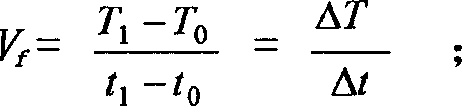

Patents

Literature

285 results about "Industrial water treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are many uses of water in industry and, in most cases, the used water also needs treatment to render it fit for re-use or disposal. Raw water entering an industrial plant often needs treatment to meet tight quality specifications to be of use in specific industrial processes. Industrial water treatment encompasses all these aspects which include industrial wastewater treatment, boiler water treatment and cooling water treatment.

Polysaccharide based scale inhibitor

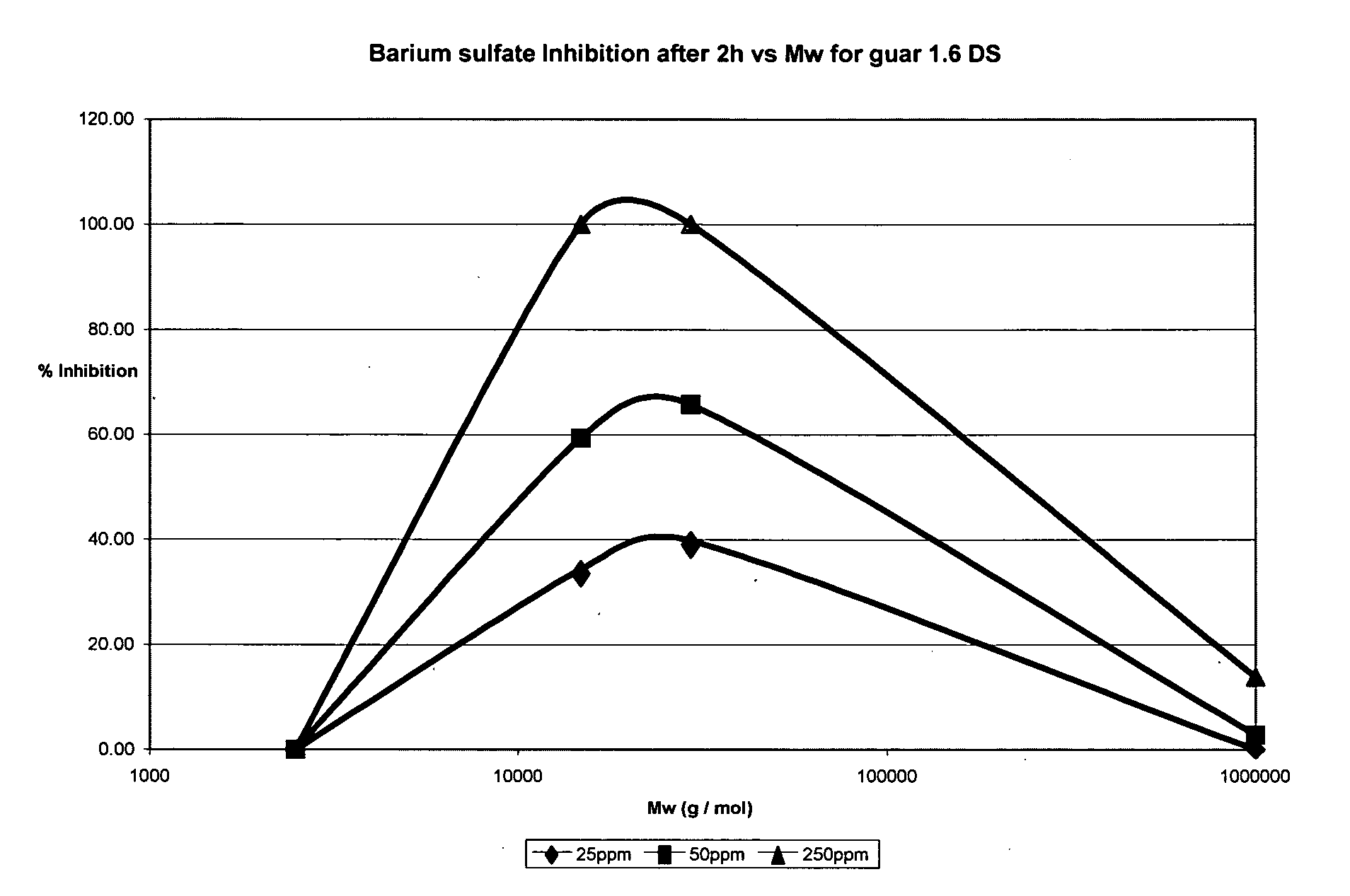

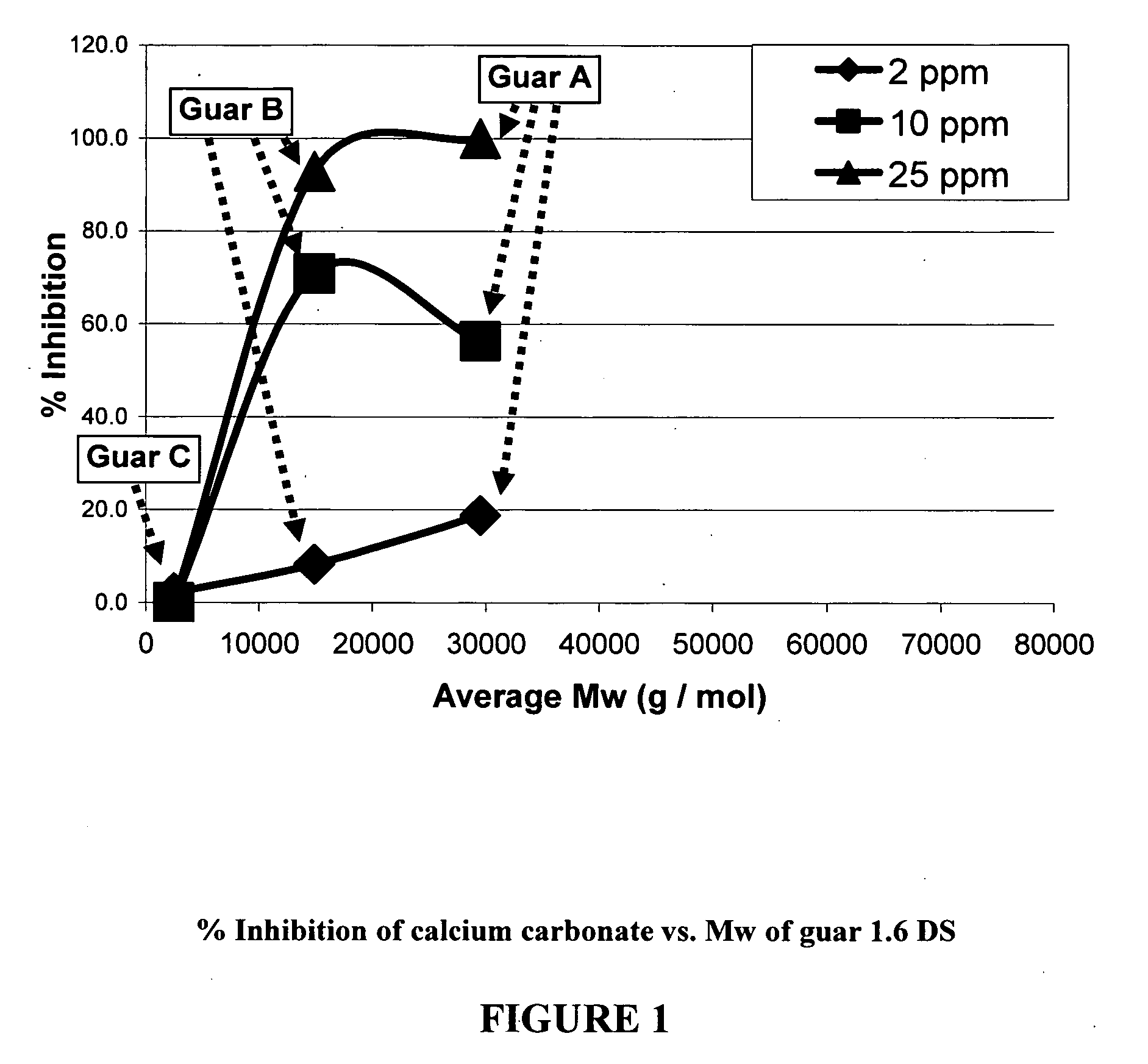

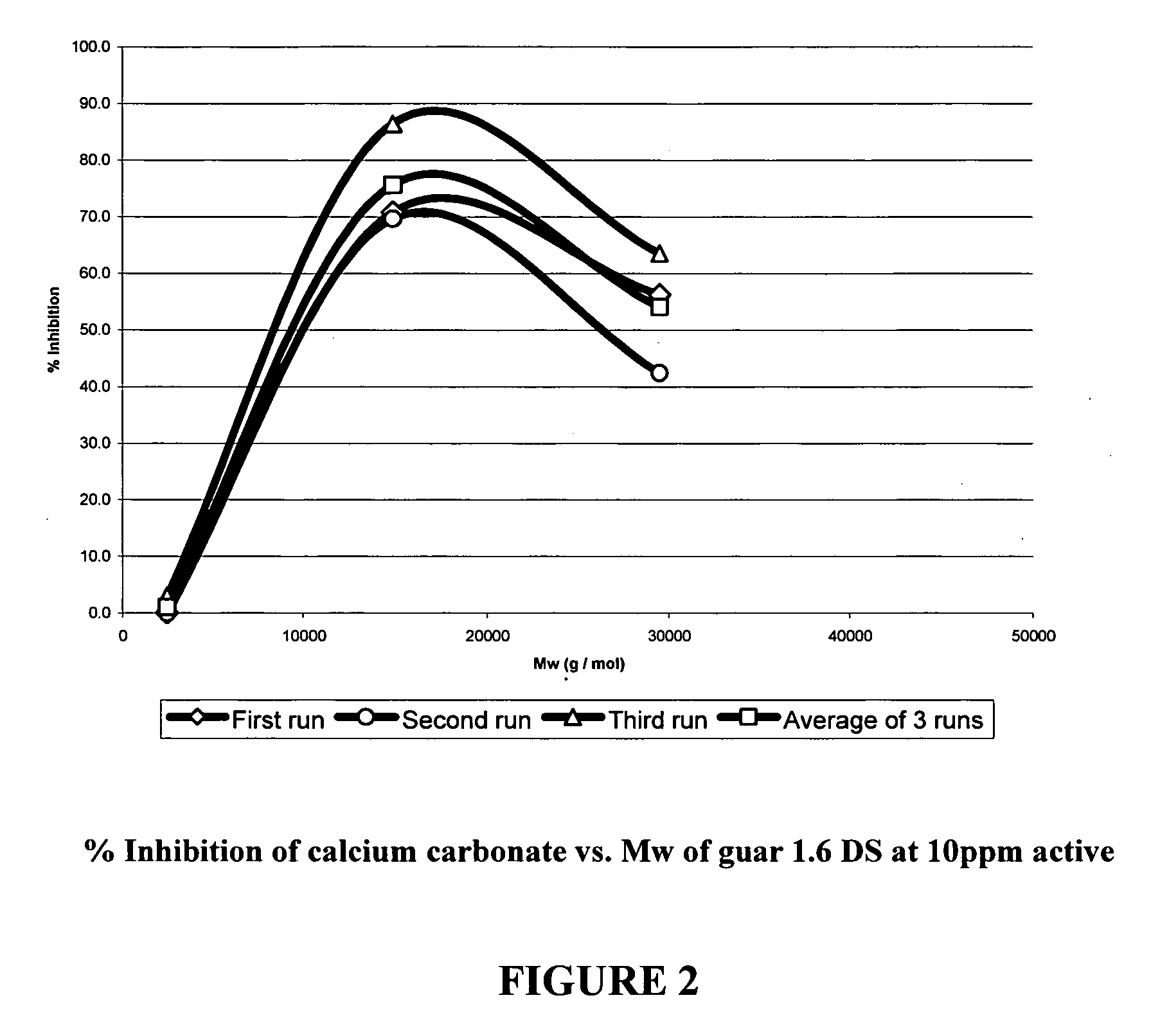

ActiveUS20080277620A1Reduce and prevent productionPrevent scalingWaste water treatment from quariesInorganic/elemental detergent compounding agentsSulfateDegree of substitution

A depolymerized-carboxyalkyl polysaccharide formed by de polymerizing a polysaccharide having from 0.5 to 3.0 degrees of substitution and reducing the molecular weight of said polysaccharide before or after said depolymerizing provides a biodegradable scale inhibitor useful to prevent deposition of scale comprising, for example, calcium, barium, sulfate and salts thereof. The depolymerized carboxyalkyl polysaccharide is particularly useful in off shore oil production squeeze treatments and in the treatment of scale formed in industrial water treatment.

Owner:RHODIA OPERATIONS SAS

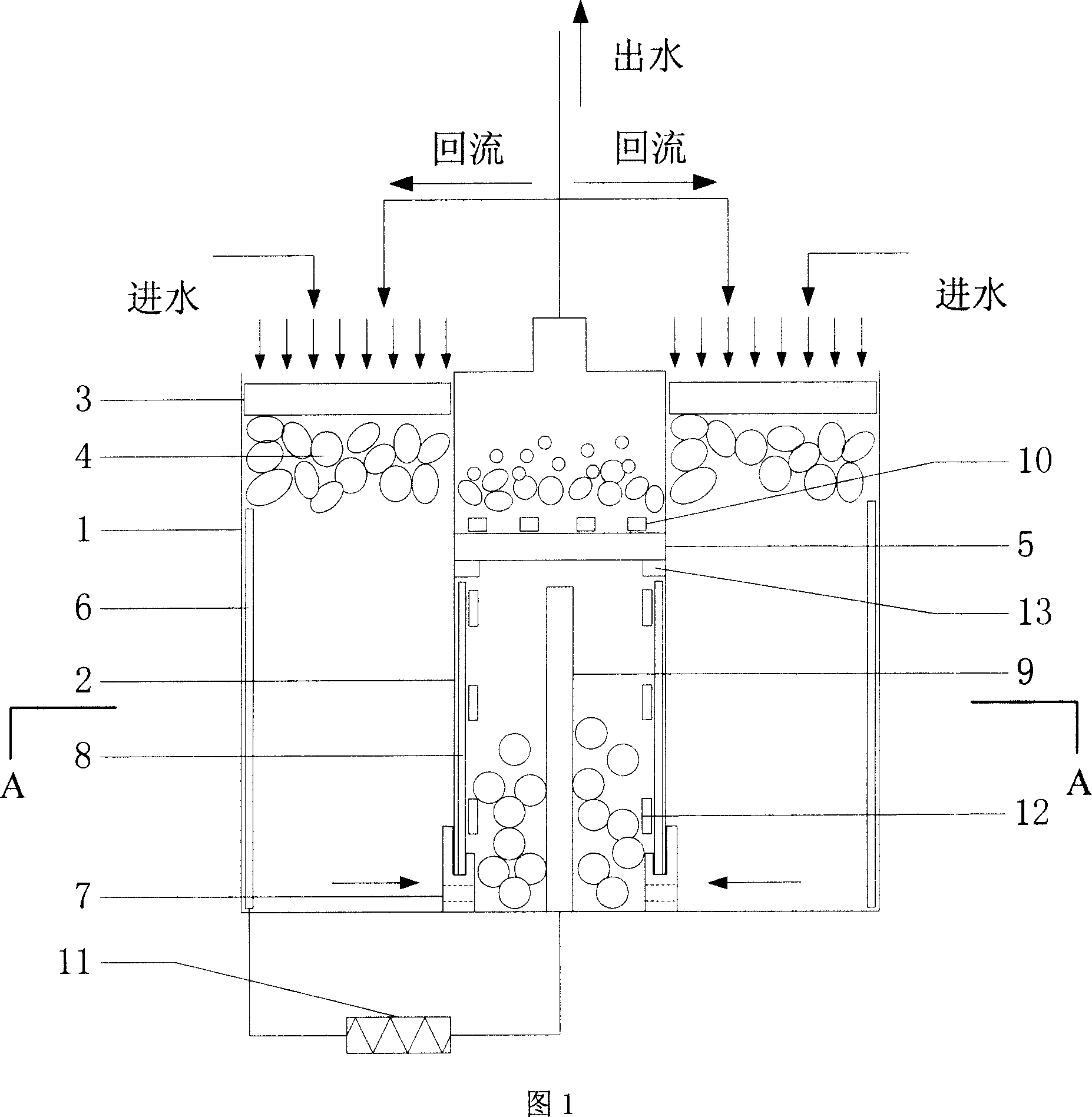

Double-drum microbial fuel cell

InactiveCN1937297ALow costLower internal resistanceBiochemical fuel cellsHigh concentrationInternal resistance

The fuel cell is composed of outer tube, inner tube, even water distributor, filler, graphite, graphite rod, and load etc. Anode chamber is surrounded by outer tube and inner tube. Sewage enters into anode chamber from the even water distributor, and flows to cathode chamber through diversion trench. Being filled to the outer tube, the filler is as carrier for microbe. Being pasted on inner wall of the outer tube, flexible graphite is in use for collecting anode current. Graphite rod setup inside cathode chamber is in use for collecting cathode current. Graphite rod, flexible graphite, and load constitute external circuit. The invention is suitable to degrading organic wastewater in high concentration, and generating electricity, or cleansing domestic sewage. The fuel cell is suitable to continuous running for long-term. Features are: low cost, low internal resistance, large capacity for generating electricity and capable of denitrifying at same time.

