Low-phosphorus efficient scale and corrosion inhibitor for circulating water treatment, and preparation method thereof

A scale and corrosion inhibitor, circulating water technology, applied in water/sludge/sewage treatment, chemical instruments and methods, complexes/solubilizer treatment, etc., can solve the problem of high phosphorus content, achieve low phosphorus content, reduce The pressure of phosphorus removal, the effect of simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

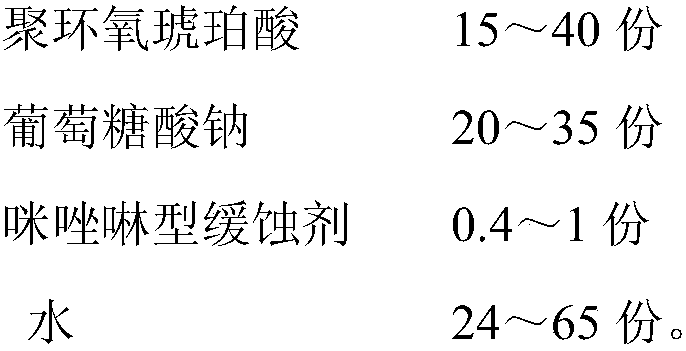

[0043] Corrosion and scale inhibitor A consists of the following raw materials in parts by weight:

[0044]

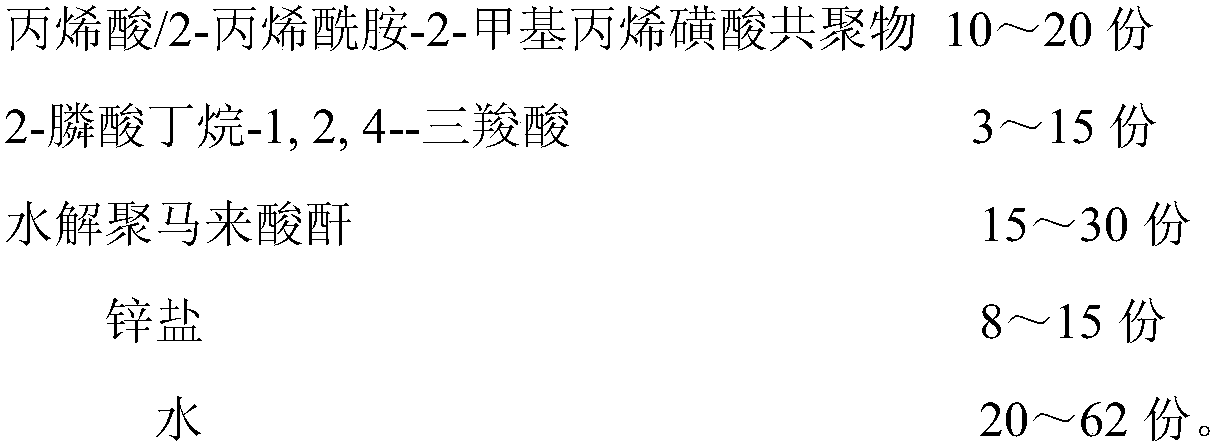

[0045] Corrosion and scale inhibitor B consists of the following raw materials in parts by weight:

[0046] Acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid copolymer ((AA / AMPS) 10 parts

[0047]

[0048] The dosing concentrations of A and B are 30mg / L and 60mg / L respectively, and the corrosion rate of the carbon steel coupon is 0.0336mm / a.

Embodiment 2

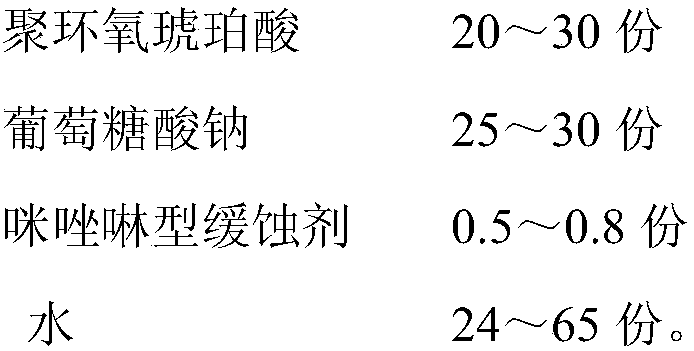

[0050] Corrosion and scale inhibitor A consists of the following raw materials in parts by weight:

[0051]

[0052] Corrosion and scale inhibitor B consists of the following raw materials in parts by weight:

[0053]

[0054] The dosage concentrations of A and B are 40mg / L and 80mg / L respectively, and the corrosion rate of carbon steel coupons is 0.0288m / a.

Embodiment 3

[0056] Corrosion and scale inhibitor A consists of the following raw materials in parts by weight:

[0057]

[0058] Corrosion and scale inhibitor B consists of the following raw materials in parts by weight:

[0059]

[0060] The dosage concentrations of A and B are 50mg / L and 100mg / L respectively, and the corrosion rate of carbon steel coupons is 0.0162m / a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com