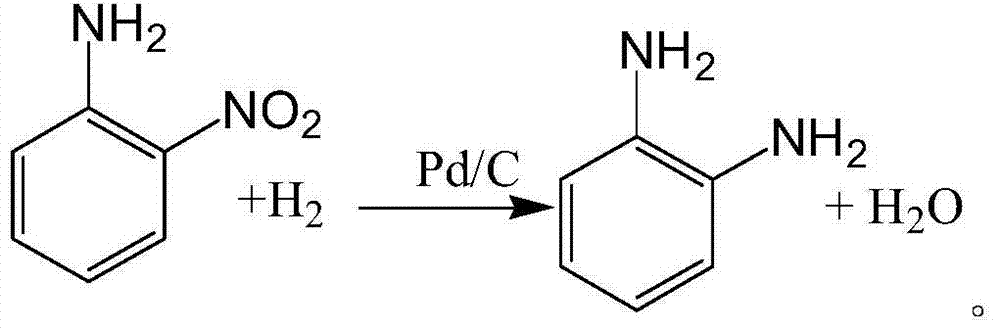

Method for synthesizing o-phenylenediamine from ortho-nitroaniline by virtue of catalytic hydrogenation

A technology of o-nitroaniline and catalytic hydrogenation, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds. The impact on production safety, and no solvent-free conditions have been found, and the effects of low pollution, short production cycle, and simple and easy post-processing have been achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The method for synthesizing o-phenylenediamine by catalytic hydrogenation of o-nitroaniline in this embodiment comprises the following steps:

[0019] Step 1, 50g o-nitroaniline and 0.05g palladium mass content are 3% palladium charcoal catalysts to join in the autoclave, first adopt the method of feeding nitrogen to get rid of the air in the autoclave, then adopt the method of feeding hydrogen The method is to get rid of the nitrogen in the autoclave;

[0020] Step 2. Heating the autoclave after nitrogen removal in step 1, and continuously feeding hydrogen into the autoclave at the same time, at a temperature of 110°C and a pressure of 1.0 MPa, the o-nitroaniline is catalytically hydrogenated Reduction reaction, stop feeding hydrogen after reacting for 8 hours, filter and recover the catalyst after water cooling, collect the filtrate after filtration, and obtain 37.9 g of o-phenylenediamine.

[0021] Through gas chromatography detection, the conversion rate of raw mat...

Embodiment 2

[0023] The method for synthesizing o-phenylenediamine by catalytic hydrogenation of o-nitroaniline in this embodiment comprises the following steps:

[0024] Step 1, 100g o-nitroaniline and 0.1g palladium mass content are 3% palladium charcoal catalysts to join in the autoclave, first adopt the method of feeding nitrogen to get rid of the air in the autoclave, then adopt the method of feeding hydrogen The method is to get rid of the nitrogen in the autoclave;

[0025] Step 2. Heating the autoclave after nitrogen removal in step 1, and continuously feeding hydrogen into the autoclave at the same time, at a temperature of 110°C and a pressure of 1.0 MPa, the o-nitroaniline is catalytically hydrogenated Reduction reaction, after 7.5 hours of reaction, the introduction of hydrogen was stopped, the catalyst was recovered by filtration after water cooling, and the filtered filtrate was collected to obtain 76.8 g of o-phenylenediamine.

[0026] Through gas chromatography detection, ...

Embodiment 3

[0028] The method for synthesizing o-phenylenediamine by catalytic hydrogenation of o-nitroaniline in this embodiment comprises the following steps:

[0029] Step 1, 50g o-nitroaniline and 0.15g palladium mass content are 3% palladium charcoal catalysts and join in the autoclave, first adopt the method of feeding nitrogen to get rid of the air in the autoclave, then adopt the method of feeding hydrogen The method is to get rid of the nitrogen in the autoclave;

[0030] Step 2. Heating the autoclave after nitrogen removal in step 1, and continuously feeding hydrogen into the autoclave at the same time, at a temperature of 110°C and a pressure of 1.0 MPa, the o-nitroaniline is catalytically hydrogenated Reduction reaction, after 8 hours of reaction, the introduction of hydrogen gas was stopped, the catalyst was recovered by filtration after water cooling, and the filtered filtrate was collected to obtain 38.1 g of o-phenylenediamine.

[0031] Through gas chromatography detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com