Owner:TSINGHUA UNIV

Water curing reverse osmosis membrane chemical cleaning method

InactiveCN101224391AExtended service lifeEasy to cleanReverse osmosisCalcium bicarbonateReverse osmosis

The invention relates to a chemical cleaning method used for a water disposal reverse osmosis membrane, relating to a chemical cleaning method used for cleaning water disposal reverse osmosis membranes in the industrial water disposal process. The invention is characterized in that NaOH solution which contains EDTA is adopted to clean microorganism, organism and silicon dioxide, etc. pollutants on the reverse osmosis membrane; HCI solution is adopted to clean calcium bicarbonate and magnesium bicarbonate filth on the reverse osmosis membrane. By adopting the method of the invention, the reverse osmosis membrane used by captive power plant water disposal can be effectively cleaned in the alumina preparation process. The invention has better cleaning effect, reliable and practiced technique and convenient operation process.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

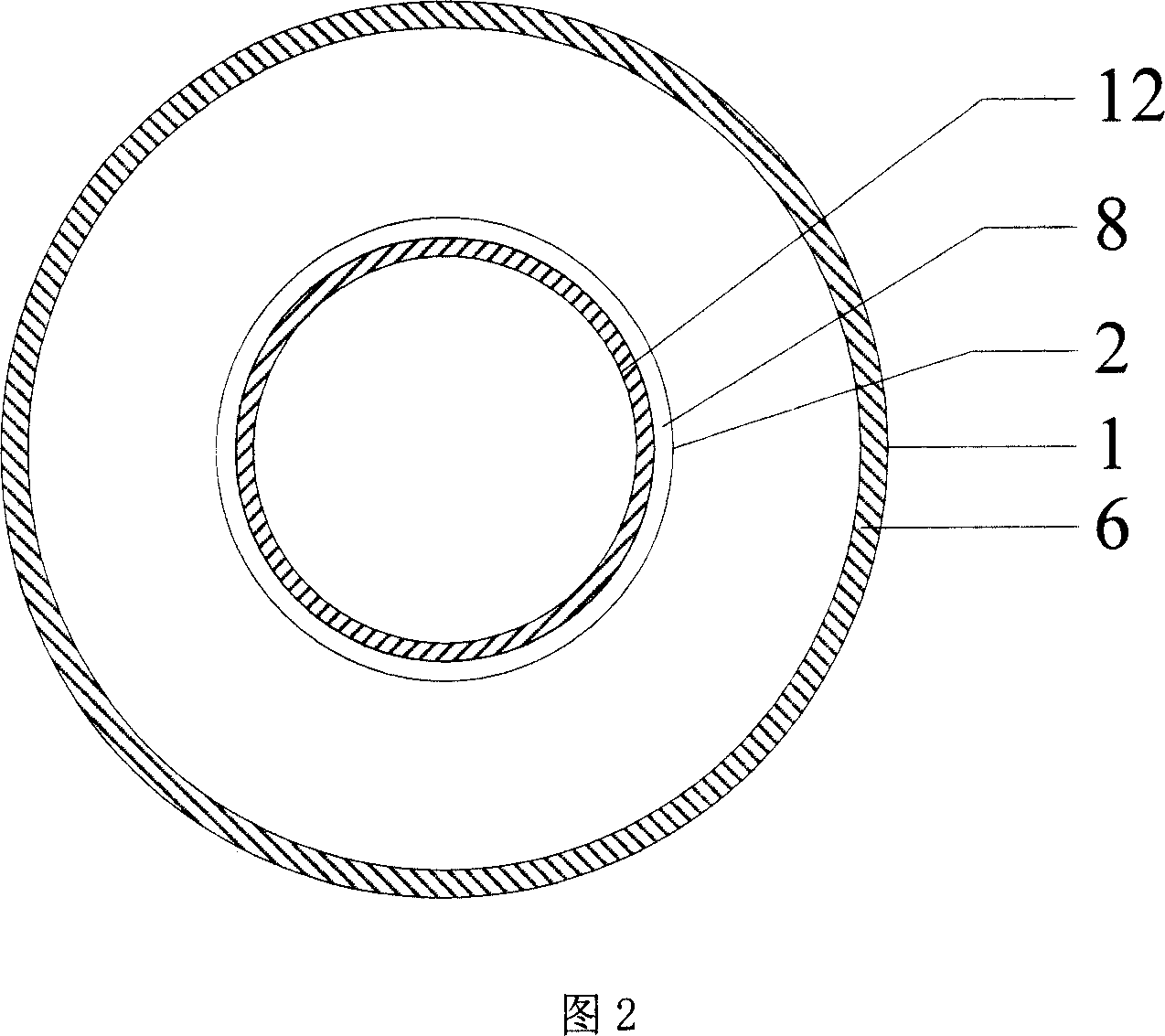

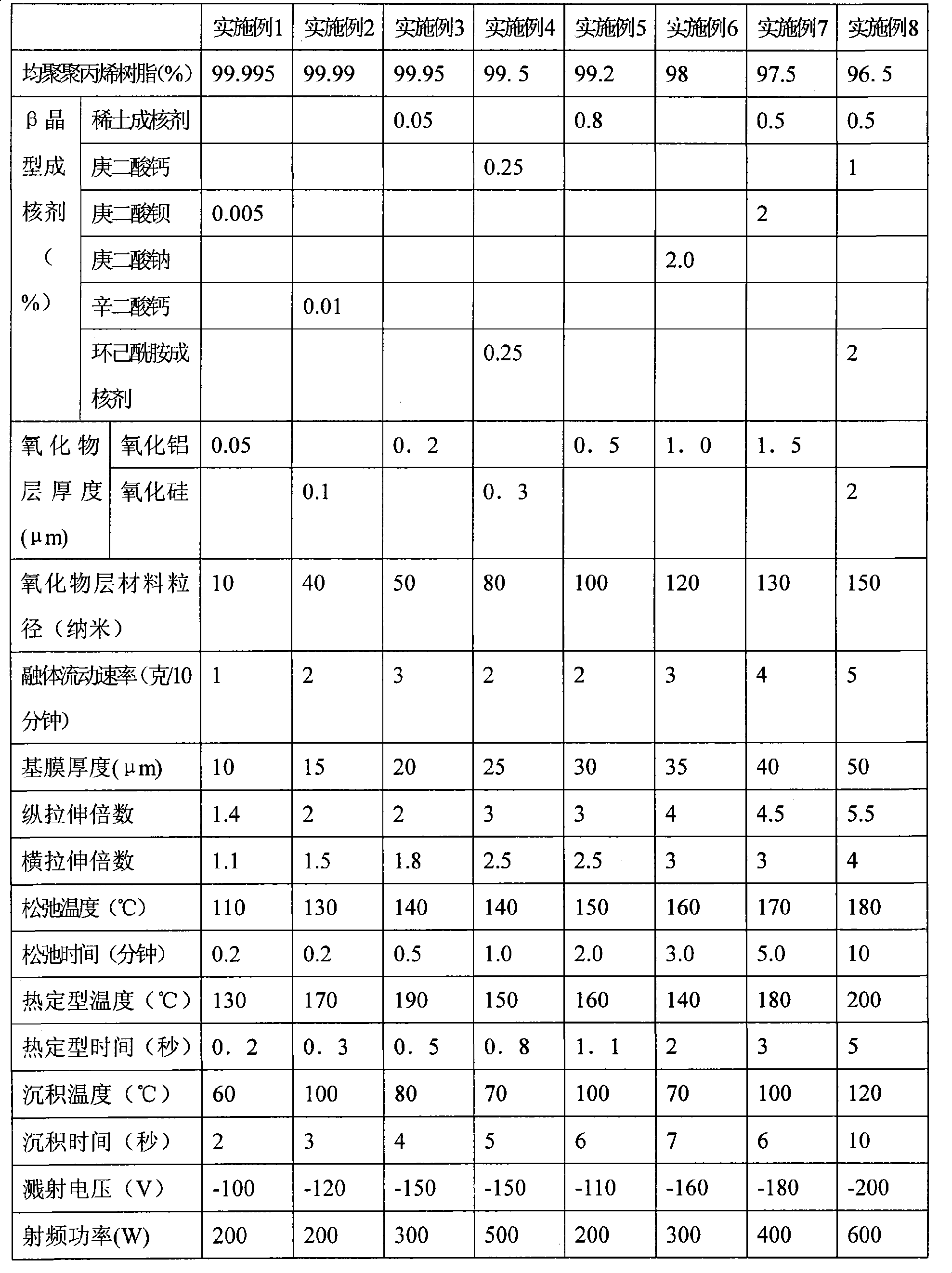

Polyolefin micropore barrier diaphragm and method for producing the same

InactiveCN101462381AImprove ionic conductivityImprove performanceSynthetic resin layered productsCell component detailsLithiumPorosity

The invention relates to a polyolefin microporous diaphragm and a manufacture method thereof, which belongs to the field of thin-film manufacture. The polyolefin microporous diaphragm consists of a polyolefin microporous basal membraneand oxide layer(s) on or / and under the polyolefin microporous basal membrane, wherein the polyolefin microporous basal membrane consists of 96.5 to 99.995 percent of homo-polypropylene resin and 0.005 to 3.5 percent of beta crystal form nucleating agent according to weight percentage; the polyolefin microporous basal membrane has the average pore size between 80 and 200 nanometers, the porosity between 30 and 50 percent and the air permeability between 1.5 and 15 ml / cm<2>.sec.atm; and the thickness of the oxide layer is between 0.05 and 2 microns. The polyolefin microporous diaphragm has the characteristics of uniform micropores, good air permeability, good thermal shrinkage properties and high ionic electrical conductivity, and can be widely applied to medical dialysis membranes, industrial water treatment membranes and lithium-ion secondary battery diaphragms.

