Processing method of urban sewage sludge reduction

A technology for urban sewage and treatment methods, which is applied in centrifugal separation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., and can solve the problems of high water content of mud cake, difficult post-treatment, and low dehydration rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

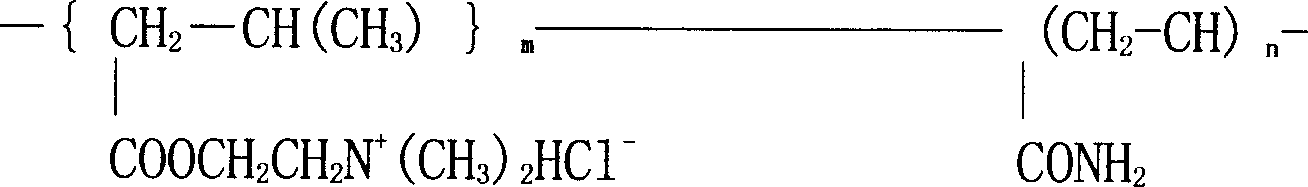

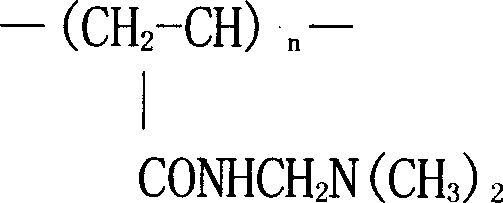

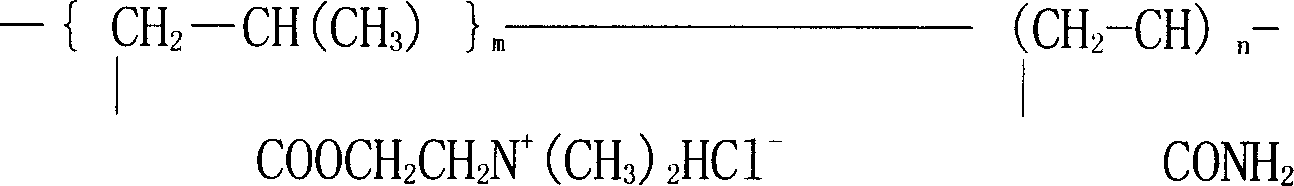

[0022] The preparation process of flocculant A of the present invention is as follows:

[0023] Using acrylamide monomer and dimethylaminoethyl methacrylate monomer as the main raw materials, first quaternize the dimethylaminoethyl methacrylate monomer, and then quaternize the acrylamide and dimethylaminoethyl methacrylate After the ammonium monomer and deionized water are mixed in a certain proportion, nitrogen is blown to remove dissolved oxygen, and finally an initiator is added for polymerization.

[0024] Wherein the quaternization reaction of dimethylaminoethyl methacrylate monomer is to add hydrochloric acid to the dimethylaminoethyl methacrylate monomer to adjust the pH value to 2-9, preferably 4-8, and the reaction is a violent exotherm The reaction should be carried out in a water bath or ice water bath or take other temperature control measures. The reaction ratio (molar ratio) of acrylamide and dimethylaminoethyl methacrylate quaternized monomer is: acrylamide: di...

Embodiment 1

[0041] In a 500ml four-necked flask equipped with a stirrer, a thermometer, a feeding tube, and a nitrogen inlet and outlet, add 15.7g of dimethylaminoethyl methacrylate, add 15ml of 1N HCl, adjust the pH value to 5.5, and then add acrylamide 28.4g, 400ml of deionized water, after mixing evenly, pass nitrogen to remove oxygen, add initiator potassium persulfate 10 -4 mol / L, react in a water bath at 50°C for 6 hours to obtain flocculant A-1. Intrinsic viscosity: 1050cm 3 / g; cationic degree is 2.3mmol / g.

Embodiment 2

[0043] In a 500ml four-neck flask equipped with a stirrer, a thermometer, a feeding tube, and a nitrogen inlet and outlet, add 9.6g of dimethylaminoethyl methacrylate, add 5ml of 1N HCl, adjust the pH value to 8.0, and then add acrylamide 38.6g, 440ml deionized water, after mixing evenly, pass nitrogen gas to remove oxygen, add initiator potassium persulfate 2×10 -4 mol / L, initiator sodium sulfite 1×10 -5 mol / L, react in a water bath at 25°C for 3 hours, and then react in a water bath at 80°C for 1.5 hours to obtain flocculant A-2. Intrinsic viscosity: 1200cm 3 / g; cationic degree is 1.2mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com