Environment-friendly composite dirt dispersion agent for oil-field flooding treatment

A scale inhibitor and dispersant, oil field water injection technology, applied in mining wastewater treatment, water/sludge/sewage treatment, scale removal and water softening, etc., can solve the problem of low solubility, single scale inhibitor effect and large water injection and other problems, to achieve the effect of reducing the use concentration and good scale inhibition and dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

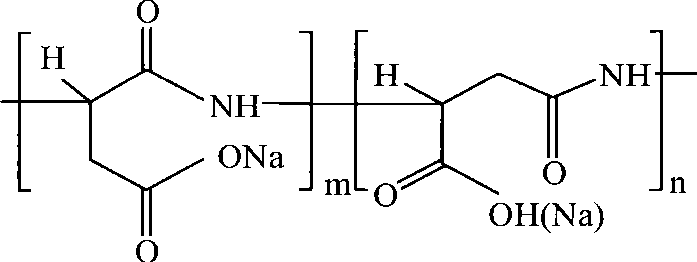

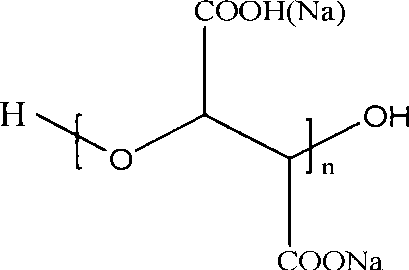

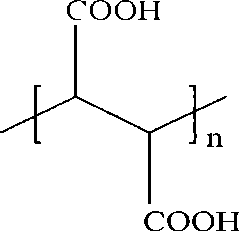

[0030] Preparation of composite scale inhibitor and dispersant: prepare 100.00g of environment-friendly composite scale inhibitor and dispersant

[0031] 20.84g of 48% solid content of hydrolyzed polymaleic anhydride (HPMA) was adjusted to pH 6-7 with about 9.60 g of 50% aqueous sodium hydroxide solution, and then 56.25 g of 40% solid content of polyaspartic acid were added Sodium (PASP) and 6.25g polyepoxysuccinate sodium (PESA) with a solid content of 40%, and then add water to meet the total weight of 100.00g, to obtain 100.00g of a composite scale inhibitor with an active ingredient of 35.00%.

[0032] The prepared composite scale inhibitor was tested for scale inhibition performance according to the method described in "China Petroleum and Natural Gas Corporation Standards - Technical Requirements for Corrosion and Scale Inhibitors for Oilfield Water Treatment Q / SY 126 - 2005". The results are shown in Table 2.

[0033] Table 2: Experimental results

[0034] Drug...

Embodiment 2

[0036] Preparation of composite scale inhibitor and dispersant: prepare 100.00g of environment-friendly composite scale inhibitor and dispersant

[0037] 24.31g of 48% solid content of hydrolyzed polymaleic anhydride (HPMA) was adjusted to pH 6 to 7 with about 11.20 g of 50% aqueous sodium hydroxide solution, and then 48.61 g of 40% solid content of polyaspartic acid were added Sodium (PASP) and 9.73g polyepoxysuccinate sodium (PESA) with a solid content of 40%, and then add water to meet the total weight of 100.00g, to obtain 100.00g of a composite scale inhibitor with an active ingredient of 35.00%.

[0038] Prepared compound scale inhibitor "China Petroleum and Natural Gas Co., Ltd. Enterprise Standard - Technical Requirements for Corrosion and Scale Inhibitors for Oilfield Water Treatment Q / SY 126 - 2005" to conduct scale inhibition performance test experiments, the experimental results See Table 3.

[0039] Table 3: Experimental results

[0040] Drug dosage mg / ...

Embodiment 3

[0042] Preparation of composite scale inhibitor and dispersant: prepare 100.00g of environment-friendly composite scale inhibitor and dispersant

[0043] 27.34g of 48% solid content of hydrolyzed polymaleic anhydride (HPMA) was adjusted to pH 6-7 with about 12.60 g of 50% aqueous sodium hydroxide solution, and then 45.57 g of 40% solid content of polyaspartic acid were added Sodium (PASP) and 9.12g polyepoxysuccinate sodium (PESA) with a solid content of 40%, and then add water to meet the total weight of 100.00g, to obtain 100.00g of a composite scale inhibitor with an active ingredient of 35.00%.

[0044] Prepared compound scale inhibitor "China Petroleum and Natural Gas Co., Ltd. Enterprise Standard - Technical Requirements for Corrosion and Scale Inhibitors for Oilfield Water Treatment Q / SY 126 - 2005" to conduct scale inhibition performance test experiments, the experimental results See Table 4.

[0045] Table 4: Experimental results

[0046] Drug dosage mg / l ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com