Patents

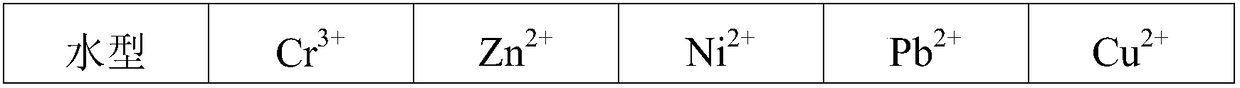

Literature

60results about How to "Large flocs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

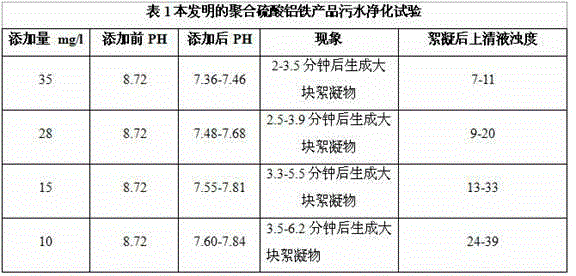

Prepn process of polymerized iron phosphosulfate

InactiveCN1486938ALarge flocsSettling fastWater/sewage treatment by flocculation/precipitationNitrite nitrogenHeavy metals

The preparation process of polymerized iron phosphosulfate includes adding ferrous sulfate into water at 70-80 deg.c until reaching saturation, filtering, adding oxidant or catalyst to convert two-valent iron into three-valent iron, and adding sodium chlorate and sodium pyrophosphate to react for 20-30 min to obtain the product. The present invention introduces phosphate radical ion to ferrous sulfate skeleton to obtain extremely high alkalisation degree of ferrous sulfacte, and the polymerized iron phosphosulfate as flocculant is easy to hydrolyze, can form large flocculate with high settling rate and may be used to well eliminate BOD, COD, heavy metal, nitrite nitrogen, etc. from sewage.

Owner:EAST CHINA UNIV OF TECH

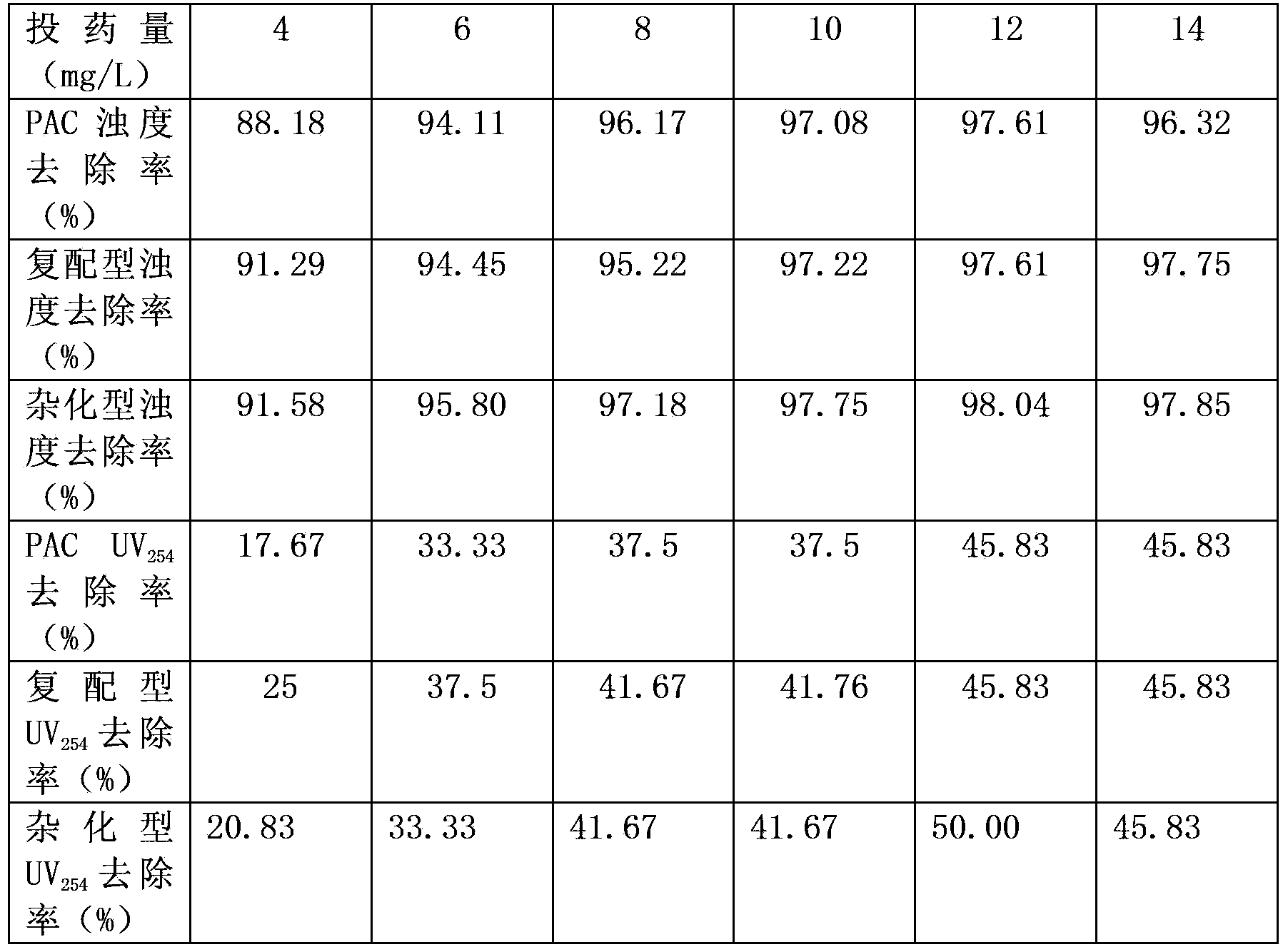

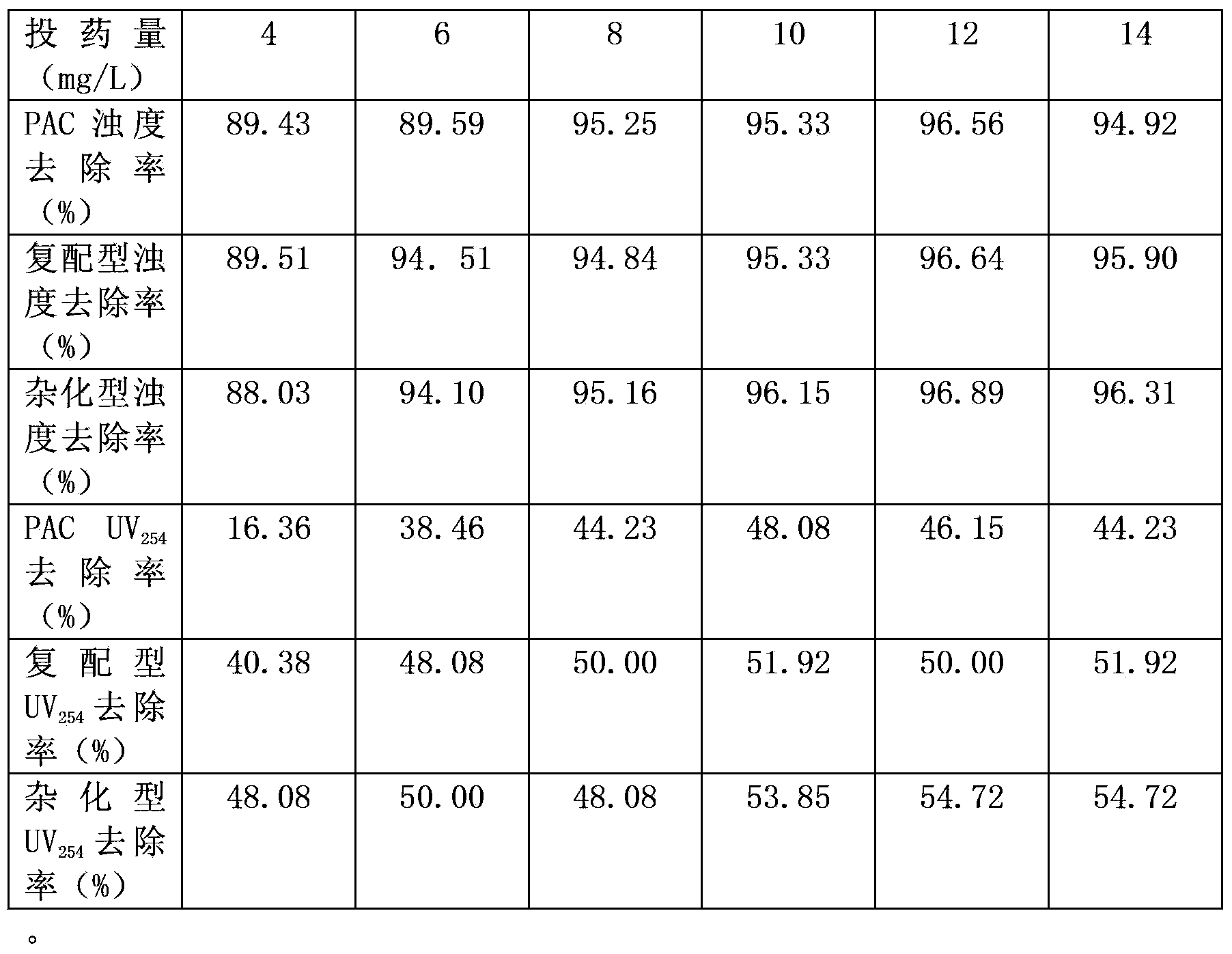

Organic-inorganic hybrid flocculant and preparation method thereof

ActiveCN103351047AGive full play to the role of adsorption and bridgingImprove adsorption bridging effectWater/sewage treatment by flocculation/precipitationAluminium chlorideSulfate radicals

The invention discloses an organic-inorganic hybrid ionic bond efficient flocculant which is characterized in that an initiator, namely ammonium persulfate is added in a DMDAAC (dimethyl diallyl ammonium chloride) polymerization process to allow a molecular chain end of a composited polymer, namely PDMDAAC (poly dimethyl diallyl ammonium chloride) to be provided with sulfate radicals, the sulfate radicals are bonded with hydroxy aluminium ions with positive charge in an ionic bond form, and the PAC (poly aluminium chloride)-PDMDAAC organic-hybrid ionic bond efficient flocculant is obtained, and fully exerts excellent charge neutralizing capacity of PAC and an adsorption bridging action of PDMDAAC. In a water treatment process, the PAC-PDMDAAC hybrid flocculant is less in dosing quantity, and a formed flocculating body is quick in sedimentation, large and compact, so that the water treatment efficiency is improved significantly.

Owner:CHONGQING UNIV

Polysilicate-metals composite flocculant and preparation method thereof

InactiveCN102249387ALarge flocsGood decolorization effectWater/sewage treatment by flocculation/precipitationSodium bicarbonatePhosphate

The invention discloses polysilicate-metals composite flocculant and a preparation method thereof and relates to flocculant for water treatment and the preparation method thereof. The method aims to solve the technical problem that the alkalization degree and polymerization degree of flocculant are increased by externally increasing alkalizer so water treatment cost is increased in the conventional polysilicate-metals composite flocculant. The polysilicate-metals composite flocculant is prepared from silicate, aluminum salt, ferric salt, an assistant agent A and an assistant agent B in a weight ratio, wherein the assistant agent A is one or combination of phosphate, calcium oxide, polyacrylamide, and chitosan; and the assistant agent B is one or combination of sodium hydroxide, potassium hydroxide, sodium carbonate, potassium carbonate, sodium bicarbonate or potassium bicarbonate. The method comprises the following steps of: adjusting pH of the aqueous solution of silicate, stirring and standing to obtain solution of polysilicate, and then adding the aluminum salt, the ferric salt, the assistant agent A and the assistant agent B, and mixing uniformly to obtain the polysilicate-metals composite flocculant. Other agents are not needed to be added, and the polysilicate-metals composite flocculant is low in cost and can be used for the field of water treatment.

