Novel non-rubber winding clutch facing

A clutch face and rubber technology, applied in clutches, friction clutches, mechanically driven clutches, etc., can solve the problems of small thermal expansion safety factor, low friction coefficient, and large thermal decay, and achieve small thermal decay, high friction coefficient, and durability. good heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] Embodiment 1, with reference to accompanying drawing.

[0008] The invention provides a new type of rubber-free winding clutch face, which mainly uses water-soluble phenolic resin as the bonding material, that is, water-soluble phenolic resin is used as a new rubber substitute material to replace the known "rubber and gasoline" glue binder.

[0009] First produce novel water-soluble phenolic resin according to the following process:

[0010] (1) 100 parts by weight of phenol and 105-115 parts by weight of formaldehyde are accurately weighed and put into a reaction vessel, and under the action of 0.1-0.2 parts by weight of a basic catalyst, heating and stirring are started.

[0011] (2) Stop heating when the material heating temperature reaches 85° C., continue stirring, and stop stirring when the material temperature reaches 95° C.

[0012] (3) When the temperature reaches 98°C, the material starts to boil and undergo a violent reaction. At this time, start timing unt...

Embodiment 2

[0025] Embodiment 2, with reference to accompanying drawing.

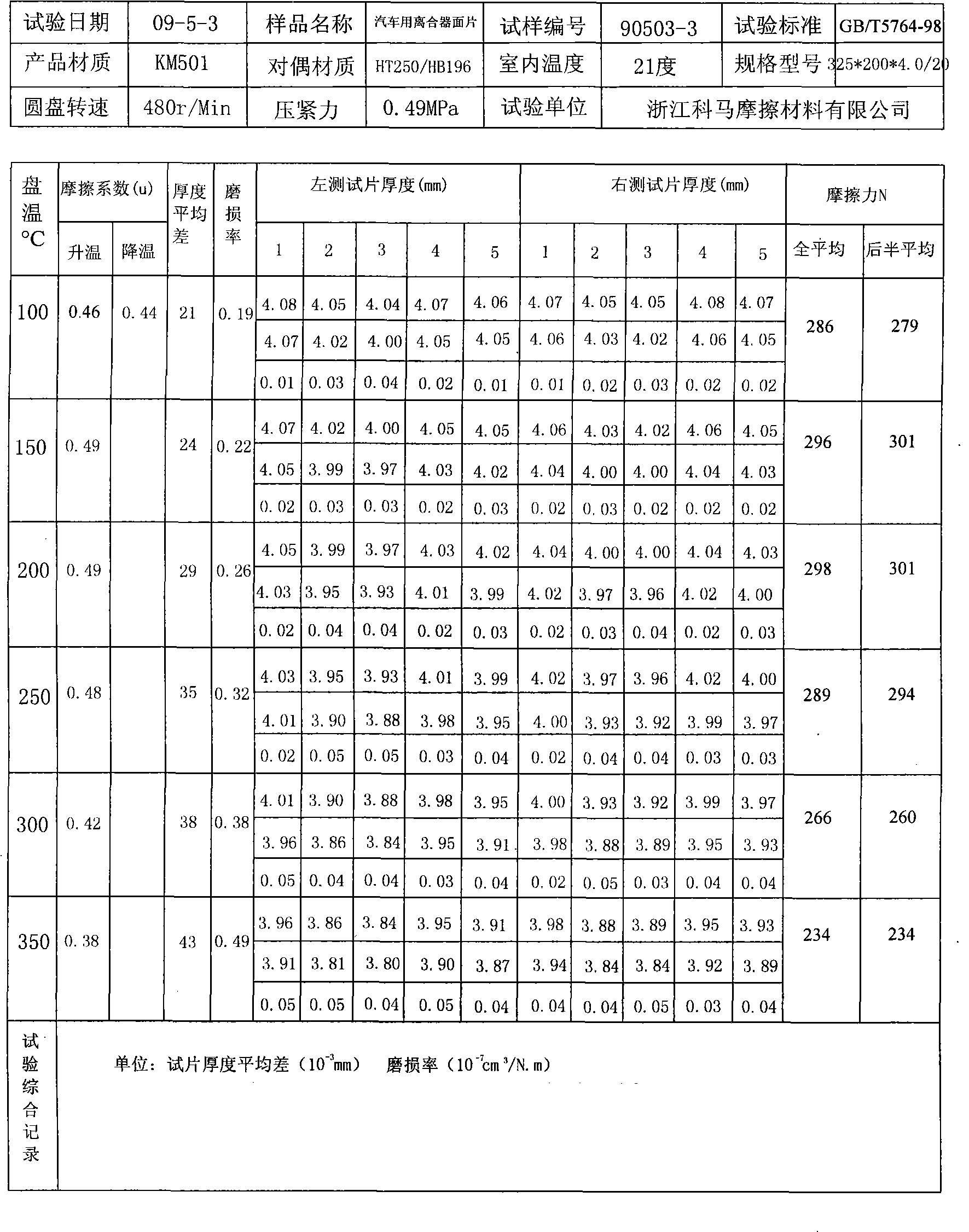

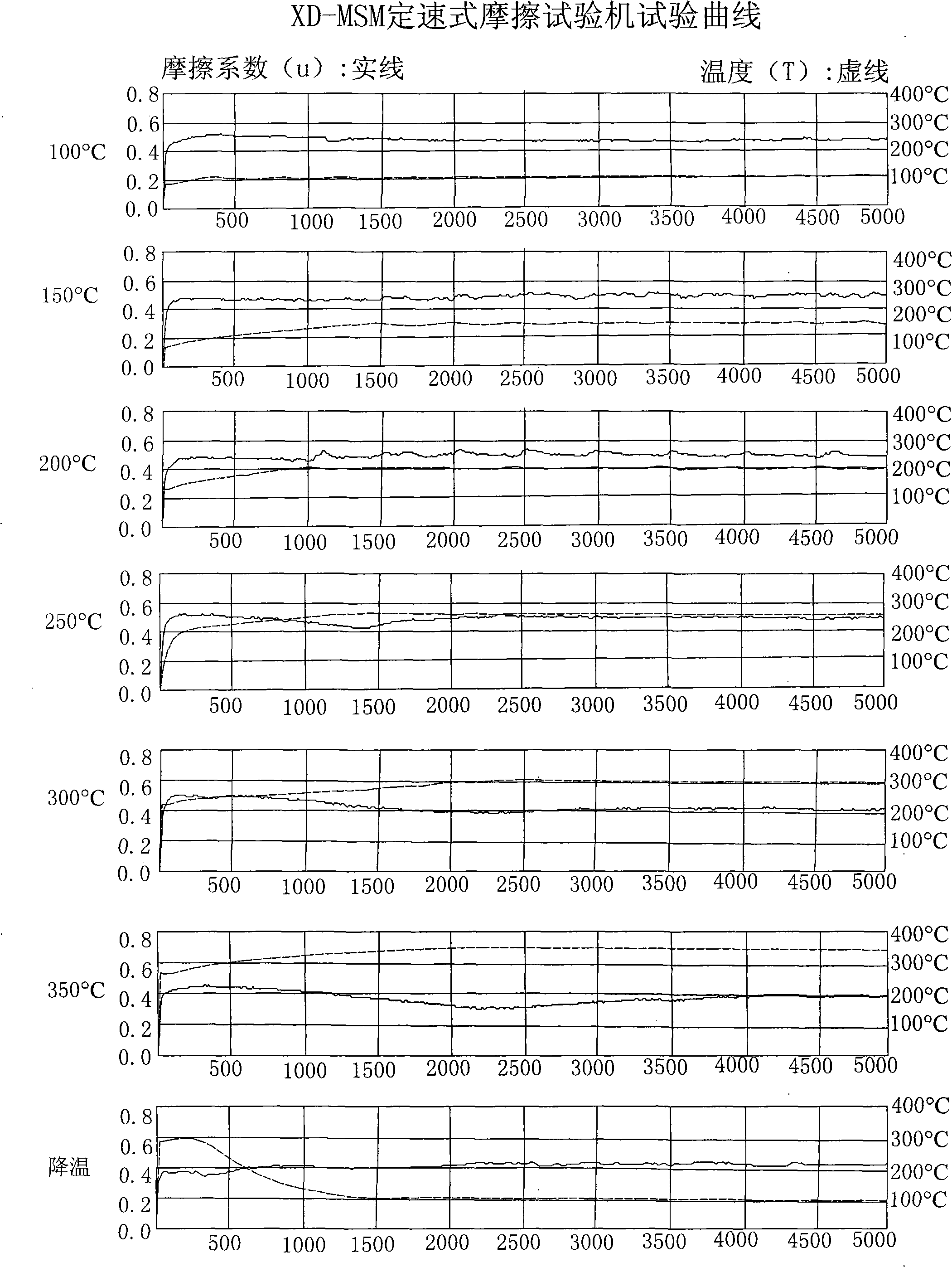

