Preparation and application of dendritic polymer polyamide-amino octa-methylene phosphonic acid

An amine octamethylene phosphonic acid and polyamide technology, applied in the field of industrial water treatment, can solve the problems of poor calcium tolerance and poor calcium phosphate scale inhibition, and achieve strong calcium tolerance and good resistance to high calcium conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

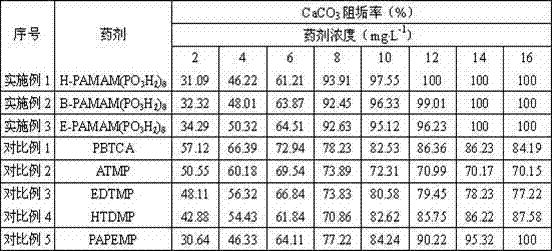

Examples

Embodiment 1

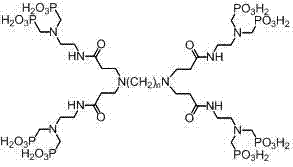

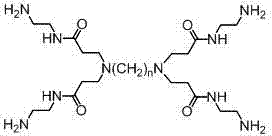

[0035] Embodiment 1: Preparation of hexamethylene diamine core polyamidoamine octamethylene phosphonic acid

[0036]Add 16.57 g of phosphorous acid (99.0%, 0.200 mol) and 25.69 g (37%, 0.26 mol) of concentrated hydrochloric acid into a four-neck flask equipped with a stirrer, condenser, thermometer, and dropping funnel, and stir well. Under cooling and stirring conditions, 57.20 g (25%, 0.025 mol) of 0-generation polyamidoamine (Hexaethylenediamine core, 0 generation, PAMAM dendrimer; hereinafter abbreviated as H-PAMAM (NH 2 ) 4 ) aqueous solution, control the rate of addition so that the temperature is 3 h 2 ) 8 ). 13 C NMR (D 2 O): δ 26.62; 28.93; 32.57; 37.27; 51.02; 52.16; 56.32; 57.30; 173.73. 31 P NMR (D 2 O): δ10.67.

Embodiment 2

[0037] Embodiment 2: Preparation of butanediamine core polyamidoamine octamethylene phosphonic acid

[0038] Add 16.57 g of phosphorous acid (99.0%, 0.200 mol) and 25.69 g (37%, 0.26 mol) of concentrated hydrochloric acid into a four-neck flask equipped with a stirrer, condenser, thermometer, and dropping funnel, and stir well. Under cooling and stirring conditions, 57.20 g (25%, 0.025 mol) of 0-generation polyamidoamine (Butanediamine core, 0 generation, PAMAM dendrimer; hereinafter abbreviated as B-PAMAM (NH 2 ) 4 ) aqueous solution, control the rate of addition so that the temperature is 3 h 2 ) 8 ). 13 C NMR (D 2 O): δ26.82; 32.92; 36.83; 50.44; 53.27; 56.82; 57.11; 175.54. 31 P NMR (D 2 O): δ9.82.

Embodiment 3

[0039] Embodiment 3: Preparation of ethylenediamine core polyamidoamine octamethylene phosphonic acid

[0040] Add 16.57 g of phosphorous acid (99.0%, 0.200 mol) and 25.69 g (37%, 0.26 mol) of concentrated hydrochloric acid into a four-neck flask equipped with a stirrer, condenser, thermometer, and dropping funnel, and stir well. Under the condition of cooling and stirring, 51.60 g (25%, 0.025 mol) of 0-generation polyamidoamine (Ethylenediamine core, 0 generation, PAMAM dendrimer; hereinafter abbreviated as E-PAMAM(NH 2 ) 4 ) aqueous solution, control the rate of addition so that the temperature is 3 h 2 ) 8 ). 13 C NMR (D 2 O): δ34.02; 36.41; 49.92; 50.50; 56.62; 57.18; 176.01. 31 P NMR (D 2 O): δ10.17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com