Owner:HARBIN INST OF TECH

Method for preparing oxidized form polysilicic acid ferro-aluminum coagulant

InactiveCN103466771ALarge flocsDense flocWater/sewage treatment by flocculation/precipitationIron sulfateLiquid product

The invention discloses a method for preparing an oxidized form polysilicic acid ferro-aluminum coagulant. The method includes the following steps that (1) a sodium silicate solution is added to a dilute sulphuric acid solution under the stirring condition, the pH value is adjusted to acidity, and standing and polymerization are conducted on the mixture to obtain low-polymerization-degree activated silicic acid; (2) ferric sulfate and aluminum sulfate are added to concentrated sulfuric acid and water to prepare an acidic sulfate ferro-aluminum solution; (3) low-polymerization-degree activated silicic acid and the acidic sulfate ferro-aluminum solution are mixed and stirred, an oxidizing agent and additive are added, stirring is stopped, after standing and curing are conducted, a stabilizing agent is added, and then liquid products are obtained; (4) the liquid products are dried and grinded to obtain the powder coagulant. The products prepared from the method combine the advantages of an iron coagulant and an aluminum coagulant, the defects of polyaluminum chloride and polyferric sulfate coagulants in the using process are overcome, and the products have the advantages of capable of integrating the polysilicic acid cementation, aggregation, adsorption and bridging effects, large in aluminum salt coagulant floc, good in decoloration performance, dense in ferric salt coagulant floc, and high in settling speed.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

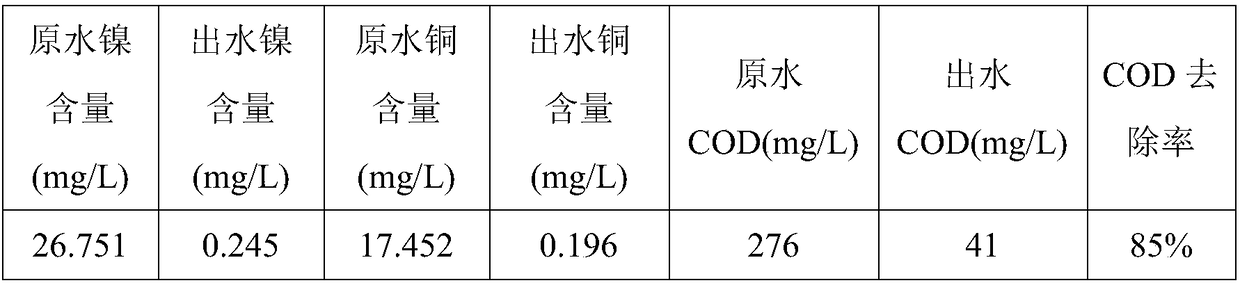

Method for producing polymeric aluminium ferric sulfate solution from industrial waste sulfuric acid generated during purification of acetylene gas and red mud

ActiveCN104445441ARealize comprehensive utilizationSave processing powerIron sulfatesWater/sewage treatment by flocculation/precipitationPhosphateRed mud

The invention discloses a method for producing a polymeric aluminium ferric sulfate solution from industrial waste sulfuric acid generated during purification of acetylene gas and red mud. The method comprises the following steps: adding water to the red mud to pulp the red mud, mixing the pulped red mud with waste sulfuric acid in a weight ratio of (2-5) to 1, stirring and mixing the materials to react for 1-4 hours to obtain a reaction mixture, standing to leach the mixture for 6-12 hours to obtain leachate, filtering the leachate to obtain filtrate, extracting rare metal impurities in the filtrate with di(isooctyl) phosphate, extracting organic matter impurities in a solution with an extracting agent and alkalifying and polymerizing raffinate to obtain the polymeric aluminium ferric sulfate solution with polymeric aluminium ferric sulfate mass content not less than 8% (in terms of aluminium ferric oxide). The method has the positive beneficial effects that the existing and potential environmental problems caused by discharge of the waste sulfuric acid after neutralizing treatment or direct discharge of the waste sulfuric acid and stacking and storage of the red mud on the land are solved; the polymeric aluminium ferric sulfate product capable of purifying sewage is produced from the waste sulfuric acid and the red mud, thus reducing environmental pollution caused by the waste sulfuric acid and the red mud; the process is simple and is easy to operate, so that the waste treatment cost is reduced; when serving as a flocculating agent, the prepared polymeric aluminium ferric sulfate product has the advantages of high settling time, large flocs, few metal residues and good sewage purifying effects.

Owner:河南开祥精细化工有限公司

Adsorption-flocculation precipitant and preparation method and application thereof

ActiveCN108946835AHigh purityGood flocculation effectWaste water treatment from metallurgical processWater/sewage treatment by flocculation/precipitationAluminium chlorideSludge

The invention relates to an adsorption-flocculation precipitant and a preparation method and an application thereof. The precipitant includes, by weight, the following raw material components: 50-80 parts of poly aluminium chloride, 40-60 parts of lotus root powder, 20-30 parts of kieselguhr, and 5-10 parts of cationic-type polyacrylamide. High purity poly aluminium chloride is prepared by adopting a simple and rapid method, is utilized as an inorganic polymer flocculant part in the adsorption-flocculation precipitant, and has the advantages of good flocculation effect, large flocs and rapid sedimentation; and through addition of nontoxic natural absorbent materials such as the lotus root powder and the kieselguhr, the treatment effect on electroplating wastewater is improved, and the difficulty of secondary treatment of sludge is reduced. The novel adsorption-flocculation precipitant can simultaneously achieve dual effects of adsorption and flocculation precipitation, thereby reducingthe treatment cost of the electroplating wastewater, and a treatment cycle is shortened.

Owner:ZHEJIANG ZHENGJIE ENVIRONMENTAL SCI & TECH CO LTD

Polymeric aluminum chloride flocculant preparation method using phthalocyanine green waste water

InactiveCN1544348AAchieve the purpose of useReduce pollutionWater/sewage treatment by ion-exchangeIron halidesAluminium chlorideLiquid product

A process for preparing polymerized aluminium chloride flocculating agent from phthalocyanine green waste water comprising, placing the type 335 weak alkaline anion exchange resin into adsorbing column, flowing dilute hydrochloric acid through the adsorbing column, rinsing the resin column with water or deionized water, processing the resin column by weak alkaline liquor, finally rinsing the adsorbing column with water or deionized water until water exhibits weak alkalinity, adjusting the pH of phthalocyanine green waste water, making it pass through the pretreated and transformed type 335 weak alkaline anion exchange resin column from normal temperature to 50 deg. C, and passing through another ion exchange resin adsorbing column, thus obtaining the phthalocyanine green waste water whose copper ion concentration meets second level standard. By concentrating the phthalocyanine green waste water treated by the resin under the condition of stirring and heating, adding in alkalinizing agents simultaneously for reaction, adjusting waste water till it exhibits weak acidity, continuously stirring and conducting heating reaction, the liquid product or solid end product can be obtained.

Owner:NANJING UNIV

Complex coagulant for advanced treatment of biochemical tail water, and its preparation method and application

ActiveCN102219290ADense flocEasy to reuseWater/sewage treatment by flocculation/precipitationAlkaline hydrolysisToxic industrial waste

The invention discloses a complex coagulant for advanced treatment of biochemical tail water, and its preparation method and application. The complex coagulant is characterized in that the complex coagulant is an inorganic polymer complex coagulant prepared form industrial waste or nonmetallic mineral materials as main materials under heating conditions through the processes of alkaline hydrolysis, acid leaching oxidation, hydrolyzation and polymerization; and the complex coagulant prepared by the preparation method contains 20 to 35% of silicon, 15 to 25% of aluminum, 6 to 11% of iron and 3 to 6% of boron. Compared with the prior arts, the preparation method has the advantages of easy acquirement of raw materials, simple process, and good economical efficiency and applicability. The inorganic polymer complex coagulant prepared by the preparation method has the advantages of good performances of adsorption and bridging, charge neutrality, bonding and gathering, and decoloration, big flocs, fast sedimentation velocity of flocs, and low use amount. The complex coagulant can be widely utilized for the field of wastewater treatment, and is especially suitable for advanced treatment ofbiochemical tail water.

Owner:CHINA PETROLEUM & CHEM CORP +1

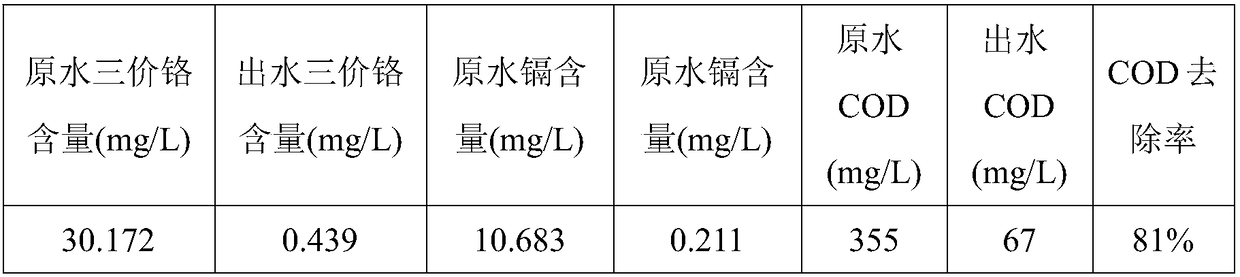

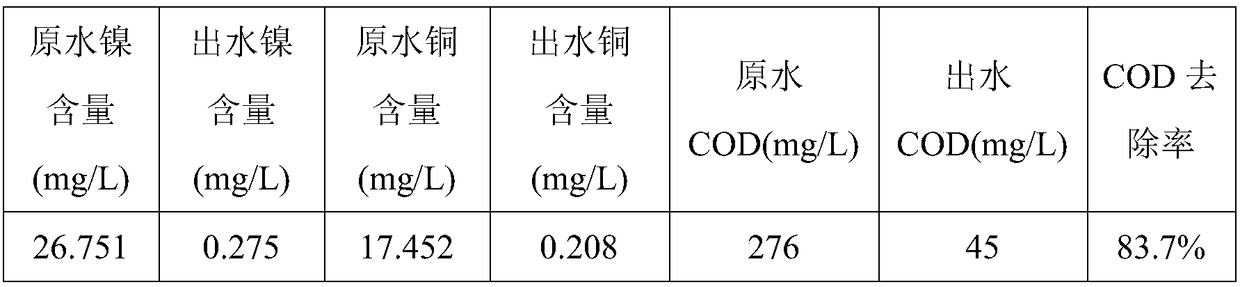

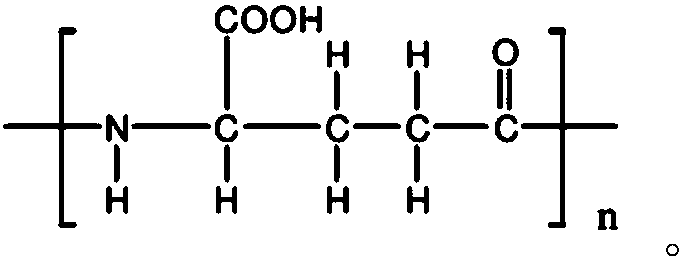

Biological composite flocculating agent for adsorbing heavy metal ions in heavy metal wastewater and applications thereof

InactiveCN108217893AImprove adsorption capacityIncrease the scope of applicationOther chemical processesWater contaminantsAluminium chlorohydrateWastewater

The invention relates to a biological composite flocculating agent for adsorbing heavy metal ions in heavy metal wastewater and applications thereof. The composite flocculating agent is prepared by compounding polyglutamic acid, polymeric aluminum chloride, and poly(aspartic acid) according to a weight ratio of 1: 4-6: 15-17. When the flocculating agent is used, at first, the pH value of heavy metal wastewater is adjusted to 6-9; then the biological composite flocculating agent is added into the heavy metal wastewater, the system is vibrated and stirred for 15 to 20 minutes, after vibration and stirring, centrifugal separation or static settlement is performed, and the flocculent precipitates that adsorb heavy metal ions are recovered and processed. The adsorbing performance and application range of the biological composite flocculating agent are both enhanced. The processing mode is simple and environmentally friendly. Furthermore, polyglutamic acid and poly(aspartic acid) can be easily degraded by organisms and will not generate secondary pollution; the preparation and application are convenient, and the cost is low.