Owner:韩伟嘉

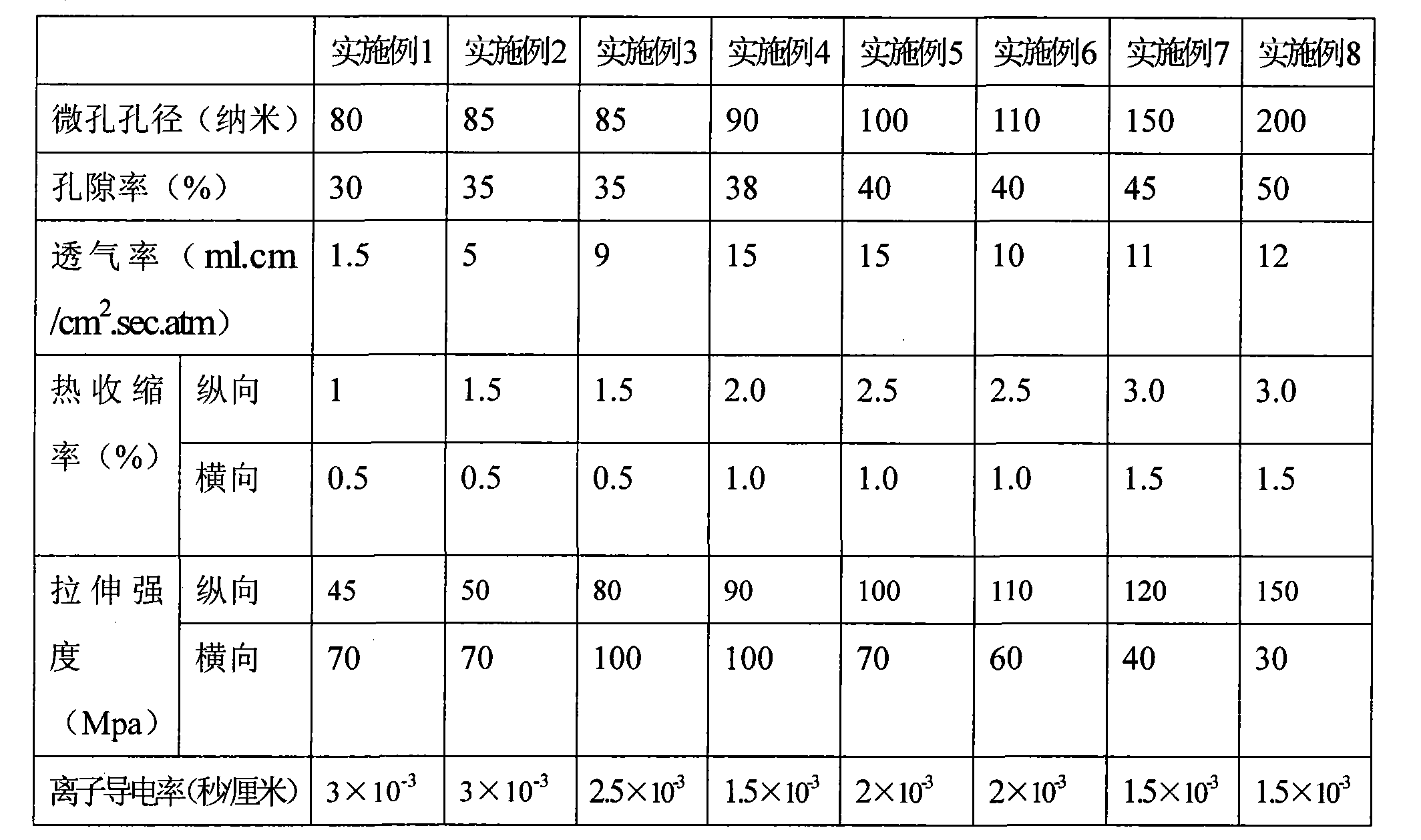

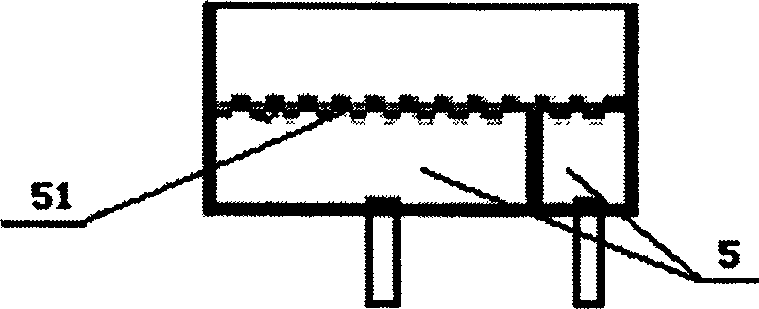

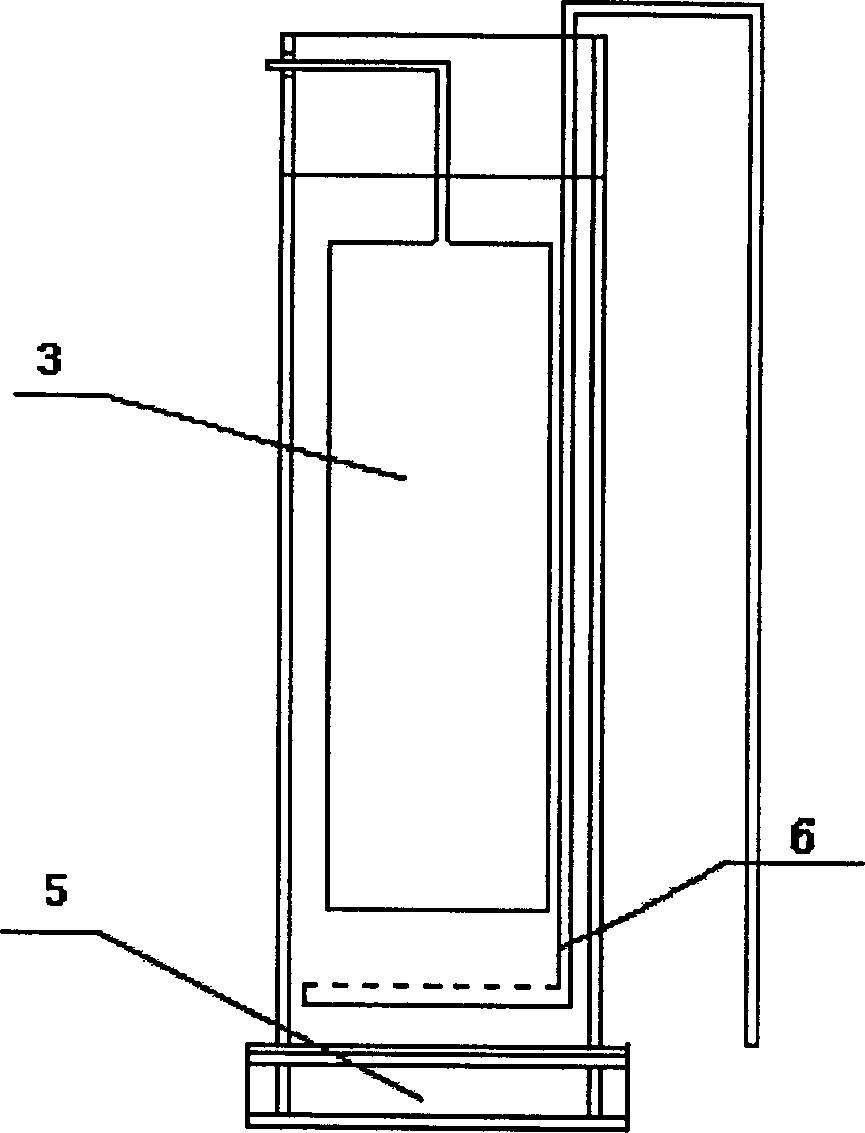

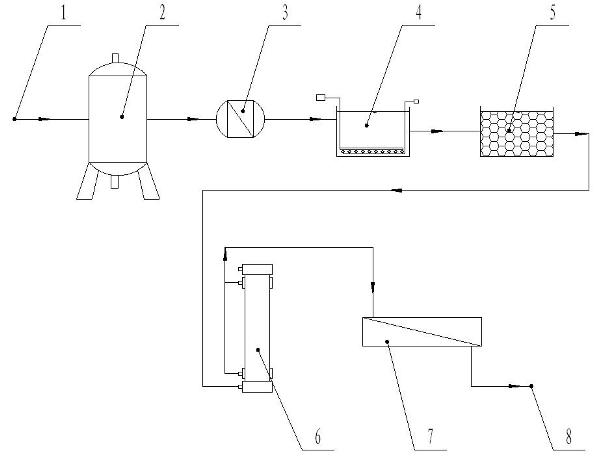

Fluidzed equipment for treating with water by using photocatalysis and oxidation

InactiveCN1415557AImproved aeration uniformityWell mixedWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisMicrowell PlateWastewater

Owner:TSINGHUA UNIV

Method for treating polymer flooding oil-extraction wastewater by employing organic modified sepiolite

InactiveCN103318984AThe activation modification process is simpleReduce dosageOther chemical processesWater/sewage treatment by sorptionBiological activationAdsorption effect

The invention relates to the field of industrial water treatment and in particular relates to a method for treating polymer flooding oil-extraction wastewater by employing organic modified sepiolite. The method comprises the following steps: 1) acid activation, namely adding a sepiolite raw material into a hydrochloric acid solution, mixing, stirring, filtering, washing, and drying to obtain sepiolite powder subjected to acid activation; 2) thermal activation, namely roasting and dehydrating the sepiolite powder subjected to acid activation, and cooling and grinding to obtain sepiolite powder subjected to thermal activation; 3) organic modification, namely adding the sepiolite powder subjected to thermal activation into an ethanol aqueous solution of cetyl trimethyl ammonium bromide, mixing, stirring, filtering, washing, drying and grinding to prepare the organic modified sepiolite powder; and 4) adsorption, namely regulating the pH value of the polymer flooding oil-extraction wastewater by using an acid, adding a water-soluble aluminum salt, adding the organic modified sepiolite powder obtained in the step 3) for adsorption, stirring or shaking, standing and settling. The sepiolite serves as a raw material and is low-price and readily available, the process for activation and modification of the sepiolite is simple, and the sepiolite is non-toxic and harmless, has an obvious adsorption effect, rapid in treatment and high in adsorption amount.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

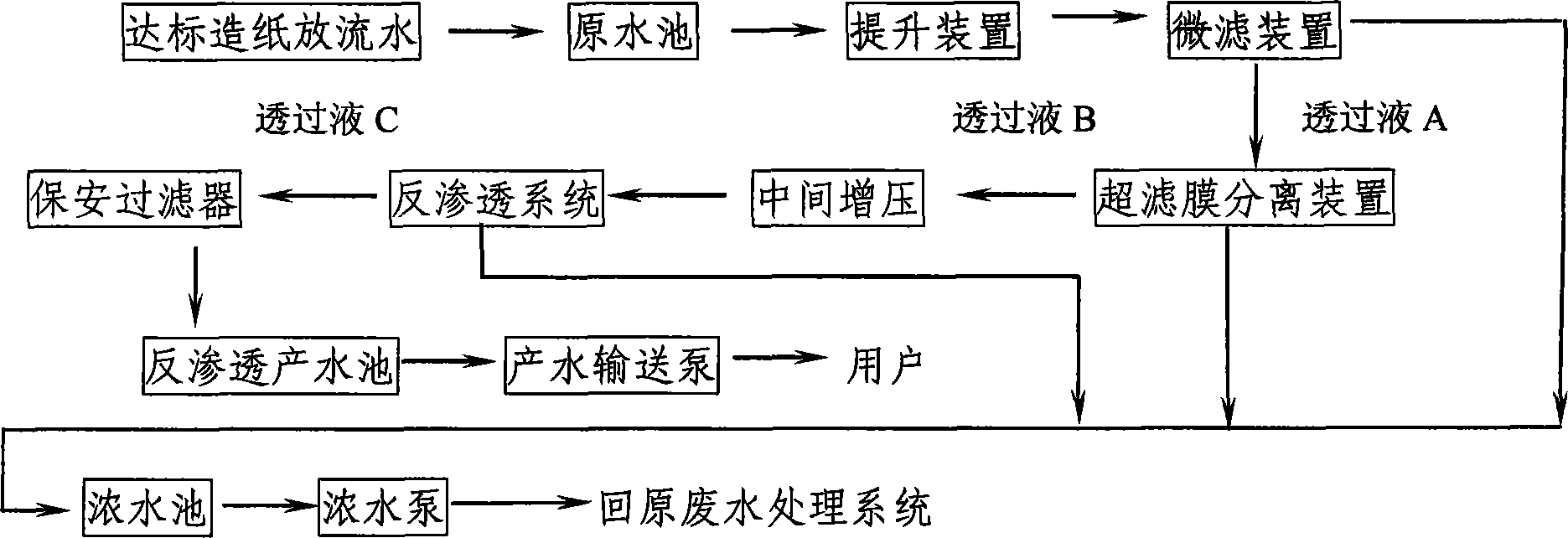

Method for reclaiming and utilizing paper-making industrial waste water

InactiveCN101186418ASolve zero emissionsSave energyWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentParticulatesFiltration membrane

The invention discloses a wastewater recycling method for paper making industry, and combines membrane technique with industrial water treatment technique. The invention comprises the steps of micro-filtration technique stage, an ultra-filtration technique stage and a reverse osmosis membrane technique stage. The micro-filtration technique stage can pretreat the discharged wastewater of paper making treated by a biochemical system, and remove the impurities of raw water. The ultra-filtration technique stage is used for the treatment of pretreated permeation liquid with ultra-filtration membrane, to further eliminate suspensions and macromolecular particulates. The reserve osmosis membrane technique stage is used for further pressurizing the permeation liquid and desalting through the reserve osmosis membrane and getting rid of COD, thus obtaining ultrapure water for a boiler used in production or permeation liquid used in paper making technique. The invention can thoroughly recycle water resource, and the indexes of the permeation liquid can reach the drinking standard of China, which can absolutely be applied to ultrapure water for the boiler used in production or paper making technique. The invention is applied to advanced recycling of discharged wastewater after wastewater treatment in paper making industry, and is also suitable for advanced recycling of discharged wastewater after wastewater treatment in such industries as printing and dyeing, iron and steel and chemical engineering, etc.

