Directed graphite-copper composite material with superhigh thermal conductivity and high strength and preparation method and application thereof

A composite material and graphite technology, used in transportation and packaging, metal processing equipment, etc., can solve the problem that the thermal conductivity of composite materials cannot be greatly improved, the uniformity of metal copper distribution cannot be guaranteed, and it is difficult to form a continuous whole, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] The invention provides a method for preparing the composite material, which not only simply solves the problem of the uniformity of copper distribution in the graphite-copper composite material, but also provides a process for improving the direction consistency of graphite sheets. The thermal conductivity of the composite material prepared by the preparation method exceeds 800W / m·K.

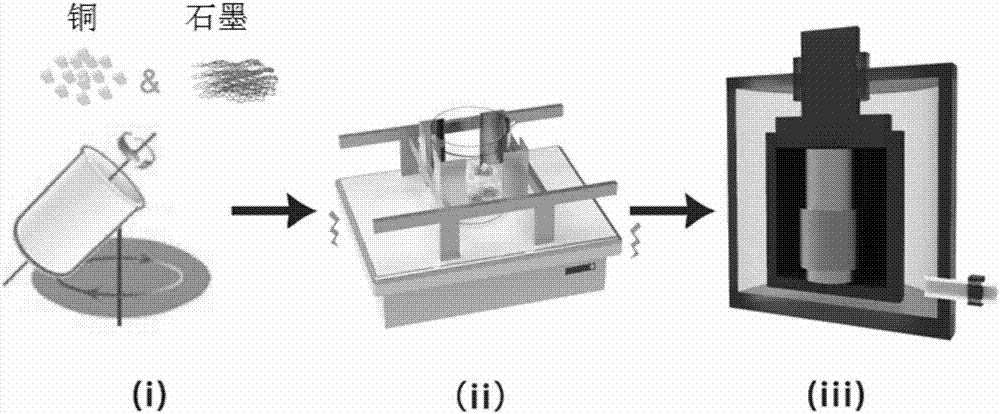

[0094] Specifically, the method includes the steps of:

[0095] a-1) providing a first mixture comprising graphite powder, copper powder and an organic solvent;

[0096] a-2) using a double-center high-speed mixer to uniformly mix the first mixture to obtain a second mixture;

[0097] a-3) Vibrating the second mixture by using a reciprocating vibration platform to obtain a third mixture;

[0098]a-4) hot pressing and sintering the third mixture to obtain the composite material.

[0099] In another preferred example, the graphite powder is in the form of scales.

[0100] In another pre...

Embodiment 1

[0146] Embodiment 1 Graphite-copper composite material 1

[0147] Preparation of graphite-copper mixture (graphite powder volume fraction is 60vol.%)

[0148] Get the flaky graphite powder (63g) with a particle size of 500 μm and the metal copper powder (178g) and a small amount of alcohol (10g) with a particle size of 7 μm in a double-center high-speed mixer to make a mixed powder. At 1500 rpm, calculated according to the total fraction of the mixed powder, flake graphite accounts for 60vol.%, copper powder accounts for 40vol.%, and mixes the materials for 1 minute. The mixed metal copper powder adheres to the graphite sheet to obtain a graphite-copper mixture. 1.

