Resin grinding wheel preparation method

A resin grinding wheel and grinding wheel technology, applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems affecting the product quality of organic grinding tool manufacturing technology, increasing grinding force of grinding wheels, waste of raw materials, etc. The effect of enhancing self-sharpening, reducing cutting temperature and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A kind of preparation method of resin grinding wheel, the mixing process of material is carried out under the fully enclosed environment, and it comprises the following steps:

[0023] Step 1: Take 30-34 parts by weight of white corundum and 24-28 parts by weight of single crystal corundum and put them into a mixer and mix them evenly to form a mixed abrasive, then add 2-3 parts by weight of anthracene oil and 5-8 parts by weight of phenolic resin solution and mix them evenly After the mixed abrasive is completely wetted, add 4 to 9 parts by weight of furfural, 1 to 2 parts by weight of creosote, phenol or cresol and mix evenly, then add 3 to 6 parts by weight of cryolite, 2 to 2 parts by weight of 5 parts by weight of naphthalene granules, plastic granules, and hollow alumina are mixed evenly, and finally 5 to 10 parts by weight of phenolic resin powder are added and mixed evenly, passed through a 250-mesh standard sieve, and screened twice. The particles that pass thr...

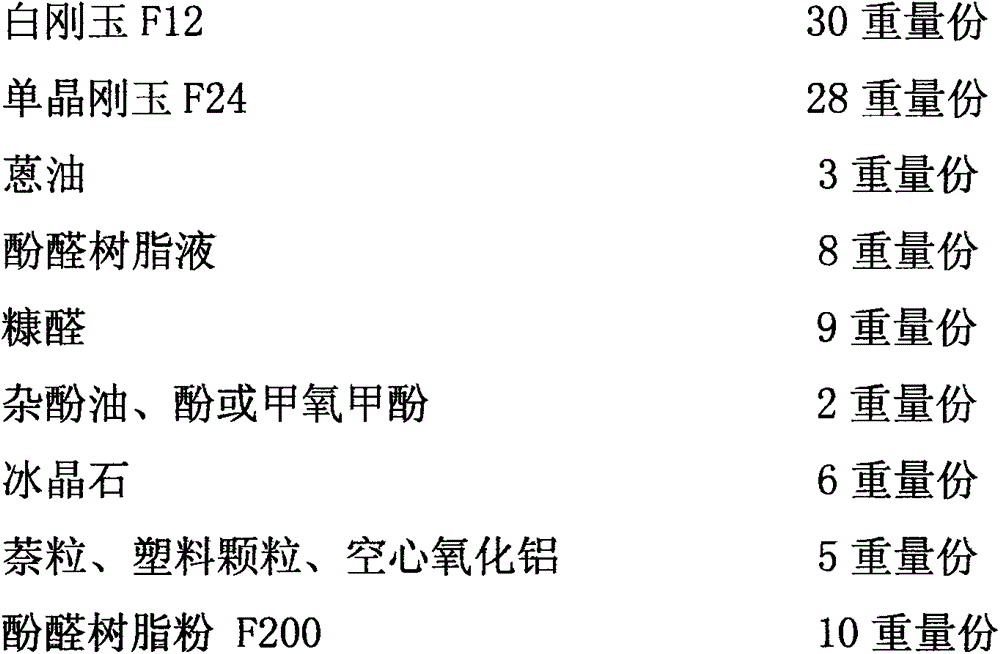

Embodiment 1

[0031]

[0032] Its preparation process is as follows:

[0033] Put the white corundum F12 and single crystal corundum F24 into the mixer according to the proportioning weight and mix them evenly to form a mixed abrasive, then add 3 parts by weight of anthracene oil and 8 parts by weight of phenolic resin solution and mix evenly, and then add 9 Mix parts by weight of furfural, 2 parts by weight of creosote, phenol or methoxycresol, then add 6 parts by weight of cryolite, 5 parts by weight of naphthalene particles, plastic particles, and hollow alumina and mix evenly, and finally add 10 parts by weight of phenolic resin Mix the powder evenly, pass through a 250-mesh standard sieve, and sieve twice, and the particles that pass through the standard sieve are used as molding materials for grinding wheel molding;

[0034] Then according to the molding density of 2.48g / cm 3 Calculate the weighed weight of the grinding wheel molding material, pour the weighed grinding wheel moldi...

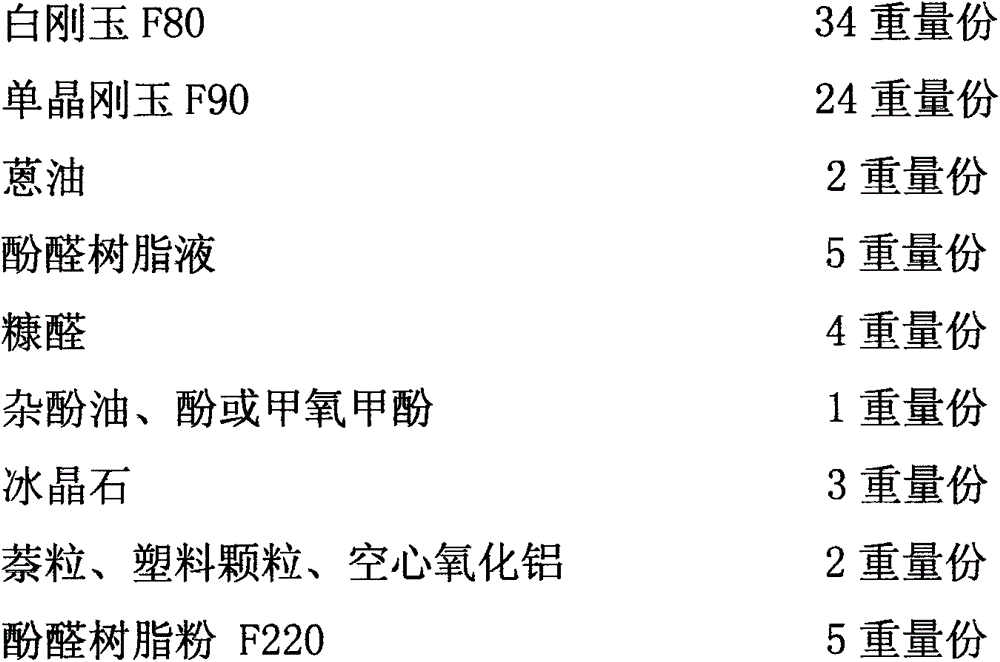

Embodiment 2

[0037]

[0038] Its preparation process is as follows:

[0039] Put the white corundum F80 and single crystal corundum F90 into the mixer according to the proportioning weight and mix them evenly to form a mixed abrasive, then add 2 parts by weight of anthracene oil and 5 parts by weight of phenolic resin solution and mix evenly, and then add 4 Mix parts by weight of furfural, 1 part by weight of creosote, phenol or cresol, then add 3 parts by weight of cryolite, 2 parts by weight of naphthalene particles, plastic granules, and hollow alumina and mix evenly, and finally add 5 parts by weight of phenolic resin Mix the powder evenly, pass through a 250-mesh standard sieve, and sieve twice, and the particles that pass through the standard sieve are used as molding materials for grinding wheel molding;

[0040] Then according to the molding density of 2.44g / cm 3 Calculate the weighed weight of the grinding wheel molding material, pour the weighed grinding wheel molding materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com