Owner:水友环保技术(苏州)有限公司

Multifunctional sewage treatment coagulant

InactiveCN107188286AEasy to separateLarge flocsWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionTherapeutic effectAdsorption effect

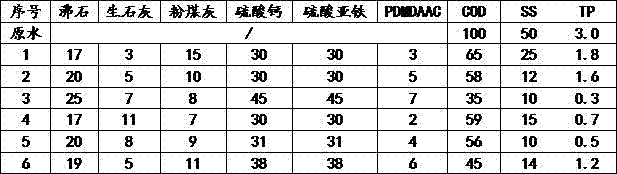

The invention discloses a multifunctional sewage treatment coagulant. The multifunctional sewage treatment coagulant comprises the following components in parts by weight: 17-25 parts of zeolite, 3-11 parts of quick lime, 7-15 parts of coal ash, 30-45 parts of calcium sulfate, 30-45 parts of ferrous sulfate, and 2-7 parts of poly dimethyl diallyl ammonium chloride. When the product is used to physicochemically treat sewage, the produced floc is large and is dense in structure, the separation of mud and water is easy, the treatment effect of the main pollution indicators of the sewage is obviously improved, and the compound coagulant with relatively high cost performance has better settling separation and adsorption effects when mainly being used to treat sewage in the leather factory and separate mud and water in channel cleanout.

Owner:郑州沃煌环保技术有限公司

System for treating antimony-containing printing and dyeing sewage

PendingCN107746154AReduce dosageImprove efficiencyTreatment using aerobic processesSpecific water treatment objectivesCooling towerSludge

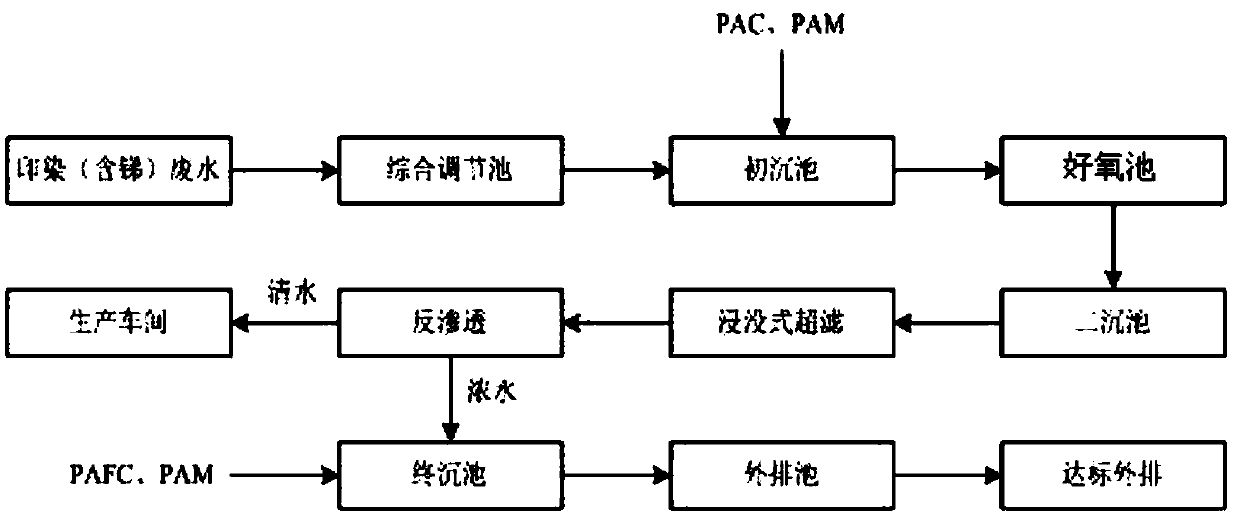

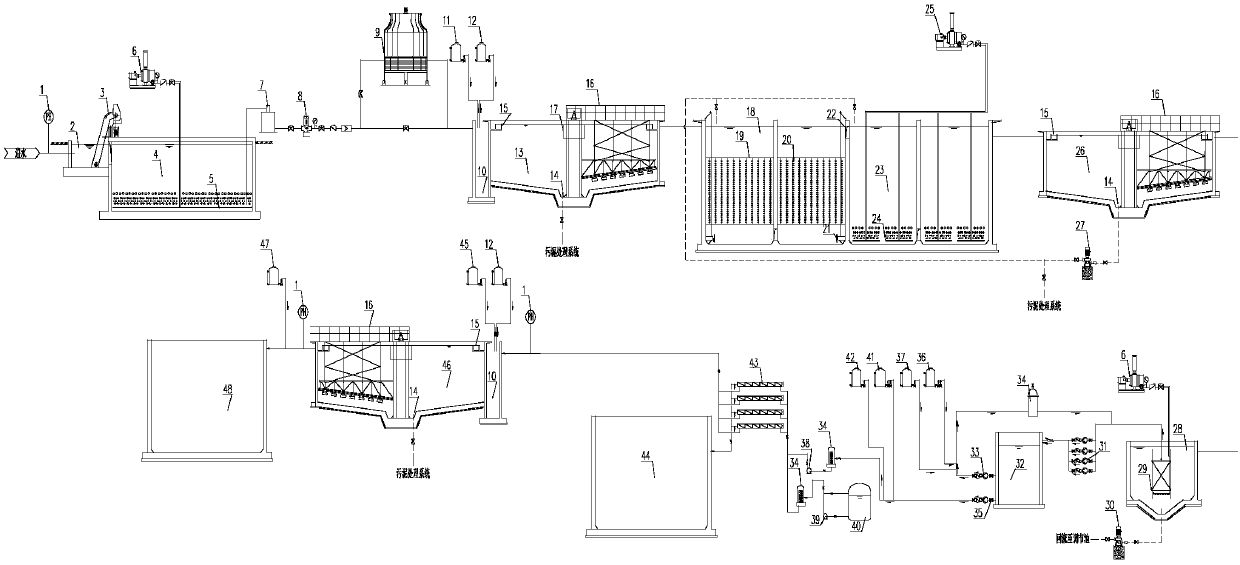

The invention discloses a system for treating antimony-containing printing and dyeing sewage. The system mainly comprises a regulating tank, a cooling tower, a primary sedimentation tank, an aerobic tank, a second sedimentation tank, an immersing-type ultrafiltration MCR tank, a reverse osmosis membrane system, a final sedimentation tank and an outer drainage tank which are used for collecting theprinting and dyeing sewage and connected sequentially through pipelines, wherein a PAC agent is added into the primary sedimentation tank so as to perform a flocculation reaction, and microorganismsare adsorbed in the aerobic tank; after sedimentation, the treated sewage is discharged from a sludge treatment system, so that the total amount of antimony in the sewage is reduced, and the application amount of a PAFC reagent which is used in a terminal process of mixing and sedimentation; RO concentrate is generated through the immersing-type ultrafiltration MCR tank and the reverse osmosis membrane system so as to achieve the concentration and enrichment of the antimony element and thus reduce the amount of sewage for antimony removing treatment, so that the efficiency of utilization of the PAFC reagent is improved, the generated RO clean water can be reused in a workshop, and therefore requirements for the reuse of reclaimed water by a printing and dyeing company are met.

Owner:HANGZHOU KAIYUAN ENVIRONMENTAL PROTECTION ENG

Preparation method of flocculant for removing low-temperature low-turbidity ammonia nitrogen wastewater

InactiveCN102774946AGood flocculation effectLarge flocsWater contaminantsWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminium chlorohydrate