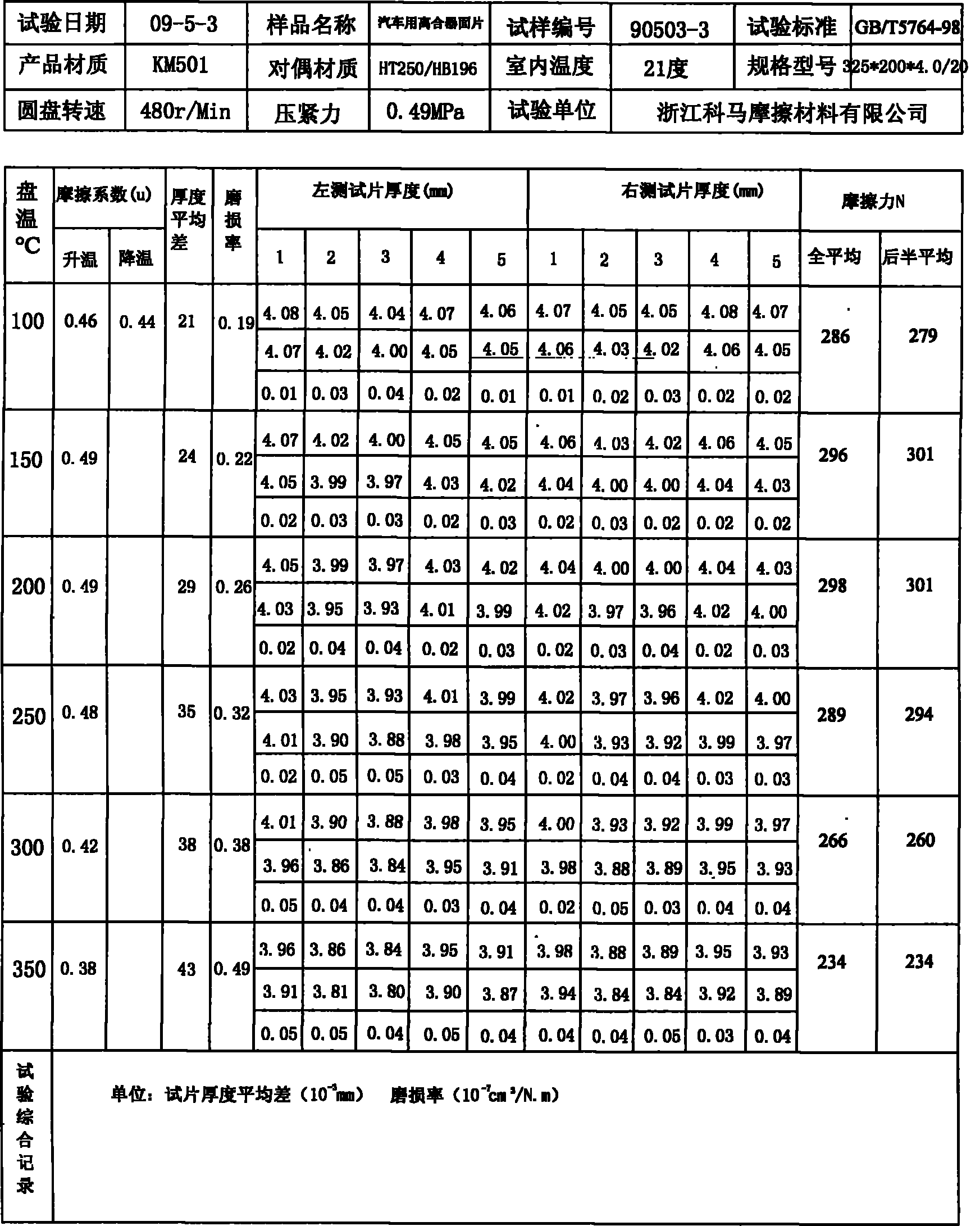

[0026] According to the GB5764-1998 standard, the friction coefficient is tested on a constant speed friction testing machine. Two samples of 25×25mm were prepared, and the coefficient of friction was measured under a positive pressure of 0.49Mpa. The test samples passed the test temperature ranges of 100°C, 150°C, 200°C, 250°C, 300°C, and 350°C to test the friction coefficient and wear rate.

[0027] One point to be explained here is that the national GB5764-1998 standard stipulates that the maximum test temperature requirement for clutch face friction coefficient and wear rate is 200°C. In order to improve product quality requirements, we increase the quality standard requirement to 350°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com