Owner:GOLD EAST PAPER JIANGSU

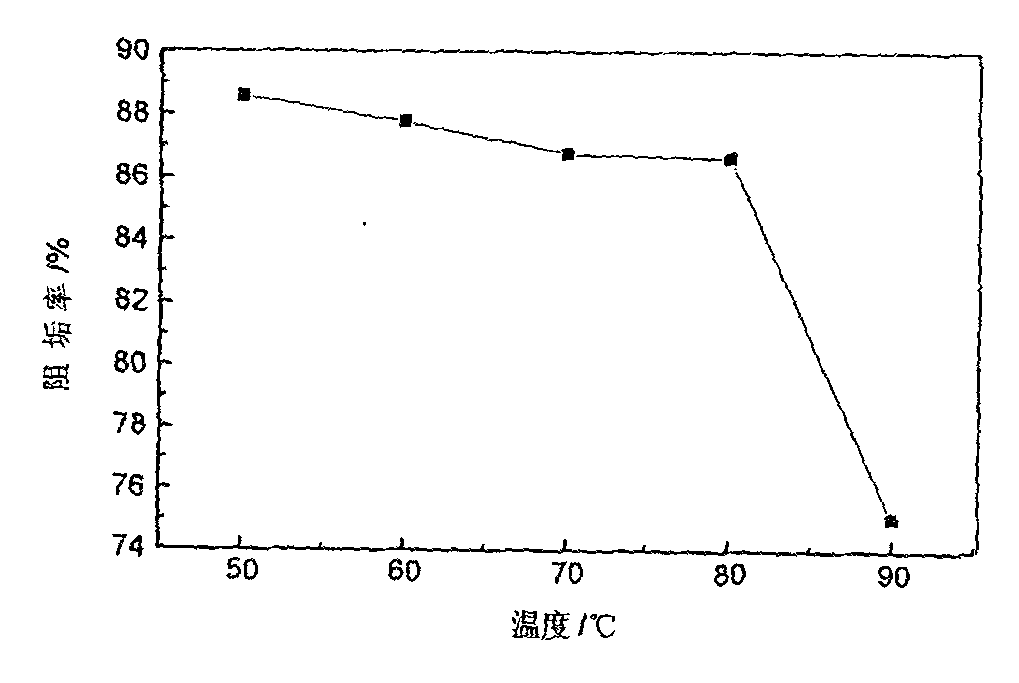

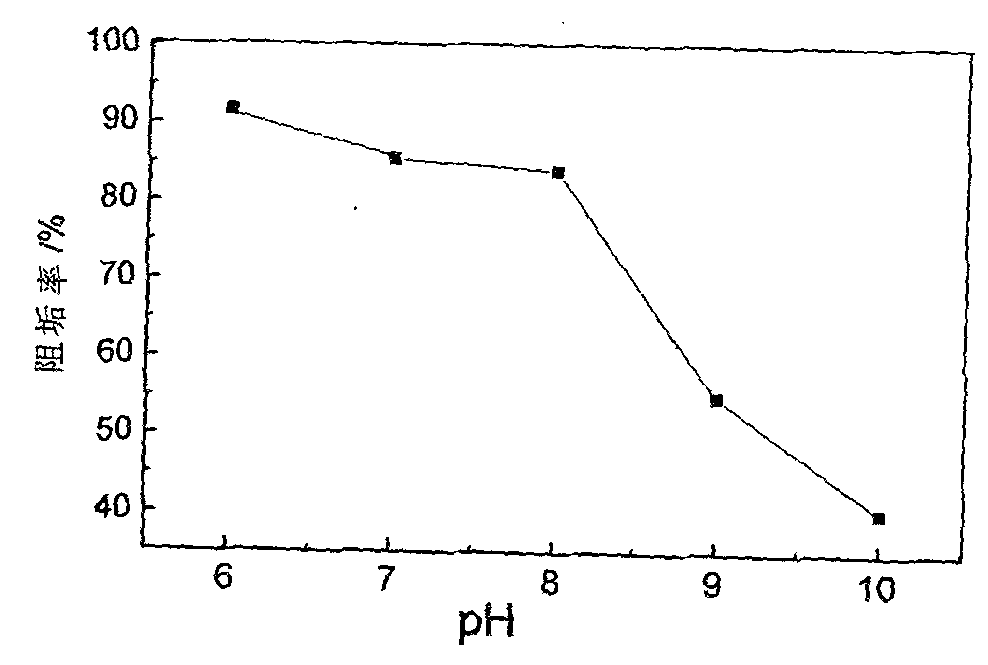

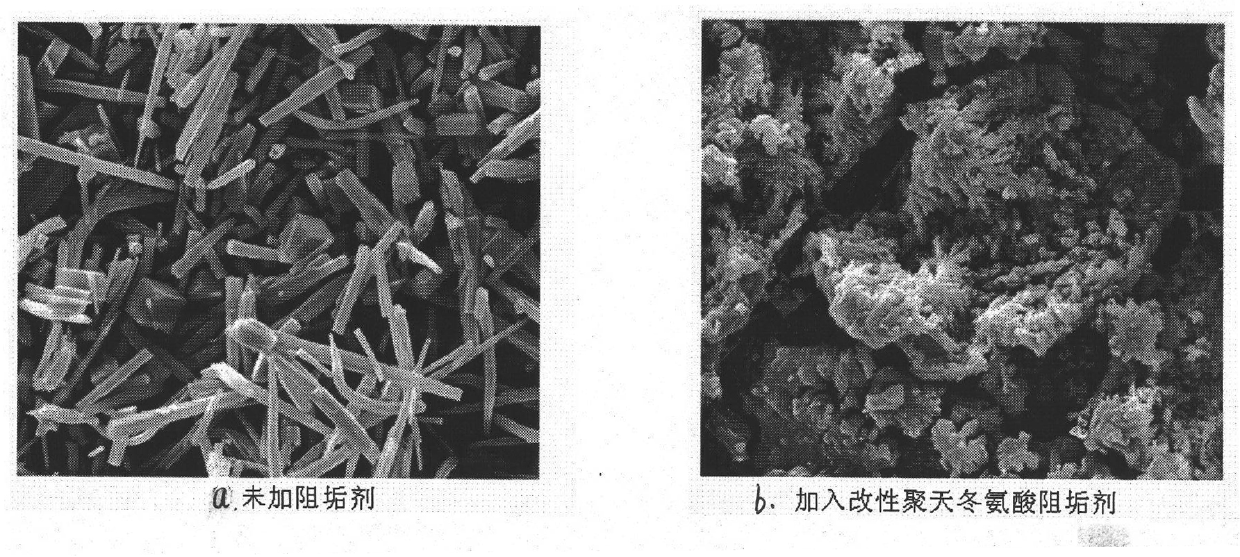

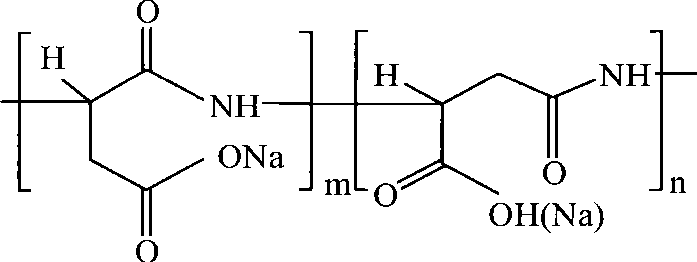

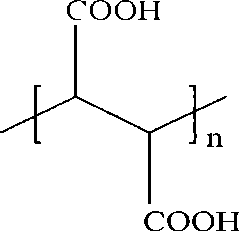

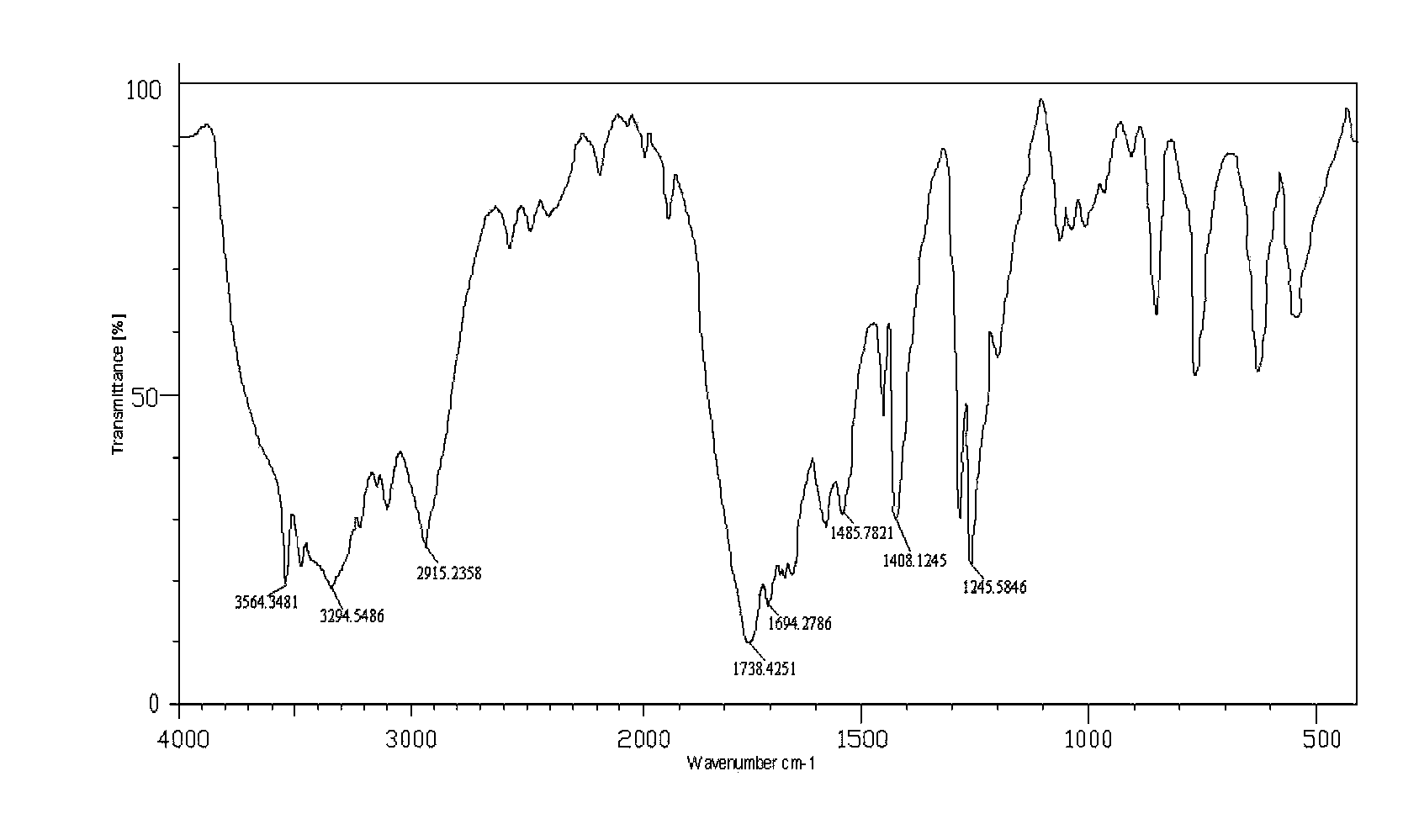

Methods for preparing and applying modified polyaspartic acid scale inhibitor

InactiveCN101792504AExcellent anti-scaling performancePromote degradationScale removal and water softeningImidePolyaspartic acid

The invention relates to methods for preparing and applying a modified polyaspartic acid scale inhibitor, which belong to the field of preparation and application of scale inhibitors. The method for preparing the modified polyaspartic acid scale inhibitor comprises the following step of: preparing polysuccinimide (PSI), polyaspartic acid (PASP) and modified polyaspartic acid (CSN-PASP). The scale inhibitor prepared by using the method has good adaptability at the temperature of 50-80 DEG C and the pH value ranging from 6.0 to 8.5. The modified polyaspartic acid scale inhibitor belongs to a polymer type scale inhibitor. A PASP molecule does not contain phosphorus, has no poison, does not destroy the ecological environment and has favorable biodegradability and water solubility, and the excellent scale inhibiting dispersion performance is particularly suitable for industrial water treatment. The aim for improving the scale inhibiting performance of the PASP is achieved by just adding a micromolecule substance in synthesis without changing other process conditions.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Biological Floc and Uses Thereof, for example, in Sludge Innocent Treatment and Industrial Water Purification Treatment

InactiveUS20190300407A1Promote high-speed reproductionSave resourcesSludge treatment by de-watering/drying/thickeningFungiMicrobial agentSludge

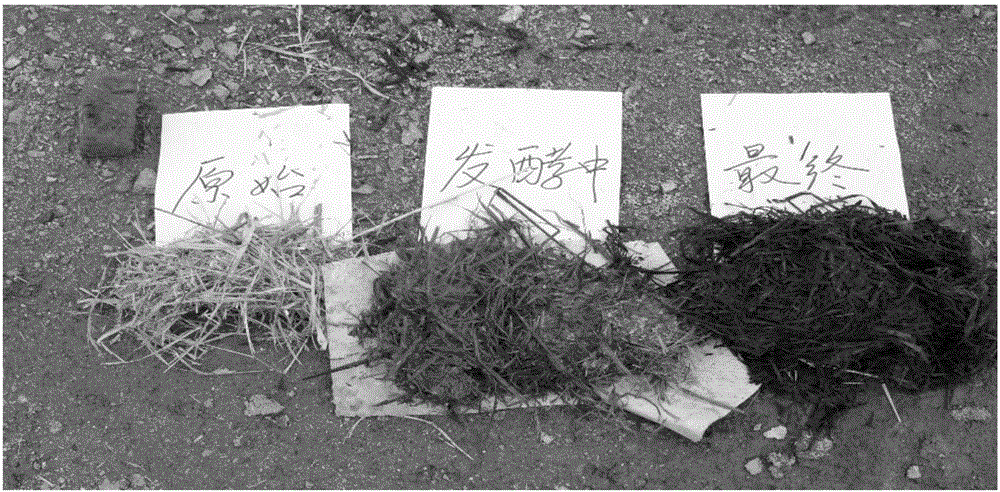

Provided are a biological floc, a process for the preparation thereof and uses thereof in aquaculture, water purification, industrial water treatment, soil remediation and improvement, and sludge innocent treatment, wherein the biofloc comprises decomposed straw powder, a first microbial agent, a nitrifying bacteria and a denitrifying bacteria, wherein the first microbial inoculant comprises Bacillus subtilis and selective actinomycetes. The process for the preparation of the biological floc comprises firstly adding the microbial agent to the decomposed straw powder, and then successively adding the nitrifying bacteria and the denitrifying bacteria. Further provided is an organic bacterial fertilizer comprising sludge, a biological floc and fermenting bacteria.

Owner:KUSN HUAKE INST OF BIOPOLYMER

Heavy metal wastewater purificant

InactiveCN101357798ARelieve pressureReduce generationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionWater qualityMetallic sulfide

Owner:SHENZHEN BANGYOUTONG TECH

LABVIEW-based variable frequency water treatment control system

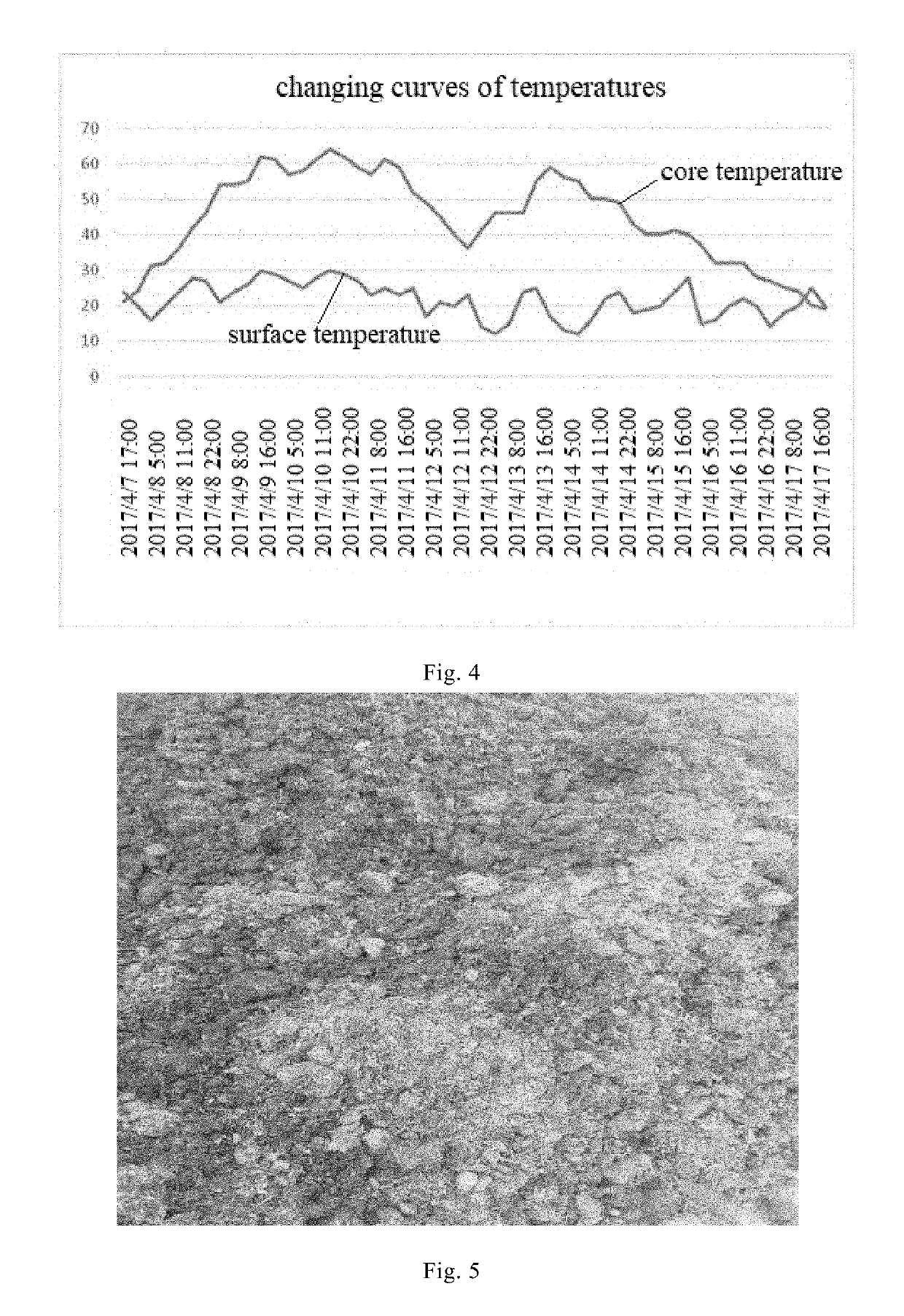

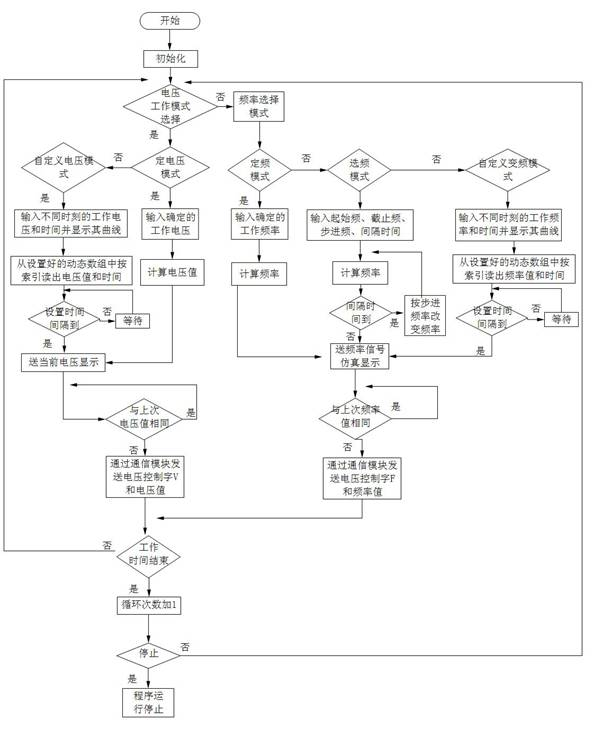

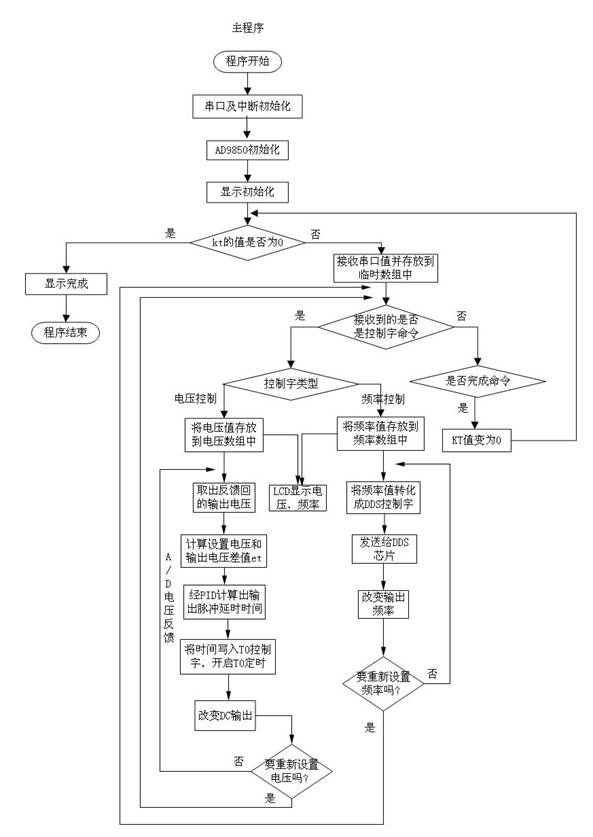

ActiveCN101866156AIncrease the scope of applicationFunction increaseProgramme controlComputer controlControl systemWater quality

The invention relates to an LABVIEW-based variable frequency water treatment control system, comprising a software control part and variable frequency water treatment control equipment, wherein the software control part comprises the LABVIEW procedure and the single chip procedure of a computer; the variable frequency water treatment control equipment comprises a computer software control platform, a serial interface module, a single chip, a DDS module, a power amplification module, a power module and a water treater. The frequency of the control equipment of the system can change between 1Hz and 1MHz without steps and the output power can be adjusted between 0W and 400W without steps. The system can meet various water treatment requirements such as sterilization, scale prevention and removal, corrosion prevention, etc. The control system has the advantages of convenient software operation, strong control function, excellent equipment performance, safe and reliable use and high applicability, can be widely applied to the fields such as central heating, air-conditioners, hot water boilers, industrial water treatment, water purification and the like and serves as an effective tool for studying the variable frequency water treatment technology.