Owner:株洲江海环保科技有限公司

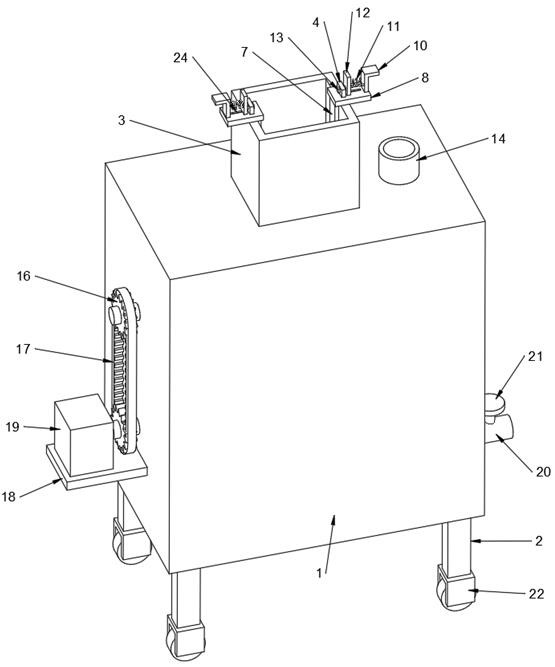

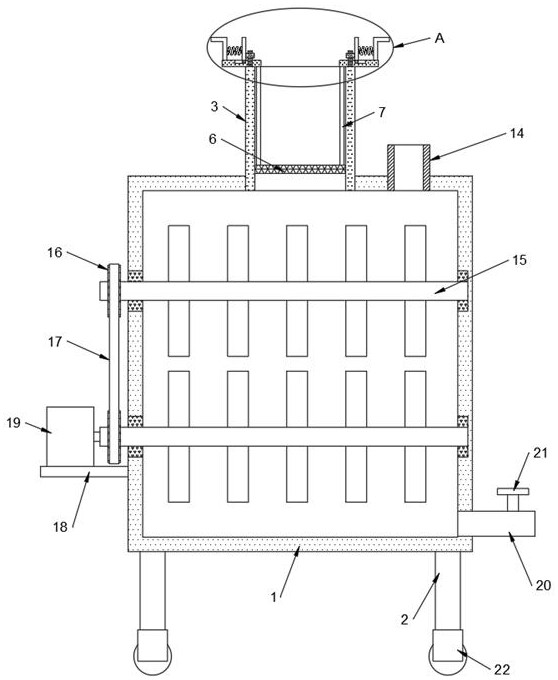

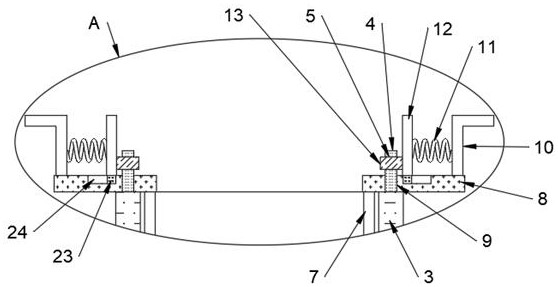

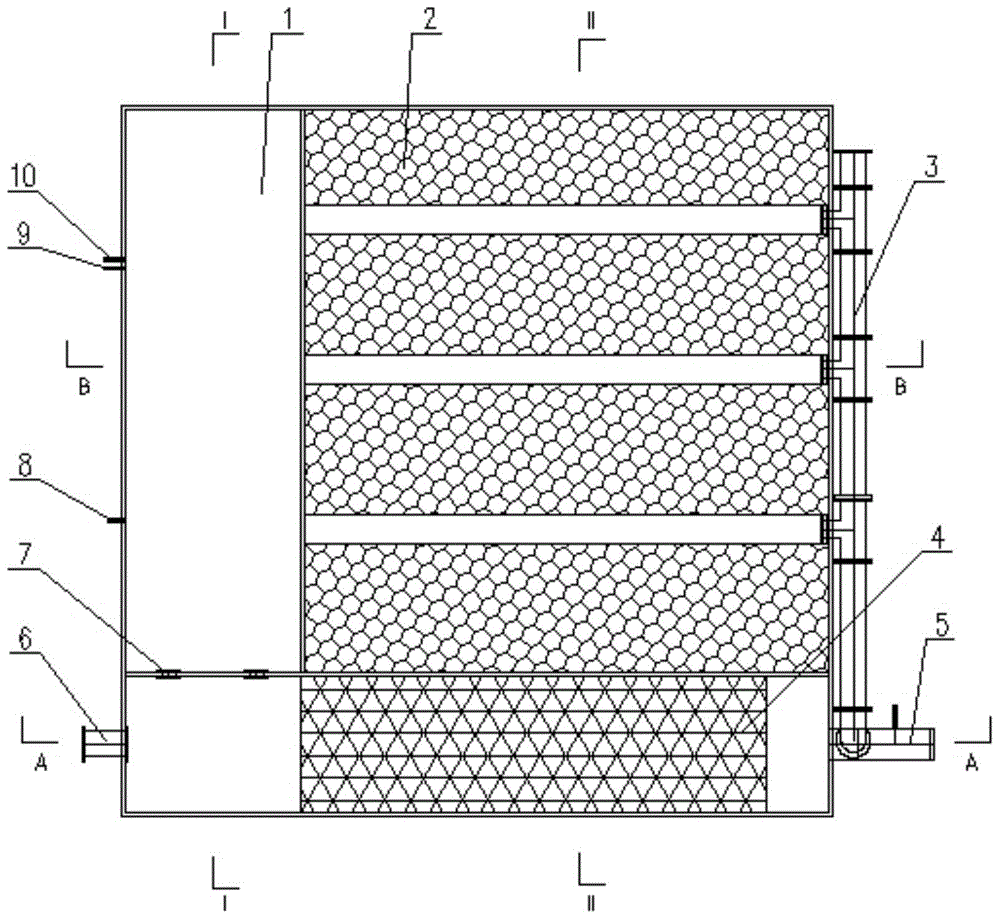

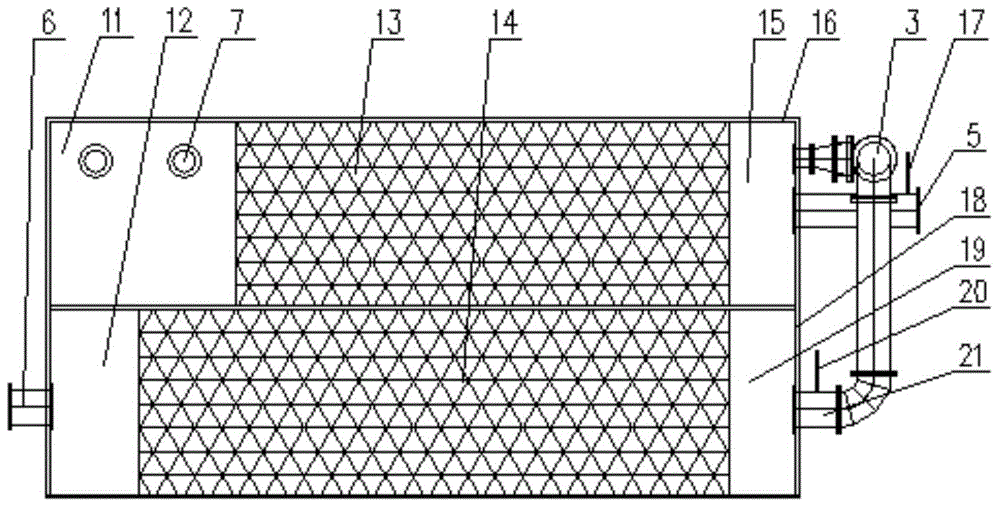

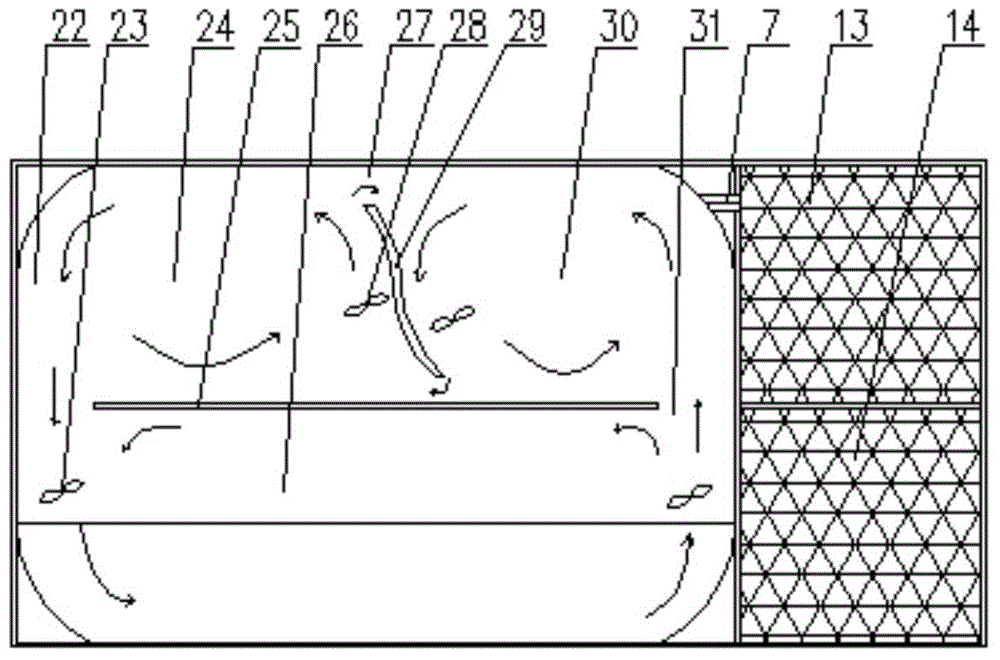

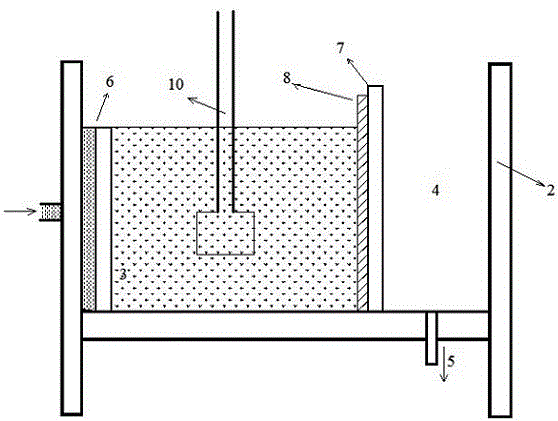

Industrial water treatment equipment and process

InactiveCN112408642AEasy to handleReduce turbidityWater treatment parameter controlSpecific water treatment objectivesIndustrial waste waterProcess engineering

