Adsorption-flocculation precipitant and preparation method and application thereof

A precipitant and flocculation technology, which is applied in flocculation/sedimentation water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problem of low molecular weight of inorganic polymer flocculants and poor adsorption and bridging ability of colloidal particles Strong, restricting wide application and other issues, to achieve the effect of reducing the difficulty of secondary processing, shortening the processing cycle, and improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

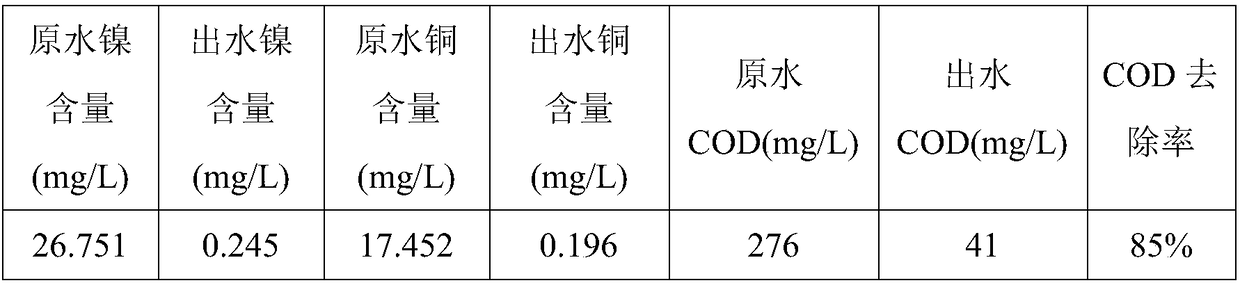

Embodiment 1

[0031] A new type of adsorption-flocculation precipitant, which is prepared from the following raw materials by weight: polyaluminum chloride: 60 parts, lotus root powder: 60 parts, diatomaceous earth: 20 parts, cationic polyacrylamide: 5 parts.

[0032] The preparation method of the above-mentioned adsorption-flocculation precipitant specifically comprises the following steps:

[0033] (1) Preparation of polyaluminum chloride: Add aluminum hydroxide to concentrated hydrochloric acid solution under stirring conditions, heat up to 110°C for 2.5 hours, after the aluminum hydroxide is completely dissolved, cool down to 55°C, and use a mass concentration of 30% NaOH solution adjusted the pH value of the solution to 4, then raised the temperature to 110°C, and reacted for 45 minutes under stirring conditions to obtain a light yellow transparent polyaluminum chloride solution, which was dried and ground at 55°C to obtain the polyaluminum chloride product; Among them, the particle si...

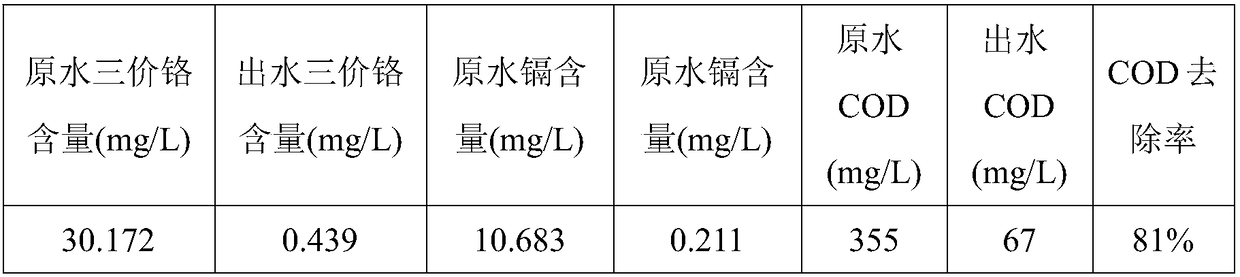

Embodiment 2

[0046] A new type of adsorption-flocculation precipitant, which is prepared from the following raw materials by weight: polyaluminum chloride: 50 parts, lotus root powder: 60 parts, diatomaceous earth 30 parts, cationic polyacrylamide: 8 parts.

[0047] The preparation method of the above-mentioned adsorption-flocculation precipitant specifically comprises the following steps:

[0048] (1) Preparation of polyaluminum chloride: Add aluminum hydroxide to concentrated hydrochloric acid solution under stirring conditions, heat up to 110°C for 2.5 hours, after the aluminum hydroxide is completely dissolved, cool down to 55°C, and use a mass concentration of 30% NaOH solution adjusted the pH value of the solution to 4, then raised the temperature to 110°C, and reacted for 45 minutes under stirring conditions to obtain a light yellow transparent polyaluminum chloride solution, which was dried and ground at 55°C to obtain the polyaluminum chloride product; Among them, the particle siz...

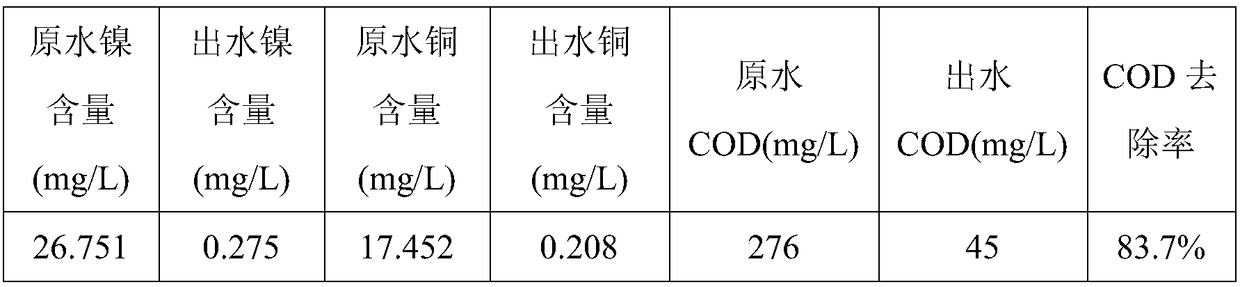

Embodiment 3

[0061] A new type of adsorption-flocculation precipitant, which is prepared from the following raw materials by weight: polyaluminum chloride: 55 parts, lotus root powder: 45 parts, diatomaceous earth: 25 parts, and cationic polyacrylamide: 7 parts.

[0062] The preparation method of the above-mentioned adsorption-flocculation precipitant specifically comprises the following steps:

[0063] (1) Preparation of polyaluminum chloride: Add aluminum hydroxide to concentrated hydrochloric acid solution under stirring condition, raise the temperature to 110°C for 3 hours, after the aluminum hydroxide is completely dissolved, cool down to 55°C, and use a concentration of 30 % NaOH solution to adjust the pH value of the solution to 4, then raise the temperature to 110°C, and react for 50 minutes under stirring conditions to obtain a light yellow transparent polyaluminum chloride solution, dry and grind at 55°C to obtain the polyaluminum chloride product; , the particle size of polyalum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com