Owner:中部知光技术转移有限公司

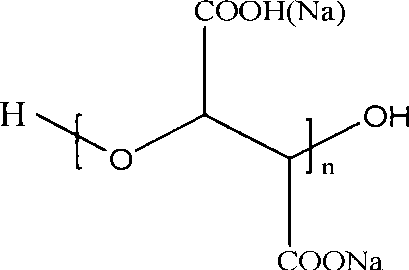

Anti-antisludging disperser and preparation method thereof

ActiveCN101186394AExcellent anti-calcium carbonate scale functionExcellent ability to disperse iron oxideScale removal and water softeningWater/sewage treatment bu osmosis/dialysisHigh concentrationReverse osmosis

The invention provides a dirt dispersion agent which is a copolymer of acrylic acid, acrylamide and organic compounds with sulfonic acid groups, the mass ratio of which is 5-40 to 1-15 to 1-15 and a preparation method thereof. The copolymer has the solid content of 30-40 percent and the molecular weight of 1000-10000; the organic compounds with sulfonic acid groups are vinyl sulfonic acid, 2-acrylamido-2-methyl-1- propane sulfonate, sodium allylsulfonate or 2-acrylamide dodecyl sulfonate. The dirt dispersion agent of the invention also comprises amido, carboxyl and sulfonate functional groups, thus leading the agent to have good function of inhibiting calcium carbonate scale as well as good performance of dispersing ferric oxide. The dirt dispersion agent still has high performance of dirt dispersion even in water with inorganic salt of high concentration and can be widely applied to a treatment system of industrial water, such as industrial circulating water and reverse osmosis water, etc.

Owner:OCHEMATE MATERIAL TECH CO LTD

Bio-floccule, preparation method and application thereof

ActiveCN106754461AImprove purification effectRipe to achieveFungiBacteriaDenitrifying bacteriaMicrobial agent

The invention relates to a bio-floccule, a preparation method thereof, and an application thereof in aquaculture, water purification, industrial water treatment, and soil repairing and improvement. The bio-floccule includes decayed straw powder, a first microbial agent, nitrifying bacteria and denitrifying bacteria. The first microbial agent includes bacillus subtilis and optional actinomycetes. The preparation method includes the following steps: adding the microbial agent and then adding the nitrifying bacteria and denitrifying bacteria successively to the decayed straw powder. The bio-floccule is prepared with the decayed straw powder as a main body and by addition of the special microbial agent, nitrifying bacteria and denitrifying bacteria. The main technical indices of the bio-floccule reach and even are better than foreign bio-floccules in the same type. In addition, a test proves that the bio-floccule has excellent purifying effects on sewage in river channels.

Owner:上海安而信环保科技有限公司

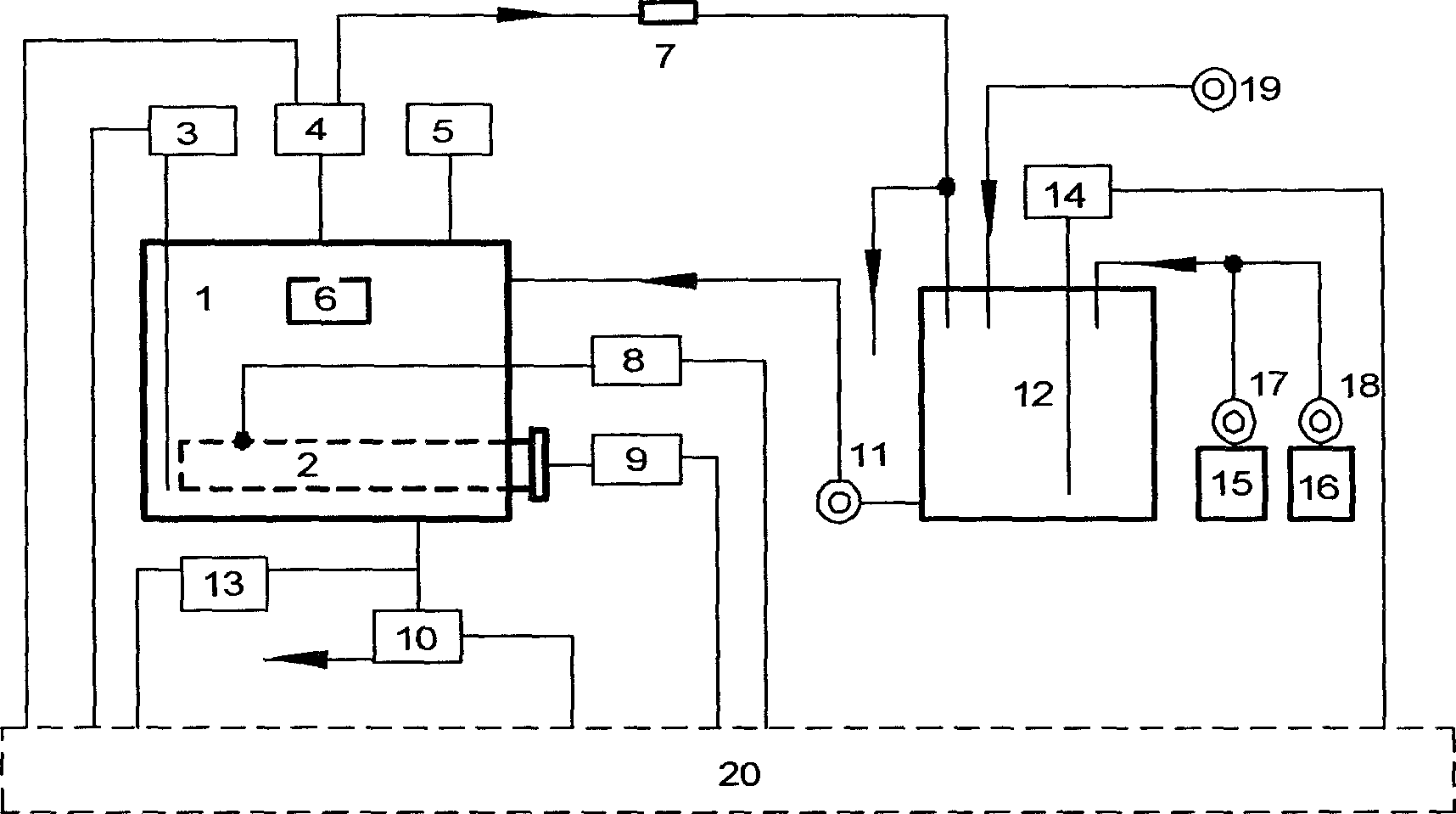

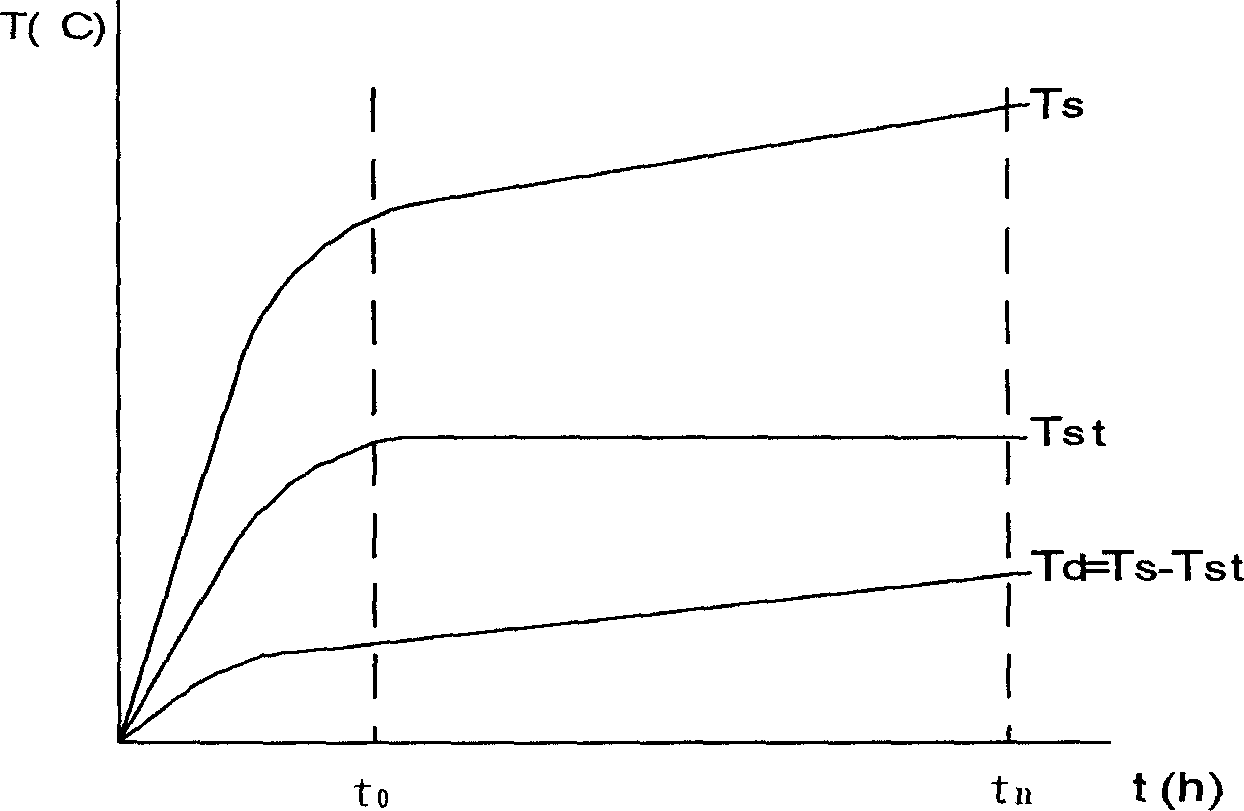

Method for testing scale and corrosion inhibition performance of reagent and apparatus for boiler water treatment

Disclosed is a method for testing scale and corrosion inhibition performance of reagent and apparatus for boiler water treatment, which comprises establishing a simulated boiler system, a scaling detection unit and a corrosion detection unit, utilizing a differential thermal principle and a weight-loss data detection and processing method to provide real operation behavior conditions of the simulated boiler, changing different water quality and medicinal composition, proportion, so as to conduct integrated dynamic test and evaluation for the boiler water treatment medicament and slow erosion property and scale-preventing characteristics when passing the water-treating equipment.

Owner:TIANJIN CHEM RES & DESIGN INST

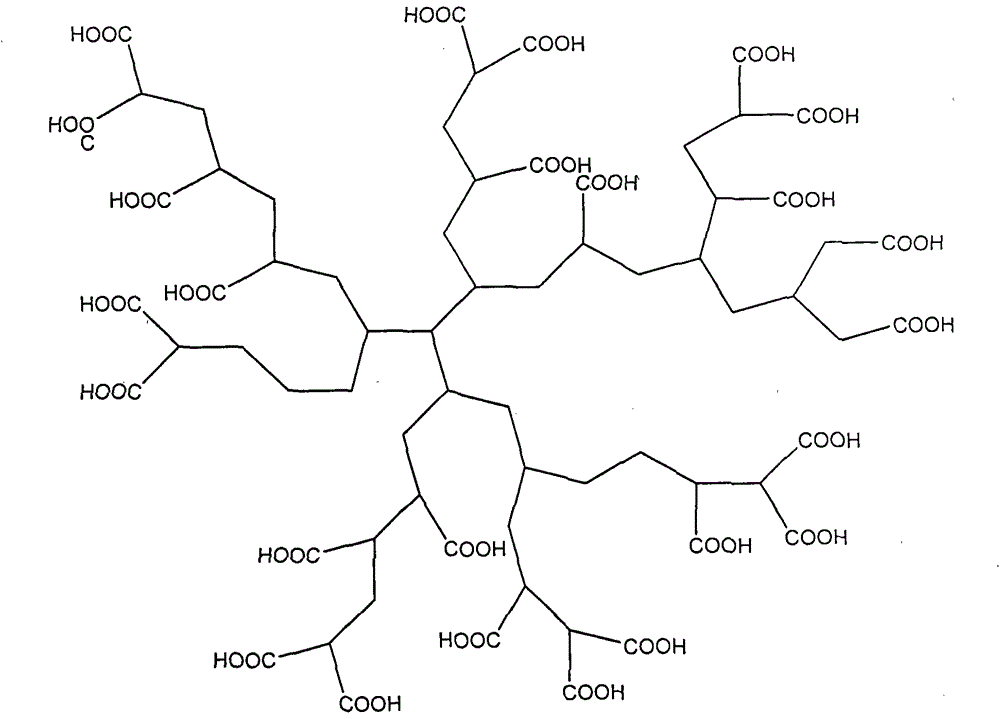

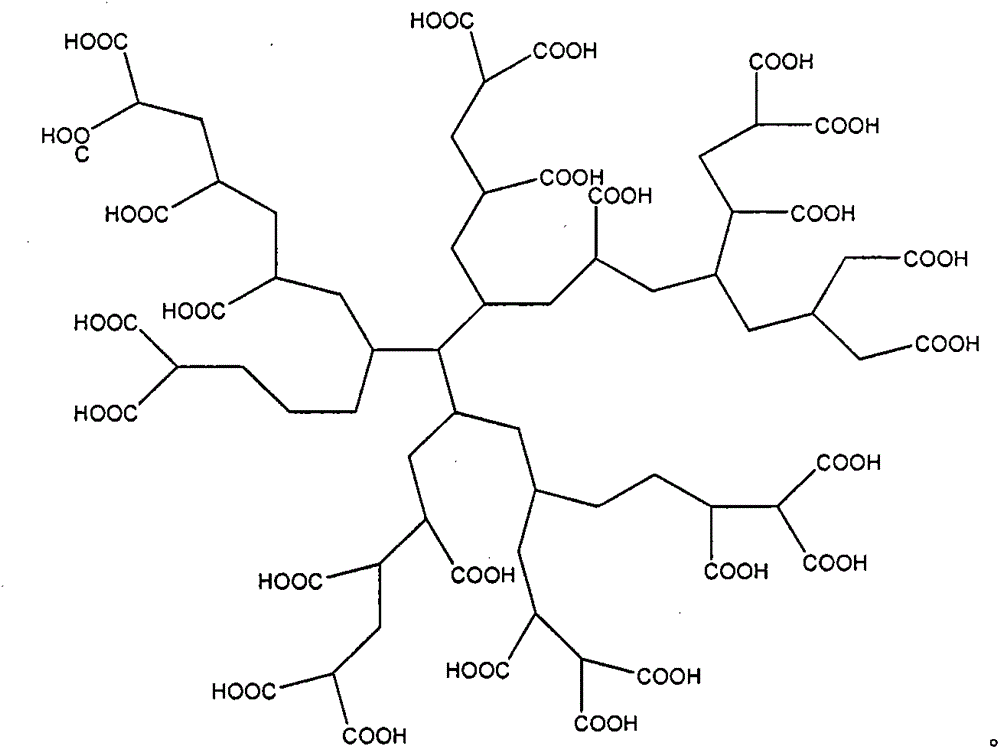

Carboxyl-terminated hyperbranched polymer scale inhibiting and preventing agent and synthesizing method

InactiveCN106146819AGood modification effectWith gapsScale removal and water softeningPetrochemicalTextile industry

The invention relates to a carboxyl-terminated hyperbranched polymer scale inhibiting and preventing agent and a preparing method thereof. By means of novel molecular design, the carboxyl-terminated hyperbranched polymer scale inhibiting and preventing agent is synthesized with a double-monomer method and a single-monomer method, the molecular structure of the carboxyl-terminated hyperbranched polymer scale inhibiting and preventing agent is a hyperbranched structure, carboxyl serves as a terminal, and an ester group or an amide group or an ester group and an amide group or the like is included in molecules. The industrial water treatment agent with the scale inhibiting and preventing performance is prepared by carrying out carboxylation modification on a carboxyl-terminated hyperbranched polymer in a melt polymerization mode, or in the mode of directly synthesizing the carboxyl-terminated hyperbranched polymer. The scale inhibiting and preventing agent is good in performance, and can be applied to the industrial process in the petrochemical industry, the textile industry, the food industry and the like.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Environment-friendly composite dirt dispersion agent for oil-field flooding treatment

InactiveCN101508492ACausing eutrophication pollutionGood scale inhibition and dispersibilityWaste water treatment from quariesScale removal and water softeningWater floodingOil field

The invention belongs to the technical field of industrial water treatment, and particularly relates to an environmental protection type composite dirt dispersion agent used for oil field water flooding treatment. The dirt dispersion agent takes polyasparagic acid, polyepoxy sodium succinate and hydrolyzed polymaleic anhydride as effective components; and the total content of the effective components is no less than 35 percent. The weight ratio of the effective components of polyasparagic acid: polyepoxy sodium succinate: hydrolyzed polymaleic anhydride is 4-12.5:1-5: 5-9. The environmental protection type composite dirt dispersion agent is phosphorus free, innocuous and biologically degradable, and has low use cost. The environmental protection type composite dirt dispersion agent can effectively prevent the sedimentation of calcium carbonate, calcium sulphate and barium sulphate, and is suitable for the dirt dispersion treatment in an oil field water flooding system.