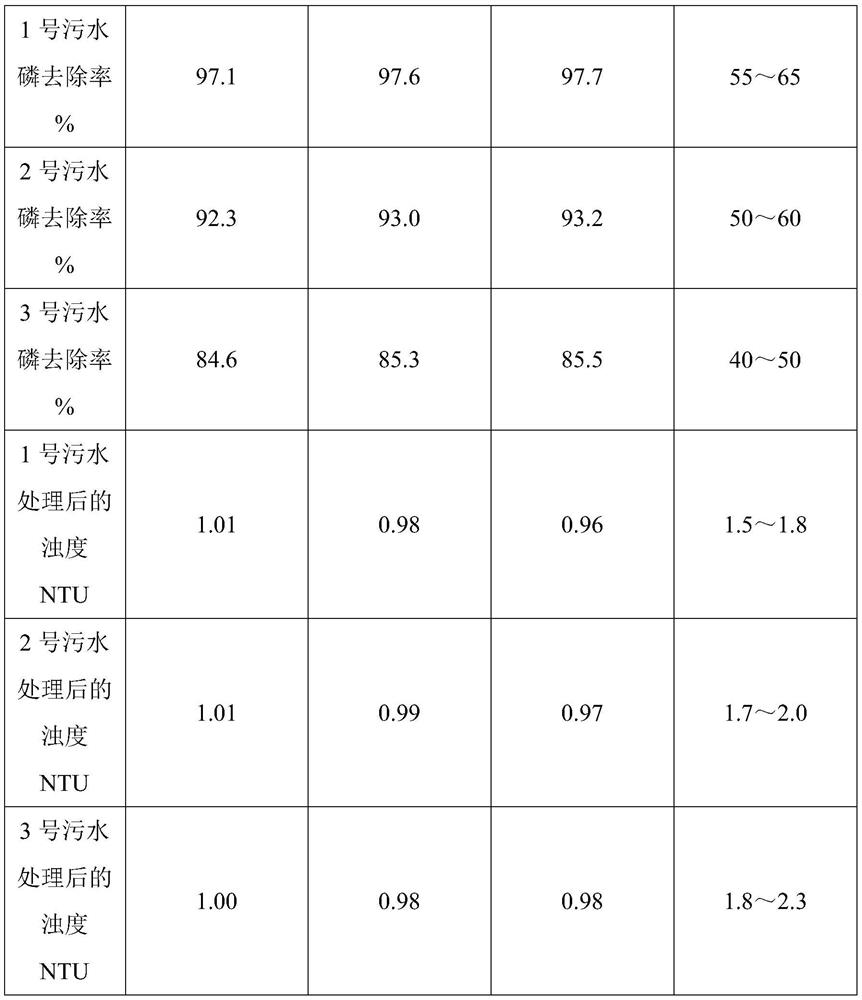

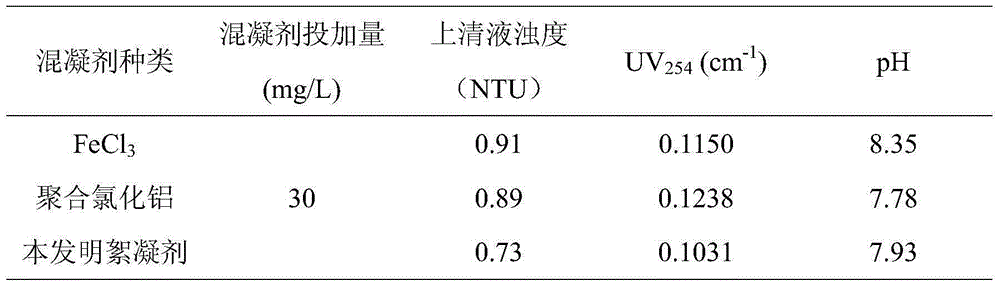

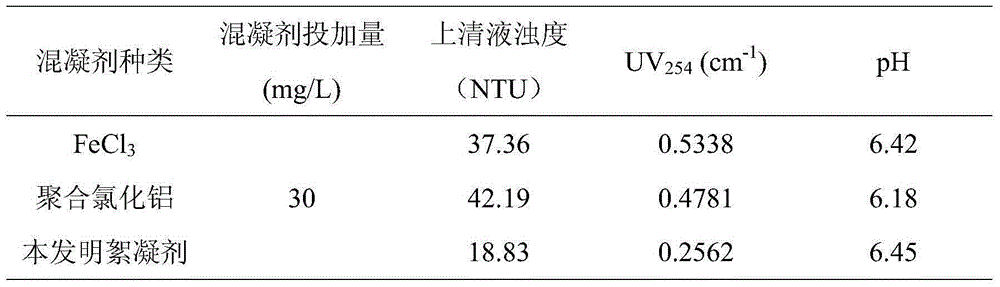

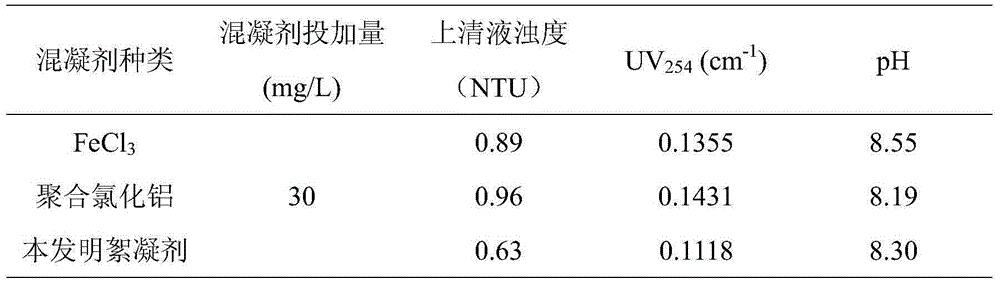

The invention discloses an industrial water treatment process, which comprises the following steps: 1) conveying industrial wastewater to industrial water treatment equipment, and retaining and filtering solid impurities in the wastewater; 2) adding a phosphorus removal agent through a dosing pipe; and 3) starting a servo motor for driving the two stirring paddles to rotate by the servo motor so as to stir, mix and remove phosphorus. According to the industrial water treatment process, the treatment process steps are optimized, the industrial water treatment equipment is adopted, a proper amount of specially-made phosphorus removal agent is added, the phosphorus removal rate is high, the turbidity of treated water is low, the treatment effect is good, and the industrial water treatment process is efficient.

