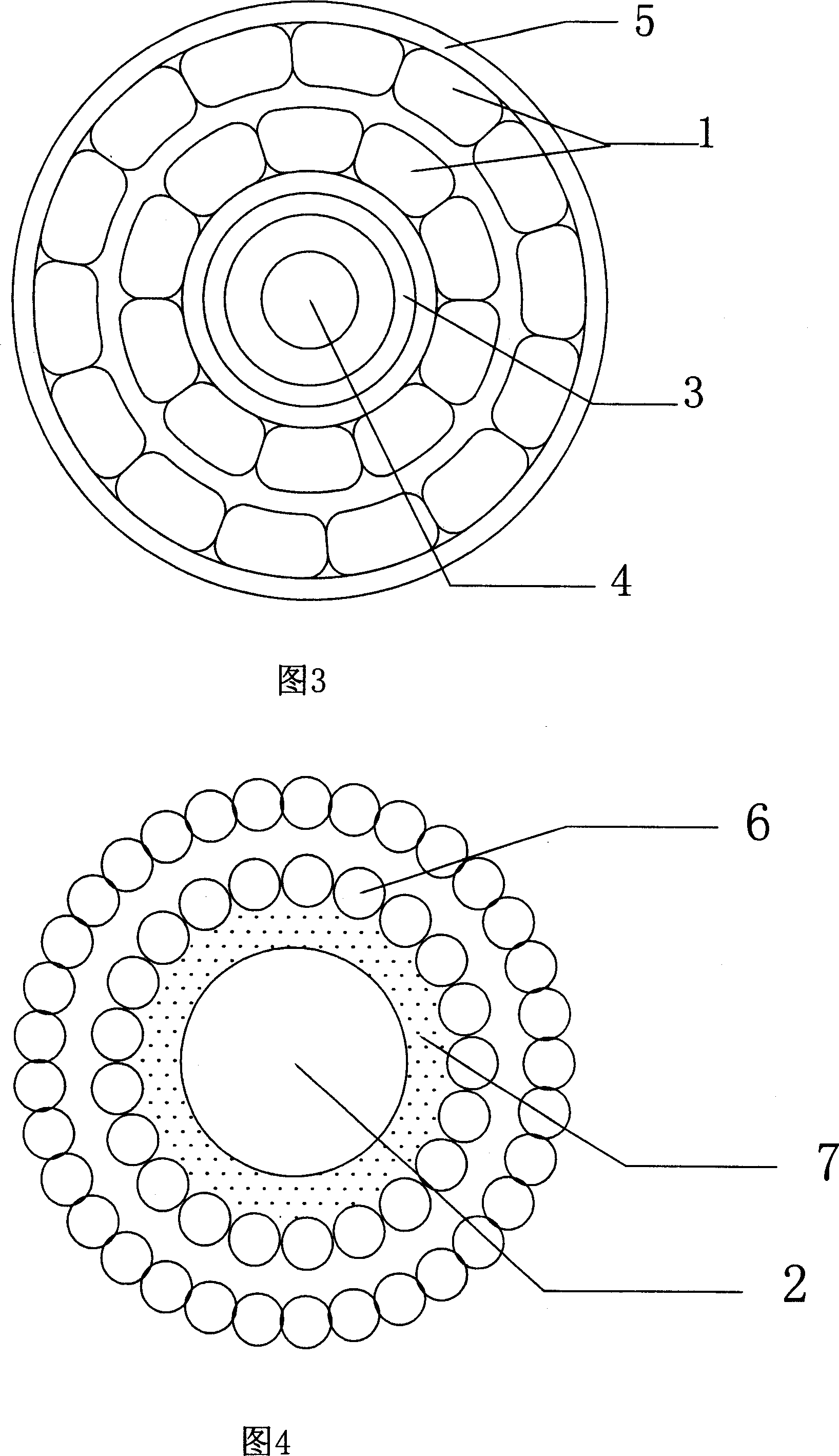

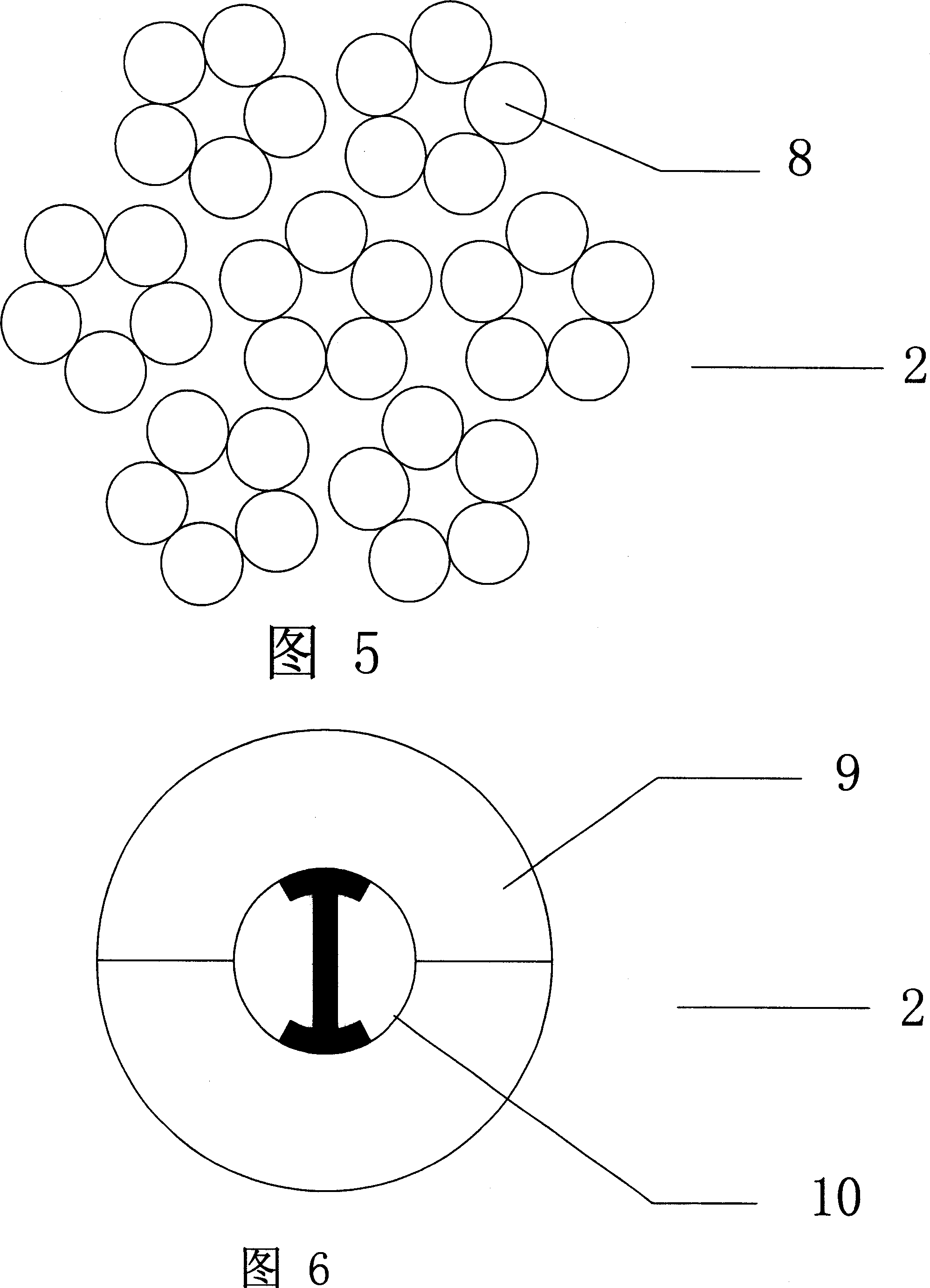

Corrosion-proof vibration-proof wire

InactiveCN101145413AHigh tensile strengthSmall outer diameterInsulated cablesInsulated conductorsBreaking strengthElectrical conductor

The invention relates to an improvement of anti-corrosion and anti-vibration overhead power transmission cables for overhead power transmission lines and is characterized in that the reinforced inner core of the twisted cable is a fiber resin-molded elongated body and has a 0.5-8 mm distance to the innermost conductor of the twisted cable. The inventive wire has the advantages of self-damping vibration protection function, reduced weight of the reinforced core molded from resin mixed with carbon fiber and / or basalt fiber (50-70 percent of the steel-core anti-corrosion and anti-vibration cable core), increased tensile strength (up to 2000-6000MPa), maximum applied stress up to 60 percent of breaking strength, reduced base number or altitude of towers, larger construction span, large current capacity (about doubled), reduced construction cost (by 10-20 percent), and increased service life (by 20-30 years).

Owner:FAR EAST COMPOSITE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com