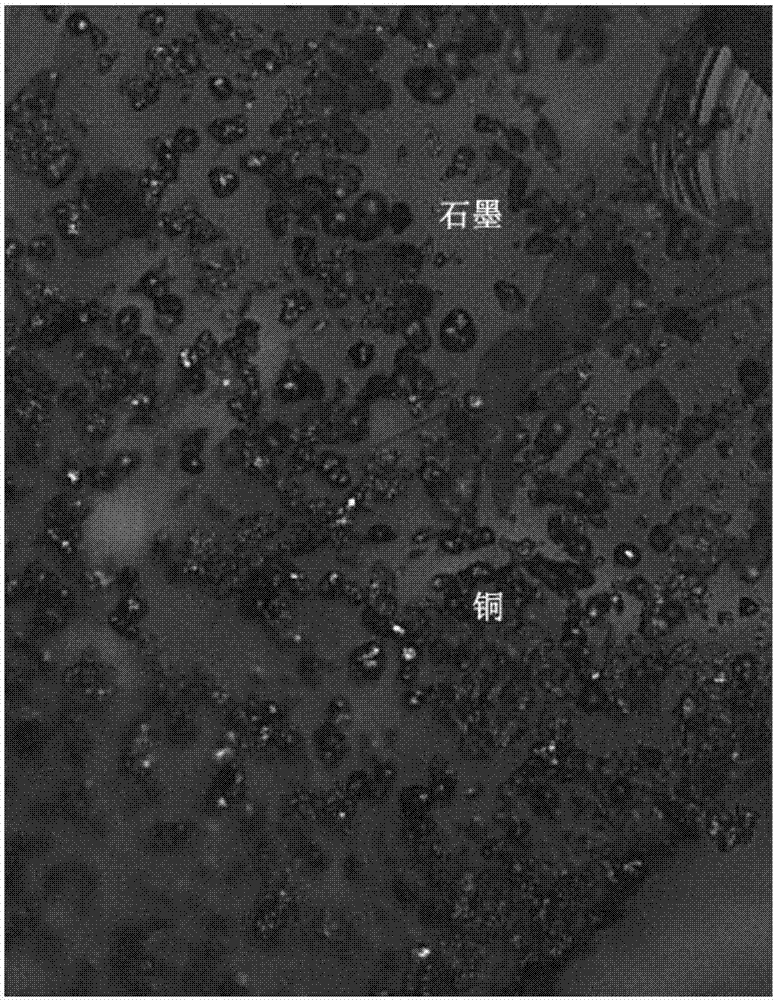

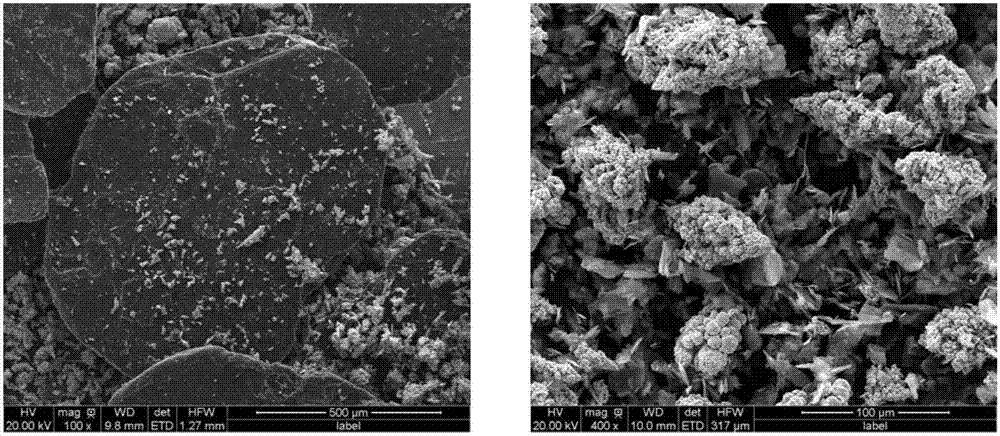

[0149] figure 2 Be the optical micrograph of embodiment 1 gained graphite-copper mixture 1, image 3 It is a scanning electron micrograph of the graphite-copper mixture 1 obtained in Example 1.

[0150] From figure 2 and image 3 It can be seen that the granular copper powder evenly covers the surface of t...

Embodiment 2

[0157] Embodiment 2 graphite-copper composite material 2

[0158] Same as Example 1, the difference is that the graphite particle size is 600 μm-800 μm.

[0159] The graphite sheet direction thermal conductivity of the composite material 2 obtained in Example 2 is 904W / m K, and the thermal conductivity perpendicular to the graphite sheet direction is 66W / m K, and the thermal expansion coefficient of the composite material 2 is 6.02ppm / K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com