Owner:神美科技有限公司

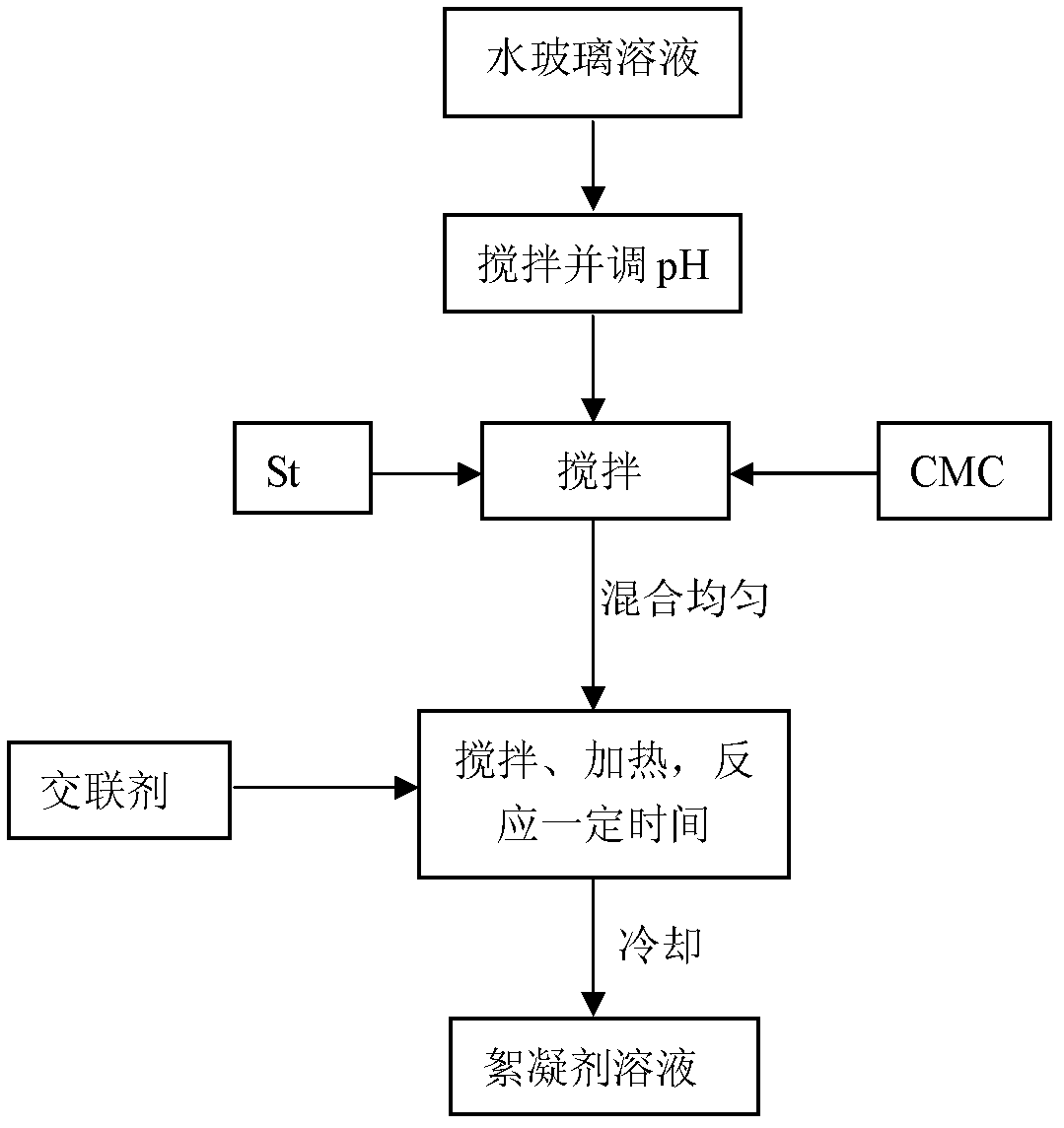

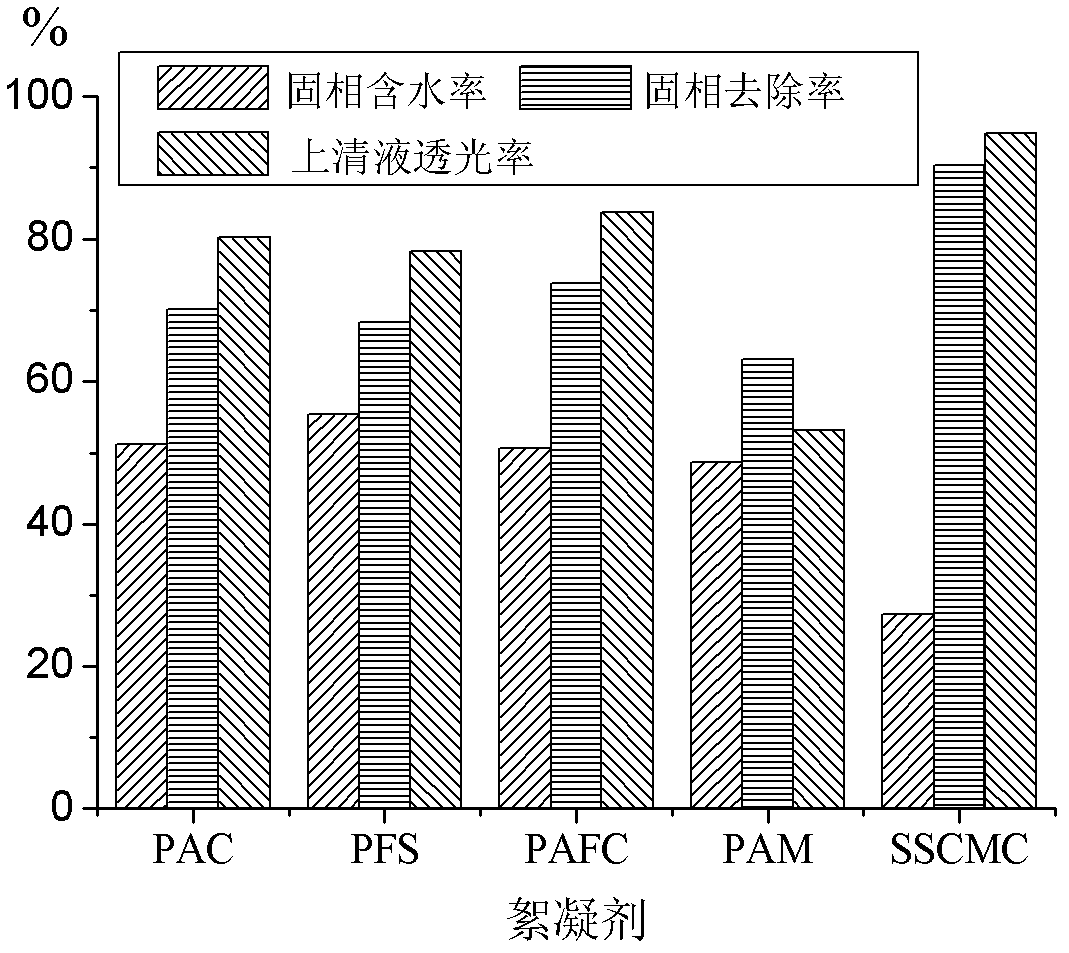

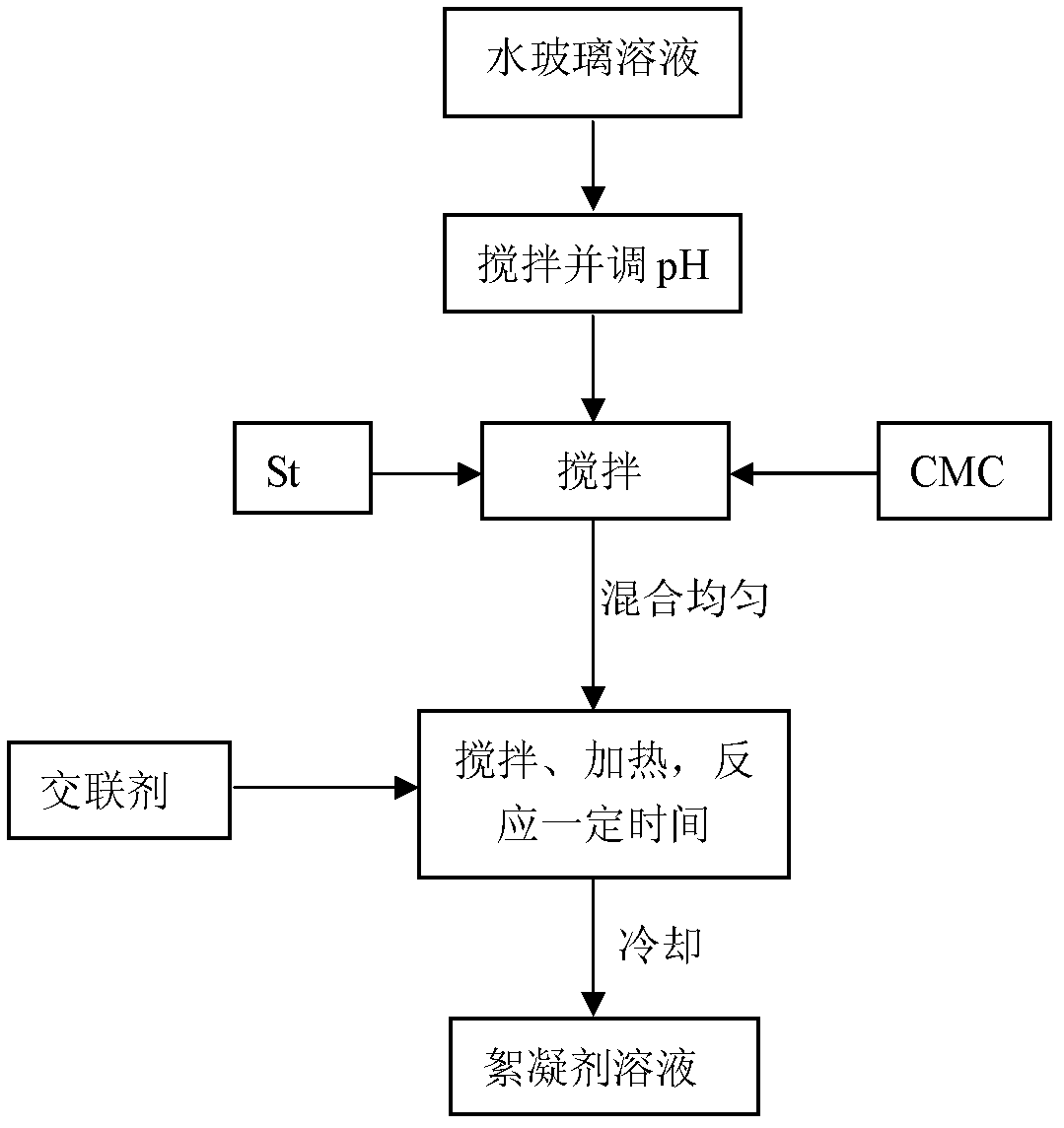

Green environment-friendly flocculant and method for preparing same

InactiveCN102633340AWide variety of sourcesLow costWater/sewage treatment by flocculation/precipitationCross-linkMoisture

The invention relates to a green environment-friendly flocculant and a method for preparing the same, wherein the green environment-friendly flocculant is applied to the solid-liquid separation treatment of a waste drilling fluid. The green environment-friendly flocculant comprises the following components: water glass, starch, sodium carboxymethylcellulose, a cross-linking agent and water. The method for preparing the flocculant comprises the following steps of: (1) preparing water glass solution and adjusting the pH of the solution to a range of 3-7 for later use; and (2) adding the starch and sodium carboxymethylcellulose to the water glass solution, stirring the mixture so that the mixture is evenly dissolved, adding the cross-linking agent to the mixture and reacting at 60-90 DEG C for 2-5 h. In case of the same dosage, the solid phase moisture content of the waste drilling fluid treated by the flocculant provided by the invention is lowest, while the solid phase removal ratio and supernatant light transmittance are highest; and the flocculating water separation capability of the flocculant is superior to that of the common inorganic flocculant and the common organic high-molecular flocculant. The flocculant prepared by the method provided by the invention has the advantages of wide raw material source, low cost, low dosage, good flocculantion effect, high adsorption capability, large formed floc, high sedimentation velocity, easiness in separation, greenness and environmental friendliness, innocuity, biodegradability and the like.

Owner:BEIJING UNIV OF CHEM TECH

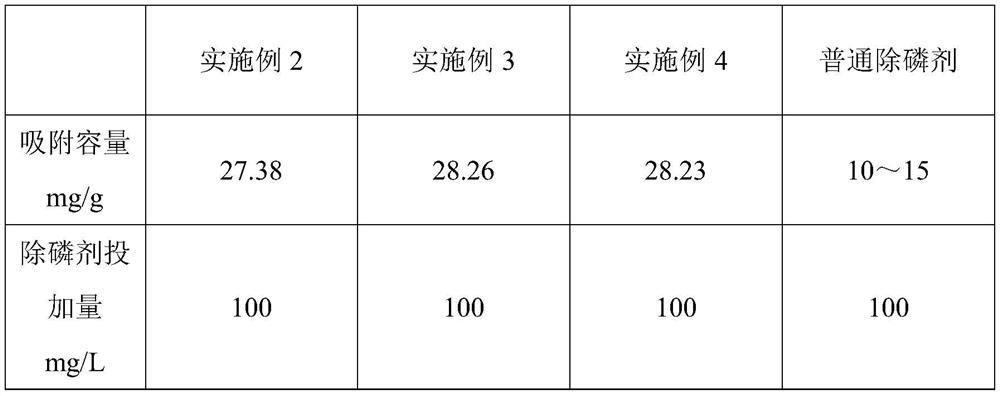

Phosphorus removal agent for sewage treatment and preparation method thereof

ActiveCN112390321AHigh removal rateReduce turbidityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionFerrous sulfate ironSulfate

The invention discloses a phosphorus removal agent for sewage treatment. The phosphorus removal agent is prepared from the following raw materials in parts by weight: 45-55 parts of ferrous sulfate pentahydrate, 12-16 parts of polyaluminum chloride, 20-27 parts of polyaluminum ferric silicate and 25-33 parts of hydroxyl iron modified montmorillonite. According to the phosphorus removal agent for sewage treatment, the raw material composition is carefully selected, the content of each raw material is optimized, ferrous sulfate pentahydrate, polyaluminum chloride, polyaluminum ferric silicate and specially-made hydroxyl iron modified montmorillonite in a proper proportion are selected, the advantages of each raw material are fully exerted, mutual complementation and mutual promotion are achieved, the product quality is greatly improved, the prepared phosphorus removal agent for sewage treatment is high in phosphorus removal rate and low in turbidity of treated water, and is an efficientphosphorus removal agent for sewage treatment.

Owner:神美科技有限公司

Method for preparing modified focculant from organic wastewater by diatomite

InactiveCN109354145ALower Zeta PotentialDestabilizingWater treatment parameter controlTreatment involving sedimentationCarboxymethyl starchSodium metasilicate

The invention discloses a method for preparing modified flocculant from organic wastewater by diatomite and belongs to the technical field of organic wastewater treatment. The method uses diatomite asraw materials, SiO2 is extracted to synthesize sodium metasilicate pentahydrate, then polyaluminium ferric silicate is prepared, and carboxymethyl starch (CMS) is used for modifying the prepared polyaluminium ferric silicate (PAFCSC) flocculant to obtain the modified flocculant. The preparation of the flocculant by diatomite meets the requirement of comprehensive utilization of natural resources.Moreover, the demand for the flocculant is very high in China and even in the whole world, aluminum and iron flocculants occupy a large market because of good treatment effects and low cost, therefore, the preparation of the PAFCS flocculant by diatomite has great economic and social significance.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method and application of flocculant for treating urban sewage

InactiveCN105152294ASettling rate is fastWide rangeWater/sewage treatment by flocculation/precipitationMunicipal sewageWater quality

The invention relates to a preparation method and application of a flocculant for treating urban sewage. The method comprises the following steps: diluting water glass of which the modulus is 2.8 to 3.5 by using water until the content of silicon dioxide is adjusted as 2 to 10 percent by weight, adding a solution to an exchange column filled with cation exchange resin to obtain a silicate gel diluent of which the content of sodium oxide is smaller than 1 percent and the pH value is smaller than 4; adding the solution into metal aluminum salt of which the silicate mole ratio is 5 to 30 under the high-rotation-speed stirring condition that the Reynolds number is greater than 6,000; adjusting the pH value of a mixture obtained by stirring as 5 to 6 by using a sodium aluminate solution of which the concentration is 5 to 10 percent by weight, so that the flocculant can be used; or performing spray drying, wherein an obtained solid also has the same effect. According to the method, multiple pollutants are flocculated and aggregated by using an aggregate with various functional groups. The flocculant is suitable for treating wastewater with various qualities, the pollutant treatment range is wide, the effect is good, the source of production raw materials is wide, the cost is low, the performance is stable, and any environmental pollution is avoided.

Owner:TIANJIN POLYTECHNIC UNIV

Preparing process for organic modified bentonite composite material

InactiveCN100467119CImprove decolorization efficiencySettling fastOther chemical processesAluminium silicatesSodium BentoniteMaterials science

The present invention discloses preparation process of organic modified bentonite composite material. The organic modified bentonite composite material is prepared with bentonite, and through adding water via stirring, adding polycondensate of dicyandiamine and formaldehyde to produce constant temperature vibration reaction, cooling to normal temperature, suction filtering, washing, drying, crushing and sieving. The organic modified bentonite composite material is used in treating dyeing effluent, and has the advantages of high efficiency, small consumption, fast deposition speed, low treating cost, etc.

Owner:JINAN UNIVERSITY

High-performance polymeric aluminium and preparation method thereof

InactiveCN109534467AImprove the coagulation effectEfficient aggregationWater/sewage treatment by flocculation/precipitationMagnesium saltWater quality

The invention discloses high-performance polymeric aluminium. The high-performance polymeric aluminium is prepared from the following main raw materials in parts by weight: 40-50 parts of modified polymeric aluminium, 15-20 parts of sodium chlorate, 10-16 parts of industrial salt, 6-9 parts of zinc chloride, 20-30 parts of 36% industrial hydrochloric acid, 10-15 parts of sodium silicate, 80-100 parts of ammonia-free distilled water and 18-25 parts of a NaHCO3 solution; and the invention further discloses a preparation method of the high-performance polymeric aluminium. According to the invention, the modified polymeric aluminium is used as a main body, and is copolymerized with the zinc chloride and polysilicic acid in a preparation process, so that a polymer combining aluminium salt, magnesium salt and zinc salt is obtained; and the sodium chlorate and the industrial salt are added, so that the high-performance polymeric aluminium is obtained; when the high-performance polymeric aluminium is used in a wastewater treatment process, the sedimentation speed of wastes is faster; the algae removal effect is good; flocs are large and dense; the sedimentation speed is fast; the adding amount is low; the cost can be effectively reduced; and therefore, the high-performance polymeric aluminium has a great significance for guaranteeing the water supply quality quality and lowering waterproduction cost.

Owner:江苏蓝遥净水剂有限公司

Desulfurization wastewater treatment device

ActiveCN103641259BReduce volumeImprove processing efficiencyMultistage water/sewage treatmentFlocculationProcess integration

The invention relates to a desulfurization wastewater treatment device which comprises a pH regulation area, a reaction area and a precipitation area, wherein the pH regulation area comprises an alkali regulation area and an acid regulation area independently arranged from each other; an upper water inlet is formed at one end of the alkali regulation area; a lower water outlet is formed on one side of the acid regulation area; a lower water inlet is formed on the other side of the acid regulation area; the alkali regulation area is communicated with the reaction area through a water outlet pipe; the reaction area is communicated with the precipitation area; and an outlet end of the precipitation area is communicated with the lower water inlet through a water outlet pipe of a precipitation tank. In the device provided by the invention, by adopting an integrated device and a high-load mixed-flow reaction unit, the volume of the reaction area is reduced; with a relatively large flocculation adsorption area, the treatment efficiency is improved, and the volume of the precipitation tank is reduced; and through a great quantity of sludge circulation, the reaction is more sufficient, and the drug is saved. The system is an efficient novel process integration device which is compact in structure and simple to control.

