System for treating antimony-containing printing and dyeing sewage

A technology of sewage treatment system and dosing system, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of being out of production reality, single factor of consideration, high operating cost, etc. Achieve the effect of accelerating floc settling, increasing flocs in sewage, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

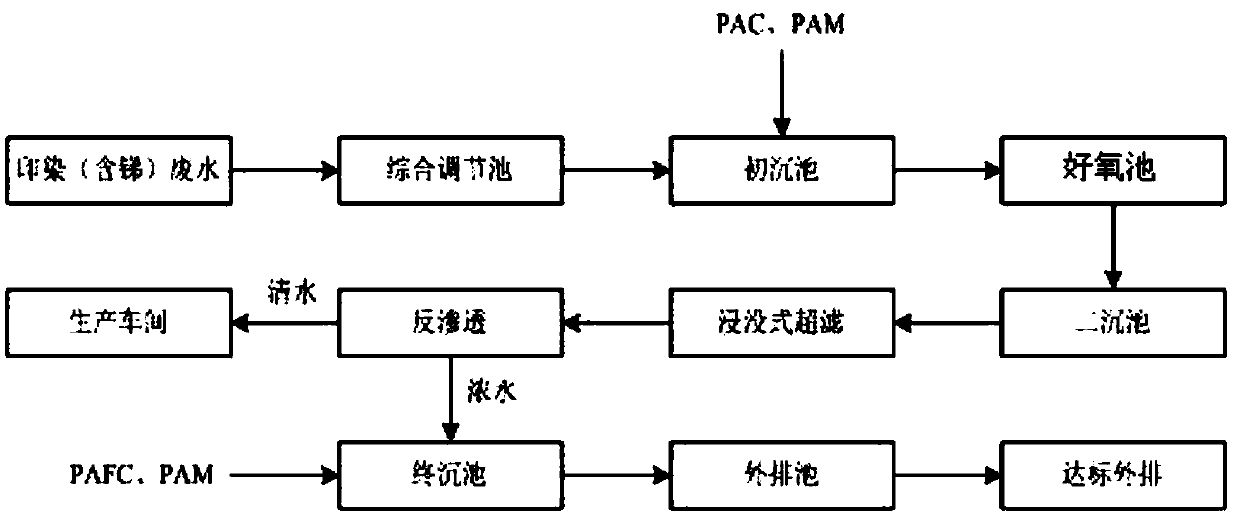

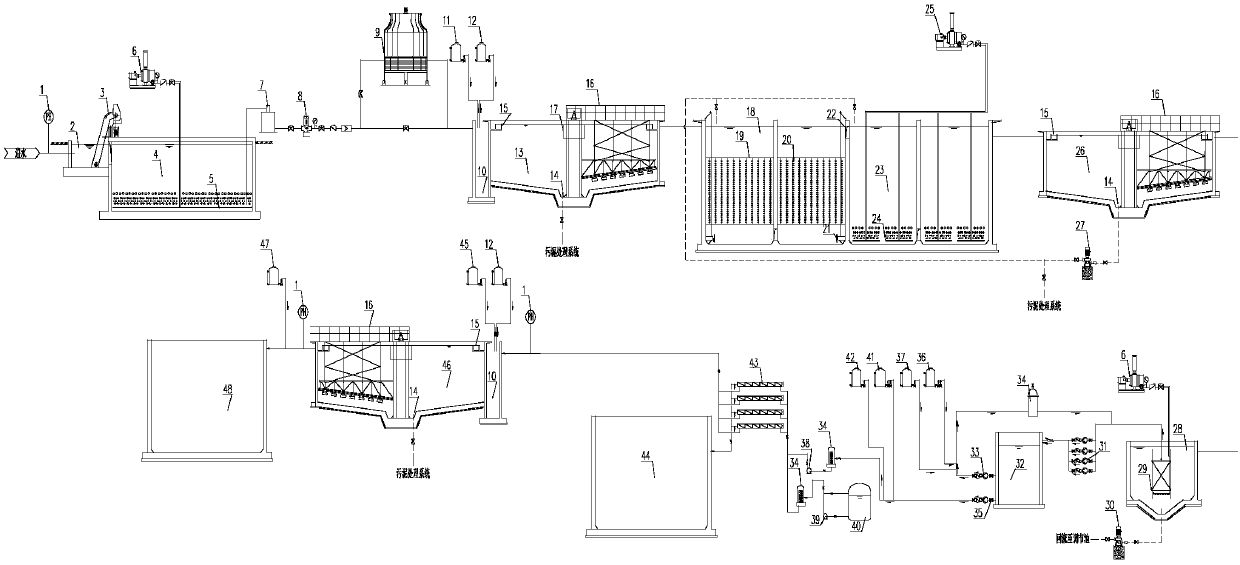

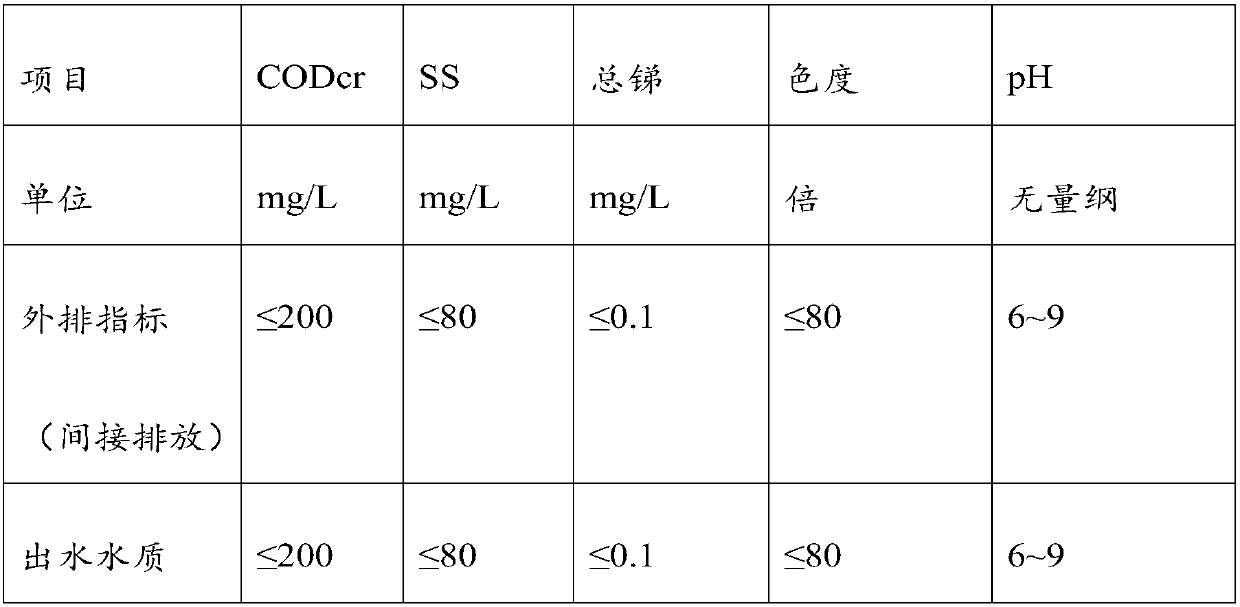

[0042] refer to figure 1 and figure 2 As shown, a sewage treatment system for removing antimony accumulated in printing and dyeing sewage in this embodiment, the grid well of the adjustment tank receives the printing and dyeing (containing antimony) sewage entering by gravity, and removes the rags through the mechanical grid and other impurities, the pH is monitored by the pH automatic control system of the adjustment tank, so as to control the dosage of chemicals in the primary sedimentation tank, and the sewage enters the water diversion tank.

[0043] A perforated aeration system is provided at the bottom of the regulating pool, and the aeration is regularly turned on for the regulating pond to prevent mud accumulation in the regulating pond.

[0044] The water diversion tank enters the cooling tower through the lifting pump for cooling treatment, and can directly enter the reaction pool of the primary sedimentation tank through valve control in winter.

[0045] The reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com