Production device and production method of biomass organic carbon-based potash fertilizer

A production device, biomass char technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of soil compaction, farmland degradation, soil and water pollution, etc., and achieve the effect of saving energy, protecting the environment, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

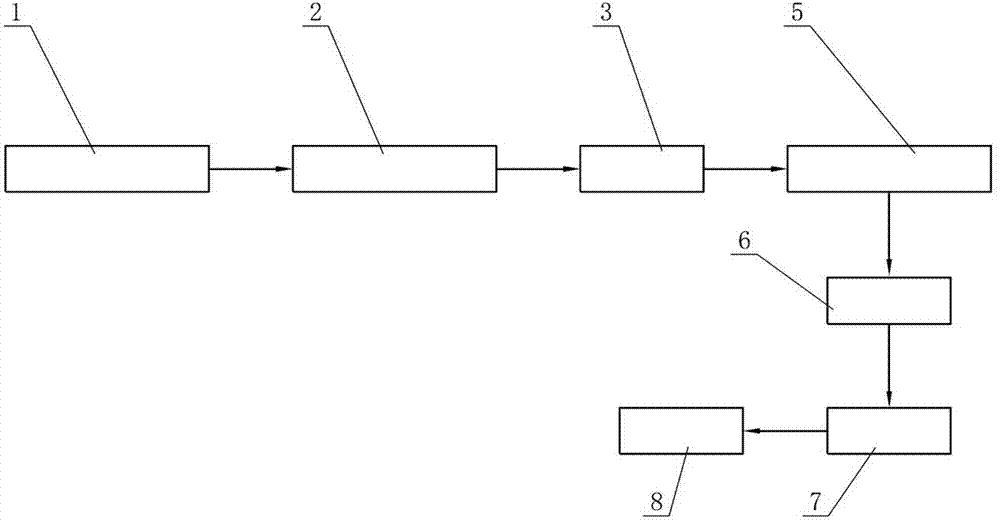

[0032] Embodiment 1: see figure 1 , a biomass organic carbon-based potassium fertilizer production device, including a placement tank 1 for stacking biomass charcoal, a pretreatment device, a granulator 6, a drying machine 7, a packaging machine 8 and a control system, the placement tank and A feeding conveyor 2 is arranged between the pre-processing equipment, and the pre-processing equipment includes a stirring mixer 5, a sieving machine 4 and a pulverizer 3, and the feeding end of the feeding conveyor 2 is placed in the placement tank 1 , its feeding end is connected with the feed port of pulverizer 3, the discharge port of pulverizer 3 is connected with the feed port of stirring mixer 5, the discharge port of stirring mixer 5 is connected with the feed port of granulator 6 connected, the discharge port of the granulator 5 is connected with the feed port of the dryer 7, the discharge port of the dryer 7 is connected with the feed port of the packaging machine 8, and the con...

Embodiment 2

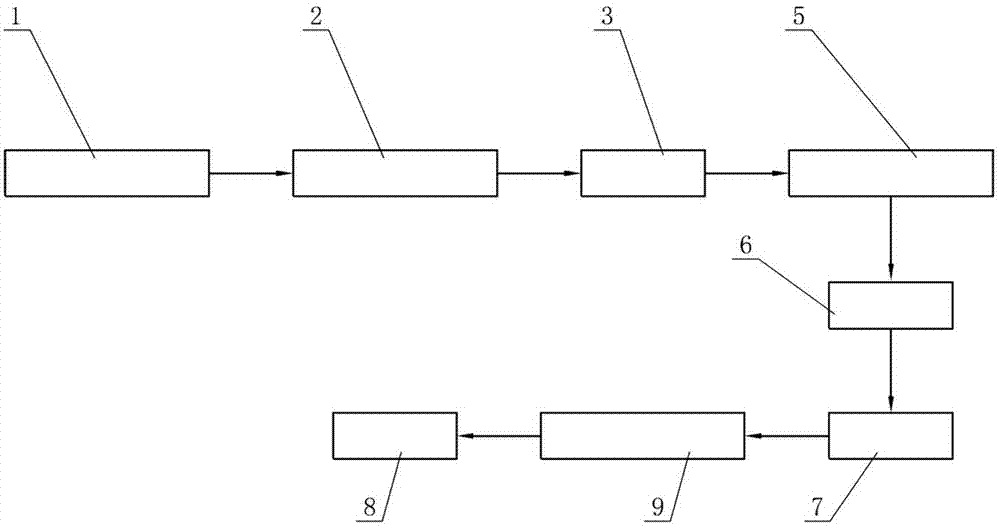

[0037] Example 2: see figure 2 , Embodiment 2 is basically the same as Embodiment 1, and the meanings represented by the symbols in the figure are the same, and the similarities will not be repeated. The difference is that a cooling device 9 is also provided between the drying machine 7 and the packaging machine 8, The feed port of the cooling device 9 is connected with the discharge port of the dryer 8 , and the discharge port of the cooling device 9 is connected with the feed port of the packaging machine 8 .

Embodiment 3

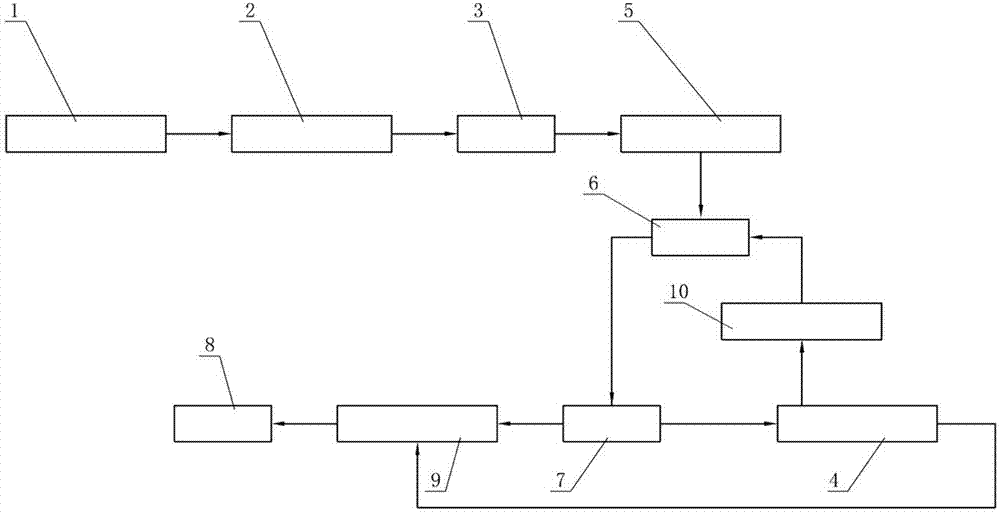

[0038] Embodiment 3: see image 3 , embodiment 3 is basically the same as embodiment 2, and the meanings represented by the symbols in the figure are the same, and the similarities will not be repeated. The difference is: a screening machine 4 and a second Two pulverizers 10, the feed port of the screening machine 4 is connected with the discharge port of the dryer 7, and the discharge port of the screening machine 4 is respectively connected with the feed port of the second pulverizer 10 and the feed port of the granulator 6 1. The feed port of the packaging equipment 8 is connected, and the discharge port of the second pulverizer 10 is connected with the feed port of the granulator 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com