Owner:北京航天环境工程有限公司

Preparation method of sewage treatment flocculating agent

ActiveCN109437377AEasy to handleEasy to prepareWater/sewage treatment by flocculation/precipitationFlocculationCalcium silicate

The invention provides a preparation method of a sewage treatment flocculating agent. The method comprises the steps of mixing onium diallyl pyrrole bromide and onium diallyl piperidine bromide uniformly to obtain a mixture, then adding a certain amount of calcium silicate and kieselguhr into the mixture, and mixing uniformly to obtain the sewage treatment flocculating agent. The sewage treatmentflocculating agent has many functional groups, the floc formed is large, the flocculation speed is fast, the time required for treatment is short, the treatment effect is good, the dosage is small, the sludge production amount is small, the turbidity removal rate of domestic sewage reaches 90%, and the COD removal rate reaches 80%.

Owner:湖南凌辉环保新材料科技有限公司

Composite coagulant for advanced treatment of biochemical tail water, as well as preparation method and application thereof

InactiveCN102633337ADense flocEasy to reuseWater/sewage treatment by flocculation/precipitationAlkaline hydrolysisHydrolysis

The invention relates to a composite coagulant for advanced treatment of biochemical tail water, as well as a preparation method and application thereof. The inorganic polymer composite coagulant containing boron, silicon, aluminum and iron, which is prepared by adopting an iron source, a boron source and a silicon-aluminum source as raw materials, is applied to coagulation purification processing coagulant of all kinds of waste water, and is particularly applied to advanced treatment of the biochemical tail water. The iron source, the boron source and the silicon-aluminum source are adopted as the raw materials; the inorganic polymer composite coagulant is prepared through alkaline hydrolysis, acid leaching oxidation, hydrolysis and polymerization under heating; and the prepared composite coagulant contains 20 percent-35 percent of silicon, 15 percent-25 percent of aluminum, 6 percent-11 percent of iron, and 3 percent-6 percent of boron. The coagulant has easy-to-get raw materials and concise process, and is economic and applicable. The obtained inorganic polymer composite coagulant has good capacities of absorption and bridging, charge neutrality, bonding aggregation and decoloration, and less dosage, and is widely applied to waste water treatment field, in particular to advanced treatment of the biochemical tail water; and the flocs are big and are fast in sedimentation velocity.

Owner:CHINA PETROLEUM & CHEM CORP +1

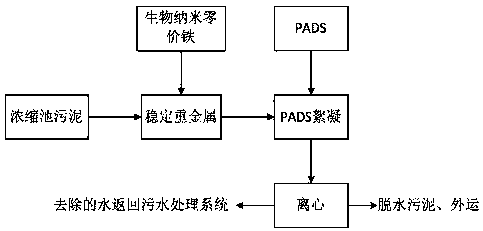

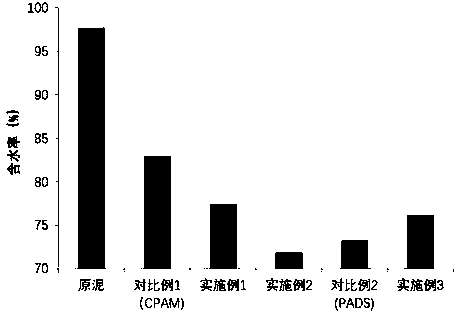

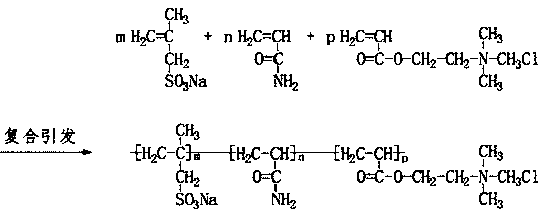

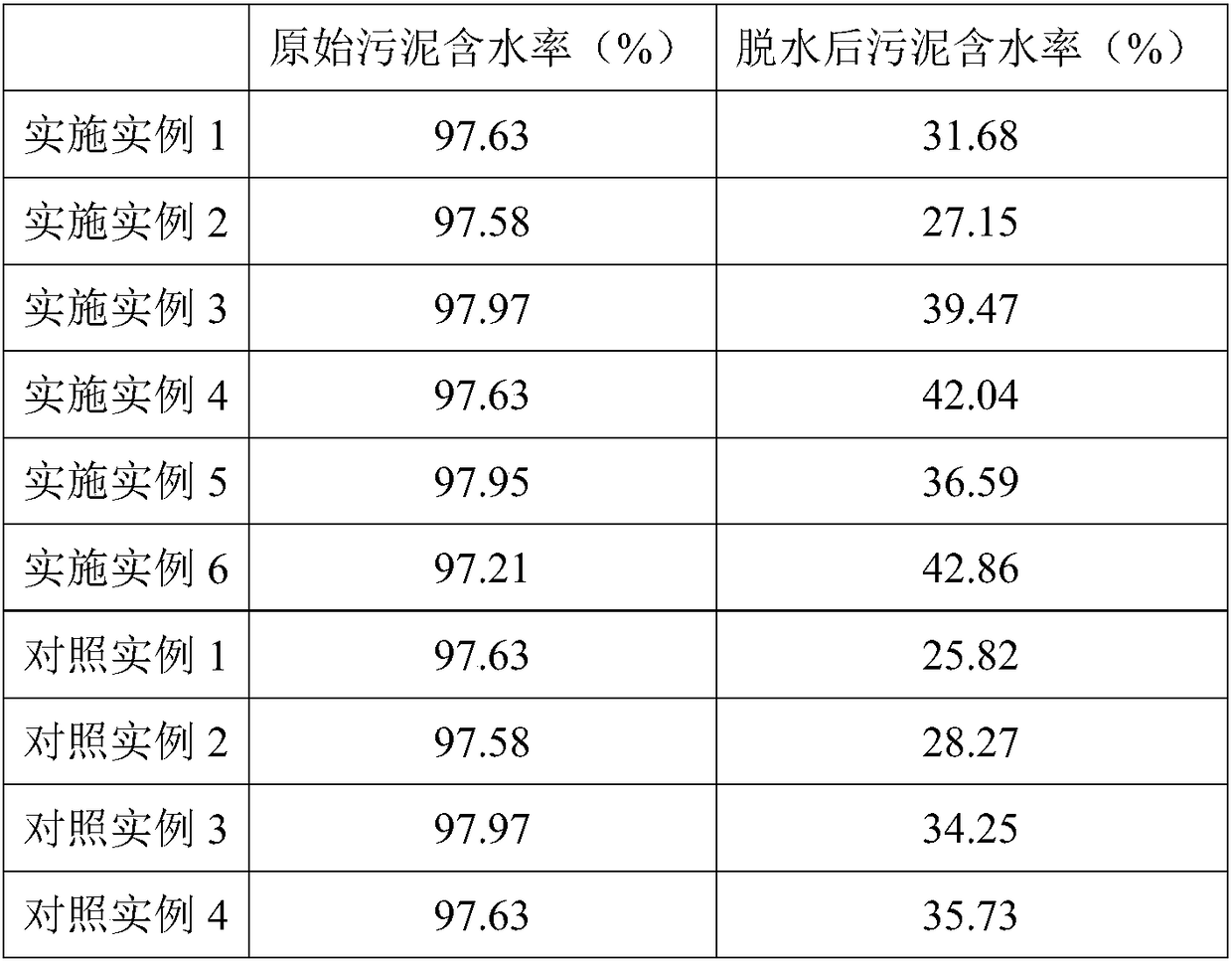

Method for conditioning sludge through amphoteric polymeric flocculant and biological nano zero-valent iron

ActiveCN108558177AContribute to settlementEnhanced flocculation and dehydrationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFlocculationSludge

The invention discloses a method for conditioning sludge through an amphoteric polymeric flocculant and biological nano zero-valent iron. The method comprises the following steps that 1, the biological nano zero-valent iron is used for conditoning the sludge, wherein a fresh biological nano zero-valent iron suspension is put into the sludge and stirred, so that heavy metal in the sludge is stablized; 2, the amphoteric polymeric flocculant P(AM-DAC-SMAS which is called as PADS for short) is used for conditioning the sludge, wherein the PADS is put in the conditioned sludge and stirred, and sludge flocculating and dewatering are achieved through a good flocculating function of PADS; 3, the sludge mixture obtained after flocculating is subjected to centrifugal dewatering. The combined use ofthe amphoteric polymeric flocculant and the biological nano zero-valent iron can reduce the migration and transformation capacity of the heavy metal, and the biological nano zero-valent iron can alsoachieve functions of a flocculating auxiliary. The method has the advantages of being low in PADS consumption, high in dewatering efficiency and wide in pH value application range; a foundation is laid for subsequent resource utilization of the sludge.