Owner:TONGJI UNIV

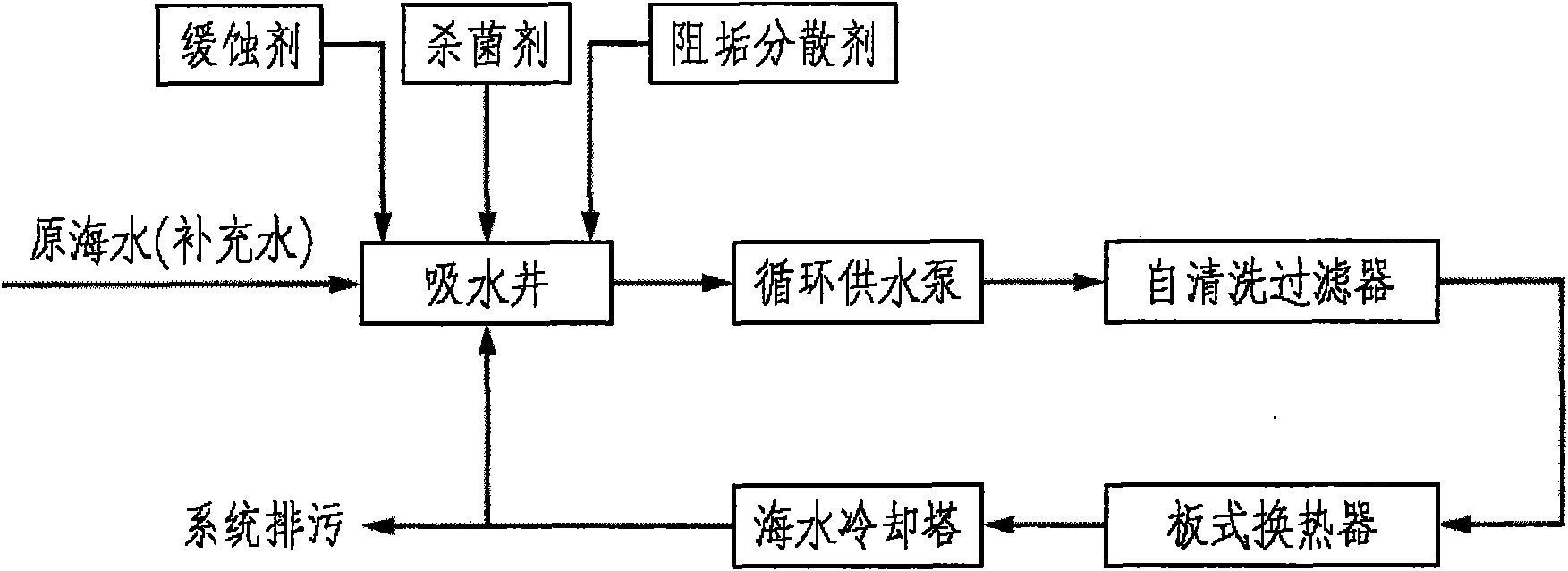

Circulating cooling water treatment method of sea water

InactiveCN101565252AReduce hydrationImprove protectionScale removal and water softeningMultistage water/sewage treatmentCooling towerConcentration ratio

The invention provides a circulating cooling water treatment method of sea water, pertaining to the technical field of industrial water treatment; the method is as follows: sea water is adopted as a cooling medium and pressurized by a circulating water supply pump, then transferred to a plate heat exchanger for heat exchange, later cooled by a sea water cooling tower after primary cooling is completed, and recycled. A self-cleaning strainer is arranged in front of the plate heat exchanger for guaranteeing the normal operation of the plate heat exchanger; a water quality stabilization dosing facility is arranged and a sea water corrosion inhibitor, an antiscalant dispersant and a disinfectant are added for preventing corrosion, scaling and fouling organism attachment in the operation of a circulating cooling water system of sea water; and the concentration ratio of the circulating cooling water system of sea water is controlled within the range from 1.3 to 1.8. The circulating cooling water treatment method of sea water has the advantages of saving fresh water resource, low sea water supplement, small pollutant discharge amount, being beneficial to the protection of environment and maintenance of ecological balance, low engineering investment and operation cost and the like, and is applicable to the industrial circulating cooling water in the industries of chemical engineering, electrical power, petrification, metallurgy, etc.

Owner:BEIJING SHOUGANG INT ENG TECH

Circulating cooling water biological treatment method

InactiveCN104211185AIncrease the concentration factorImprove water qualityBiological water/sewage treatmentSulfurPurple Nonsulfur Bacteria

The invention discloses a circulating cooling water biological treatment method and belongs to the technical field of industrial water treatment. The method includes the steps of arranging a packed bed in a circulating cooling water tank for providing conditions for implantation of added microorganisms and disposing a circulation pump beside the circulating cooling water tank; adding four kinds of bacteria of yeast, purple non-sulfur bacteria, acetic acid bacteria and bacillus bacteria which are mixed in any proportion to the circulating cooling water tank, wherein the total monthly amount of the bacteria liquid is 0.05-1% of the water in a system; arranging a sludge removal pump in the circulating cooling water tank for regular sludge removal. Furthermore, the invention also provides a method for adjusting the pH of the circulating cooling water system. The circulating cooling water biological treatment method can improve the concentration multiple of the circulating cooling water, reduce the amount of make-up water of the circulating cooling water system, and is fast, easy, effective and environmentally friendly.

Owner:付永全 +3

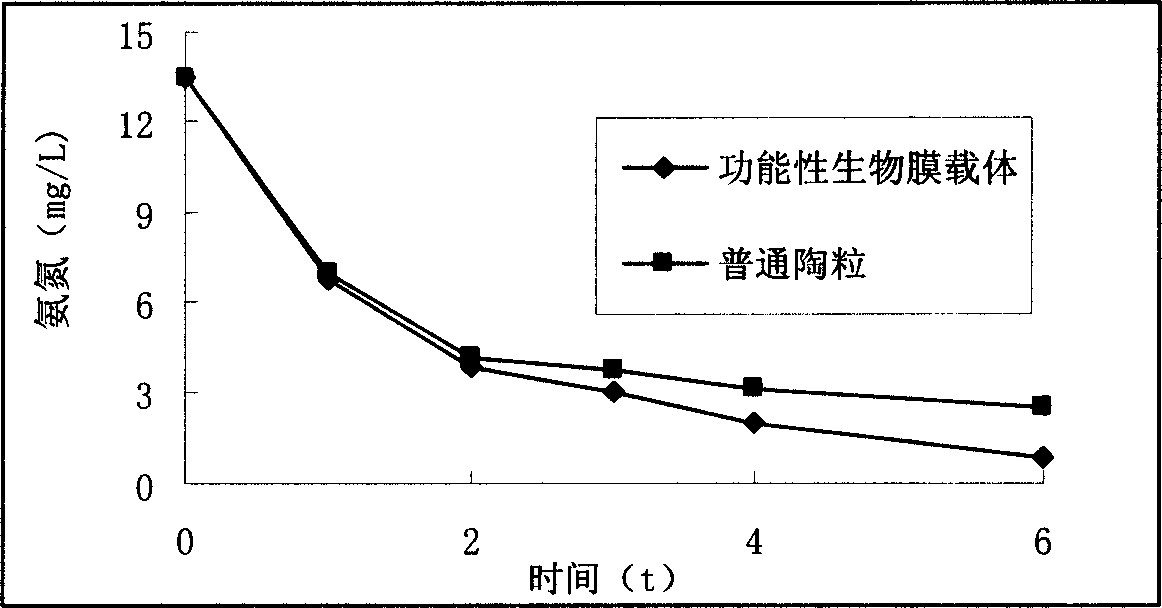

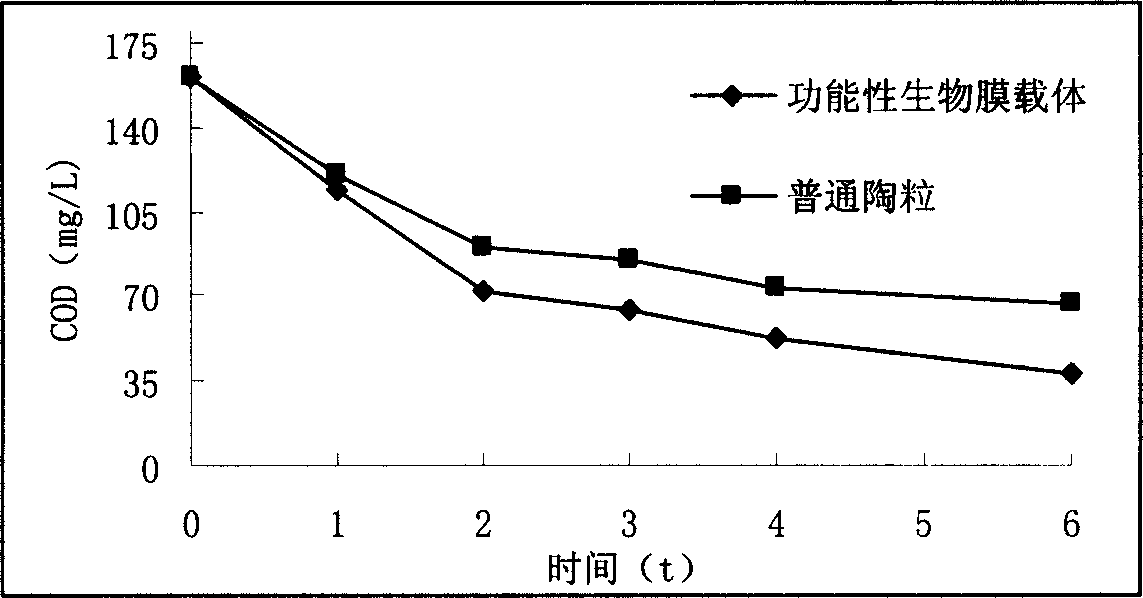

Functional biomembrane carrier, its preparation method and use

InactiveCN1843972APromote rapid formationPromote growthTreatment using aerobic processesSustainable biological treatmentMontmorilloniteWastewater

The invention discloses a functional biologic membrane carrier, method for preparation and use thereof, wherein the carrier is prepared from (by weight percent) hydrotalcite 5-15%, montmorillonite 10-20%, aluminum oxide 5-15%, diatomite 40-70% and tourmaline 1-10% through batching, granulating, and burning for forming.

