Method for preparing diamond-copper composite material by virtue of metallization of high-temperature blending surface

A surface metal and composite material technology, which is applied in the field of copper-based composite material preparation, can solve the problems of expensive preparation equipment and increase the application of diamond/copper composite material substrates, and achieve simple process, high interface connection strength and low synthesis temperature. Effect

Inactive Publication Date: 2012-03-21

HUAZHONG UNIV OF SCI & TECH

View PDF6 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the preparation of diamond / copper composites by these three methods greatly increases and limits the application of diamond / copper composite substrates in electronic engineering because the preparation equipment is too expensive.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

example 2

example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Login to View More

Abstract

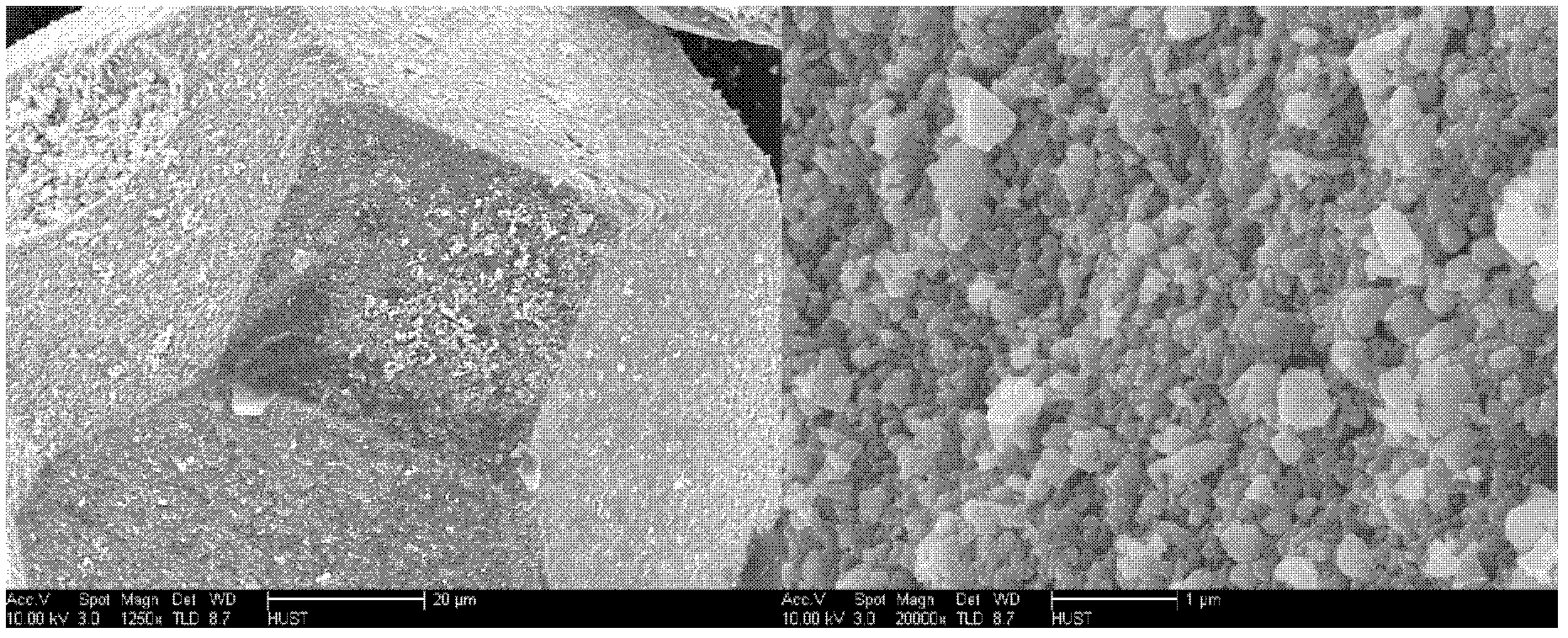

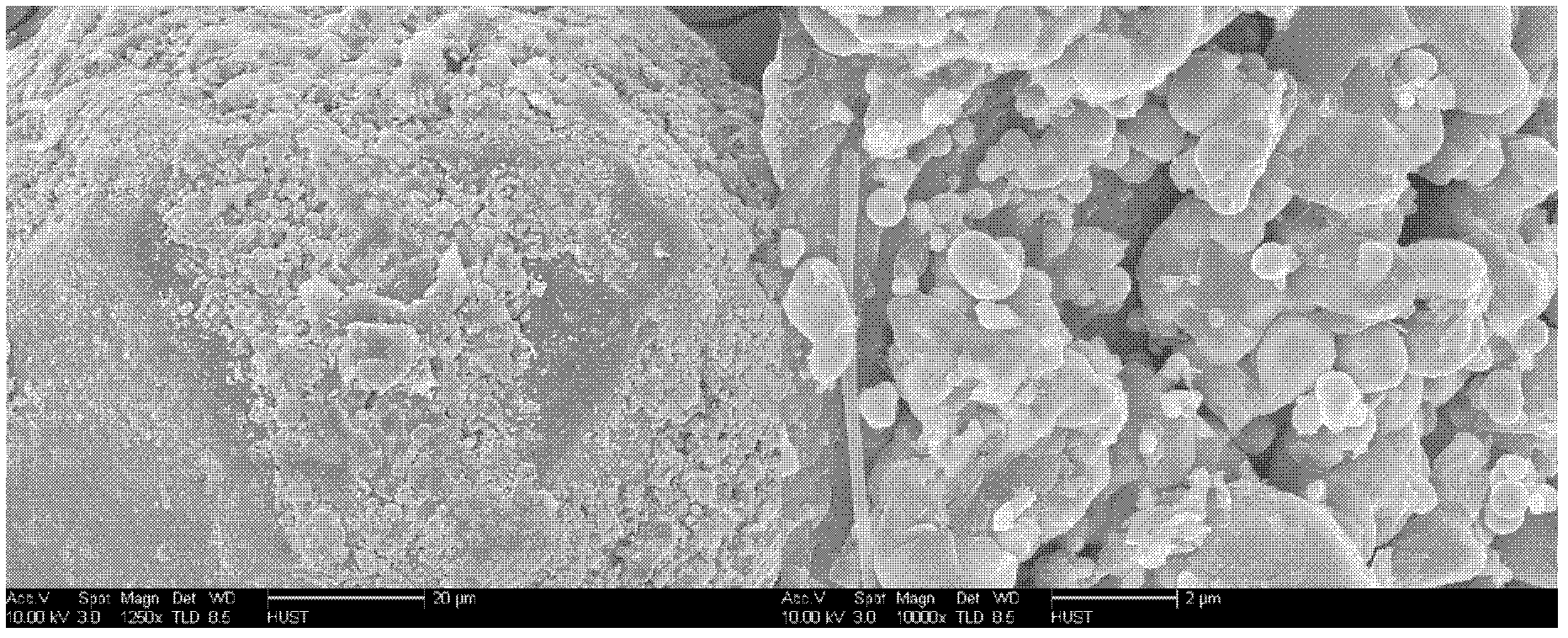

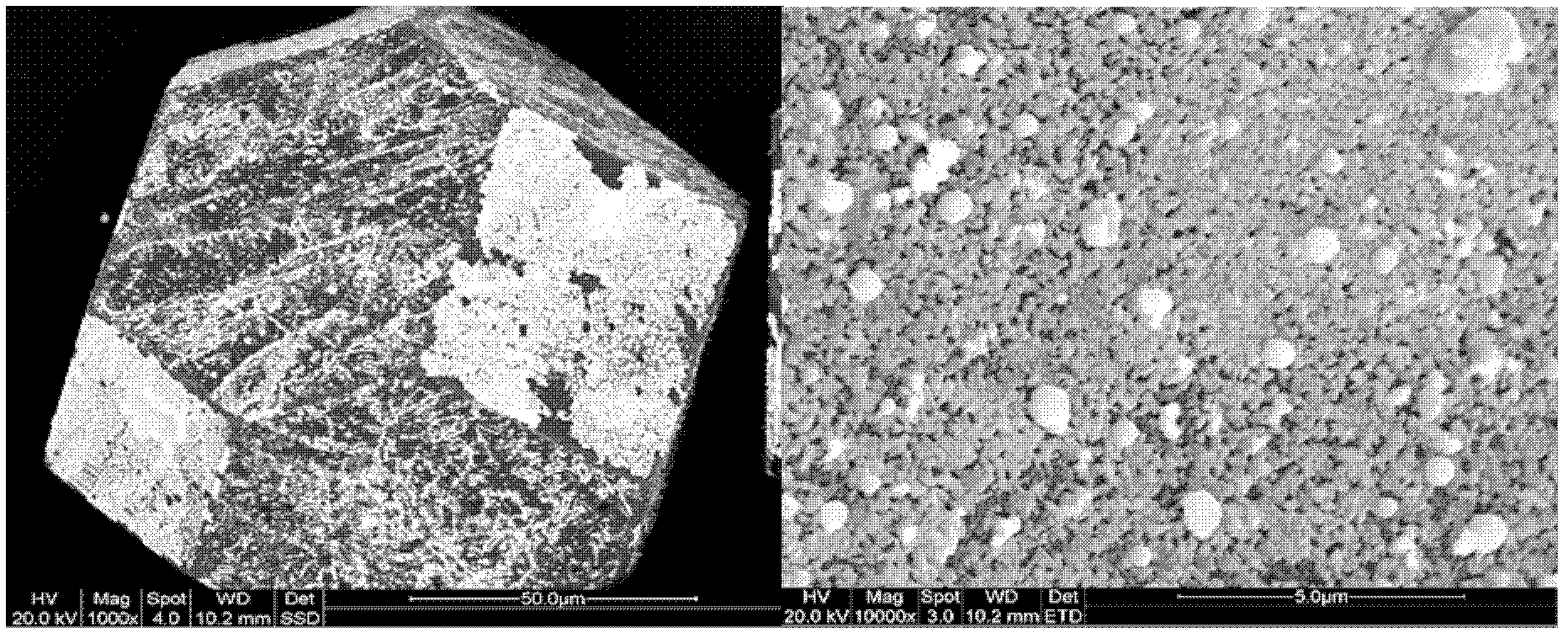

