Method for producing diamond reinforced Cu-matrix compound material by surface metallization and chemical deposition

A copper-based composite material, diamond reinforced technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of large interface thermal resistance, side effects of heat conduction improvement, low interface bonding strength, etc. Good overall performance, strong operability, low thermal expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

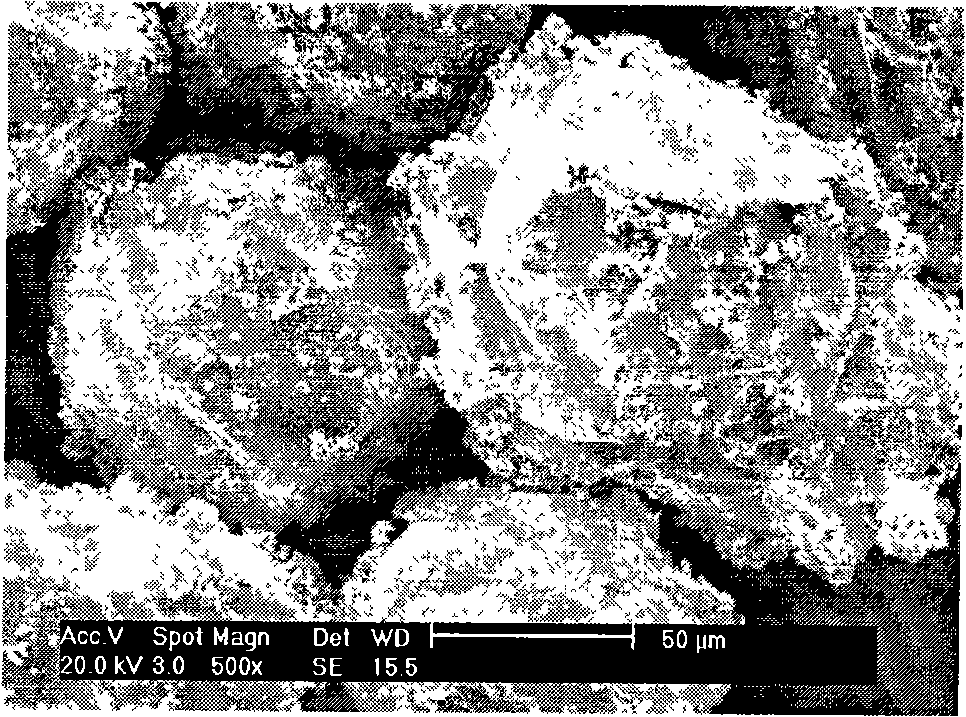

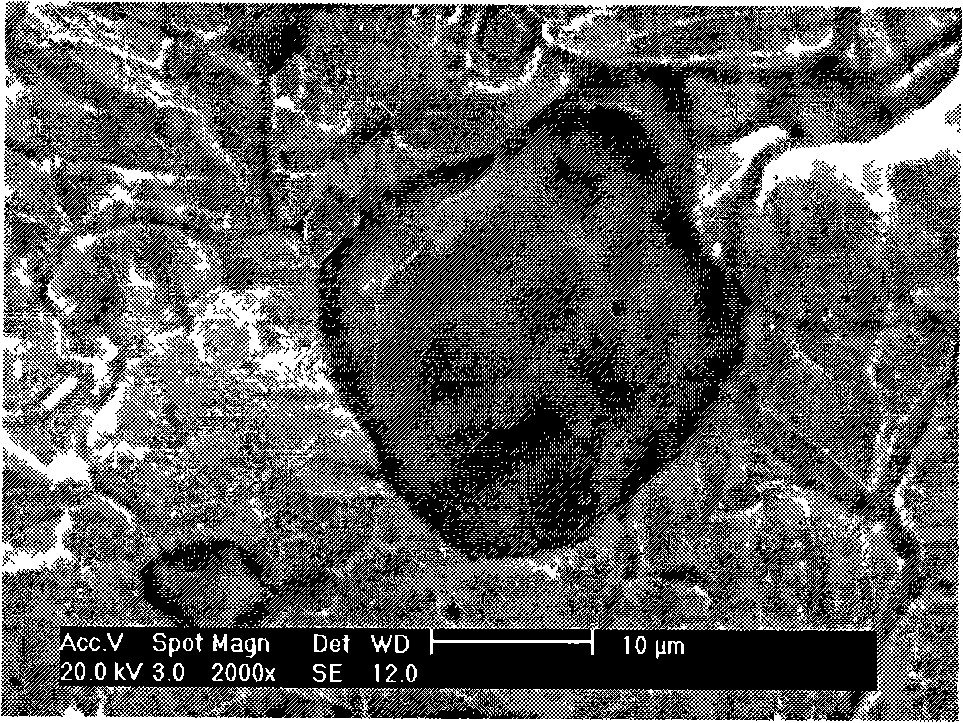

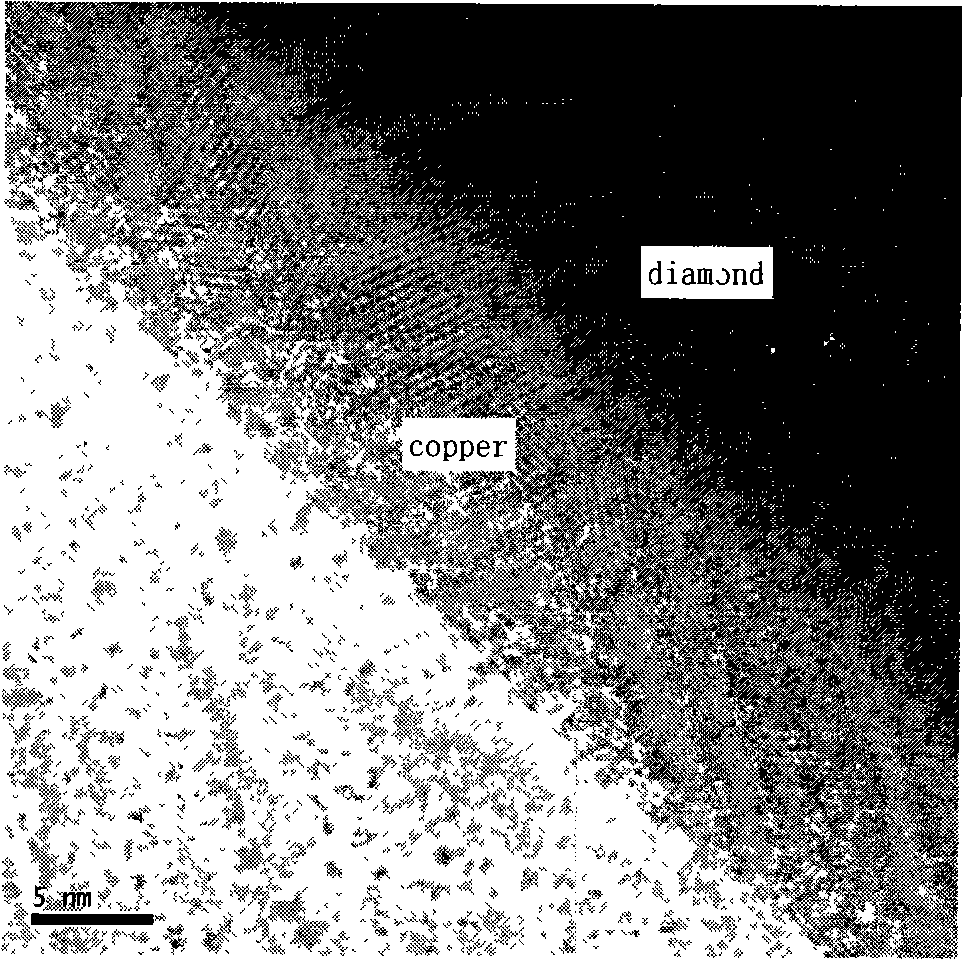

[0029] Pour 10 grams of diamonds with a particle size of 89 to 104 microns into deionized water to make a 100g / L slurry, pour into a mixed acid solution prepared by 150ml of hydrochloric acid and 50ml of nitric acid, and soak for 70 hours; then perform ultrasonic cleaning for 15 minutes , filter out the diamond and wash it to neutral with deionized water, then add the diamond to 1000ml of SnCl with a concentration of 20g / L 2 2H 2 In O solution, sensitize at room temperature for 0.5 hours, filter out the diamond, and wash it with deionized water until neutral; then add 500ml of diamond with a concentration of 0.5g / L PdCl 2 , activated at 70°C, filtered out the diamonds, washed them with deionized water until neutral; finally added 1000ml of Na with a concentration of 40g / L to the diamonds 2 h 2 PO 2 ·H 2 O solution, carry out reduction treatment at normal temperature for 0.5 hours, filter out, wash with deionized water until neutral and set aside.

[0030] Add the followin...

example 2

[0038] Example 2. The processing conditions of the present embodiment are the same as in Example 1, except that the average particle size of the diamond added is changed, and the average particle size of the diamond used is 74-89 μm. The performance of the prepared diamond-reinforced copper-based composite material is: the density is 5.878g / cm 3 , the thermal conductivity is 486W / m·k, and the thermal expansion coefficient is 5.4μm / m·℃.

example 3

[0039] Example 3. The process conditions of the present embodiment are the same as in Example 1, except that the average particle size of the diamond added is changed, and the average particle size of the diamond used is 61-74 μm. The performance of the prepared diamond-reinforced copper-based composite material is: the density is 5.823g / cm 3 , the thermal conductivity is 441W / m·k, and the thermal expansion coefficient is 6.25μm / m·℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com