Random copolymer and pinning composition comprising same

A technology of random copolymer and pinned layer, which can be used in chemical instruments and methods, synthetic resin layered products, photoengraving process of pattern surface, etc., and can solve the problems of insufficient bonding and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

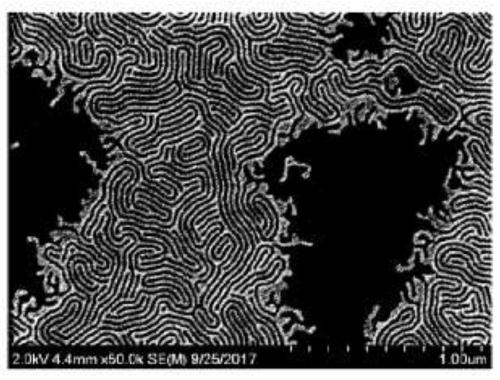

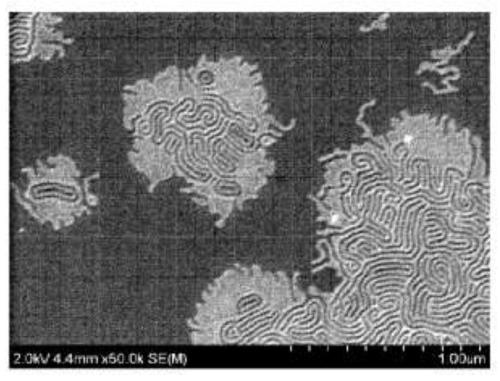

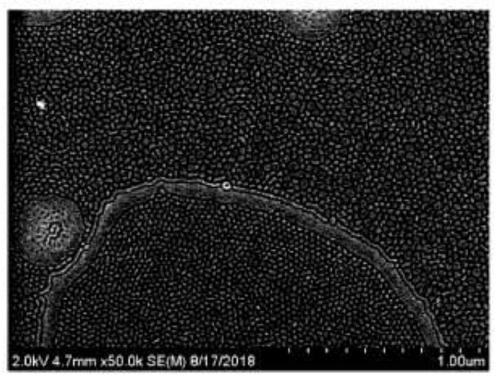

Image

Examples

preparation example 1

[0157]Preparation Example 1. Synthesis of Monomer (A)

[0158] A compound (DPM-C12) of the following formula A was synthesized in the following manner. Hydroquinone (10.0g, 94.2mmol) and 1-bromododecane (23.5g, 94.2mmol) were placed in a 250mL flask, dissolved in 100mL of acetonitrile, then an excess of potassium carbonate was added thereto and under nitrogen React at 75°C for about 48 hours. After the reaction, remaining potassium carbonate was filtered off, and acetonitrile used in the reaction was also removed. A mixed solvent of DCM (dichloromethane) and water was added thereto to treat the mixture, and the separated organic layer was collected and passed through MgSO 4 for dehydration. Subsequently, the target product (4-dodecyloxyphenol) (9.8 g, 35.2 mmol) was obtained as a white solid phase in about 37% yield using DCM (dichloromethane) in column chromatography.

[0159]

[0160] 1 H-NMR (CDCl 3 ): δ6.77(dd, 4H); δ4.45(s, 1H); δ3.89(t, 2H); δ1.75(p, 2H); δ1.43(p...

preparation example 2

[0167] Preparation example 2. Synthesis of random copolymer (B)

[0168] 1.677 g pentafluorostyrene, 0.084 g (methacryloyloxy)methylphosphonic acid (hMAPC1), 10 mg RAFT (reversible addition-fragmentation chain transfer) reagent (2-cyano-2-propyl disulfide Benzoate), 6mg V-40 (1,1'-azobis(cyclohexanecarbonitrile)) and 1.777g benzotrifluoride were placed in a 10mL flask (Schlenk flask), and the After stirring at room temperature for 30 minutes, RAFT (reversible addition-fragmentation chain transfer) polymerization was carried out at 95° C. for 3 hours. After polymerization, the reaction solution was precipitated in 200 mL of methanol as an extraction solvent, filtered under reduced pressure, and then dried to prepare a random copolymer (B). In the random copolymer (B), the content of units derived from pentafluorostyrene was about 94.3% by weight.

preparation example 3

[0169] Preparation Example 3. Synthesis of Random Copolymer (C)

[0170] 2.974g of the monomer (A) of Preparation Example 1, 0.081g of (methacryloyloxy)methylphosphonic acid (hMAPC1), 10mg of RAFT (reversible addition-fragmentation chain transfer) reagent (2-cyano-2- Propyl dithiobenzoate), 6 mg V-40 (1,1'-azobis(cyclohexanecarbonitrile)) and 1.777 g benzotrifluoride were placed in a 10 mL flask (Schlenk flask), and placed in After stirring at room temperature for 30 minutes under nitrogen atmosphere, RAFT (reversible addition-fragmentation chain transfer) polymerization was carried out at 95° C. for 3 hours. After polymerization, the reaction solution was precipitated in 200 mL of methanol as an extraction solvent, filtered under reduced pressure, and then dried to prepare a random copolymer. In the random copolymer (C), the content of units derived from the monomer (A) of Production Example 1 was about 96.8% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com