The invention belongs to a preparation technique of a copper-based composite material, and discloses a method for preparing a diamond-copper composite material by virtue of metallization of a surface. The method comprises the following steps of: mixing diamond micropowder with copper powder and powder formed by strong carbide elements, wherein the particle size of diamond is 80-300mu m, the content of the strong carbide elements is 1-10wt%, and the mass fraction of the copper powder is 20%-85%; blending the obtained mixed powder for 10-90 minutes at the temperature of 1050-1150 DEG C, and then cooling along with a furnace; sieving to select the powder with the particle size of 80-300 mu m; mixing the mixed powder with the copper powder again, wherein the mass fraction of the copper powderis 40%-95%; quickly heating the mixed powder material to 850-950 DEG C for sintering at the sintering pressure of 30-50MPa; and then, cooling the obtained product to a room temperature along with thefurnace to obtain the diamond-copper composite material. The method for preparing the diamond-copper composite material has the advantages that the operability of the metallization of the surface of the diamond is strong; the process is simple; the wetting property of a matrix and an enhancer in the prepared diamond-copper composite material is improved greatly; and as an electronic encapsulatingmaterial, the composite material has better comprehensive property, wherein the thermal conductivity is up to 672 W / m.K, the thermal expansion is lower than 7.6 mu m / m. DEG C, and the compactness reaches above 96%.

Description

technical field The invention belongs to the preparation technology of copper-based composite materials, in particular to a method for metallizing the surface of diamond powder and preparing high thermal conductivity diamond-copper composite materials. Background technique With the continuous improvement of chip integration, electronic packaging is developing in the direction of miniaturization, light weight and high performance, which makes the operating temperature of the circuit continue to rise, and the heating rate per unit volume of the system continues to increase, resulting in unstable system operation. In order to obtain stable performance, heat dissipation conditions must be improved, so the importance of electronic packaging in the field of microelectronics continues to increase, and the demand for new electronic packaging materials is also increasing. High-quality diamond is the material with the highest thermal conductivity known in the world, which can reach 20...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C26/00C22C9/00C22C1/10

Inventor 马南钢白华郎静马一

Owner HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com