Owner:ZHEJIANG UNIV

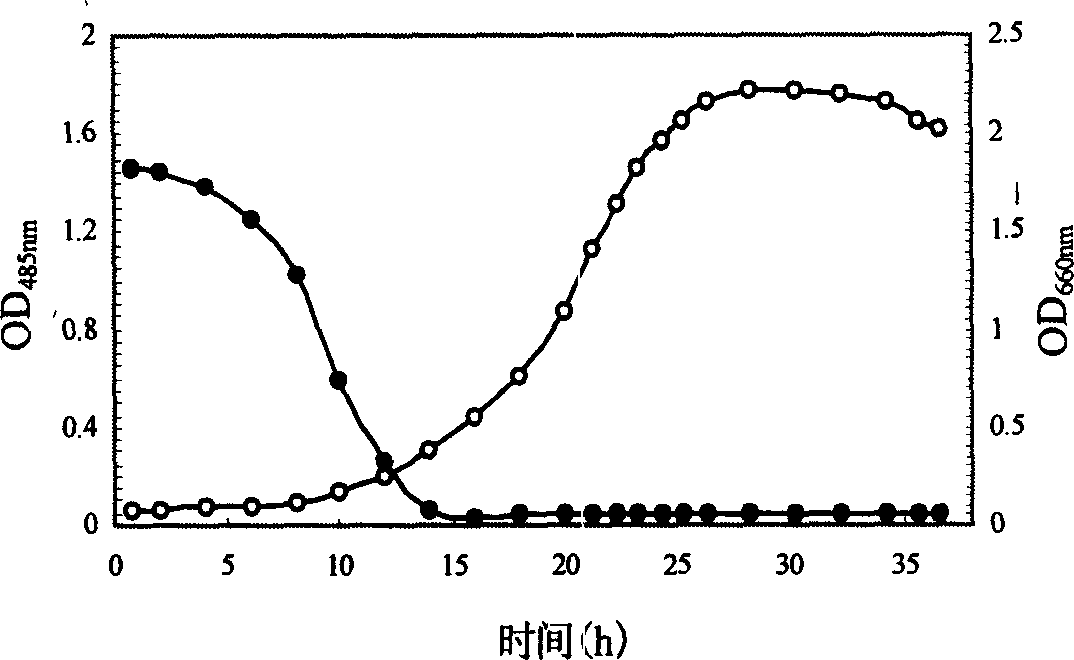

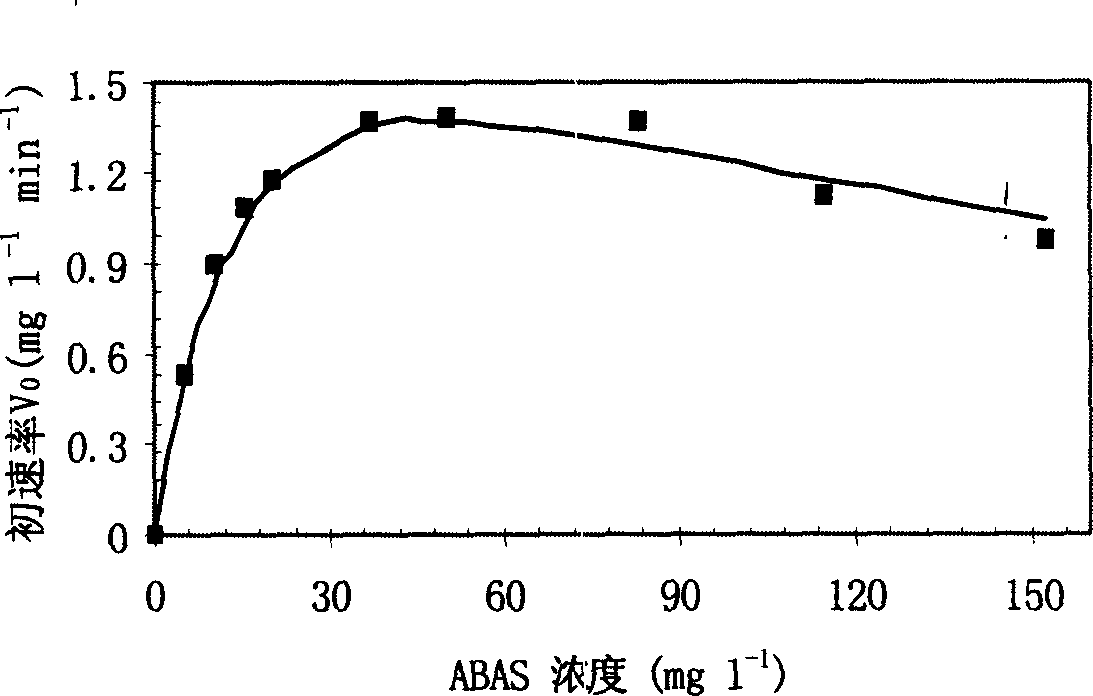

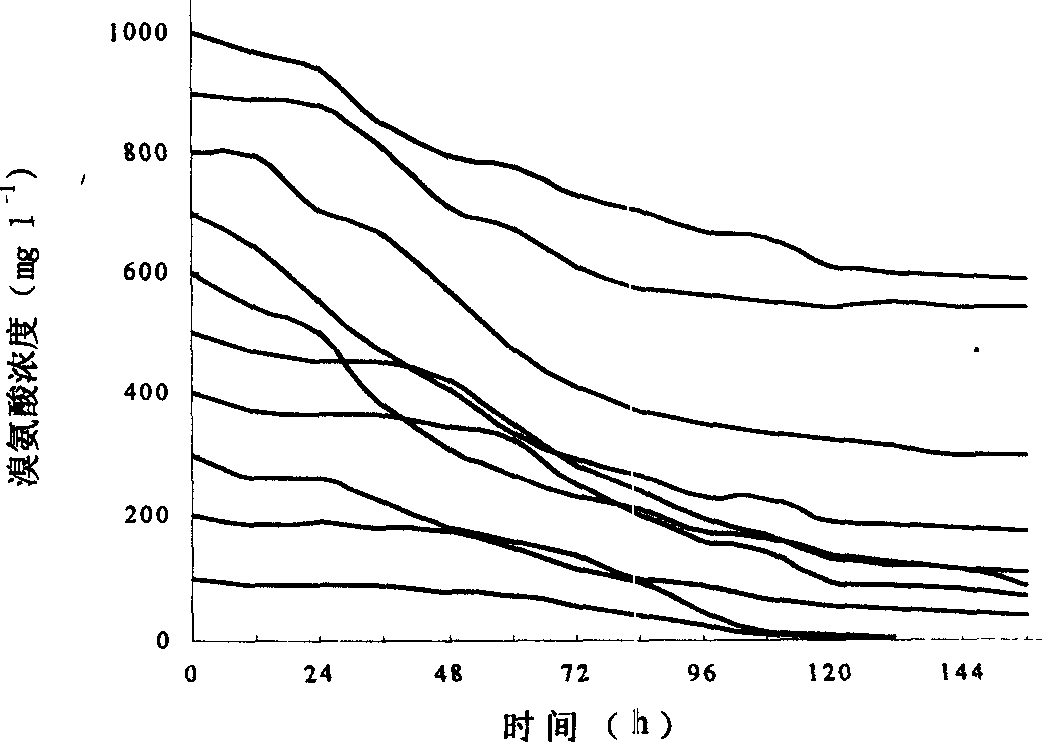

Sphingol monospore bacterial strain and its application in anthraquinone dye waste water decolour

InactiveCN1618953AStrong decolorization abilityFast degradationBacteriaWater/sewage treatmentSludgeBio engineering

A sphingomonas xenophaga QYY (CGMCC No.1172) is disclosed, which features that the bromamino acid as the intermediate of anthraquinone dye is the unique carbon and nitrogen sources for its growth, so its cells can destroy the anthraquinone rings. As a result, it has strong decolor capacity and can be used to decolor the sewage of anthraquinone dye.

Owner:DALIAN UNIV OF TECH

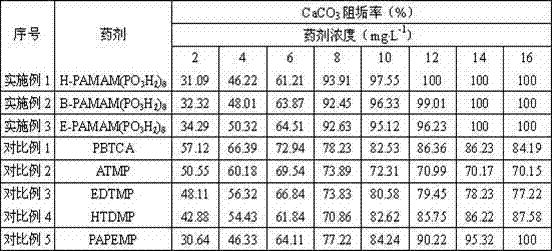

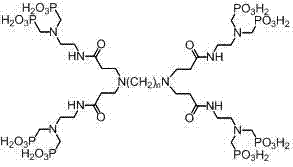

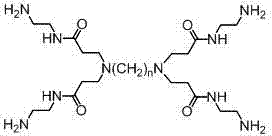

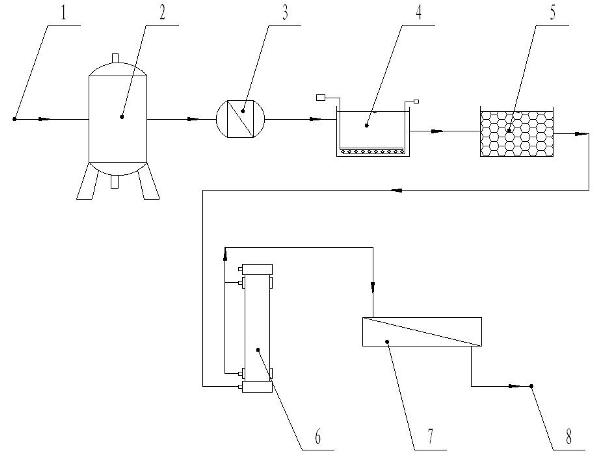

Preparation and application of dendritic polymer polyamide-amino octa-methylene phosphonic acid

ActiveCN103242365AOvercoming the Weakness of Poor InhibitionWaste water treatment from quariesGeneral water supply conservationPolymer scienceReverse osmosis

Owner:TONGJI UNIV

Advanced purification and recycling method and device of nondegradable organic industrial wastewater

ActiveCN102358650AReduce the burden onRealize purification and reuseWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemical oxygen demandFiltration

The invention provides a method for carrying out water resource advanced treatment on nondegradable organic industrial wastewater subjected to conventional biochemical treatment, recycling high-quality water and implementing zero discharge of industrial wastewater. The water, which is discharged after carrying out conventional biochemical treatment on coking wastewater, dyeing wastewater or any other nondegradable organic industrial wastewater, is used as the treatment object, and an advanced oxidization technique, a membrane technique and an industrial water treatment technique are combined. The invention is characterized in that the method and device comprises the following hydraulic procedures and devices: 1) medium filtration: removing particles; 2) self cleaning and filtration; 3) COD (chemical oxygen demand) decomposer; 4) visible light catalytic oxidation; 5) ultrafiltration membrane section; and 6) reverse osmosis membrane section, thereby finally preparing the high-quality water as a substitute for new recycled water in production.

Owner:BEIJING CRYSTEC TECH

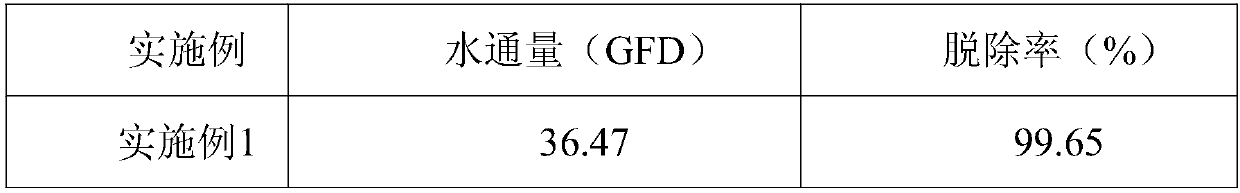

Preparation method of modified pollution-resistant hybridized reverse osmosis membrane

ActiveCN107694357AGood antibacterialGood pollution resistanceSemi-permeable membranesMembranesDispersityCompound organic

The invention belongs to the technical field of composite reverse osmosis membranes and particularly relates to a preparation method of a modified pollution-resistant hybridized reverse osmosis membrane. According to the preparation method, by introducing a combined inorganic nano-particle of a graphene oxide nano-particle, nano-Ag and nano-SiO2 an dissolving the combined inorganic nano-particle by virtue of a compound organic solvent, the result shows that an inorganic nano-material has relatively good dispersity in a polymer film matrix and further has relatively good consistency between twophases of the inorganic nano-particle and a polymer. A polyamide functional layer is hybridized and is grafted with hydrophilous an NH2-PEG-OH molecular chain through chemical reaction, so that the hydrophily of a membrane is improved, and the prepared composite membrane has relatively excellent antibacterial property, pollution resistance and thermal stability and further has huge prospects in industrial water treatment.

Owner:VONTRON TECH CO LTD

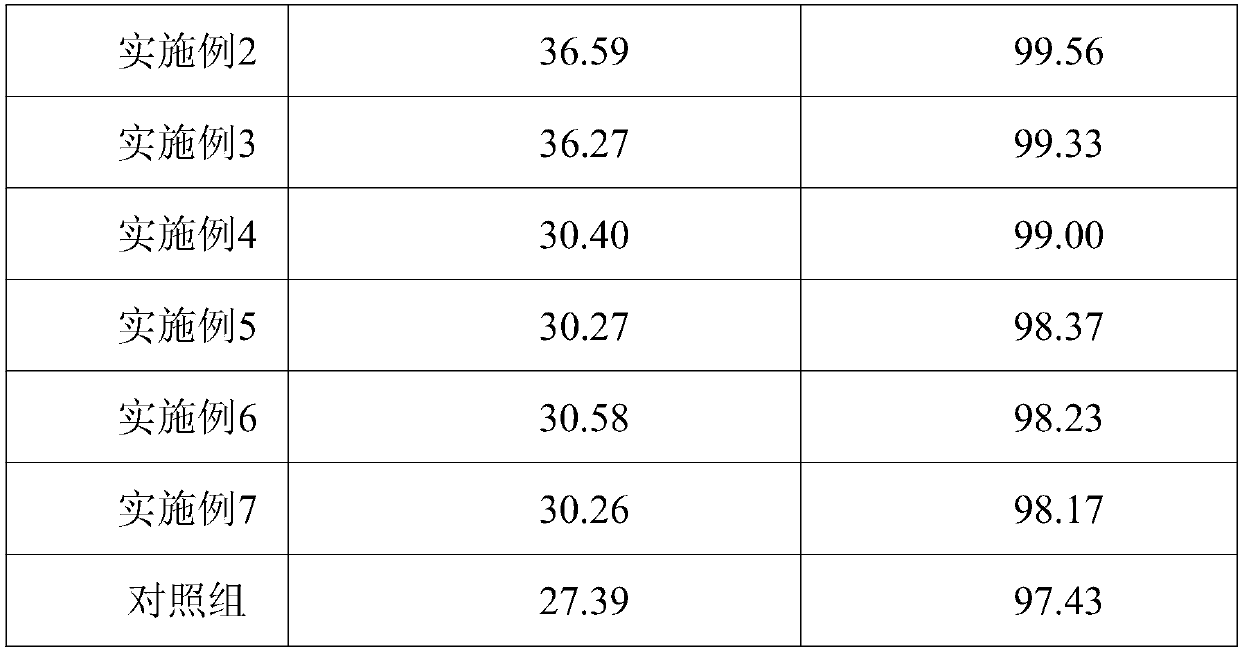

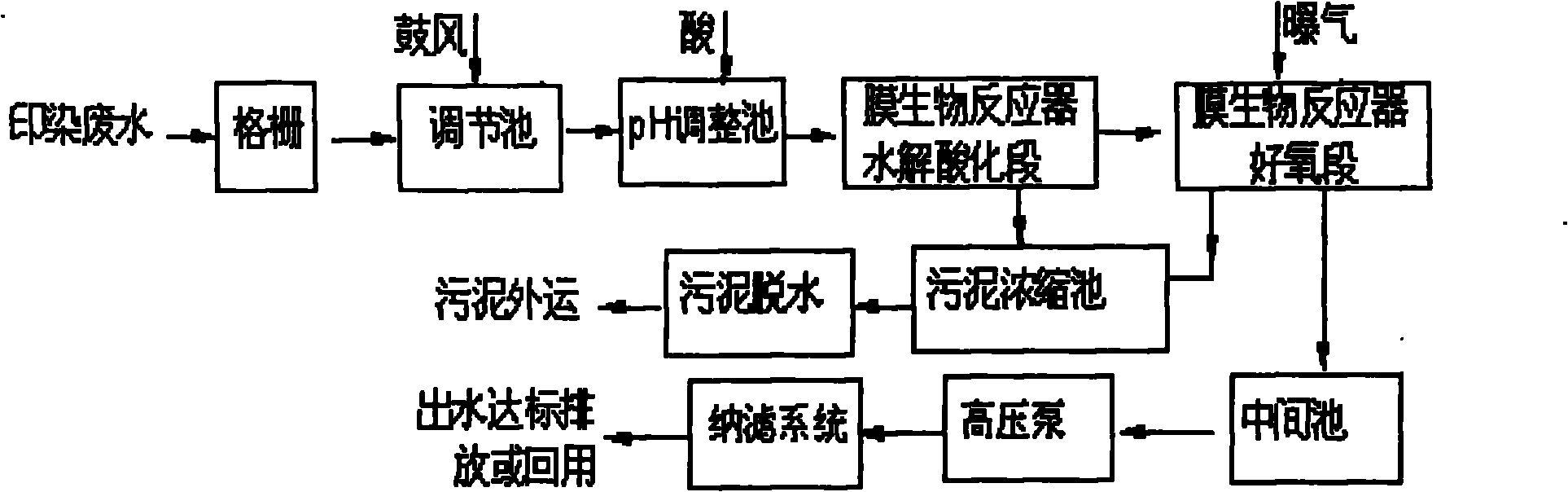

Treatment method of printing and dying wastewater

ActiveCN101830597AReduce power consumptionImprove processing efficiencyFatty/oily/floating substances removal devicesTreatment with aerobic and anaerobic processesActivated sludgeTreatment effect

The invention relates to the field of industrial water treatment, in particular to a treatment method of printing and dying wastewater. The treatment method solves the problems of complex operation, high energy consumption, high sludge disposal cost, low treatment efficiency, big occupation area and the like existing in the prior art of printing and dying wastewater treatment. The invention provides the treatment method of the printing and dying wastewater, with lower operation cost, low energy consumption, stable treatment effect and small occupation area. The printing and dying wastewater is pumped into the hydrolytic acidification section of a membrane biological reaction basin after the pH value of the wastewater is regulated; a pulse water distribution mode is adopted, and thus, auxiliary equipment of a water-power impeller is not needed; mud and water separation is carried out by replacing the traditional biochemical reaction basin and sedimentation basin process with a membrane bioreactor process, and thus, drug is added for settling is not needed; activated sludge is trapped to increase microbial biomass in the biochemical basin, thereby increasing the biochemical reaction rate; the produced water of the membrane biological reaction basin is treated by adopting a nanofiltration membrane separation system, and therefore, the produced water can be discharged after reaching standards.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