Owner:山西正和热电工程有限公司

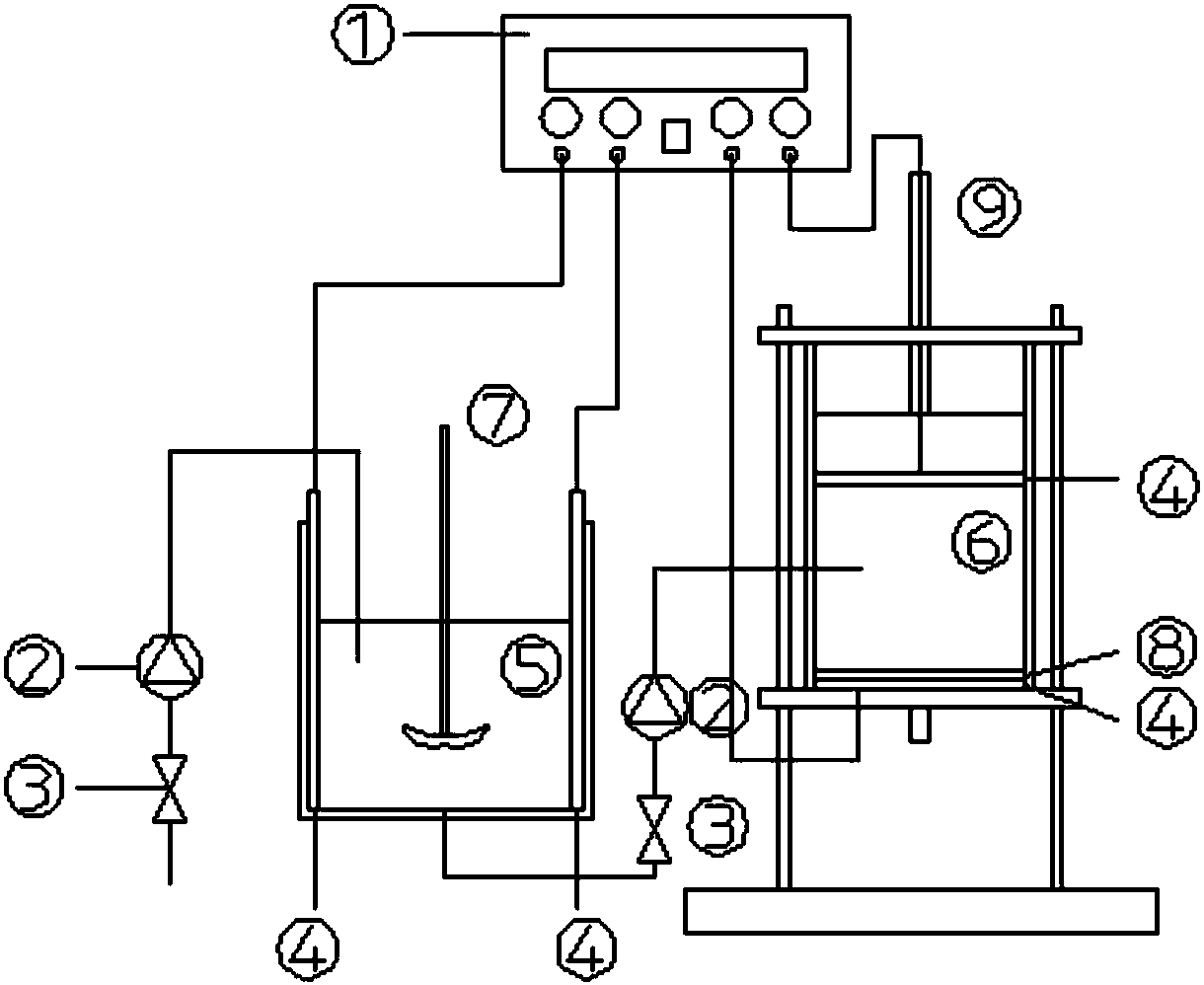

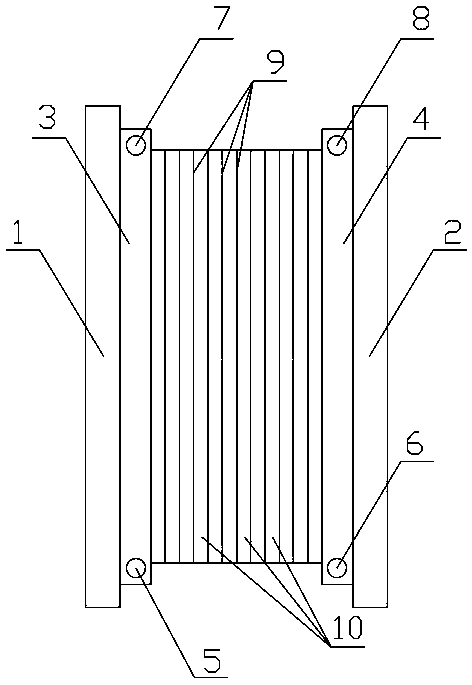

Method and device for promoting free radical conditioning and pressure-vertical electric field dewatering of sludge through microelectrolysis

InactiveCN108423951ALower Zeta PotentialLarge flocsSludge treatment by de-watering/drying/thickeningWater/sewage treatment apparatusBound waterElectrolysis

The invention discloses a method and a device for promoting free radical conditioning and pressure-vertical electric field dewatering of sludge through microelectrolysis. The method comprises main steps as follows: sludge is stirred, a direct-current electric field is applied, and iron powder and a conditioning agent are added for conditioning; the sludge enters a pressure-vertical electric fielddewatering device for dewatering. According to the method, the microelectrolysis process of an iron powder induction electrode is enhanced through the electric field, generation of Fe<2+> is promoted,activation of sulfate is realized, sulfate free radicals and high-valence iron ions are produced, electrolysis-oxidation-flocculation coordinated conditioning is performed on the sludge, the functions of cracking of the sludge structure, bound water release and floc reconstitution are played, and the dewatering effect of the conditioned sludge in the pressure-vertical electric field is enhanced.The dewatering efficiency is high, the water content of the sludge can be reduced to 50% or below, and the water content of the sludge is effectively reduced. Besides, the method and the device also have the advantages that the reaction time is short, operation is simple, the application range is wide and the like.

Owner:BEIJING FORESTRY UNIVERSITY

Flocculating agent for treating coking wastewater, and preparation method and application thereof

InactiveCN106365284AGood removal effectEasy to settleWater/sewage treatment by flocculation/precipitationEmulsionChemistry

The invention discloses a flocculating agent for treating coking wastewater, and a preparation method and application thereof. The flocculating agent is prepared from the following raw materials in parts by weight: 30 to 38 parts of erionite, 8 to 16 parts of rosin glycerin ester, 1 to 8 parts of aluminum stearate and 5 to 13 parts of acrylic emulsion. The erionite and the rosin glycerin ester are mixed and pulverized; a prepared aluminum stearate solution is added for sealed soaking; hot stirring is performed to obtain pretreatment materials; the acrylic emulsion is added; in the ozone atmosphere, heating and sealed stirring, ultrasonic treatment and high-temperature calcination are performed to obtain the flocculating agent. The flocculating agent is used for treating the coking wastewater; the coking wastewater color intensity and the COD (chemical oxygen demand) removal effect are more excellent; flocs generated by the flocculating agent are great, and can be easily settled. The flocculating agent has the advantages that the material taking is simple; the preparation process is simple; the operation is easy; the property of the flocculating agent is stable; the activity is high; the adsorption capacity is high; the buffer capability is high; no corrosiveness exists; safety, non-toxicity and harmlessness are realized; the secondary pollution cannot be caused on the water quality; the flocculating agent is applicable to industrial production.

Owner:刘可

Food sewage treatment flocculant, preparation method and applications thereof

ActiveCN105236530AWill not reduce the effect of useReduce the use effectWater/sewage treatment by flocculation/precipitationPotassium persulfateSulfite salt

The present invention provides a food sewage treatment flocculant preparation method, which comprises: dissolving dimethyl diallyl ammonium chloride and an acrylamide monomer in distilled water according to a ratio of 1:1-10 to form a solution with a concentration of 20-40 wt%; respectively preparing potassium persulfate and sodium sulfite as initiators, and preparing cerium sulfate as a catalyst; taking liquid water glass with a modulus of 2.8-3.5, diluting the water glass with water, adjusting the content to achieve a silica content of 2-10 wt%, loading the solution onto an exchange column filled with a cation exchange resin to obtain a silica sol dilute solution with a sodium oxide content of less than 1 wt% and the pH value of less than 1-4; and carrying out reaction polymerization to obtain the food sewage treatment polysilicic acid / polyacrylamide composite flocculant. According to the present invention, the flocculant is used for food sewage treatment or drinking water and wastewater treatment, can effectively remove floating impurities and water-soluble pigments in food sewage, and is suitable for industrial production and applications.

Owner:TIANJIN POLYTECHNIC UNIV

Industrial acid wastewater treating agent

InactiveCN110776071AEfficient flocculationReduce or eliminate usageWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationFlocculationSulfate radicals

The invention relates to the technical field of wastewater treating agents, and particularly provides an industrial acid wastewater treating agent. The treating agent is mainly prepared from raw materials as follows: slaked lime, alkaloid, calcium lignosulfonate, a flocculating agent and sodium silicate. Compared with the prior art, the treating agent has the beneficial effects as follows: the prepared flocculant can better improve pH of effluent and has an efficient flocculation function, experiments prove that the prepared flocculant can regulate the pH of acid wastewater with pH being 1-3 to 7-8, produce large flocs with salt, oil, chloride ions or sulfate radicals as well as metal ions and has the characteristic of high produced floc settling speed, meanwhile, the use amount of polyacrylamide can be effectively reduced or removed, and the production process is simple, convenient to use and environmentally friendly.

Owner:XINJIANG DELAND

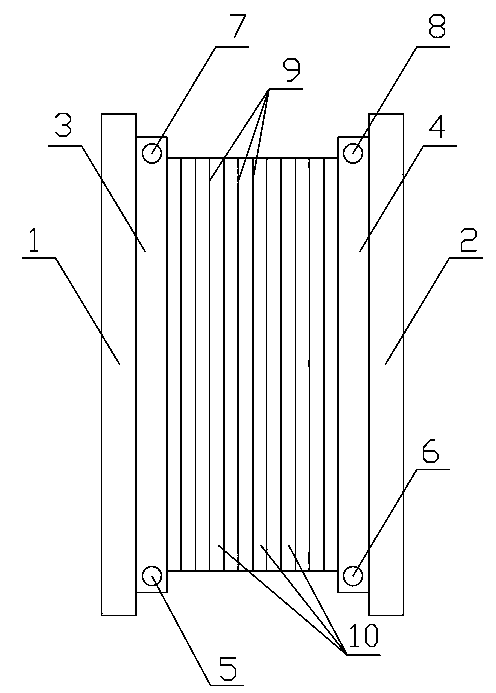

A method and equipment for sludge dewatering

InactiveCN104108849BDecreased Zeta PotentialLarge flocsSludge treatment by de-watering/drying/thickeningAgitatorProcess engineering

A sludge dehydrating method and a device therefor are provided. The method includes steps of: adding sludge into a reacting device, stirring, adding a magnetic material at the same time, reacting, switching an electric field power supply on for the reacting device, and applying a horizontal pressure to dehydrate the sludge. The addition of the magnetic material can increase the sludge floc size and destroy structures of sludge extracellular polymers, thus improving the dehydrating property of the sludge. In addition, the micro magnetic field, electric conduction, and other properties of the magnetic material assist dehydration of the electric field. Free water and a part of bound water in the sludge are finally removed. The device for the method comprises the reacting device, a stirrer, the power supply, a pressurizing device, and the like, and has characteristics of simple operation processes and stable performance. The method effectively reduces the water content of the sludge, reduces the volume of the sludge and improves the sludge reclamation potential. Applications show that: the sludge dehydrating method and the device therefor can allow the water content of the sludge to be 10-50%.

Owner:BEIJING FORESTRY UNIVERSITY

Preprocessing method for black liquor in diffusion dialysis recycling pulp manufacture

ActiveCN103352389AExtended service lifeHigh recovery rateRegeneration of alkali lyeDialysis membranesFlocculation

The invention relates to a preprocessing method for black liquor in diffusion dialysis recycling pulp manufacture, and belongs to the technical field of pulp manufacture. The preprocessing method comprises the following steps: adding flocculant into the black liquor, which contains sodium hydroxide with the concentration of 8-30 g / L, for flocculation, and keeping the concentration of the flocculant at 5-10 mg / L; filtering through a sheet frame filter with the bore diameter of 1,100-1,300 g / m<2>; then filtering through a millipore filtration membrane with the bore diameter of 0.1-1 micrometer to reduce the concentration of large particle impurity; recycling lignin to obtain the preprocessing liquid used for diffusion dialysis treating for a cation exchange membrane. Through adopting specific preprocessing method to process the black liquor before entering the diffusion dialysis process, the preprocessing method can increase the recovery rate of alkali and hemicelluloses in the black liquor, reduce damage to the diffusion dialysis membrane system caused by the alkali liquid, prevent blockage of the diffusion dialysis membrane, prolong the service life of the membrane, and guarantee the smooth progress of diffusion dialysis and follow-up handling.

Owner:YIBIN HIEST FIBER +2

Preprocessing technology for black liquor in diffusion dialysis recycling pulp manufacture

InactiveCN103352388AExtended service lifeHigh recovery rateRegeneration of alkali lyeDialysis membranesFlocculation

The invention relates to a preprocessing technology for black liquor in diffusion dialysis recycling pulp manufacture, and belongs to the technical field of pulp manufacture. The preprocessing method comprises the following steps: adding flocculant into the black liquor, which contains sodium hydroxide with the concentration of 8-30 g / L, for flocculation, and keeping the concentration of the flocculant at 5-10 mg / L; filtering through a sheet frame filter with the bore diameter of 1,100-1,300 g / m<2>; then filtering through an ultrafiltration membrane with the bore diameter of 20-1,000 angstroms to reduce the concentration of large particle impurity; recycling lignin to obtain the preprocessing liquid used for diffusion dialysis treating for a cation exchange membrane. Through adopting specific preprocessing method to process the black liquor before entering the diffusion dialysis process, the preprocessing method can increase the recovery rate of alkali and hemicelluloses in the black liquor, reduce damage to the diffusion dialysis membrane system caused by the alkali liquid, prevent blockage of the diffusion dialysis membrane, prolong the service life of the membrane, and guarantee the smooth progress of diffusion dialysis and follow-up handling.

Owner:YIBIN HIEST FIBER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com