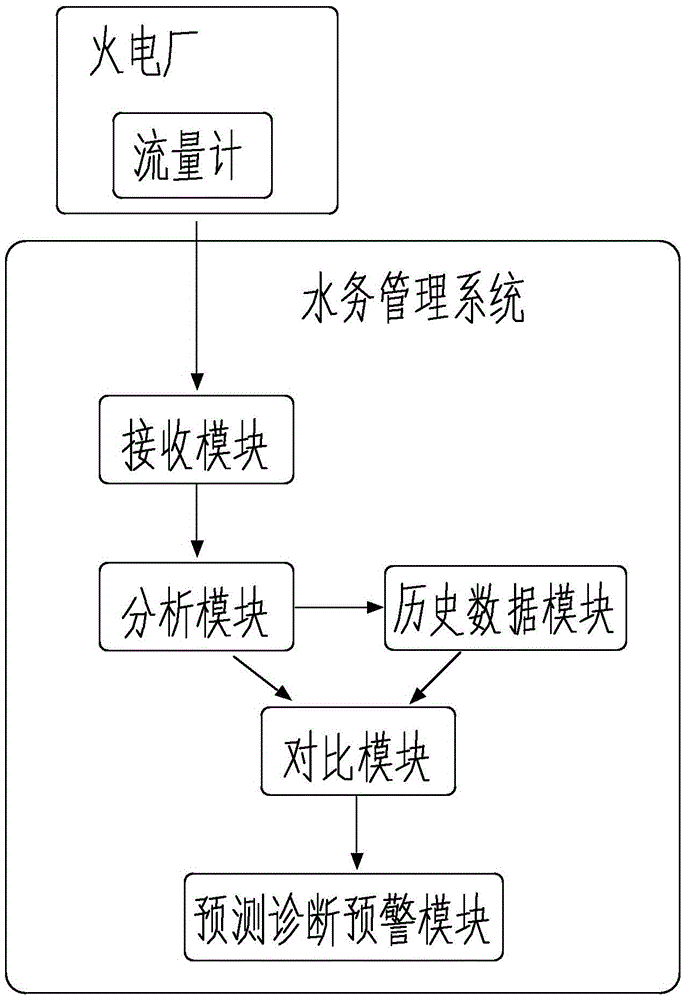

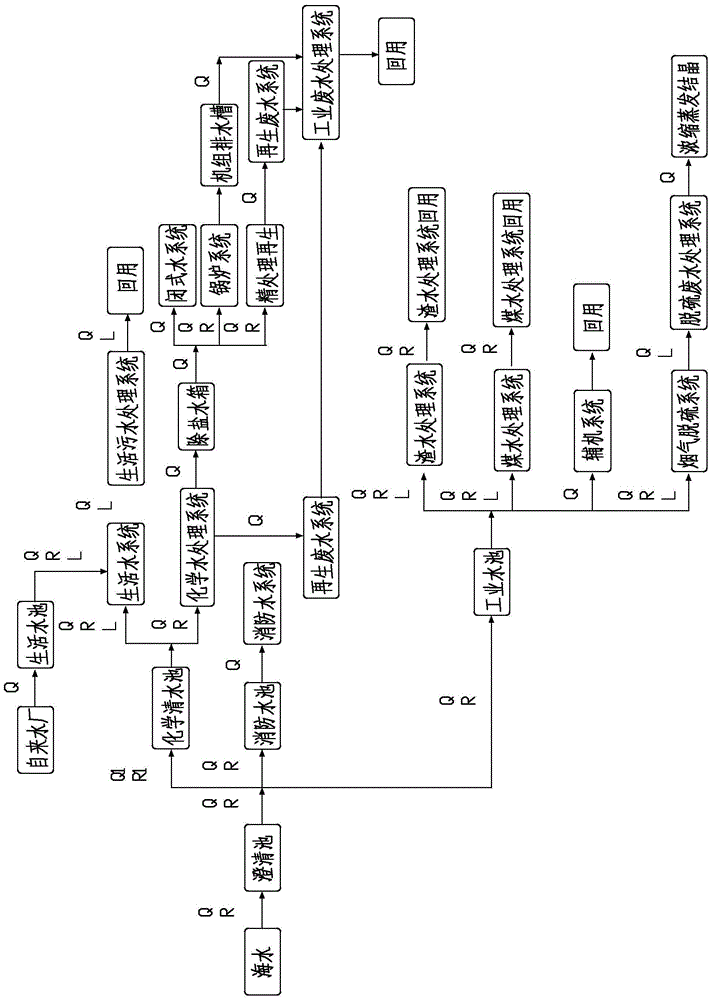

Thermal power plant real-time water affair monitoring system and monitoring method

PendingCN105527915ARealize dynamic monitoringImprove water-saving facilitiesProgramme controlComputer controlWater savingWater leakage

The invention relates to a thermal power plant real-time water affair monitoring system and a thermal power plant real-time water affair monitoring method, which solve the problems in the prior art that water affairs cannot be managed in real time, water cannot be used reasonably, pipe network leakage is difficult to discover and the like. The thermal power plant real-time water affair monitoring system provided by the invention comprises a plurality of functional reservoirs, a living water system, a fire fighting water system, an industrial water system and a water affair management system, wherein the living water system, the fire fighting water system and the industrial water system are connected with the corresponding functional reservoirs, water inlet pipes and water outlet pipes of the functional reservoirs, the living water system, the fire fighting water system and the industrial water system are provided with monitoring meters, the monitoring meters are in signal connection with the water affair management system, and water affair real-time monitoring is achieved through the water affair management system. The thermal power plant real-time water affair monitoring system and the thermal power plant real-time water affair monitoring method have the advantages of detecting water affair information in real time, conducting real-time monitoring and calculation by using the water affair management system, calculating power generation water consumption online, discovering unreasonable water utilization phenomenon and water leakage defects of a pipe network, improves water saving facilities, and achieves gradient utilization of water resources.

Owner:ZHEJIANG ZHENENG TECHN RES INST

Efficient alkyl ether carboxylate type dirt dispersion agent and application thereof

InactiveCN103058399APromote hydrationGood dispersionScale removal and water softeningCarboxylic saltNuclear chemistry

The invention relates to an alkyl ether carboxylate type dirt dispersion agent. The dirt dispersion agent contains carboxyl and ether group functional groups. The invention aims to provide an application of the dirt dispersion agent disclosed by the invention to an industrial water treatment system, particularly a circulating cooling water system. The invention aims to provide an application method of the dirt dispersion agent disclosed by the invention; when being used, the dirt dispersion agent can be used separately and can also be compounded with other dirt dispersion agents or corrosion inhibitors to be used. According to the alkyl ether carboxylate type dirt dispersion agent, the alkyl ether carboxylate has very high tolerance on calcium and has a good dirt dispersion effect on difficultly-dissolved salts including calcium carbonate dirt, calcium sulfate dirt, calcium phosphate dirt and the like in the water under the conditions of high hardness, high alkali, high temperature and high pH (Potential of Hydrogen); and the alkyl ether carboxylate type dirt dispersion agent has the advantages of safety in use, low toxicity, easiness for biological degradation and environmental friendliness, is applicable to automatic medicine adding control, and is convenient to use, and so on.

Owner:NANJING YUSHUI SCI & TECH

Barium-strontium scale inhibitor

InactiveCN103771594AEnvironmentally friendlyTime-efficient macrosScale removal and water softeningPotassium persulfateHydrolysate

The invention relates to a barium-strontium scale inhibitor, belongs to the technical field of industrial water treatment agent designing and is especially suitable for water containing barium-strontium scale and calcium-barium-strontium composite scale in the oil field. A terpolymer and poly(sodium epoxysuccinate) are compounded according to a mass percent ratio of 1: 0.1-5.0 to form the barium-strontium scale inhibitor. Maleic anhydride is added with acrylic acid or methacrylic acid and acrylic acid ester and the mixture undergoes a copolymerization reaction under the action of potassium persulphate as an initiator to produce the terpolymer. A hydrolysate of maleic anhydride and sodium hydroxide is added with sodium tungstate as a catalyst and hydrogen peroxide as an oxidizing agent, the mixture undergoes a reaction to produce sodium epoxysuccinate, the sodium epoxysuccinate is added with a sodium-calcium compound alkali as an initiator and the mixture undergoes a polymerization reaction to produce the poly(sodium epoxysuccinate). The barium-strontium scale inhibitor does not contain phosphorus, has a small use amount and good effects, can be effectively used for preventing barium-strontium scale, calcium scale and calcium-barium-strontium composite scale in the oil field, has excellent barium-strontium scale inhibition performances, has a low cost, can be prepared by a simple method and is environmentally friendly.

Owner:YANGTZE UNIVERSITY

Antiscale scale-remover for industrial water treatment

InactiveCN1666963ANot easy to form clogging phenomenonPrevent secondary scalingScale removal and water softeningFertilizer plantWater cycling

This invention discloses an antiscale and scale remover that used in industrial cycle cooling water disposal. It is composed by humic acid natrium, sodium carbonate, starch, sodium heametaphosphate, the weight percentage is humic acid natrium 15-30%, sodium carbonate 65-75%, starch 2-10%, sodium heametaphosphate 1.2-2%. The compound can improve the water flowability and dispersibility. It belongs to environmental protection product and is no pollution. It has high temperature resistant. Sterilization can be done in working condition. It can be applied to calcium carbide furnace, ferrosilicon furnace, calcium silicon furnace, transformer and cooling water cycling and antiscale and scale remove of carbonization equipment in fertilizer plant.

Owner:翟春生

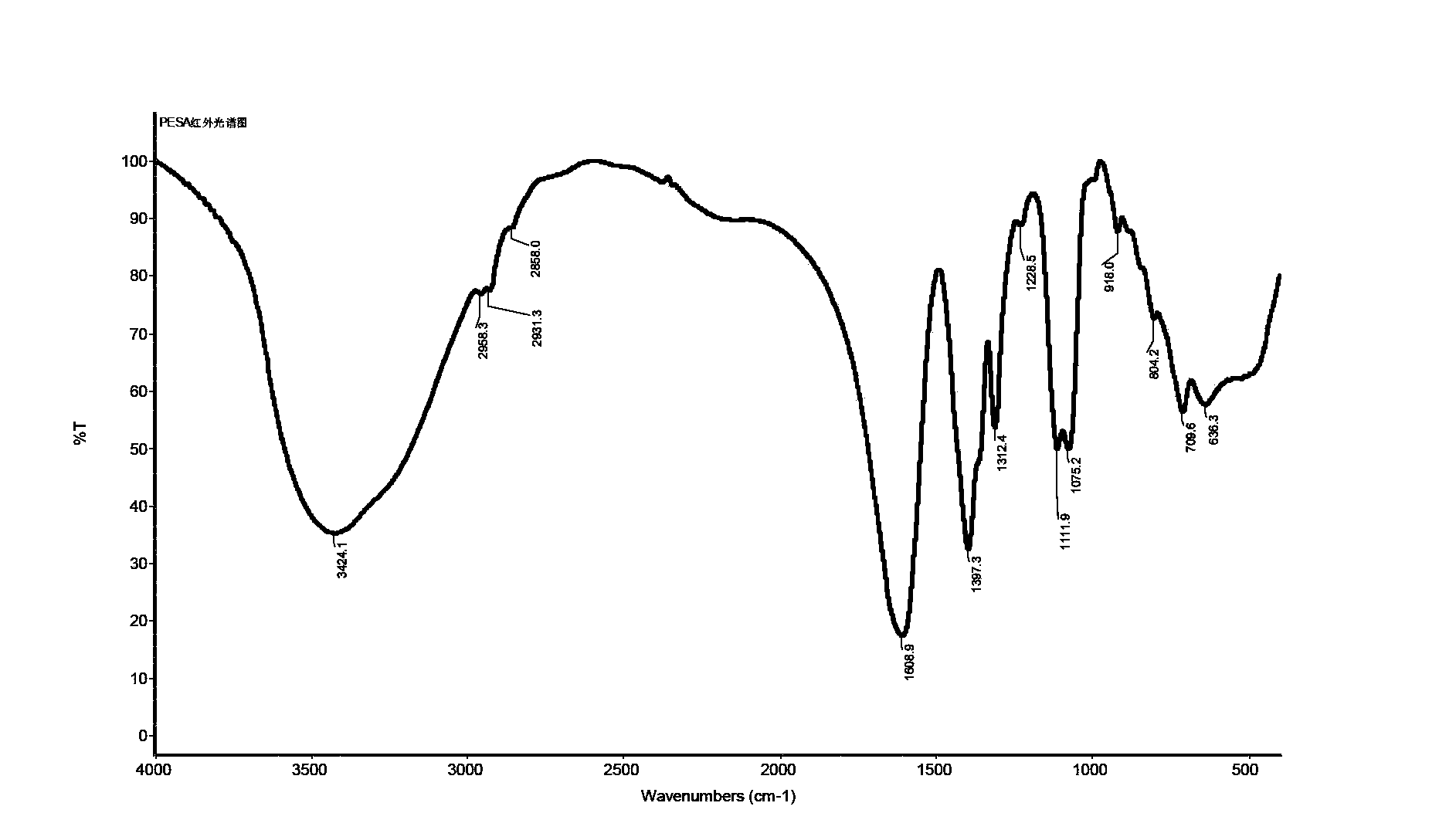

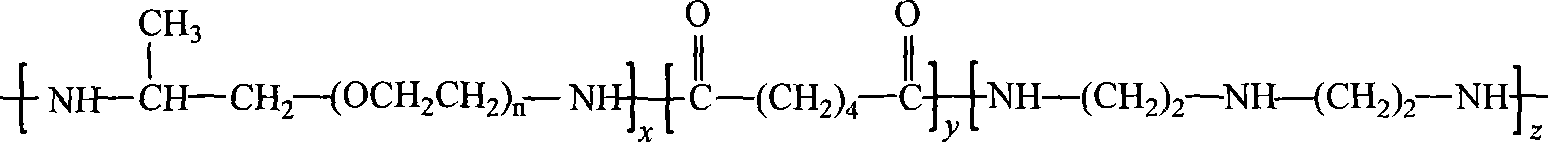

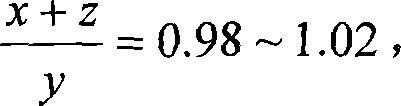

Non-ionic polymeric compound for inhibiting deposition of silicon dioxide/silicate dirt in water and method of producing same

InactiveCN101245140AHas an ether bondWith secondary amine bondScale removal and water softeningPolymer scienceRoom temperature

The invention pertains to the technical field of industrial water treatment, which more particularly relates to a non-ionic polymer which restricts the depositions of silica / silicates in water and a preparation method thereof. The polymer is a non-ionic copolymer which contains ether linkage, secondary amine linkage and peptide linkage, substantially the non-ionic copolymer is a hexanedioic acid / amino terminated polyether / divinyl three amine copolymer. According to the regular condensation polymerization principle, a certain amount of amino terminated polyether D230 and a certain amount of divinyl three amine are mixed uniformly by water, and then a certain amount of hexanedioic acid is added in and stirred for dissolving. The condensation polymerization is carried out again under certain temperature and the released moisture in the process is removed. After 3-5 hours of condensation polymerization, the temperature is reduced to 120-125 DEG C and a certain amount of deionized water is added which is stirred for 2-3 hours under the same temperature. Subsequently the temperature is cooled to the room temperature and the required polymer is obtained. The polymer has good restriction and dispersal effects on the deposits of silicon dioxide / silicate in the water system and is a novel non-ionic polymer which is phosphate-free and biodegradable.

Owner:TONGJI UNIV

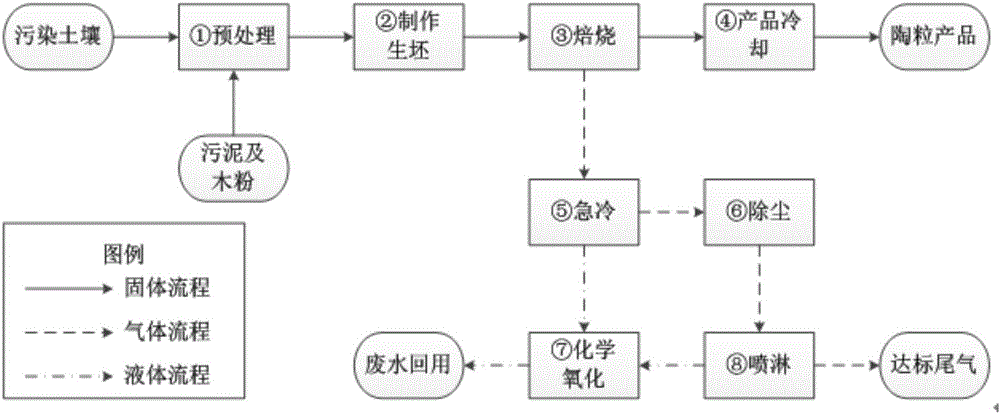

Repairing and resourceful treatment method of contaminated soil

InactiveCN106560461ANo leaching toxicityMeet relevant standardsCeramic materials productionCeramicwarePolycyclic aromatic hydrocarbonSludge

The invention discloses a repairing and resourceful treatment method of contaminated soil. The repairing and resourceful treatment method comprises the steps of controlling the particle size of the contaminated soil to be 80 meshes or below, adding sludge, wood powder, and water in certain proportion into the soil, mixing the materials to prepare a raw blank in a prilling disk, adjusting moisture, afterwards sending the raw blank into a rotary kilin to be subjected to roasting treatment, tail gas treatment, industrial water treatment and the like. Through the adoption of the repairing and resource treatment method to treat the soil which is contaminated by polycyclic aromatic hydrocarbons, not only the purpose of repairing the soil is achieved, problem of application orientation of the repaired soil is also solved, and the prepared ceramsite can directly create economic benefits.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com